A processing method for oblique holes of channel steel parts

A processing method and oblique hole technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing efficiency, cumbersome processing process, high operation intensity, etc., and achieve improved processing efficiency and simple processing process , Safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the embodiments provided by the accompanying drawings.

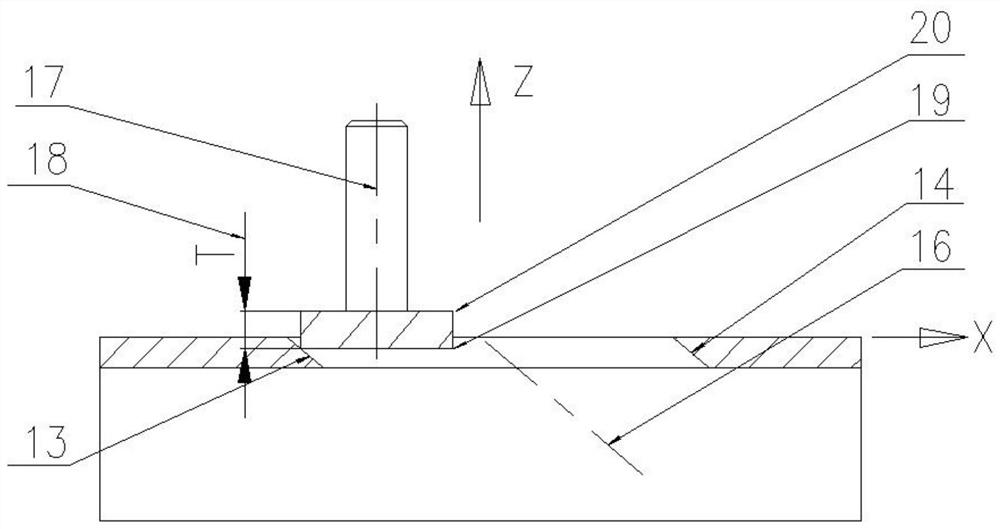

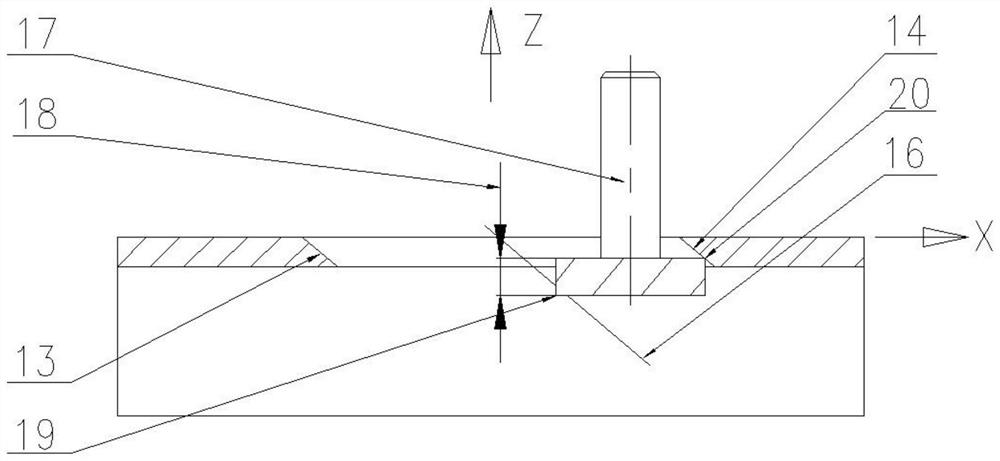

[0017] The method for processing the oblique hole of the channel steel part includes three steps: step 1, processing preparation, step 2, parameter setting, and step 3, processing implementation.

[0018] Processing preparation stage: CNC milling machine XKA5032A is selected as the processing equipment for milling inclined holes in channel steel. The workpiece is clamped horizontally, and the T-shaped milling cutter is spared. The axis of the milling cutter is perpendicular to the surface of the inclined hole. The axis of the milling cutter and the axis of the inclined hole do not have to be parallel.

[0019] Parameter setting stage:

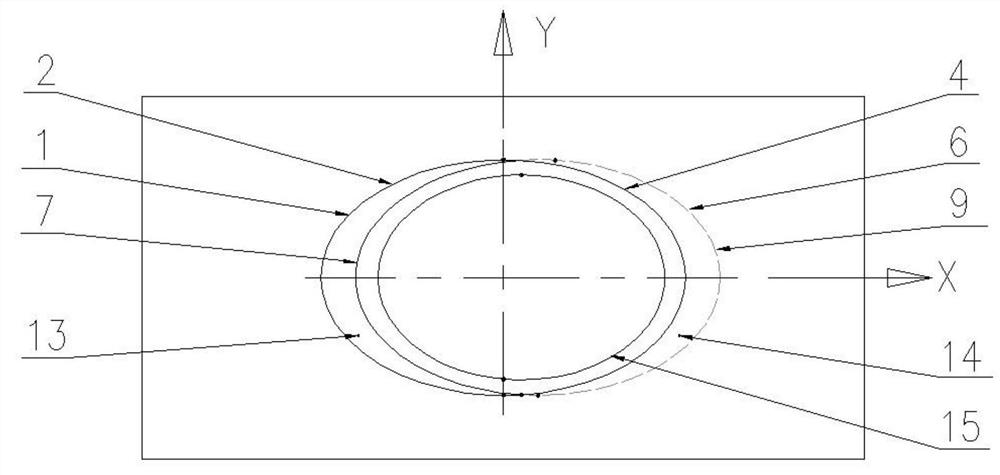

[0020] Extract the line frame of the inclined hole: use CAD software to draw the three-dimensional solid map of the inclined hole of the channel steel, extract the line frame 1 of the opening and the line frame 6 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com