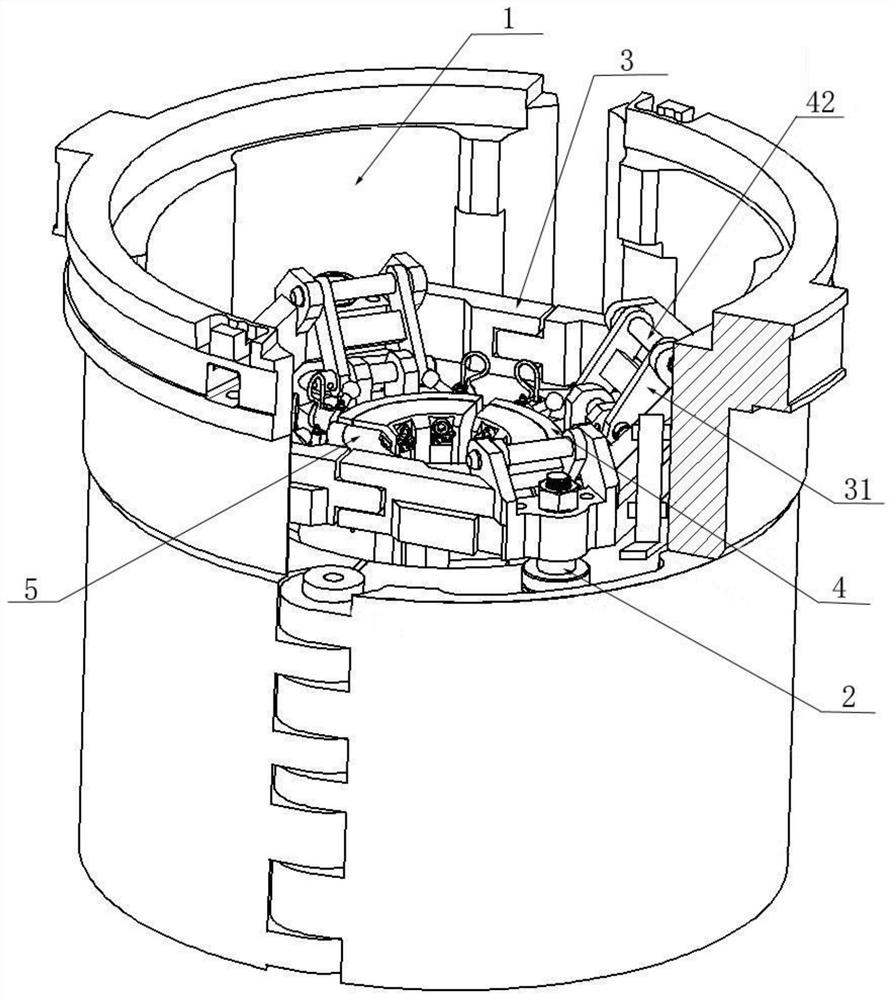

Electric slip

A technology of electric slips and slips, which is applied to drilling equipment, instruments, display devices, etc., can solve the problems of numerous pipelines on site, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

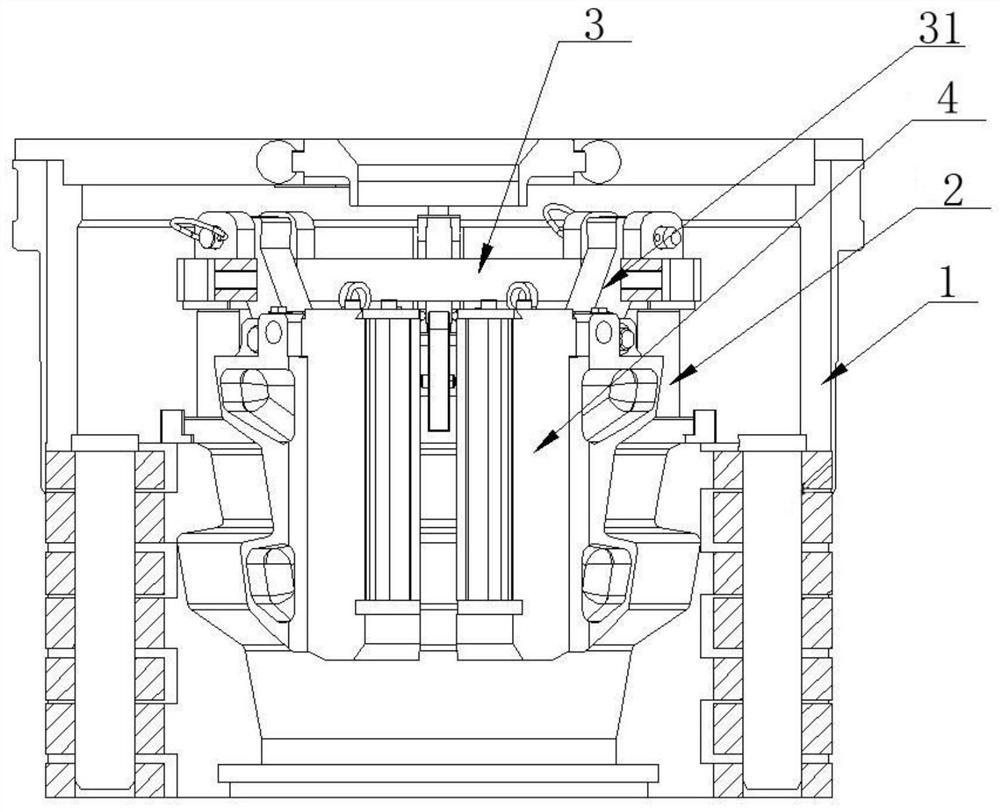

Method used

Image

Examples

Embodiment approach

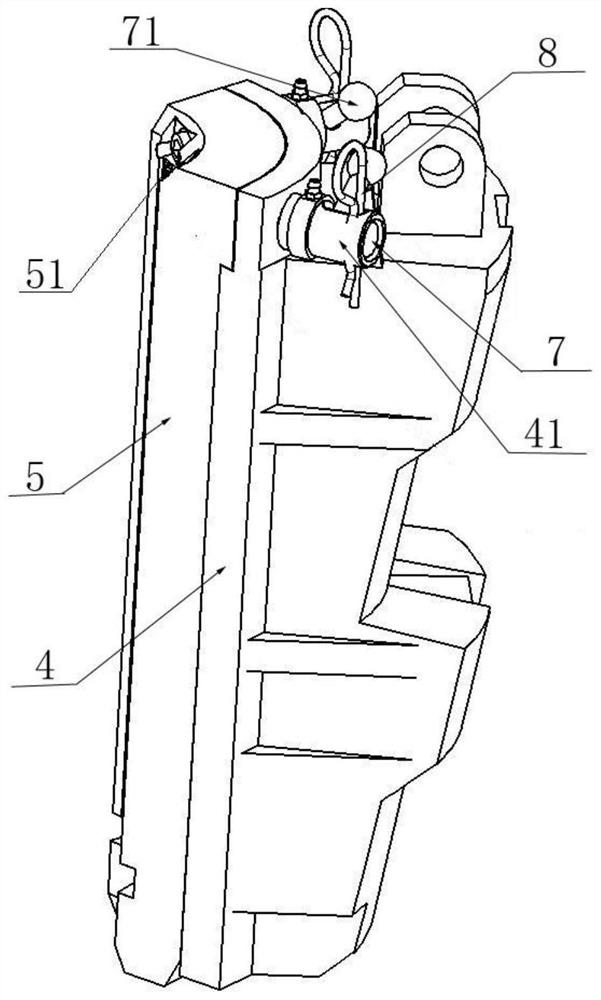

[0040] Driven by the lifting electric cylinder 2, the balance beam 3 rises, and at this time, the safety electric cylinder 63 in the safety mechanism is in a power-off state, and the piston rod end of the safety electric cylinder 63 is retracted, driving the safety lever 62 to lean towards the balance beam 3 side, and close to the side end of the balance beam 3, without hindering the rise of the balance beam 3, as the balance beam 3 continues to rise, the support of the balance beam 3 is lost, and the safety lever 62 is further inclined to the balance beam 3 below;

[0041] When the slip body 4 rises to the sensing position of the ascending travel switch, the lifting electric cylinder 2 acts to stop continuing to rise and keep the slip body 4 at the current position. After the balance beam 3 goes down to the safety lever 62, it is resisted by the safety lever 62, so as to avoid the situation of stuck drilling caused by the continued decline, which plays a role of mechanical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com