Augmentin strain enrichment expanding culture reactor

A technology of reactors and strains, which is applied in the field of expansion reactors, can solve the problems of slow start-up of reactors, limited reaction efficiency, and large dead zone area, so as to promote sludge granulation, improve treatment efficiency, and reduce dead zones. The effect of area area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

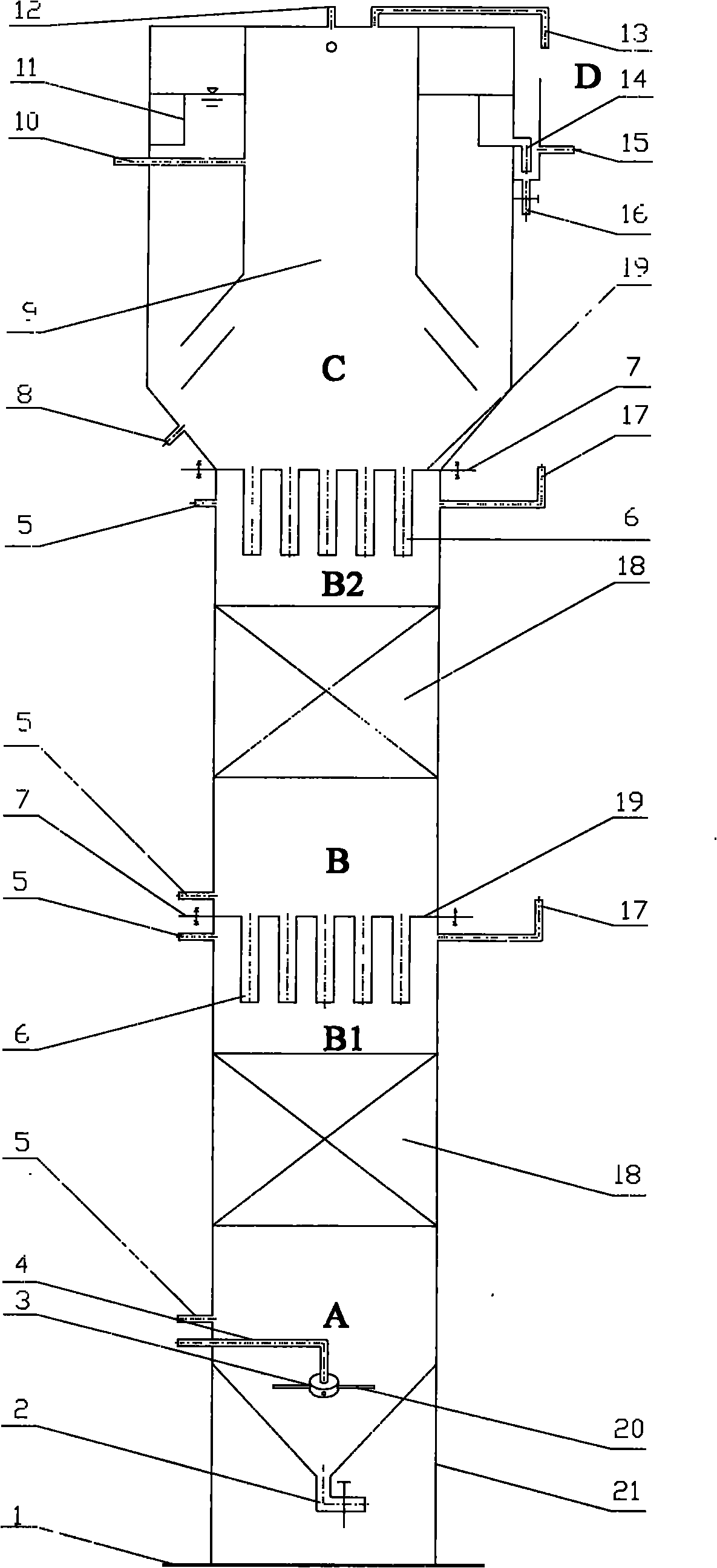

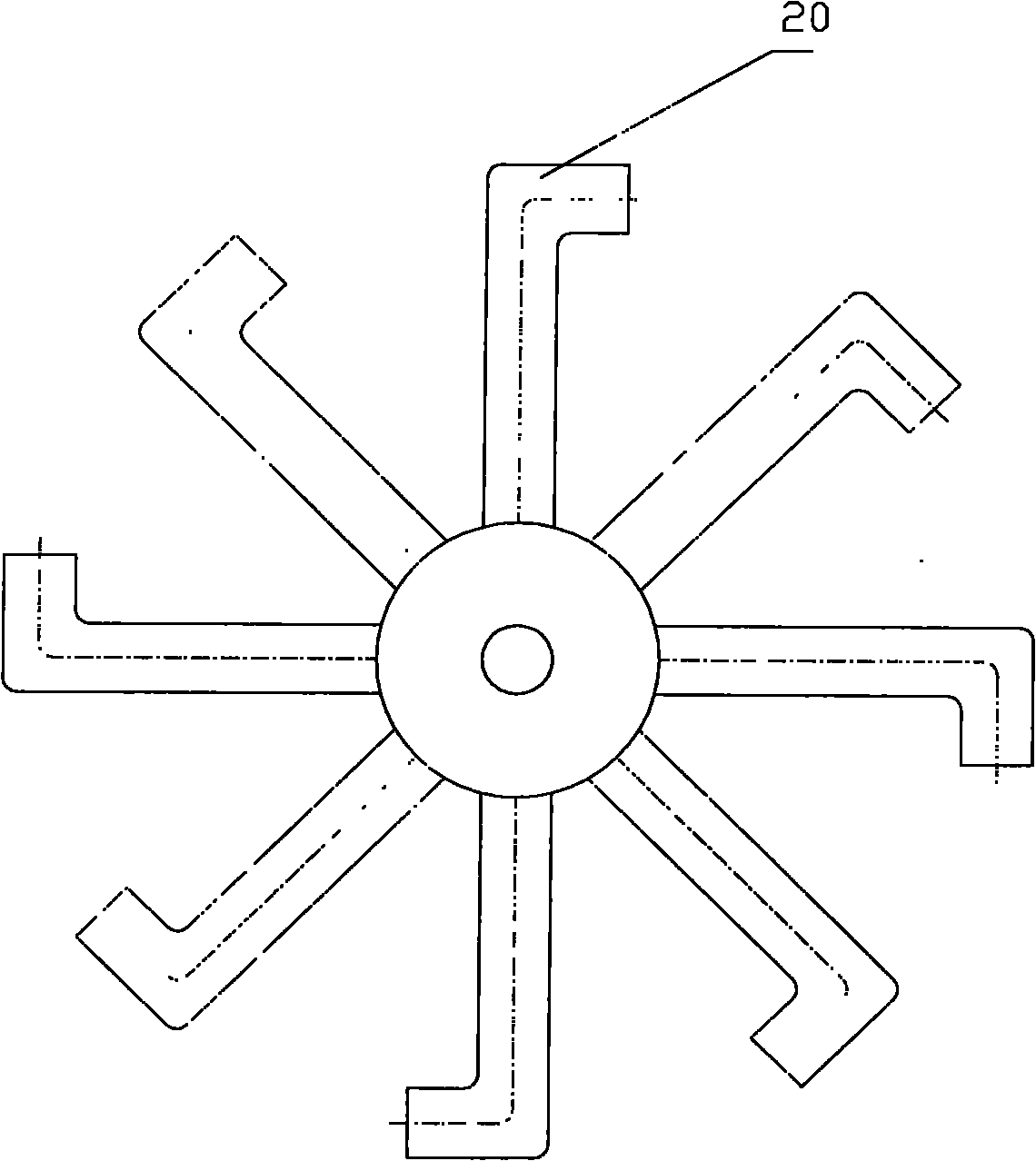

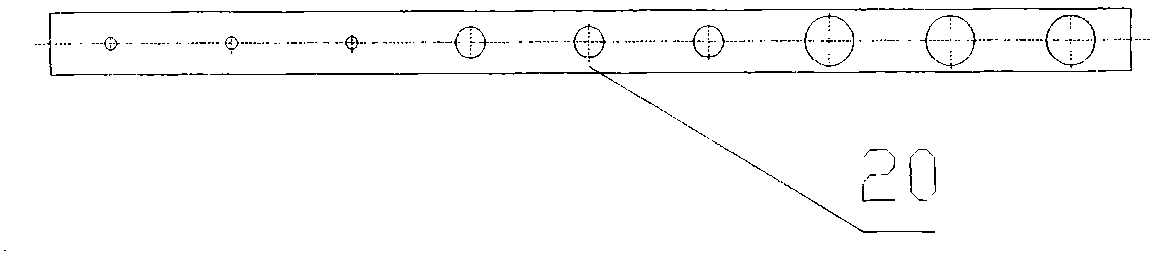

[0024] As shown in the figure, the main body of the Angie strain enrichment expansion reactor includes a water distribution system (A), a reaction system B, a separation system C and a liquid sealing system D from bottom to top; the bottom of the water distribution system A is provided with a base 1 , support 21 and mud discharge pipe 2, the middle part of the water distribution system A is provided with a swirl water distributor 3, and the swirl water distributor 3 is provided with a perforated pipe 20 and a water inlet pipe 4; the reaction system B is divided into the first one placed up and down with the same structure. The reaction zone B1 and the second reaction zone B2, the first reaction zone B1 and the second reaction zone B2 are provided with caged floating ball packing layer 18, extension pipe 6, five-hole partition 19 and flange 7 in sequence from bottom to top , the upper and lower parts of the side walls of the first reaction zone B1 and the second reaction zone B2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com