Preparation method for hierarchical pore perovskite catalyst

A perovskite and catalyst technology, which is applied in the field of preparation of multi-level porous perovskite catalysts, can solve the problems of catalytic activity limitation, reducing the contact area of reaction gas and catalyst active sites, etc., so as to reduce industrial waste gas and shorten the circulation and diffusion path , Improve the effect of mass transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

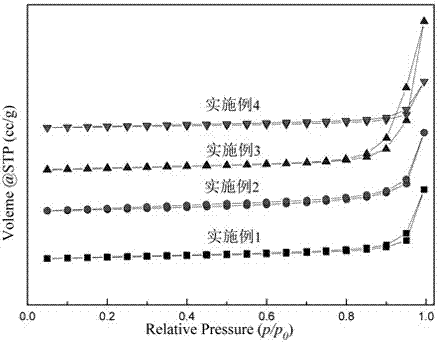

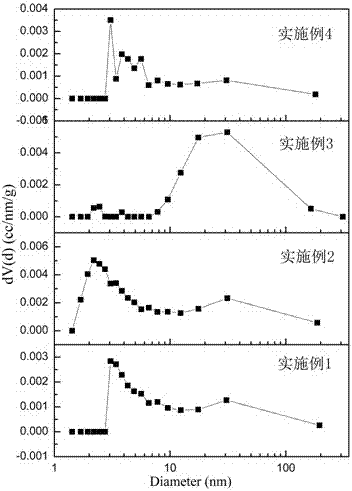

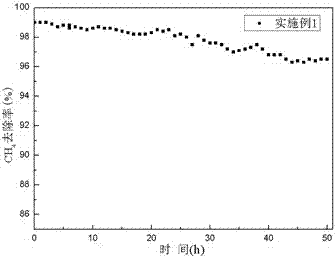

Embodiment 1

[0030] (1) Weigh lanthanum nitrate and cobalt nitrate at a molar ratio of 1:1, and weigh La(NO 3 ) 3 •6H 2 O 8.99g, Co(NO 3 ) 2 •6H 2 05.97g and complexing agent citric acid 10.31g, described citric acid molar number is 1.2 times of the sum of lanthanum nitrate and cobalt nitrate molar number;

[0031] (2) Add the mixture of lanthanum nitrate and cobalt nitrate and complexing agent weighed in step (1) into deionized water in sequence. After adding the deionized water, the total concentration of metal ions in the metal nitrate mixture is 0.1mol / L, That is, the total concentration of lanthanum nitrate and cobalt nitrate is 0.1mol / L, stir at room temperature for 0.5h, and mix the ingredients evenly;

[0032] (3) Heat and stir the product obtained in step (2) at 80°C, the water evaporates continuously, gradually forming a sol, and continue stirring until the color of the colloid becomes darker, until a wet gel is formed;

[0033] (4) The wet gel obtained in step (3) was left...

Embodiment 2

[0040] (1) Weigh lanthanum nitrate, strontium nitrate and cobalt nitrate at a molar ratio of 0.9:0.1:1, and weigh La(NO 3 ) 3 •6H 2 O 8.26g, Sr(NO 3 ) 2 0.44g and Co(NO 3 ) 2 •6H 2 O 6.10g and complexing agent EDTA18.31g, described complexing agent is ethylenediaminetetraacetic acid EDTA, and described ethylenediaminetetraacetic acid EDTA molar number is 1.5 times of the sum of lanthanum nitrate and cobalt nitrate molar number.

[0041] (2) Add the mixture of lanthanum nitrate, strontium nitrate and cobalt nitrate and complexing agent weighed in step (1) into deionized water in sequence, and then adjust the pH of the solution to 2~5. After adding deionized water, the metal nitrate mixture The total concentration of metal ions in the medium is 10mol / L, that is, the total concentration of lanthanum nitrate, strontium nitrate and cobalt nitrate is 10mol / L, and stirred at room temperature for 2h;

[0042] (3) Heat and stir the product obtained in step (2) at 60°C, the wate...

Embodiment 3

[0050] (1) Weigh lanthanum nitrate, cerium nitrate and cobalt nitrate at a molar ratio of 0.9:0.1:1, and weigh La(NO 3 ) 3 •6H 2 O 8.26g, Sr(NO 3 ) 2 0.44g and Co(NO 3 )2•6H 2 O 6.10g and complexing agent citric acid 8.58 g, described citric acid molar number is 1 times of the sum of lanthanum nitrate and cobalt nitrate molar number;

[0051] (2) Add the mixture of lanthanum nitrate, cerium nitrate and cobalt nitrate and complexing agent weighed in step (1) into deionized water in sequence. After adding the deionized water, the total concentration of metal ions in the metal nitrate mixture is 2mol / L, stirred at room temperature for 4h;

[0052] (3) Heat and stir the product obtained in step (2) at 90°C, the water evaporates continuously, gradually forming a sol, and continue stirring until the color of the colloid becomes darker, until a wet gel is formed;

[0053] (4) Let the wet gel obtained in step (3) stand for 48 hours to age, dry at 80°C, and grind to 200 mesh; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com