Patents

Literature

97results about How to "Achieve axial fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

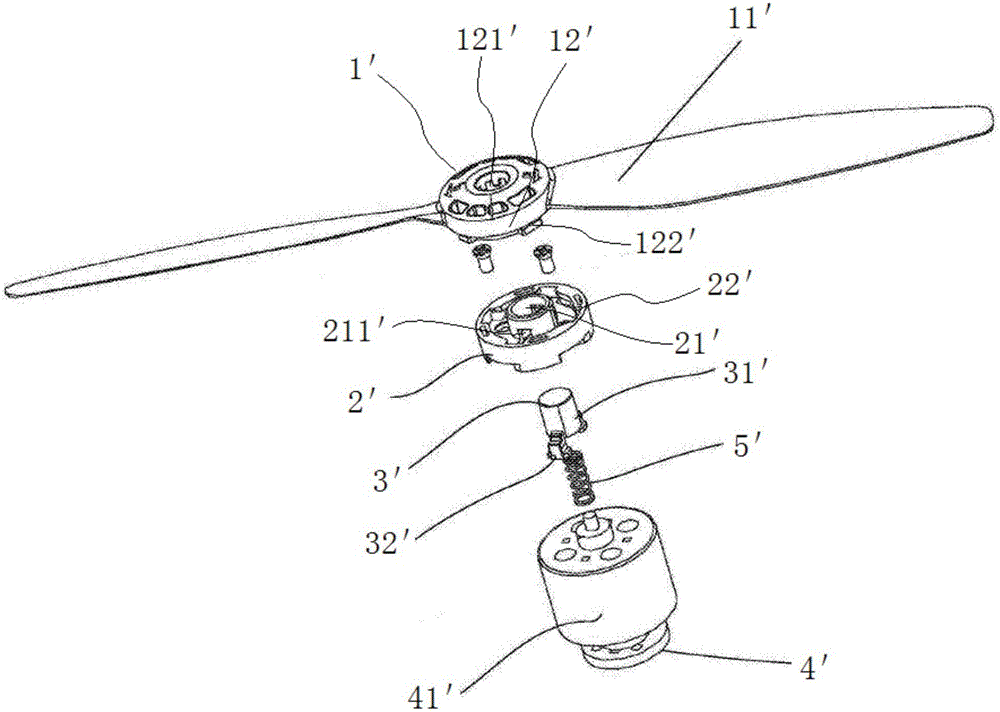

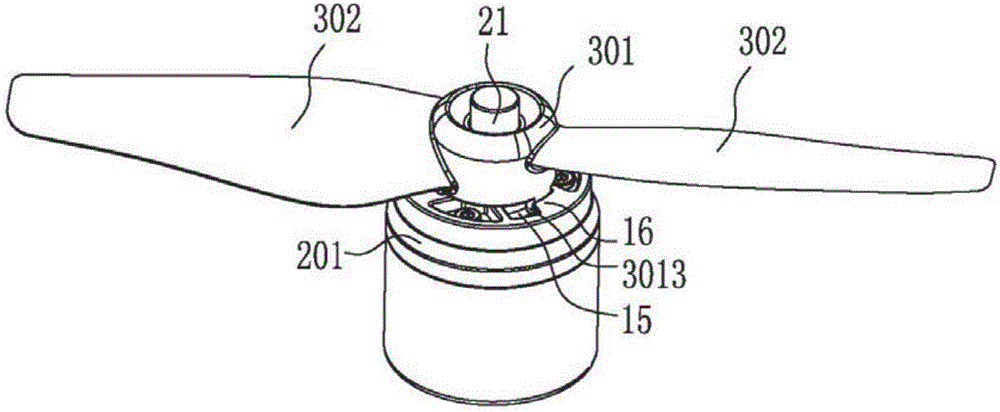

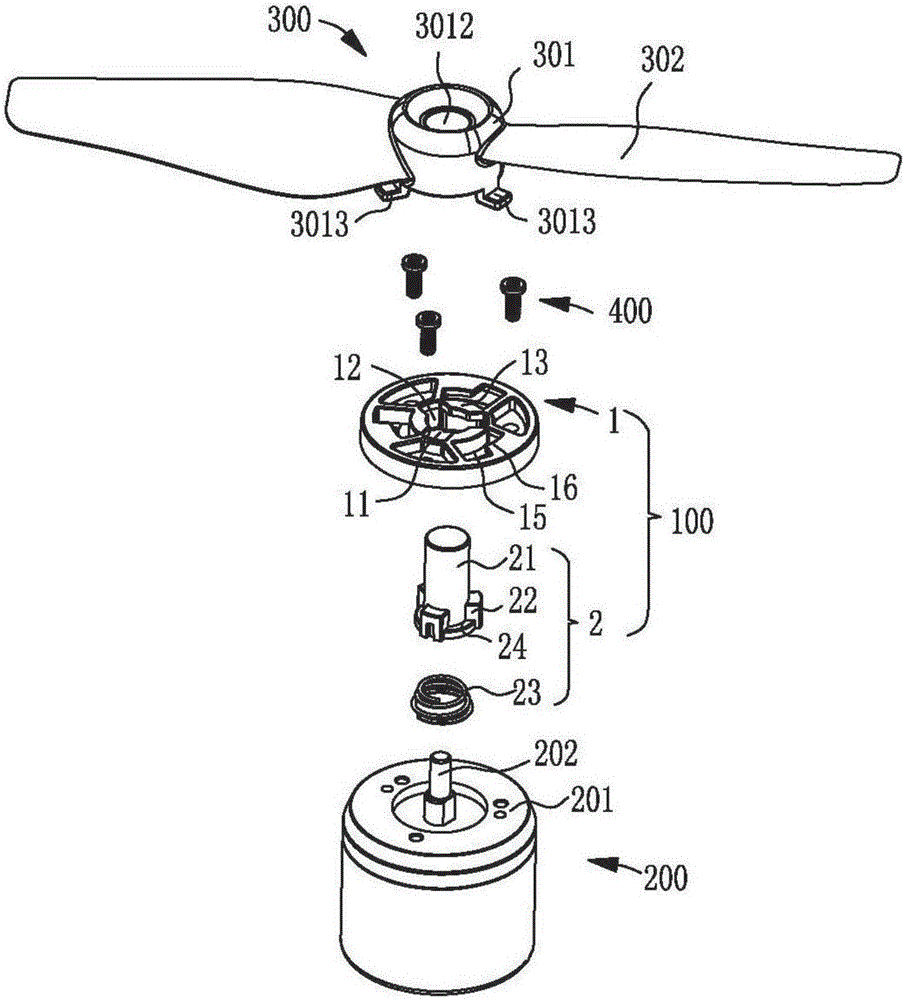

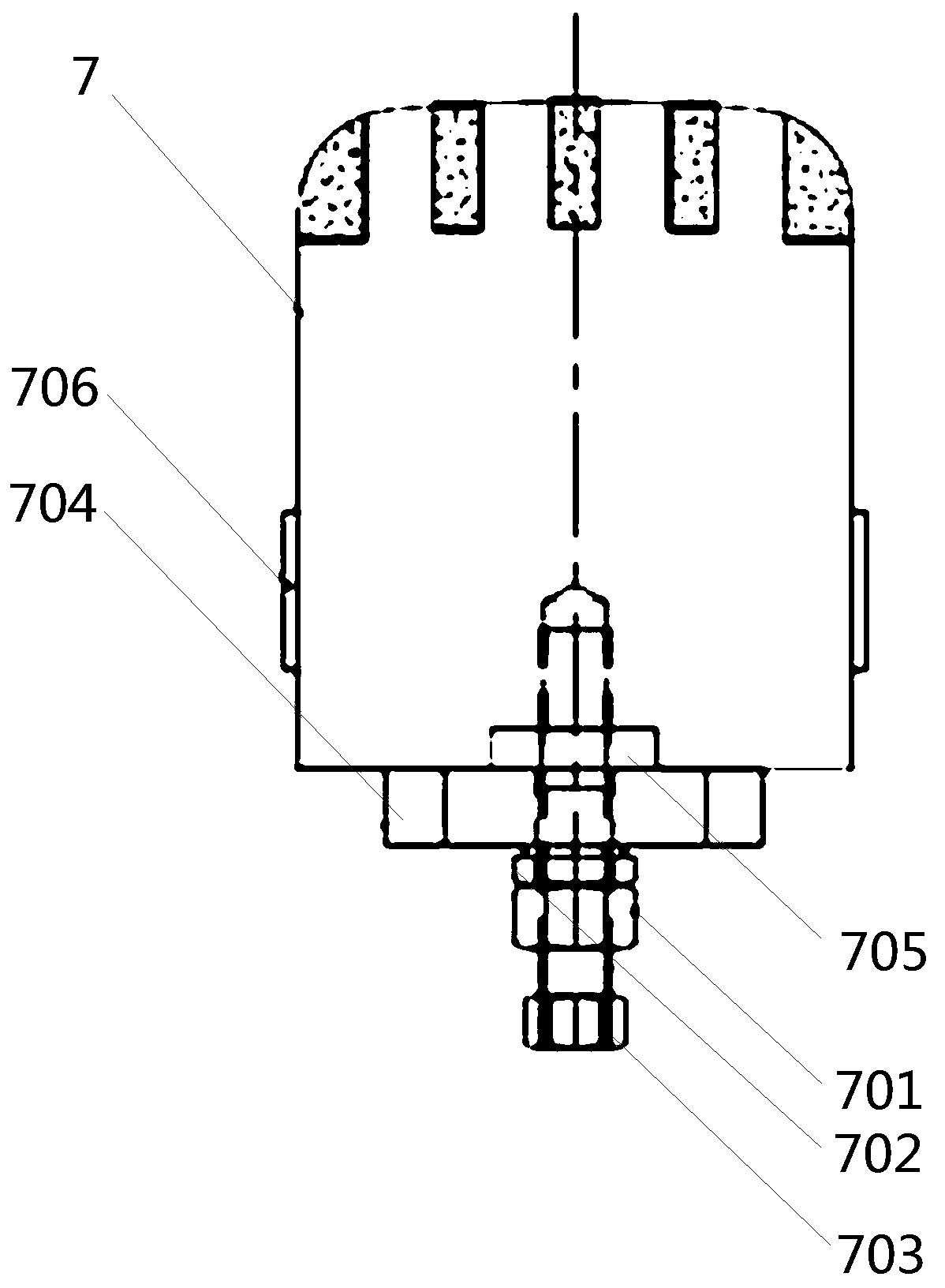

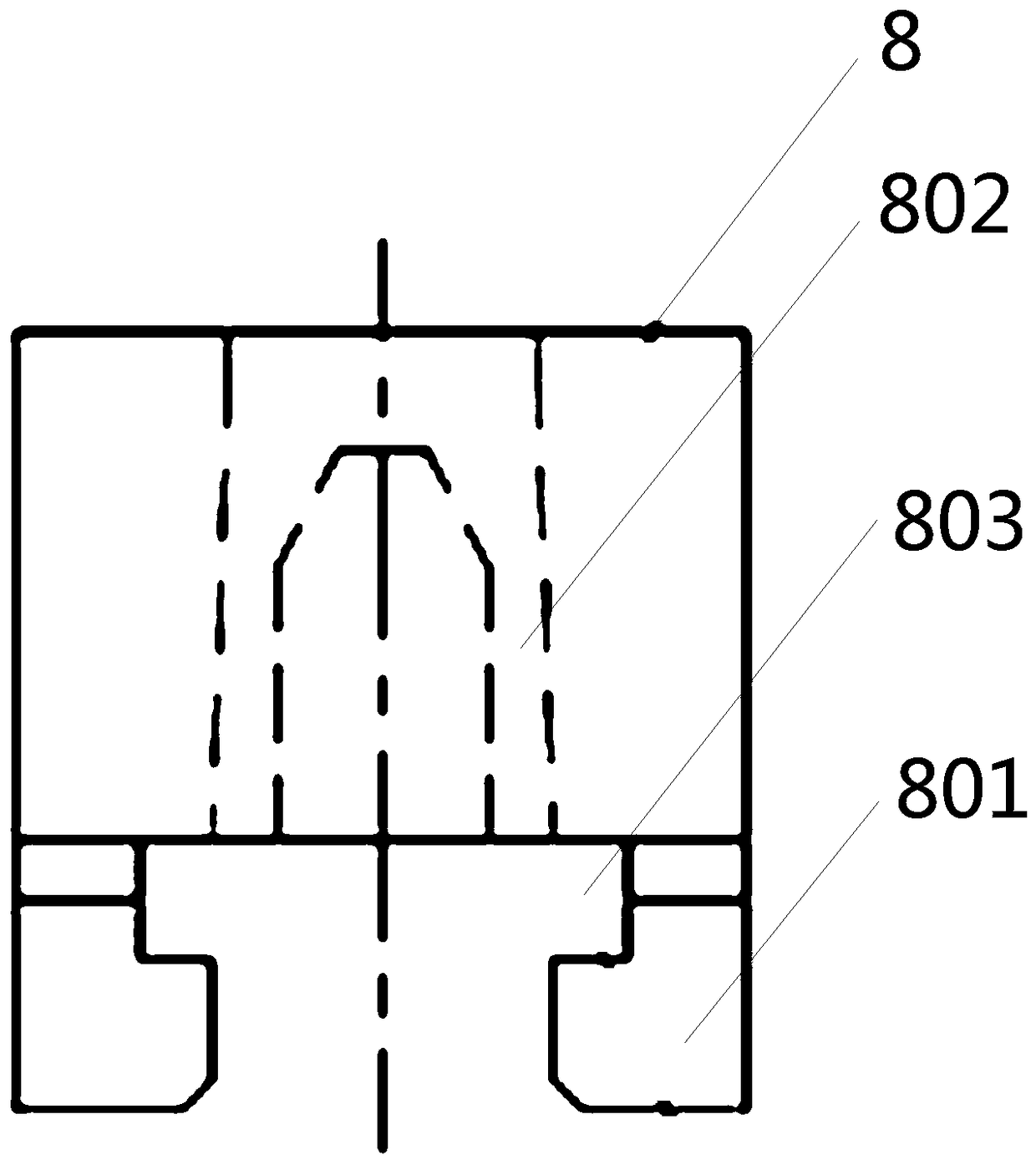

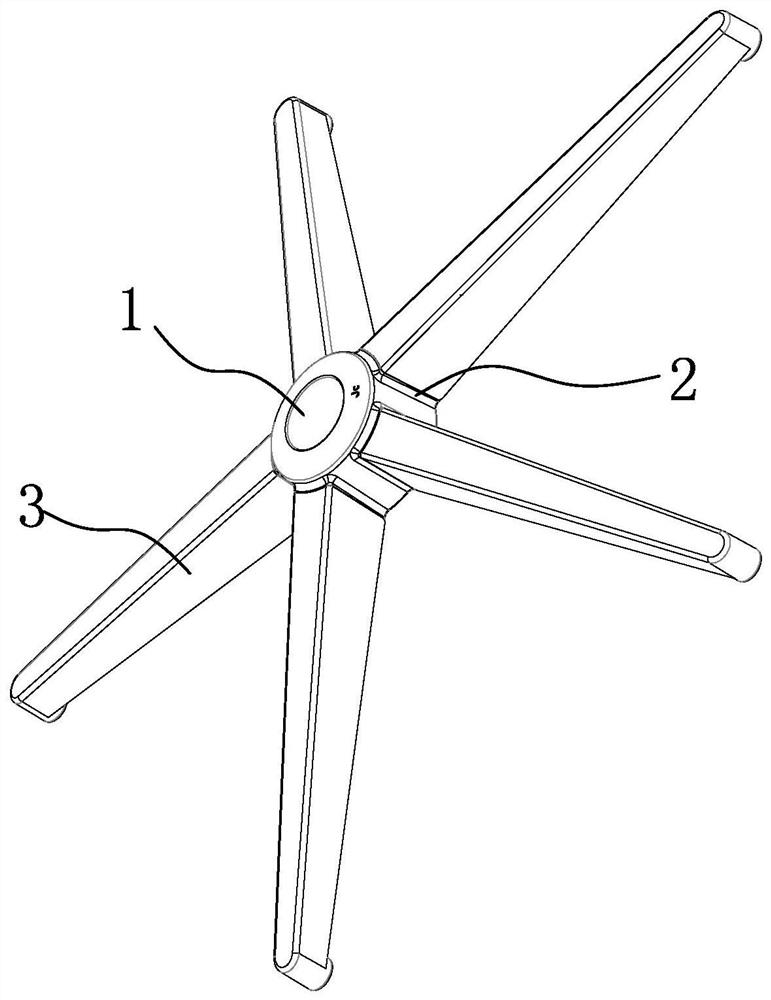

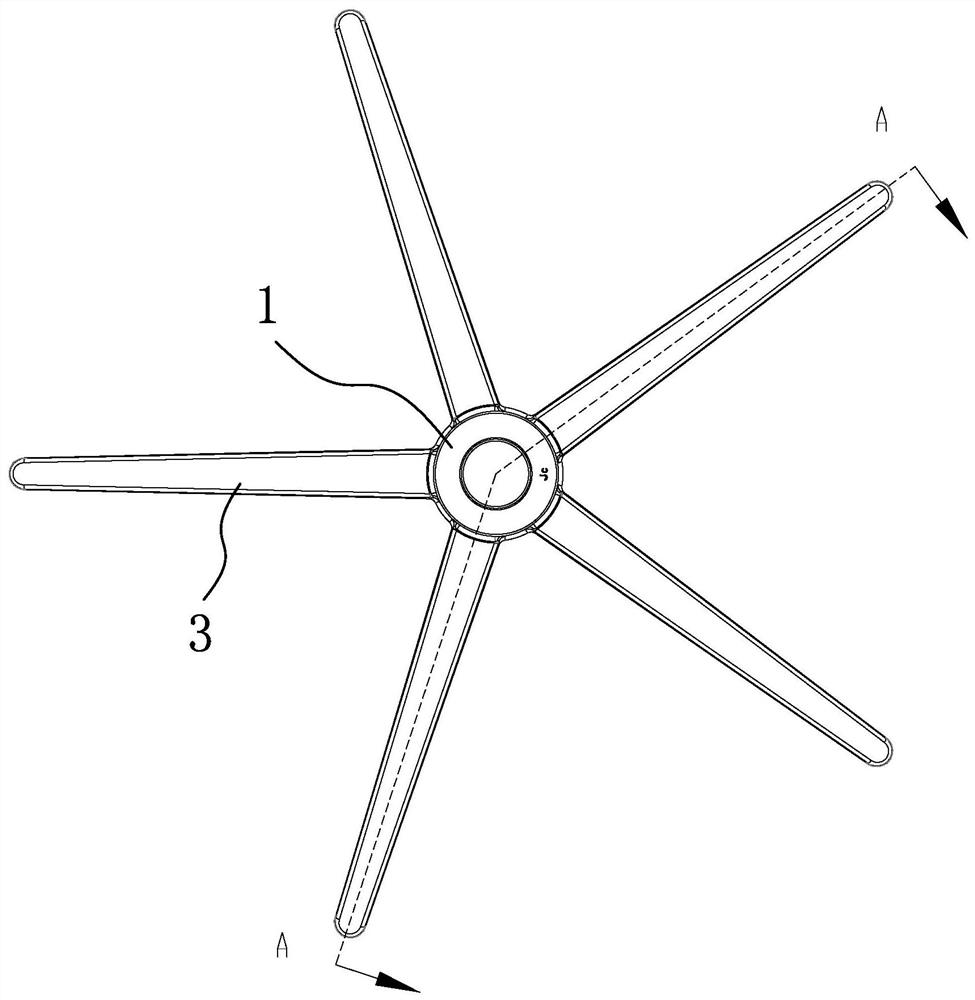

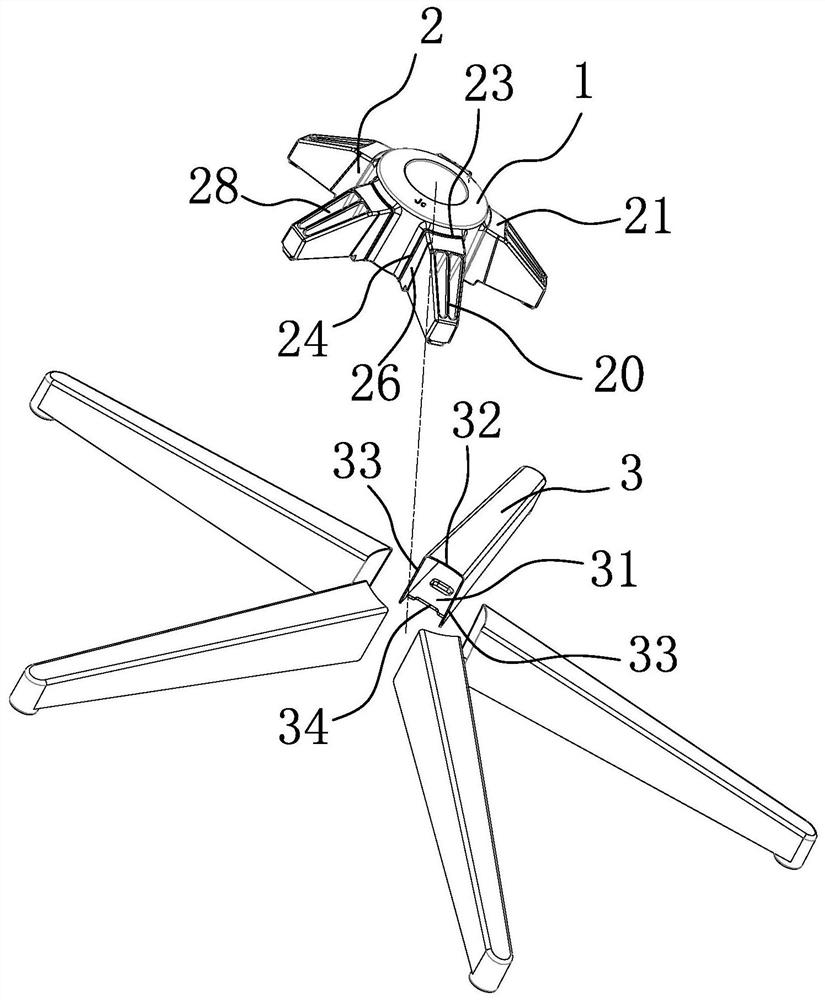

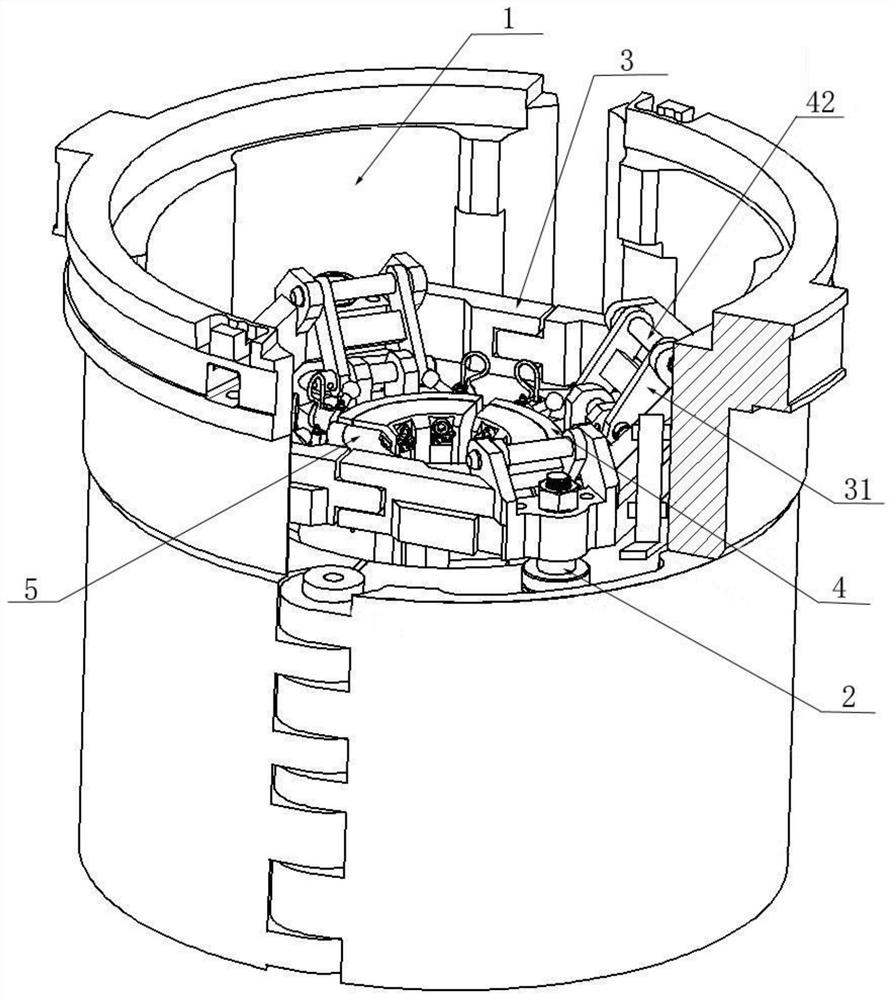

Aircraft and propeller fast disassembly device thereof, fast-disassembly propeller and propeller base component

The invention provides an aircraft and a propeller fast disassembly device thereof, a fast-disassembly propeller and a propeller base component. The propeller fast disassembly device comprises a fast-disassembly propeller and a propeller base component; the fast-disassembly propeller comprises a seat body and a blade arranged on the seat body; the propeller base component comprises a fixed seat and a key switch; a clamping mechanism in detachable connection through rotation is arranged between the fixed seat and the seat body; the key switch is provided with a key body suitable for pressing touch and a key block fixed on the key body; multiple positioning structures corresponding to the key block when the seat body is in a clamping position are formed on the side of the seat body facing the fixed seat; and the key block is embedded into the positioning structure in a state without external force pressing and clamped between the fixed seat and the seat body, thus the peripheral movement of the fast-disassembly propeller is limited by the key block and a positioning slot, and such limitation is different from axial force limitation, therefore the mechanical strength is improved and an effect of good stability is realized.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

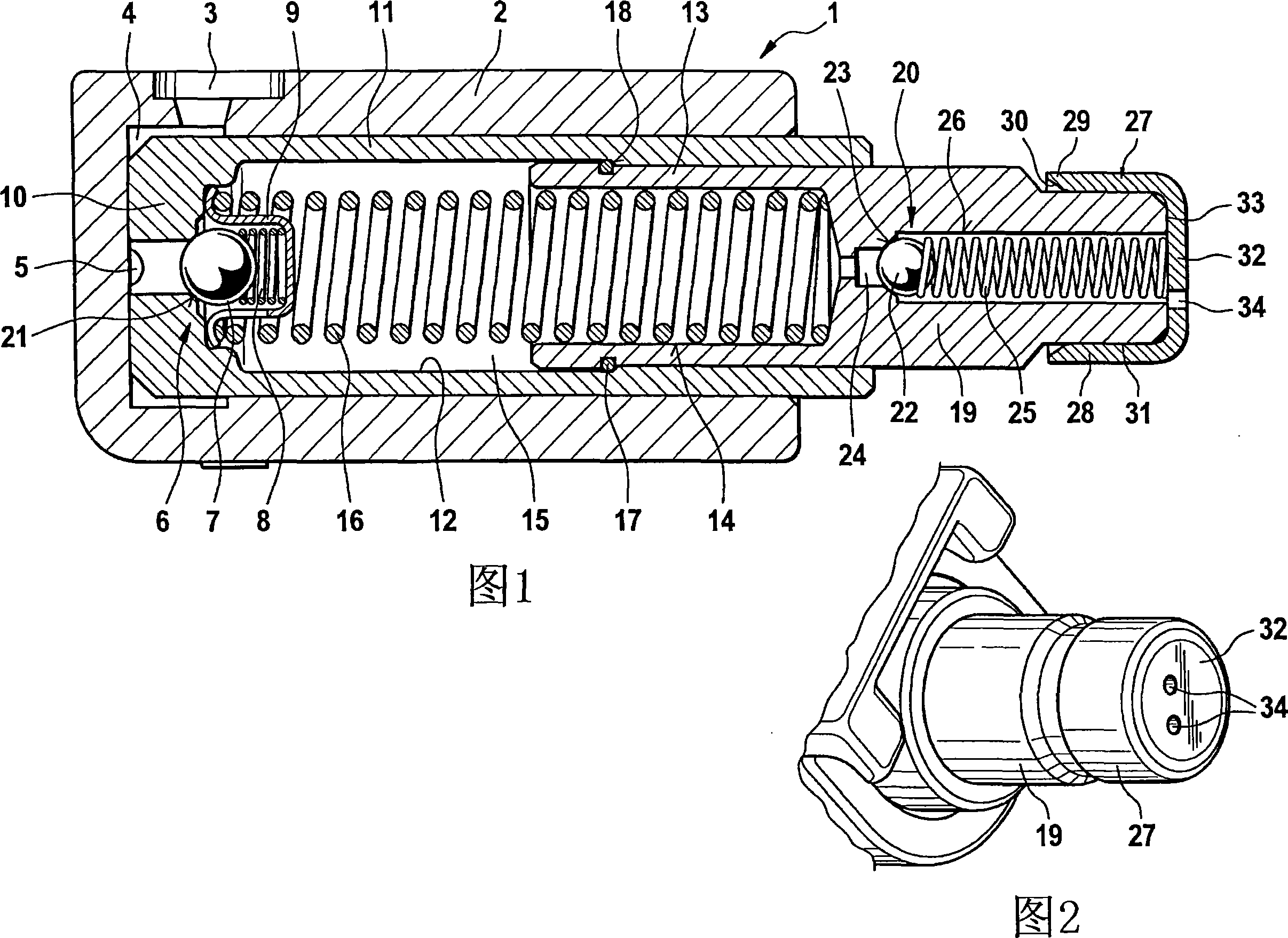

Hydraulic tensioner

InactiveCN101061331AEasy to transformReduce manufacturing costGearingLocking mechanismRemote control

To provide a remote control system which is operable by using a portable terminal only when a person is present near a vehicle.The remote control system is formed of a receiving means for receiving a door locking request signal or a door unlocking request signal, a door locking mechanism, a signal determining means for determining whether a signal received by the receiving means is the door locking request signal or the door unlocking request signal, a locking instructing means for transmitting a locking instruction signal to the locking mechanism, an unlocking instructing means for transmitting an unlocking instruction signal to the locking mechanism, and a person checking means for checking whether or not a person is present near the vehicle, and transmitting a person confirmation signal to the unlocking instructing means. If the signal determining means determines that the signal received by the receiving means is the door locking request signal, the locking instructing means transmits the locking instruction signal to the locking mechanism. If the signal determining means determines that the signal received by the receiving means is the door unlocking request signal, the unlocking instructing means transmits the unlocking instruction signal to the locking mechanism on condition that the locking mechanism receives the person confirmation signal in a predetermined time period.

Owner:SCHAEFFLER TECH AG & CO KG

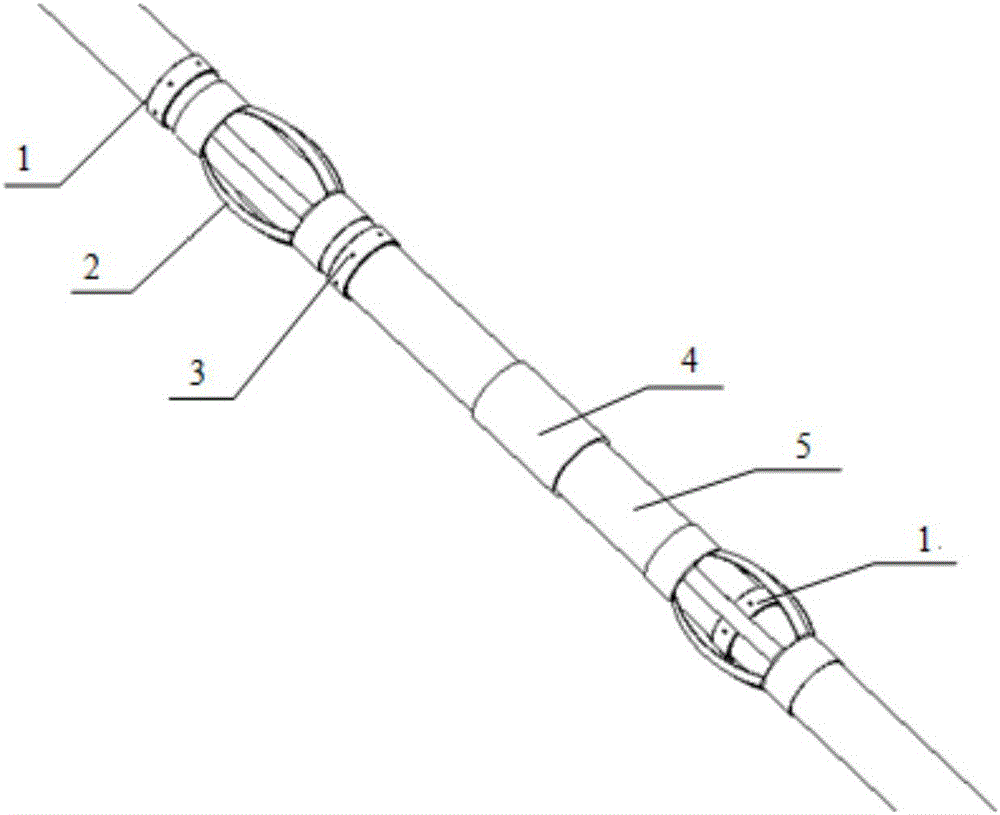

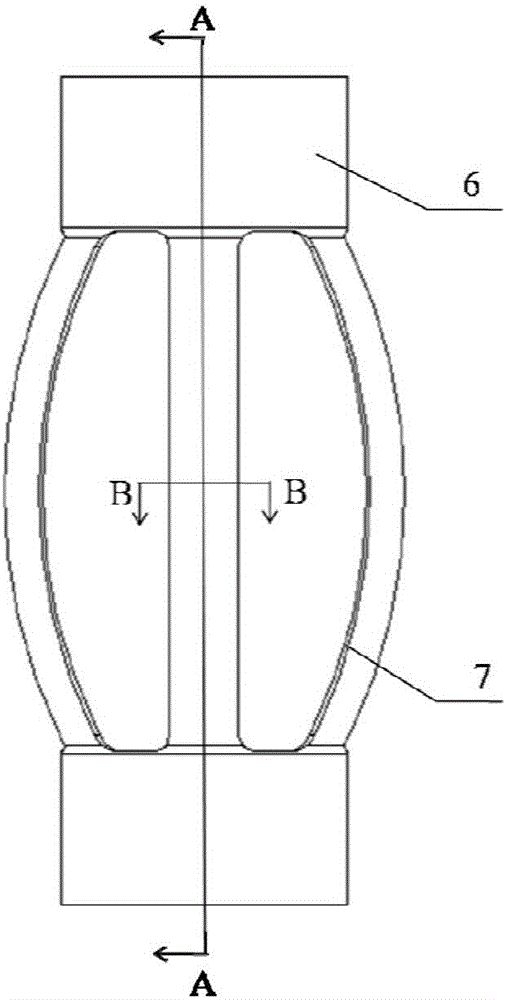

Integral type casing centralizer and manufacturing method thereof

The invention provides an integral casing centralizer and a manufacturing method thereof, belonging to the field of oil and gas well cementing. The integral casing centralizer is processed by uniform wall thickness material pipe or plate, including hoops at both ends, and limbs located between the hoops at both ends; the limbs are evenly distributed on the circumference, and each The two ends of each limb are respectively connected with the hoops at both ends; each limb is arched outward; the outer diameter of the centralizer formed by all the limbs is smaller than or equal to the inner diameter of the upper casing.

Owner:CHINA PETROLEUM & CHEM CORP +1

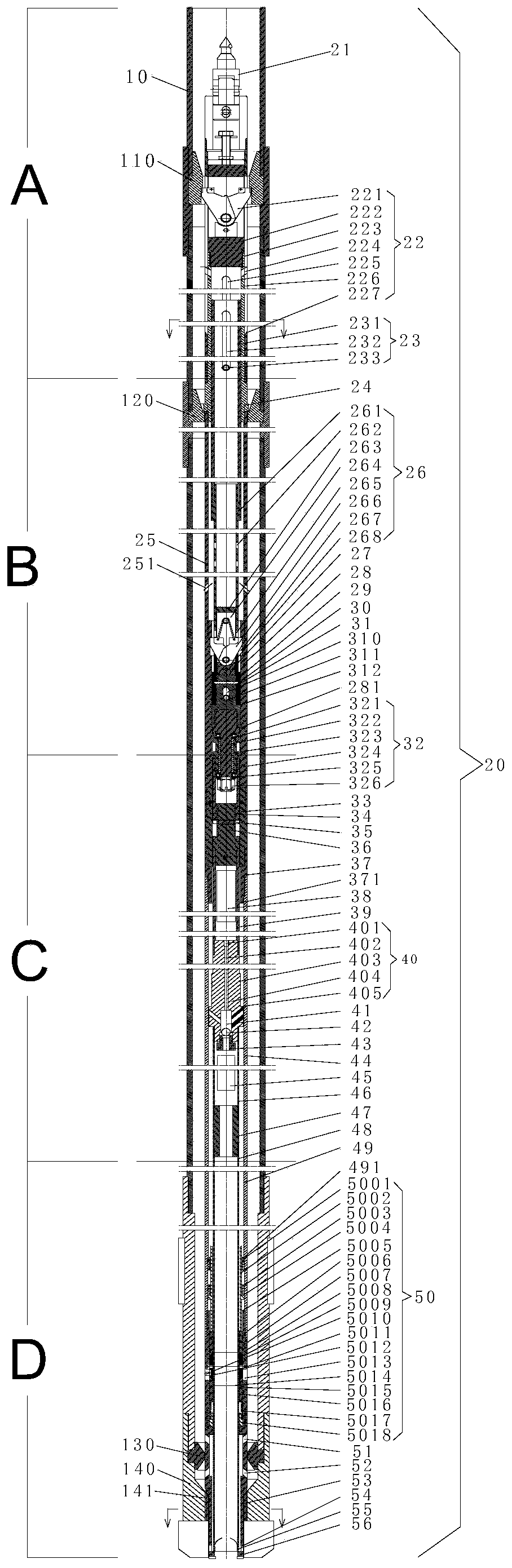

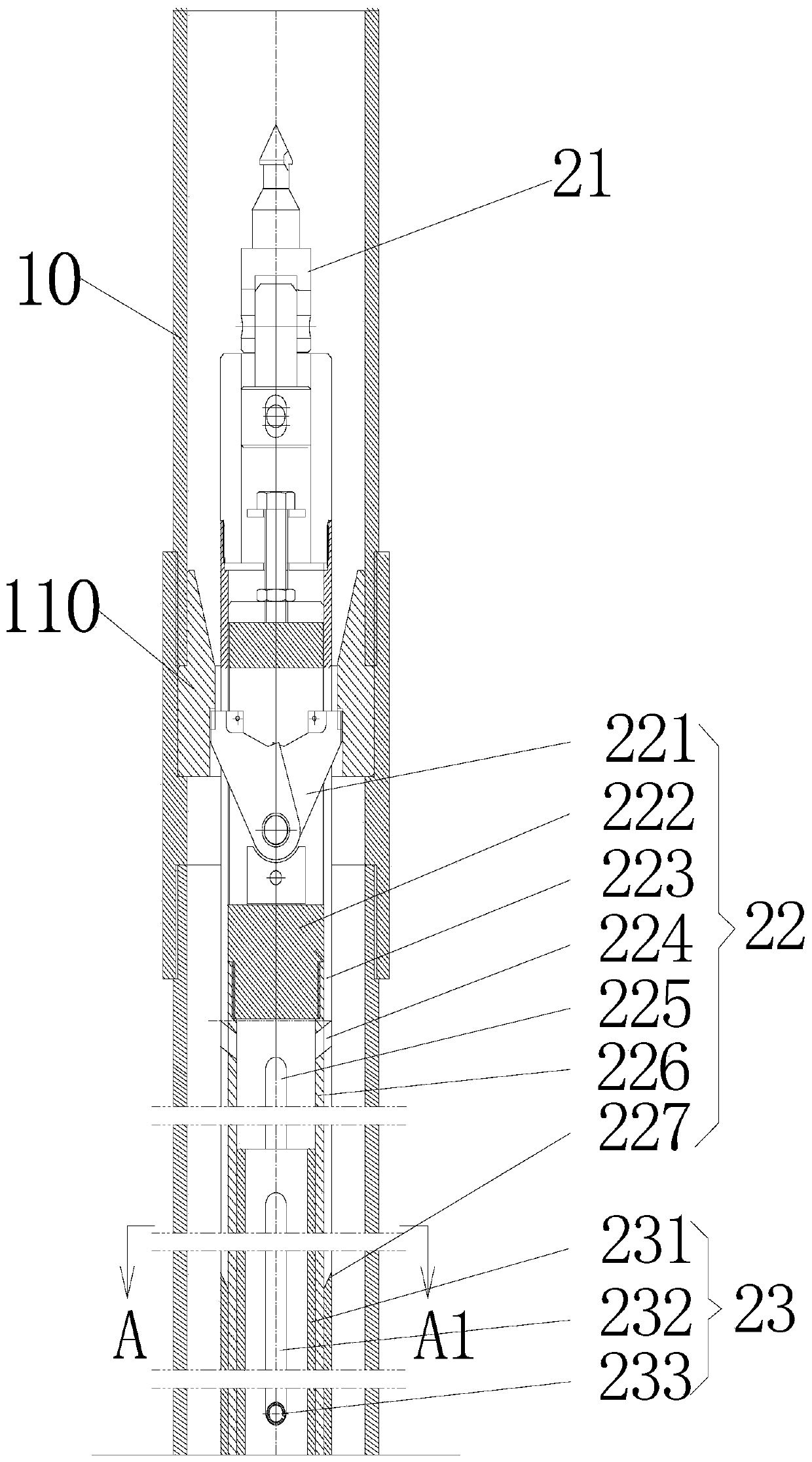

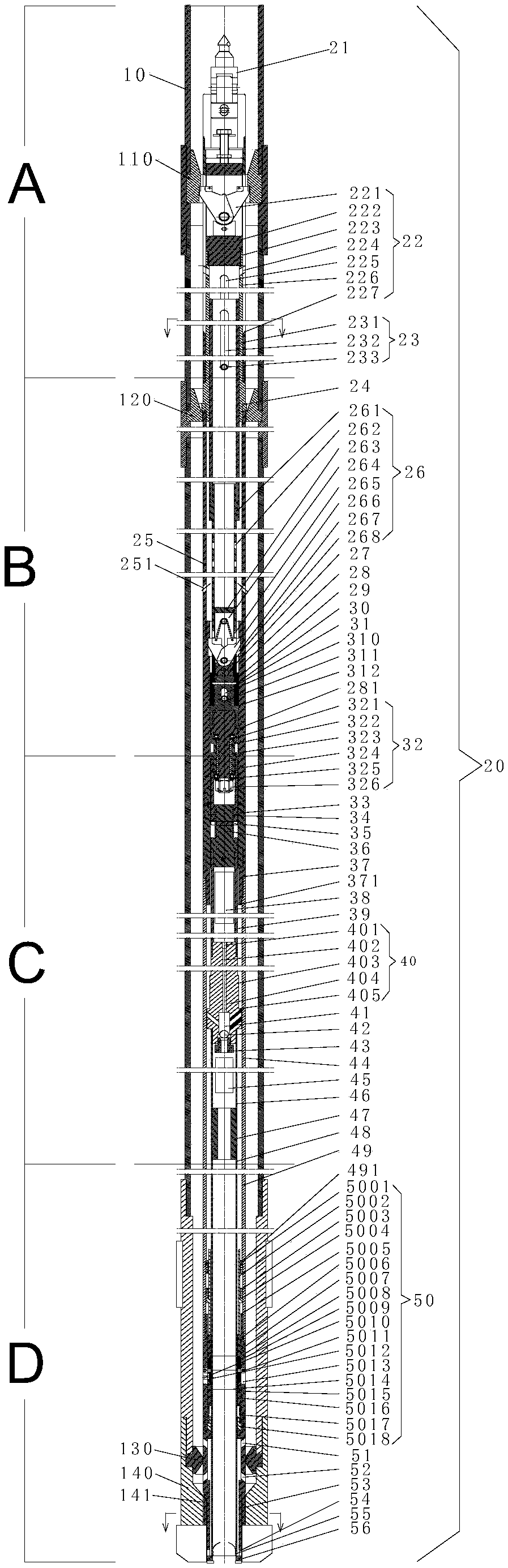

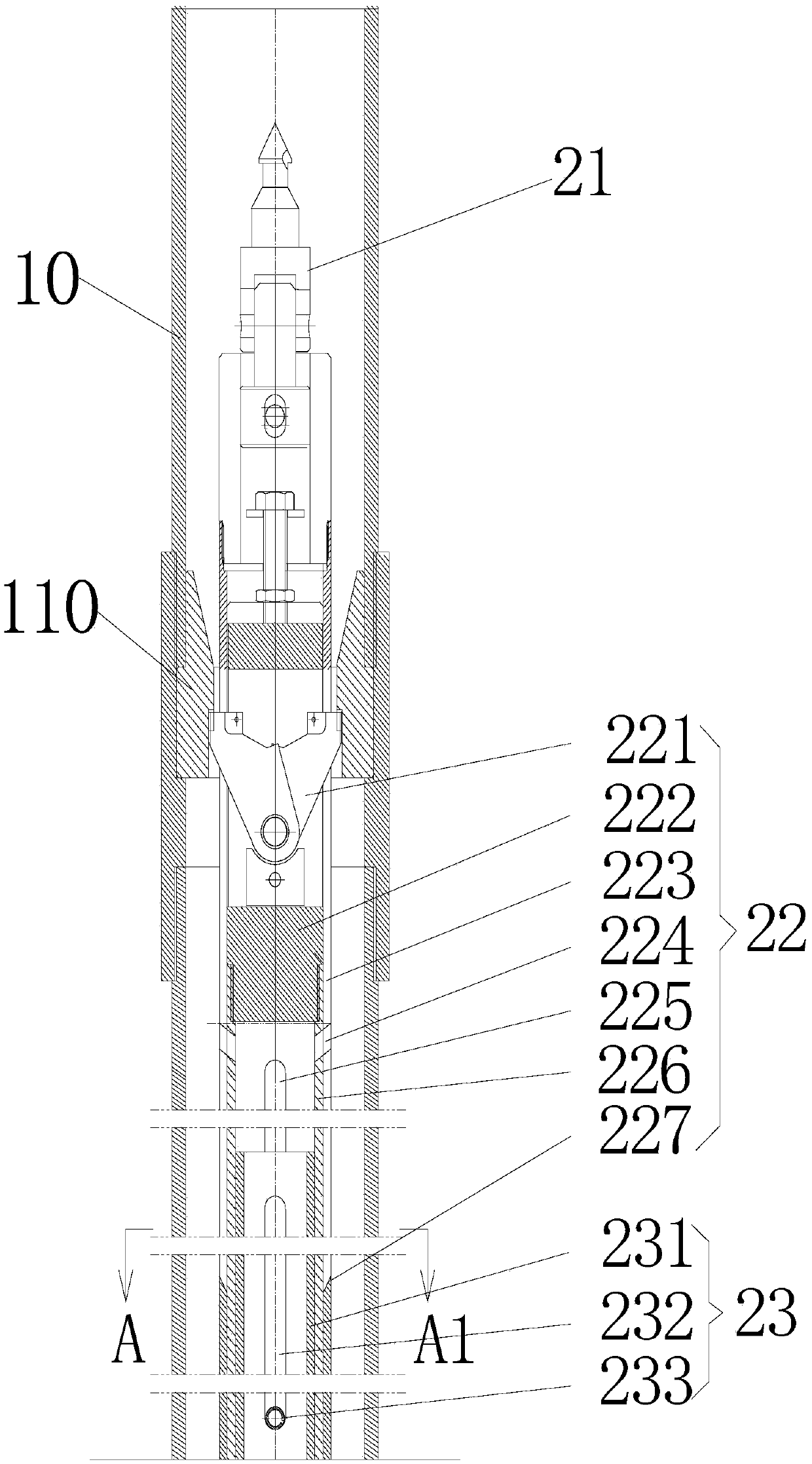

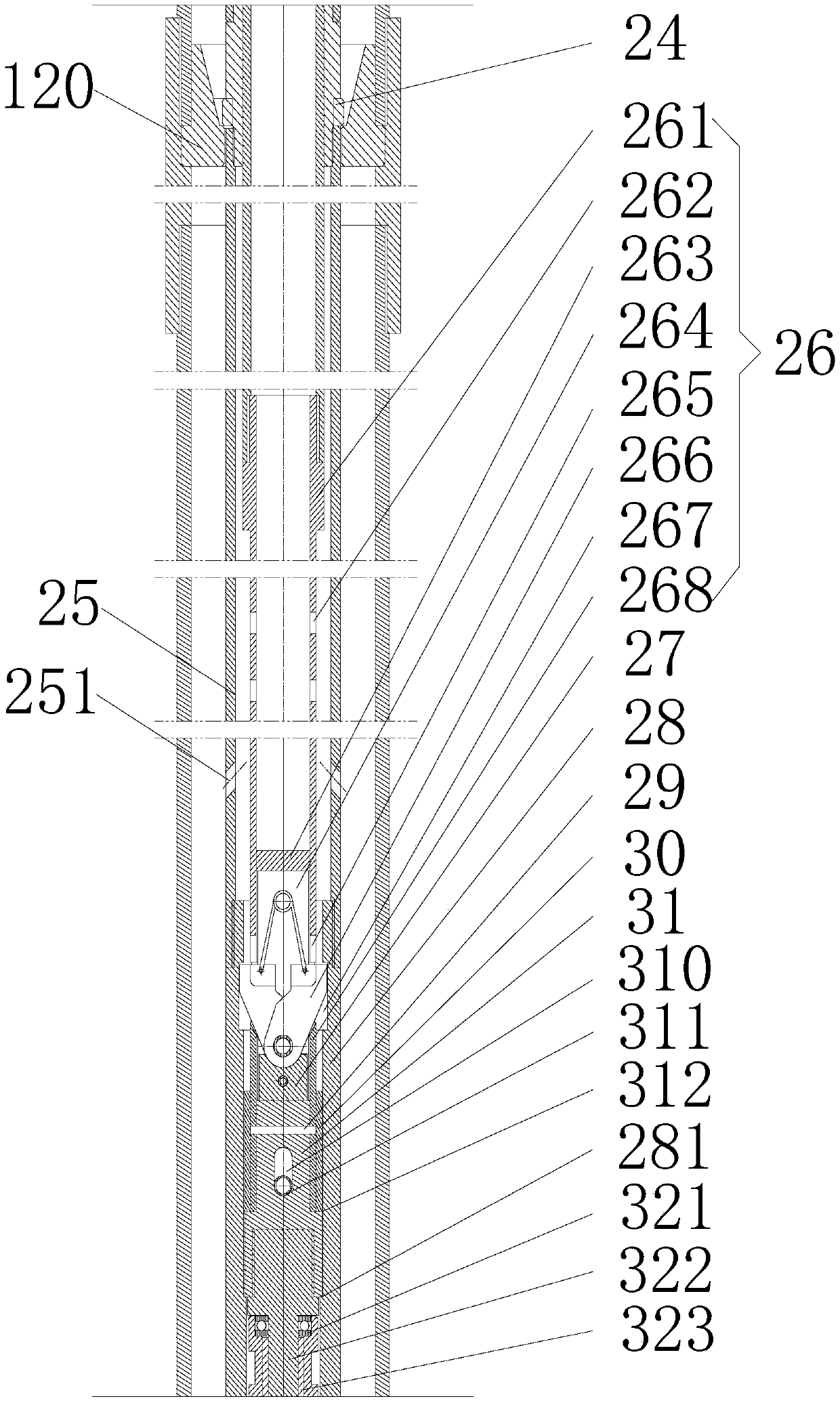

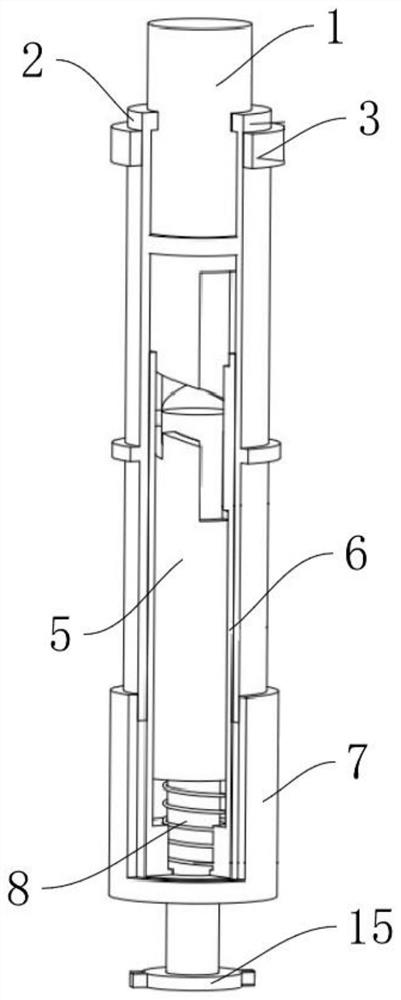

Rotary pressure maintaining coring method for ocean drilling

ActiveCN109854195ARealize the pressure holding effectRealize holding pressure samplingUnderwater drillingBorehole/well accessoriesRock coreEngineering

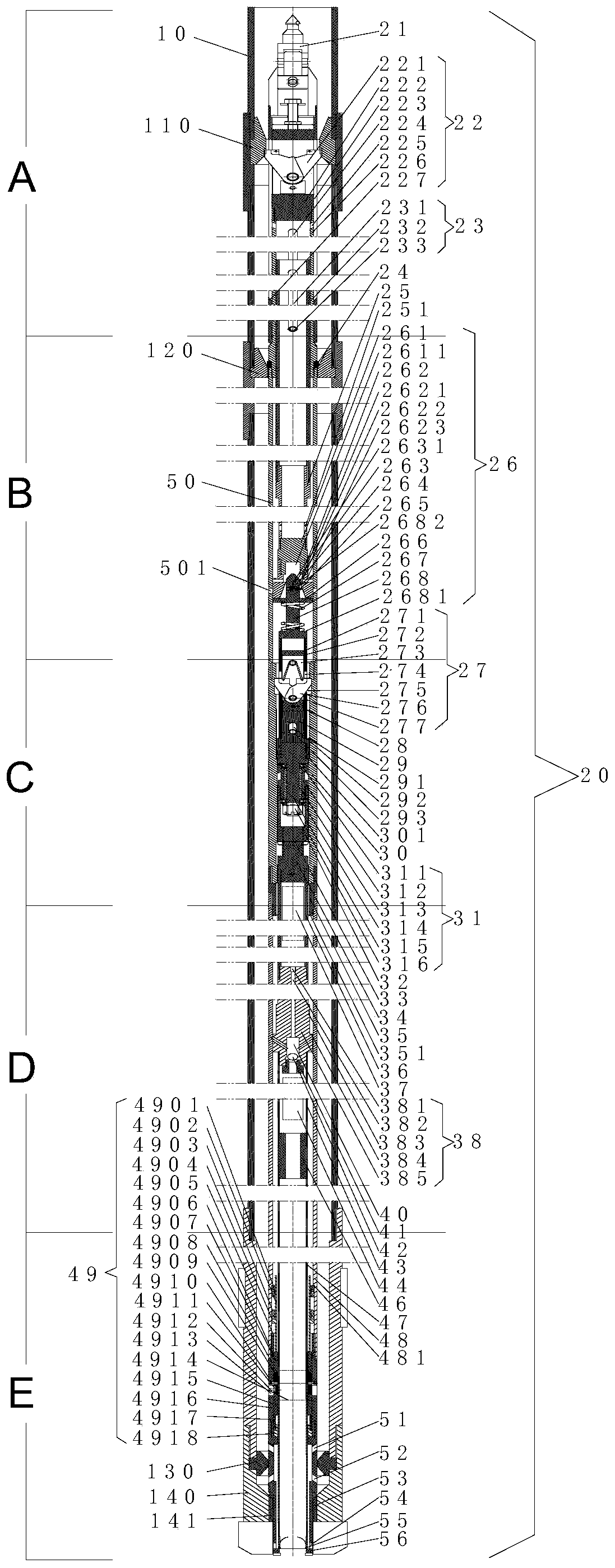

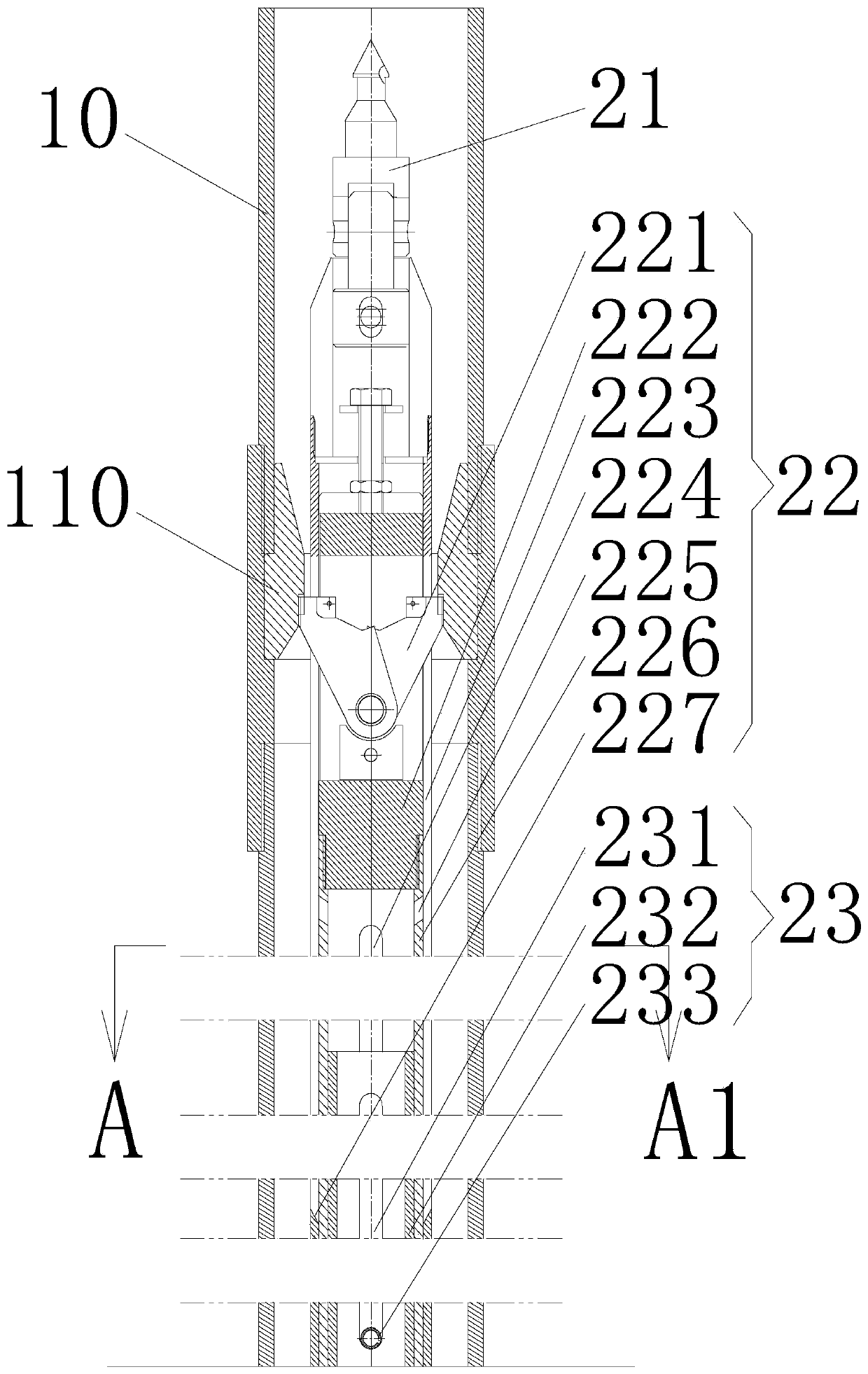

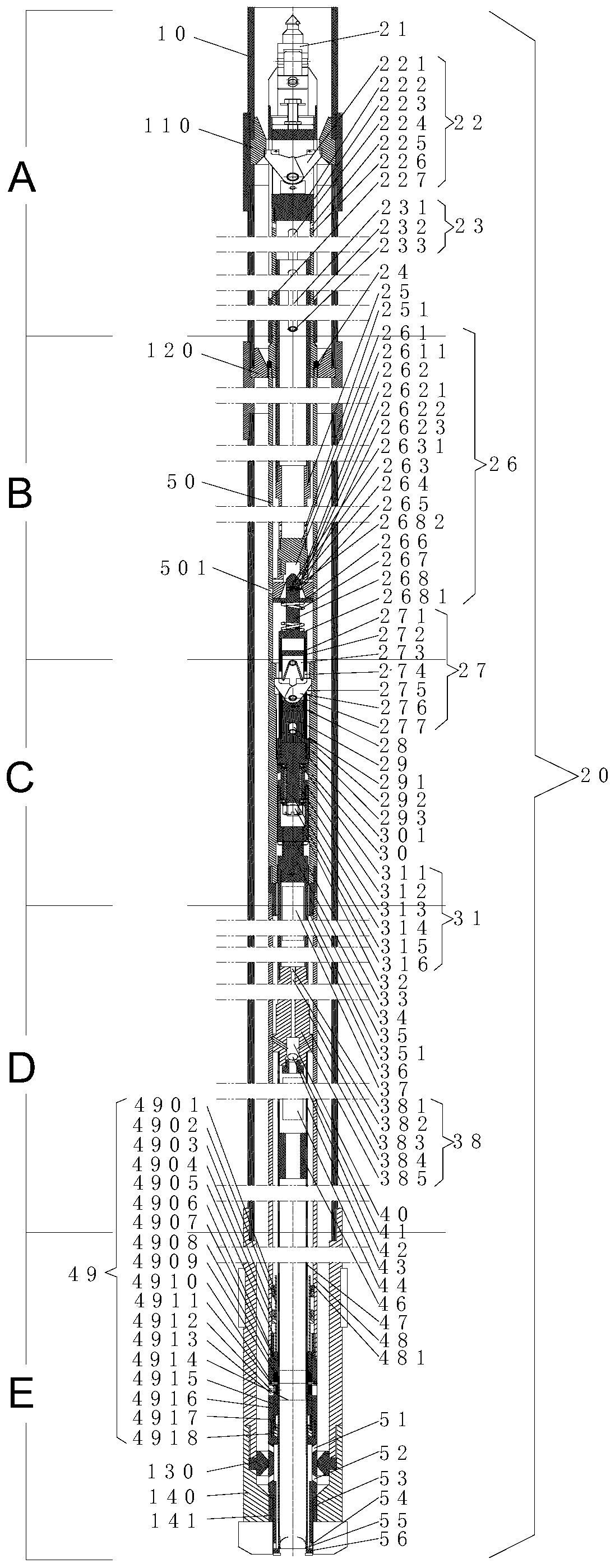

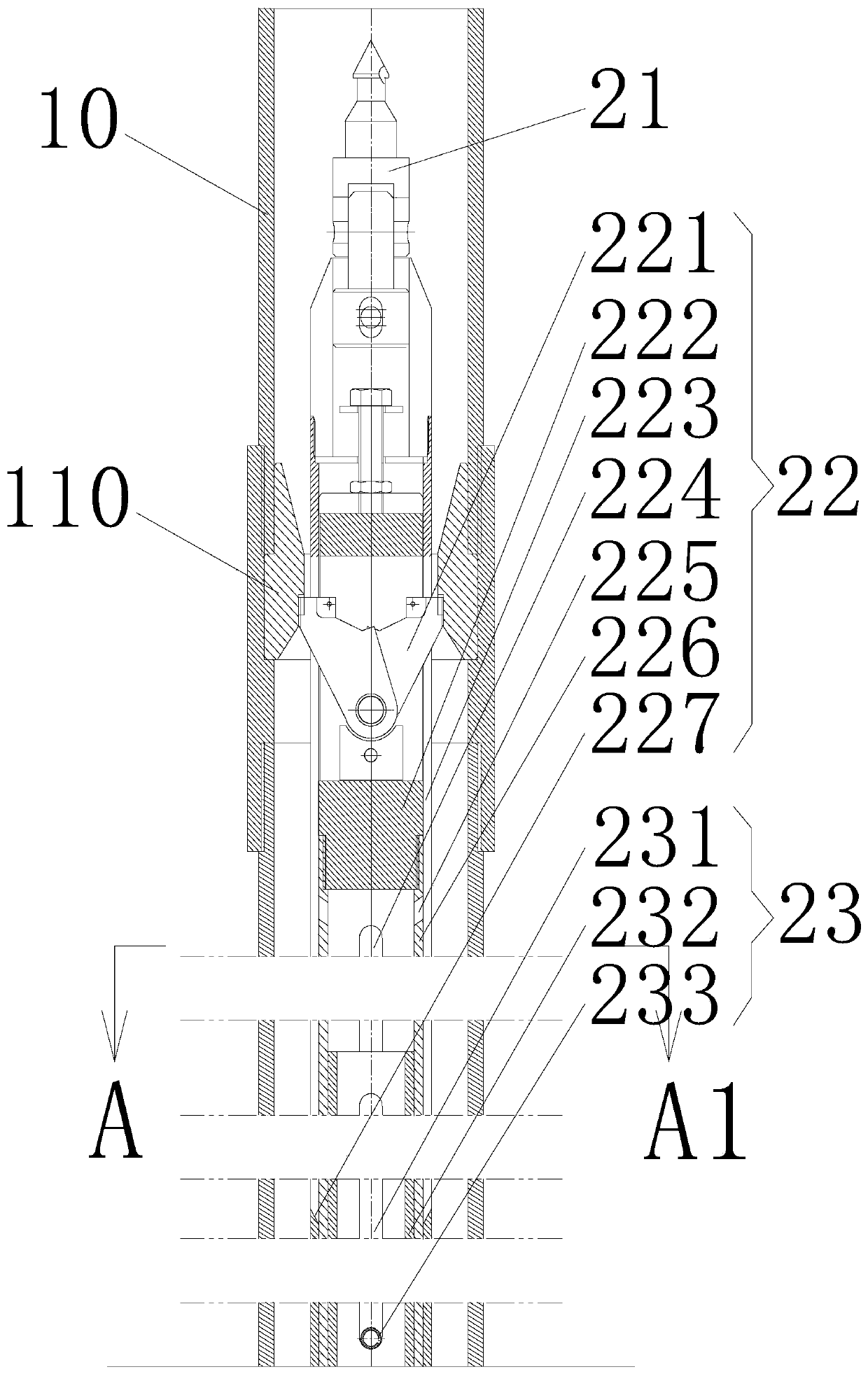

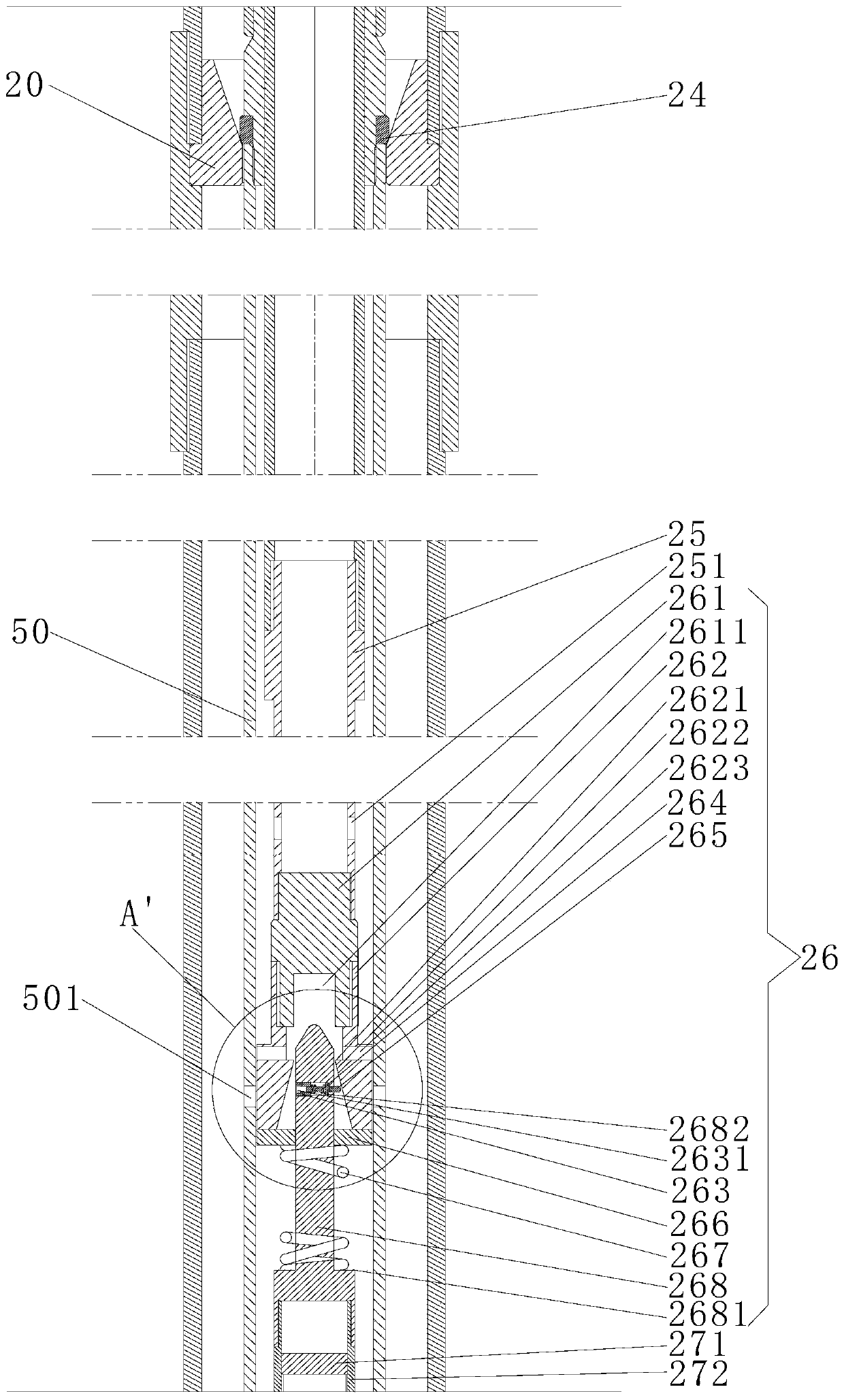

The invention relates to a rotary pressure maintaining coring method for ocean drilling. The method includes the following steps: 1) placing an inner tube assembly into an outer tube assembly at the bottom of a hole by a salvage spear head; 2) sending the inner tube assembly to the outer tube assembly by a rope for sitting clamping, then simultaneously drilling down to a bottom hole stratum, and performing rotary core sample coring through cooperation of an outer tube drill bit and a middle tube drill bit together; 3) driving a shear pin of an inner tube assembly b by the f salvage spear headto cut and removing clamping with the inner tube assembly, then sliding upward along an inner tube assembly a, allowing a core tube containing a core sample to slide upward into the inner tube assembly a, and giving thrust to a ball valve by a spring through a ball valve driving nipple, and driving the ball valve to slide downward and achieving overturn of 90 degrees; and 4) making the inner tubeassembly remove clamping from an appearance assembly and pulling out of a wellhead by the salvage spear head, taking out the core sample, and completing a pressure maintaining coring process. The method achieves rotary pressure maintaining sampling, can adapt to a quaternary system sedimentary stratum and bed rock, and is wider in application range.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

Safe marine drilling rotary pressure-maintaining coring method

ActiveCN109751003ARealize the pressure holding effectRealize holding pressure samplingCore removalRock coreEngineering

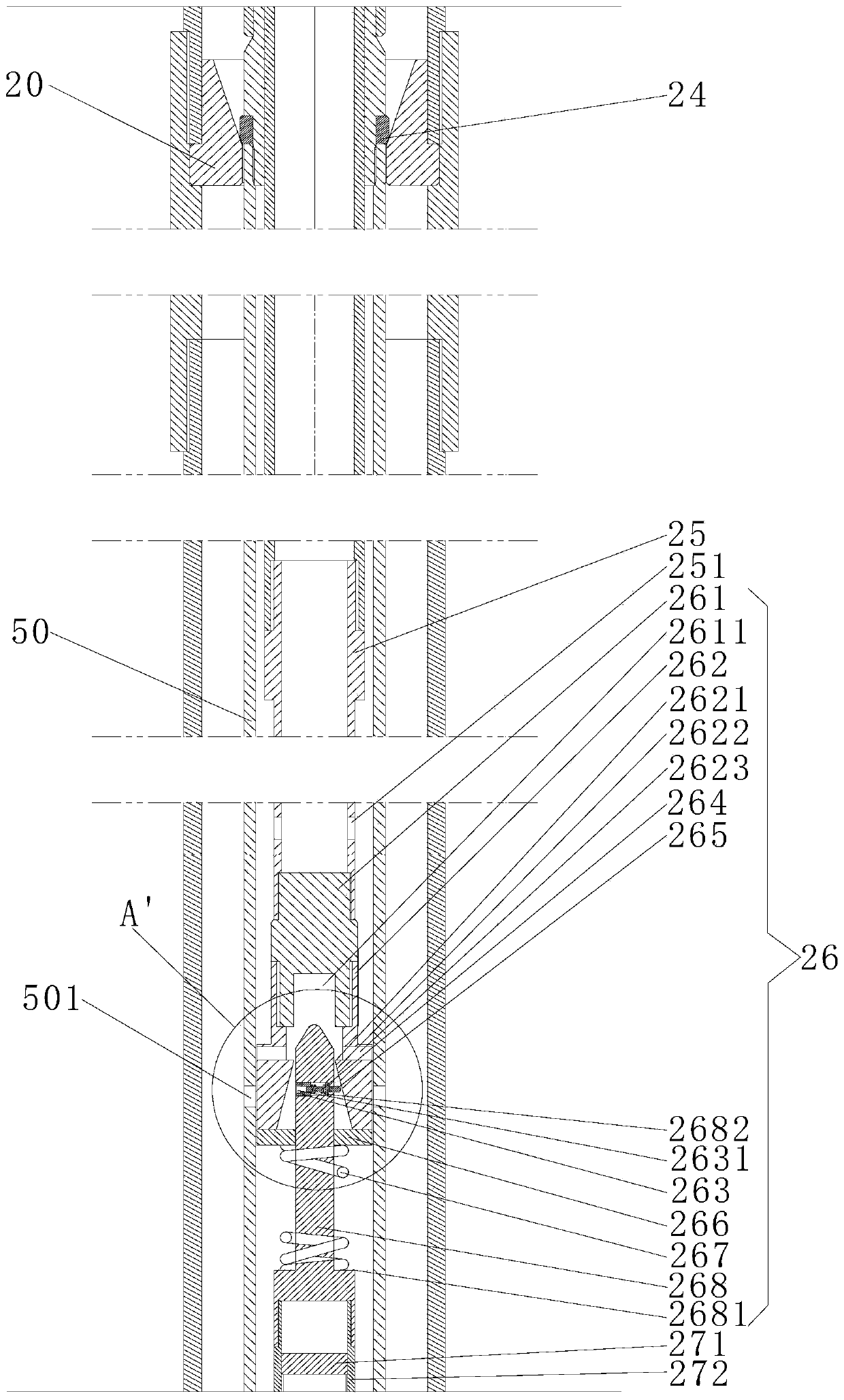

The invention relates to a safe marine drilling rotary pressure-maintaining coring method, which comprises an outer pipe assembly and an inner pipe assembly mounted in the outer pipe assembly. A drillbit is arranged at the bottom end of the outer pipe assembly, the inner pipe assembly comprises an inner pipe assembly a and an inner pipe assembly b, the inner pipe assembly b is installed in the inner pipe assembly a and can move in the axial direction of the inner pipe assembly a, the inner pipe assembly a comprises a fishing spearhead, an elastic clamping mechanism, a piston pipe, a middle pipe short section, a sealing short section, an energy accumulator connecting pipe, a middle pipe and a pressure-maintaining ball valve turnover sealing mechanism which are sequentially connected from top to bottom, the inner pipe assembly b comprises a lifting device, a connecting mechanism, an elastic clamp hanging mechanism, a single-action mechanism, a conversion connector, an adjusting connector, an energy accumulator connecting pipe, a sealing mechanism, a temperature and pressure instrument connecting pipe, a rock core pipe connecting short section and a rock core pipe which are sequentially connected from top to bottom. The safe rotary pressure-maintaining sampling method can adapt to fourth-system sedimentary stratums and bedrock, and is more reliable in application.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

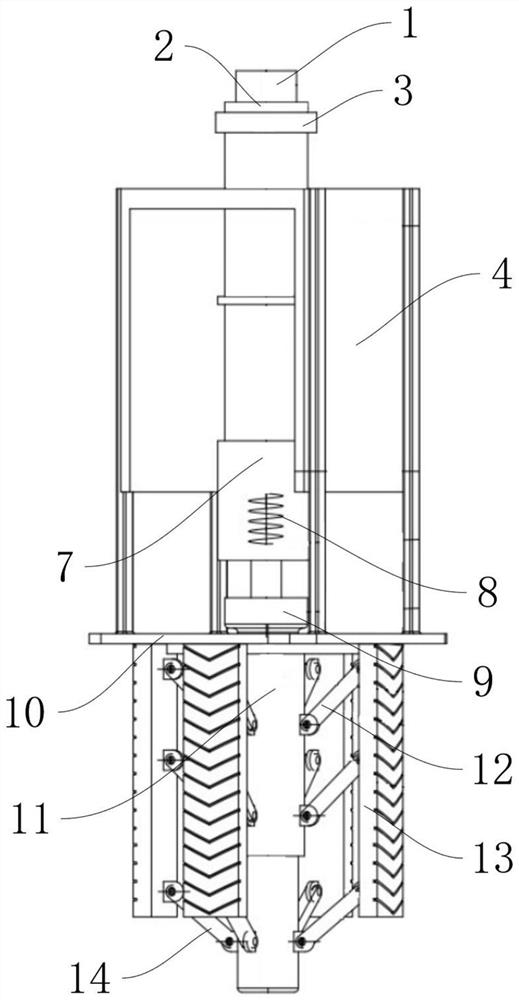

Natural gas hydrate rotary pressure maintaining coring device

ActiveCN109653696ARealize the pressure holding effectRealize holding pressure samplingConstructionsWell/borehole valve arrangementsRock coreEngineering

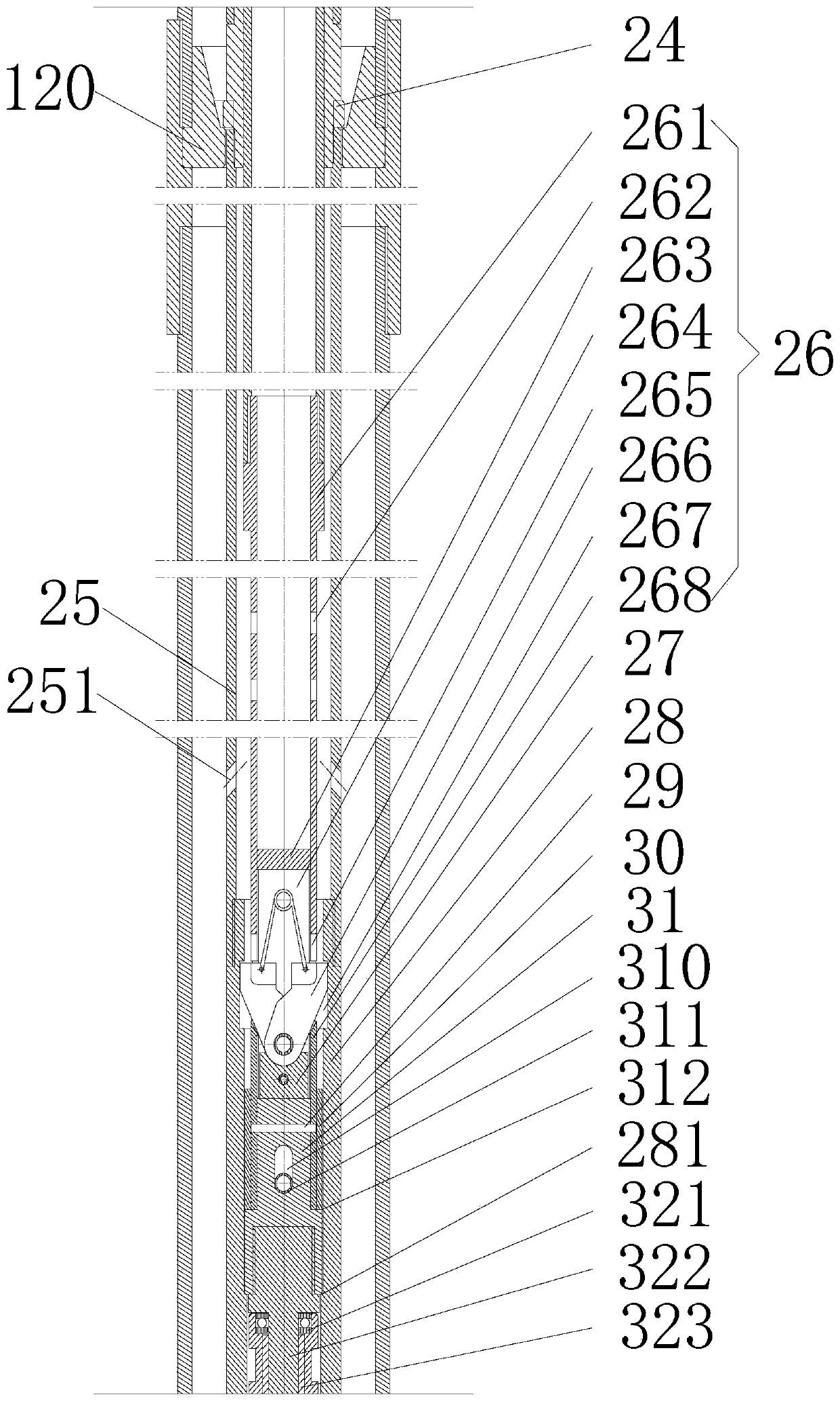

The invention relates to a natural gas hydrate rotary pressure maintaining coring device which comprises an outer pipe assembly and an inner pipe assembly mounted in the outer pipe assembly, a drilling bit is arranged at the bottom end of the outer pipe assembly, the inner pipe assembly comprises an inner pipe assembly a and an inner pipe assembly b, the inner pipe assembly b is mounted in the inner pipe assembly a and can move along to the axis direction of the inner pipe assembly a, the inner pipe assembly a comprises a fishing spearhead, an elastic card mechanism, a lengthening pipe, a middle pipe short joint, a short connector, a sealing short joint, a connecting pipe, a middle pipe and a pressure retaining ball valve overturning and sealing mechanism which are sequentially connected from top to bottom, and the inner pipe assembly b comprises a lifting device, an elastic card hanging mechanism, an elastic pin short joint, an single-acting mechanism, a transformation connector, an adjusting connector, a connecting pipe, a sealing mechanism, a connecting long pipe, a connecting long pipe short joint and a rock core pipe which are sequentially connected from top to bottom. According to the device, rotary pressure maintaining sampling is achieved, the device can adapt to quaternary sedimentary land layers and bed rock and wider in application range.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

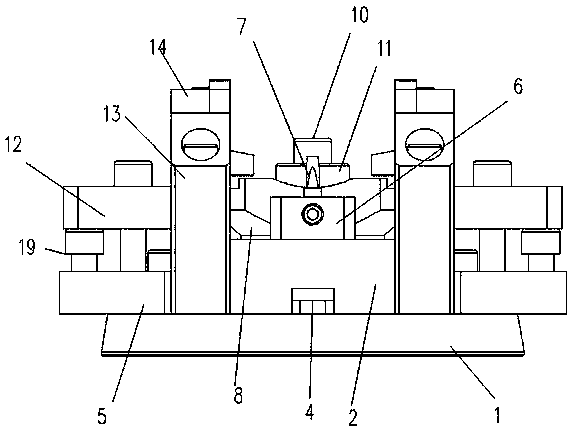

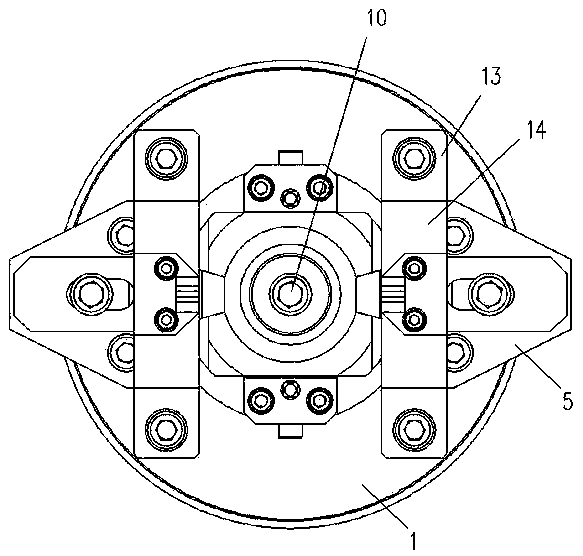

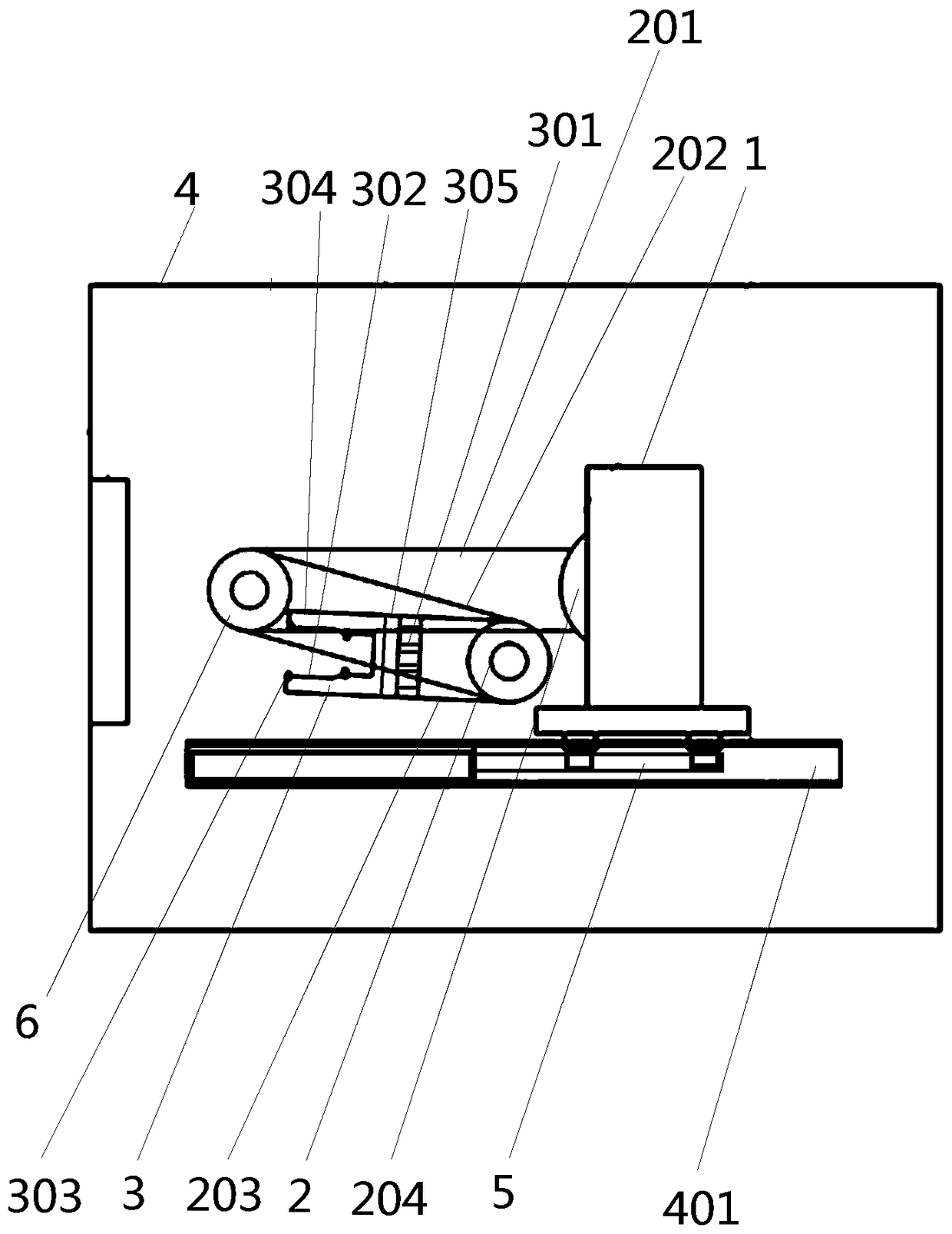

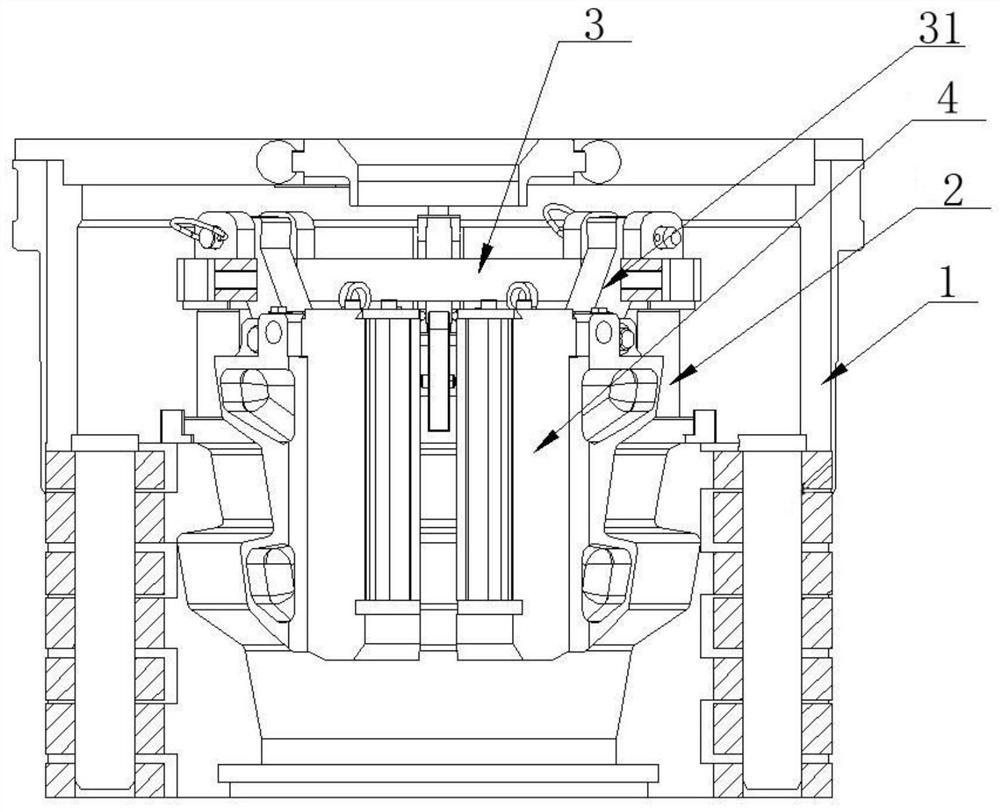

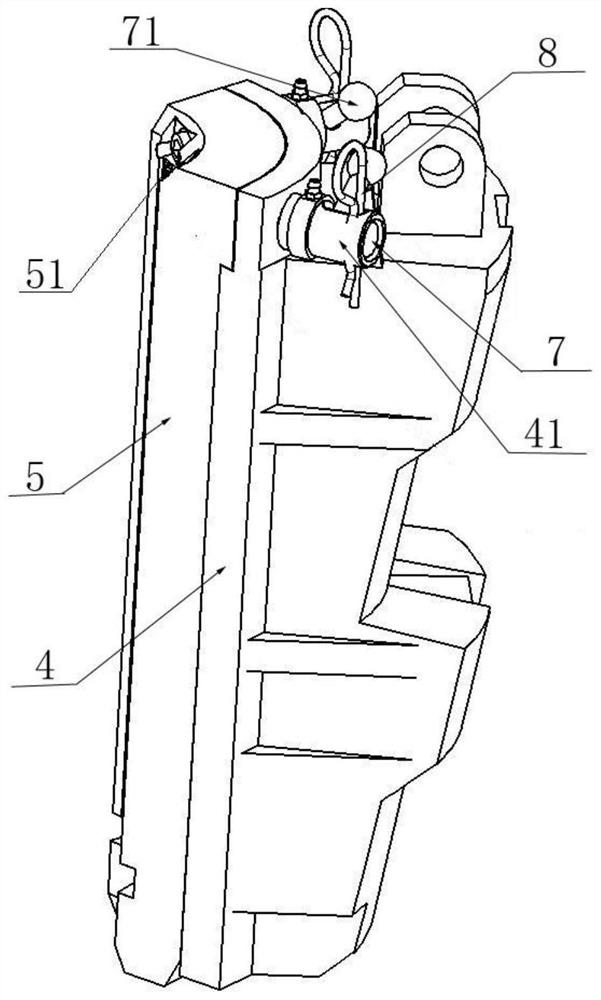

Floating vehicle fixture for differential shell and clamping method

ActiveCN104259910AAvoid interferenceFor smooth dischargePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

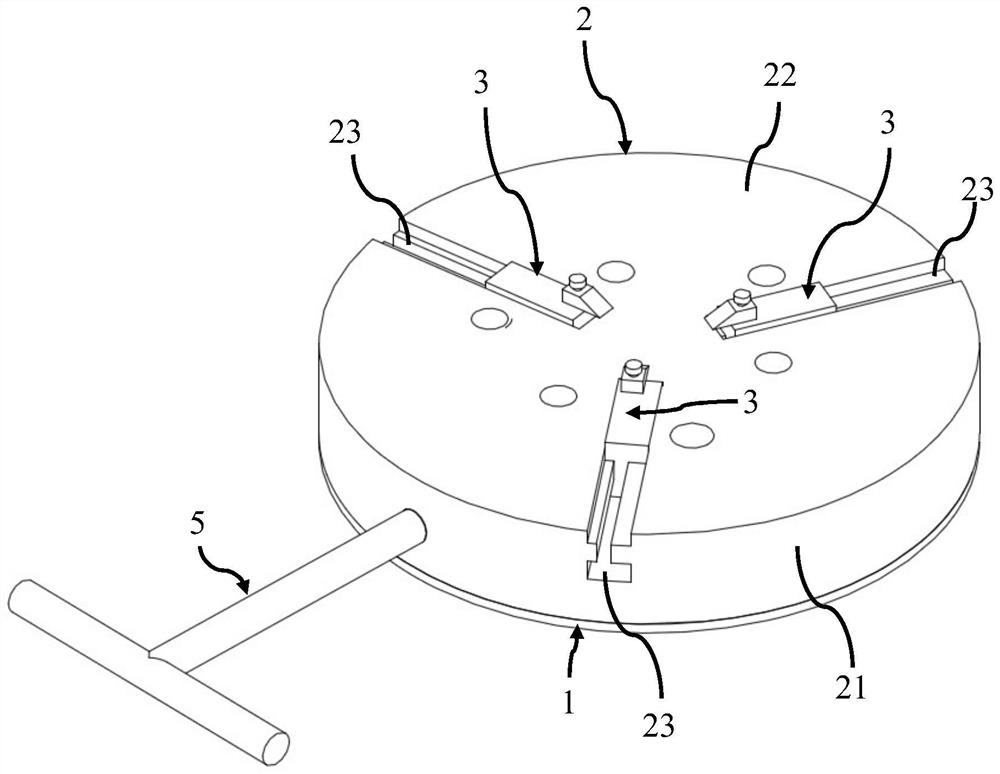

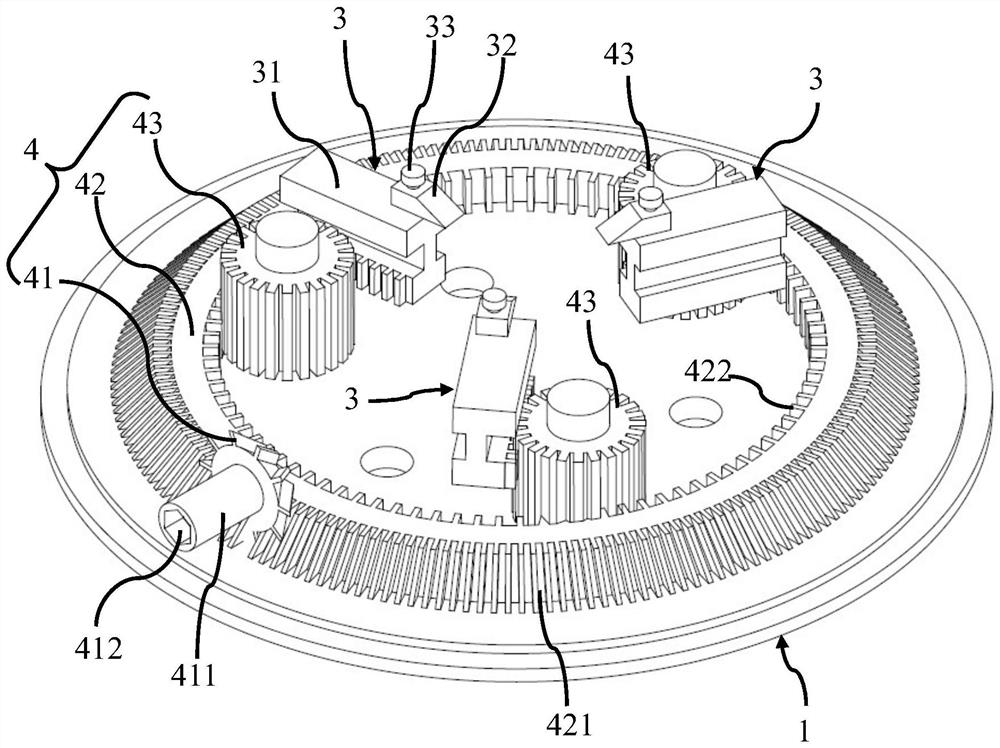

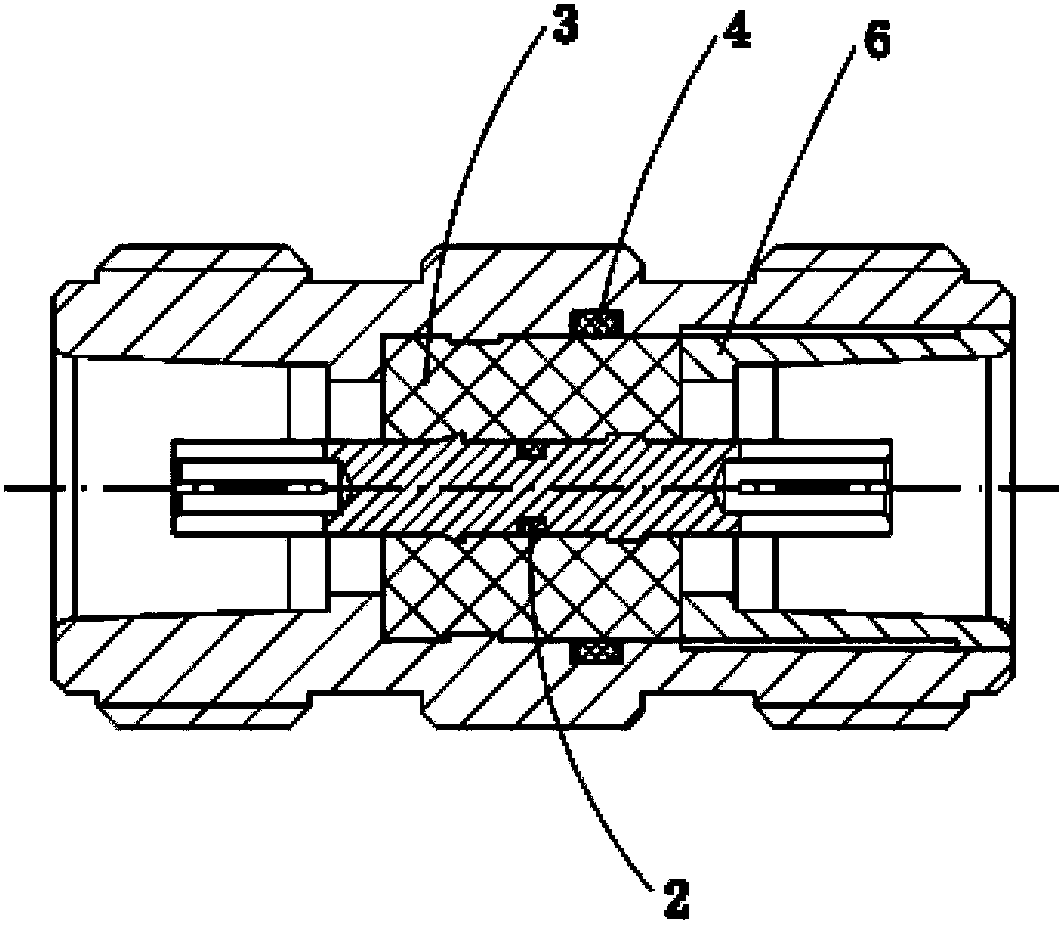

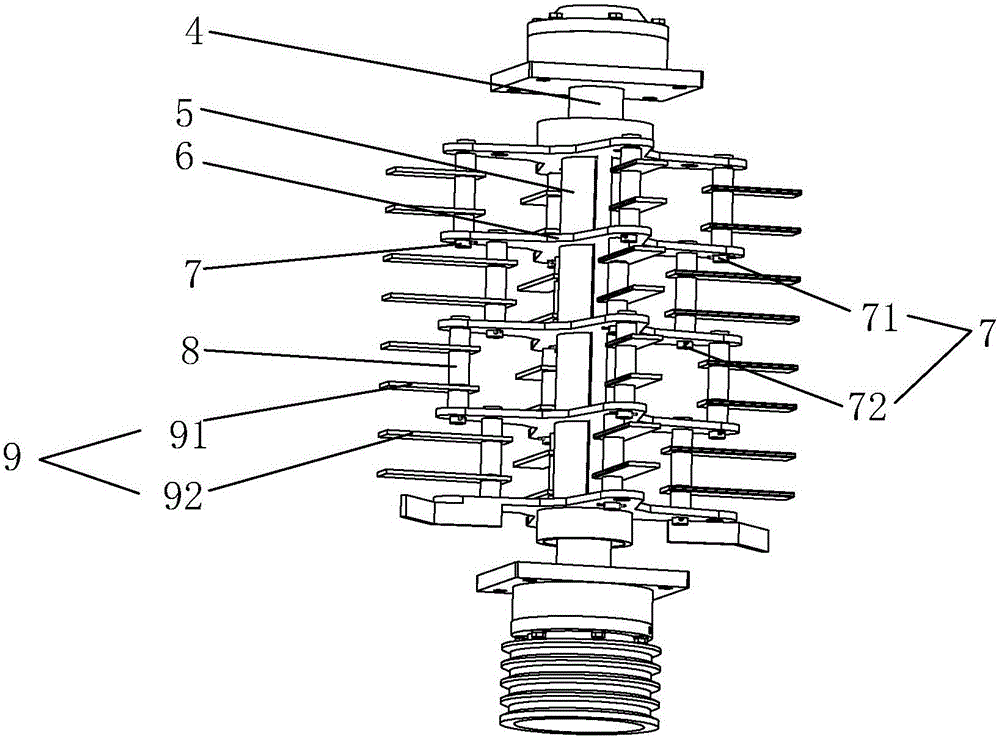

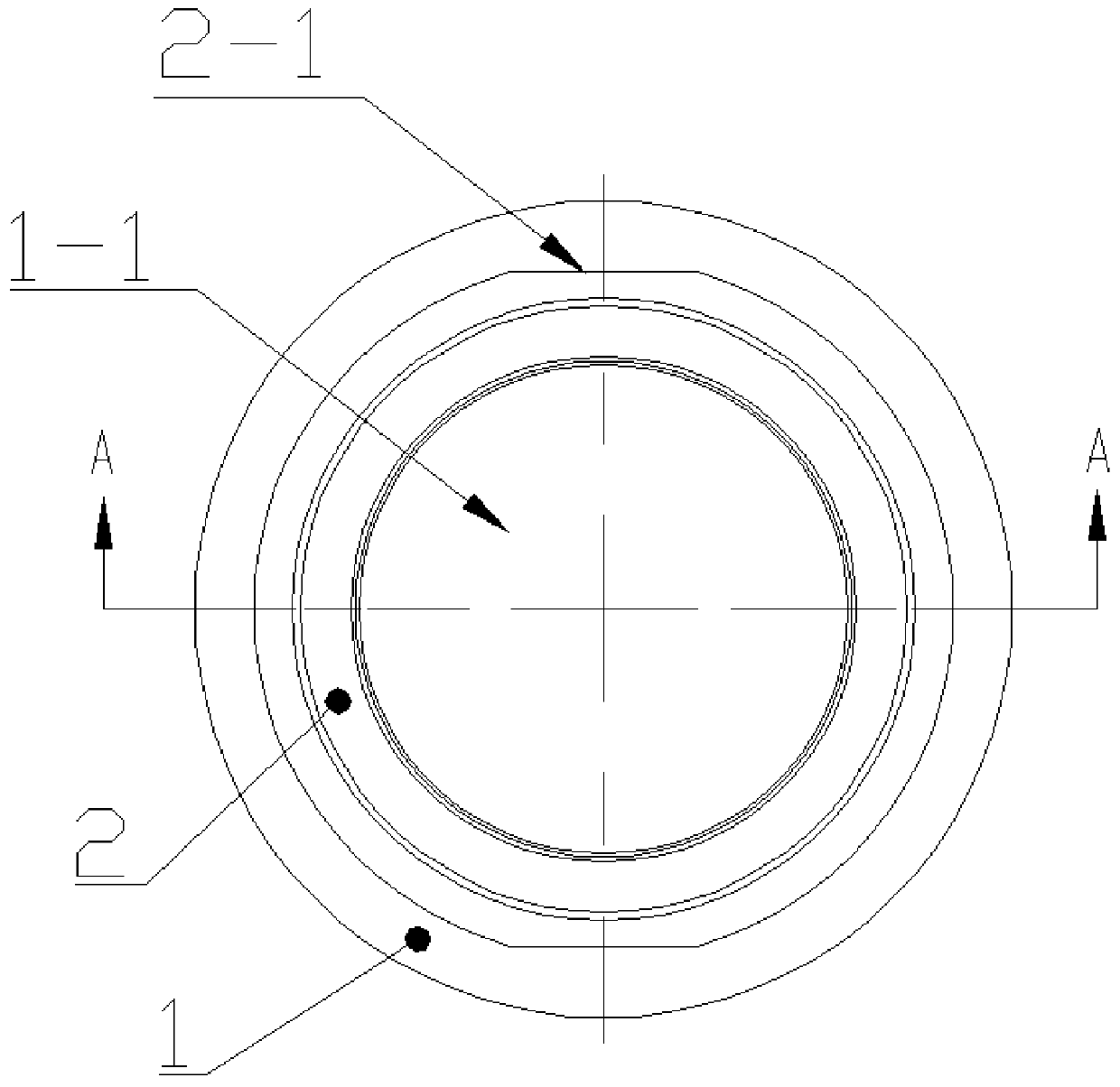

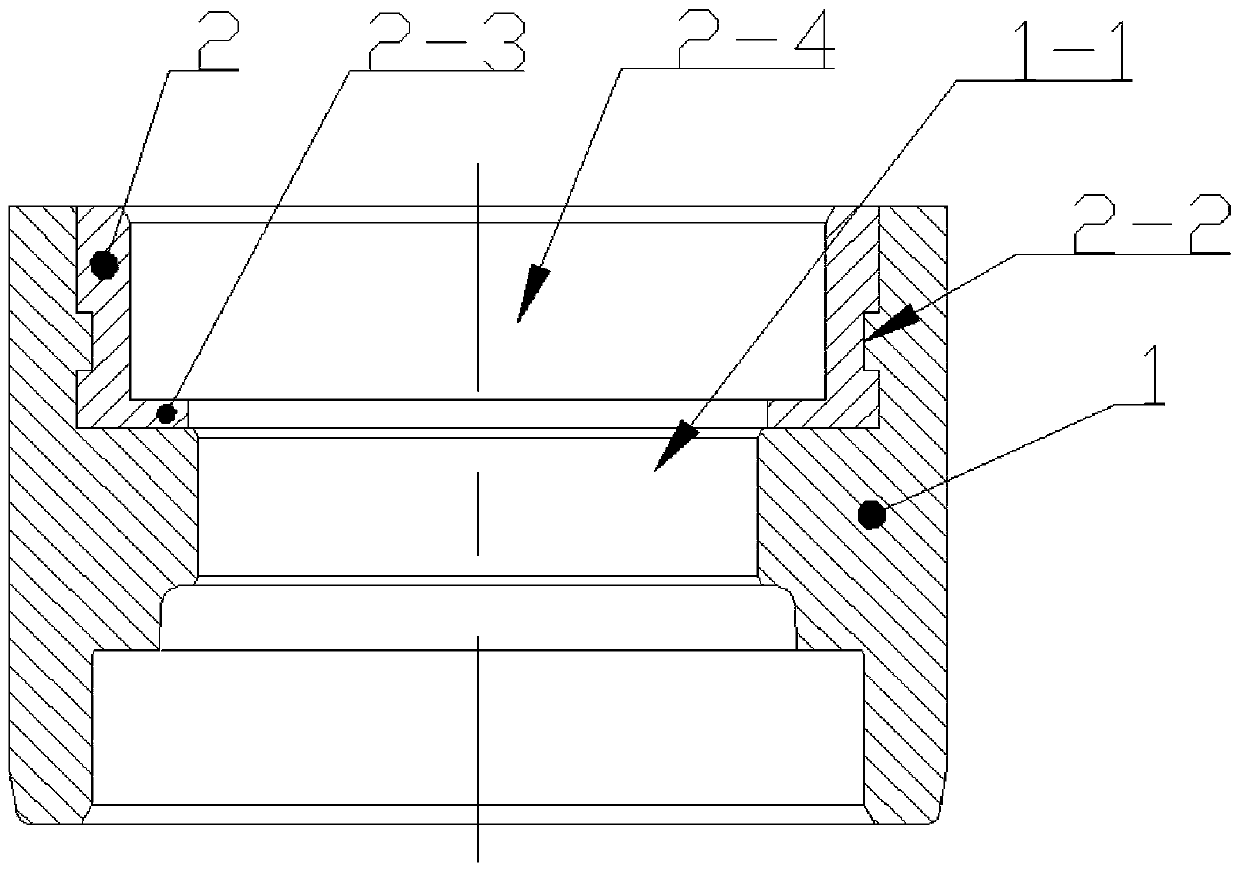

Clamp

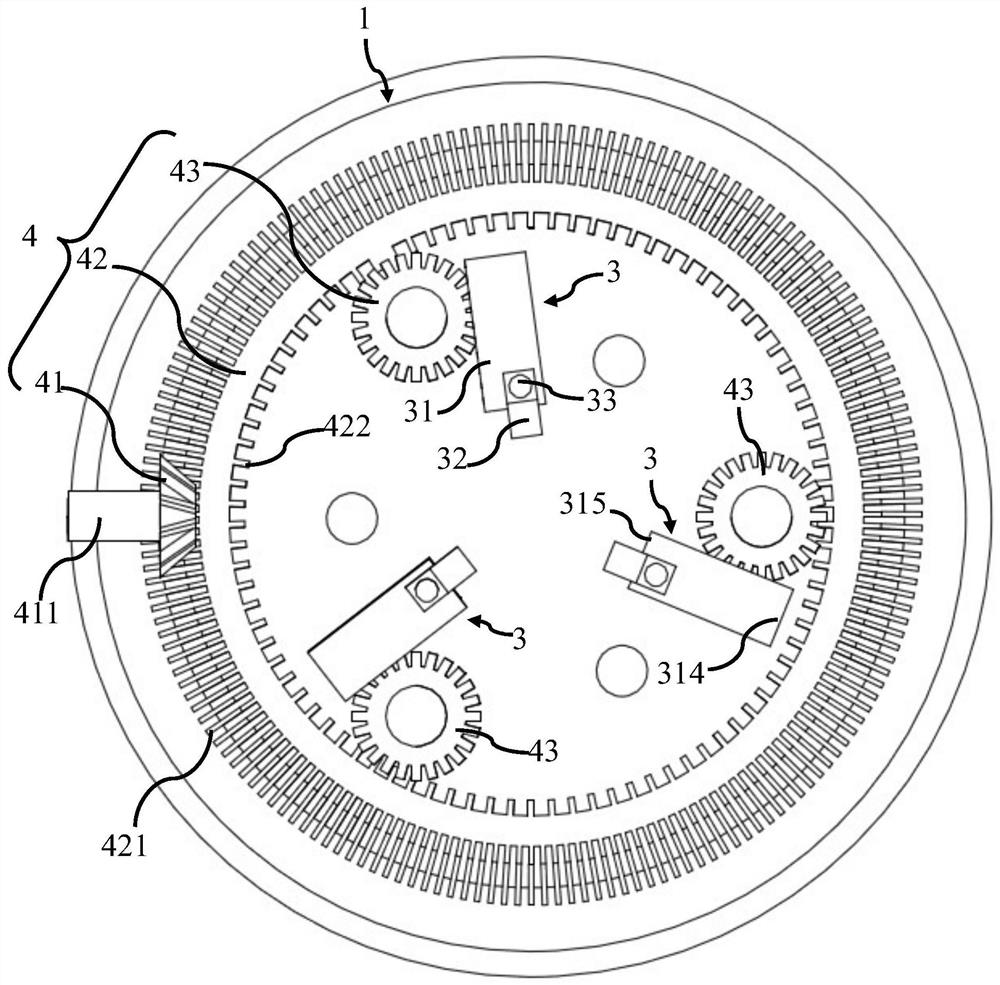

InactiveCN111993305AAchieving circumferential self-centeringAchieve axial fixationWork holdersCircular discPhysics

The invention discloses a clamp. The clamp comprises a base, a disc cover and multiple clamping claws. The disc cover comprises a circle of disc cover side plate and a disc cover top plate. Multiple top plate guide grooves are formed in the disc cover top plate. Each clamping claw comprises a clamping claw sliding rail and a clamping claw pressure head. The top faces of the clamping claw sliding rails are located above the disc cover top plate, and the clamping claw pressure heads are mounted on the top faces of the clamping claw sliding rails through locking bolts. At least part of each clamping claw pressure head can stretch out of the corresponding clamping claw sliding rail by facing the center of the disc cover top plate. A transmission device used for driving the multiple clamping claw sliding rails to move synchronously is mounted in the disc cover. According to the clamp, self centering of a sample disc can be achieved, it is ensured that the sample disc is located at the center position of the disc cover plate, meanwhile, peripheral and axial fixing of the sample disc is achieved, loosening and up-and-down motion are avoided in the experiment process of the sample disc, and testing precision is improved.

Owner:SHENHUA SHENDONG COAL GRP

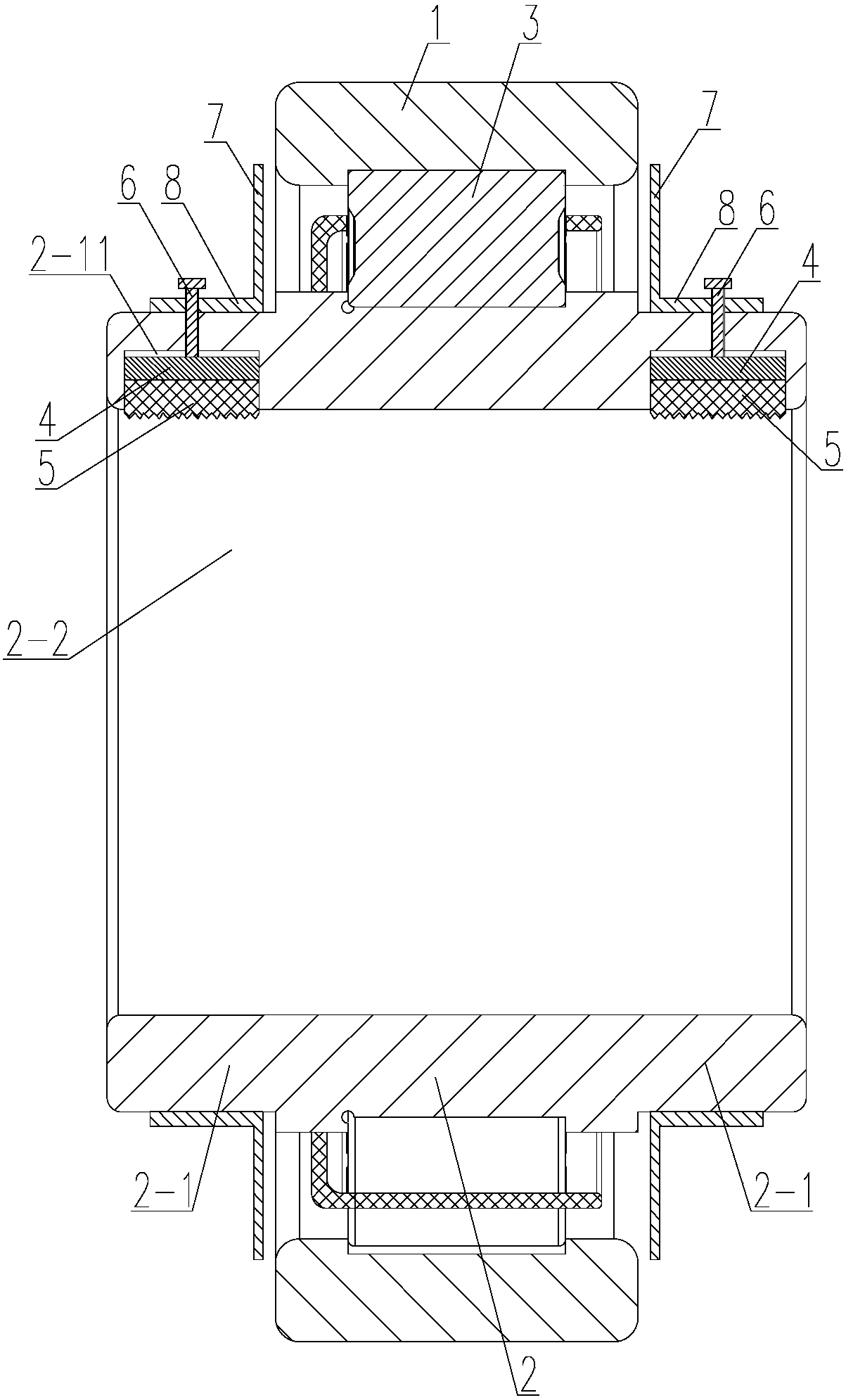

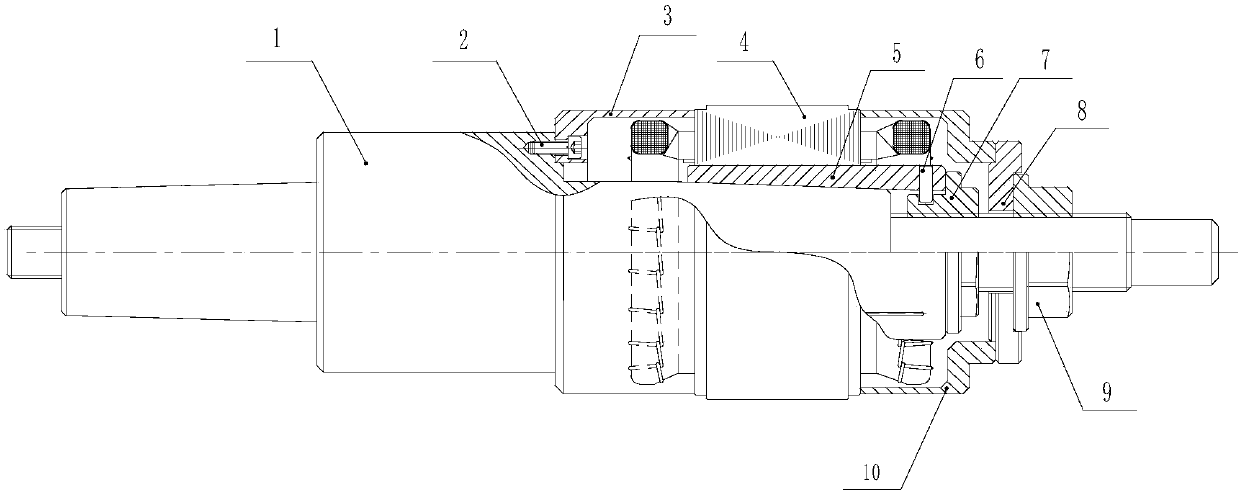

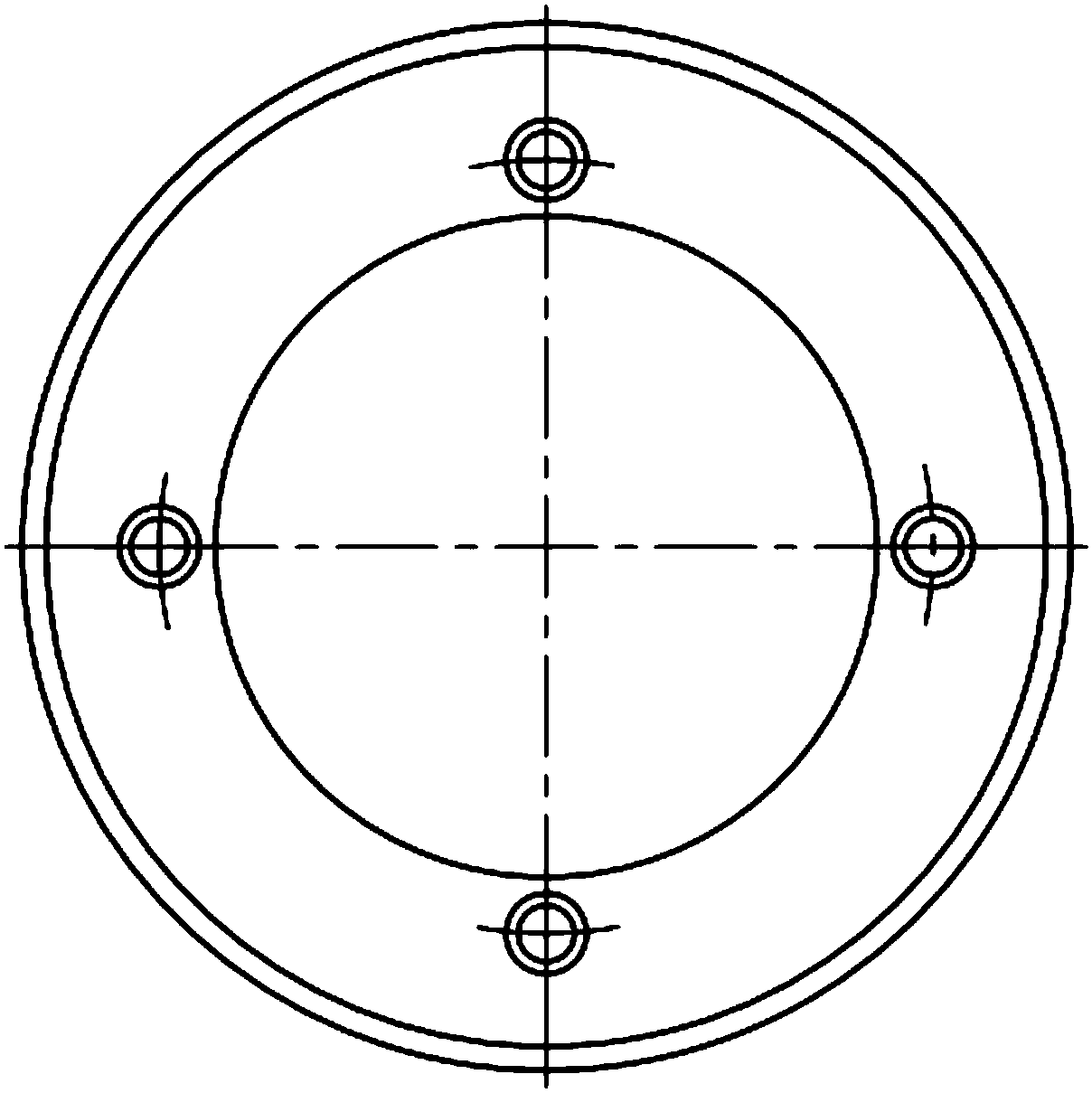

Cylindrical roller bearing

PendingCN107687477AReduce entryExtended service lifeElastic bearingsBearing unit rigid supportEngineeringSlide plate

The invention belongs to the technical field of bearings, and in particular relates to a cylindrical roller bearing, which includes an outer ring, an inner ring and several rollers. There are flanges extending outward at both ends, and the inner ring has a shaft hole. The shaft hole of the inner ring passes through the flange along its axis direction, and the inner peripheral surface of the flange is provided with an arc-shaped groove communicating with the shaft hole. , the arc-shaped groove is slidingly provided with a matching arc-shaped plate, the inner surface of the arc-shaped plate is fixed with an arc-shaped rubber block, and the arc-shaped plate is pushed by tightening the locking screw, and the arc-shaped rubber block is held against On the rotating shaft, so as to realize the axial fixation of the bearing on the rotating shaft, wherein, the arc-shaped plate can evenly set off the arc-shaped rubber block, so that the arc-shaped rubber block can better touch the rotating shaft, and the contact between the arc-shaped rubber block and the rotating shaft The large area allows the bearing to be axially positioned on the rotating shaft more reliably.

Owner:江苏持华科技有限公司

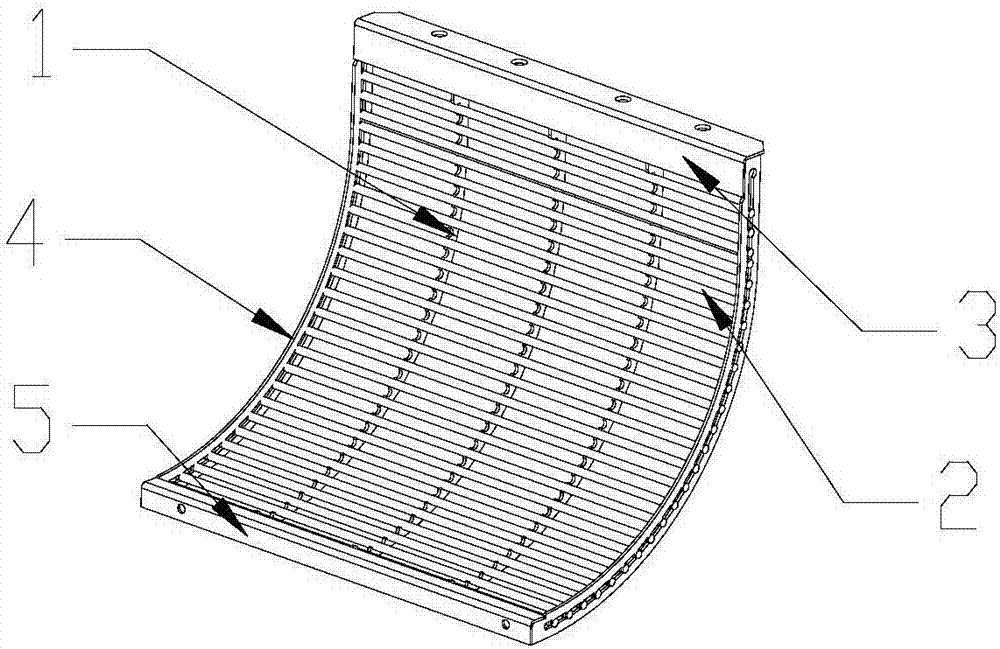

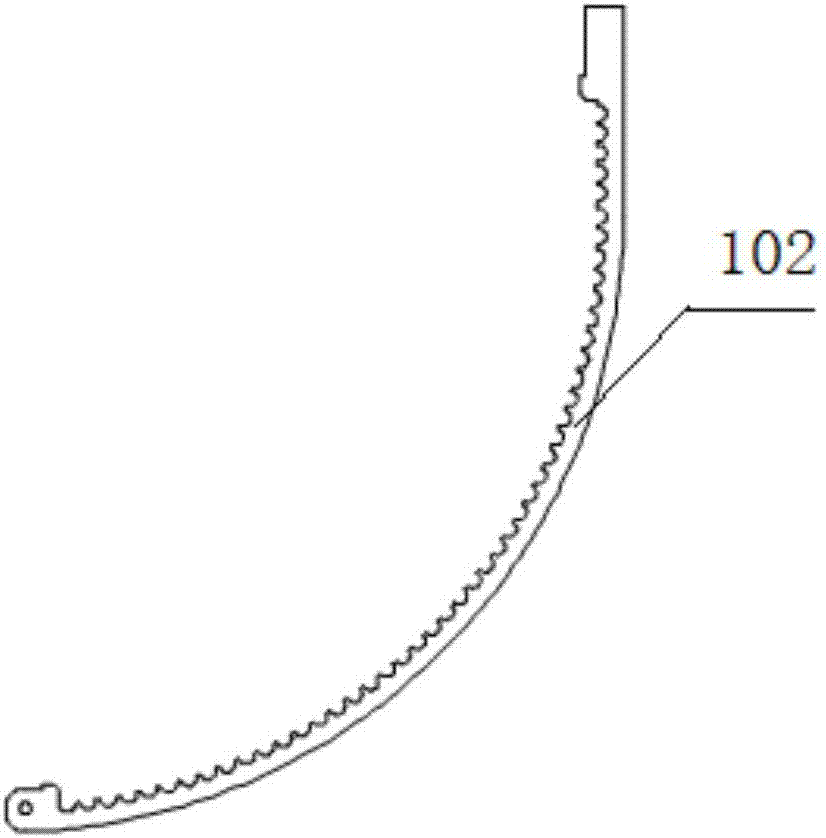

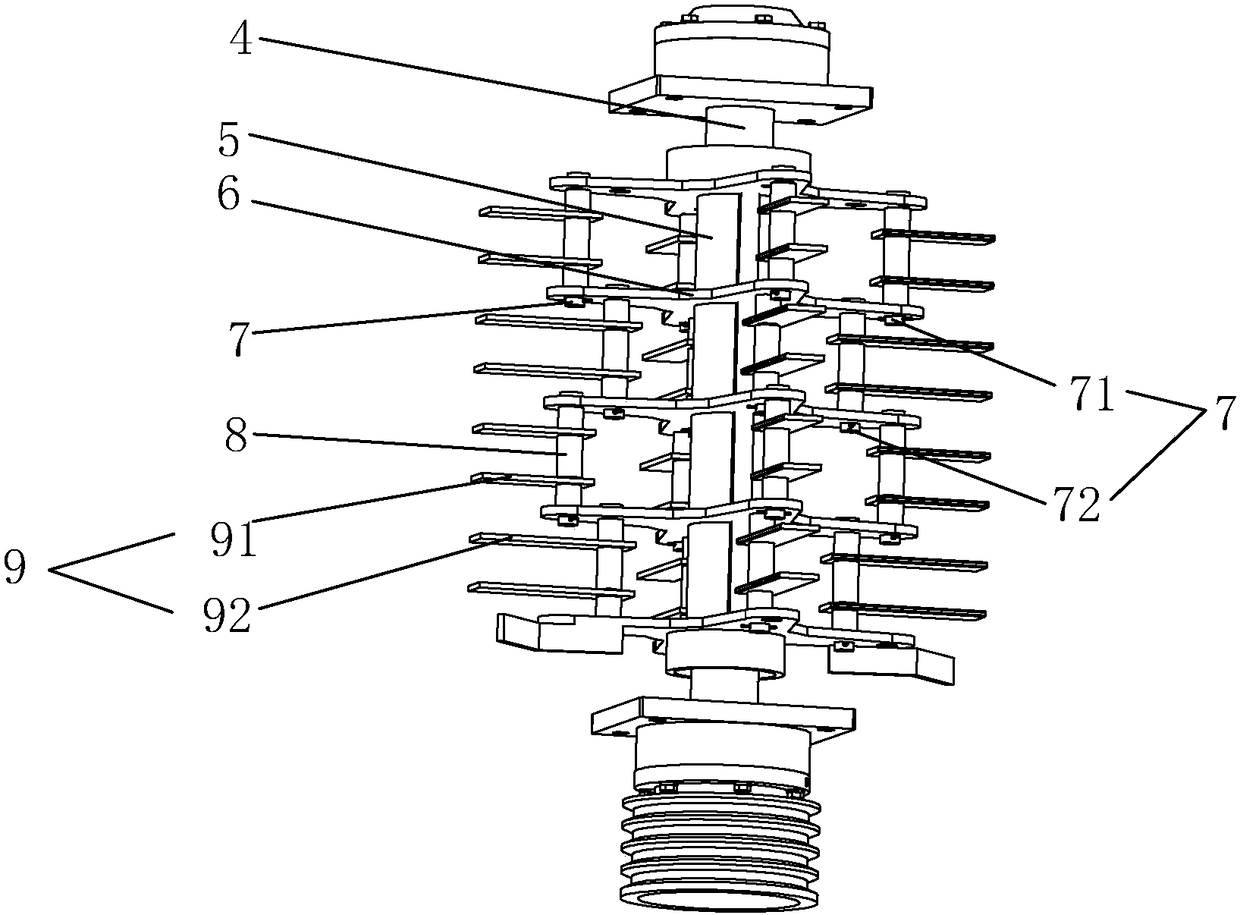

Corn threshing concave plate with adjustable grid intervals

The invention provides a corn threshing concave plate with adjustable grid intervals. The corn threshing concave plate comprises a fixing mechanism for grid circular steels, grid circular steels, an upper connecting plate, two grid circular steel slide slot plates and a lower connecting plate, wherein the fixing mechanism for grid circular steels comprises a fixing plate and a connecting plate; the upper end of the connecting plate is detachably connected with the upper connecting plate; the upper end of the fixing plate is fixedly connected with the lower end of the connecting plate; a hinge hole is formed at the lower end of the fixing plate and is hinged with the lower connecting plate; the top ends of the grid circular steel slide slot plates are respectively in fixed connection with the two ends of the upper connecting plate; the bottom ends of the grid circular steel slide slot plates are respectively in fixed connection with the two ends of the lower connecting plate; the grid circular steels can slide in the slide slots of the grid circular steel slide slot plates; the fixing mechanism for grid circular steels is started for adjusting the positions of the grid circular steels in the slide slots of the grid circular steel slide slot plates, so that the adjustment for the intervals of the grid circular steels can be realized. The corn threshing concave plate can adjust the intervals of the grid circular steels according to the variety and size of the corn, so that the crashed rate and loss rate of the corn can be reduced and the threshing effect of the corn can be promoted.

Owner:JIANGSU UNIV

Safety natural gas hydrate rotating pressure maintaining coring device

PendingCN109826578ARealize the pressure holding effectRealize holding pressure samplingCore removalBedrockEngineering

The invention relates to a safe natural gas hydrate rotating pressure maintaining coring device, which comprises an outer pipe assembly and an inner pipe assembly arranged in the outer pipe assembly,wherein a drill bit is arranged at the bottom end of the outer pipe assembly; the inner pipe assembly comprises an inner pipe assembly a and an inner pipe assembly b; the inner pipe assembly b is arranged in the inner pipe assembly a and can move in the axial direction of the inner pipe assembly a; the inner pipe assembly a comprises a fishing spear head, an elastic clamping mechanism, a piston pipe, a middle pipe nipple, a sealing nipple, an accumulator connecting pipe, a middle pipe and a pressure maintaining ball valve overturning sealing mechanism which are sequentially connected from topto bottom; the inner pipe assembly b comprises a lifting device, a connection mechanism, a spring clip suspension mechanism, a single action mechanism, an adapter, a regulating connector, an accumulator connection pipe, a sealing mechanism, a thermostatic instrument, a core pipe connection nipple and a core pipe. The safe rotating pressure-maintaining sampling device can be suitable for quaternarysedimentary strata and bedrock, and is more reliable in application.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

Tearing knife replacing manipulator and control method thereof

ActiveCN108555930ASimple structureEasy extractionMetal working apparatusTunnelsEngineeringManipulator

The invention discloses a tearing knife replacing manipulator which solves the problems that potential safety hazards exist and labor time is consumed when tearing knives are replaced in the prior art. The tearing knife replacing manipulator comprises a fixed base, a rotary arm and a manipulator palm which are sequentially connected; the fixed base is arranged on a horizontal moving track inside ashield tunneling machine chamber in a sliding mode; the rotary arm comprises three mechanical arms which are sequentially connected and can rotate relatively; the free end of the rotary arm is connected with the manipulator palm which can rotate around the axis of the manipulator palm; a hexagon hole matched with a fixing nut of a tearing knife is formed in the axial direction of the manipulatorpalm; and the outer end portion of the hexagon hole is provided with a telescopic clamping jaw which can stretch and retract in the radial direction of the hexagon hole. The invention further discloses a control method of the tearing knife replacing manipulator. The tearing knife replacing manipulator is simple in structure and convenient to produce and manufacture, the production cost is reduced,the design structure is ingenious, the tearing knife can be rapidly and remotely controlled and replaced, and the construction efficiency is greatly improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

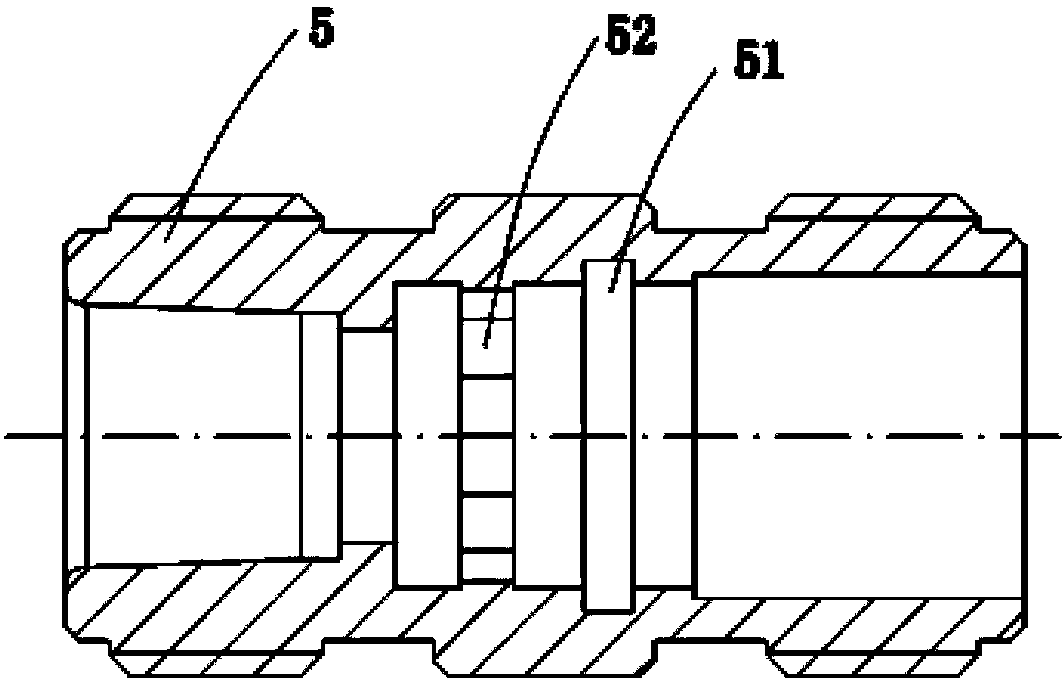

Air-tightness joint with double female ends

InactiveCN103427225AAchieve airtightnessSmooth transmissionSecuring/insulating coupling contact membersCoupling contact membersMating connectionElectrical conductor

The invention discloses an air-tightness joint with double female ends which comprises an inner conductor at the center, an insulating medium coaxially sleeved outside the inner conductor, and an outer conductor with a stepped hole type inner cavity. The insulating medium is arranged in the stepped hole of the outer conductor and is coaxially arranged together with the outer conductor; a fixing block is connected to an opening part of a stepped hole of the outer conductor in a close fit manner; the fixing block and the step surface of the stepped hole form axial limitation at two ends of the insulating medium. The air-tightness joint with double female ends has a simple structure, good air tightness, strong environment tolerance, reliable mechanical performances, excellent electric performances and high assembling efficiency, and is suitable for production on a large scale.

Owner:安徽蓝麦通信股份有限公司

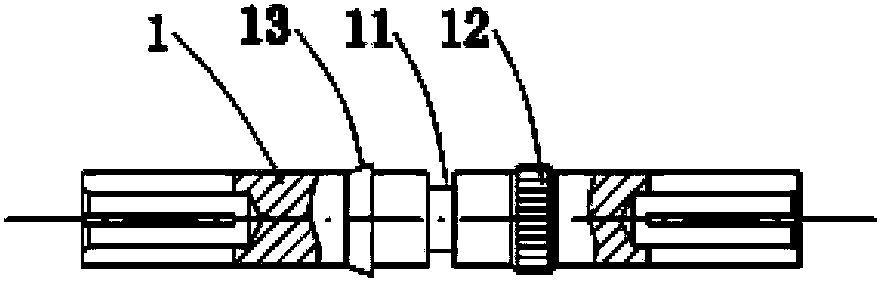

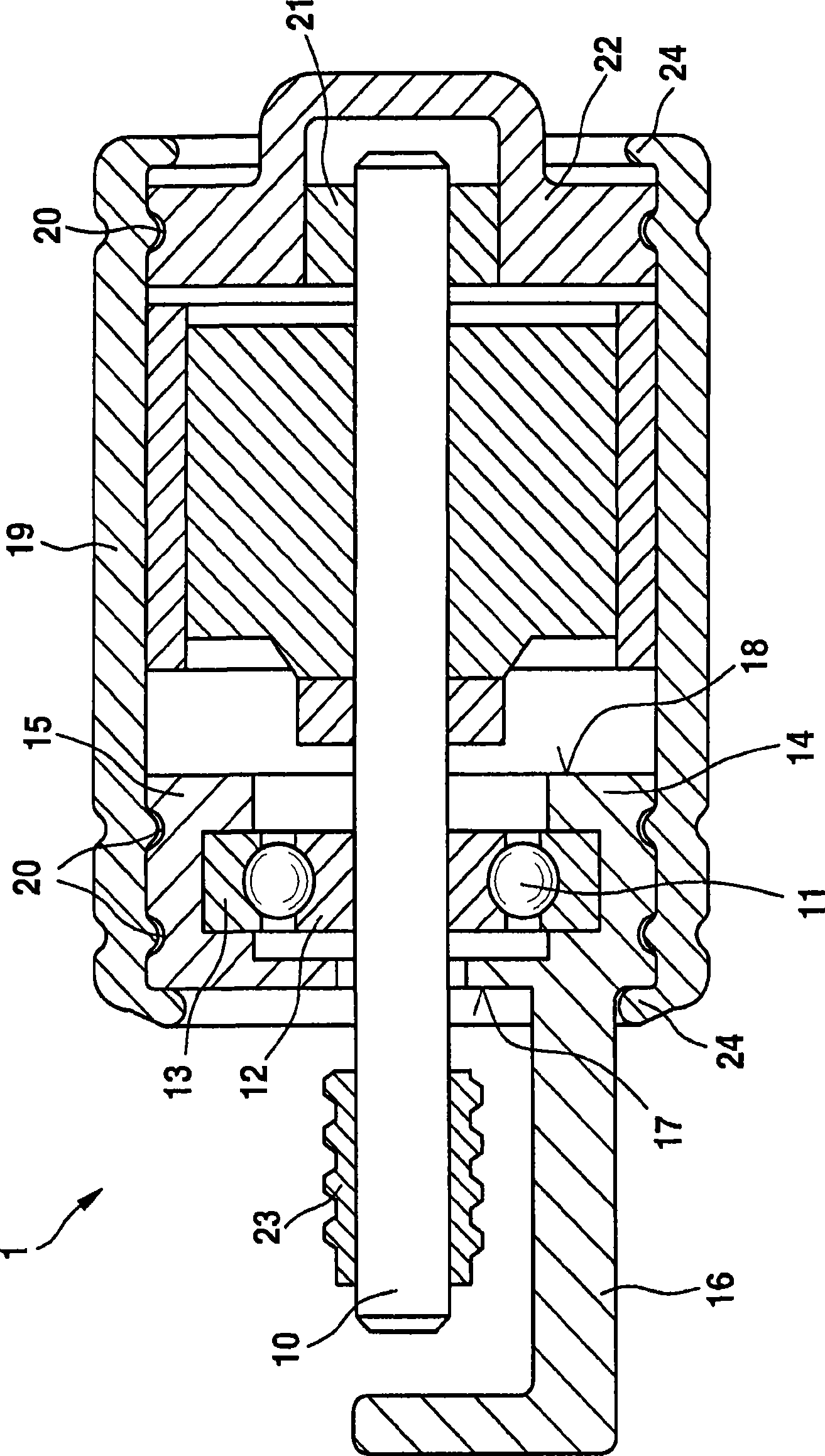

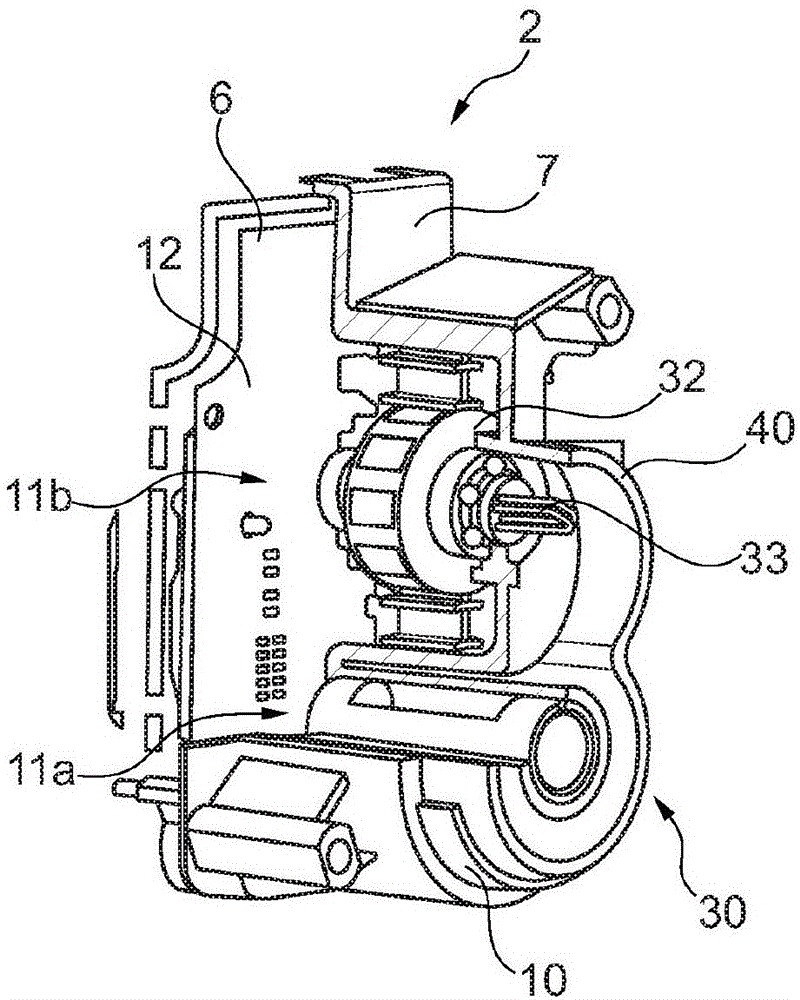

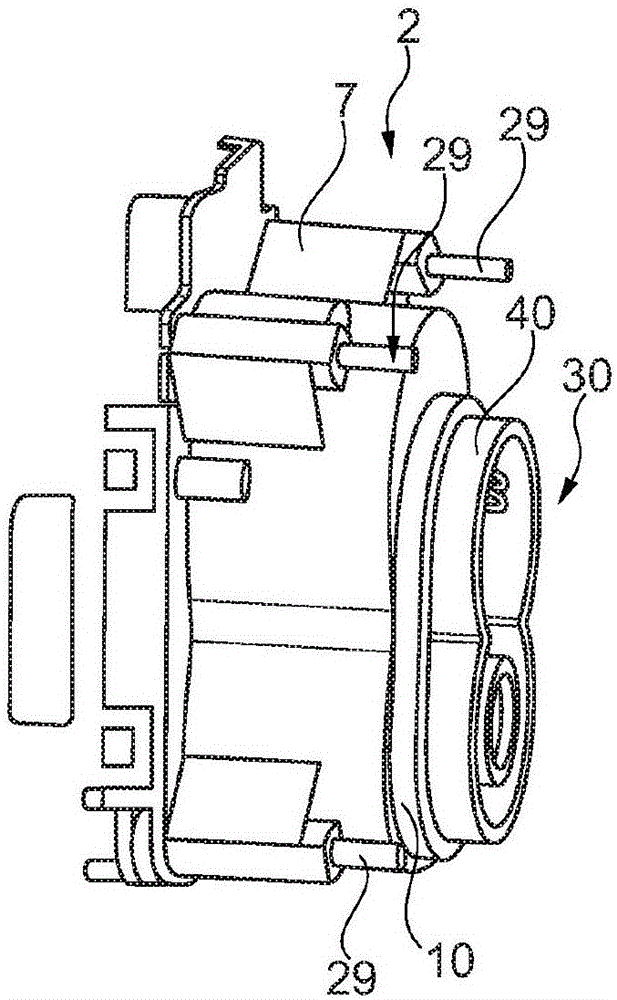

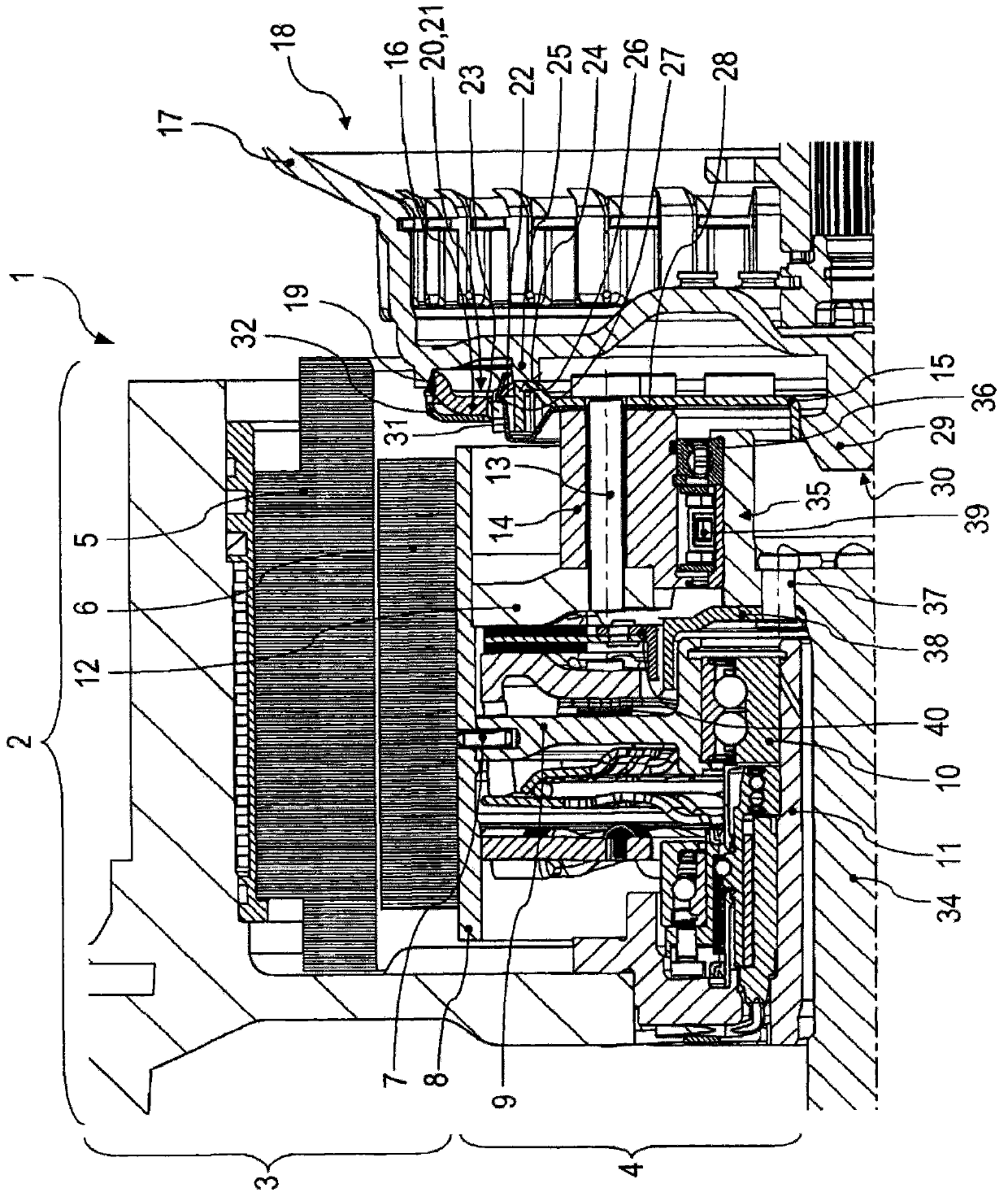

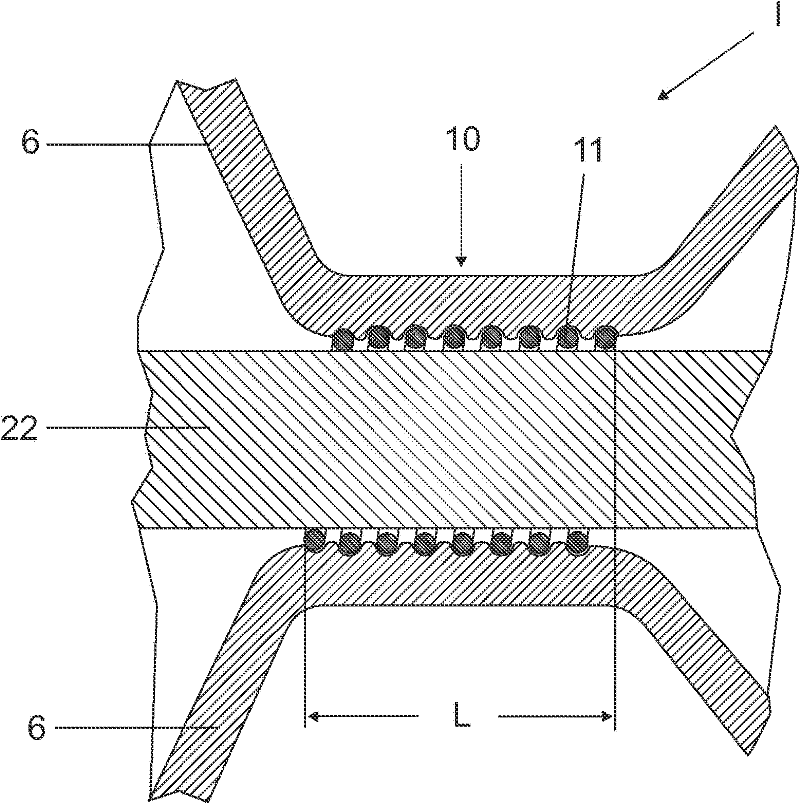

Electric motor, in particular for the windscreen wiper drive of a motor vehicle, with improved seating for the armature shaft bearing

InactiveCN101512875AEasy to installAchieve installationWindowsShaftsRolling-element bearingEngineering

The invention relates to an electric motor (1), in particular for the windscreen wiper drive of a motor vehicle, comprising an armature shaft (10), which is mounted by means of at least one anti-friction bearing (11). Said bearing has an inner bearing ring (12), joined to the armature shaft (10) and also an outer bearing ring (13), held in a bearing seat, the latter consisting of a first half-shell (14) and a second half-shell (15), which are fitted together with their interiors facing one another to form a closed radially symmetrical bearing seat. The invention thus provides an electric motor (1) for the windscreen wiper drive of a motor vehicle with a simple seating for the anti-friction bearing (11) of the armature shaft (10).

Owner:ROBERT BOSCH GMBH

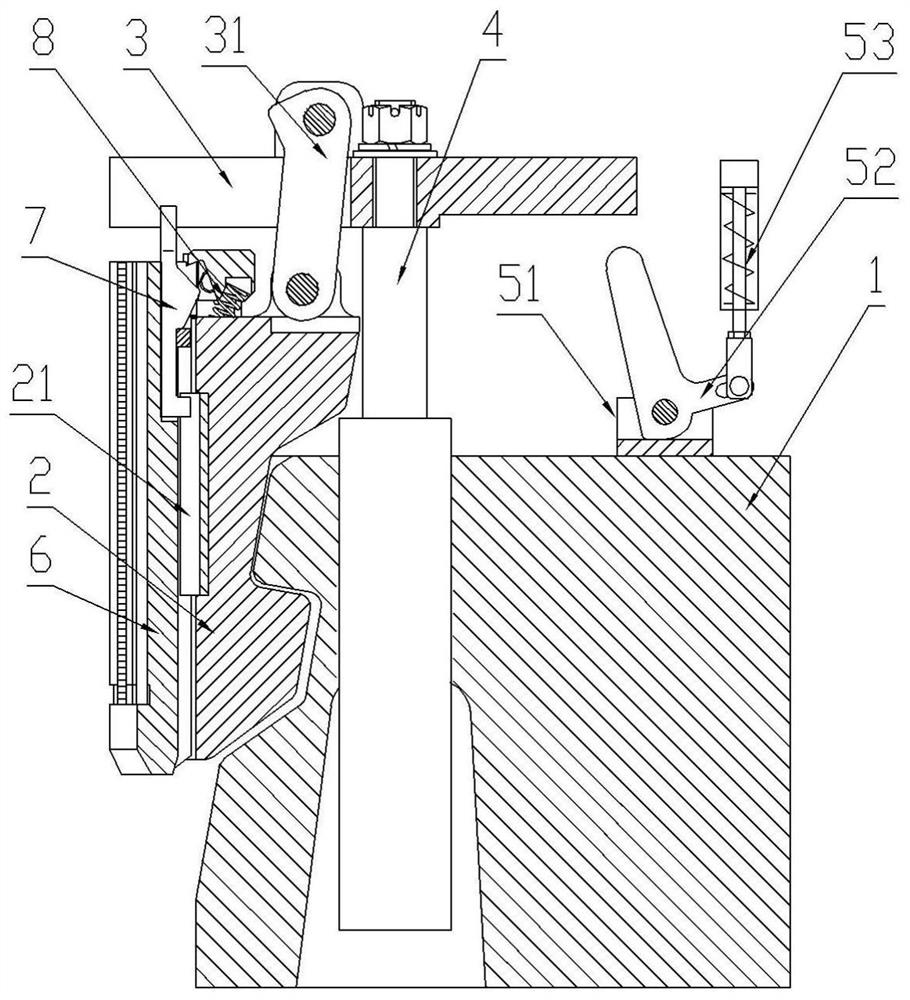

Multifunctional drilling slip

PendingCN112824644AAchieve axial fixationEffective rightingDrilling rodsDrilling casingsWell drillingStructural engineering

The invention provides a multifunctional drilling slip. The multifunctional drilling slip comprises a main body, a slip body, a balance beam, a lifting air cylinder and a first safety mechanism, wherein the lifting air cylinder, the slip body and the first safety mechanism are arranged in the main body, the piston rod end of the lifting air cylinder is connected with the balance beam, the balance beam is connected with the slip body through a connecting rod, the first safety mechanism comprises a safety base, a safety lever and a safety air cylinder, the safety base is fixedly arranged on the main body, the safety lever is rotationally arranged on the safety base, and the safety air cylinder is arranged at one end of the safety lever. The first safety mechanism can effectively prevent the phenomena of drilling jamming and pausing caused by the fact that in the drilling process, after air of the lifting air cylinder is cut off accidentally, single pneumatic locking fails and the slip body descends.

Owner:JIANGSU RUTONG PETRO MASCH CO LTD

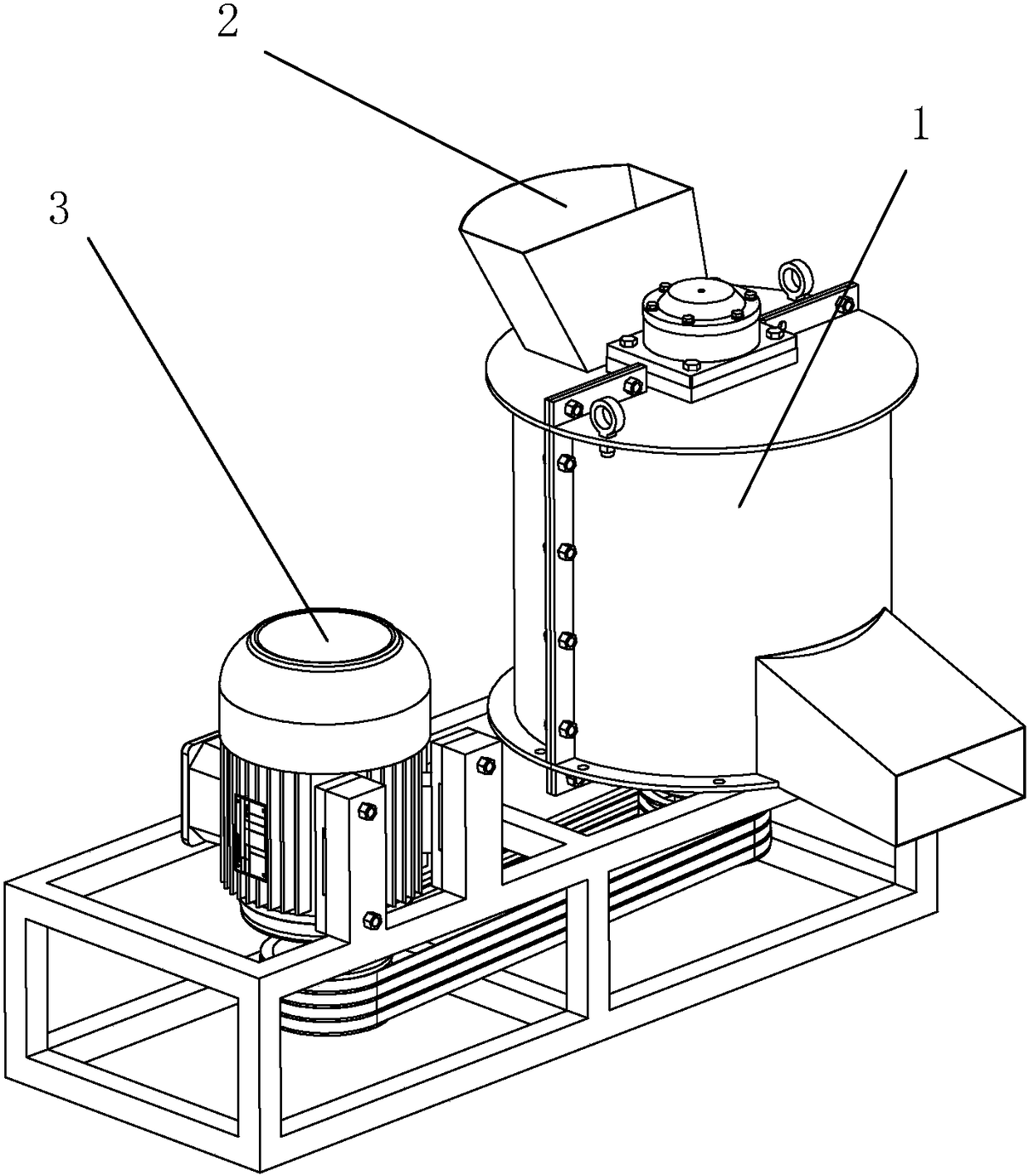

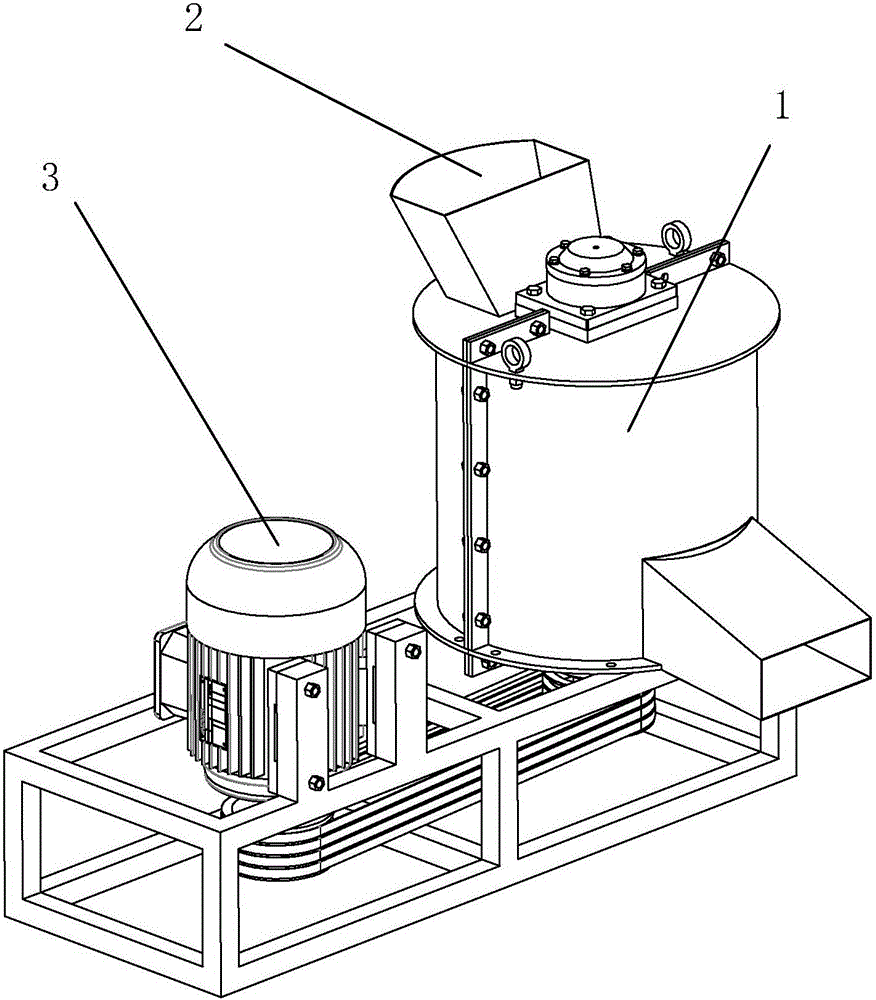

A kind of straw shredder

ActiveCN105960965BImprove cutting effectRealize the function of installationCuttersEngineeringCentrifugal force

The invention discloses a straw crushing machine. The straw crushing machine comprises a machine box, wherein a rotating shaft is arranged in the machine box, a plurality of mounting plates are arranged on the rotating shaft in the axial direction of the rotating shaft, a mounting seat with mounting holes is arranged at one end, far away from the rotating shaft, of each mounting plate, and one connecting shaft is mounted on the adjacent mounting seats through the corresponding mounting holes and rotationally connected with one cutter. According to the scheme, a new mechanical structure is adopted. The straw crushing machine has the advantages and effects as follows: in the striking and cutting-off processes of the cutters, straw is attached to the cutters so that the straw can be cut off by the cutters, the cutters rotate due to increase of stress and unload the straw, the cutters return to the original positions under the action of centrifugal force and can work normally, the stability of the machine is improved, and the machine is not easily damaged.

Owner:浙江中翠环保设备有限公司

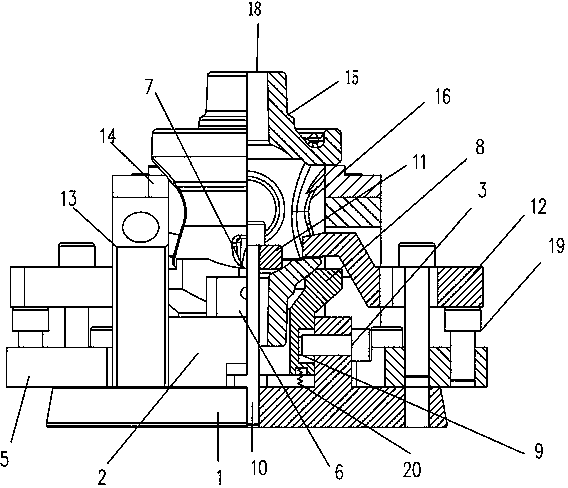

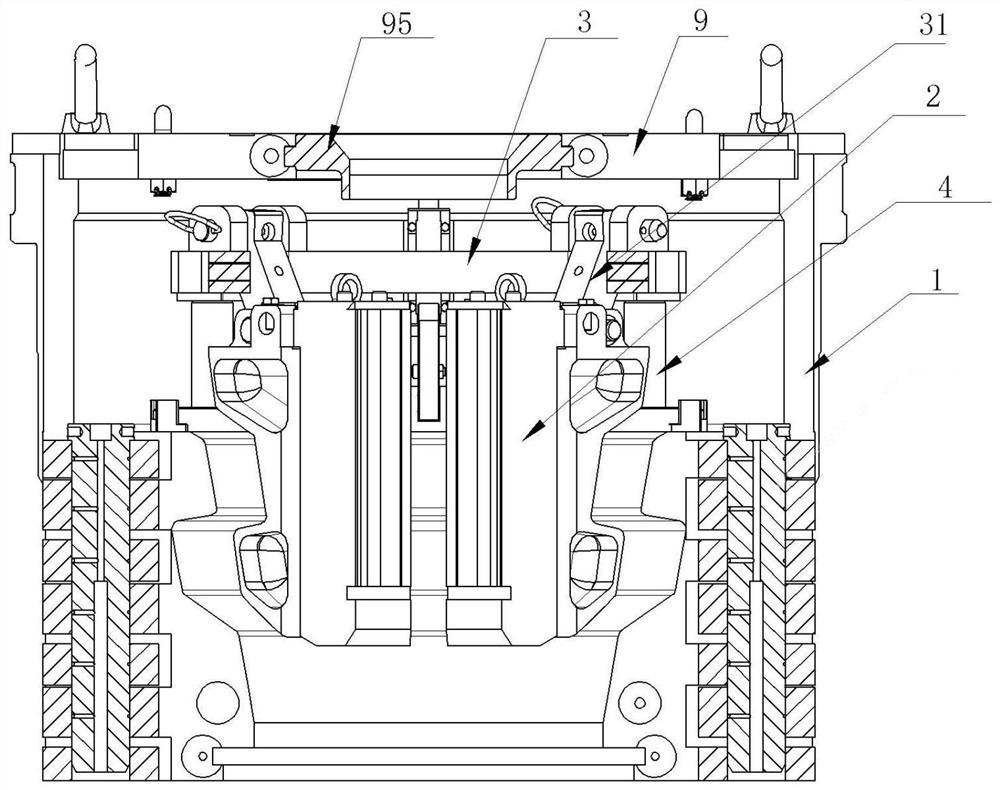

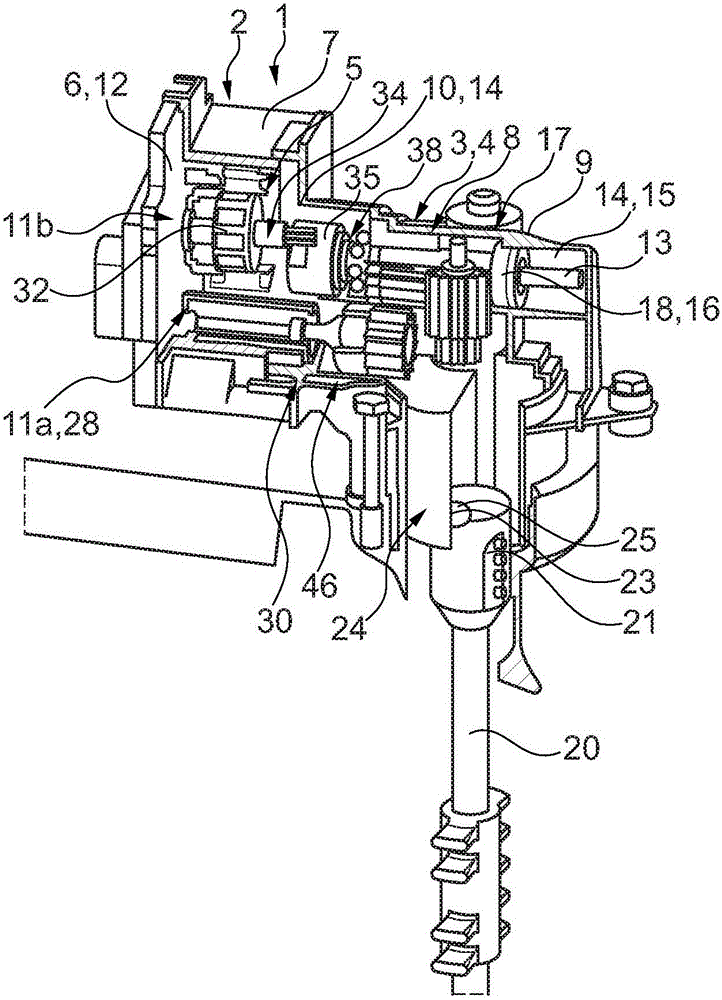

Actuator, in particular a shiftable-transmission actuator, having axially positioned and fixed components

ActiveCN106133405AEasy to manufactureFirmly connectedAssociation with control/drive circuitsGearing controlActuatorControl theory

The invention discloses an actuator, in particular a shiftable-transmission actuator, having axially positioned and fixed components. The invention relates to an actuator (1) for selecting and shifting at least two speeds of a transmission, comprising a motor (5) and at least one speed-changing device (4), which converts a motion of the motor (5) into shifting motion and / or into a selecting motion of a shifting shaft (20), wherein at least two components of the actuator (1) connected to each other are fastened to each other by means of a plastically shaped retaining region (95). The invention further relates to a method for connecting two components of such an actuator (1).

Owner:SCHAEFFLER TECH AG & CO KG

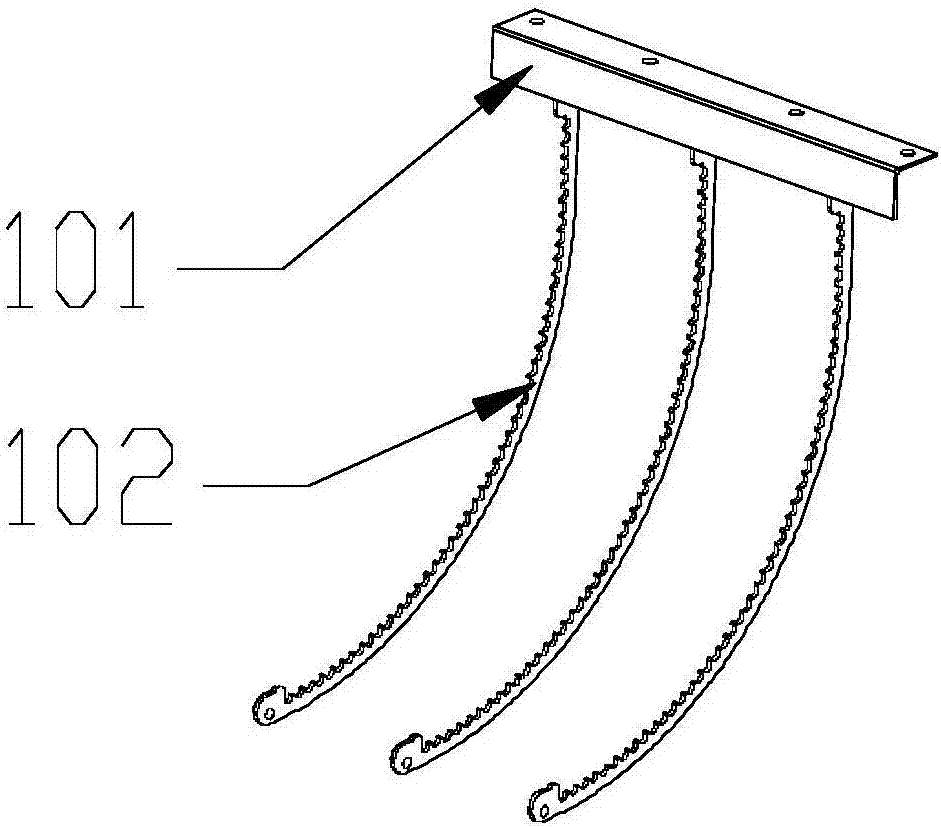

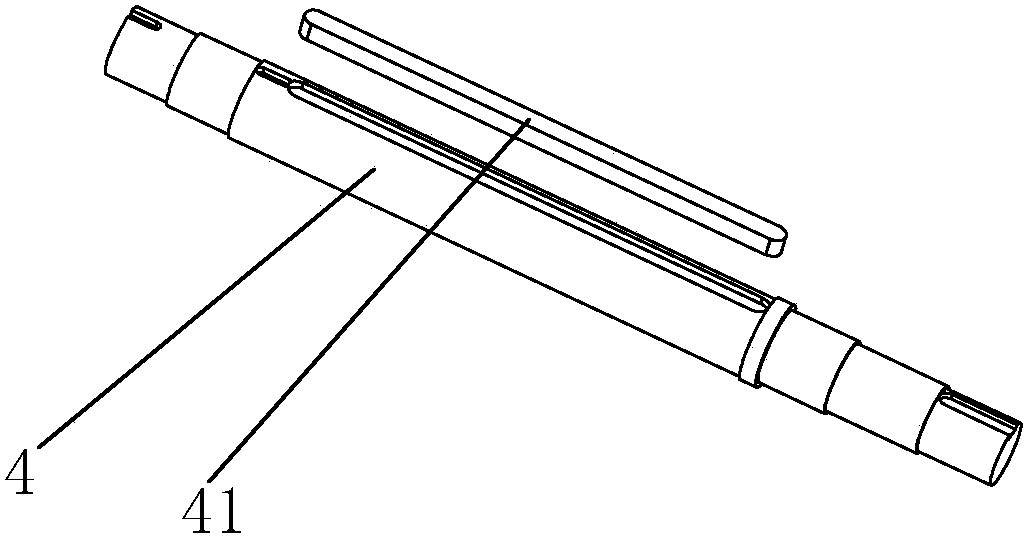

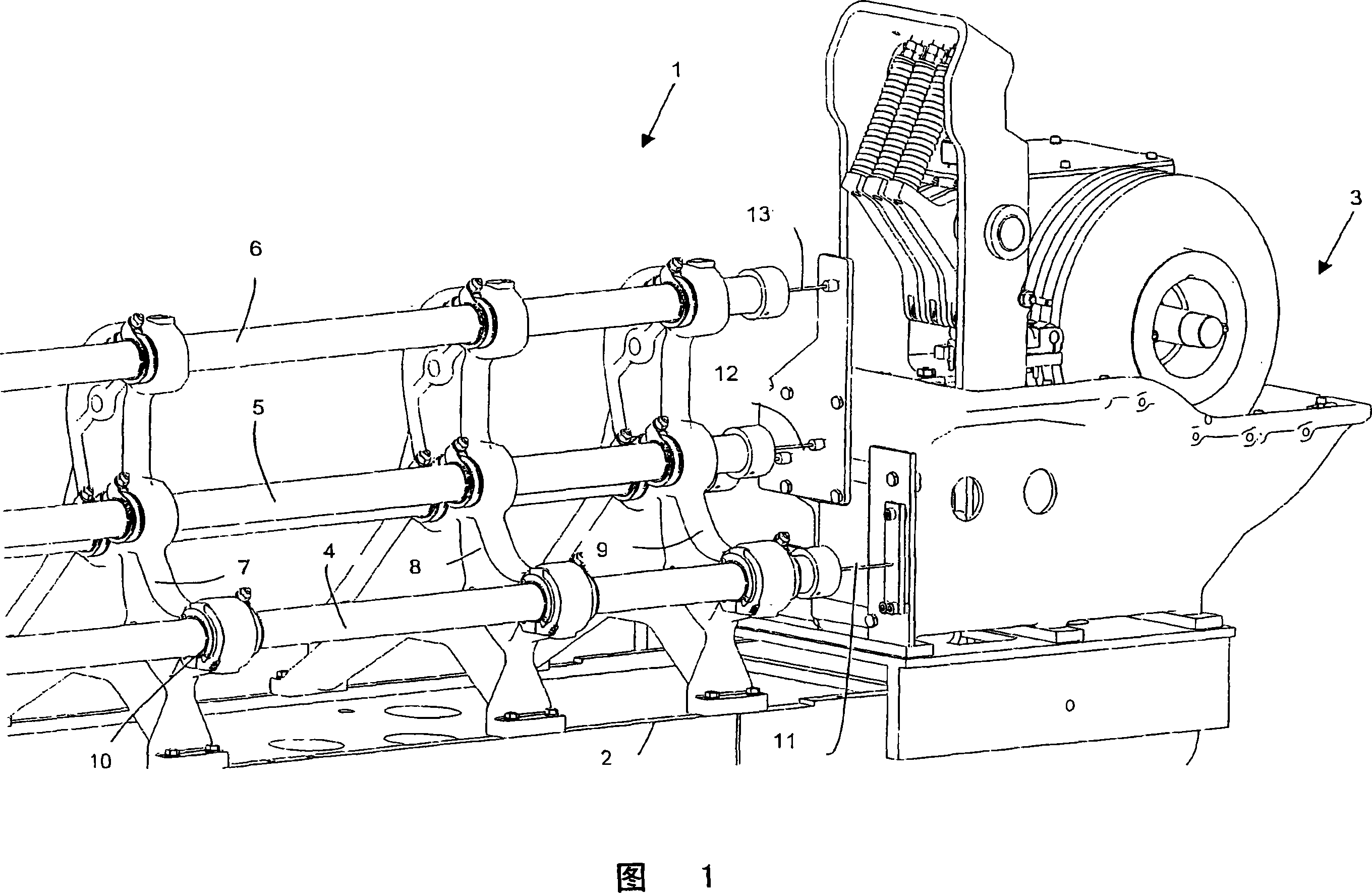

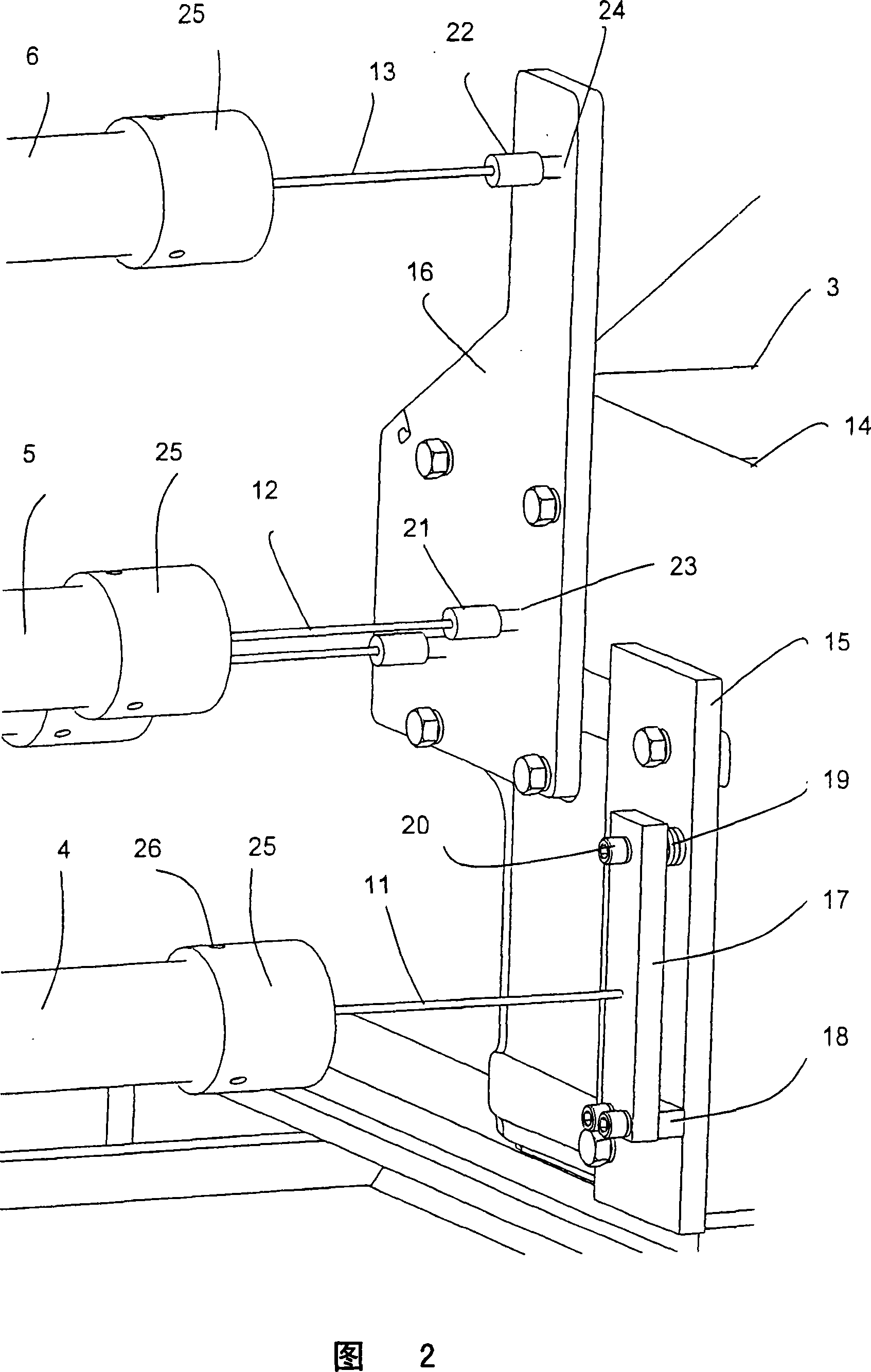

Warp knitting machine

The invention relates to a warp knitting machine (1) having a body (2) and at least one axially extending bearing shaft (4, 5, 6) for a knitting tool shaft, which are rotatably supported And is fixed in the axial direction relative to a fixedly positioned machine component (3) to the machine body (2). It is desirable to facilitate the axial fixation of the support shaft. Provision is made for this to connect the bearing shafts (4, 5, 6) to the machine component (3) in the axial direction via a torsion link (11, 12, 13).

Owner:KARL MAYER STOLL R&D GMBH

Clamp suitable for clamping object with circular through hole characteristic

ActiveCN112894663AIncreased clamping area and reliabilityLight in massWork holdersRatchetControl theory

The invention discloses a clamp suitable for clamping an object with a circular through hole characteristic, and belongs to the technical field of special clamps. The clamp suitable for clamping the object with the circular through hole characteristic comprises a fixed plate; a rotary adjusting device is inserted to the fixed plate; a supporting frame is fixedly connected to the bottom end of the fixed plate; a claw-shaped internal expansion clamping device is connected to the supporting frame; the rotary adjusting device comprises a lifting rod; the outer side of the lifting rod is movably sleeved with a fixed sleeve; the top end of the fixed sleeve is fixedly connected with a check ring; the bottom of the fixed sleeve is sleeved with a sleeve cover; an inner sleeve is fixedly connected to the inner bottom face of the sleeve cover; a ratchet wheel clamping shaft is further sleeved into the inner sleeve; the bottom end of the ratchet wheel clamping shaft is fixedly connected with a fixed connecting rod; the bottom end of the fixed connecting rod is fixedly connected with a clamping ring; and the clamping ring is matched with the claw-shaped internal expansion clamping device. The problem that common design on the market is inconvenient to clamp objects with circular through hole characteristics is effectively solved.

Owner:HEFEI UNIV OF TECH

Straw crushing machine

ActiveCN105960965AImprove cutting effectImprove processing efficiencyCuttersEngineeringCentrifugal force

The invention discloses a straw crushing machine. The straw crushing machine comprises a machine box, wherein a rotating shaft is arranged in the machine box, a plurality of mounting plates are arranged on the rotating shaft in the axial direction of the rotating shaft, a mounting seat with mounting holes is arranged at one end, far away from the rotating shaft, of each mounting plate, and one connecting shaft is mounted on the adjacent mounting seats through the corresponding mounting holes and rotationally connected with one cutter. According to the scheme, a new mechanical structure is adopted. The straw crushing machine has the advantages and effects as follows: in the striking and cutting-off processes of the cutters, straw is attached to the cutters so that the straw can be cut off by the cutters, the cutters rotate due to increase of stress and unload the straw, the cutters return to the original positions under the action of centrifugal force and can work normally, the stability of the machine is improved, and the machine is not easily damaged.

Owner:浙江中翠环保设备有限公司

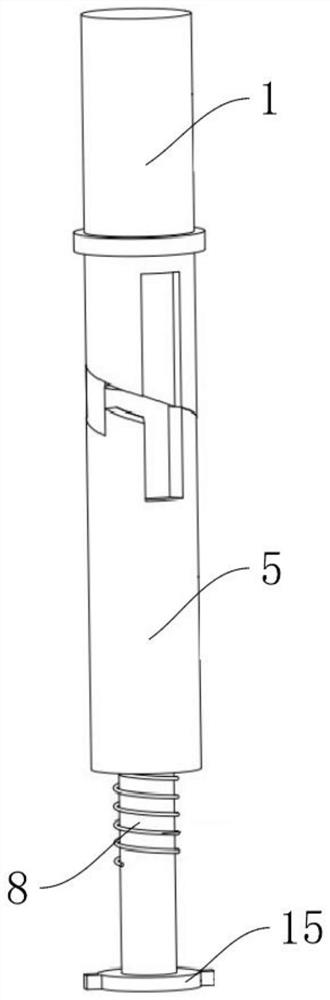

Combined detachable chair leg

PendingCN111631547AGood load-bearing performanceSimplify the assembly processStoolsChairsEngineeringPhysical therapy

A combined detachable chair leg comprises a middle disc seat and five single-foot connecting seats, and the five single-foot connecting seats are connected to the circumference of the middle disc seatand are uniformly distributed in the circumferential direction; the upper surface of each single-foot connecting seat is provided with an avoiding inclined plane and a matching inclined plane I whichare sequentially connected from outside to inside; the combined detachable chair leg also comprises five overturning assembly single feet in one-to-one correspondence with the single-foot connectingseats; matched inclined planes II are arranged on the inner walls of the upper sides of the ends, close to the single-foot connecting seats, of the overturning assembly single feet; an inner axial locking structure is arranged between the end, close to the middle disc seat, of each single-foot connecting seat and the end, close to the single-foot connecting seat, of the corresponding overturning assembly single foot, and when the overturning assembly single feet overturn upwards to enable the matching inclined planes I to be matched with the matching inclined planes II, the overturning assembly single feet can be limited from moving towards the side of the middle disc seat excessively in the axial direction of the single-foot connecting seats by inner axial locking structure, and an outeraxial concave-convex locking structure for preventing the corresponding overturning assembly single foot from being separated outwards along the axial direction of the corresponding single-foot connecting seat is arranged between one end, far away from the middle disc seat, of the lower surface of each single foot connecting seat and the lower side edge of the corresponding overturning assembly single foot.

Owner:李晨欢

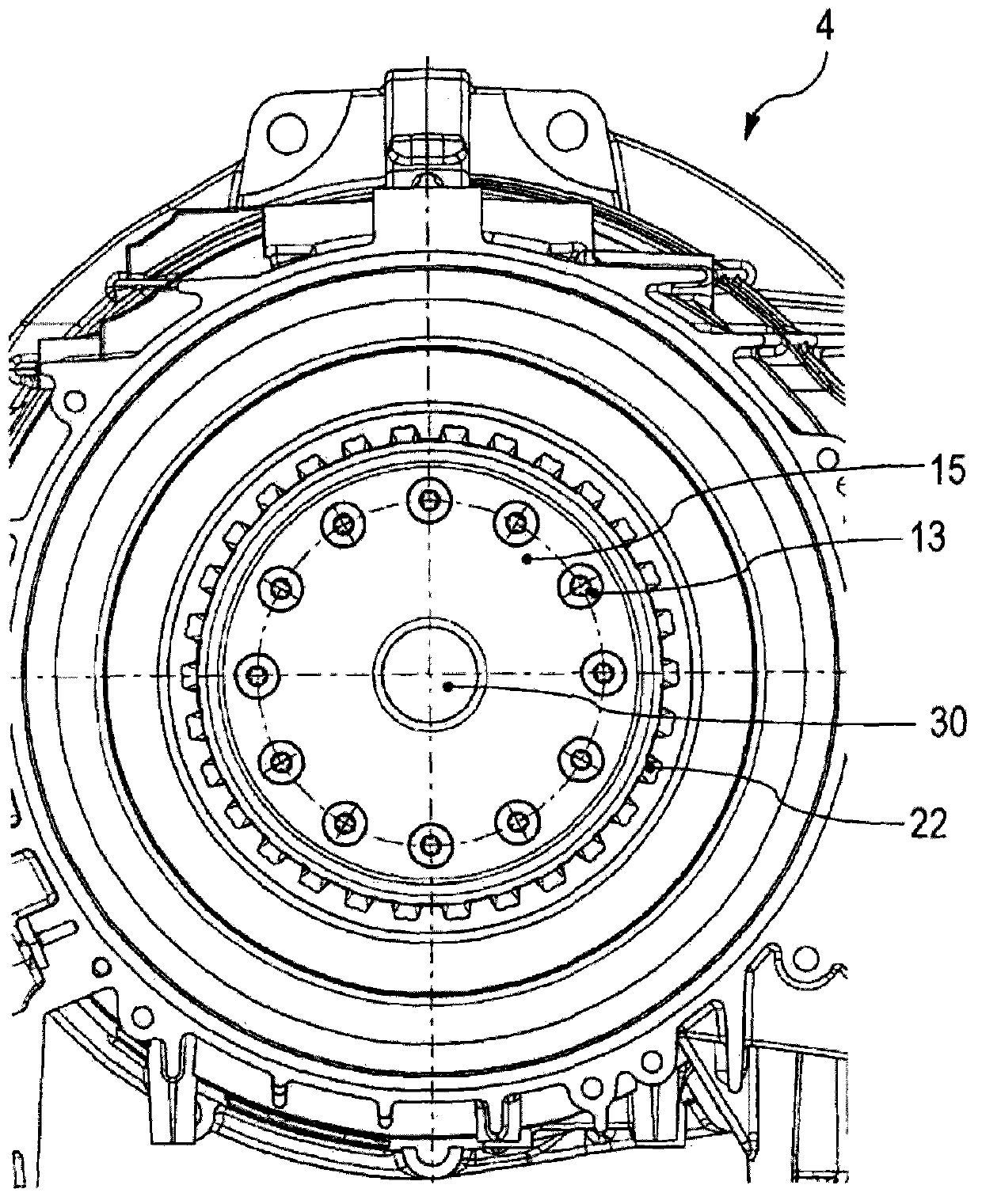

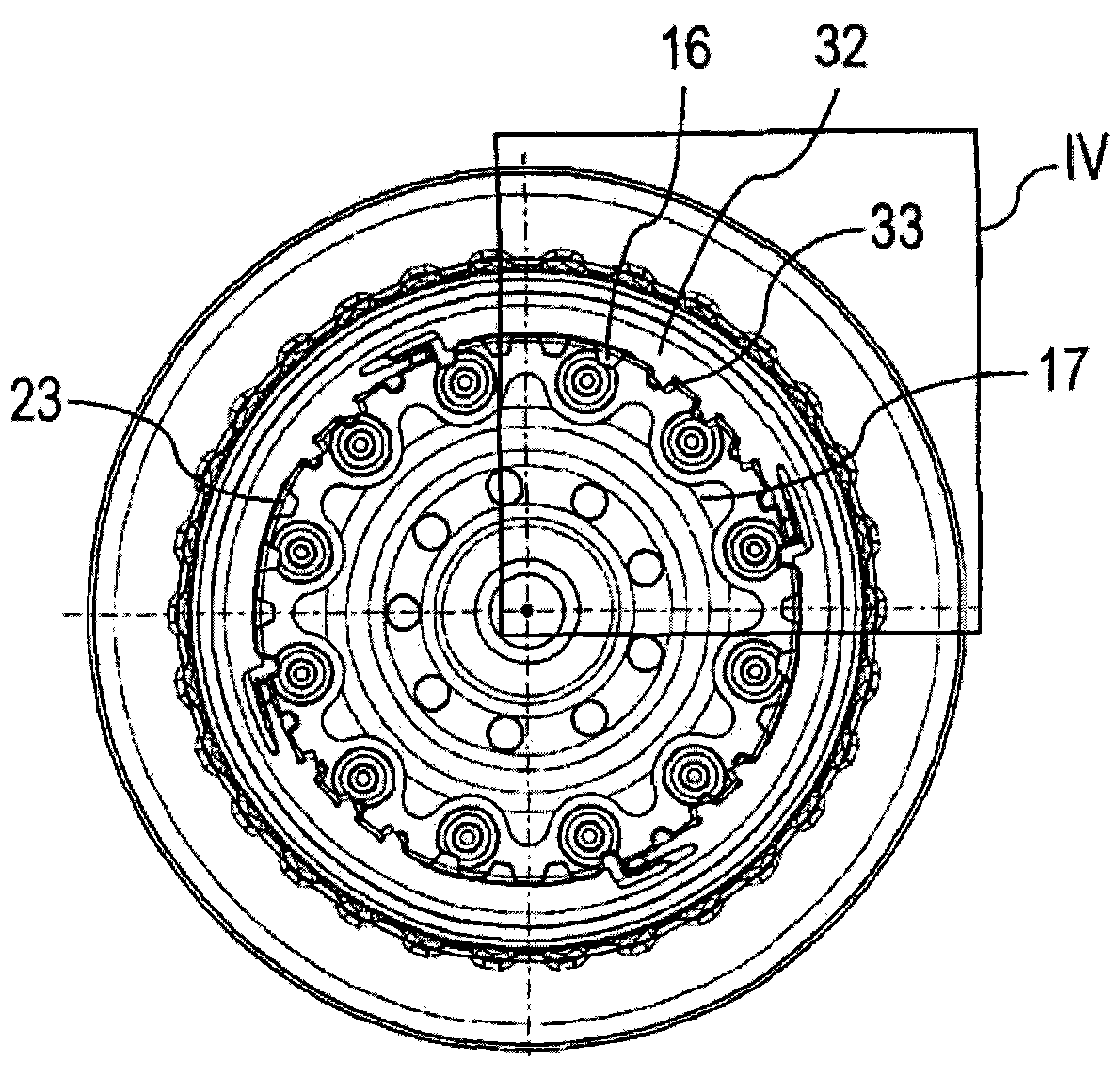

A torque transfer device connected with a torque converter with the aid of gear engagement

ActiveCN103395359AEasy to useLow costGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingMotor driveCombustion

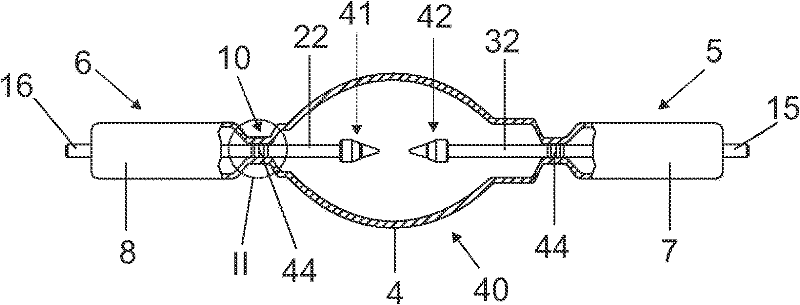

The powertrain (1) has a hybrid module (2) that is provided with an electric machine (3). A circuit unit (4) is provided between an internal combustion motor-driven flange (34) and a gear box-tied up transducer (18). The circuit unit is provided to decouple electric machine by flange. The hybrid module is provided with a transducer through a gear (20).

Owner:SCHAEFFLER TECH AG & CO KG

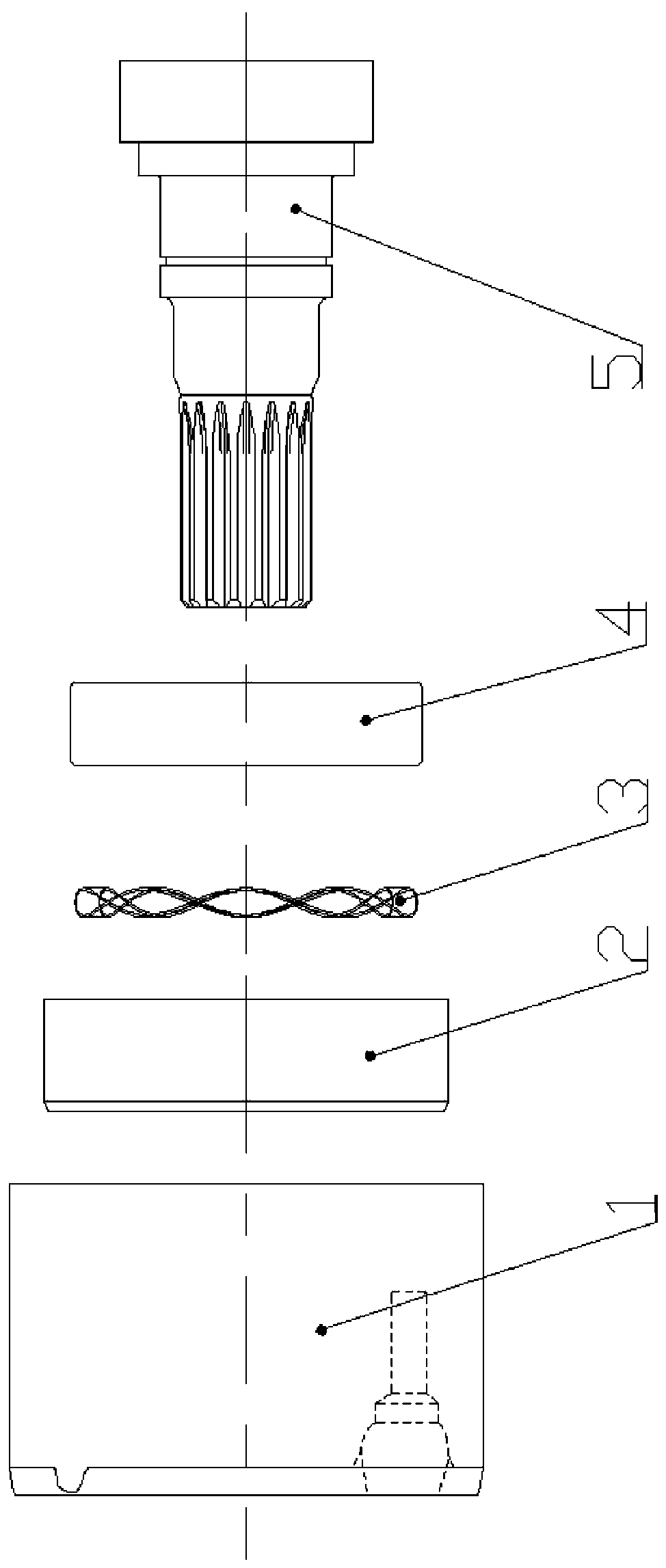

Discharge lamp

ActiveCN102414773AImprove impact resistanceHigh strengthVessels or leading-in conductors manufactureHigh-pressure discharge lampsGas-discharge lampEngineering

A discharge lamp (1), comprising two opposing electrodes (2, 3), has at least in the region of an electrode rod (32) a narrower section (9) in the lamp shaft (5) for centering and guiding the corresponding electrode (3). A damping / guiding element, such as a resilient wire helix (11) or an embossed foil, or both, is disposed between the electrode rod (32) and the inside of the narrower section (9) and improves the guiding and damping of the electrode (3), in particular in the case of shocks or vibrations. The risk of damaging the lamp shaft (5) in the region of the narrower section (9) can thus be reduced.

Owner:OSRAM GMBH

Assembly structure of automobile reduction gearbox body and motor shaft

PendingCN109831063AHigh tensile strengthIncrease elasticityMechanical energy handlingGearing detailsWave shapeEngineering

The invention relates to an assembly structure of an automobile reduction gearbox body and a motor shaft. The assembly structure comprises a reduction gearbox body and the motor shaft, wherein the motor shaft is provided with a bearing and matches the inner ring of the bearing; the box body is provided with a stepped hole; a steel sleeve is fixed in the large-diameter hole of the stepped hole; thesteel sleeve is abutted against the shoulder of the stepped hole; the outer ring of the bearing is in clearance fit with the shaft hole of the steel sleeve; one end of the steel sleeve abutted against the shoulder of the stepped hole is provided with a flange extending toward a shaft center; a wave spring for compensating a bearing clearance is disposed between the flange and the outer ring of the bearing; and the end portion of the motor shaft extends into the cavity of the box body from the small-diameter hole of the stepped hole. The assembly structure is stable, firm in connection betweenthe steel sleeve and the reduction box body, avoids the axial movement of the motor shaft, and reduces vibration and noise.

Owner:CHONGQING TSINGSHAN IND

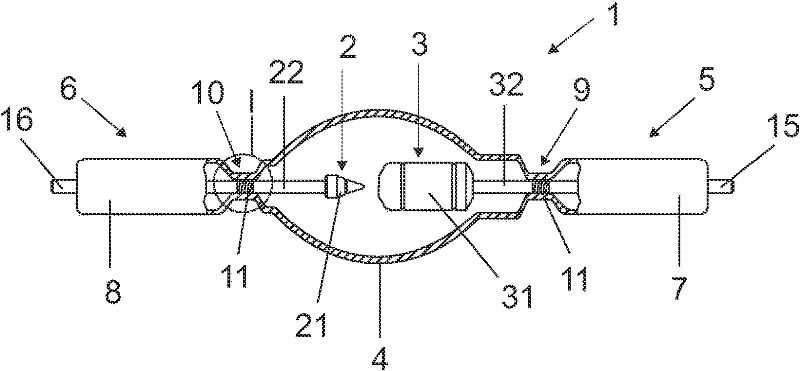

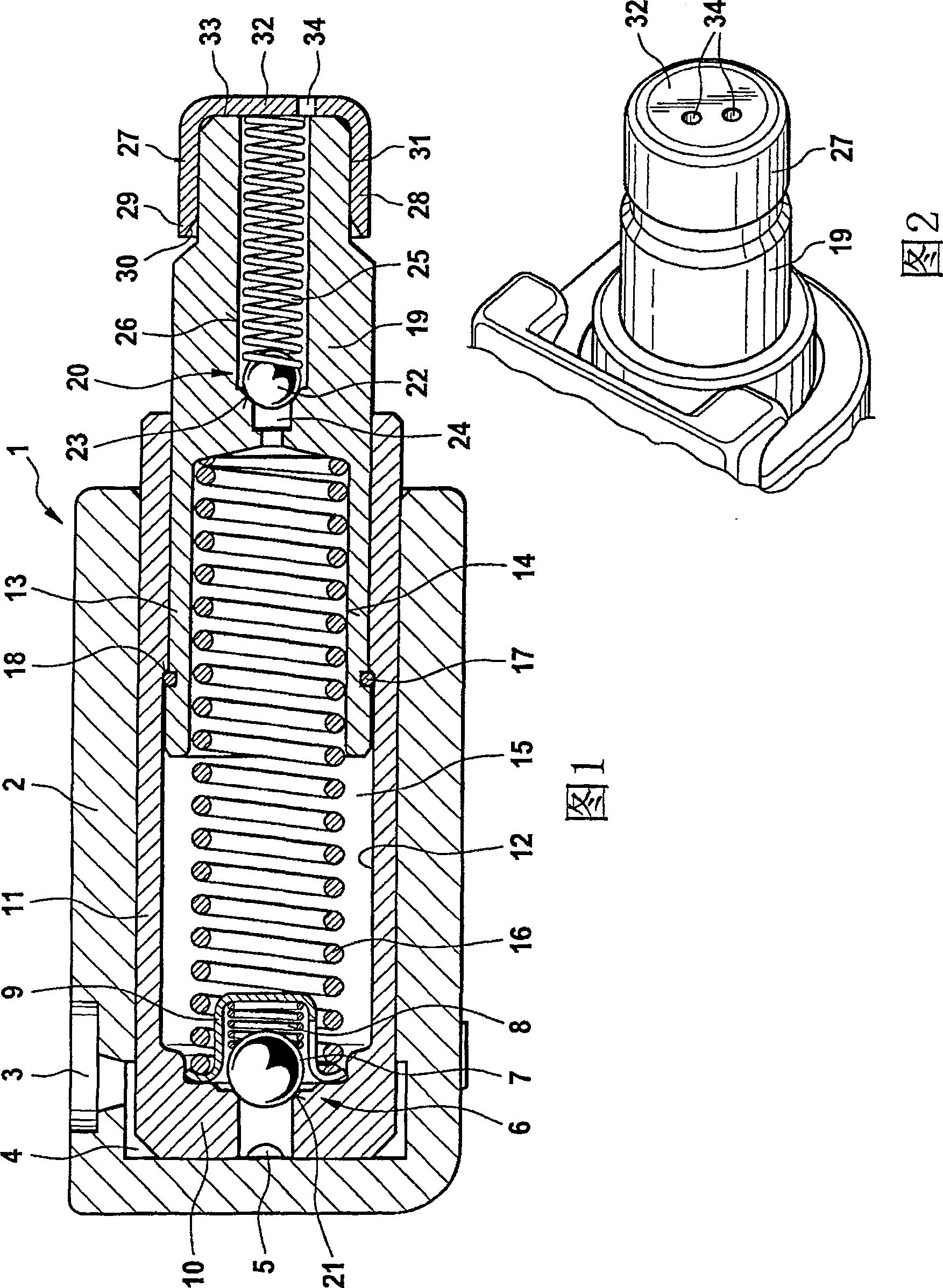

Hydraulic tensioner

InactiveCN100532883CEasy to transformReduce manufacturing costGearingMachines/enginesEngineeringInternal combustion engine

The invention relates to a hydraulic tensioning device for a traction mechanism, especially a hydraulic tensioning device for a traction mechanism of an internal combustion engine. The valve is arranged in the axial middle bore and opens outwards, the middle bore contains the opening and is fastened by a pot-shaped cover, which is supported on the piston bottom and maintains a friction-closed connection with the piston bottom. The advantage of the hydraulic tensioning device is that it can be manufactured cheaply and is easy to handle, characterized in that the pot-shaped cover is formed as a thin-walled sleeve (27) with a sleeve bottom (32) and is connected to the narrowing of the piston bottom (19) The peripheries of the ends (31) of the tubes are preferably connected by a press fit, and the openings (34) are axially disposed within the bottom (32) of the sleeve.

Owner:SCHAEFFLER TECH AG & CO KG

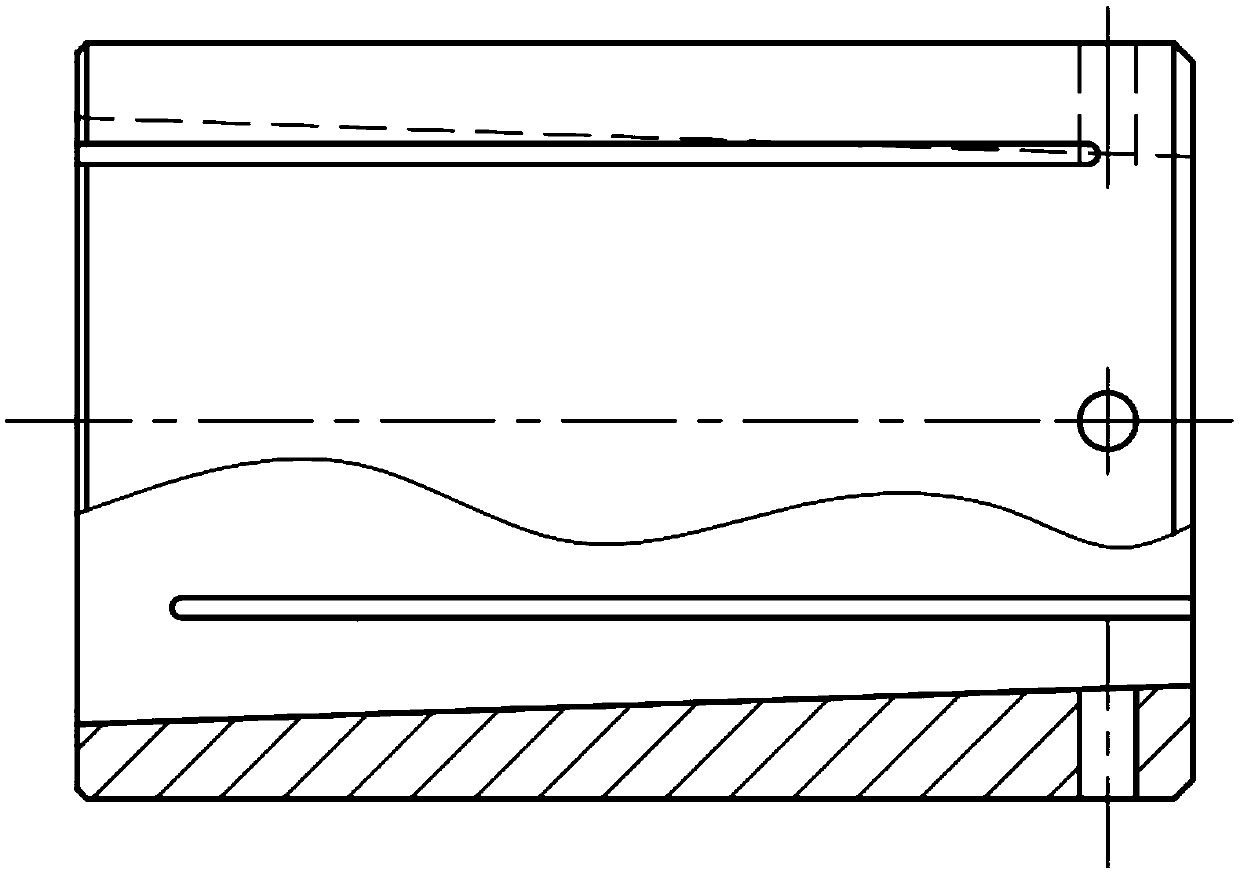

Hydraulic cylinder

The invention proposes a hydraulic cylinder. The hydraulic cylinder comprises a cylinder body; two ends of the cylinder body are respectively a cylinder bottom and a cylinder head; a piston and a piston rod are arranged in the cylinder body; one end of the piston rod is fixed with the piston, and the other end of the piston rod extends out of the cylinder head; the cylinder body is divided into a rod cavity and a rodless cavity by the piston; the cylinder body is coated with a cylindrical fixed cylinder; the fixed cylinder has a circular cylinder bottom, and a cylindrical side wall arranged on the cylinder bottom; the cylinder bottom is positioned on the side of the cylinder head, and is rotationally connected with the piston rod for extending out of the cylinder head; the fixed cylinder can axially move along with the piston rod; multiple fixed grooves are formed in the cylinder bottom; a manipulator is arranged on the piston rod for extending out of the cylinder head, and can extend out to accommodate in the fixed grooves; and the outer wall of the cylinder body and the side wall are in threaded connection. Through interaction of threads, the hydraulic cylinder realizes axial fixation of the piston rod without continuously keeping the pressure of the rodless cavity, so that the energy consumption is reduced, and the service life of a hydraulic system is prolonged.

Owner:HEFEI XIELI HYDRAULIC TECH CO LTD

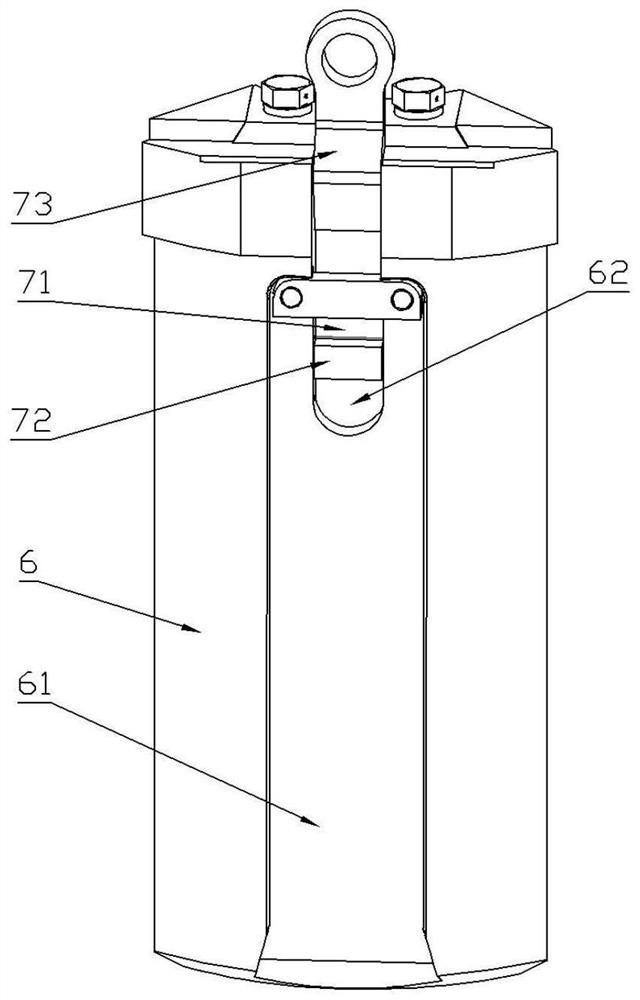

Electric slip

PendingCN112983302AIntuitive identificationAchieve axial fixationDrilling rodsDrilling casingsLine tubingEngineering

The invention provides an electric slip. The electric slip comprises a main body, a lifting electric cylinder, a balance beam, a slip body, a tooth plate carrier and a safety mechanism, wherein the lifting electric cylinder and the safety mechanism are arranged in the main body; the piston rod end of the lifting electric cylinder is connected with the balance beam; the balance beam is connected with the slip body through a connecting rod; the tooth plate carrier is detachably arranged on the slip body; the safety mechanism comprises a safety base, a safety lever and a safety electric cylinder; the safety base is fixedly arranged on the main body; the safety lever is rotatably arranged on the safety base; and the safety electric cylinder is arranged at one end of the safety lever. The electric slip solves the problem that various field pipelines are inevitably available by adopting a pneumatic or hydraulic control mode; and through locking arrangement on the slip body and the tooth plate carrier, the condition that a tooth plate is accidentally dropped possibly caused by misoperation is avoided, and the tooth plate carrier can be replaced more simply and conveniently by directly using an identifier.

Owner:JIANGSU RUTONG PETRO MASCH CO LTD

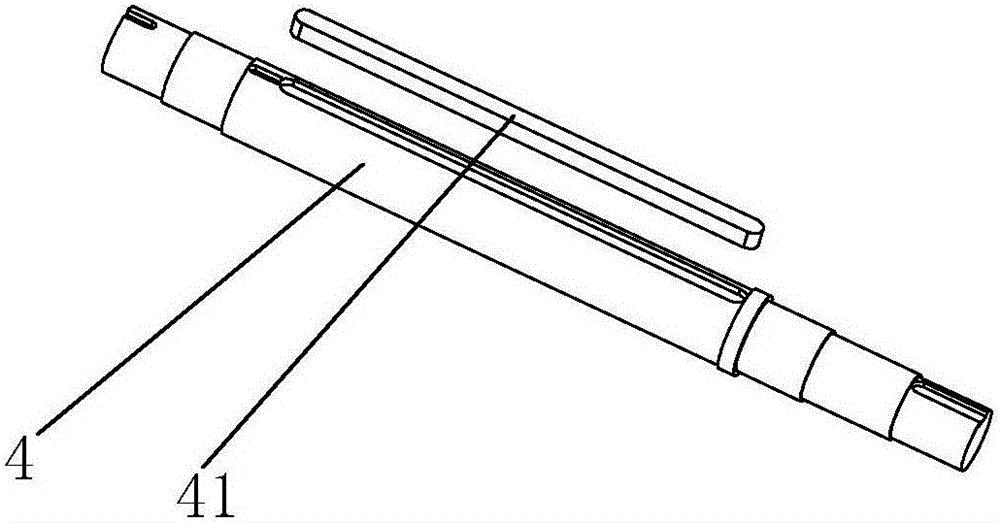

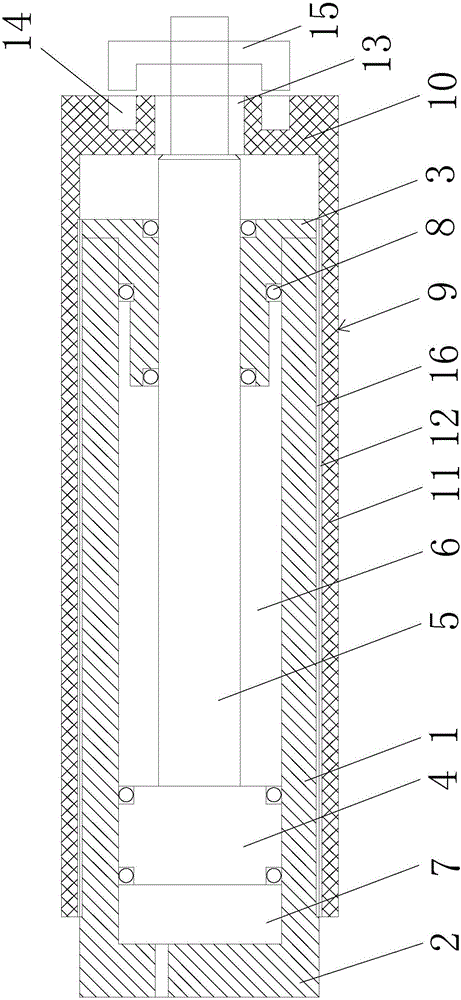

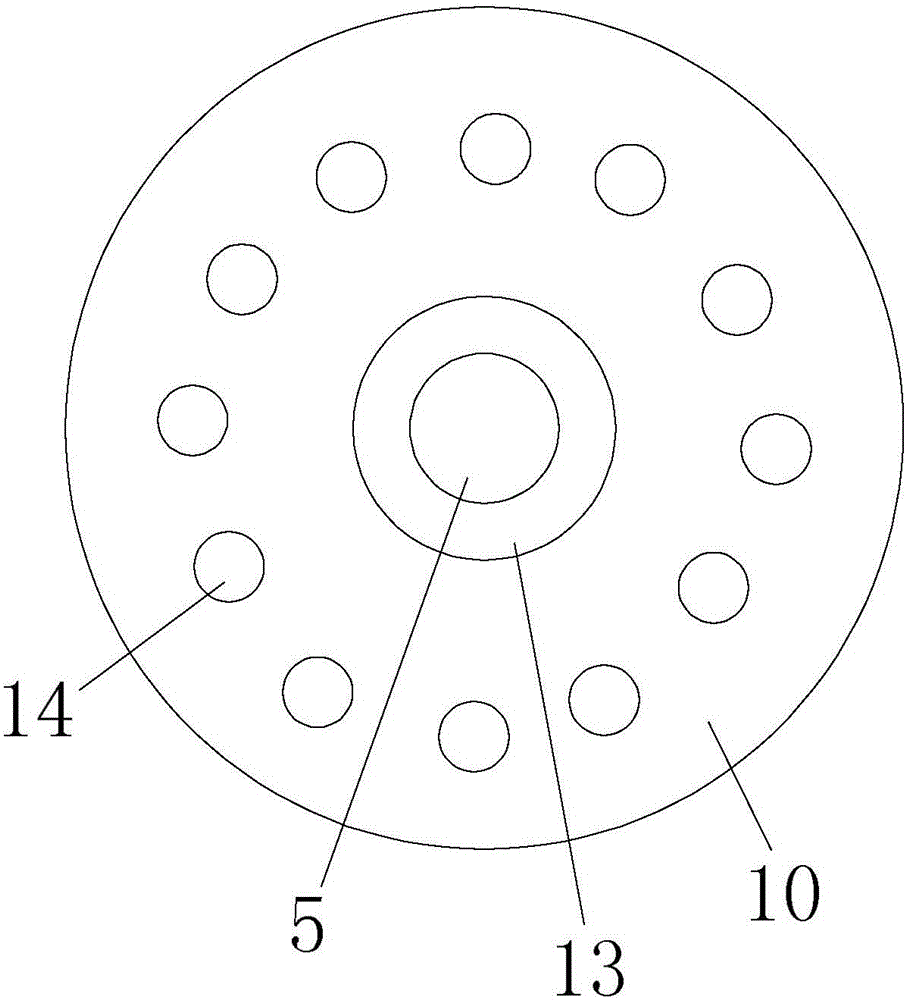

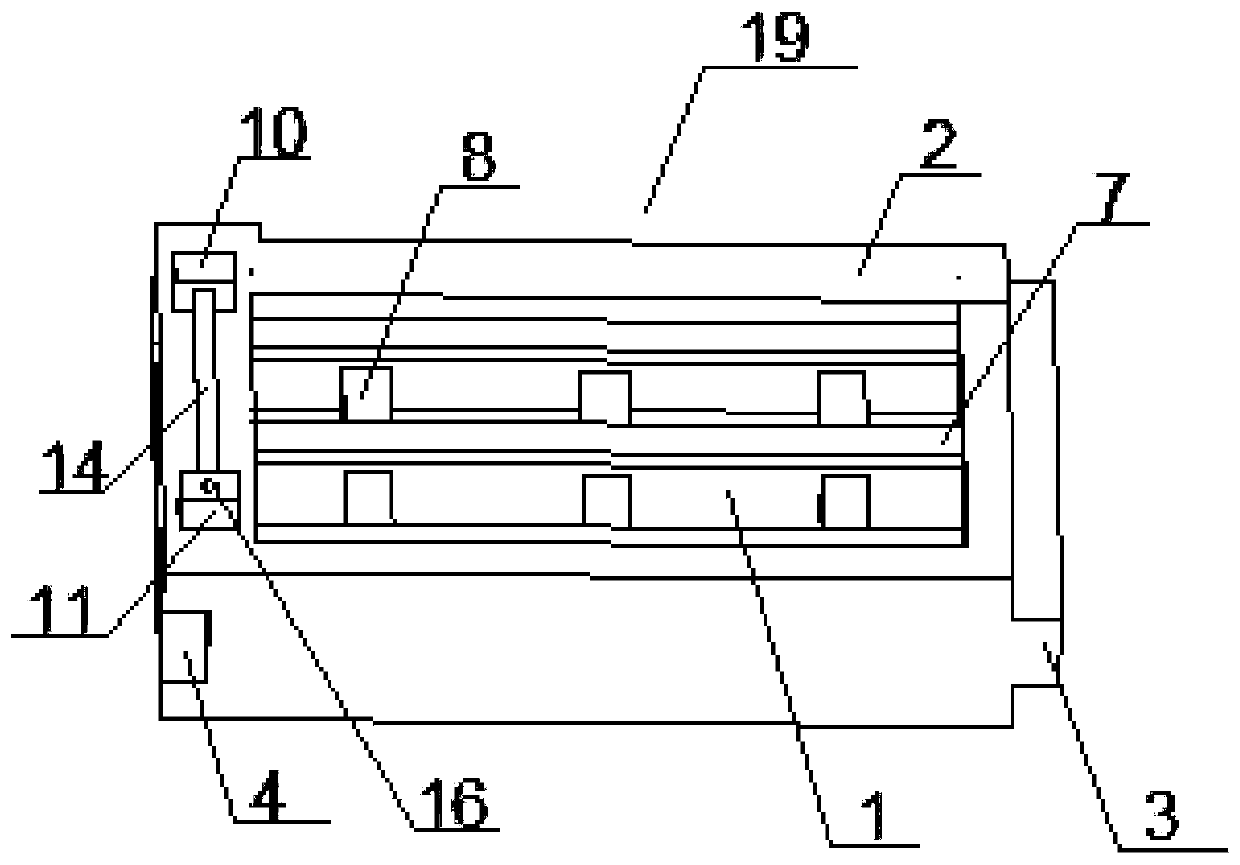

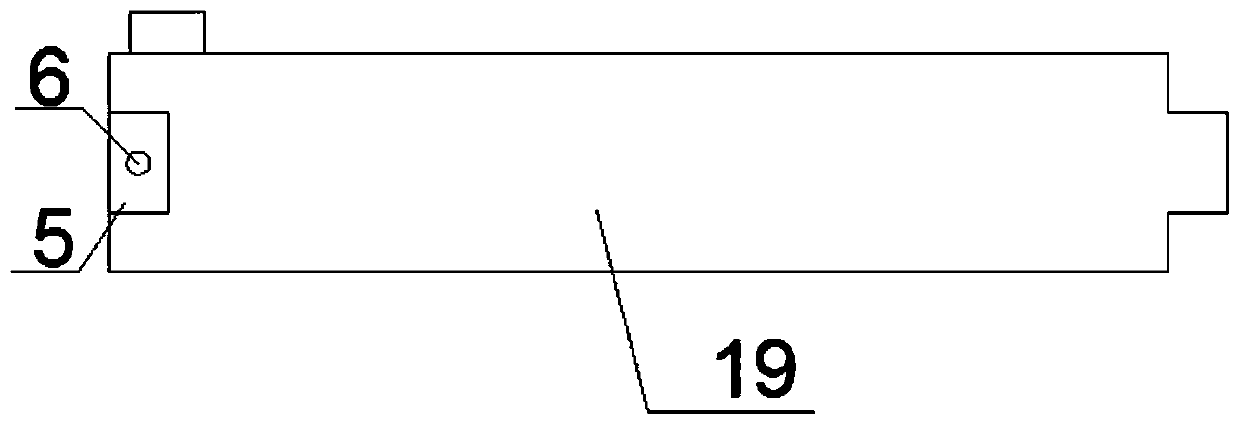

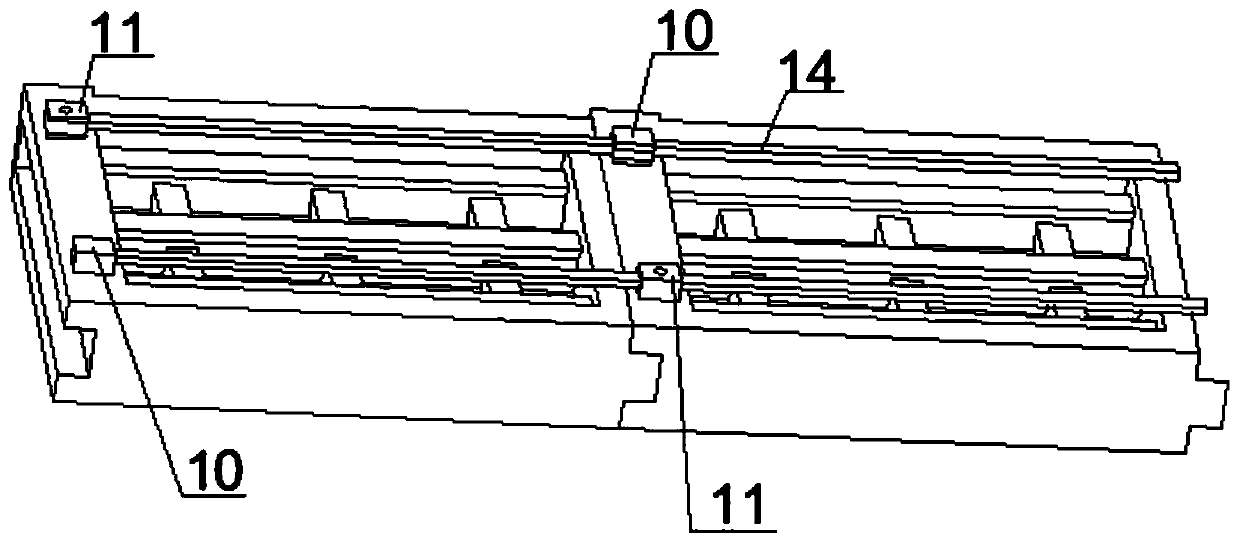

Forklift motor stator processing tool and operation method thereof

ActiveCN109639071AGuaranteed coaxialAchieve axial fixationManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention discloses a forklift motor stator processing tool and an operation method thereof. The main content is that a mould cover plate is fixedly mounted on a cylindrical positioning boss on amandrel by a hexagon socket head screw; a winding stator core is mounted on a tensioning sleeve and a left end face of the winding stator core is placed on a right end surface of the mould cover plate, the tensioning sleeve is mounted on a conical section of the mandrel, a left locking nut is mounted on a threaded section of the mandrel and the left locking nut is placed on the right end face of the tensioning sleeve, the cylindrical pin is installed in a radial mounting hole formed in the riser sleeve, and the tail end of the cylindrical pin is clamped in the annular clamping slot formed in the left locking nut, and a mould press plate is mounted on the cylindrical positioning boss on the mould backing plate, the right locking nut is mounted on the threaded section of the mandrel and theleft locking end of the right locking nut is placed on the bottom surface of the annular groove on the mould backing plate. The forklift motor stator processing tool has a simple structure, is low incost, is simple to install, and the processing precision and work efficiency can be improved.

Owner:ZHEJIANG JINLONG ELECTRICAL MASCH CO LTD

Aluminum template with high use efficiency and relatively material saving

InactiveCN110630006AThe connection is tight and firmIncrease fit areaAuxillary members of forms/shuttering/falseworksForming/stuttering elementsTime costMechanical engineering

The invention discloses an aluminum template with high use efficiency and relatively material saving. The aluminum template includes a plurality of template bodies, T-shaped inserting parts are fixedto one sides of the template bodies, and T-shaped grooves are formed in the other sides of the template bodies; every two adjacent template bodies are connected together through the cooperation of theT-shaped inserting parts and T-shaped grooves, the cooperation area of the T-shaped inserting parts and T-shaped grooves is relatively large, so that the connection between the corresponding templatebodies is more stable and tight, and meanwhile, the T-shaped inserting parts are provided with internal threaded holes; positioning plates are fixed to one ends of the T-shaped grooves, the radial direction of the connection positions of the template bodies is fixed, the bottom surfaces of the adjacent template bodies are positioned through the positioning plates, so that the bottom surfaces area same horizontal line, the overall structure is more stable, meanwhile, the installation and disassembly are simpler, the use efficiency is improved, and time cost is saved; and reinforcing devices are oppositely arranged on every two adjacent template bodies, the template bodies are axially fixed through the reinforcing devices, the connection of the template bodies is further reinforced, and the security of the connection of the template bodies is improved.

Owner:浙江华铁应急设备科技股份有限公司

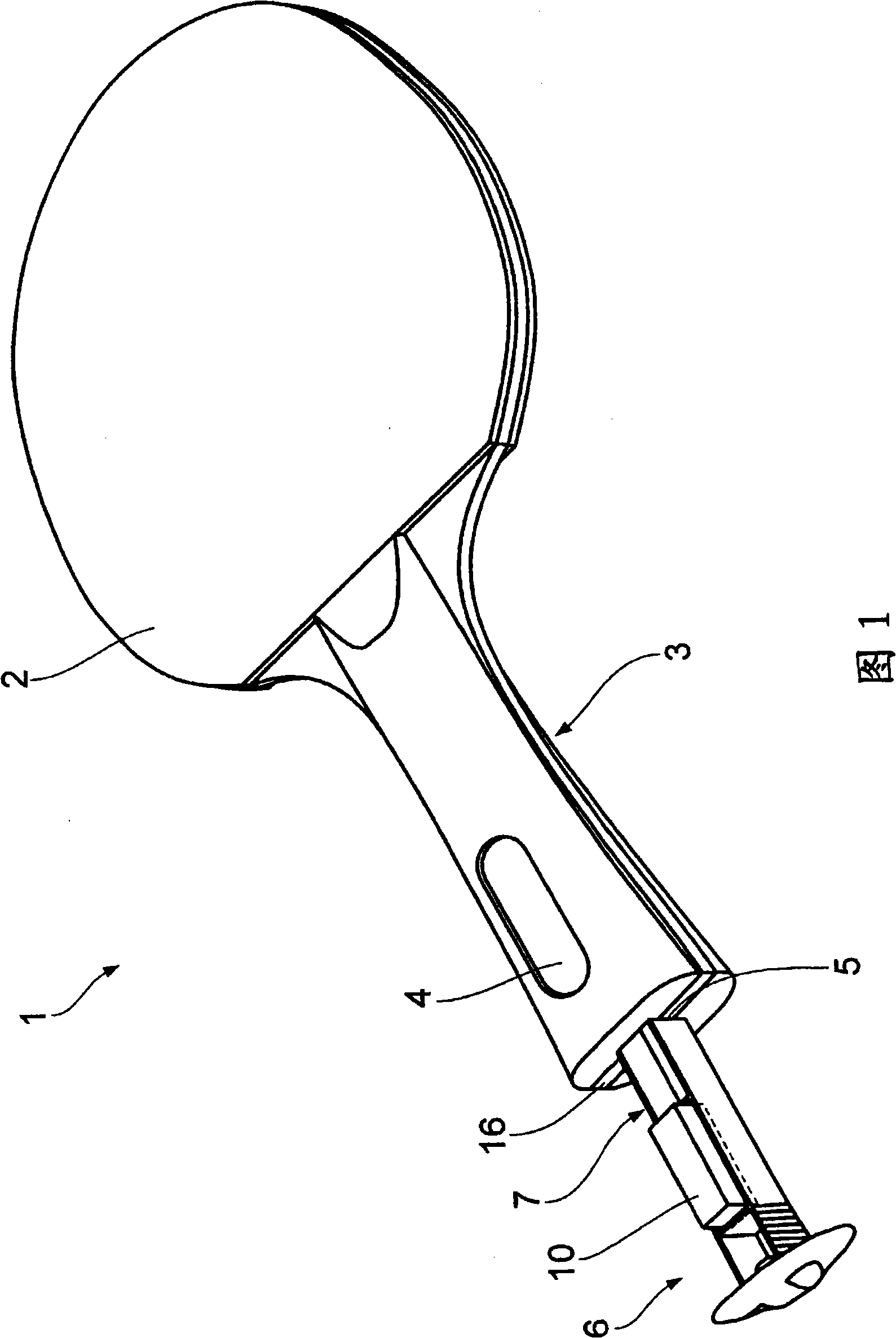

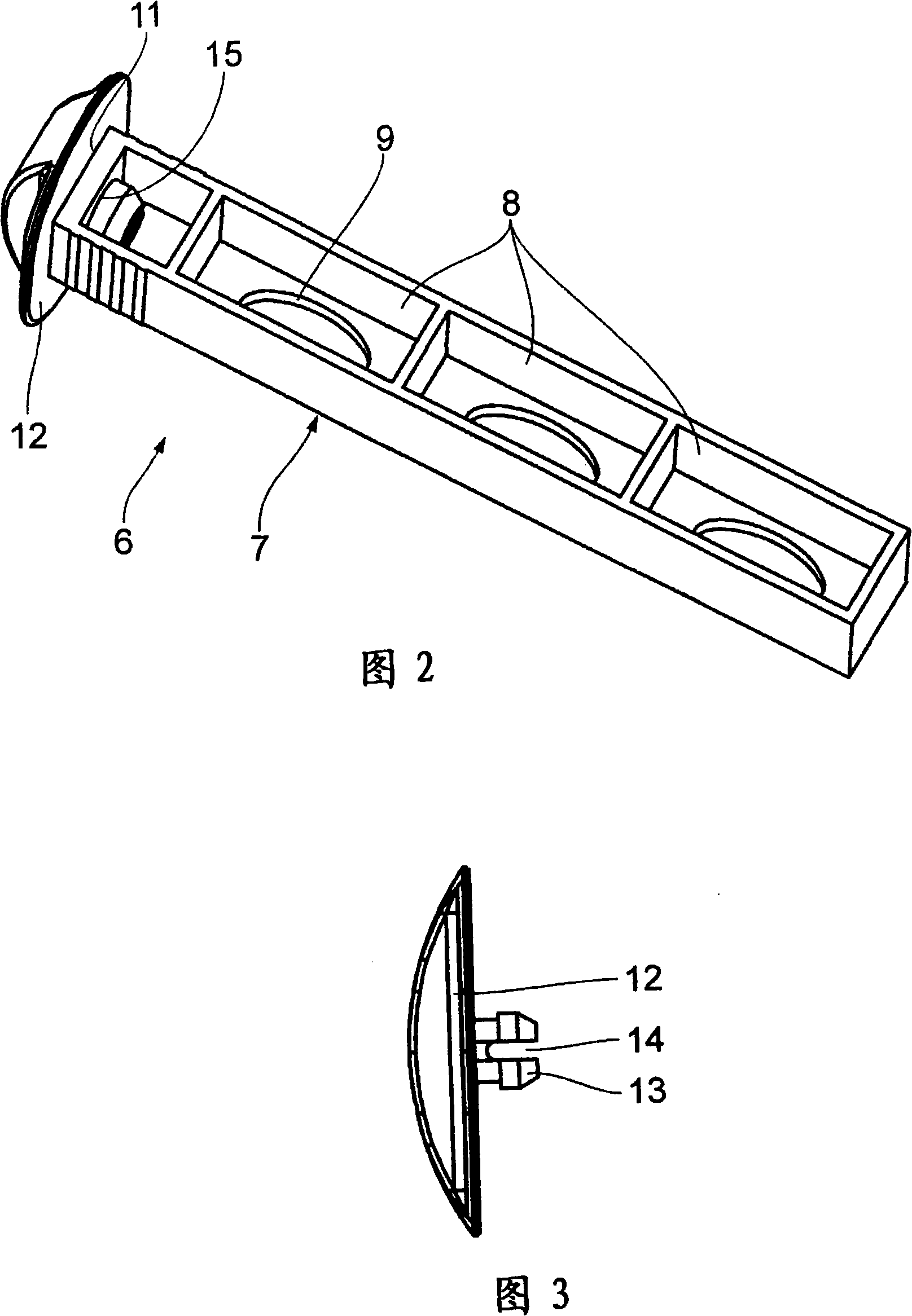

Table tennis bat

InactiveCN101332353AAchieve axial fixationGuaranteed swingabilityGolf clubsRacket sportsMicrochiropteraEngineering

The present invention relates to a pingpong bat (1) comprising a bat plate (2) and a bat handle, wherein a gravity center deflection device for pingpong is arranged in the pad handle.

Owner:PERSEUS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com