Non-contact type concrete resistivity testing instrument

A non-contact, concrete technology, applied in the measurement of resistance/reactance/impedance, instruments, measuring devices, etc., can solve the problems of one-sided results, poor stability and repeatability of resistivity, damage to concrete structures, etc., to achieve simple and reproducible structure. The effect of good performance and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are further descriptions of the technical content of the present invention, but not limitations to the essential content of the present invention.

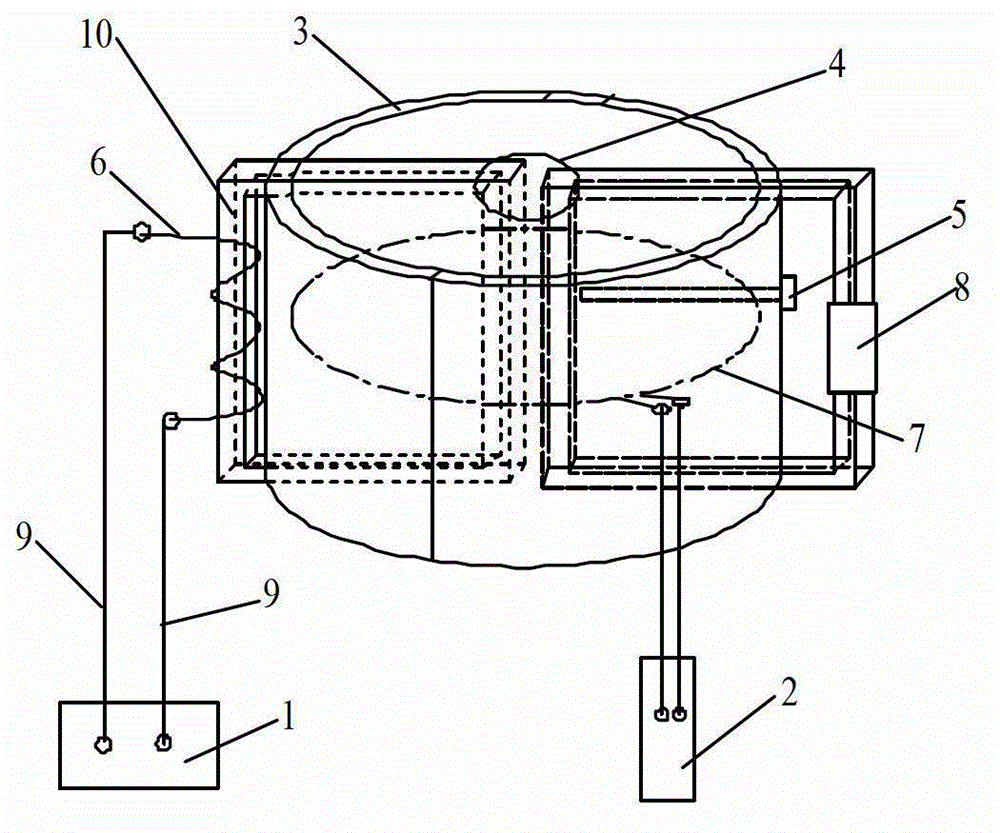

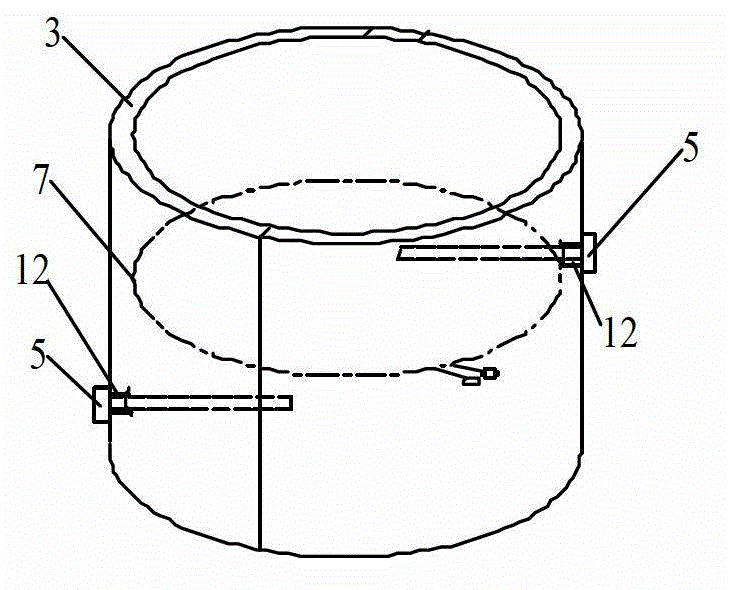

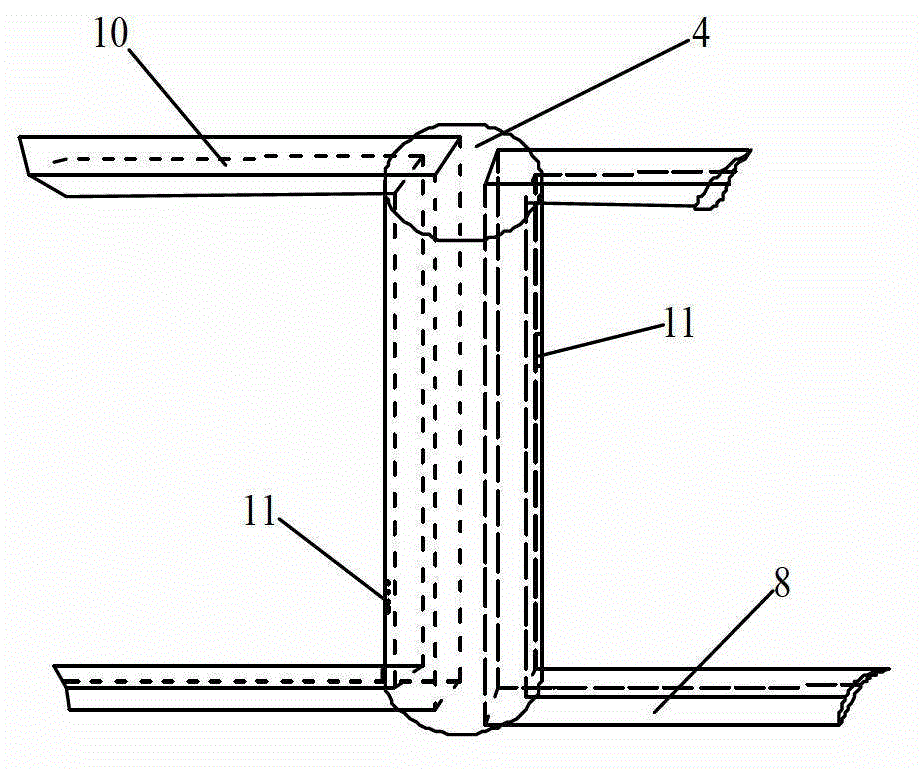

[0029] Concrete resistivity tester includes power supply 1, current tester 8, voltage tester 2, iron core 10, outer working core 3, wire 9, inner working core 4, bolt 5, 11 threaded hole, 12 through hole , primary coil 6 and induction coil 7. The concrete resistivity tester includes an inner working core 4 and an outer working core 3. The inner working core 4 and the outer working core 3 are assembled into a double-shell structure with bolts 5. The bolts 5 pass through the outer working core. The through hole 12 on the barrel 3 is connected with the threaded hole 11 on the inner working core barrel 4 to achieve the fastening parts of the double-shell barrel structure, and the double-shell barrel structure is provided with an annular iron core 10 and a current measuring instrument 8. The annular iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com