Drawing method of thin film solar cell and thin film solar cell device

A technology for solar cells and scribing equipment, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of high cost, achieve simple production methods, improve conversion efficiency, and reduce the effect of dead zone area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

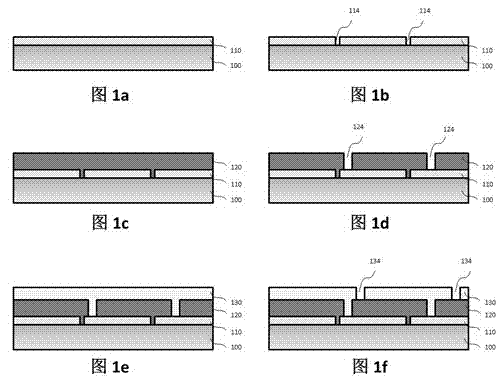

Embodiment 1

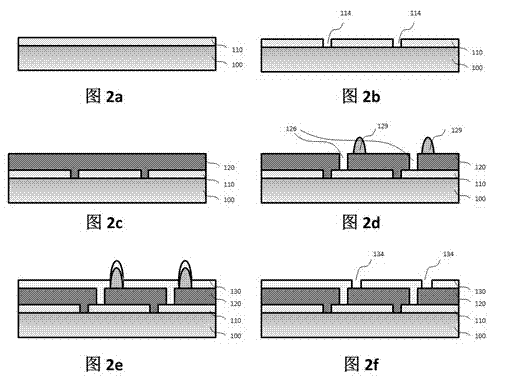

[0031] figure 2 Series is a schematic diagram of the laser scribing method for thin film solar cells of the present invention. figure 2 a is a substrate 100 with a transparent oxide TCO film layer 110, which is subjected to the first laser scribing P1 to form a TCO groove 114 ( figure 2 b), then cleaning the glass substrate 100, and then coating the semiconductor film 120 on the scribed TCO film layer 110 ( figure 2 c).

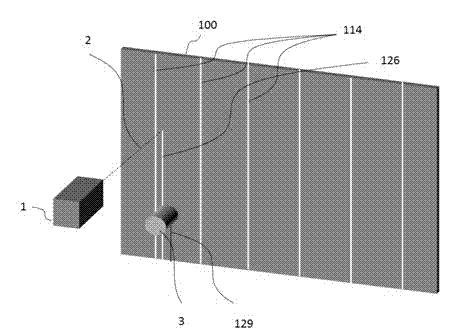

[0032] when using image 3 In the scribing equipment shown, the glass substrate 100 is subjected to two scribing lines P2 and P3 at the same time, and the laser scribing line P2 penetrates the semiconductor film layer 120 to form a second groove 126, see figure 2 d; the inkjet printing head is used as a soluble line forming device to simultaneously print and form a soluble material line 129 on the other side of the second groove 126 as a third groove preparation layer, see figure 2 d.

[0033] Continue to plate the back electrode film layer 130 on ...

Embodiment 2

[0037] The laser scribing method is the same as the first embodiment. The difference is when using image 3 In the scribing equipment shown, the glass substrate 100 is first subjected to the second laser scribing line P2, and the laser scribing line P2 penetrates the semiconductor film layer 120 to form the second groove 126, see figure 2 d; After the second groove 126 is formed, the laser printing head serves as the soluble line forming device 3 to print and form the soluble material line 129 on the other side of the second groove 126 as the third groove preparation layer, see figure 2 d.

[0038]Continue to plate the back electrode film layer 130 on the semiconductor film layer 120, then use water or an organic solvent to clean to remove the soluble line preparation layer 129 and the back electrode material deposited on the soluble line preparation layer 129, so that the back electrode layer A third trench 134 is formed on the film 130 .

[0039] From Figure 4a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com