Nano carbon-doped porous fiber single electrode, membrane electrode and preparation method

A technology of porous fibers and nanofibers, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems that the conductivity of nanofiber films needs to be improved, so as to increase the catalytic active area, improve the life of membrane electrodes, and increase conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

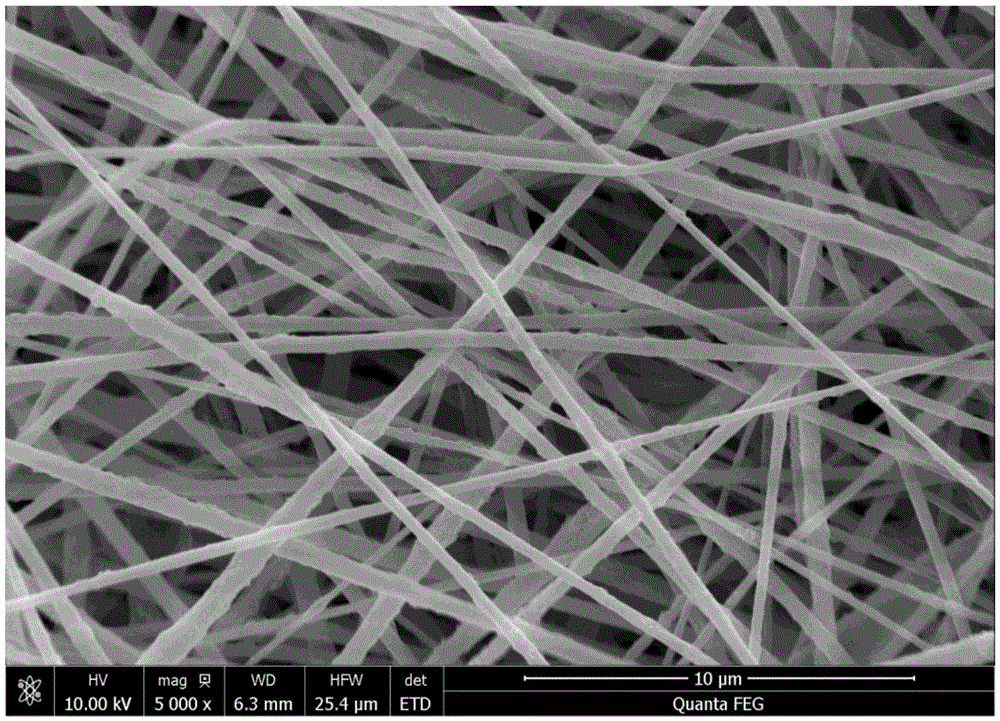

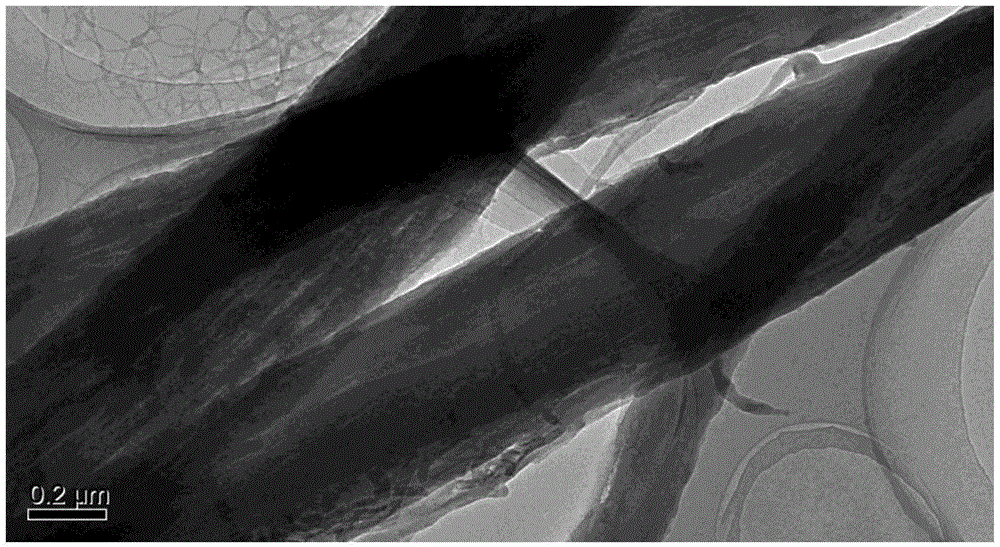

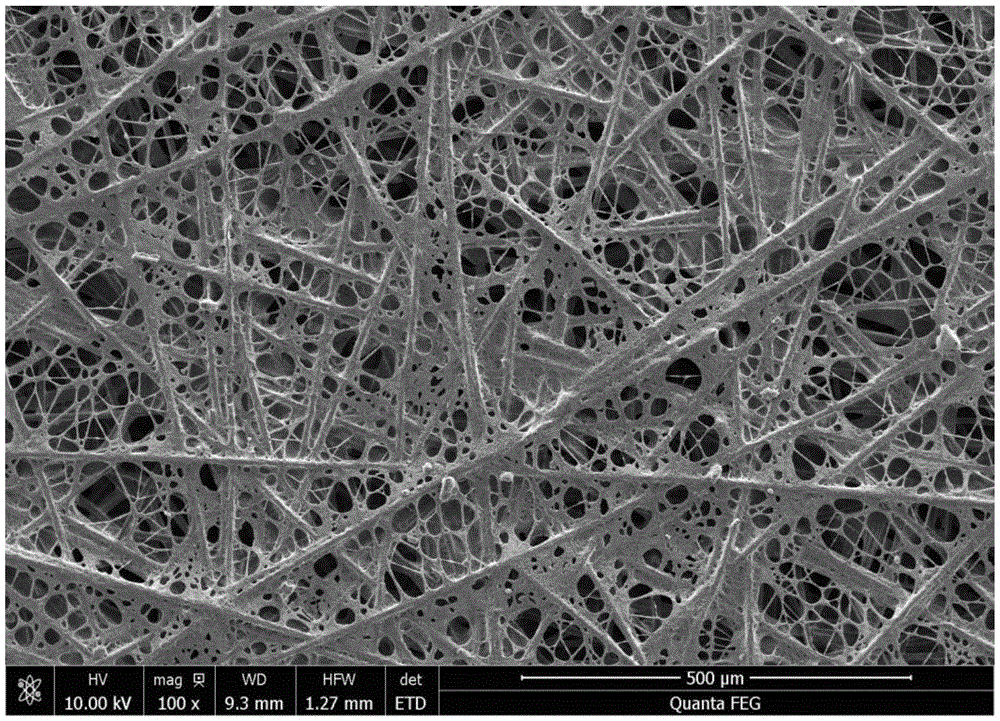

[0045] Weigh 0.5g of polyacrylonitrile (PAN) powder and 10g of N,N-dimethylformamide (DMF), mix them in a beaker, and stir at 60°C for 0.5h with a magnetic stirrer to form a uniformly mixed translucent PAN. polymer solution, and then put 0.3g single-walled carbon nanotubes (SWCNTs) into the polymer solution, ultrasonically 0.5h to disperse the SWCNTs in the polymer solution evenly, then stir it at 50°C with a magnetic stirrer, and 0.5 g of polyvinylidene fluoride (PVDF) powder was added several times in small amounts to finally obtain a uniformly mixed co-spun polymer solution. Fix the hydrophobically treated gas diffusion layer material on the receiving drum of the electrospinning device. The process of hydrophobic treatment is to immerse the carbon paper in the polytetrafluoroethylene hydrophobic agent for 10 minutes, and calcined at 350°C for 30 minutes. minutes, wherein the solid content of the hydrophobic agent is 15-25 wt%. Use a 2ml or 5ml syringe to take 2ml to 3ml of...

Embodiment 2

[0052]Weigh 0.6g of polyacrylonitrile (PAN) powder and 10g of N,N-dimethylformamide (DMF), mix them in a beaker, and stir at 60°C for 0.5h with a magnetic stirrer to form a uniformly mixed translucent PAN. polymer solution, then put 0.3g multi-walled carbon nanotubes (MWCNTs) into the polymer solution, ultrasonically 0.5h to disperse the MWCNTs evenly in the polymer solution, then stir it with a magnetic stirrer at 50°C, and 0.4 g of polyvinylidene fluoride (PVDF) powder was added several times in small amounts to finally obtain a uniformly mixed co-spun polymer solution. Fix the hydrophobically treated gas diffusion layer material on the receiving drum of the electrospinning device. The process of hydrophobic treatment is to immerse the carbon paper in the polytetrafluoroethylene hydrophobic agent for 10 minutes, and calcined at 340 ° C for 30 minutes, wherein the solid content of the hydrophobic agent is 15-25 wt%. It was electrospun on the side of the hydrophobic carbon pa...

Embodiment 3

[0060] Weigh 0.8g of polyacrylonitrile (PAN) powder and 10g of N,N-dimethylformamide (DMF), mix them in a beaker, and stir at 60°C for 0.5h with a magnetic stirrer to form a uniformly mixed translucent PAN. polymer solution, then put 0.2g graphene oxide (GO) into the polymer solution, ultrasonically disperse GO in the polymer solution for 0.5h, then stir it at 50°C with a magnetic stirrer, and a small amount of Add 0.3g of polyvinylidene fluoride (PVDF) powder one by one, and finally obtain a uniformly mixed co-spun polymer solution. Fix the hydrophobically treated gas diffusion layer material on the receiving drum of the electrospinning device. The process of hydrophobic treatment is to immerse the carbon paper in the polytetrafluoroethylene hydrophobic agent for 10 minutes, and calcined at 330°C for 30 minutes. minutes, wherein the solid content of the hydrophobic agent is 15-25 wt%. Use a 2ml or 5ml syringe to take 2ml to 3ml of the co-spun polymer solution and fix it on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com