Hot-blast stove column one-time clamping turning clamping device

A hot blast furnace and furnace column technology, which is applied in the field of metallurgical equipment manufacturing, can solve the problems of complex clamping and disassembly of furnace column machining, low processing efficiency, and many disassembly and assembly procedures, and achieves easy clamping and alignment, fabrication and installation. Convenience and the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

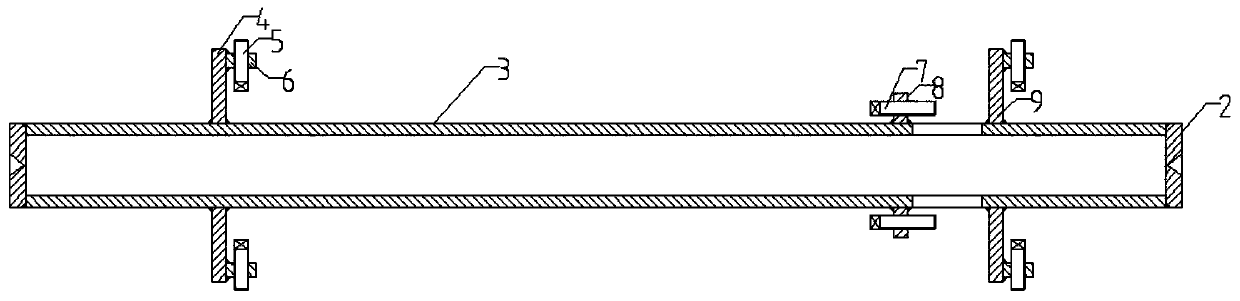

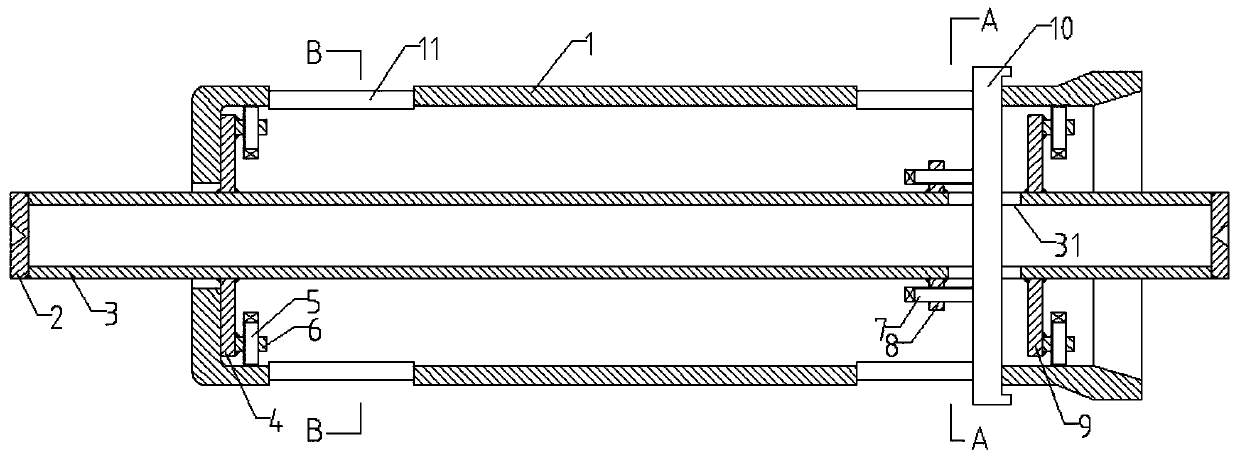

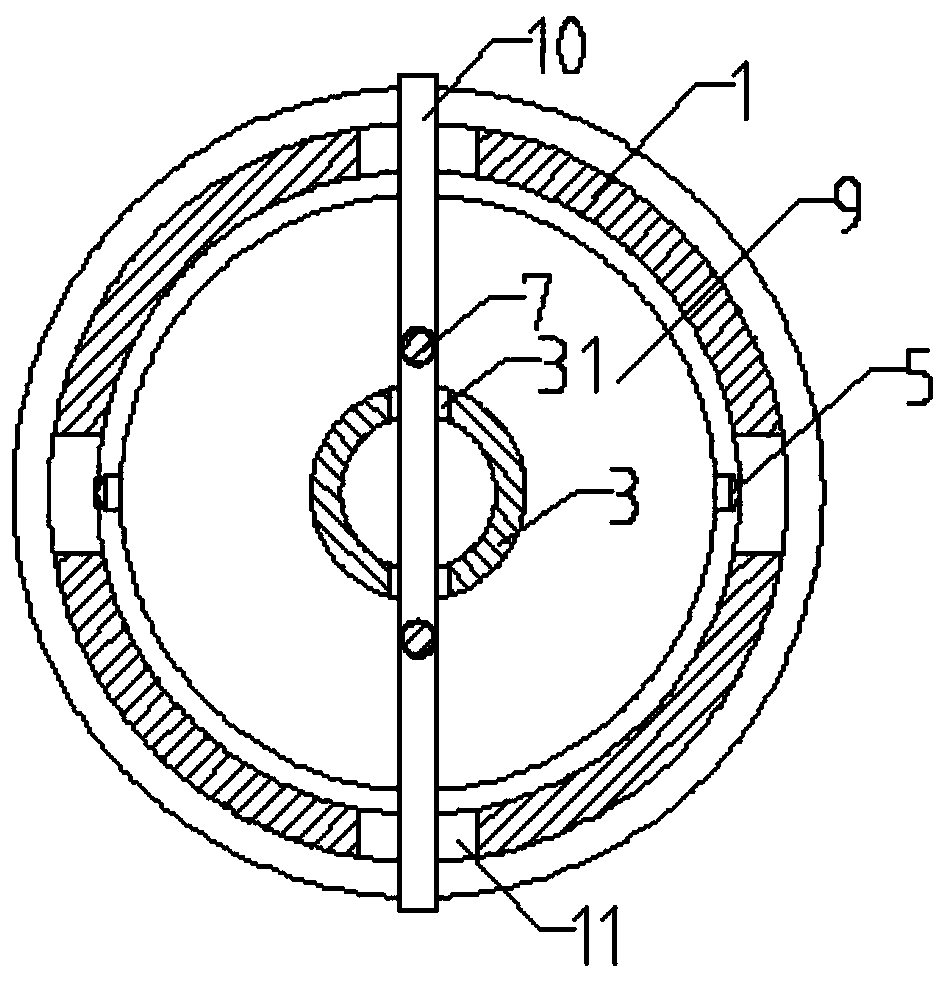

[0021] Such as Figure 1 to Figure 4 As shown, the one-time clamping and turning clamping device of a hot blast stove column of the present invention includes a support rod 3, a disc one 4, a disc two 9 and a weight 10, and the disc one 4 and the disc two 9 are spaced apart and Vertically sleeved on the outer wall of the support rod 3, the support rod 3 is provided with a positioning hole 31 passing through the support rod 3 in the radial direction, and the positioning hole 31 is located between the first disc 4 and the second disc 9 and is close to the second disc 9 , the support rod 3 is provided with an axial positioning device, and the axial positioning device is located on the side wall of the support rod 3 close to the positioning hole 31 and away from the second disk 9, the weight 10 can pass through the positioning hole 31 and the left side and the The axial p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com