Fuel cell stack flow field plate capable of supporting high-current density discharging

A fuel cell stack and high current density technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve problems such as increased contact resistance, no advantages, complex stack structure, etc., to reduce shape and position errors, The effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

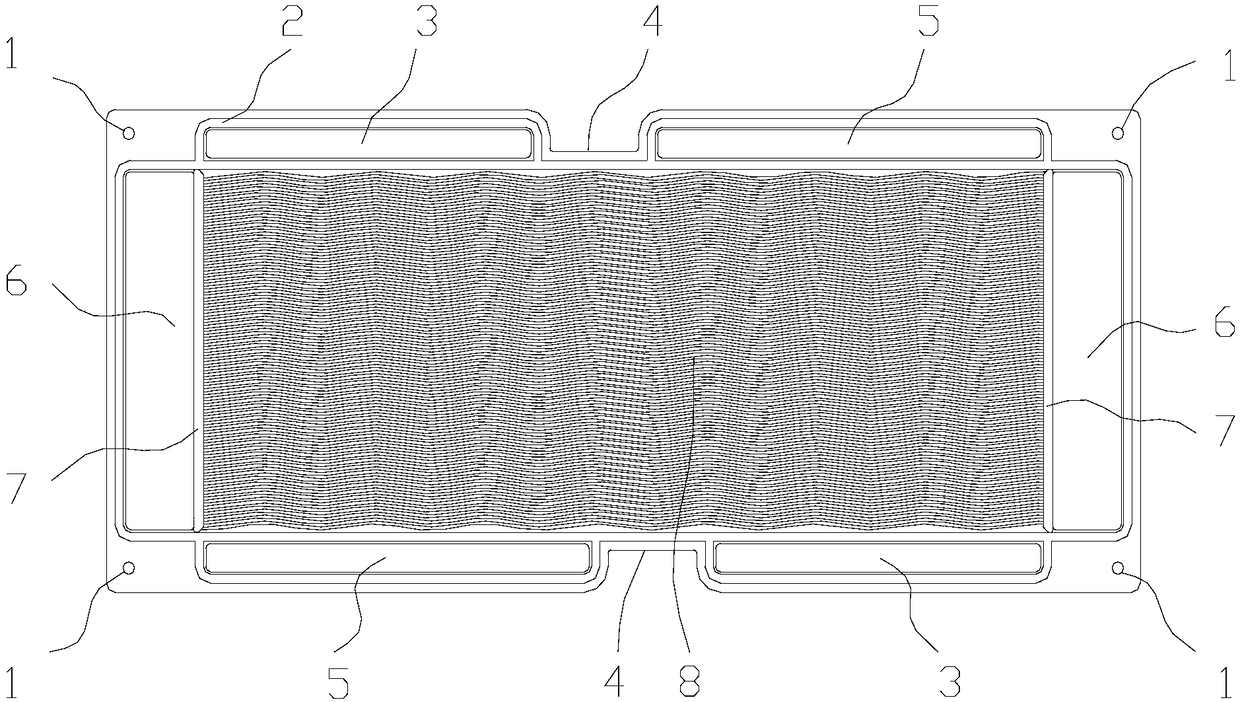

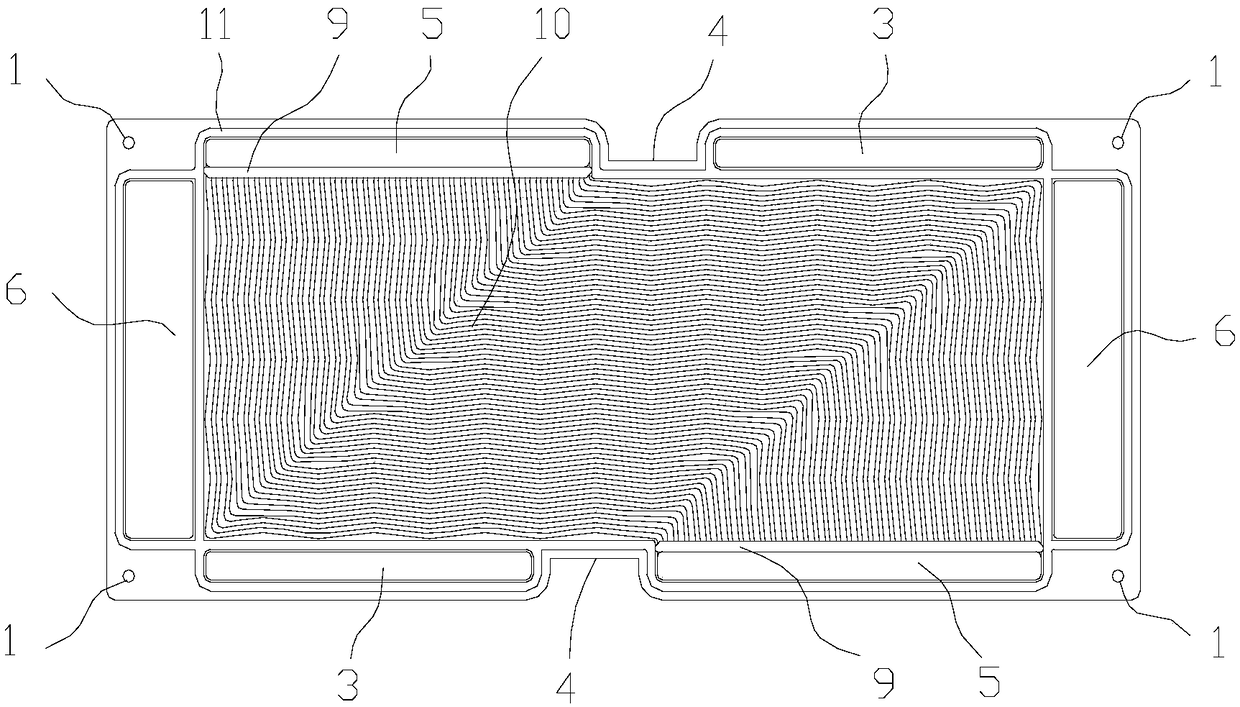

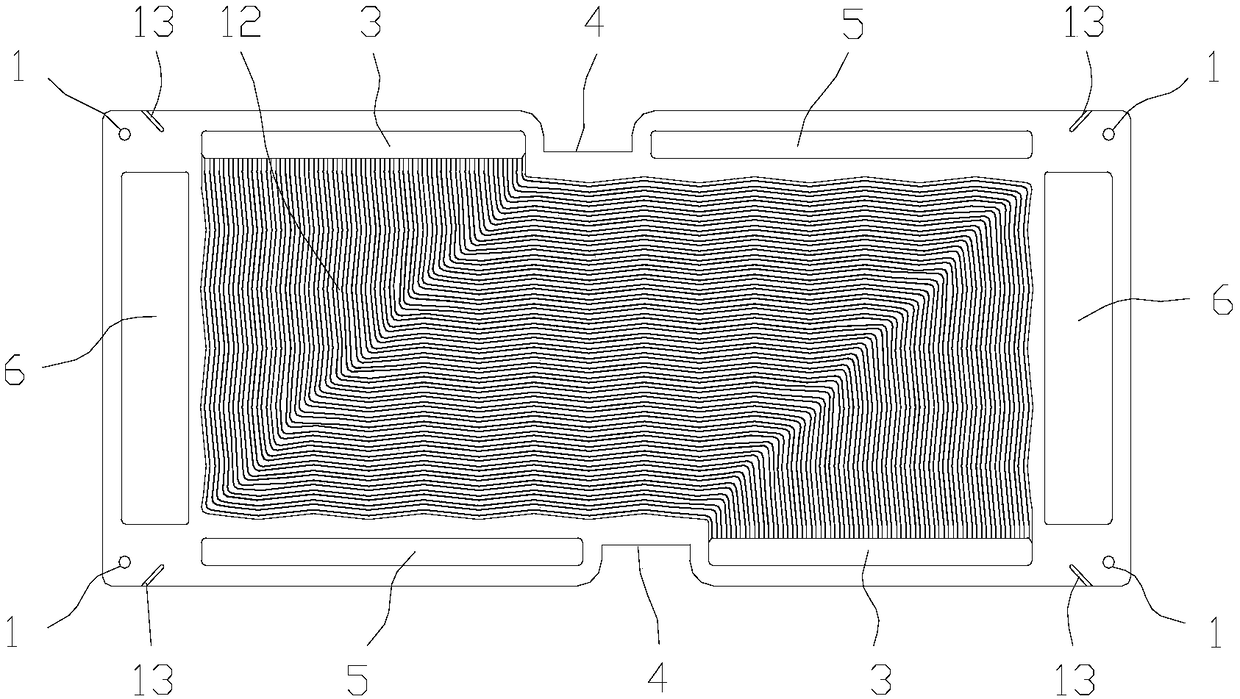

[0080] A fuel cell stack flow field plate supporting high current density discharge, including a cathode flow field plate and an anode flow field plate oppositely connected on the back, and its structures are as follows figure 1 and figure 2 As shown, the fronts of the cathode flow field plate and the anode flow field plate are respectively processed with corrugated air flow field channels 8 and hydrogen flow field channels 10. This water corrugated design is conducive to increasing the turbulent flow of air and hydrogen. , to achieve the effect of promoting its transmission in the direction perpendicular to the gas diffusion layer. A cooling water flow field channel 12 is processed between the back of the cathode flow field plate and the anode flow field plate, such as image 3 As shown, in this embodiment, the backside of the anode flow field plate is processed, and the cathode flow field plate and the anode flow field plate are combined by laser welding to form the follow...

Embodiment 2

[0089] The difference from Embodiment 1 is that in this embodiment, the metal cathode flow field plate and the anode flow field plate are combined using sealant instead of welding. Such as Figure 4 As shown, the back side of the anode flow field plate, that is, the side of the water flow field, around the cooling water flow field channel 12, increases the preformed glue line that can be used to install or use a high-viscosity sealant to form a seal in situ. sealing groove. If pre-formed glue lines are installed, the glue lines must be completely flattened after the stack assembly is pressed to ensure good electrical contact; if a high-viscosity sealant is used to form the seal in situ, it needs to be sealed before the sealant cures. Use corresponding clamps to press the cathode and anode flow field plates together until the sealant is completely cured before releasing. The advantage of adopting this combination method is to avoid thermal swelling, deformation, twisting or w...

Embodiment 3

[0094] The difference from the previous two embodiments is that in this embodiment, the material of the flow field plate is changed to graphite, and the rest are the same as in Example 2. In this embodiment, a sealant is used to combine the cathode flow field plate and the anode flow plate. field board. Compared with metal plates, graphite plates have excellent corrosion resistance, but slightly poorer electrical conductivity than metal plates.

[0095] The design of the graphite flow field plate is exactly the same as that of the second embodiment, and will not be repeated here.

[0096] Likewise, the present embodiment adopts active area 340cm 2 The flow field plate and MEA are used to assemble a 15-section small electric stack. Figure 12 For its polarization curve, the test conditions are as follows: the air / hydrogen stoichiometric ratio is 2.5 / 1.4; the air / hydrogen inlet pressure is 120kPa / 125kPa; the air / hydrogen inlet humidity is controlled at 80%RH. It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com