Active composite suspended filler

A suspended filler, active technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of lack of pore adsorption, difficult formation of biofilm, and insufficient surface roughness. Achieve the effect of maintaining original activity, accelerating growth, and improving oxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

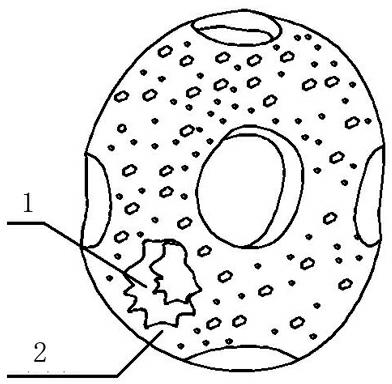

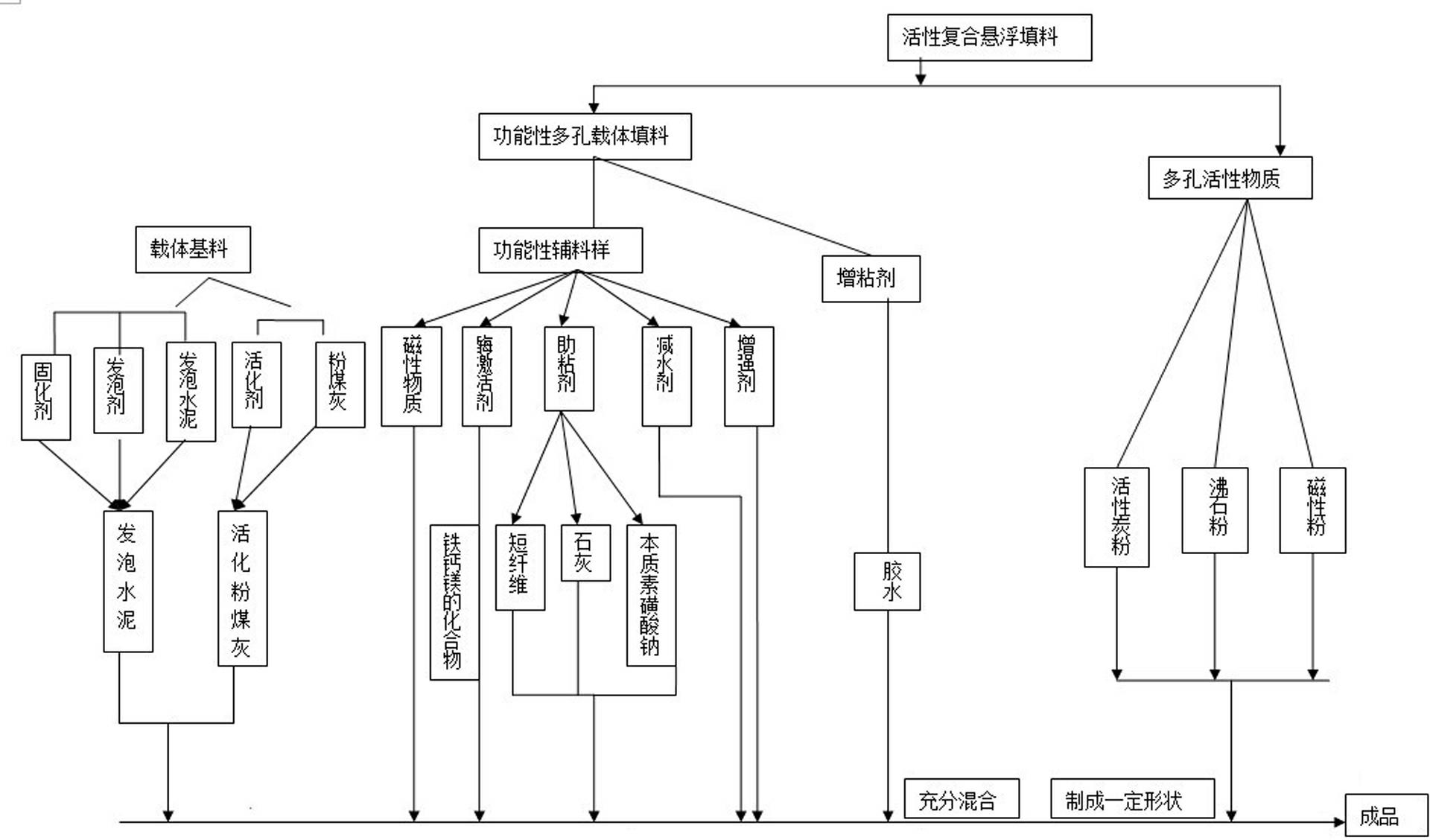

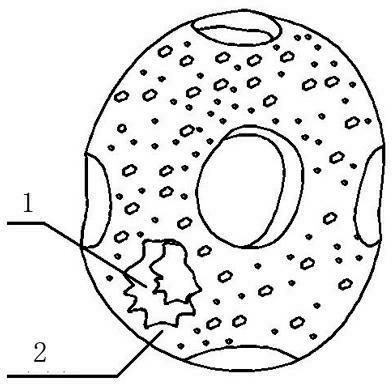

[0015] according to figure 1 As shown, the present invention has foamed cement, activated fly ash is the carrier base material, and the functional auxiliary material is infiltrated into the carrier base material to become a porous carrier filler 1. The porous carrier filler is preferably a spherical hollow body with a specific gravity less than 1 , the ratio of the composition of the above materials is as follows, foamed cement: activated fly ash: functional auxiliary materials ≈ (15-50): (20-60): (5-30), and then on the outer surface of the porous carrier filler Stick a layer of porous active and magnetic powder material layer to become active suspension filler.

[0016] The present invention can also according to specific production steps, according to figure 1 , figure 2 Shown in more detail listed in the following four steps to complete:

[0017] The first step of making porous carrier filler:

[0018] 1. Prepare foamed cement samples first: foam the cement foami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com