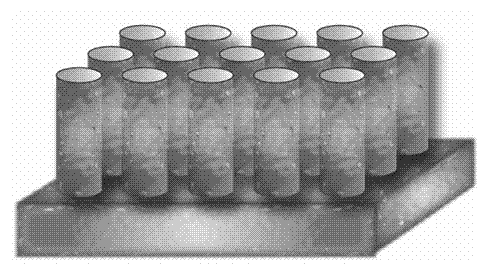

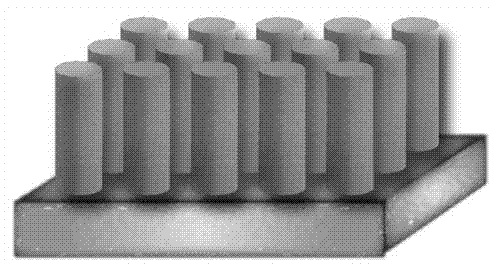

Three-dimensional proton conductor based ordered single electrode and membrane electrode as well as preparation methods

A proton conductor and single-electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as negative impact on mechanical properties, increase and mass transfer capacity, improve utilization, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put the Pt target into the evaporation chamber, put a 3D structure proton conductor into the sample chamber, and vacuum the evaporation chamber to 4×10 -4 Pa, electron beam current 27A, evaporation for about 15 seconds, a layer of active metal Pt catalyst of about 1.2nm is uniformly plated on the side of the proton conductor with fibers and the surface of the fibers, and a Pt loading of 0.05 mg / cm is prepared. 2 single electrode.

[0037] Evaporate in the same way for 8 minutes, the thickness of the coating is about 3.7nm, and prepare another Pt loading of 0.15 mg / cm 2 single electrode.

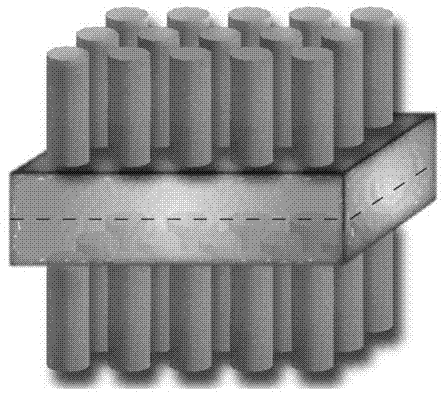

[0038] Take a single electrode, drop a few drops of Nafion solution on the back of the fiber surface to make it cover the entire surface, then stick the back of the fiber surface of another single electrode on it, and dry it in an oven at 80°C to obtain a film electrode.

[0039] The membrane electrode and two pretreated gas diffusion layers are hot-pressed to obtain a high-performa...

Embodiment 2

[0046] Put the Pt target into the evaporation chamber, put a 3D structure proton conductor into the sample chamber, and vacuum the evaporation chamber to 4×10 -4 Pa, electron beam current 27A, evaporation for about 15 seconds, a layer of active metal Pt catalyst of about 1.2nm is uniformly plated on the side of the proton conductor with fibers and the surface of the fibers, and a Pt loading of 0.05 mg / cm is prepared. 2 single electrode.

[0047] Evaporate in the same way for 8 minutes, the thickness of the coating is about 3.7nm, and prepare another Pt loading of 0.15 mg / cm 2 single electrode.

[0048] Take a prepared single electrode, drop a few drops of the above-mentioned short-chain Nafion solution on the back of the fiber surface to make it cover the entire surface, then stick the back of the fiber surface of another single electrode on it, and place it in an oven at 80°C dry to obtain a membrane electrode.

[0049] The membrane electrode and two pretreated gas diffusi...

Embodiment 3

[0056] Put the Pt target into the evaporation chamber, put a 3D structure proton conductor into the sample chamber, and vacuum the evaporation chamber to 3×10 -4 Pa, electron beam current, 28A, vapor deposition for about 30 minutes, uniformly coat a layer of 14nm active metal Pt catalyst on the side of the 3D structure proton conductor with fibers and the surface of the fibers, and prepare a Pt loading of 0.2 mg / cm 2 single electrode.

[0057] Evaporate for 40 minutes with the same method, the thickness of the coating is about 20nm, and another Pt loading is 0.3 mg / cm 2 single electrode.

[0058] Take a prepared single electrode, drop a few drops of sulfonated polysulfone resin solution on the back of the fiber surface to make it cover the entire surface, then stick the back of the fiber surface of another single electrode on it, and place it at 100°C drying in an oven to obtain a membrane electrode.

[0059] The membrane electrode is pressed together with two pretreated ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com