Patents

Literature

296results about How to "Efficient discrimination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

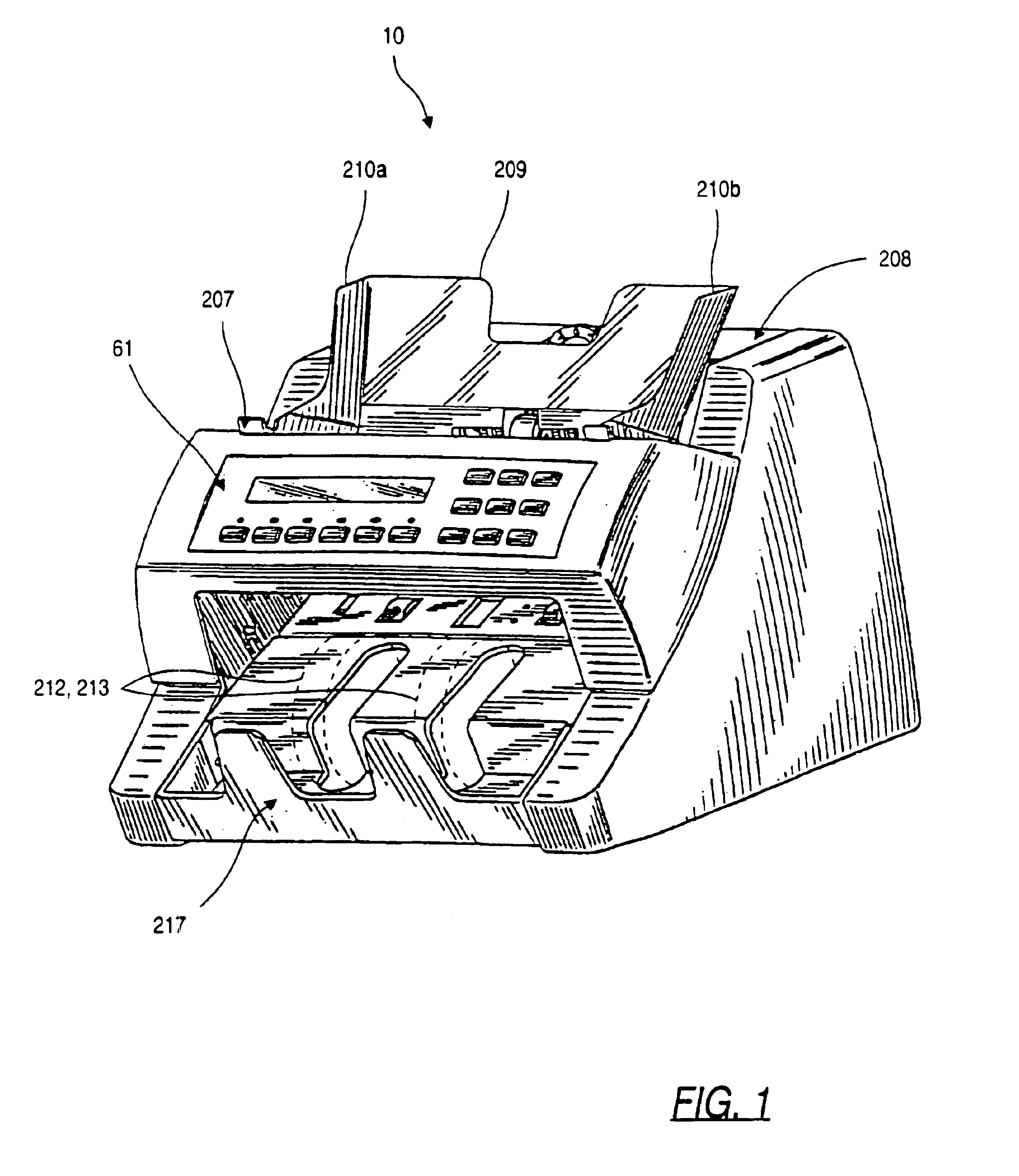

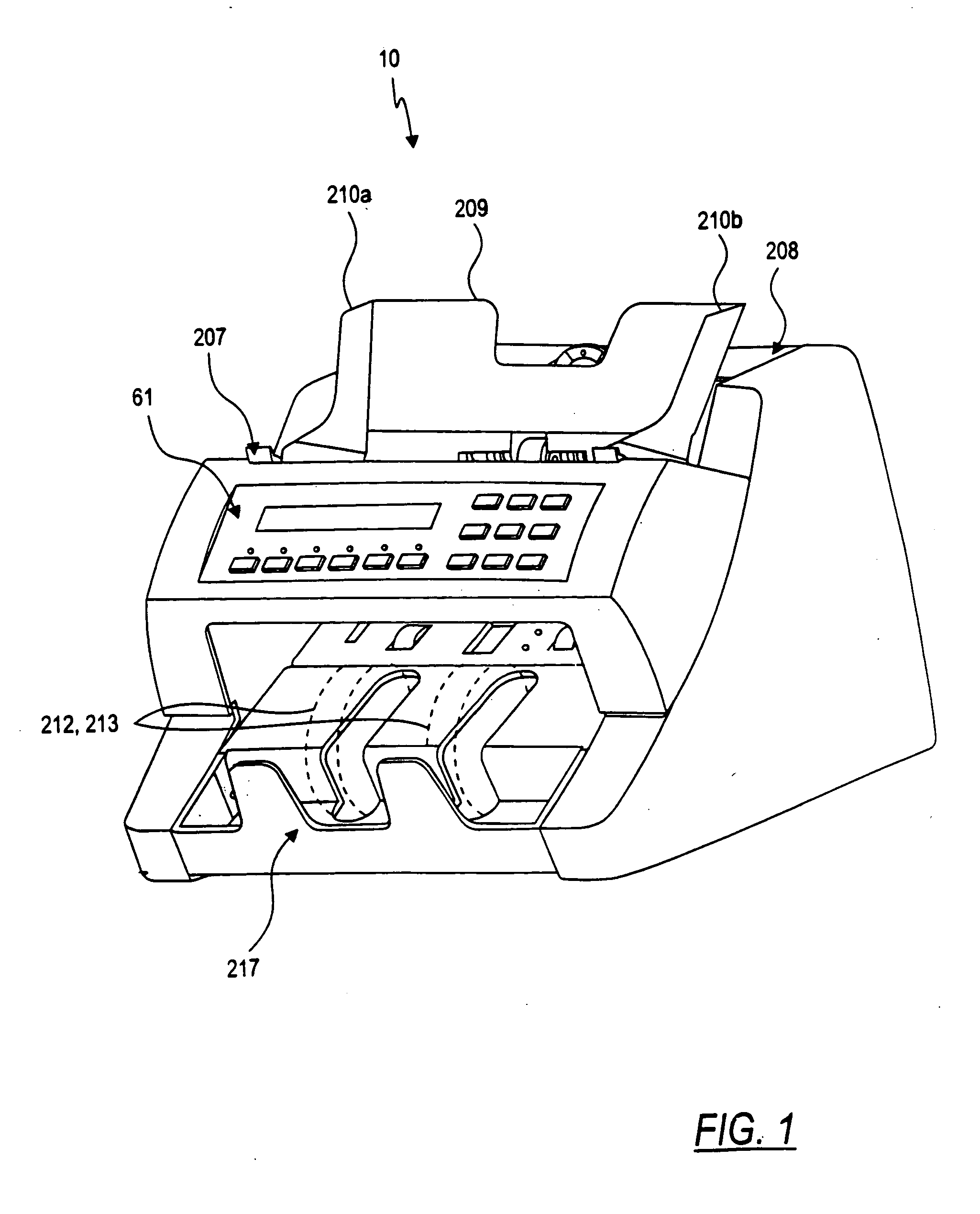

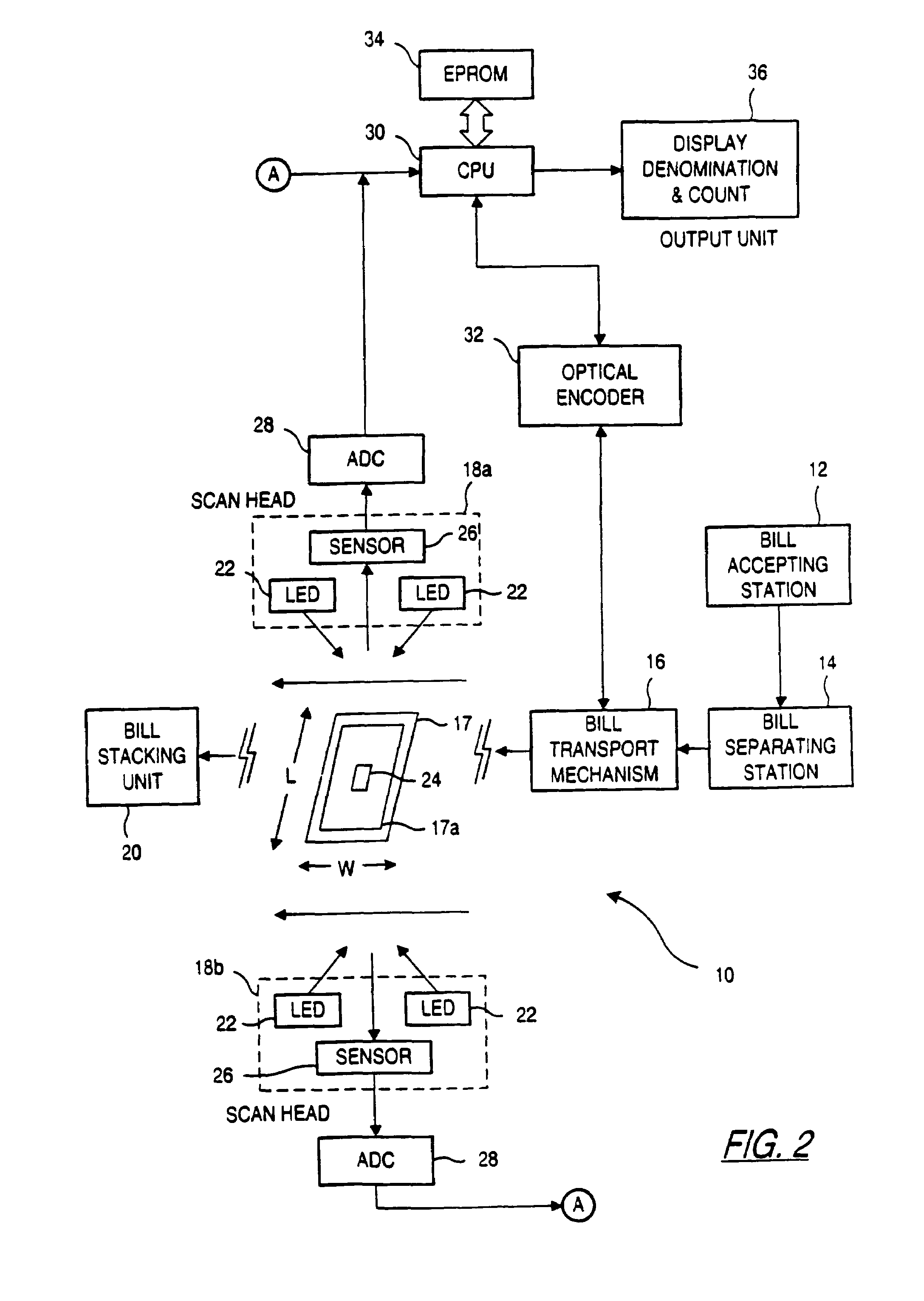

Method and apparatus for discriminating and counting documents

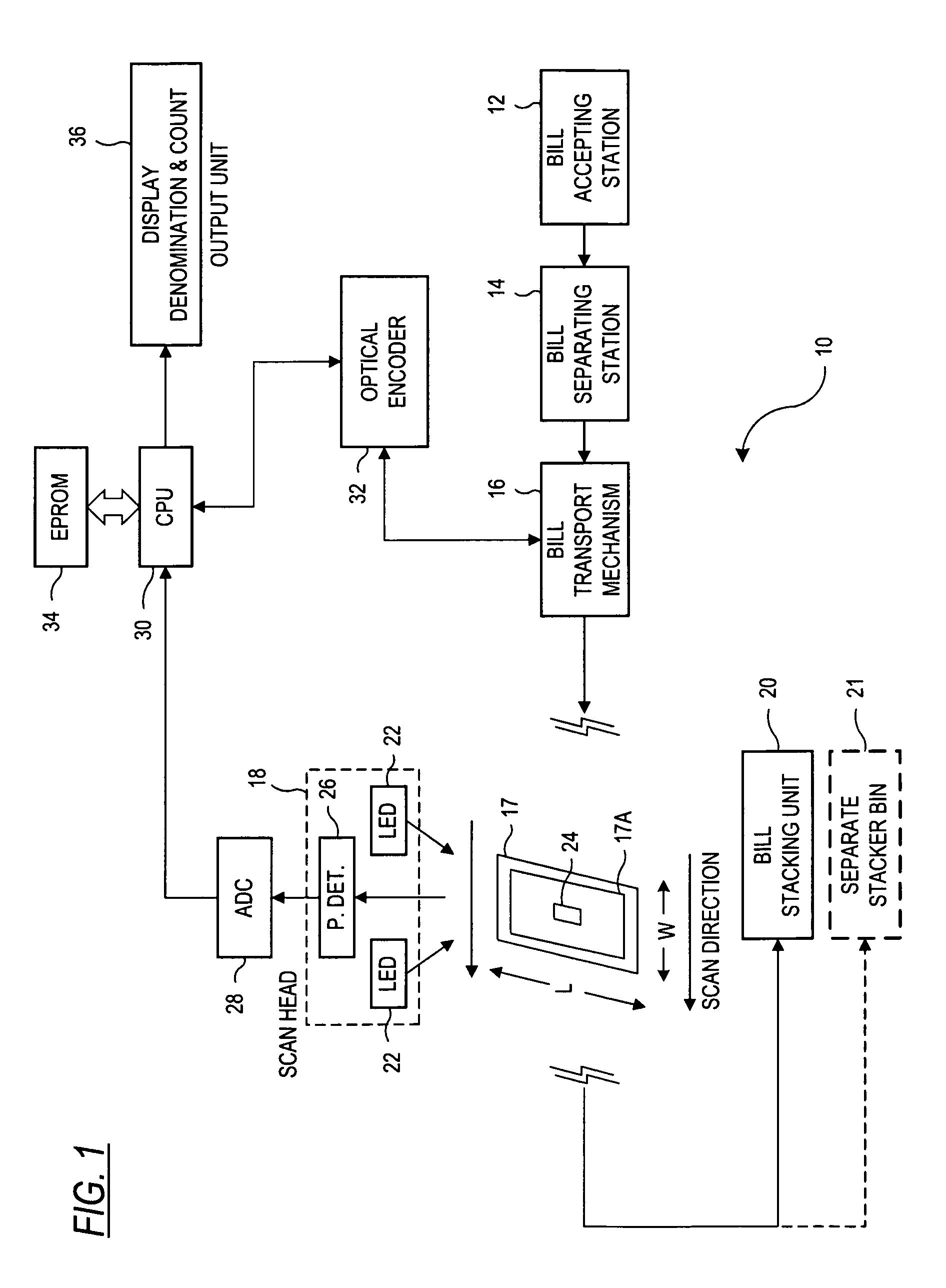

InactiveUS6980684B1Efficient countingEfficient discriminationCoin/currency accepting devicesCharacter and pattern recognitionEngineeringIdentification device

Owner:CUMMINS-ALLISON CORP

Method and apparatus for discriminating and counting documents

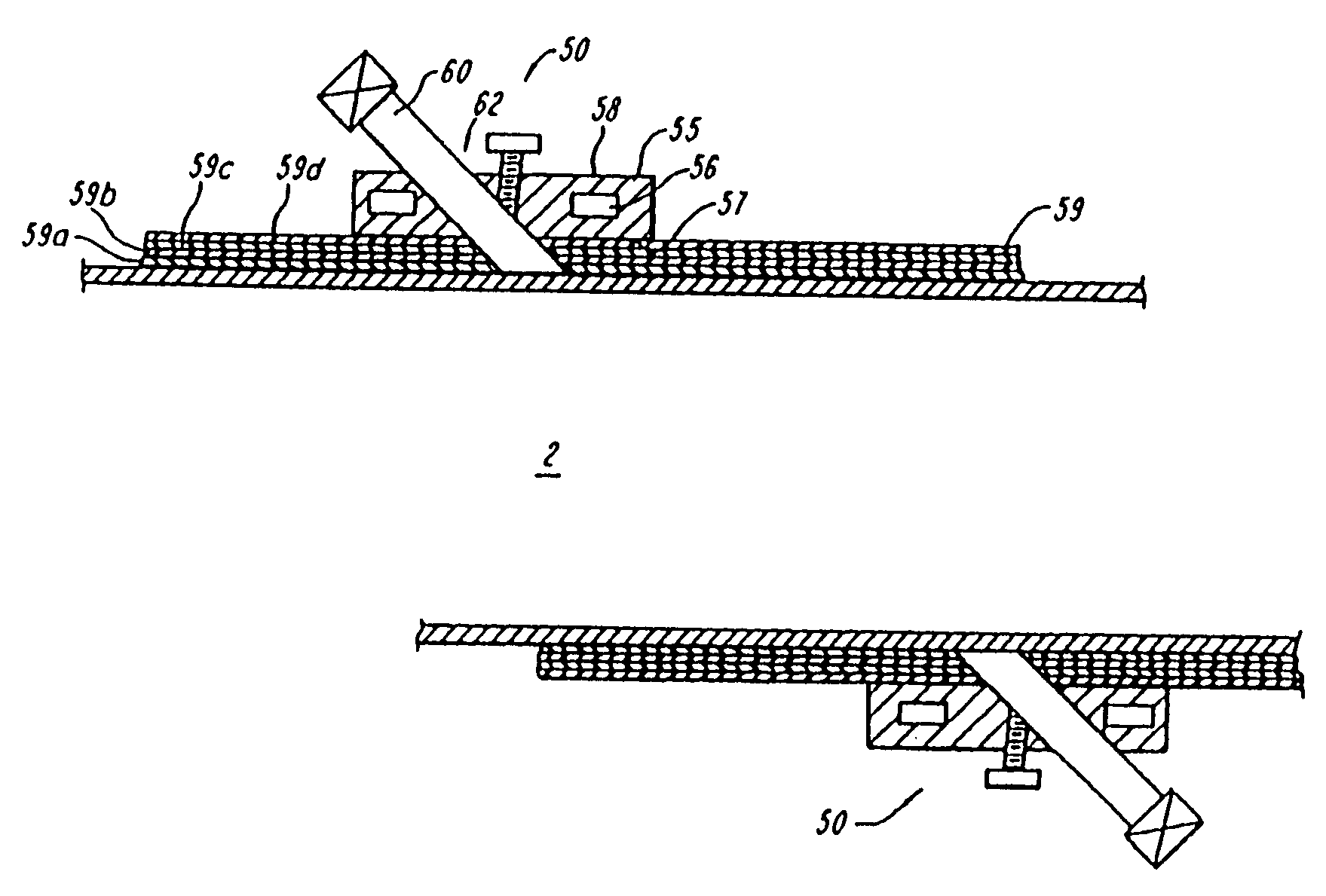

InactiveUS6915893B2Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringMechanical engineering

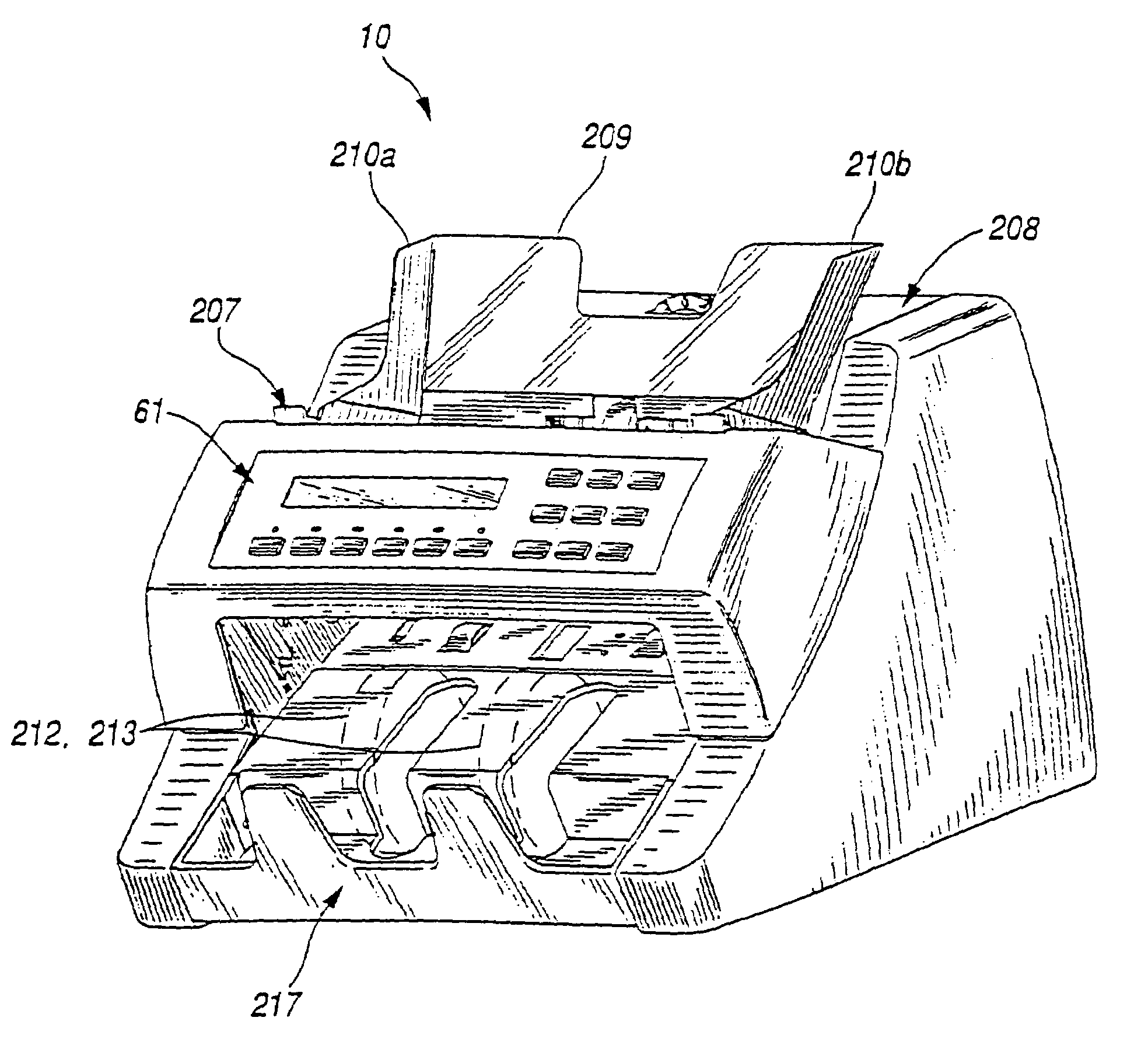

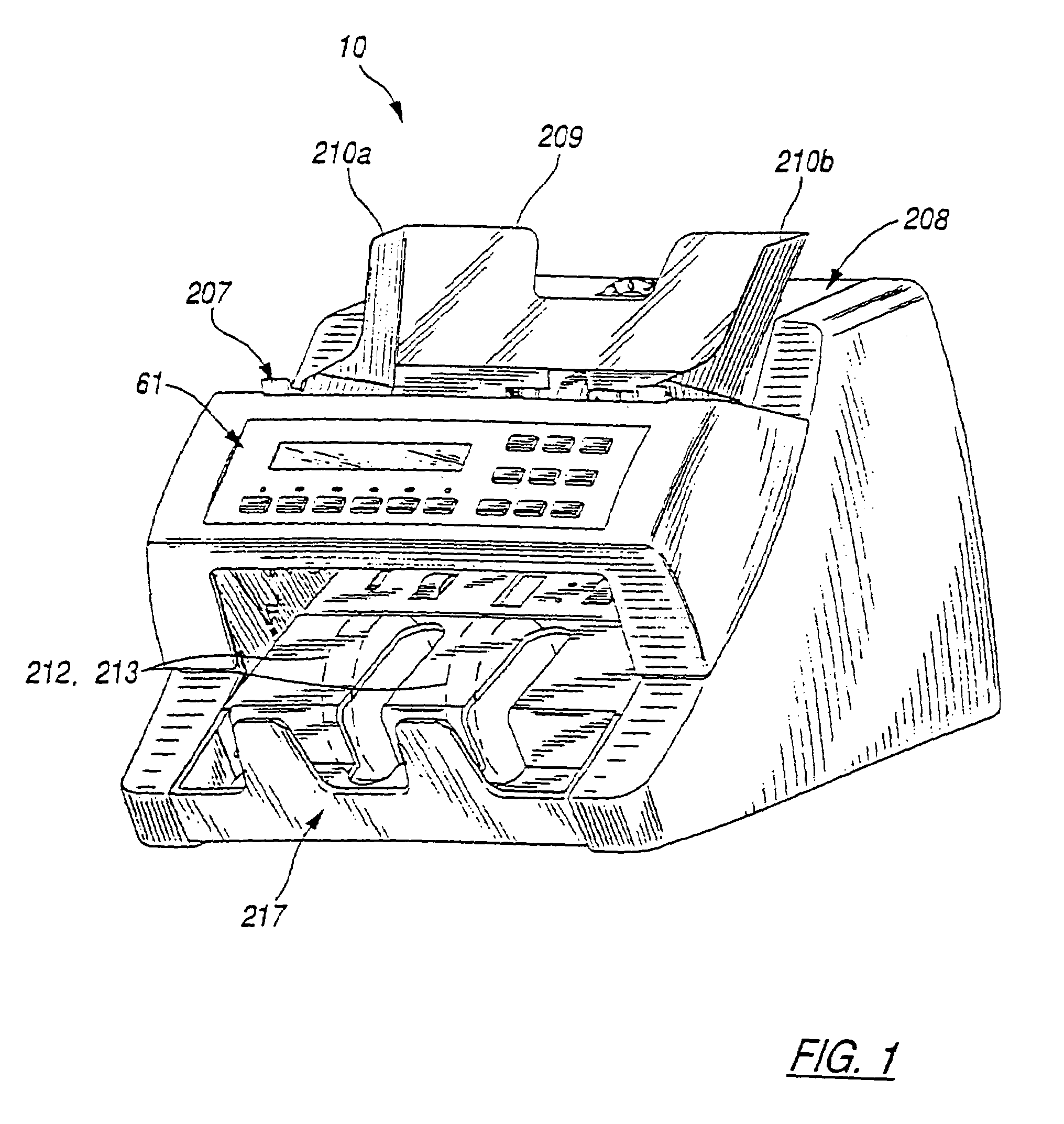

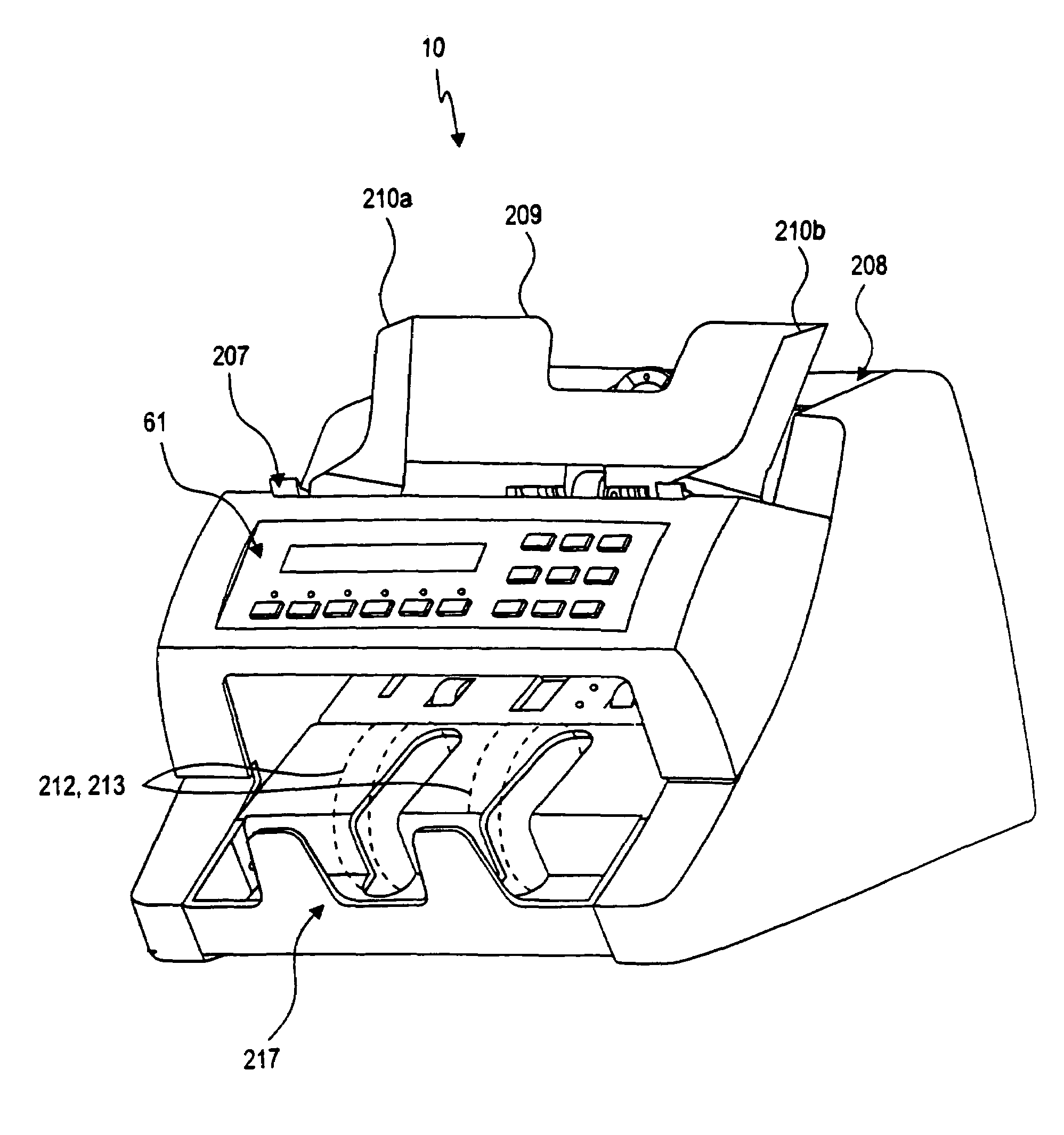

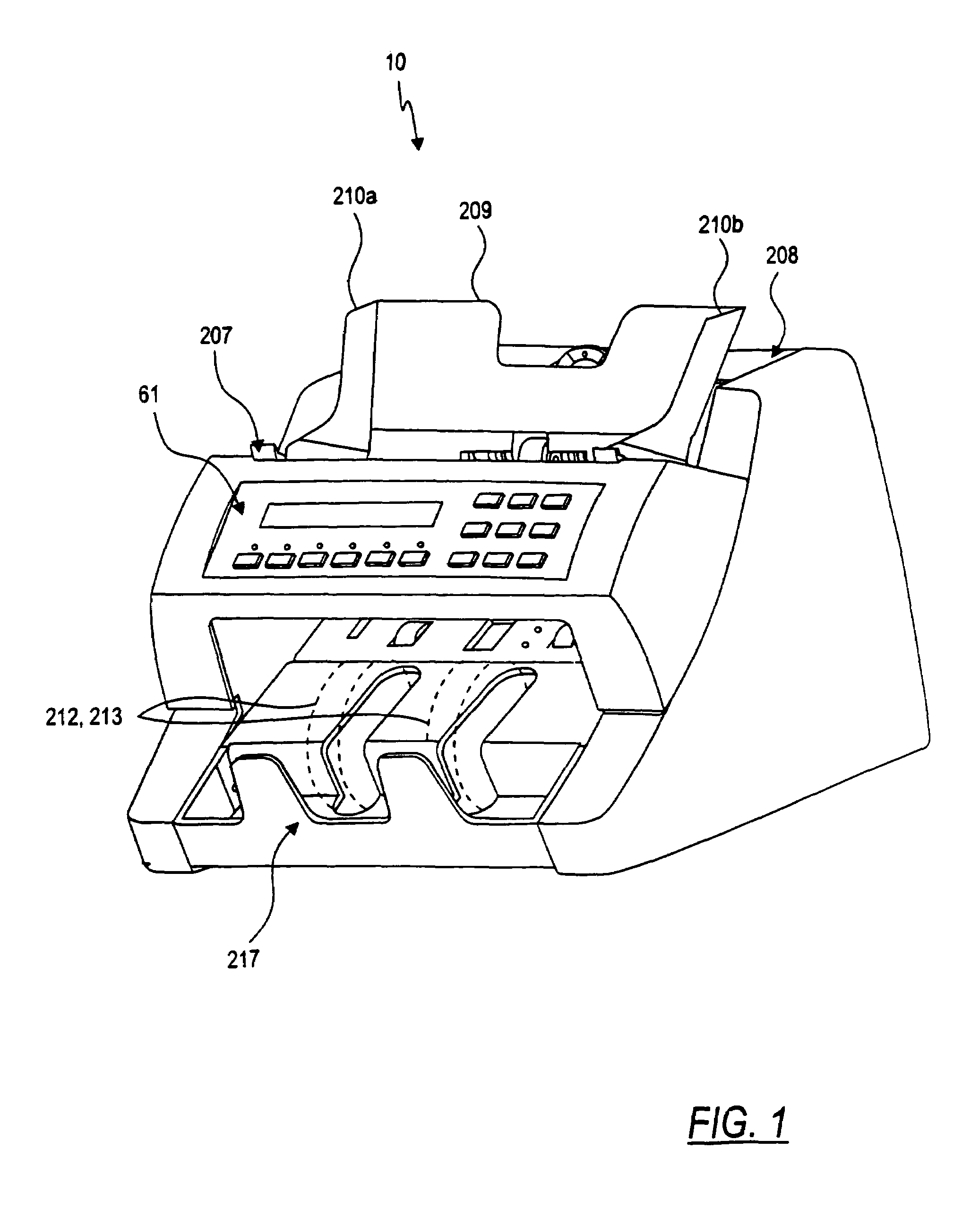

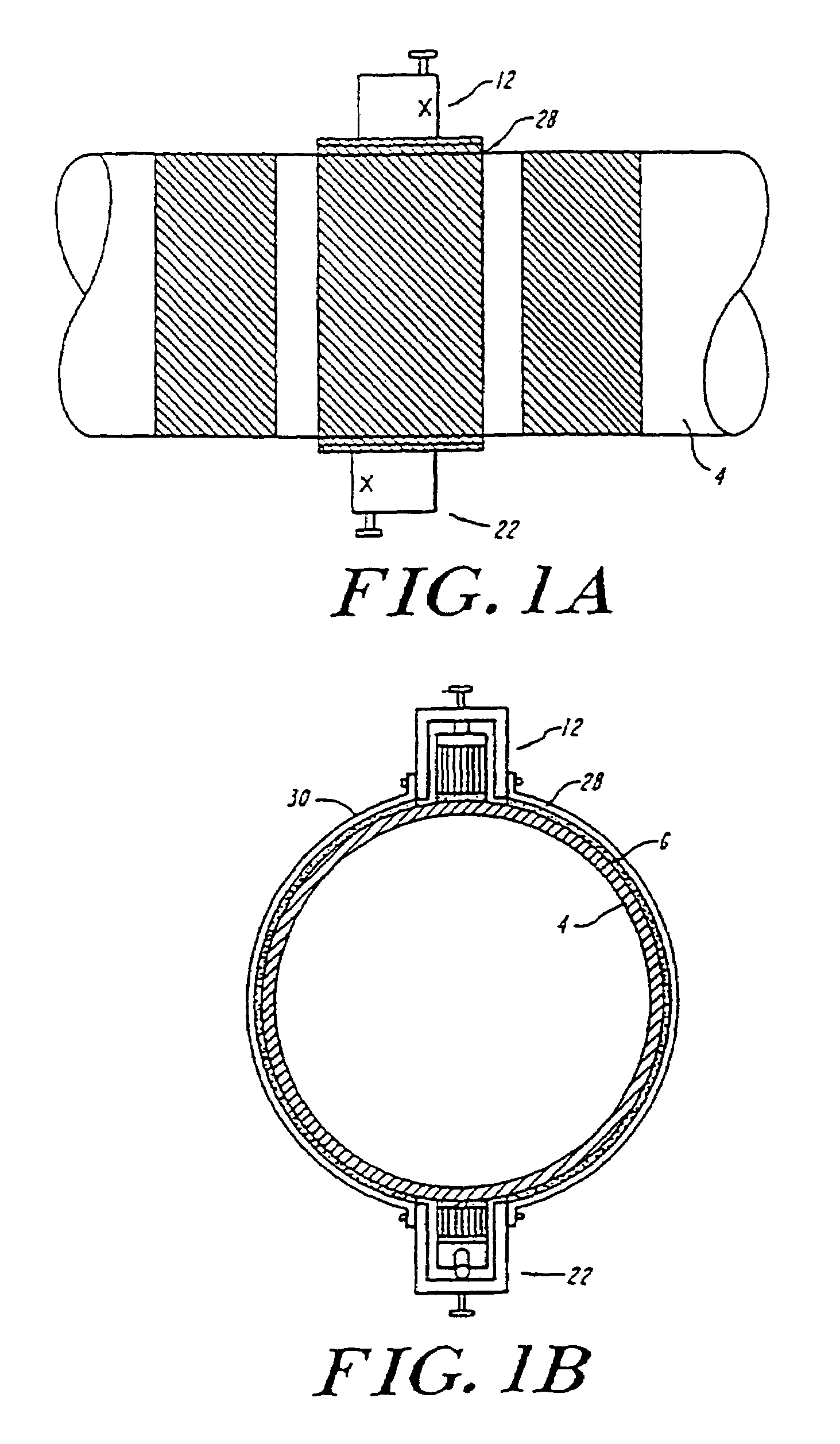

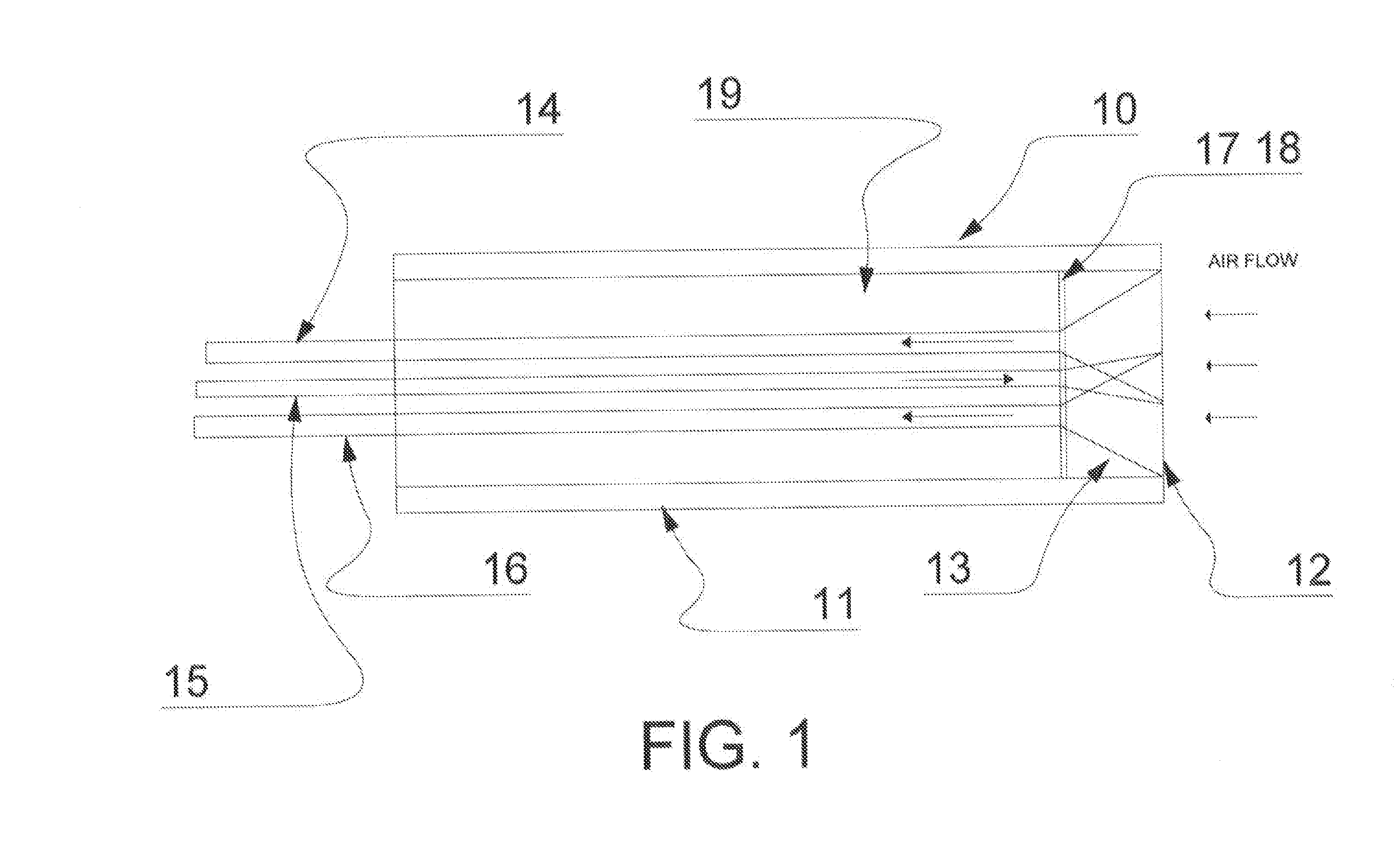

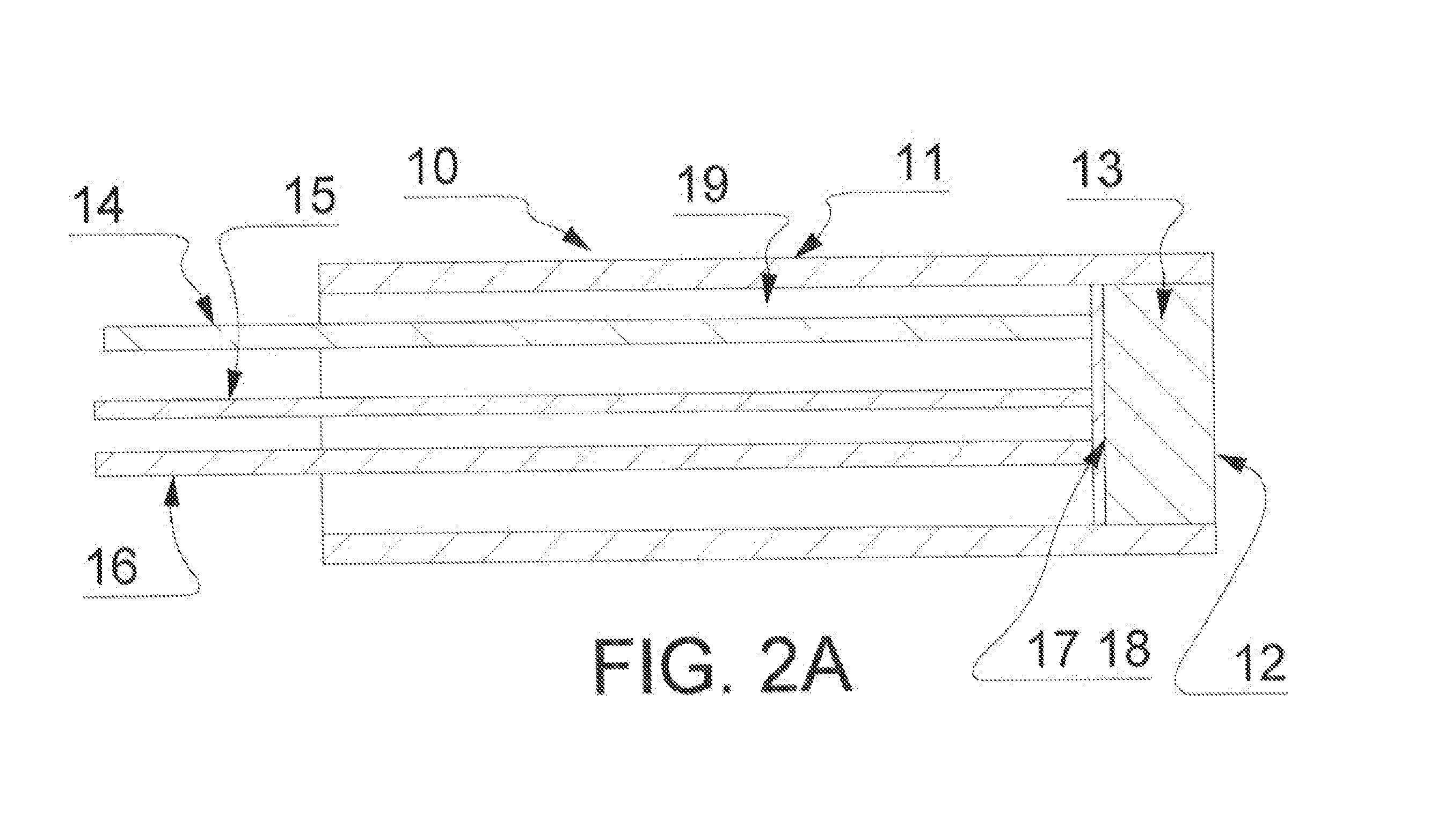

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

Method and apparatus for discriminating and counting documents

InactiveUS20050213803A1Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringPaper document

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

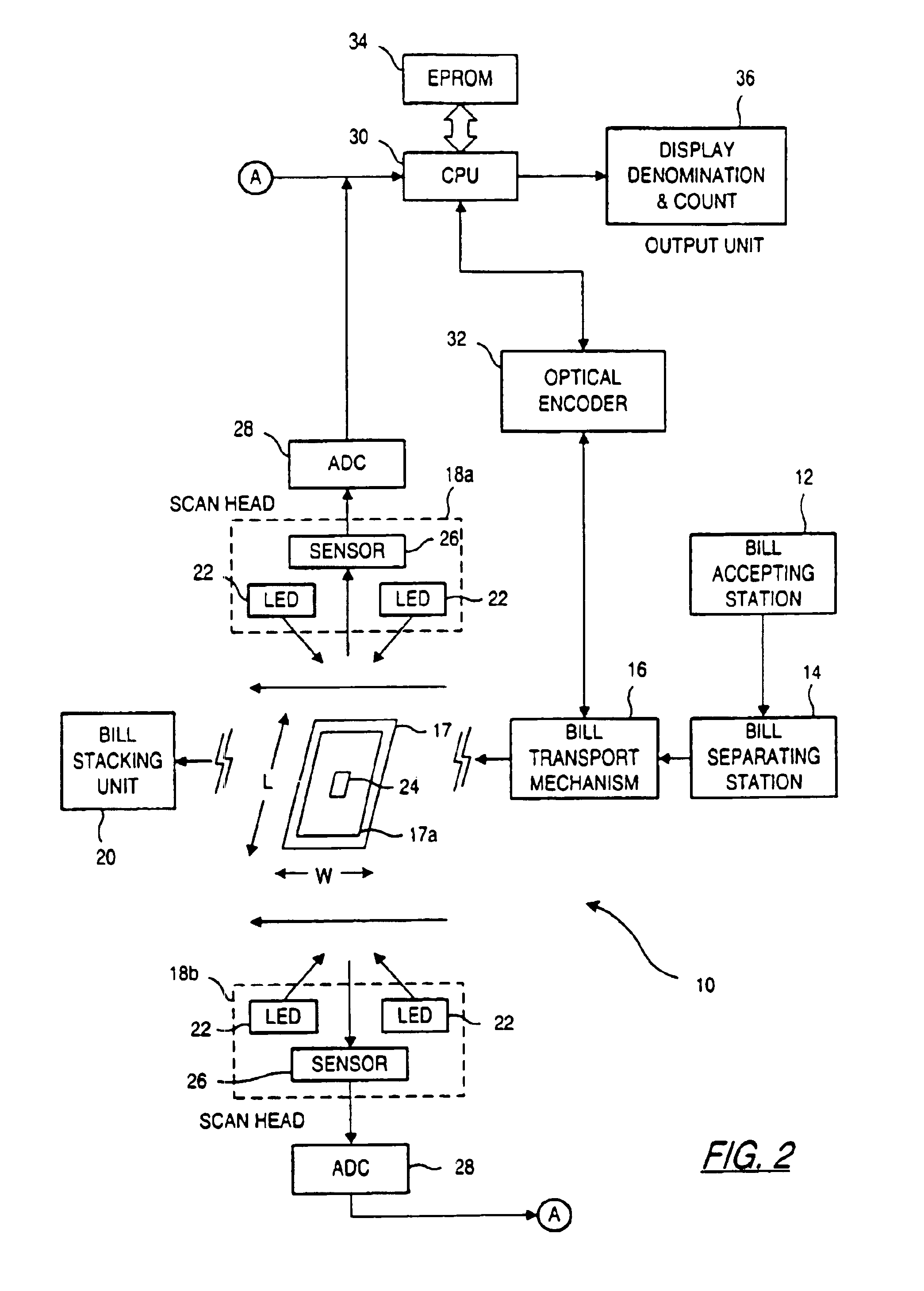

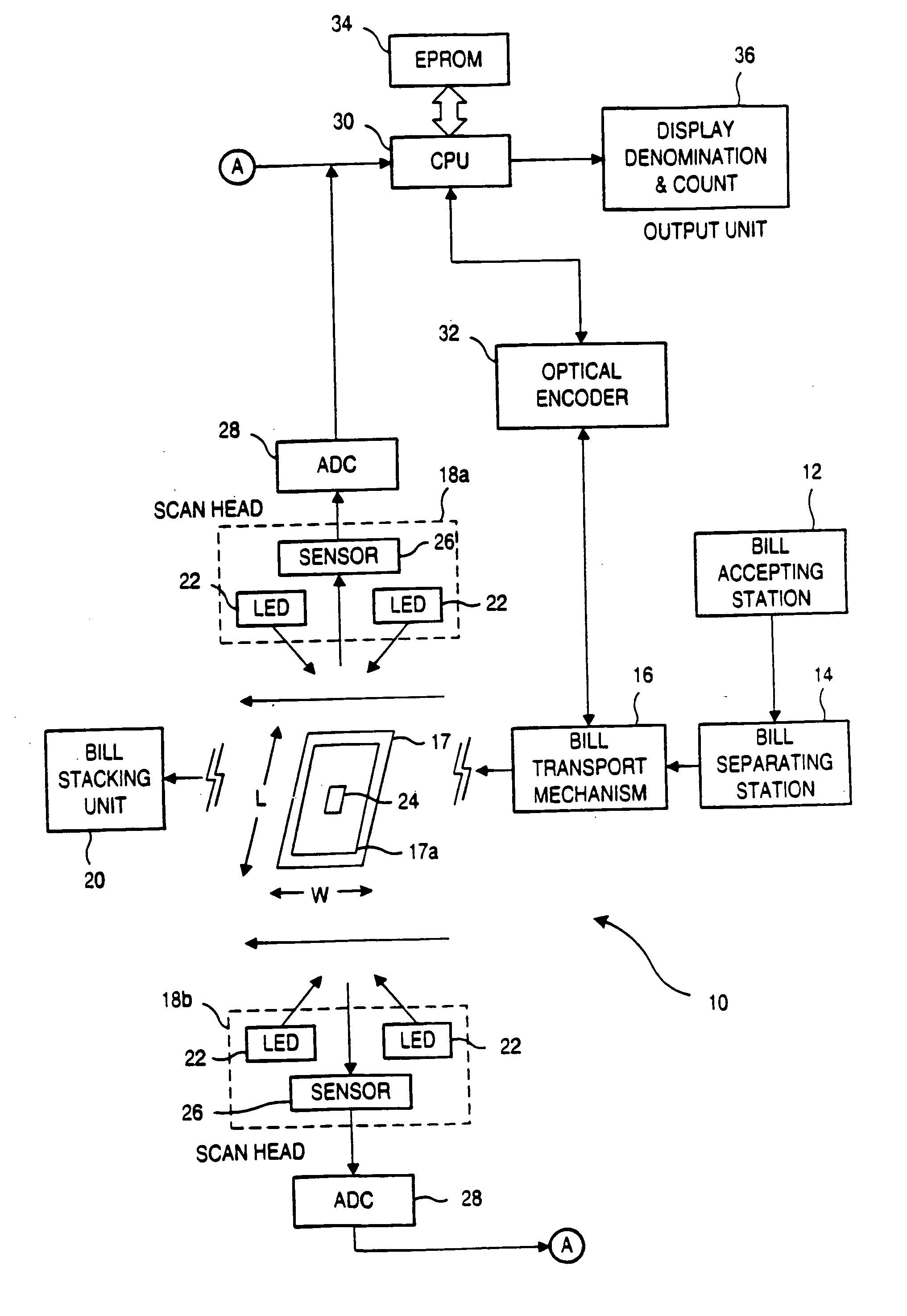

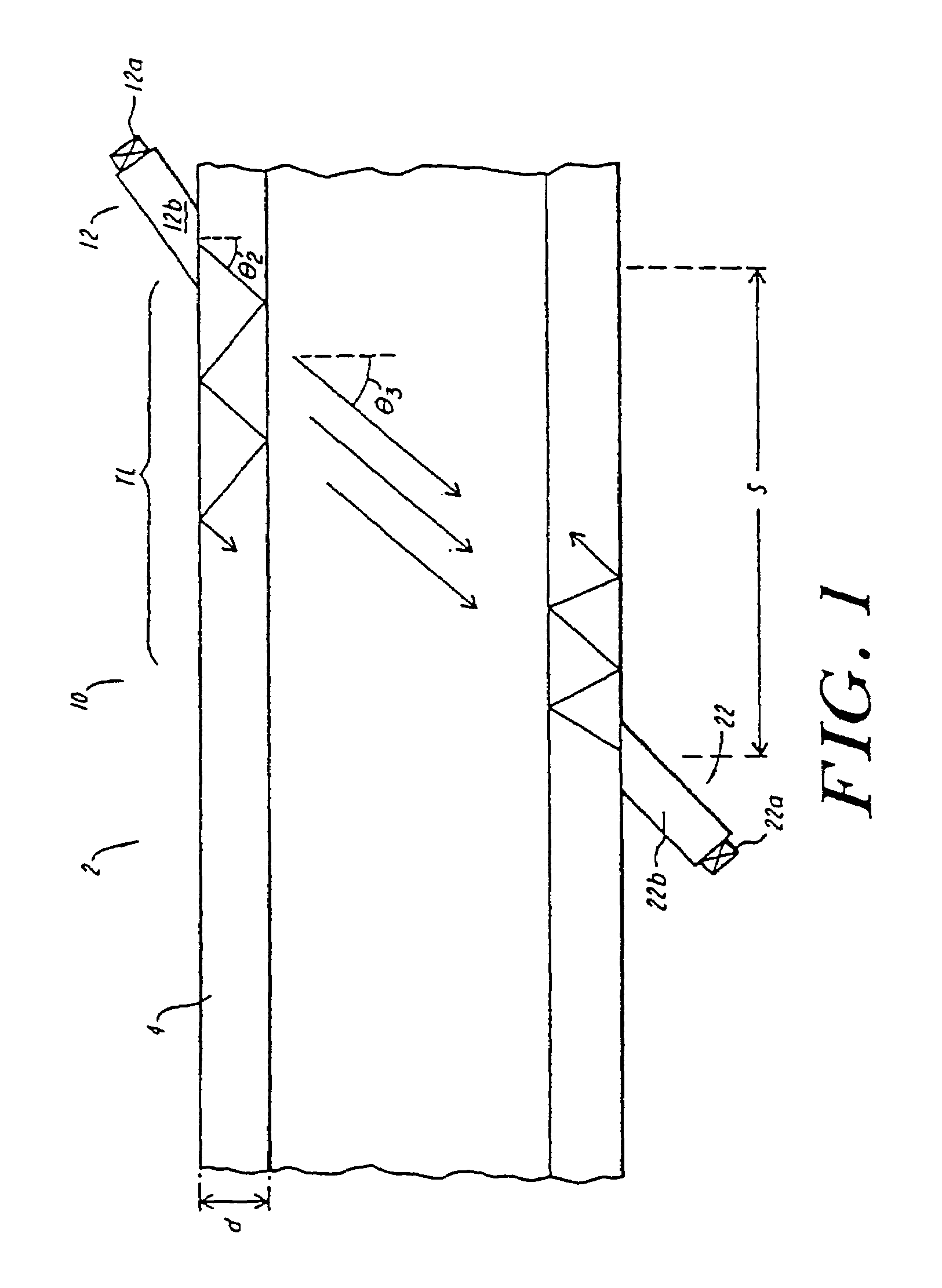

Method and apparatus for currency discrimination

InactiveUS7248731B2Efficient discriminationIncrease speedComplete banking machinesPaper-money testing devicesEngineeringImproved method

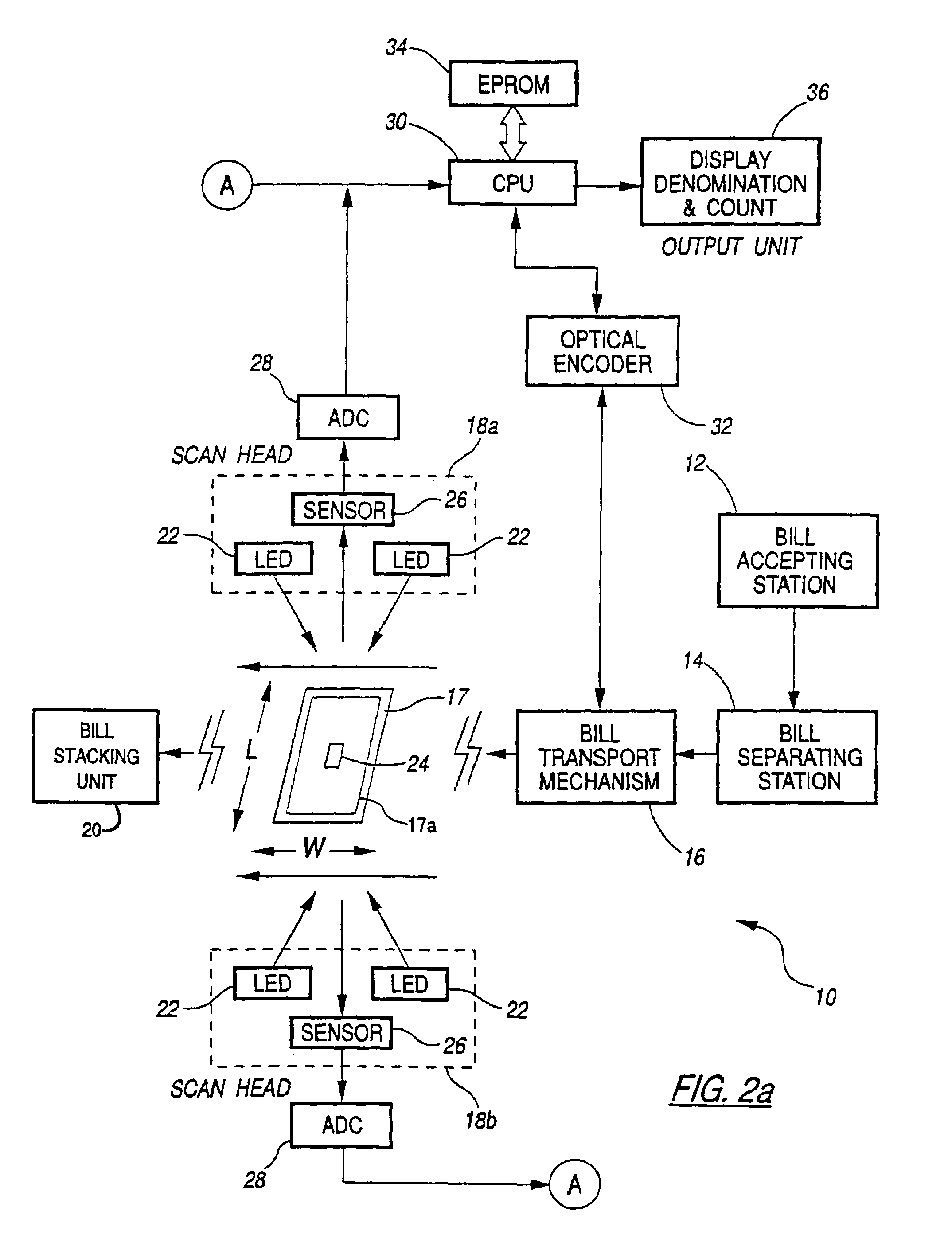

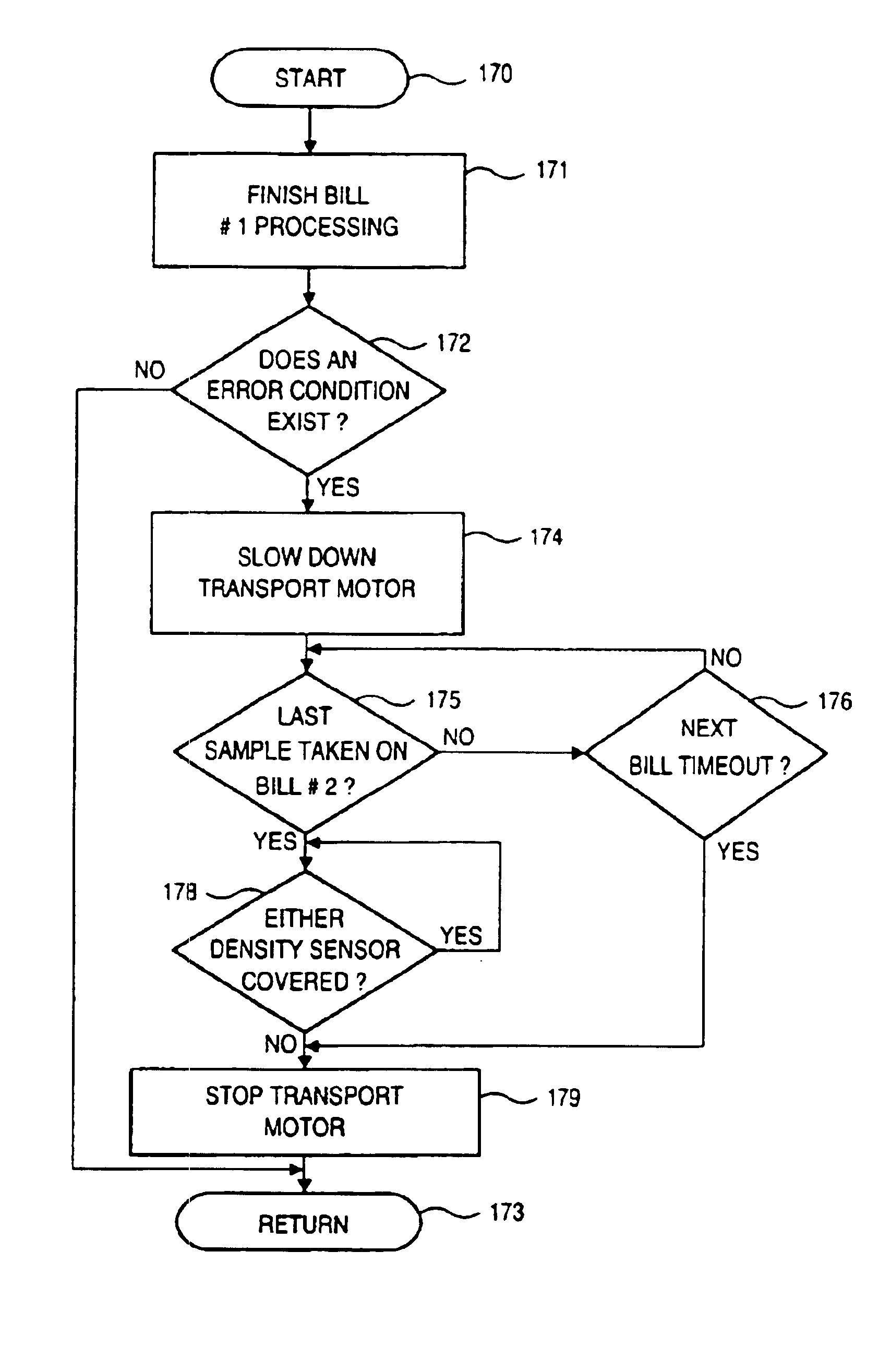

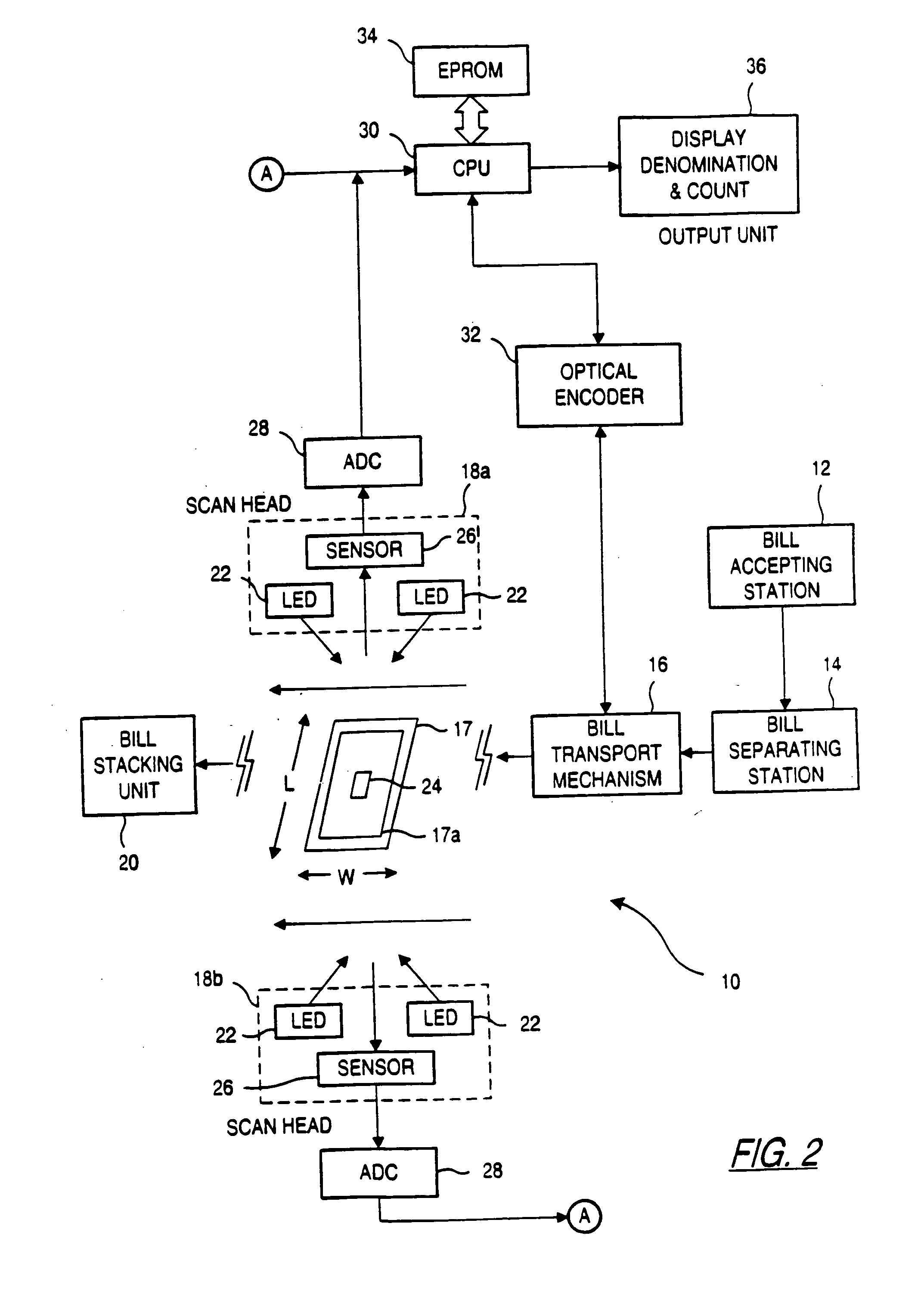

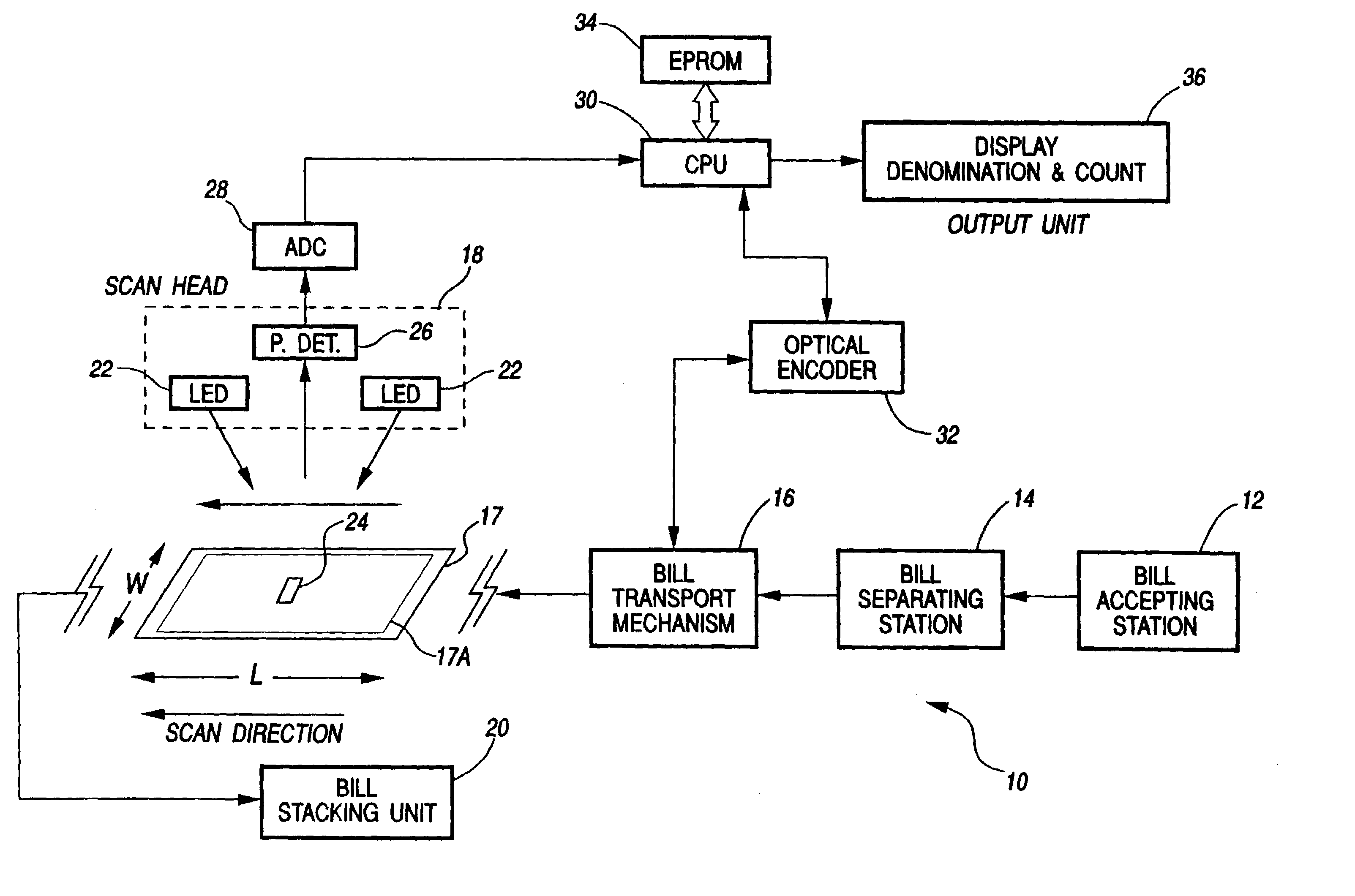

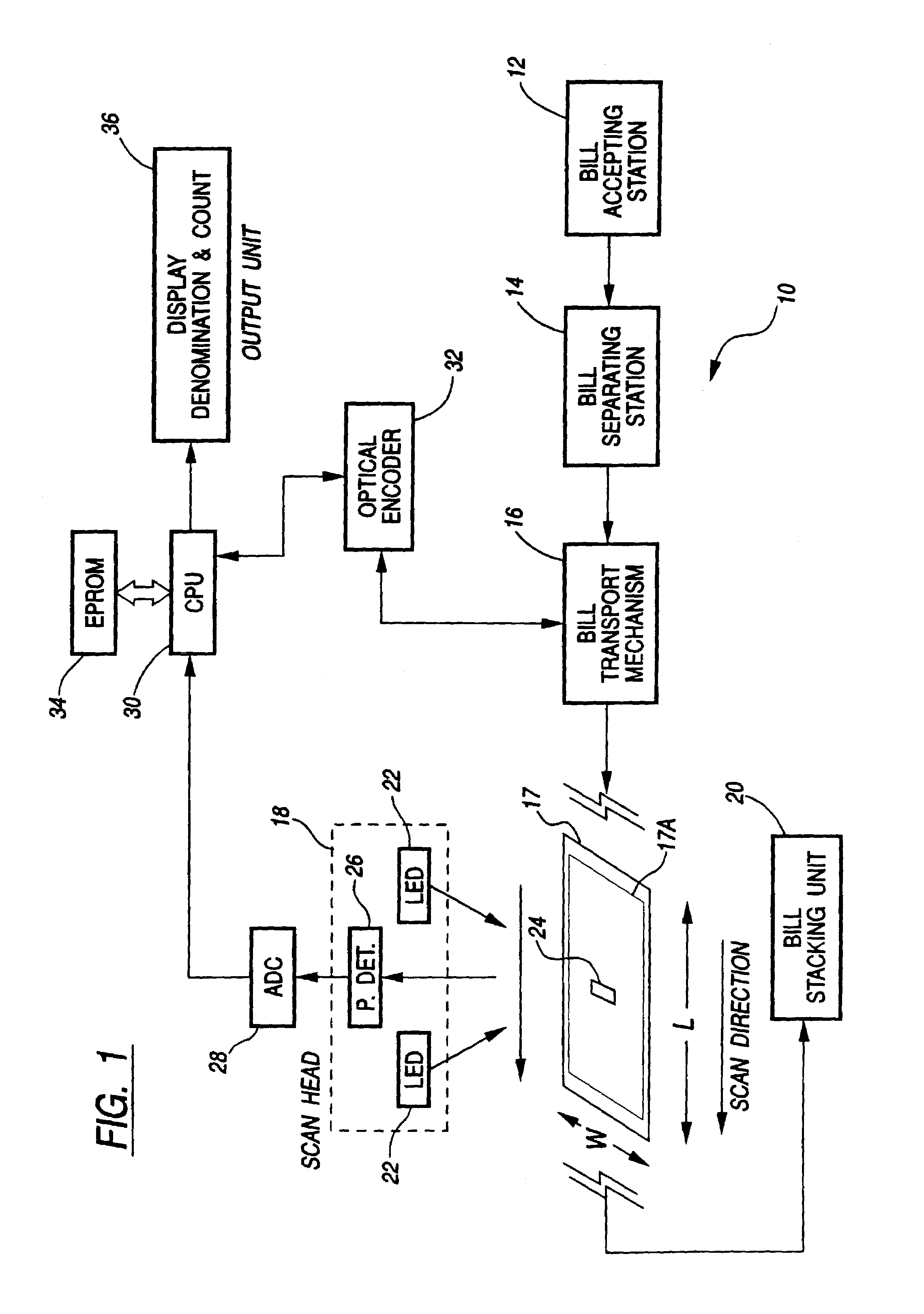

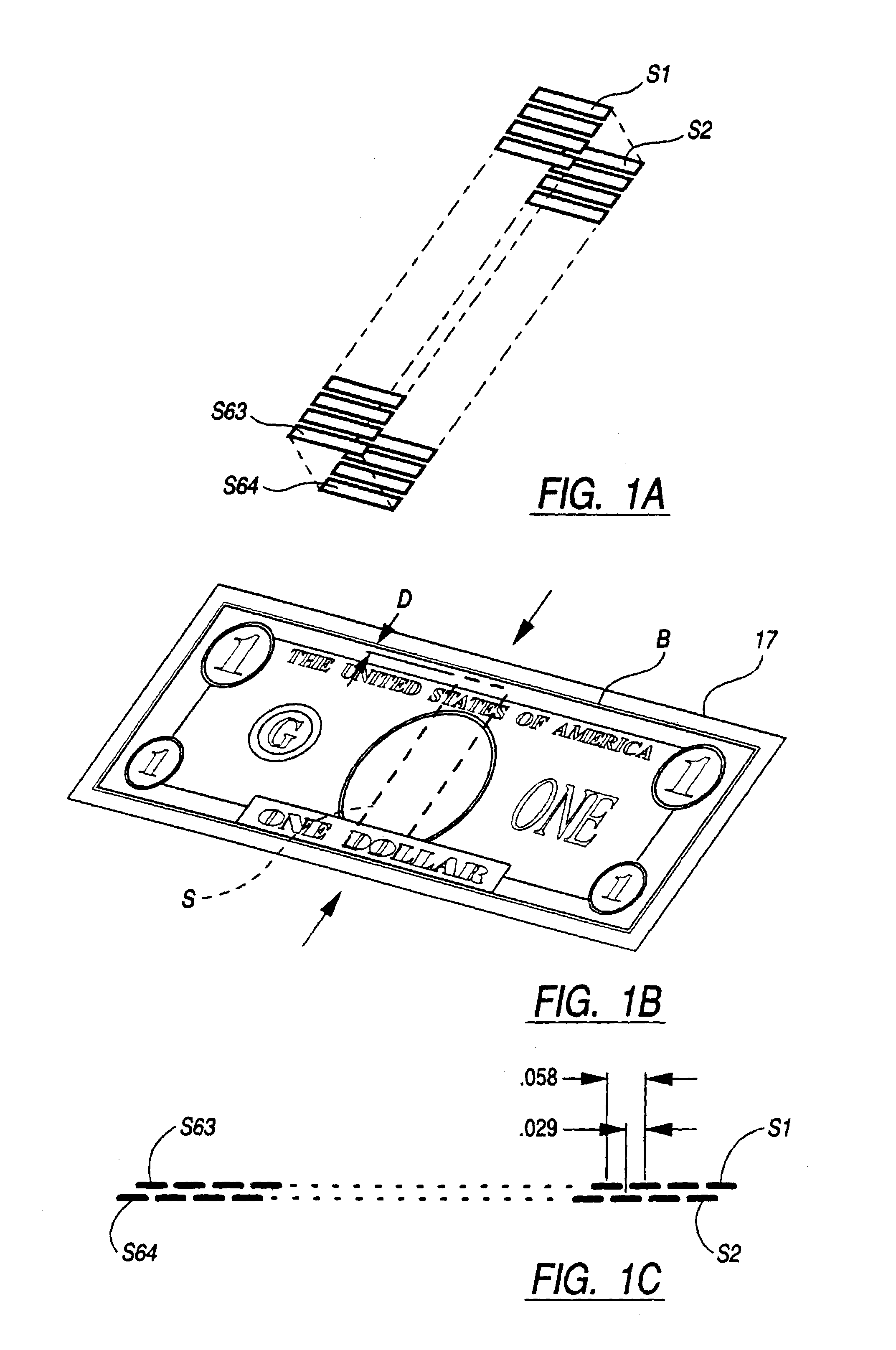

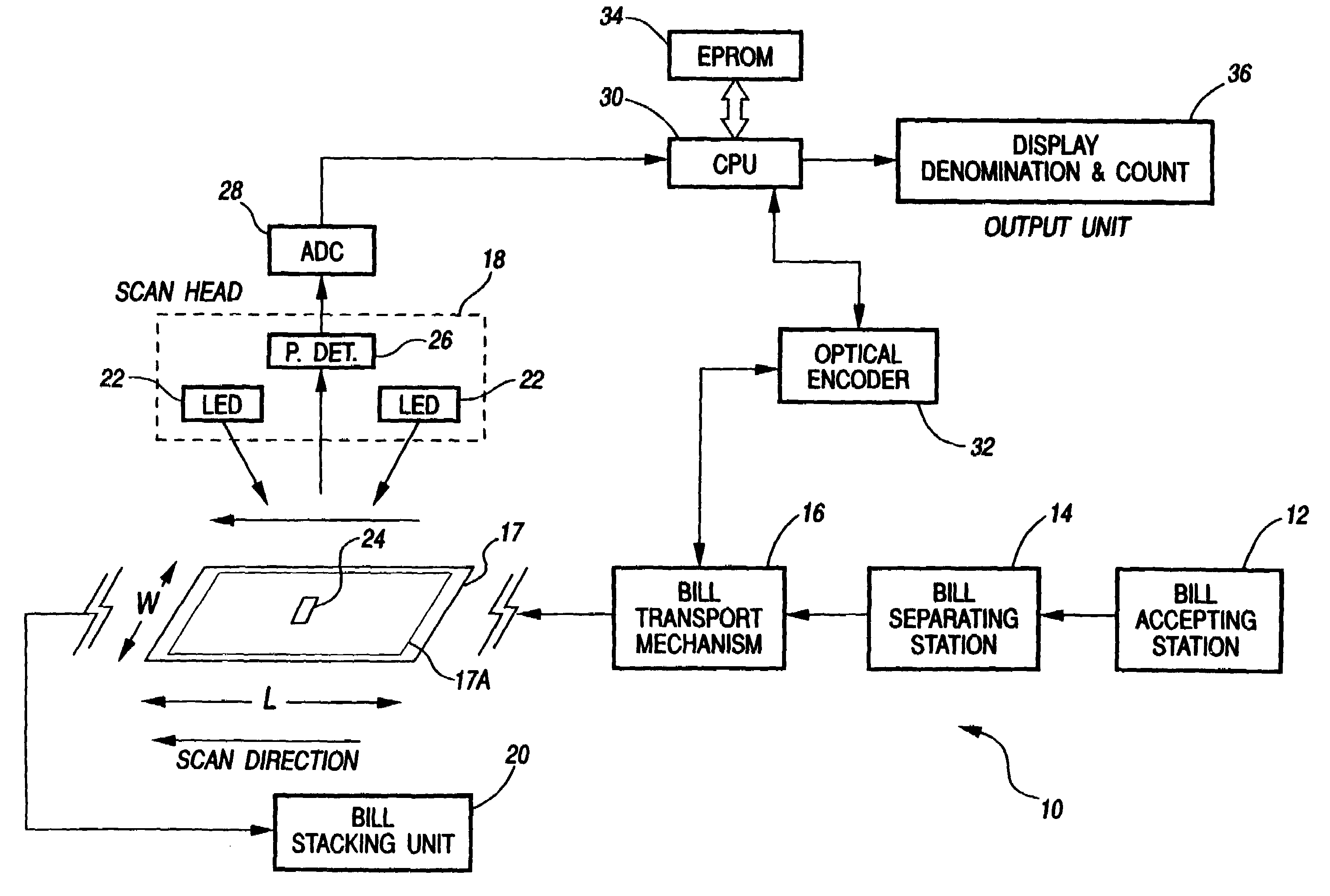

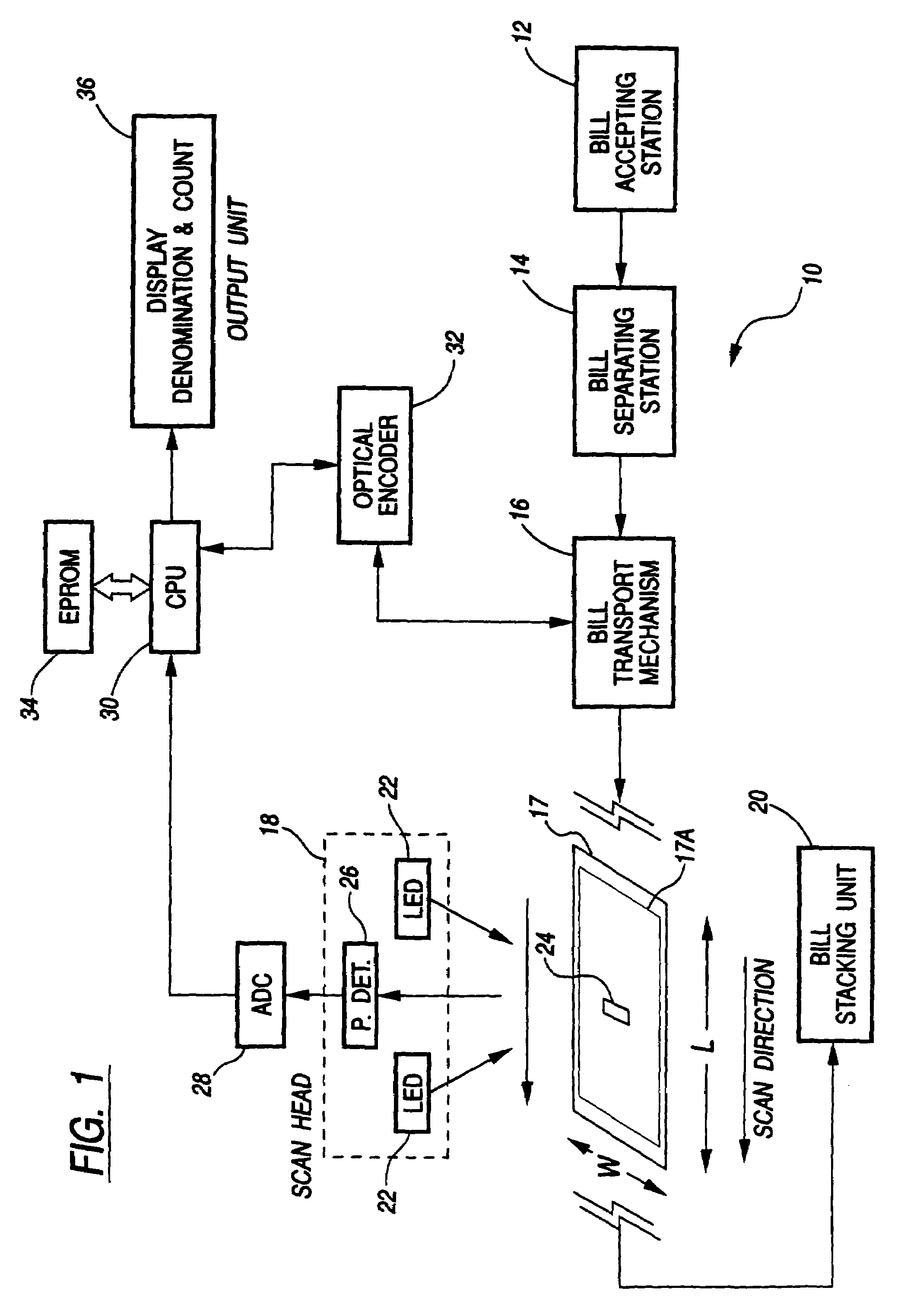

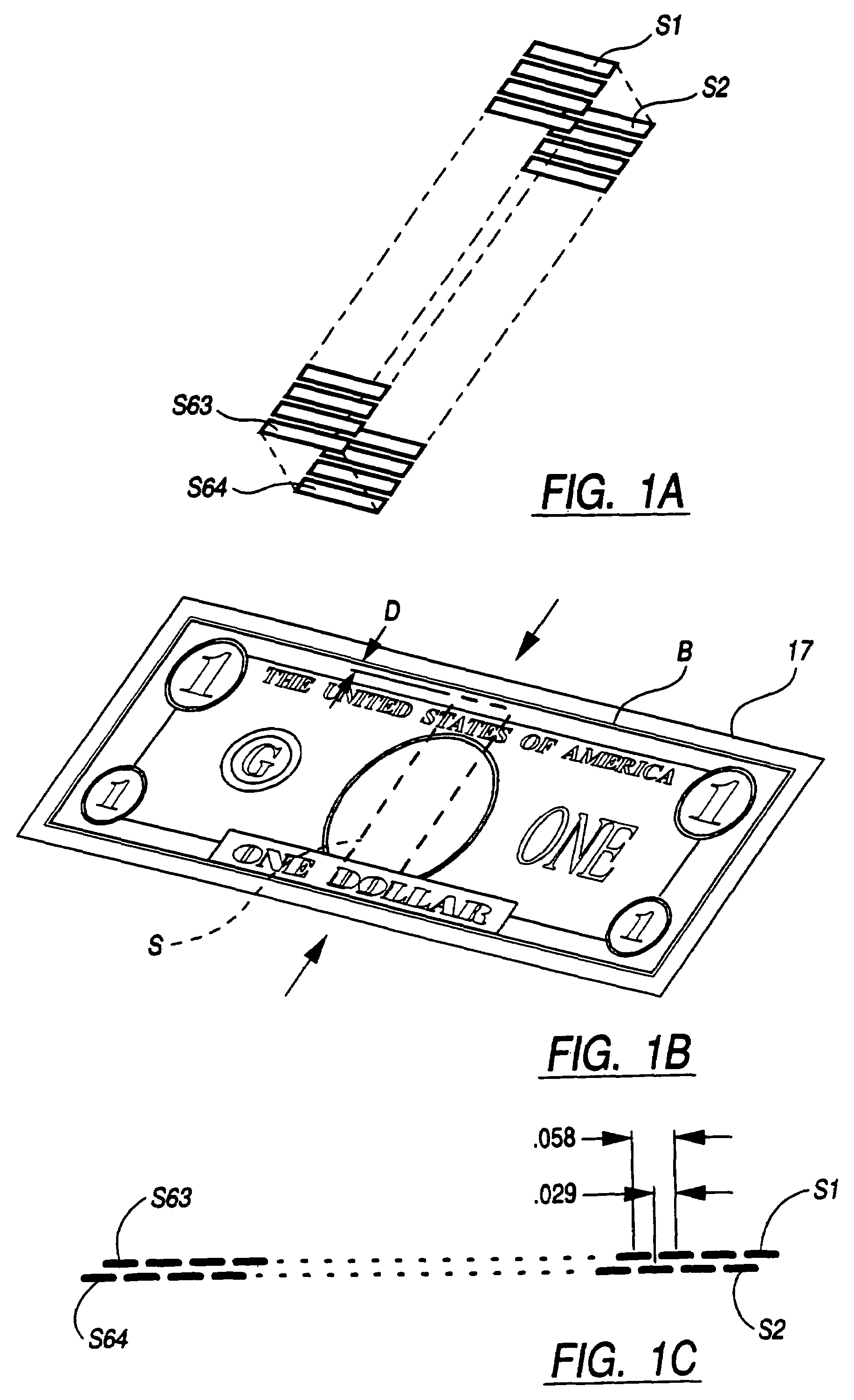

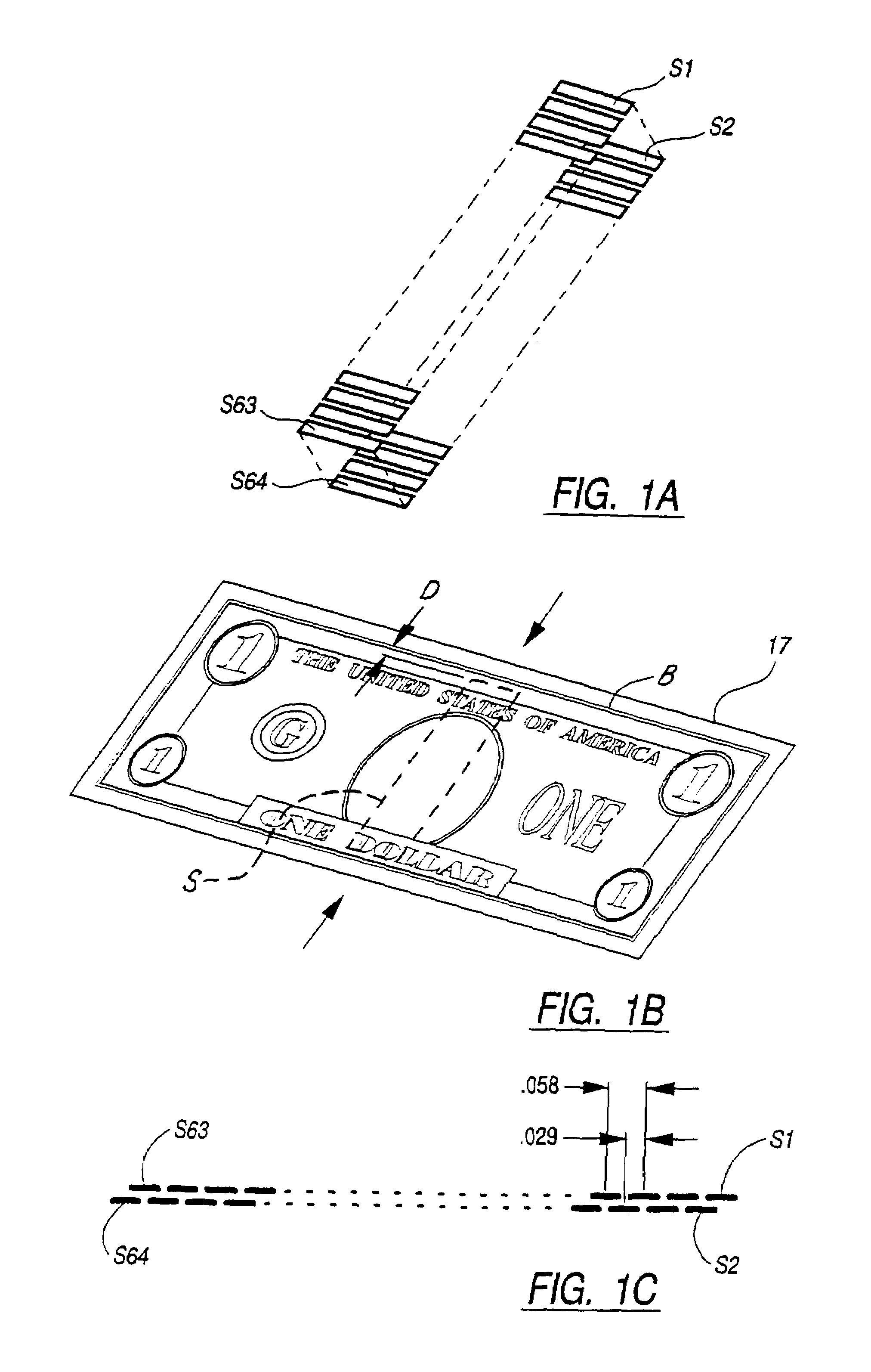

An improved method and apparatus for discriminating between currency bills of different denominations uses an optical sensing and correlation technique based on the sensing of bill reflectance characteristics obtained by illuminating and scanning a bill along one of its dimensions. A series of detected reflectance signals are obtained by sampling and digitally processing, under microprocessor control, the reflected light at a plurality of predefined sample points as a currency bill is moved across an illuminated strip with a preselected dimension parallel to the direction of transport of the bill. The sample data is subjected to digital processing, including a normalizing process, whereby the reflectance data represents a characteristic pattern that is unique for a given bill denomination and incorporates sufficient distinguishing features between characteristic patterns for discriminating between different currency denominations. A plurality of master characteristic patterns are generated and stored using original bills for each denomination of currency to be detected. The pattern generated by scanning a bill under test and processing the data samples is compared with each of the prestored master patterns to generate, for each comparison, a correlation number representing the extent of similarity between corresponding ones of the plurality of data samples for the compared patterns. Denomination identification is based on designating the scanned bill as belonging to the denomination corresponding to the stored master pattern for which the correlation number resulting from pattern comparison is determined to be the highest, subject to a bi-level threshold of correlation.

Owner:CUMMINS-ALLISON CORP

Method and apparatus for currency discrimination

InactiveUS7590274B2Efficient discriminationIncrease speedComplete banking machinesPaper-money testing devicesSingle sampleAlgorithm

An improved method and apparatus for discriminating between currency bills of different denominations uses an optical sensing and correlation technique based on the sensing of bill reflectance characteristics obtained by illuminating and scanning a bill along one of its dimensions. A series of detected reflectance signals are obtained by sampling and digitally processing, under microprocessor control, the reflected light at a plurality of predefined sample points as a currency bill is moved across an illuminated strip with a preselected dimension parallel to the direction of transport of the bill. The sample data is subjected to digital processing, including a normalizing process, whereby the reflectance data represents a characteristic pattern that is unique for a given bill denomination and incorporates sufficient distinguishing features between characteristic patterns for discriminating between different currency denominations. A plurality of master characteristic patterns are generated and stored using original bills for each denomination of currency to be detected. The pattern generated by scanning a bill under test and processing the data samples is compared with each of the prestored master patterns to generate, for each comparison, a correlation number representing the extent of similarity between corresponding ones of the plurality of data samples for the compared patterns. Denomination identification is based on designating the scanned bill as belonging to the denomination corresponding to the stored master pattern for which the correlation number resulting from pattern comparison is determined to be the highest, subject to a bi-level threshold of correlation.

Owner:CUMMINS-ALLISON CORP

Method and apparatus for currency discrimination and counting

InactiveUS7536046B2Efficient countingEfficient discriminationComplete banking machinesImage analysisStackerBank note

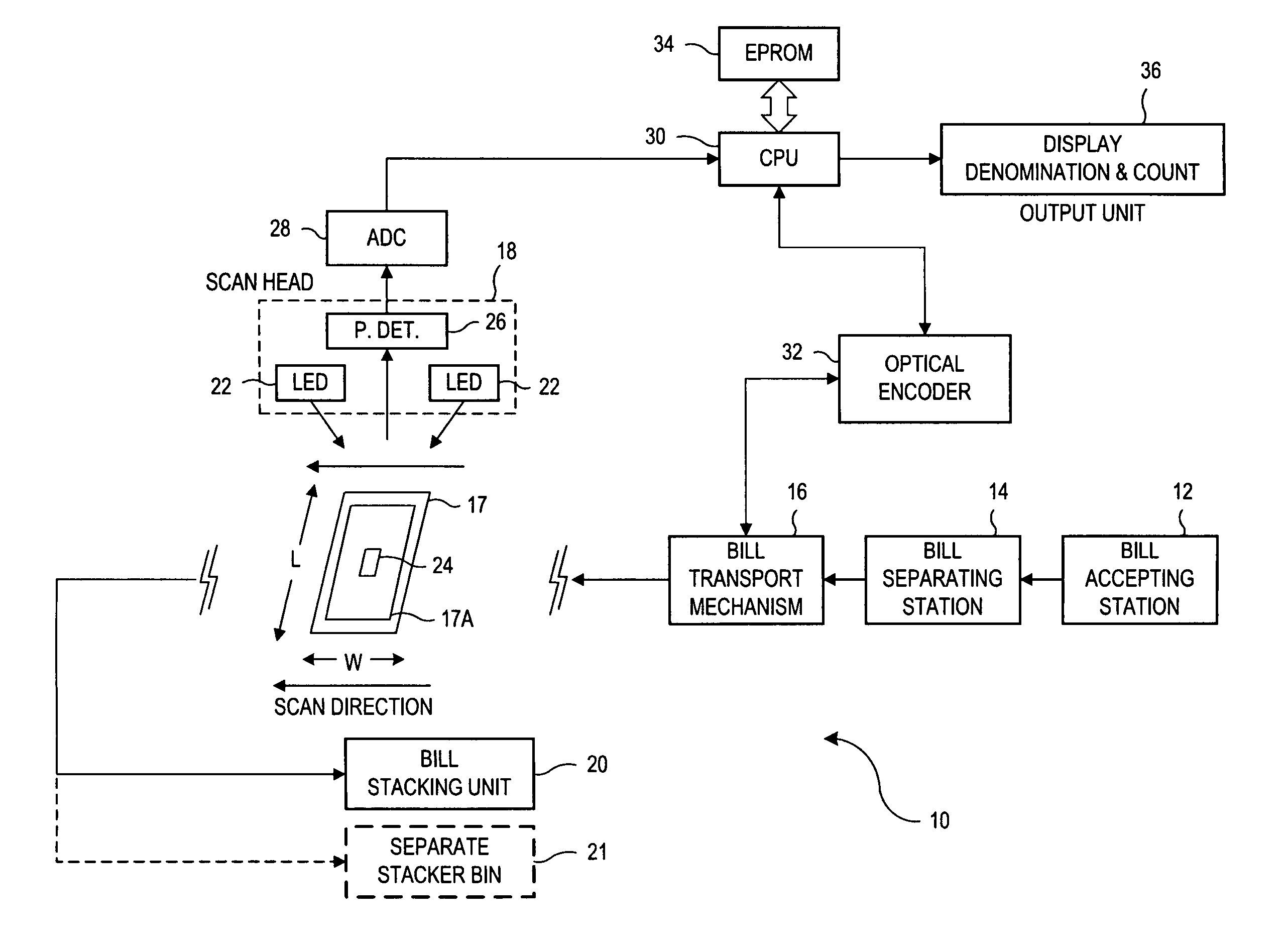

A currency evaluation device for receiving a stack of U.S. currency bills and rapidly evaluating all the bills in the stack comprises an input receptacle adapted to receive a stack of U.S. currency bills of a plurality of denominations to be evaluated. According to one embodiment, a transport mechanism transports the bills, one at a time, from the input receptacle along a transport path at a rate of at least about 800 bills per minute. A denomination discriminating unit which includes a detector positioned along the transport path evaluates the bills. The device comprises a single denominated bill output receptacle positioned to receive bills whose denomination have been determined by the discriminating unit including bills of a plurality of denominations. A separate stacker bin is provided and a diverter positioned along the transport path routes bills whose denomination cannot be determined to the separate stacker bin.

Owner:CUMMINS-ALLISON CORP

Method and apparatus for discriminating and counting documents

InactiveUS7817842B2Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringDocumentation

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

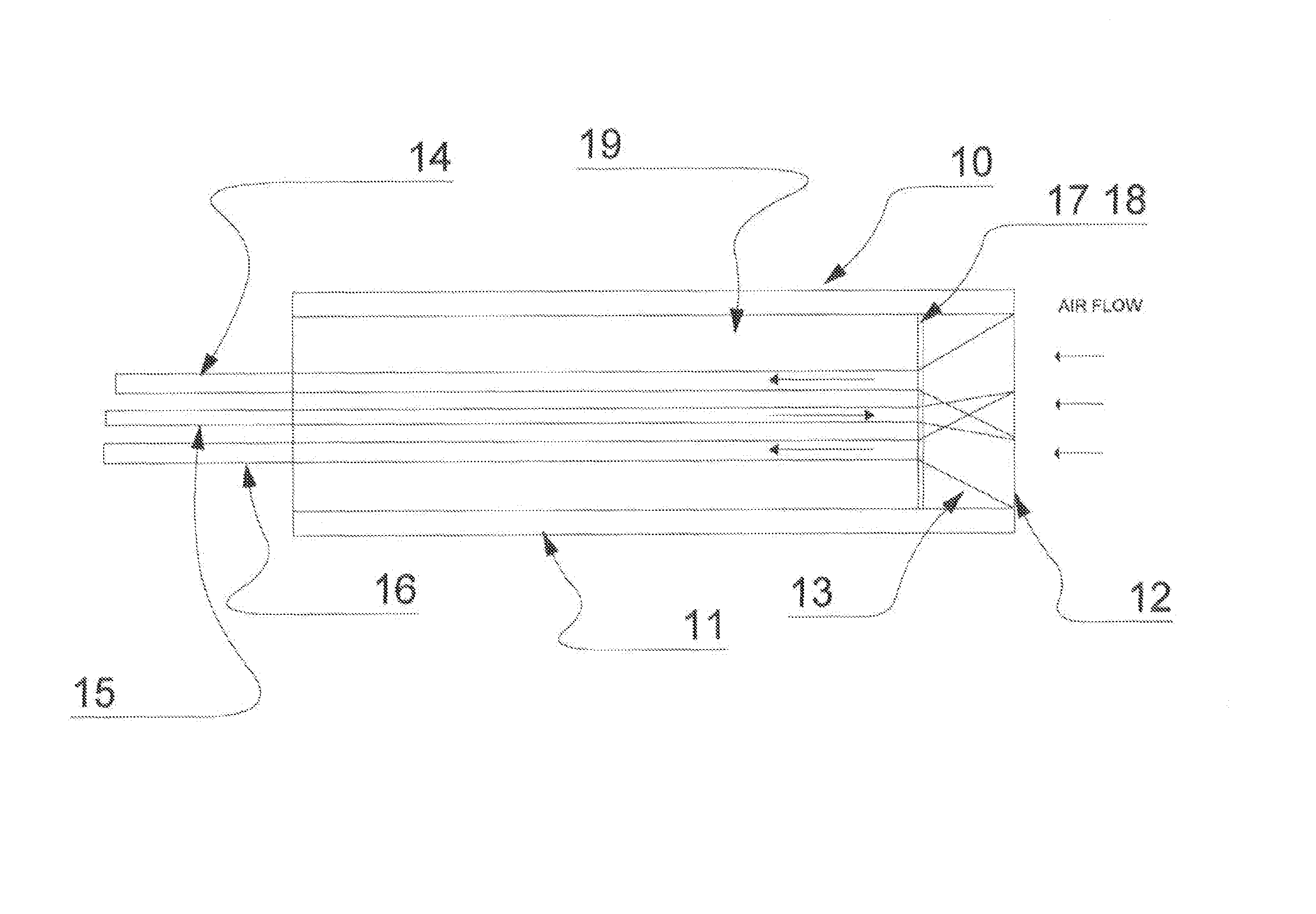

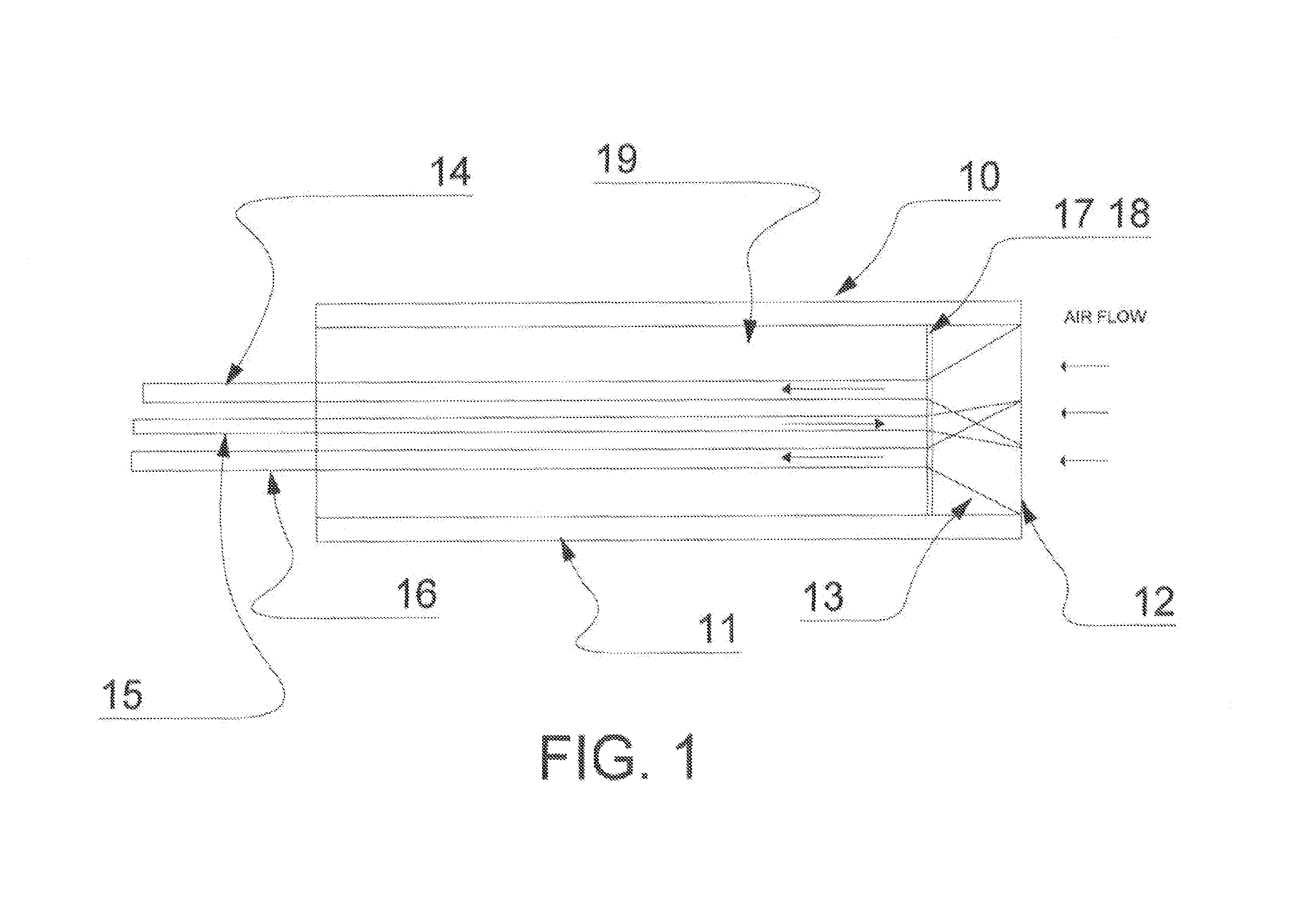

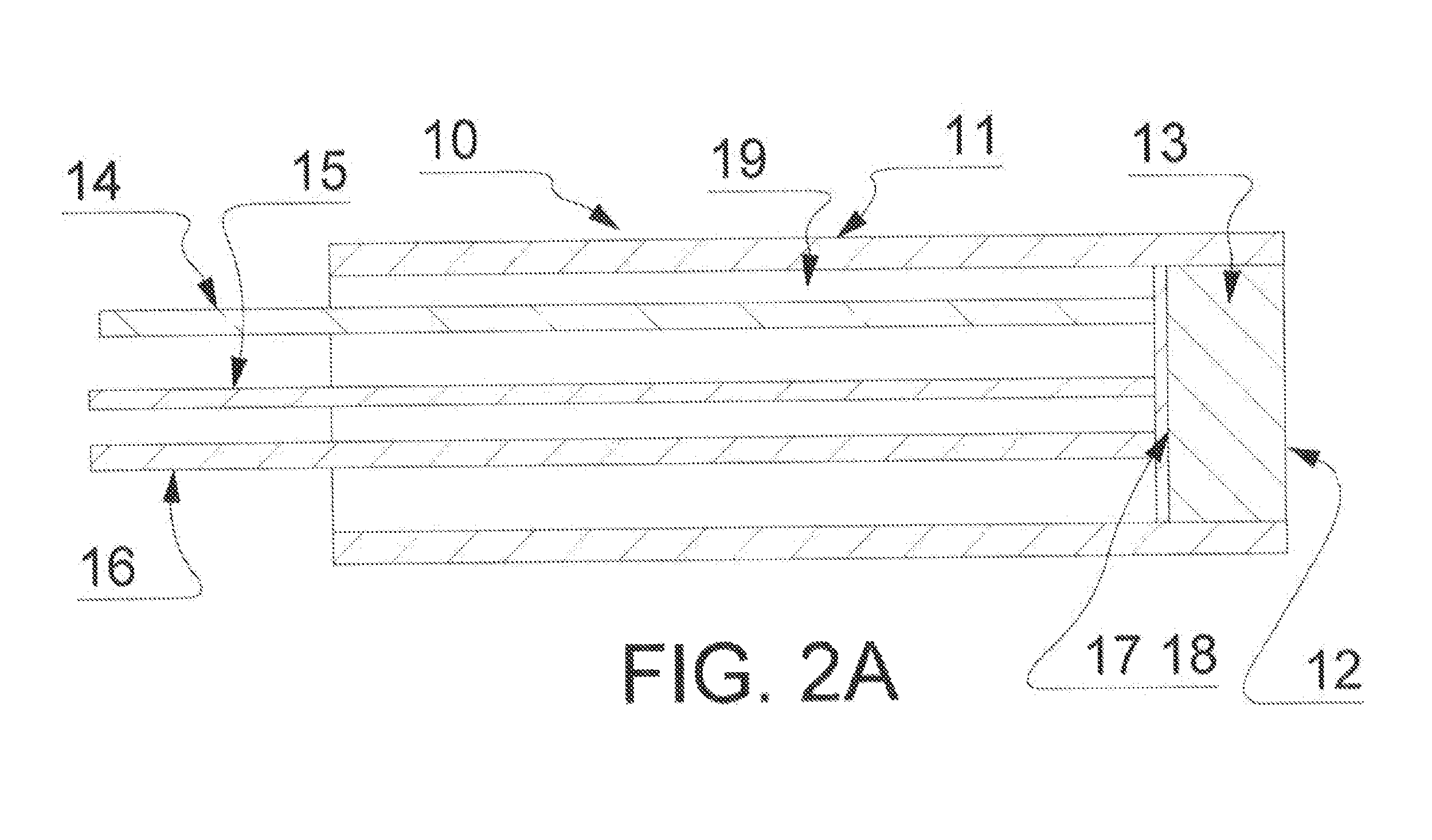

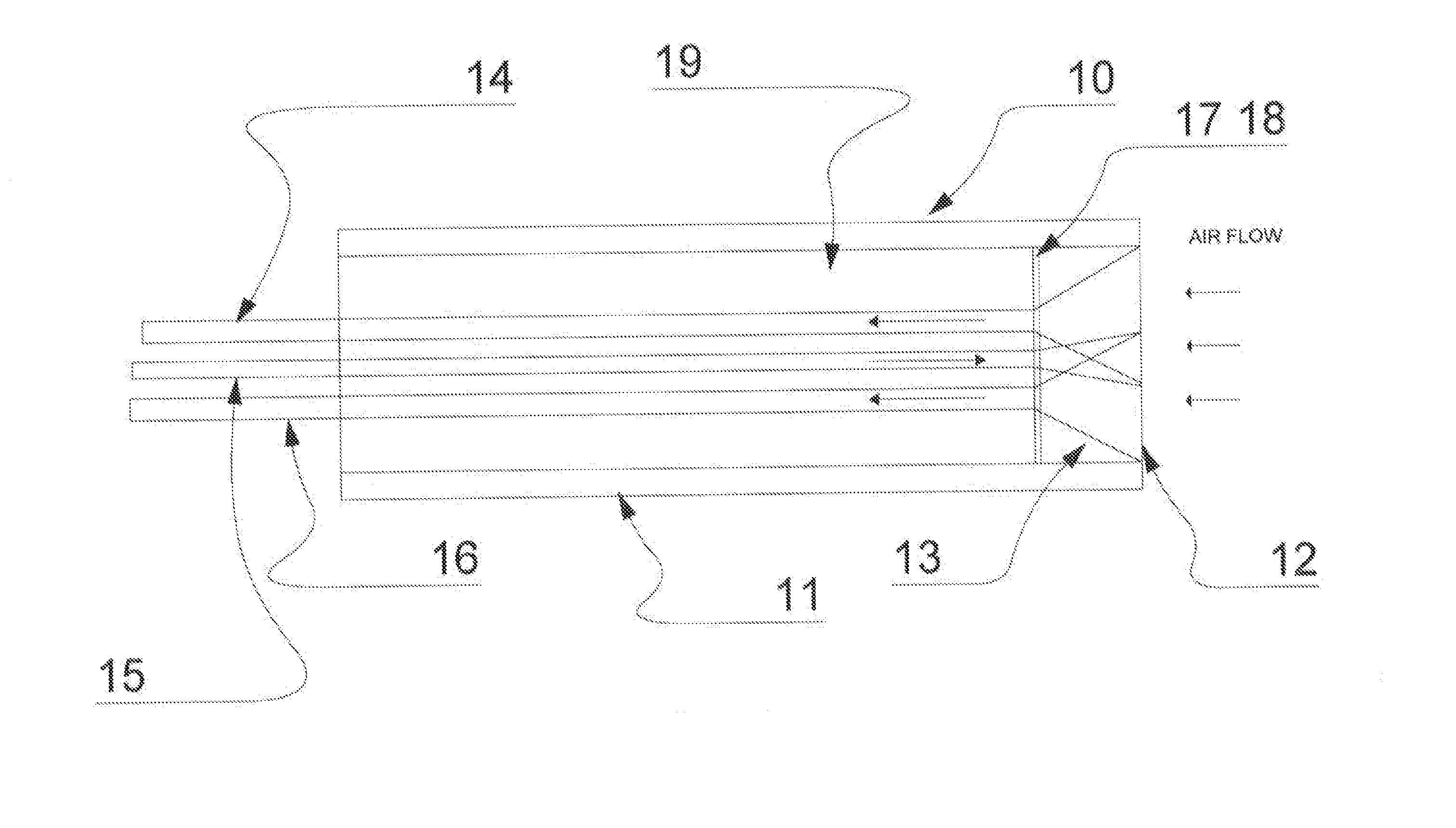

Inflight ice detection system

InactiveUS7370525B1Efficient discriminationSimple systemDe-icing equipmentsInstrumentsElectrical conductorSurface mounting

A dual channel inflight ice detection system to detect ice accretion on an aircraft surface by illuminating an ice collecting surface mounted on an aircraft with linear polarized light. The backscattered light is acquired in two light conductors one with polarization sensitivity aligned to the transmitted light and the second with polarization sensitivity orthogonal to the first. The presence of ice is determined by the change in the ratio of light intensities in the two light conductors.

Owner:SWAN INT SENSORS

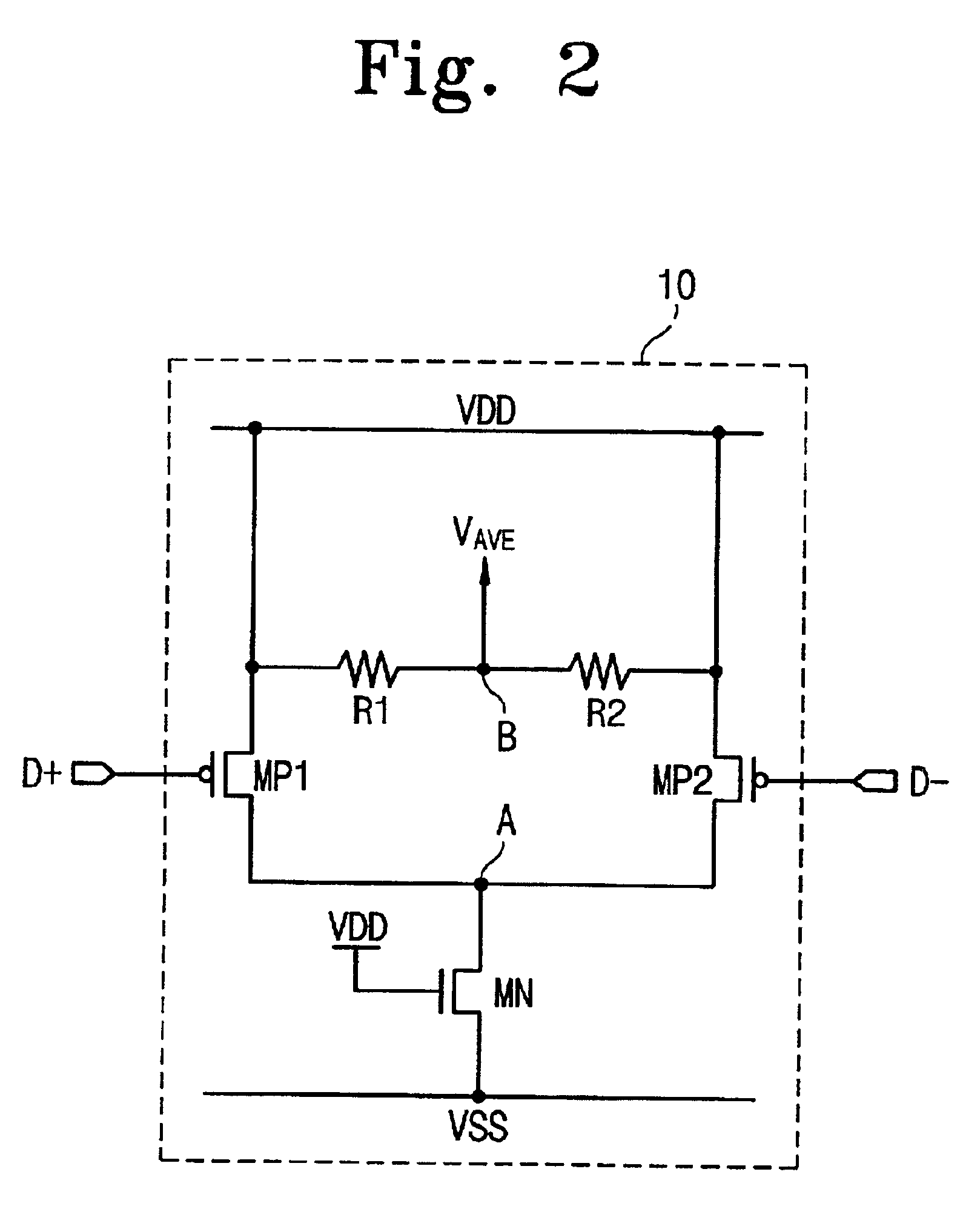

Mobile terminal and charge current setting method thereof

InactiveUS20110095722A1Efficient discriminationAvoid misuseCircuit authenticationPower supply for data processingCharge currentClosed loop

Disclosed are a mobile terminal capable of effectively discriminating a mobile terminal charger so as to set an appropriate charge current, and a method for charging a charge current thereof. To this end, when a charger (e.g., Travel Adaptor (TA)) is inserted via a cable, a short-circuited state of a data pin of the charger is checked such that a route is switched to form a closed loop defined by data pins and provided with predetermined power when the data pin of the charger is in the short-circuited state, and the voltage applied to the formed closed loop is compared with a predetermined reference value, thereby determining a type of the charger. Therefore, when various types of chargers are inserted in the mobile terminal via a cable, the corresponding type of charger is determined so as to set an appropriate charge current, resulting in ensuring a fast charging operation and minimizing damage on the charger.

Owner:LG ELECTRONICS INC

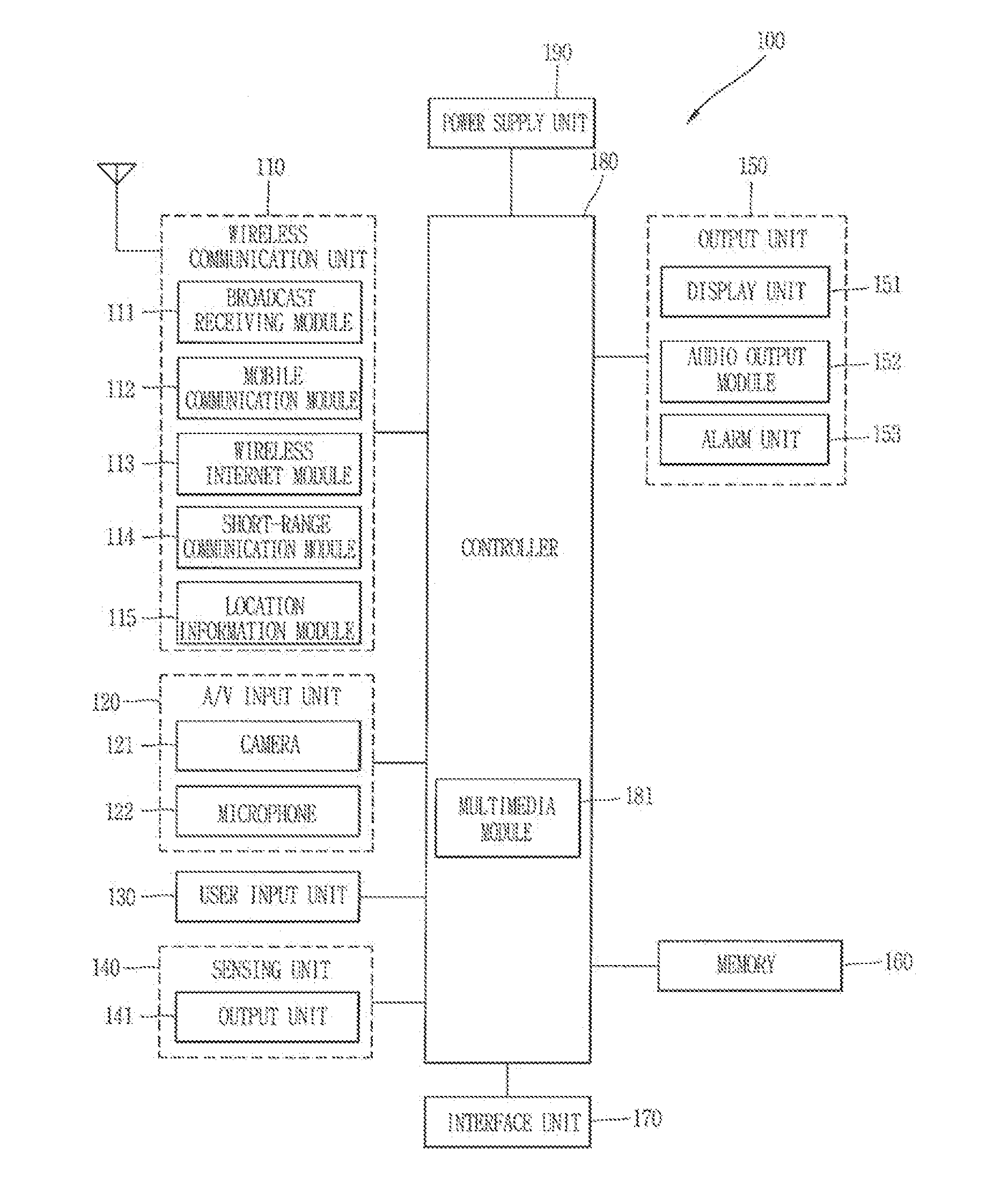

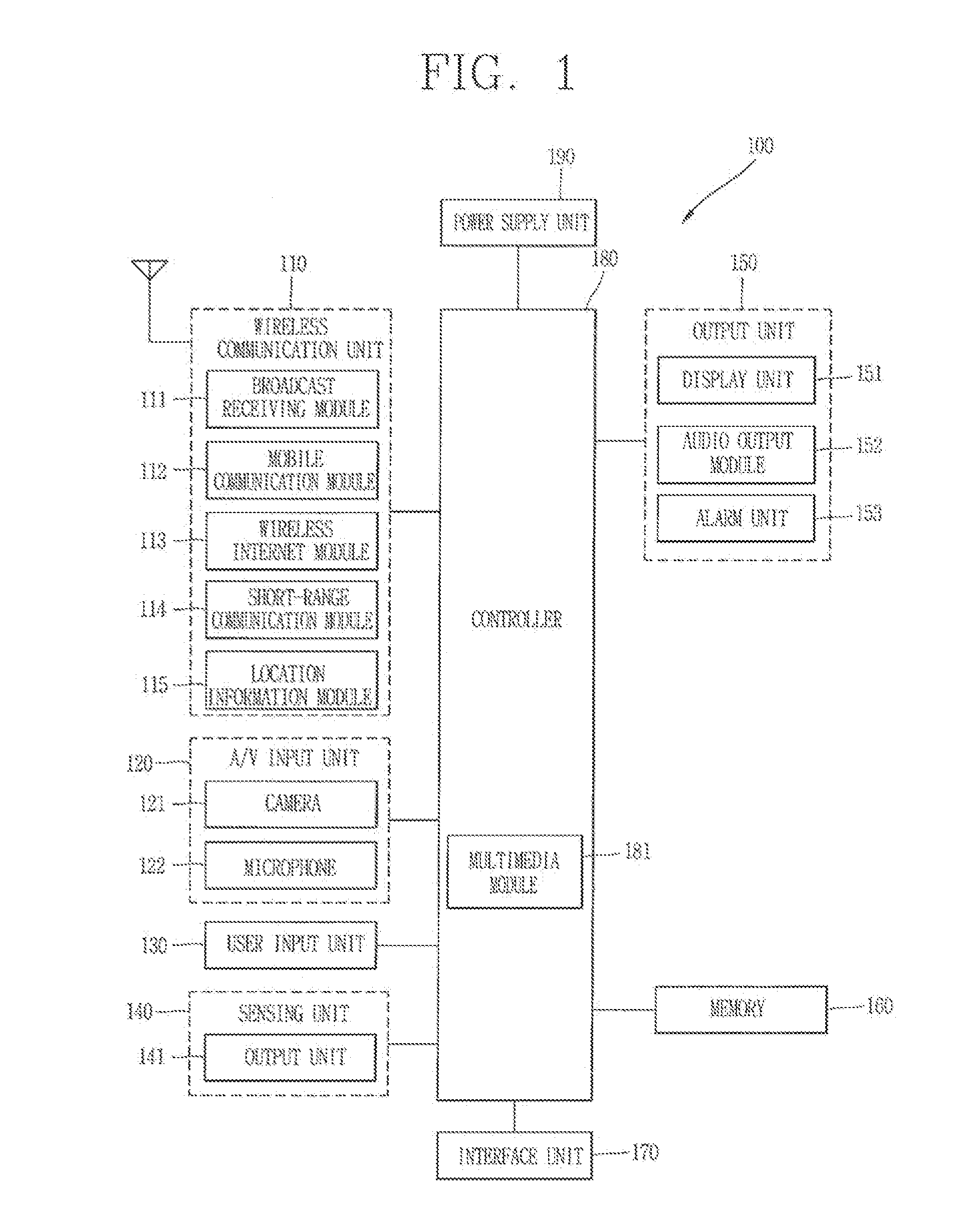

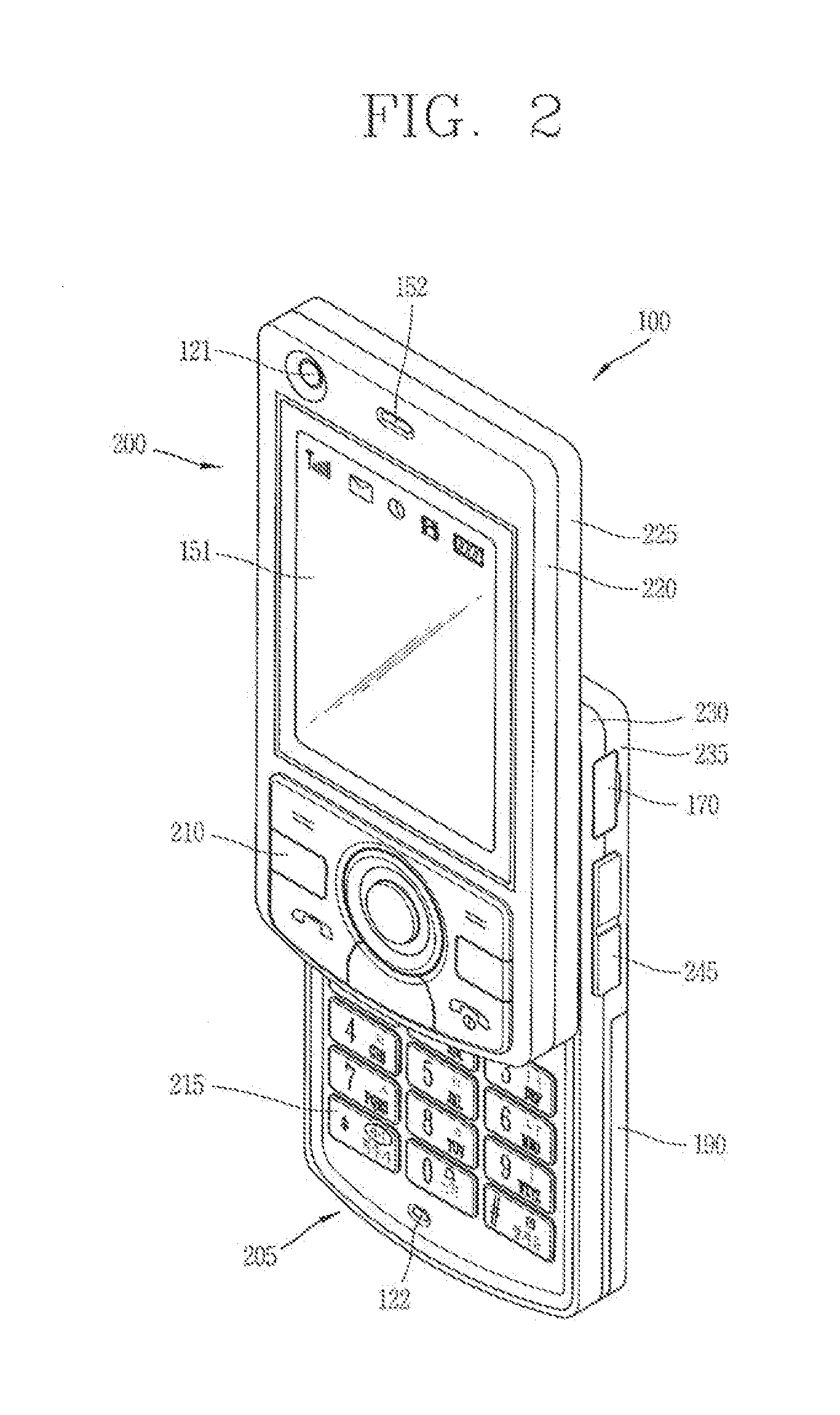

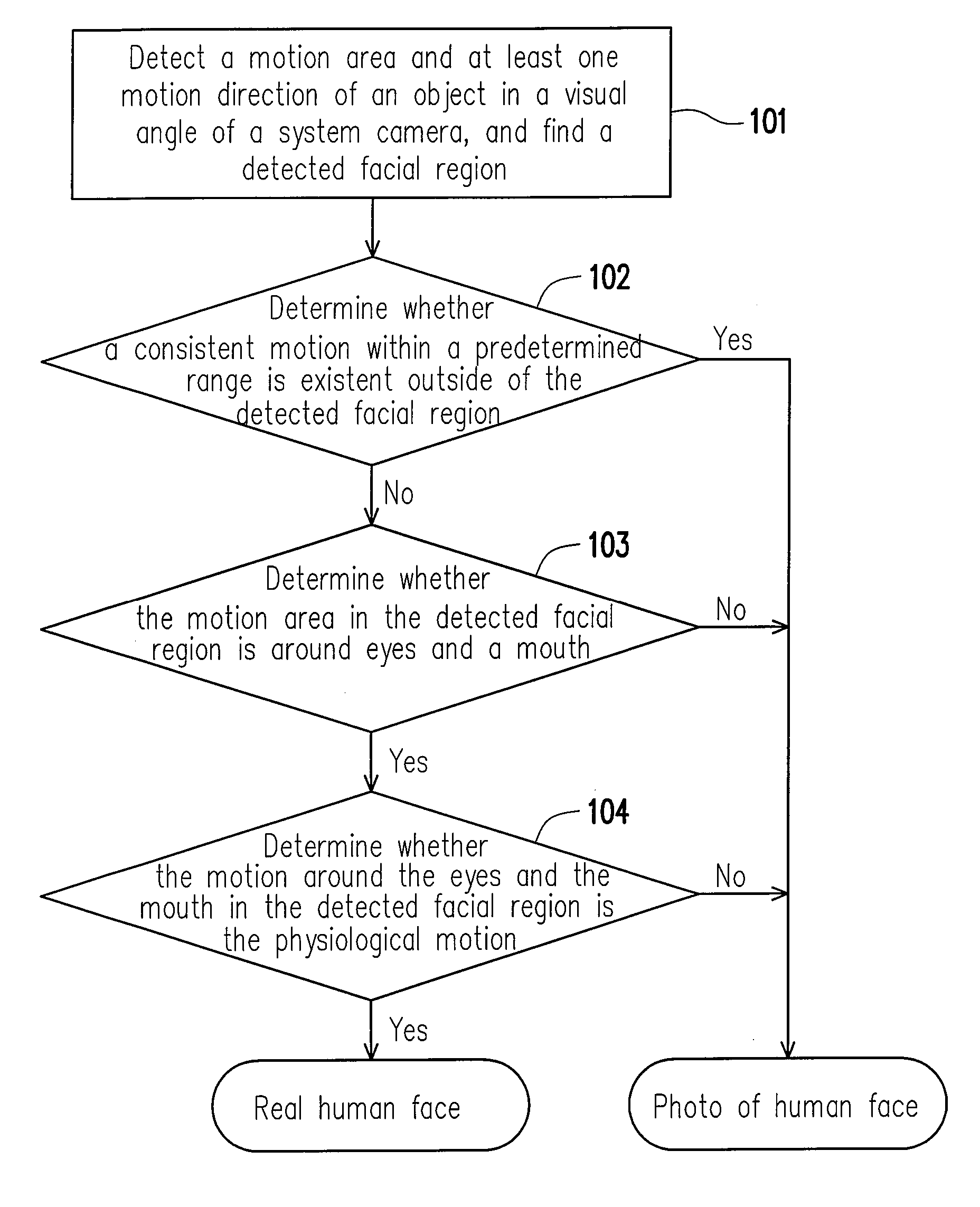

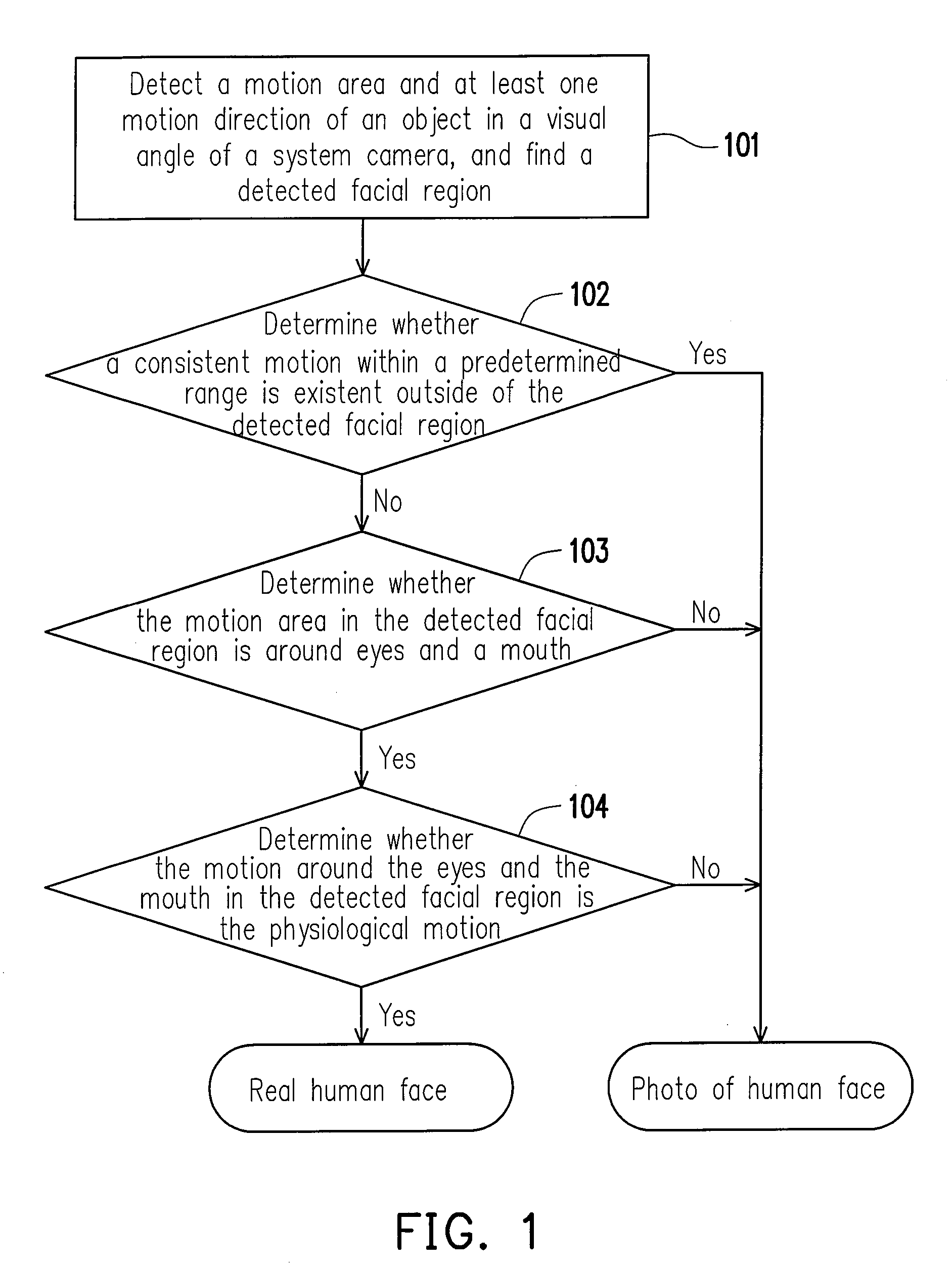

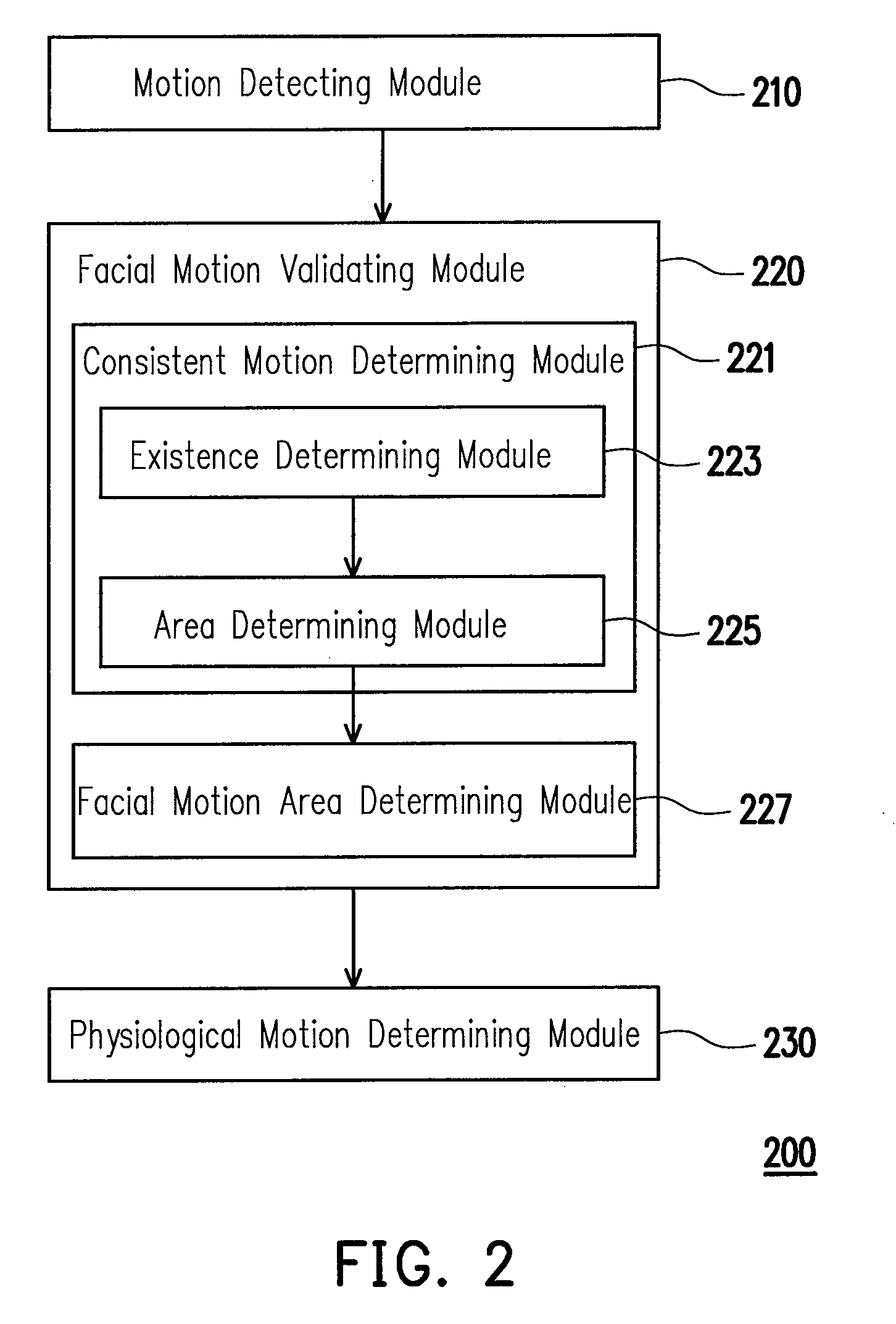

Method and system of live detection based on physiological motion on human face

InactiveUS20090135188A1Increase reliabilityEfficiently discriminateAnimationSpoof detectionMotion directionFacial recognition system

A method and a system of live detection based on a physiological motion on a human face are provided. The method has the following steps: in step a, a motion area and at least one motion direction in visual angle of a system camera are detected and a detected facial region is found. In step b, whether a valid facial motion exists in the detected facial region is determined. If a valid facial motion is inexistent, the object is considered as a photo of human face, otherwise, the method proceeds to step c to determine whether the facial motion is a physiological motion. If not, the object is considered as the photo of human face, yet considered as a real human face. The real human face and the photo of human face can be distinguished by the present invention so as to increase the reliability of the face recognition system.

Owner:TSINGHUA UNIV

Flow measurement system with reduced noise and crosstalk

InactiveUS7000485B2High sensitivityIncrease powerVolume/mass flow measurementSonificationUltrasonic sensor

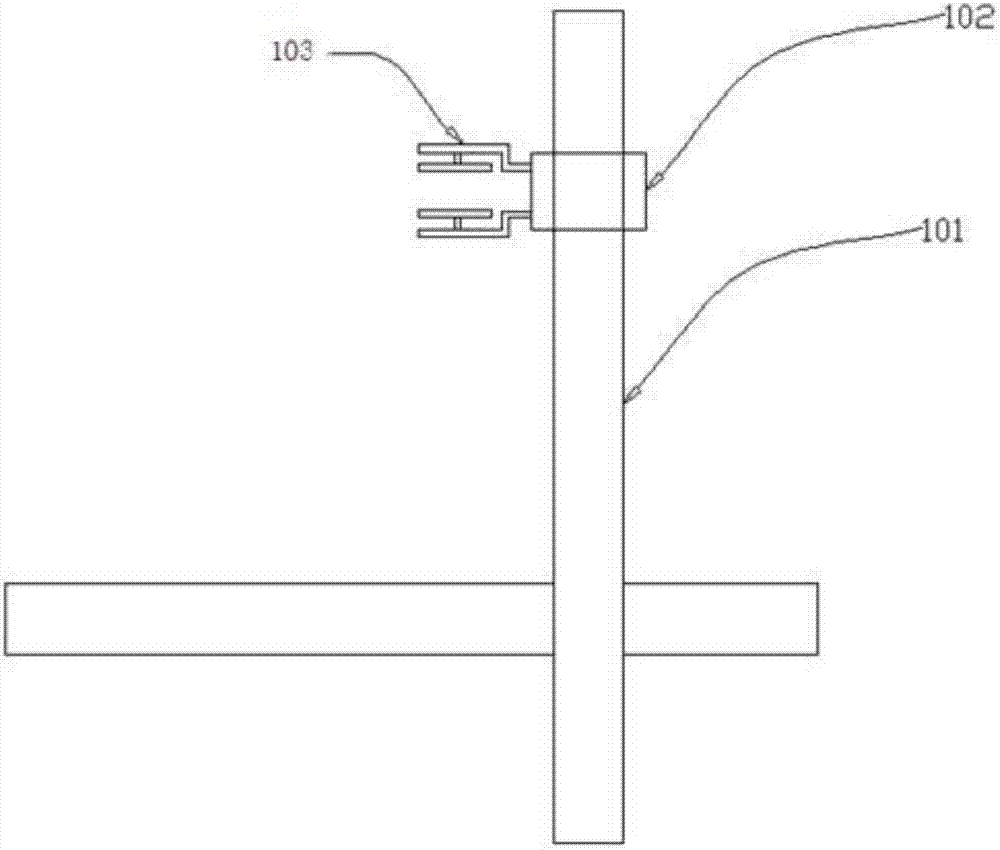

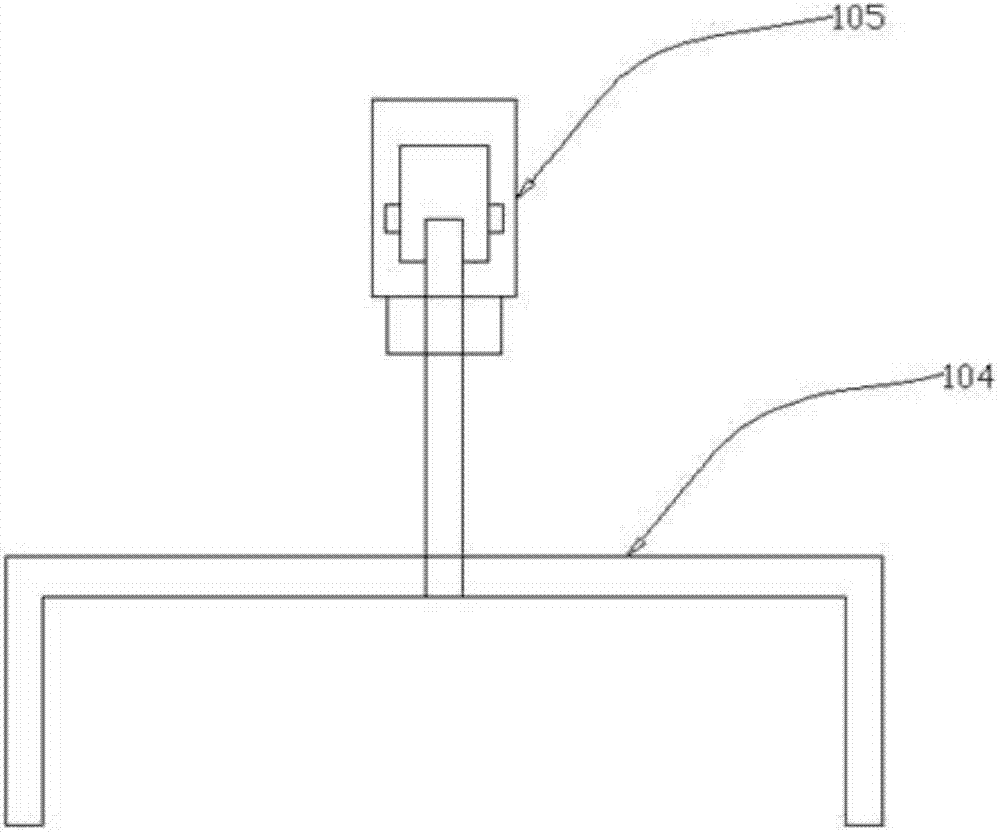

A flow measurement system including at least first and second ultrasonic transducers coupled to an existing conduit, a damping material about the conduit between the first and second ultrasonic transducers to prevent crosstalk, a damping material about the conduit upstream of the first ultrasonic transducer to attenuate system background noise travelling in the conduit at large, and a damping material about the conduit downstream of the second ultrasonic transducer to attenuate system background noise travelling in the conduit at large.

Owner:GE INFRASTRUCTURE SENSING

Rapid lens flaw detection method and apparatus thereof

InactiveCN102735695AReduce false positive rateEfficient discriminationMaterial analysis by optical meansMathematical morphologyComputer science

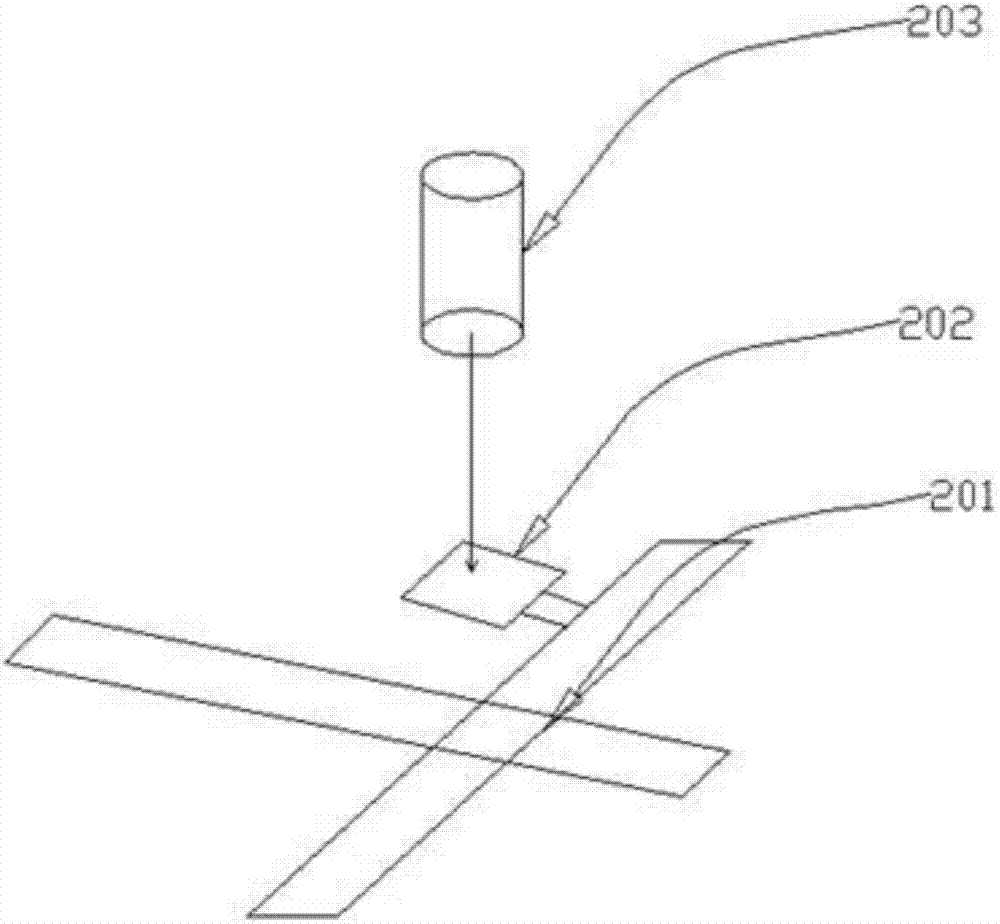

The invention discloses a rapid lens flaw detection method and an apparatus thereof. The method comprises the following steps: equally dividing the surface of a lens to be detected into n<2> parts, respectively obtaining the images of all the parts, and obtaining n<2> images within a preset time which is used for controlling the image obtaining rate; 2, carrying out median filtering, black hat transformation and binary processing on the n<2> images respectively, and partitioning off defective images; 3, carrying out opening operation on the defective images to filter out non-flaw interference parts; and 4, drawing contours of the defective images subjected to non-defective interference filter, there are flaws on the surface of the lens to be detected if there is a counter, and no flaws are on the surface of the lens to be detected if there is no counter. The rapid lens flaw detection method provided in the invention allows scratches on the lens to be clearly detected through a surface defect detection method based on the mathematical morphology under the high speed motion of a platform, and defect types to be effectively discriminated, and has the characteristics of fast speed, objective detection result and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

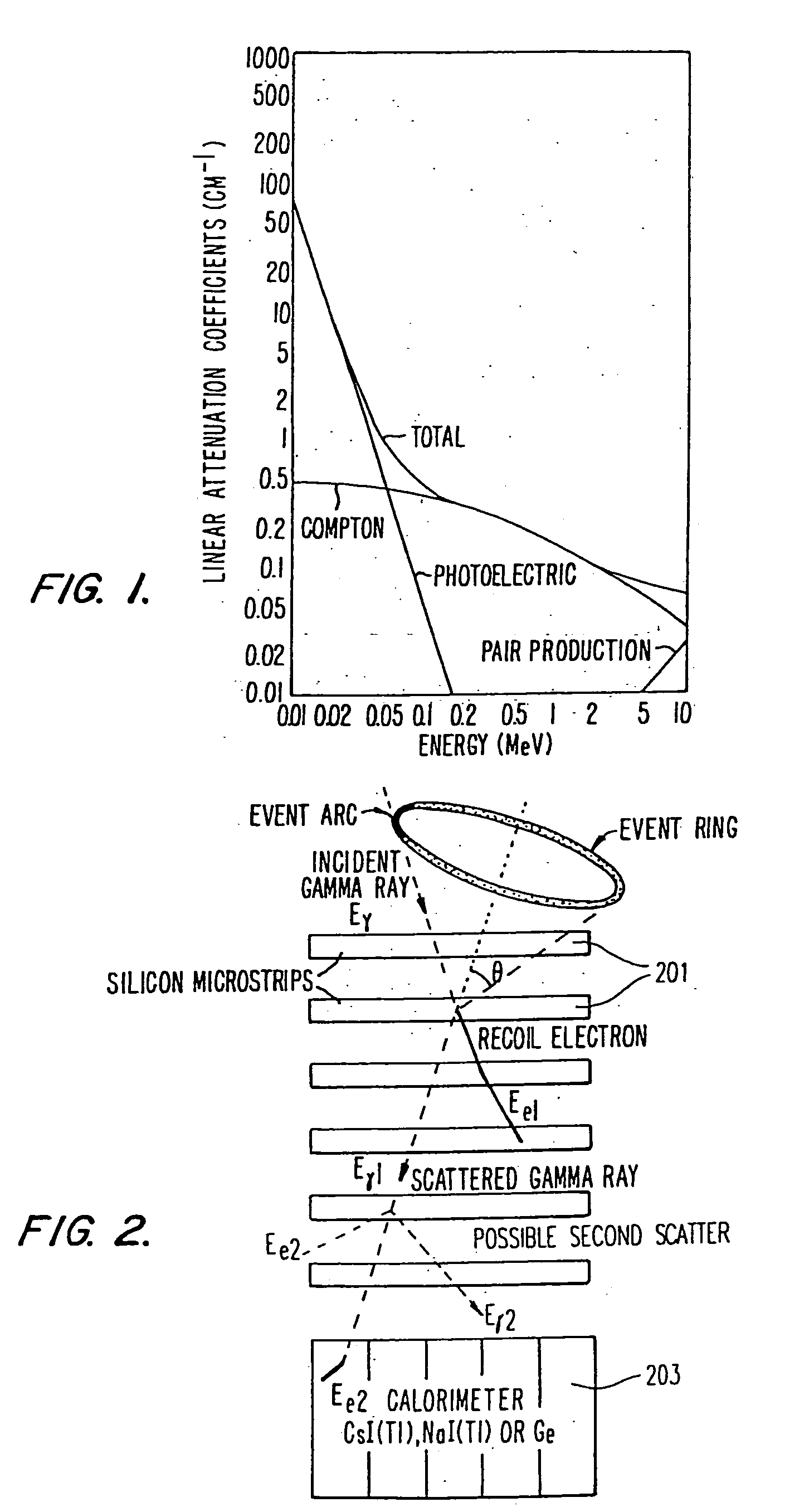

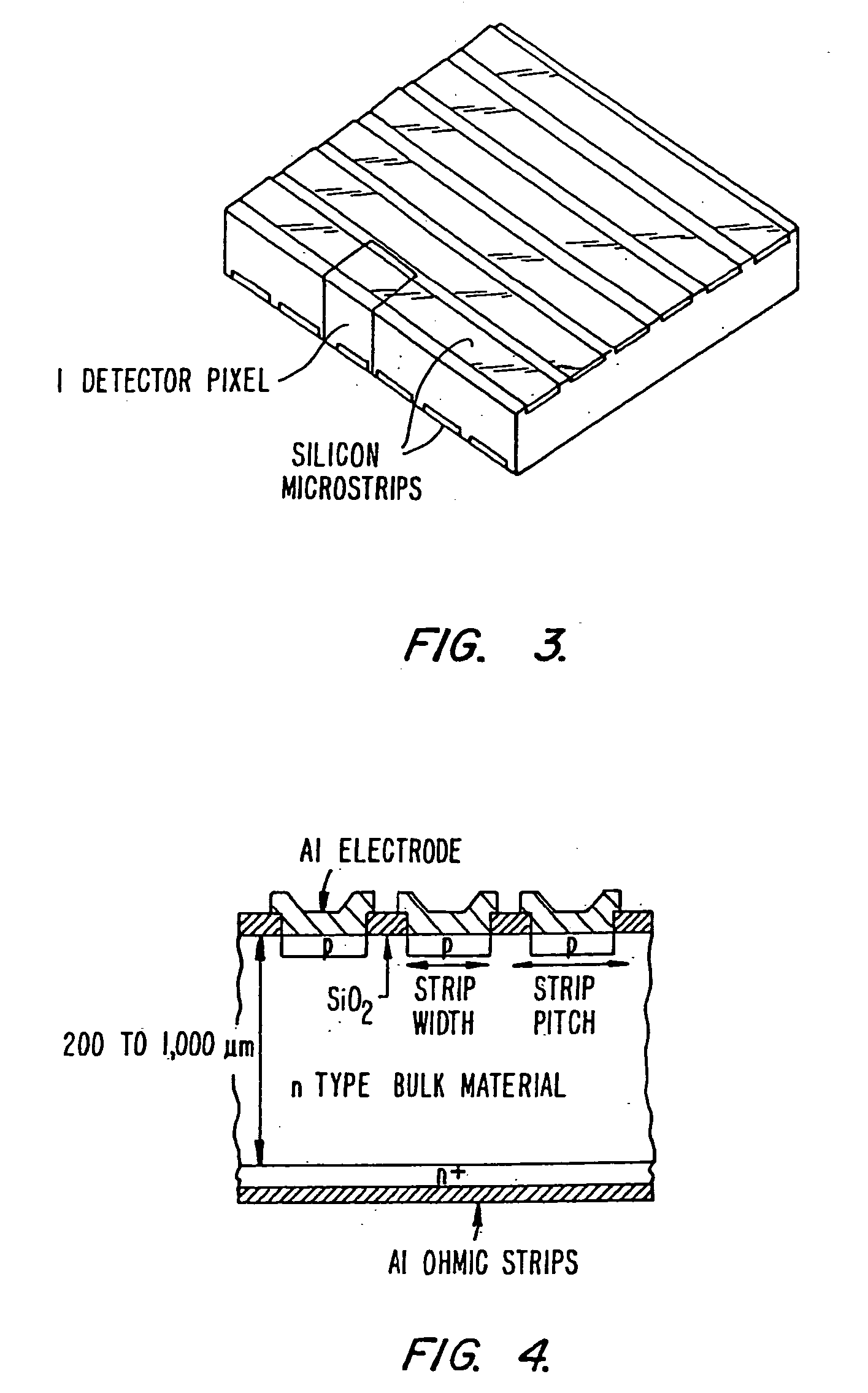

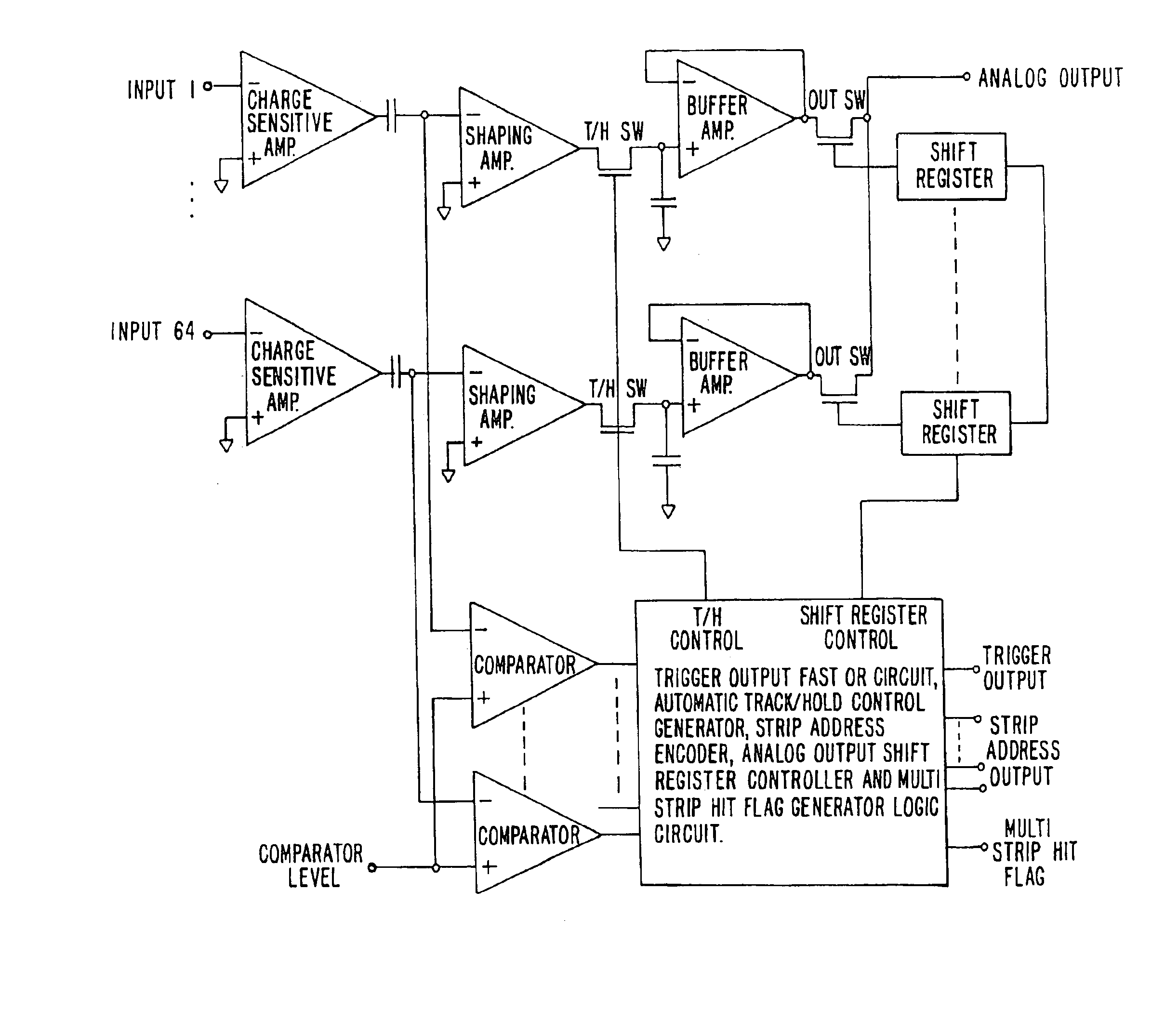

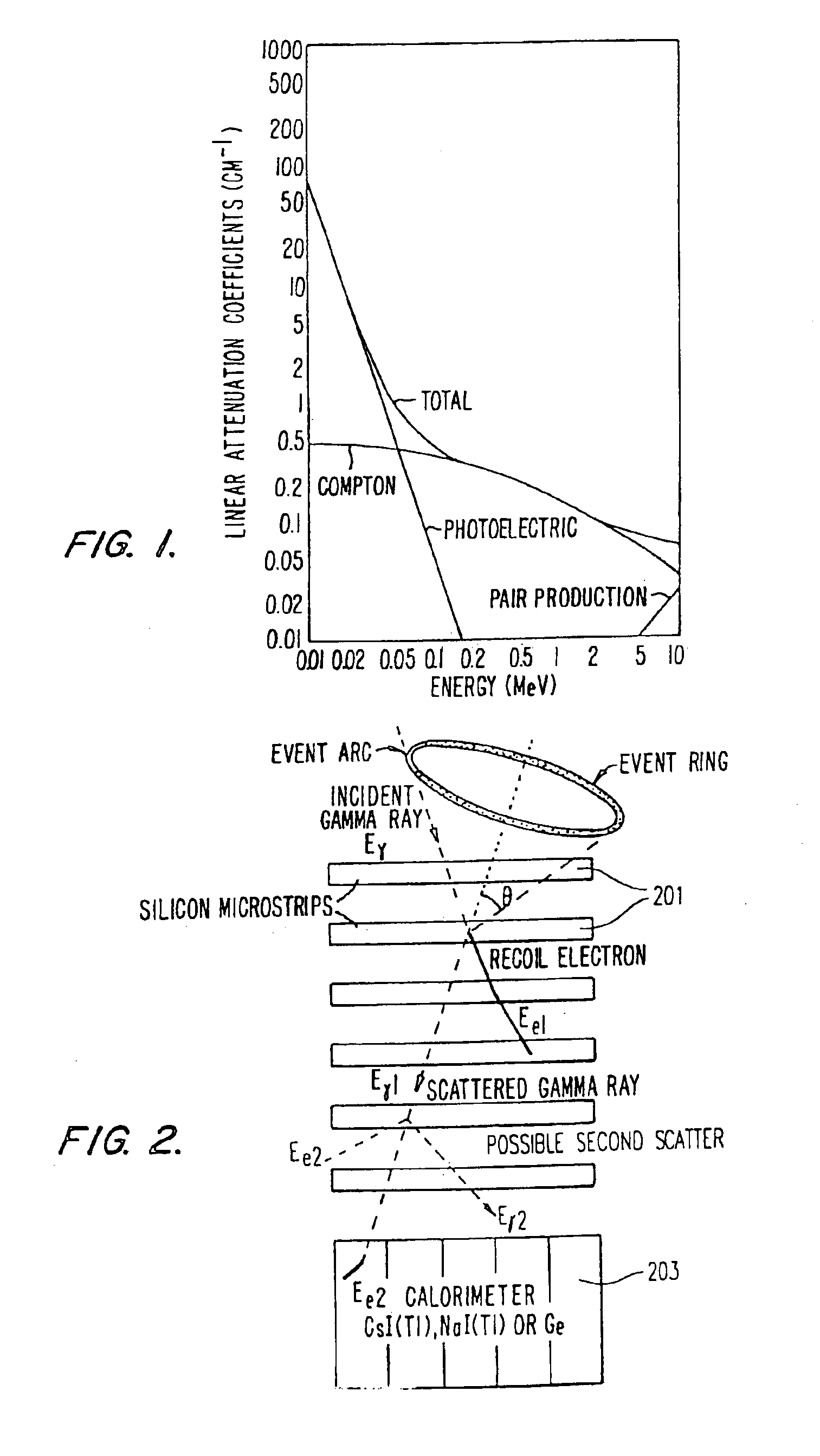

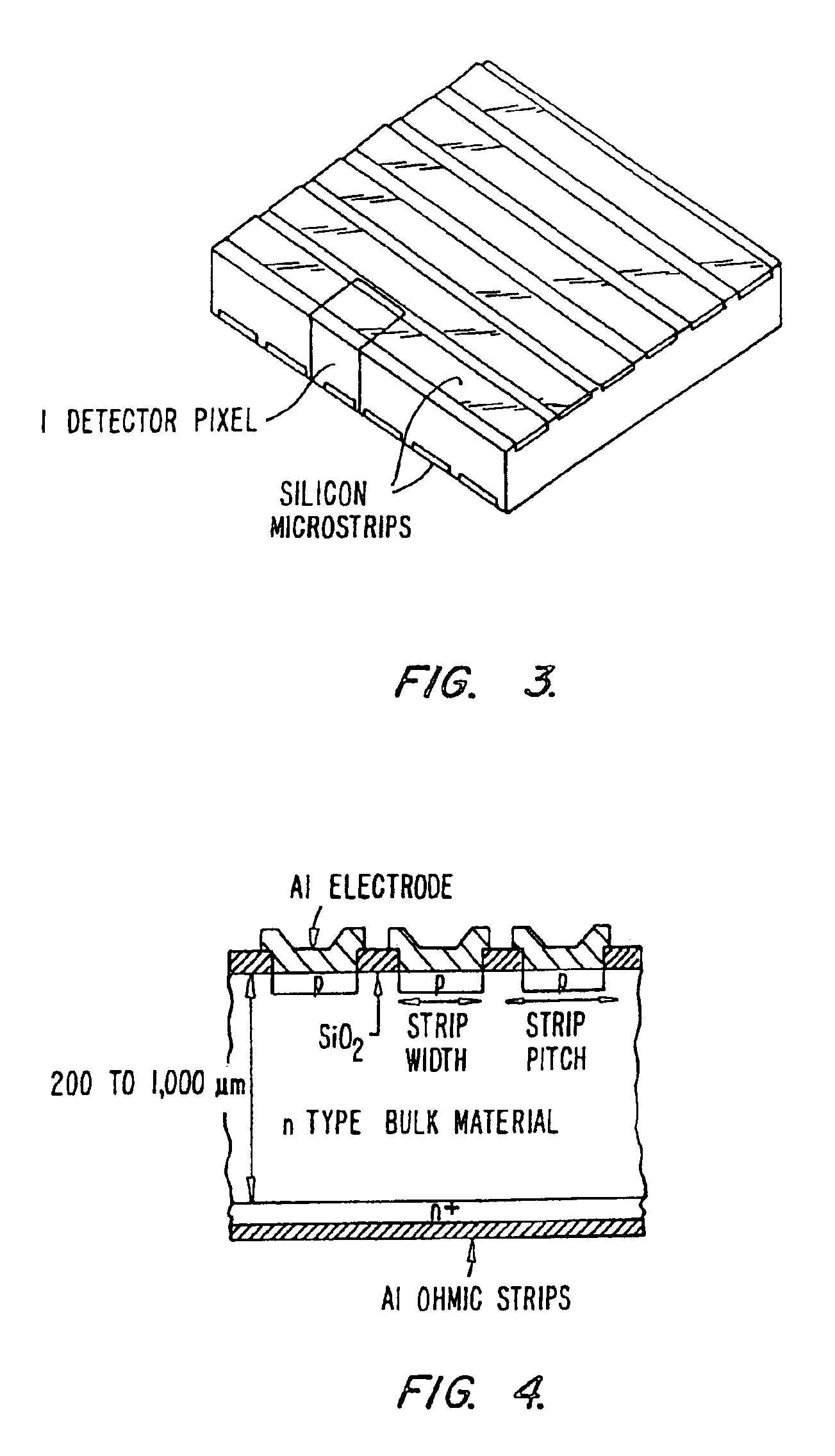

Method and apparatus for gamma ray detection

InactiveUS20050173643A1High sensitivityImprove spatial resolutionSolid-state devicesMaterial analysis by optical meansHodoscopeRecoil electron

A high sensitivity, three-dimensional gamma ray detection and imaging system is provided. The system uses the Compton double scatter technique with recoil electron tracking. The system preferably includes two detector subassemblies; a silicon microstrip hodoscope and a calorimeter. In this system the incoming photon Compton scatters in the hodoscope. The second scatter layer is the calorimeter where the scattered gamma ray is totally absorbed. The recoil electron in the hodoscope is tracked through several detector planes until it stops. The x and y position signals from the first two planes of the electron track determine the direction of the recoil electron while the energy loss from all planes determines the energy of the recoil electron.

Owner:NOVA R&D

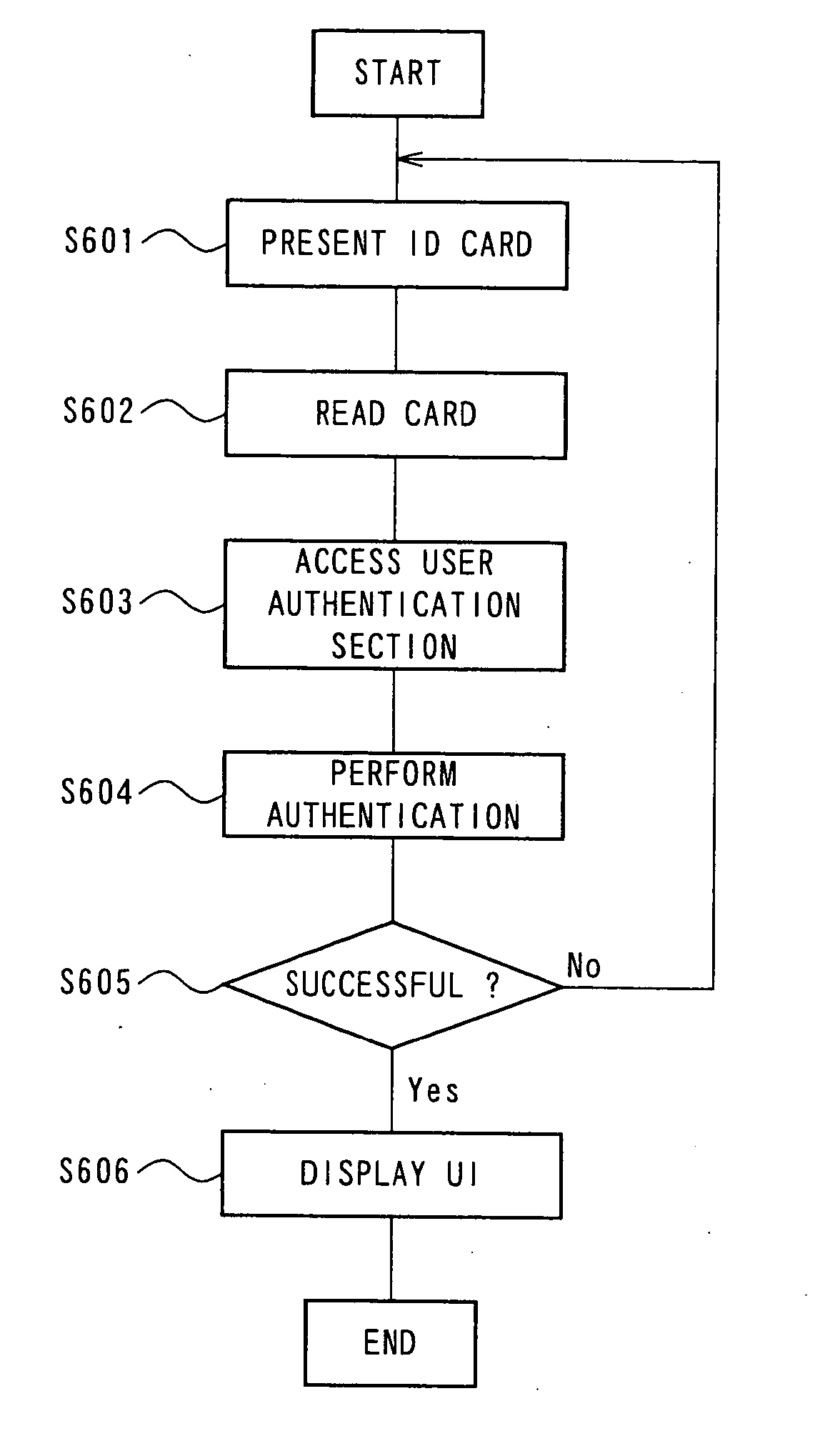

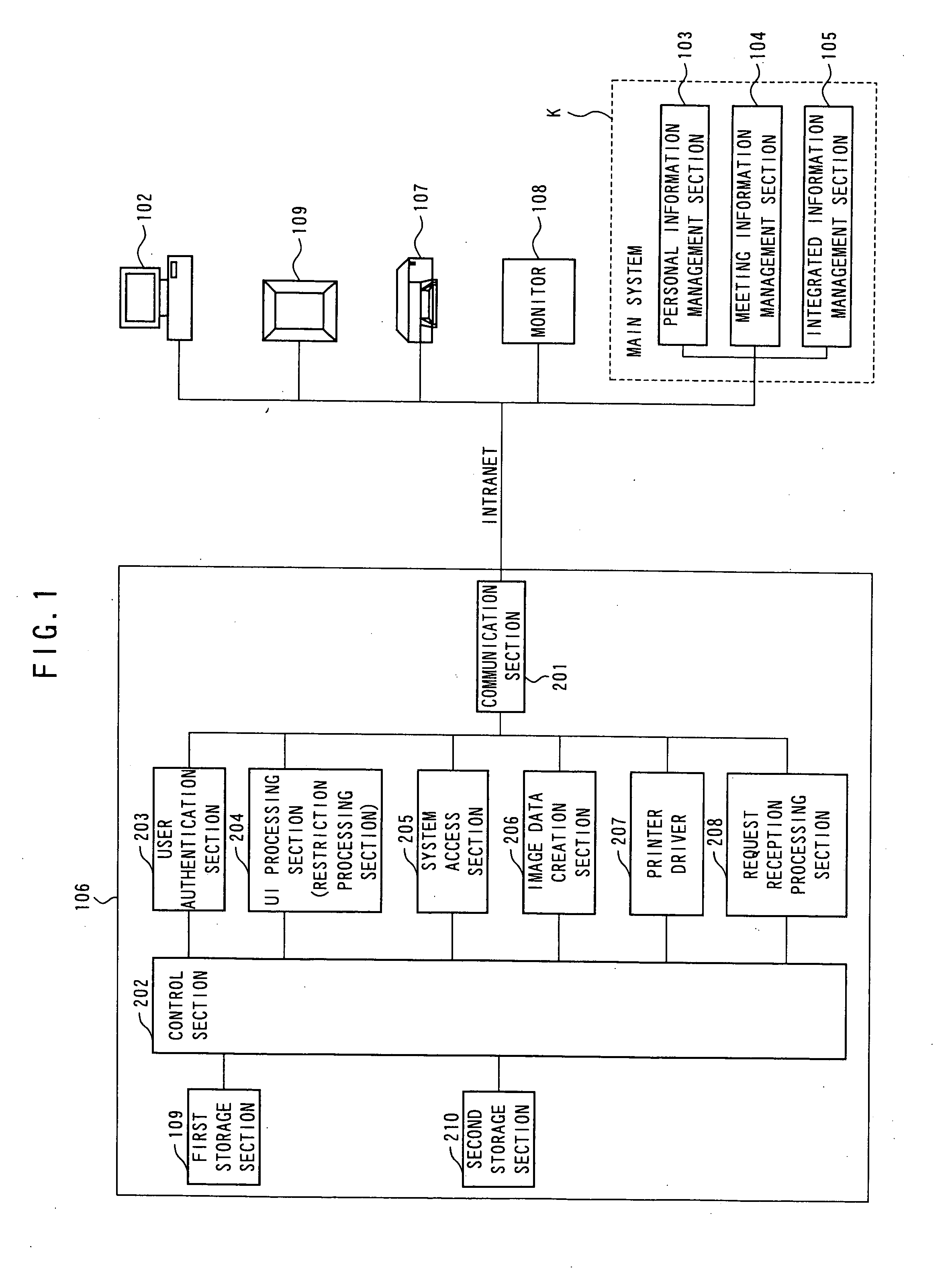

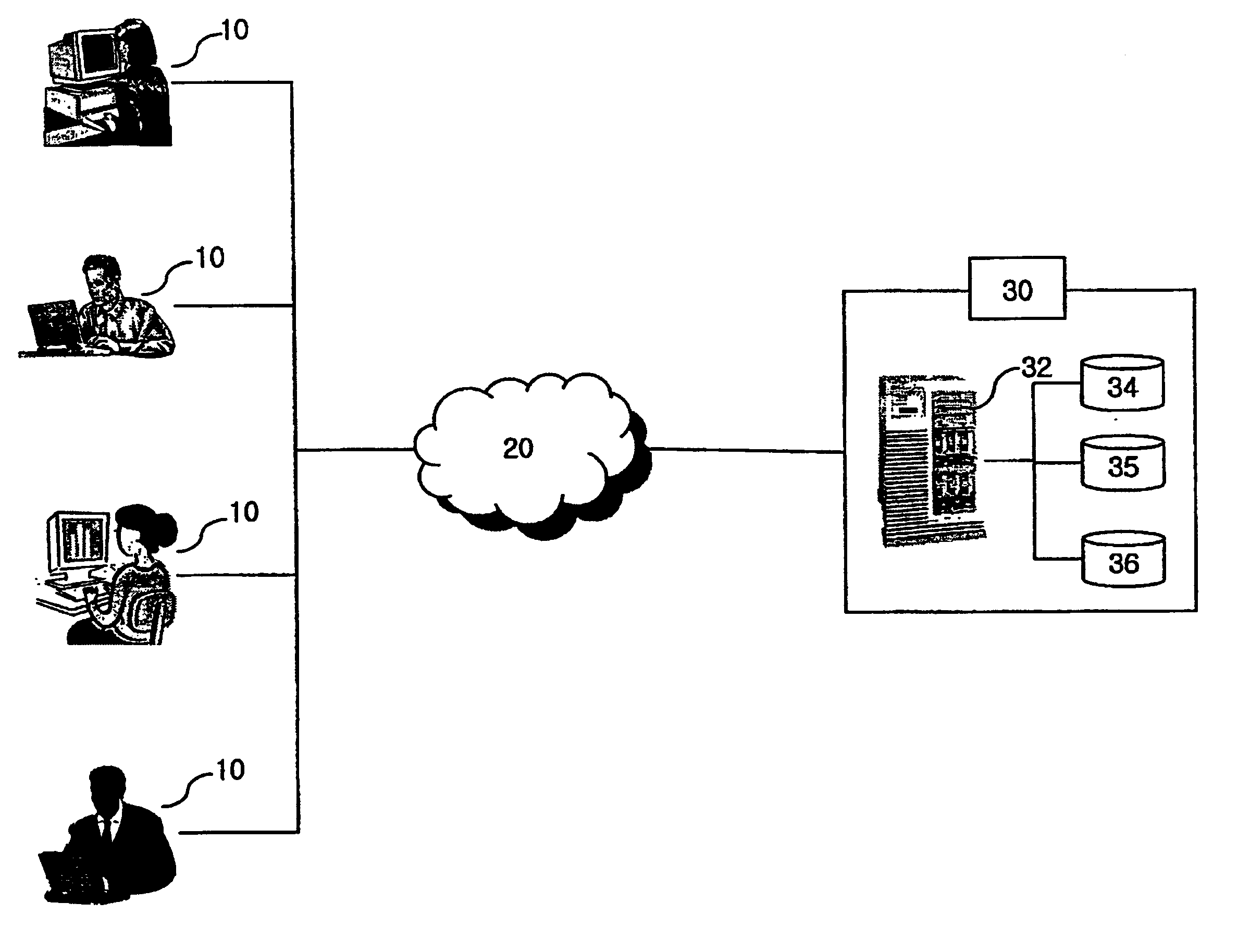

Image processing apparatus, image processing method and image processing program

InactiveUS20050204145A1Efficiently discriminate and processMinimizing human work and operationReservationsUser identity/authority verificationUser authenticationComputer graphics (images)

An image processing apparatus, an image processing method and an image processing program is provided which efficiently discriminate and process varying pieces of image data for materials corresponding to individual participants to a meeting, while minimizing the human work or operation required. The apparatus includes a user authentication section that acquires ID information to identify each user from among a plurality of users, and performs user authentication based on the ID information; a setting information acquisition section that acquires information for image formation associated with the users authenticated by the user authentication section; and an image data creation section creates image data for images to be formed on sheets of paper based on the setting information acquired by the setting information acquisition section.

Owner:KK TOSHIBA +1

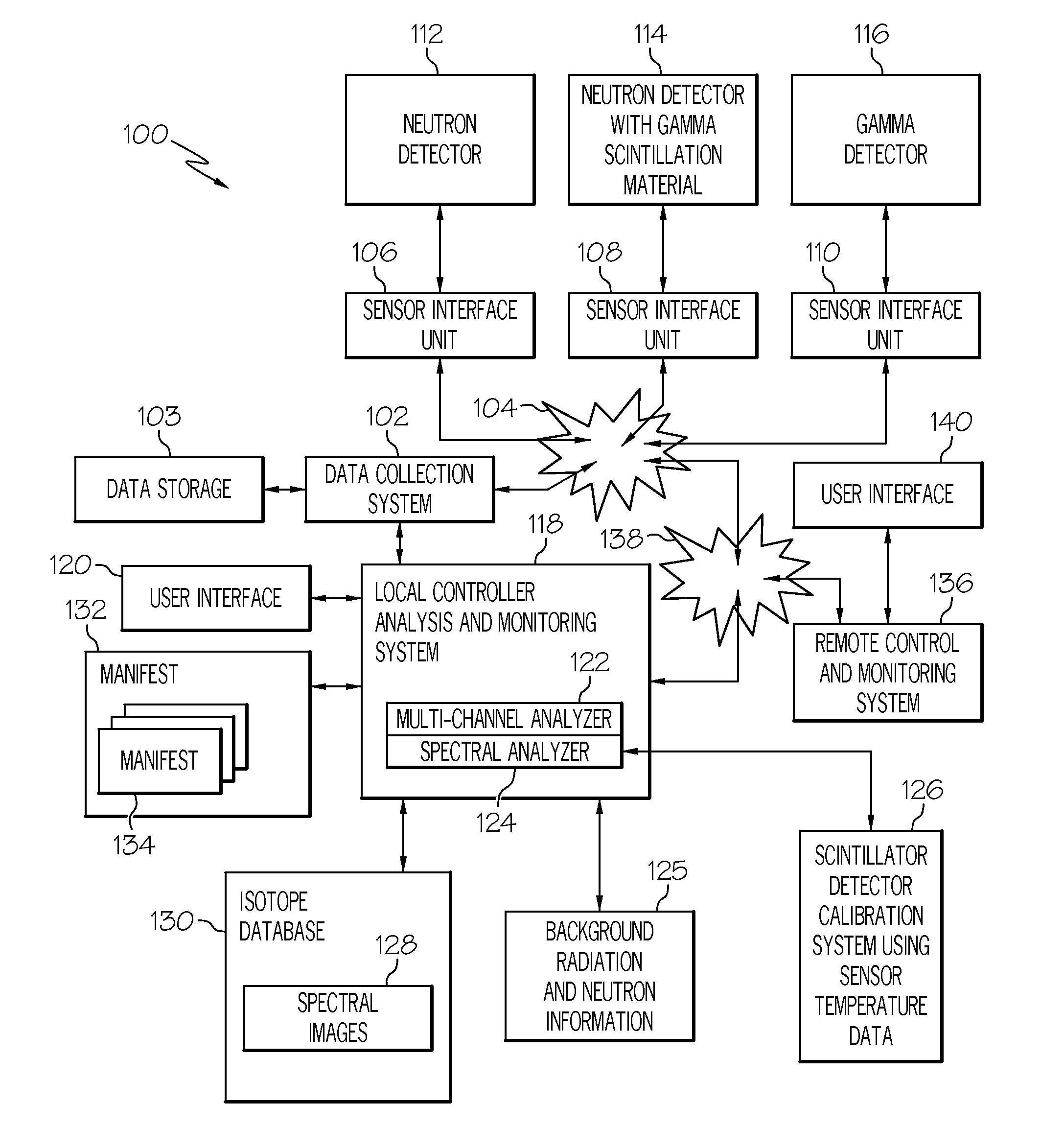

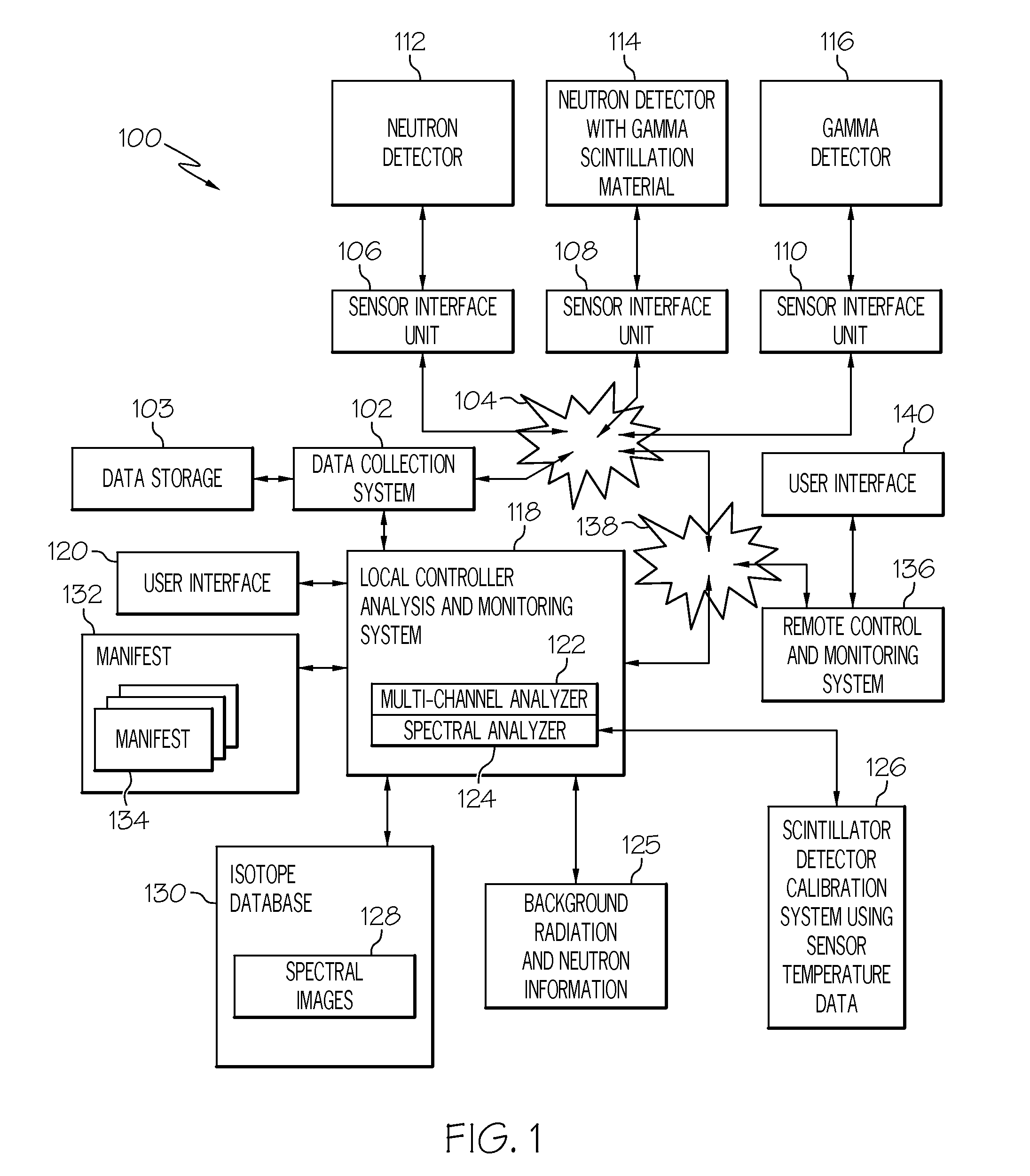

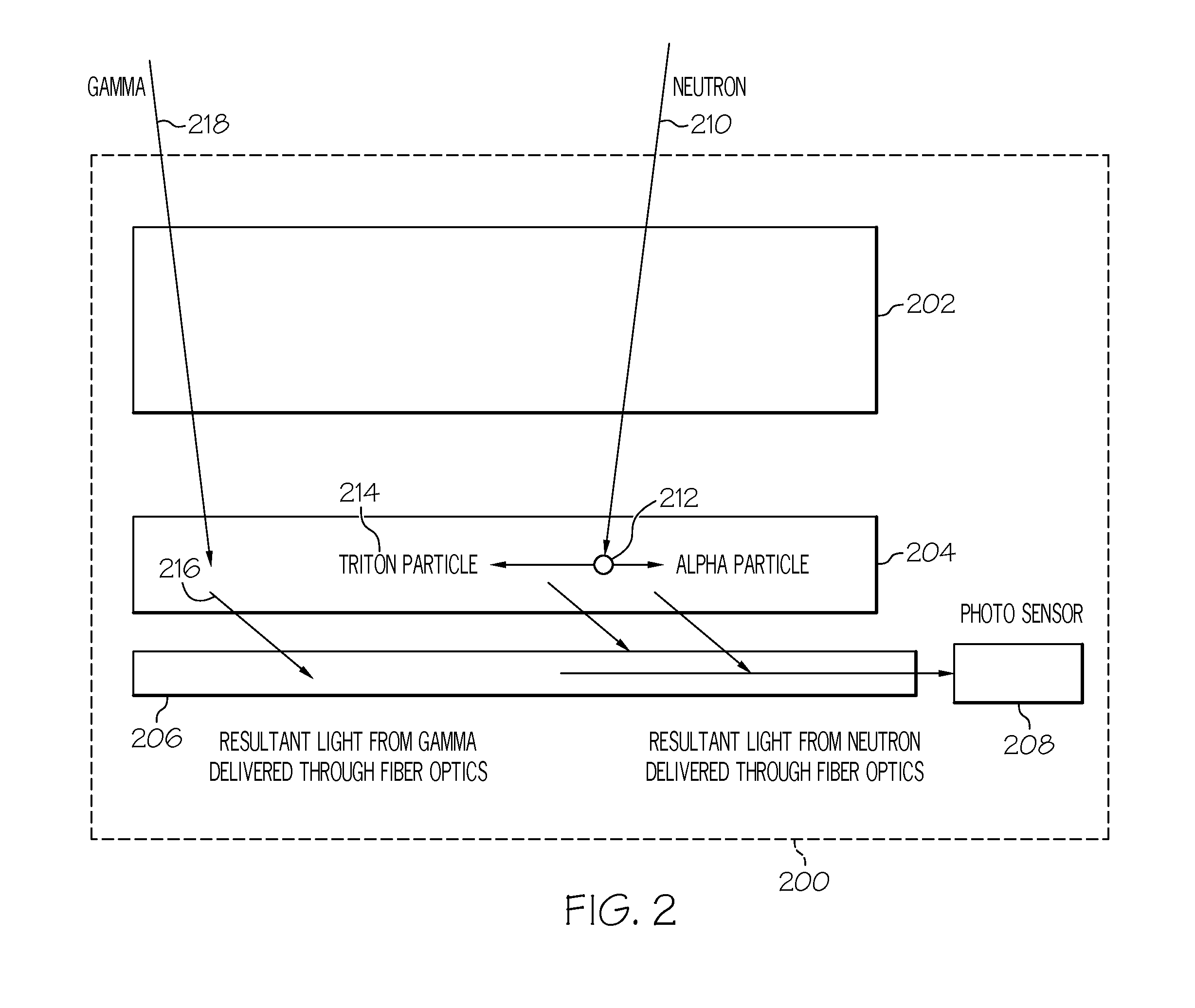

System and method for increased gamma/neutron detection

InactiveUS20100226580A1Increased gammaIncreased neutron detector performanceMaterial analysis by optical meansCharacter and pattern recognitionInformation processingIsotope

A system detects at least one of nuclear and fissile materials. The system includes a plurality of high speed scintillator detectors. Each high speed scintillator detector in the plurality of high speed scintillator detectors includes at least one photo sensor and a pre-amp circuit adapted to eliminate pulse stretching and distortion of detected light pulses emitted from scintillation material when interacting with neutron particles and / or gamma particles. An isotope database includes a plurality of spectral images corresponding to different known isotopes. An information processing system is adapted to compare spectral data received from each high speed scintillator detector to one or more of the spectral images and identify one or more isotopes present in an object or container being monitored.

Owner:INNOVATIVE AMERICAN TECH

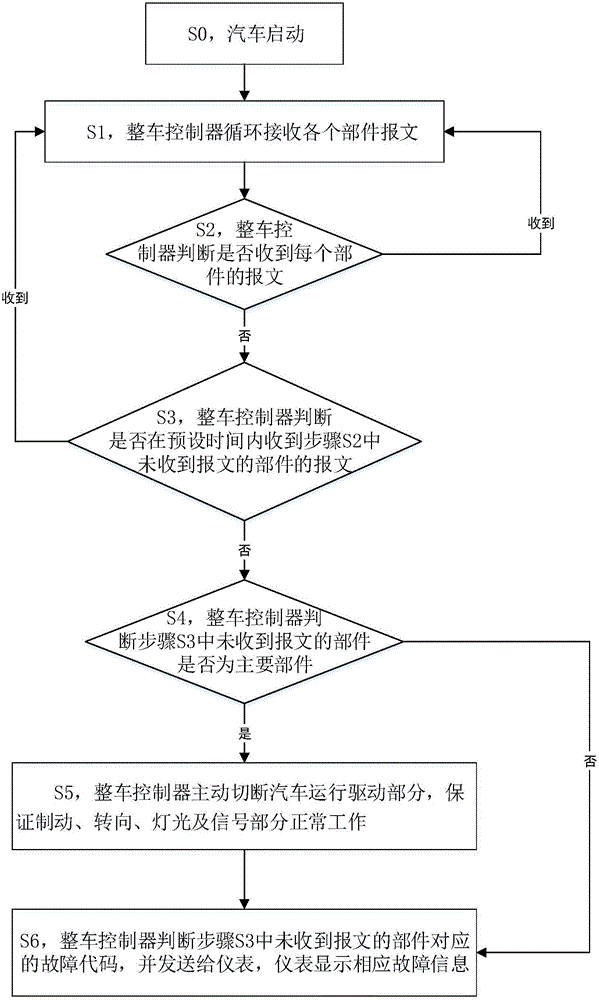

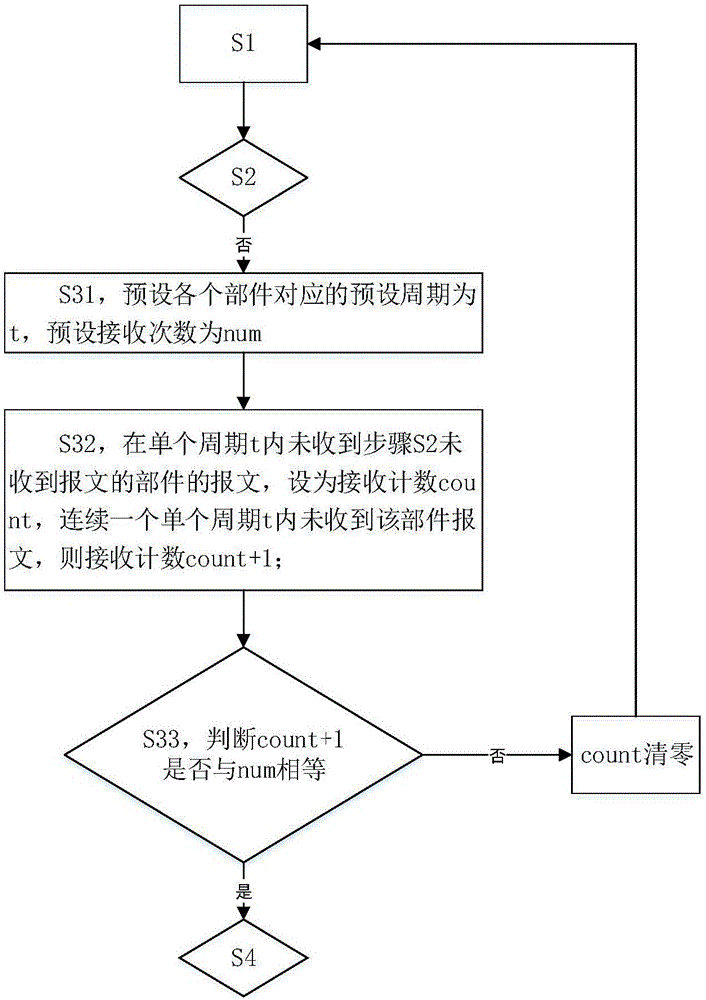

CAN communication bus system-based fault diagnosis method

ActiveCN106094798AEnsure safetyEfficient discriminationProgramme controlElectric testing/monitoringDiagnosis methodsEmbedded system

The invention belongs to the automobile control technical field and provides a CAN communication bus system-based fault diagnosis method. The method includes the following steps that: a vehicle is started; a vehicle controller receives the messages of various components circularly; the vehicle controller judges whether the vehicle itself receives the messages of each component; if the vehicle controller does not receive the messages of each component, the vehicle controller judges whether itself receives the message of a certain component in a preset time period; and if the vehicle controller does not receive the message of the component in the preset time period, the vehicle controller judges a fault code corresponding to the component and transmits the fault code to an instrument, and the instrument displays corresponding fault information. With the CAN communication bus system-based fault diagnosis method of the invention, a CAN communication bus system is protected; the fault of the CAN communication bus system can be judged; judgment on whether each component of the vehicle malfunctions can be facilitated; and measures against the fault are taken, so that the safety of the driving of the vehicle can be ensured.

Owner:JIANGSU KAWEI AUTOMOBILE IND GRP CO LTD

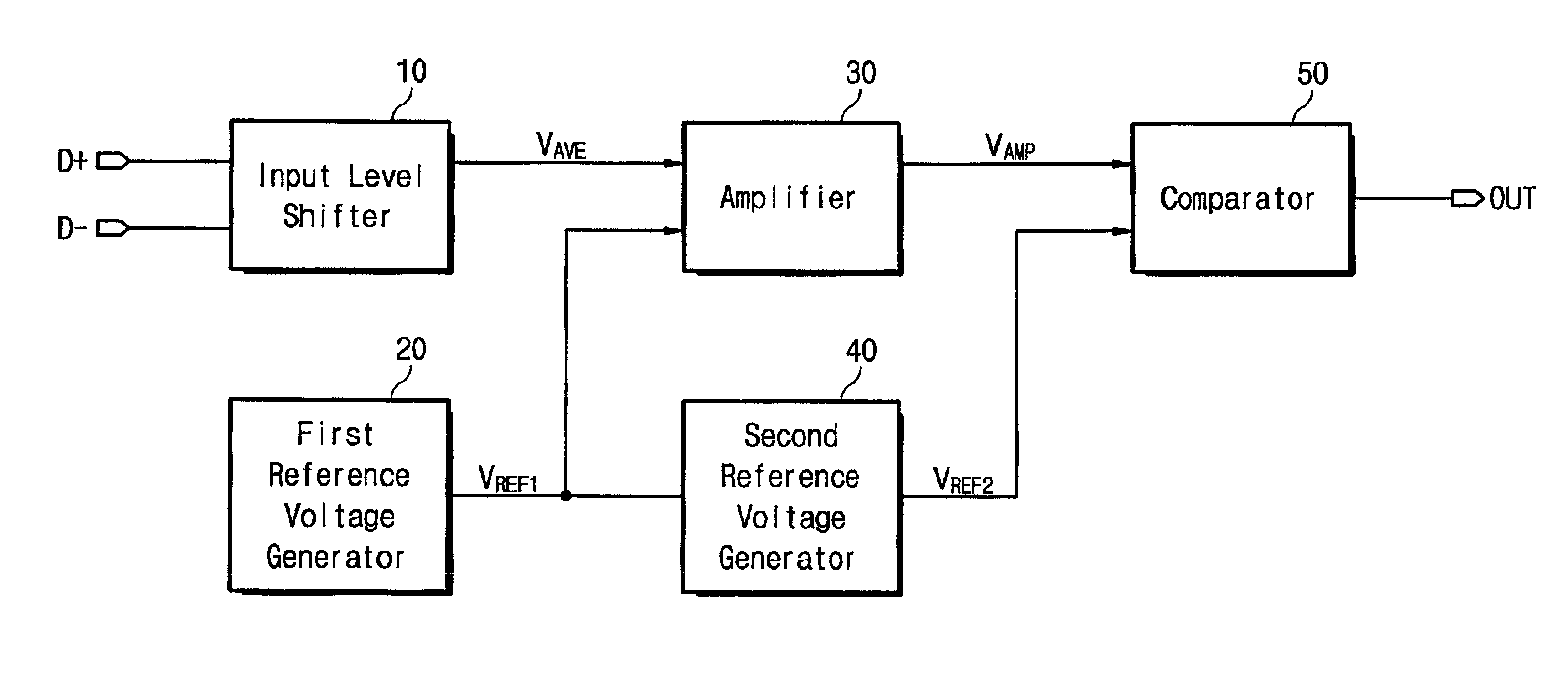

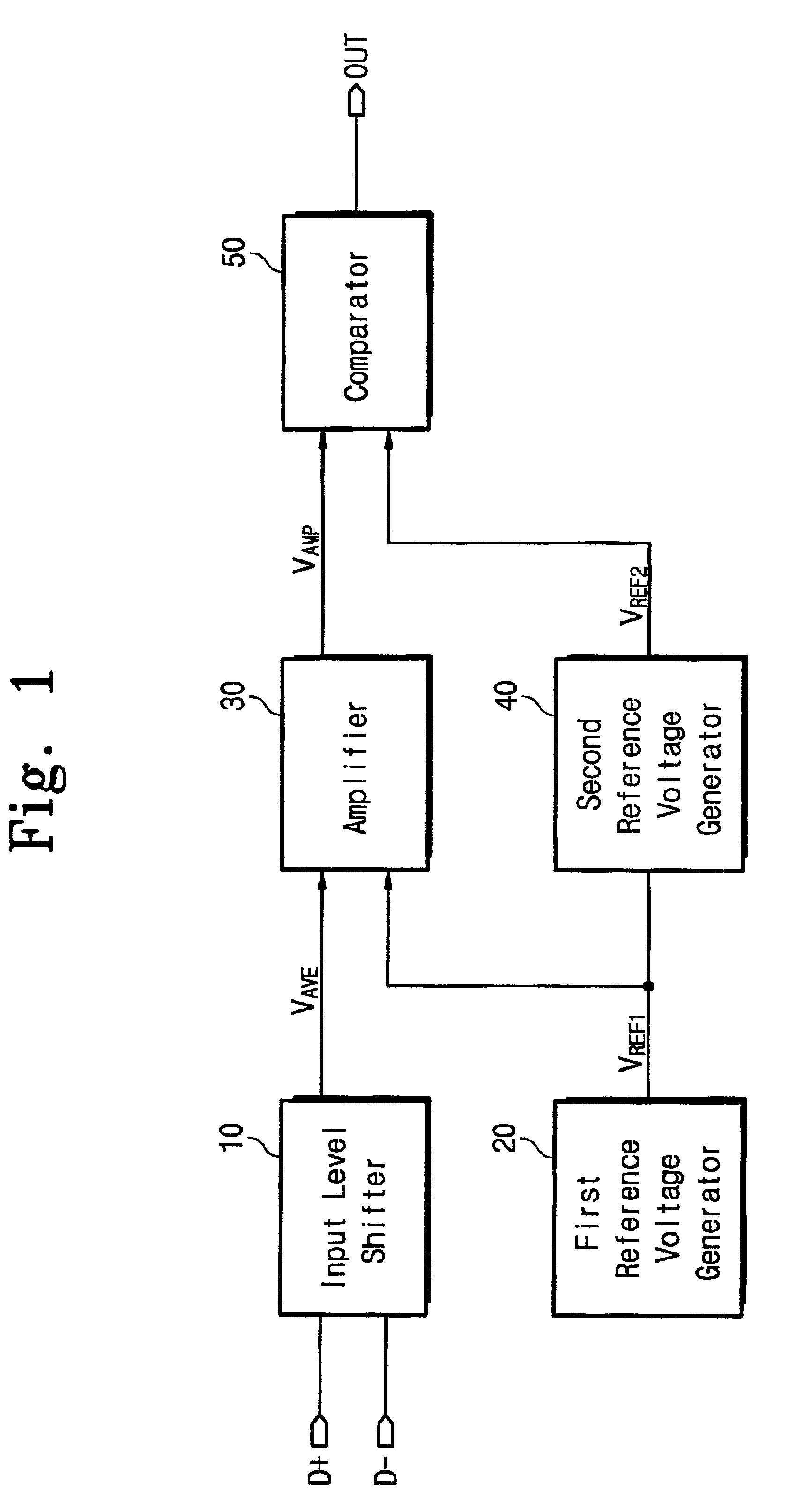

Squelch detection circuit

InactiveUS6859645B2Easy to useEfficient detectionOscillations generatorsTransmissionVoltage generatorAudio power amplifier

Disclosed is a transmission envelope detector referred to a squelch detection circuit for effectively detecting an element of transmission data in a high speed serial data transmission system. The squelch detection circuit of the invention includes a differential input level shifter, a first reference voltage generator, an amplifier, a second reference voltage generator, and a comparator. The squelch detection circuit can detect whether the transmission data is a noise or signal element even at a cross point of the transmission data, resulting in achieving stable data transmission.

Owner:SAMSUNG ELECTRONICS CO LTD

Water sky line detection method based on gradient saliency

The invention relates to a water sky line detection method based on gradient saliency. The method comprises steps as follows: a frame image is acquired by an optical imaging instrument, and if the image is a color image acquired by an ordinary camera, the image is subjected to standardization processing, and a 24-bit RGB (red green blue) color image is obtained; if the image is a gray image acquired by an infrared imaging instrument, the image is subjected to standardization processing, and an 8-bit gray image is obtained; the obtained standardized image is subjected to Gaussian downsampling and the like. A gradient magnitude matrix and a gradient direction matrix of the image are calculated respectively according to the type of the image acquired by the optical imaging instrument, all gradient information of an original image is reflected in the result, and accuracy of the water sky line detection result is guaranteed. Line segment detection based on a region growing algorithm is performed sequentially from high to low according to the gradient saliency, and the problem of severe noise interference due to the fact that gradient information is directly used for detection is solved.

Owner:HARBIN ENG UNIV

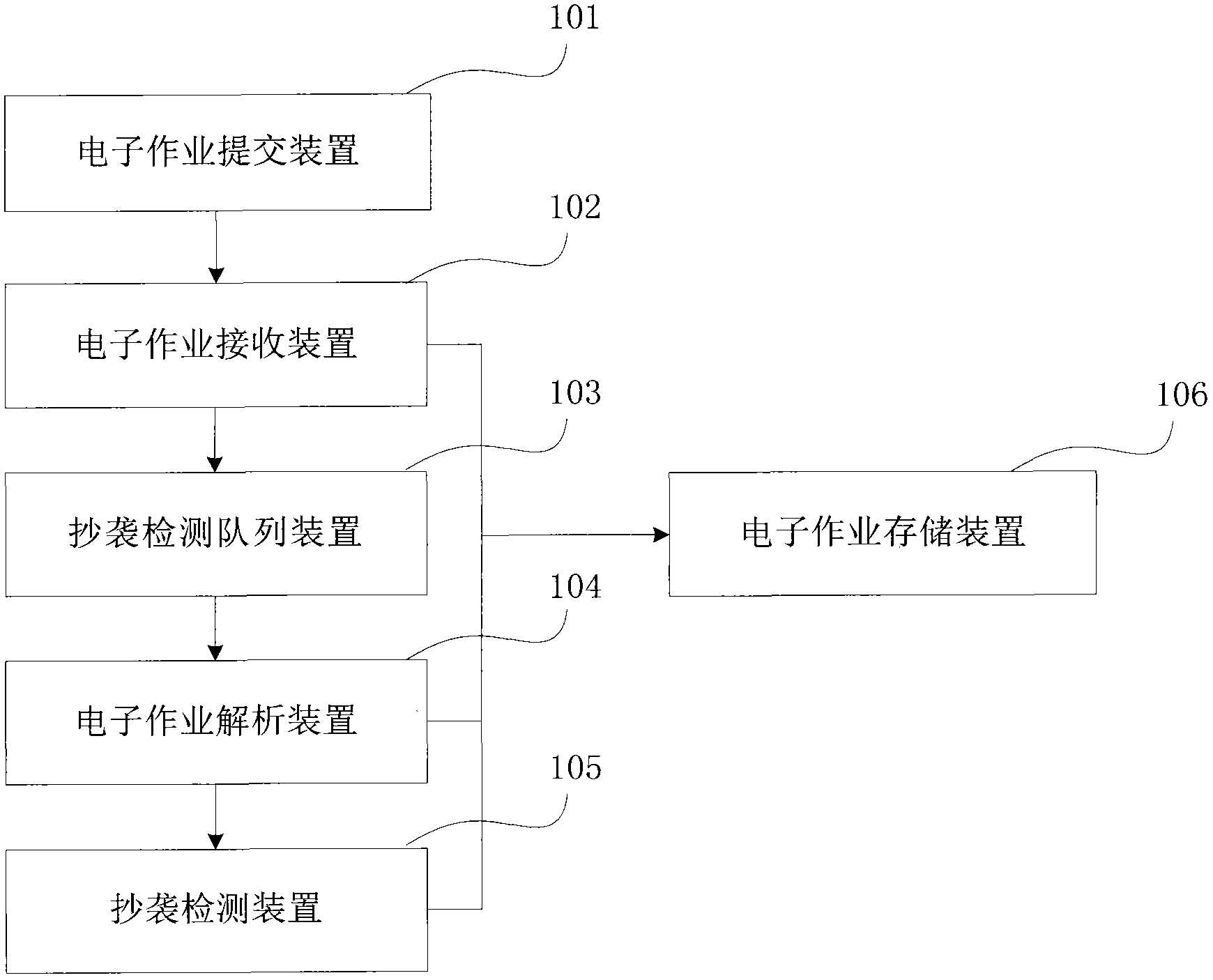

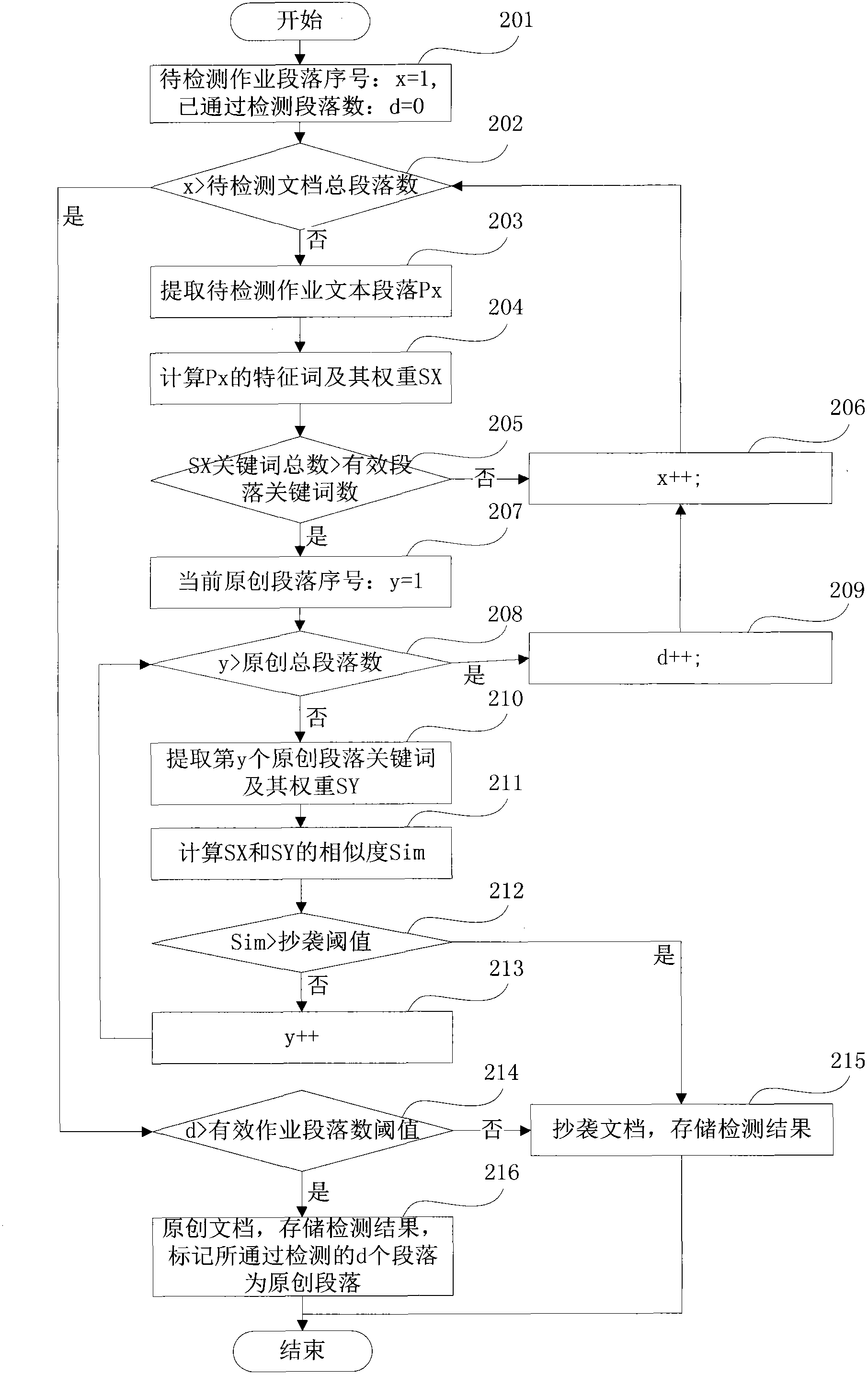

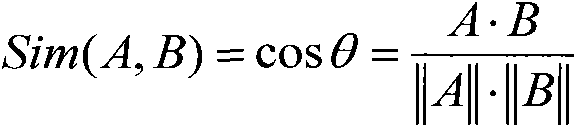

Electronic homework plagiarism preventing system and method based on paragraph plagiarism detection

InactiveCN103678528AResolve attributionSolve paralysisNatural language data processingSpecial data processing applicationsPlagiarism detectionComputer science

The invention discloses an electronic homework plagiarism preventing system and method based on paragraph plagiarism detection. The electronic homework plagiarism preventing system comprises an electronic homework submitting device, an electronic homework receiving device, a plagiarism detecting queue device, an electronic homework analyzing device, a plagiarism detecting device and an electronic homework storage device. The method includes: the electronic homework receiving devices receives electronic homework submitted through the electronic homework submitting device and adds the same into the plagiarism detecting queue device; the plagiarism detecting queue device detects plagiarism by using paragraph as the detecting unit and combining effective paragraph judging. The method using paragraph as the detecting unit and combining a queue mechanism for plagiarism detection has the advantages that system efficiency and stability are increased while the electronic homework polarizing multiple electronic homework can be judged, the attribution of the original homework can be judged, and plagiarism prevention can be achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Inflight ice detection system

InactiveUS20080110254A1Efficient discriminationSimple systemDe-icing equipmentsInstrumentsElectrical conductorSurface mounting

A dual channel inflight ice detection system to detect ice accretion on an aircraft surface by illuminating an ice collecting surface mounted on an aircraft with linear polarized light. The backscattered light is acquired in two light conductors one with polarization sensitivity aligned to the transmitted light and the second with polarization sensitivity orthogonal to the first. The presence of ice is determined by the change in the ratio of light intensities in the two light conductors.

Owner:SWAN INT SENSORS

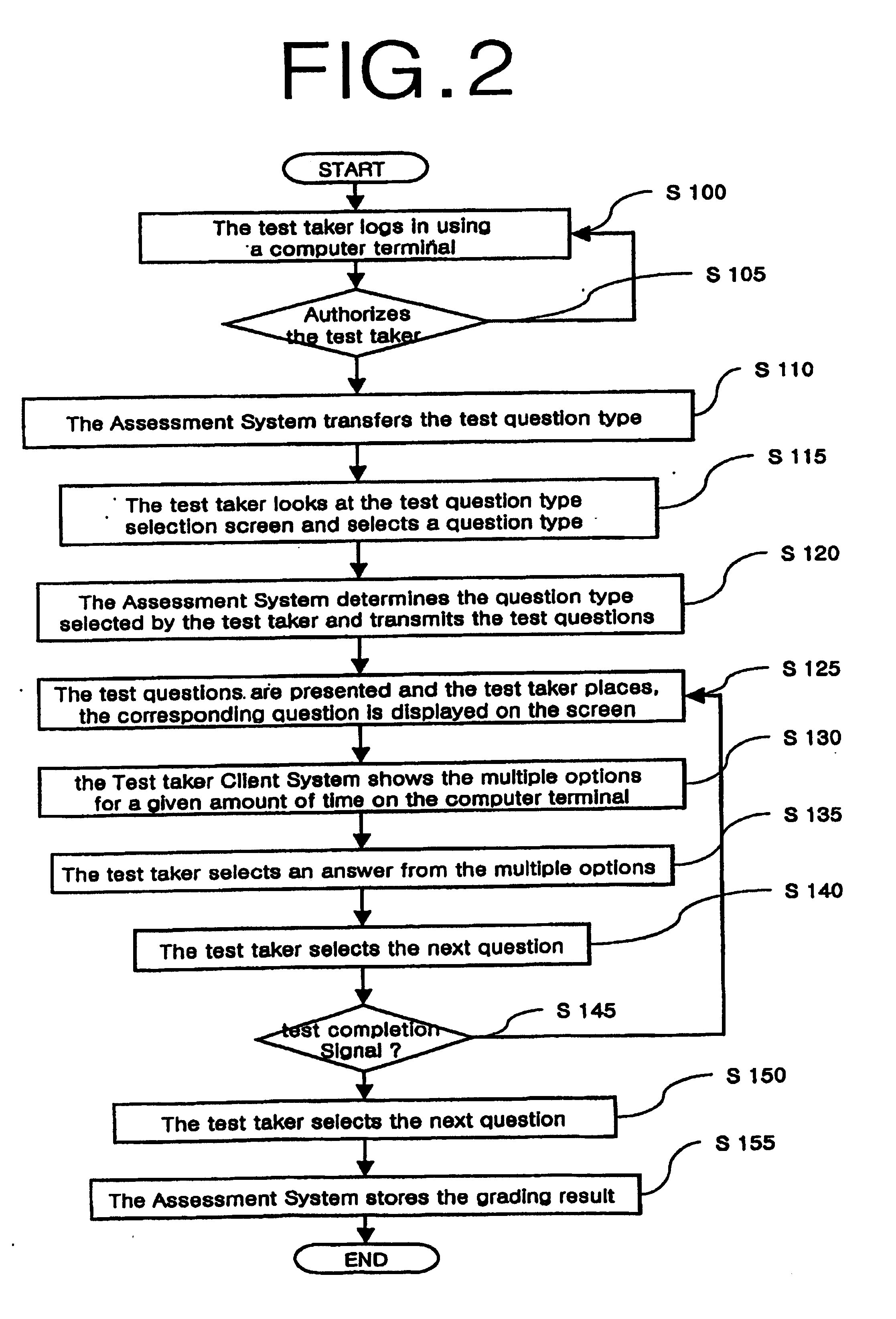

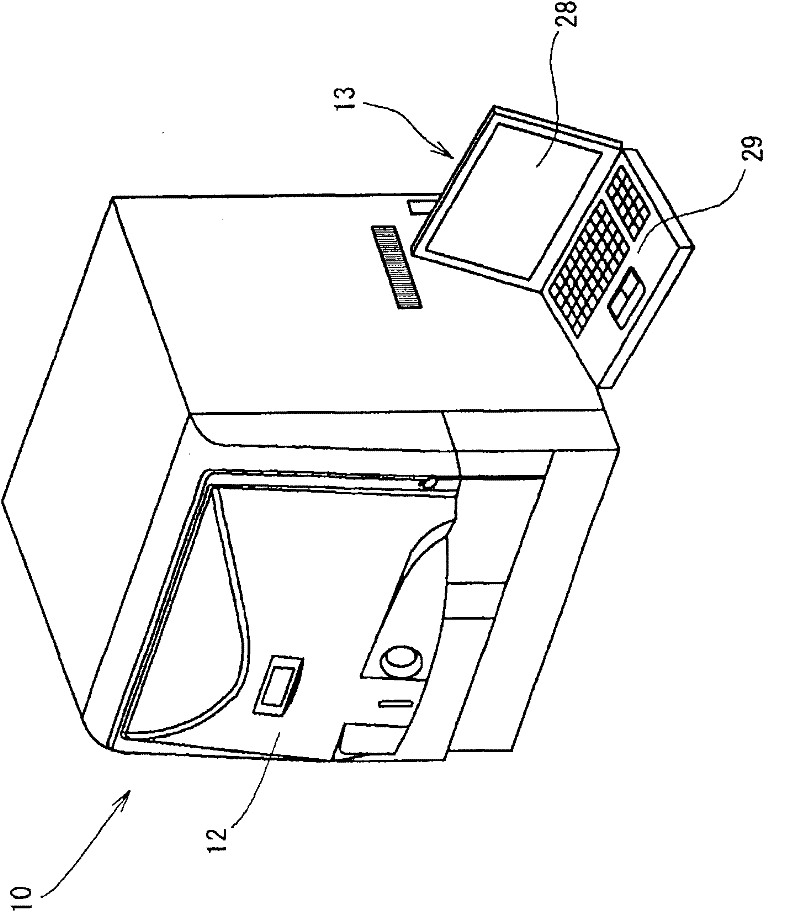

Modified multiple-choice testing system using computer and the method of same

InactiveUS20060088811A1Efficient discriminationAssess the test takers' abilityData processing applicationsElectrical appliancesTest questionChoice test

The present invention relates to a modified multiple choice testing system using the computer and the method of the same. The test questions are displayed on the screen without the options. The options of the question are presented on the screen contingent upon the student's mouse click. They remain on the screen for a pre-determined duration. The student is allowed to make a selection within that time period. When the time is over, the options disappear from the screen and the test question type test taker can no longer answer the question. This invention will serve as an accurate and reliable assessment tool.

Owner:PARK JOO YONG

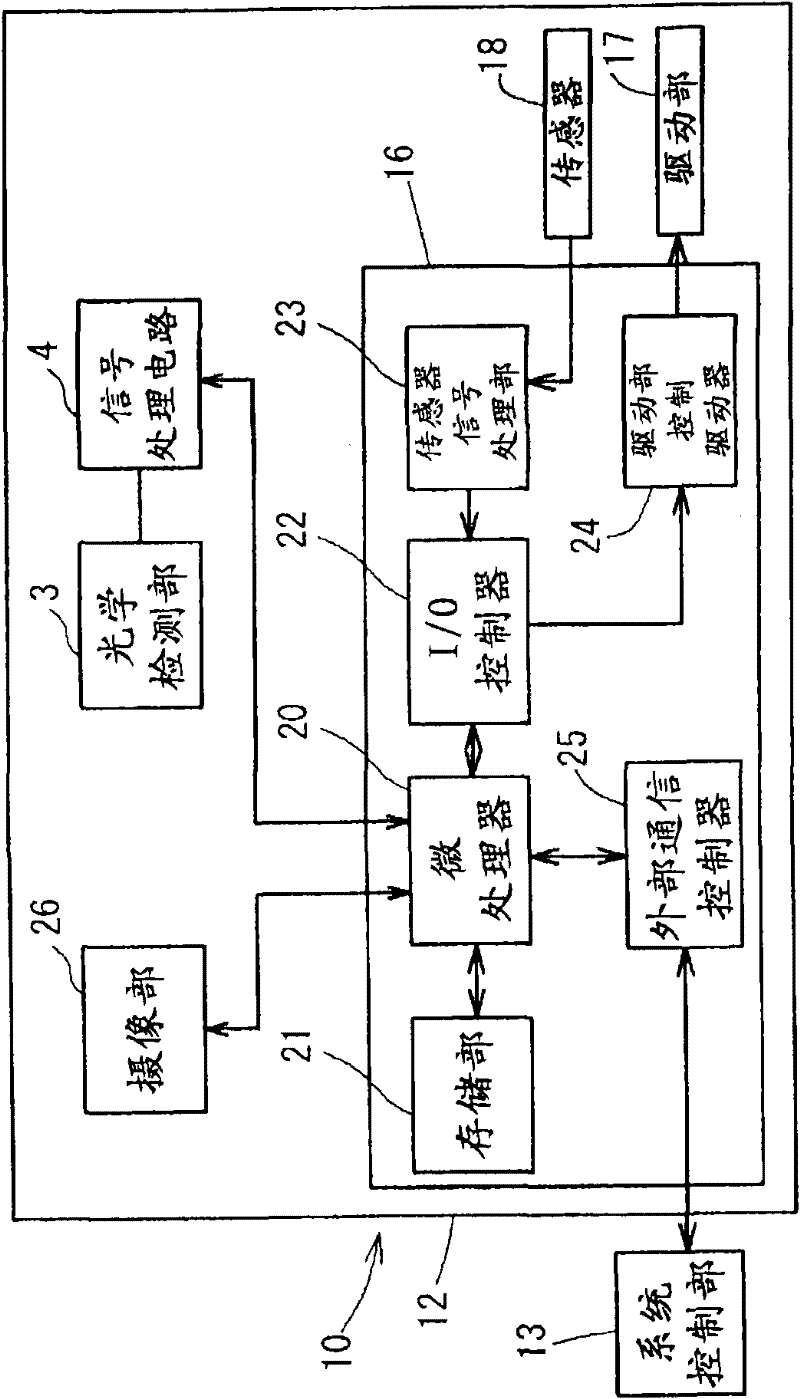

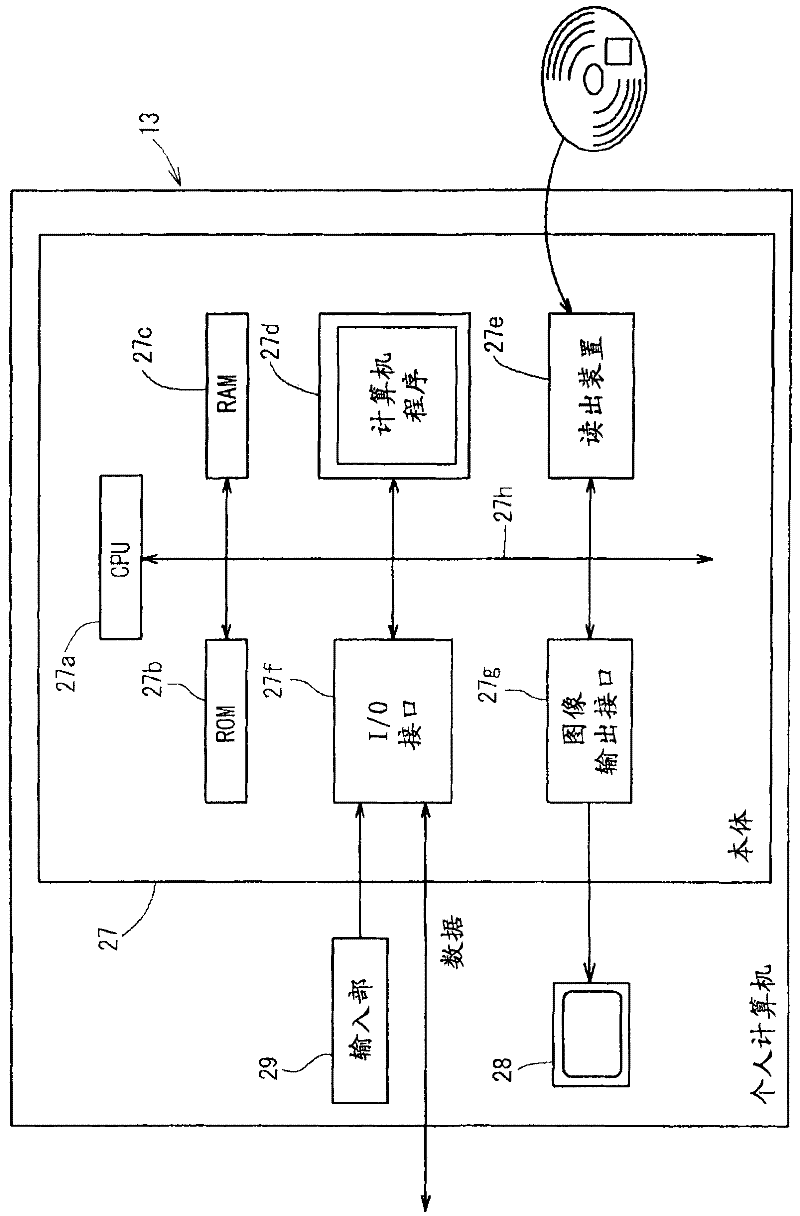

Cell analyzing apparatus and cell analyzing method

InactiveCN102053057AImprove reliabilityAccurate identificationIndividual particle analysisAnalysis methodComputer science

A cell analyzing apparatus, comprising: a parameter obtaining section for obtaining a characteristic parameter from a cell in a measurement sample; an imaging section for capturing an image of the cell in the measurement sample; an analyzing section for counting a cell in which the characteristic parameter meets a predetermined requirement among the cells in the measurement sample as a counting target and generating output data based on a counting result; a display section for displaying an image of the cell meeting the predetermined requirement and the output data; and an input section for receiving an instruction to specify the image displayed on the display section, wherein the analyzing section excludes a cell relevant to the specified image from the counting target and regenerates the output data is disclosed. A cell analyzing method is also disclosed.

Owner:SYSMEX CORP

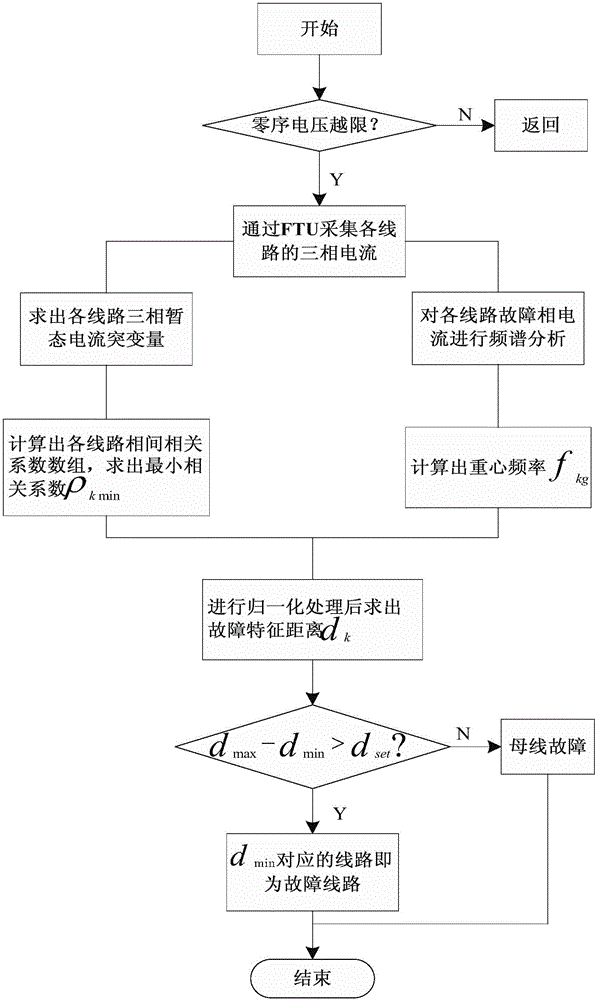

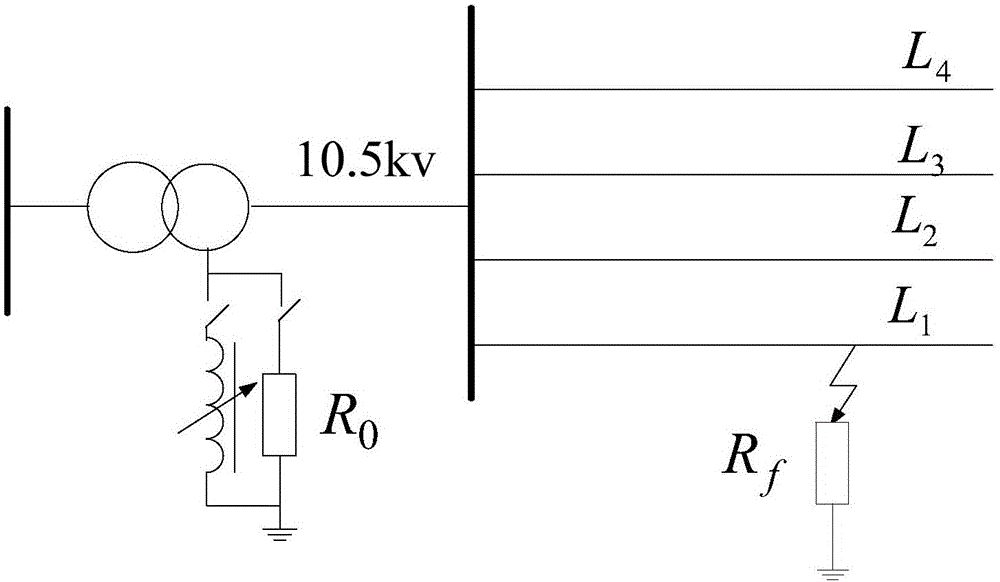

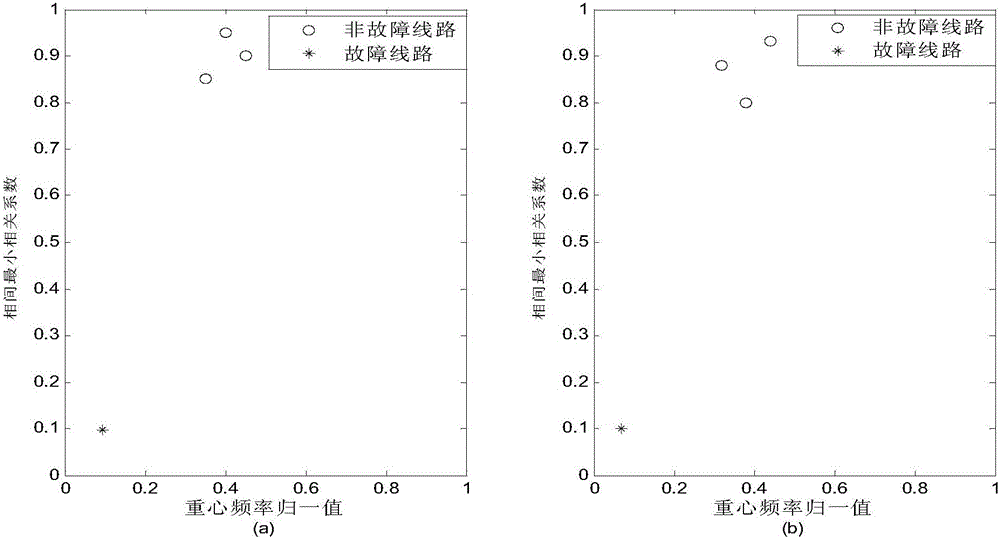

Fault line selection method based on phase current transient characteristic

ActiveCN105974264AEfficient discriminationLine selection is validFault locationPhase currentsCorrelation coefficient

The method discloses a fault line selection method based on a phase current transient characteristic. The method comprises the following steps of S1, continuously measuring a distribution line outlet zero sequence voltage value and determining whether a power distribution network generates a grounding fault; S2, processing collected phase current data, extracting a transient phase-current sudden-change amount of each line, and carrying out interphase pairwise correlation analysis so as to obtain an interphase minimum correlation coefficient rhok min; S3, carrying out spectral analysis on each line fault phase current and calculating a gravity frequency fkg; S4, carrying out normalization processing on a fault characteristic quantity and acquiring normalization values, establishing a two-dimensional coordinate system based on the normalization values, and determining each line fault characteristic coordinate point; and calculating a fault characteristic distance dk between each line fault characteristic coordinate point and a reference point (0, 0) so as to determine a bus fault. The method possesses advantages that a principle is simple; practicality is high; an anti-interference capability is good; accuracy is high and so on.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

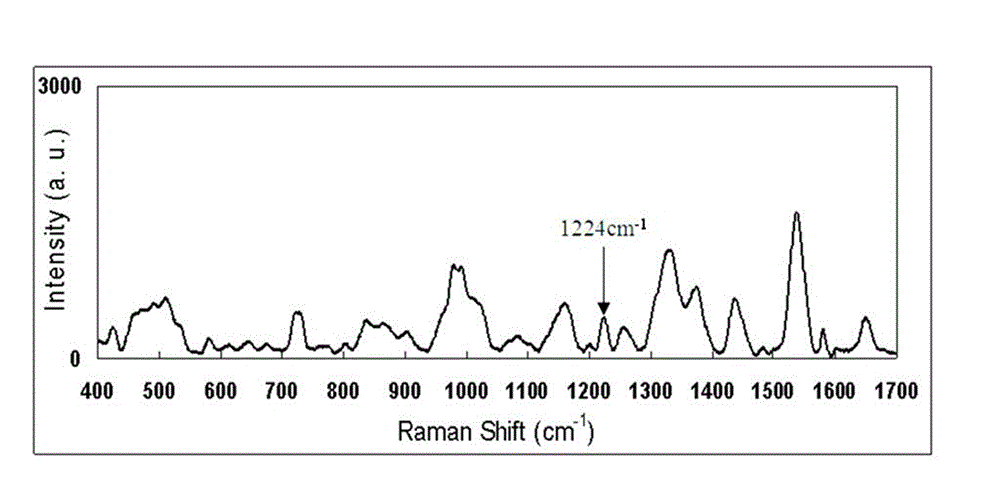

Laser-Raman spectrum method for rapidly detecting content of Sudan red I in chili powder

InactiveCN104359894AEfficient discriminationProtection of rights and interestsRaman scatteringFood safetyLaser raman

The invention discloses a laser-Raman spectrum method for rapidly detecting the content of Sudan red I in chili powder, belonging to the technical field of food safety detection. The method comprises the following steps: (1) determining a characteristic Raman peak and a peak movement range; (2) drawing a Sudan red I standard curve; (3) preparing a to-be-detected sample solution; (4) detecting the to-be-detected sample solution by a Raman spectrometer to obtain a Raman spectrum of a sample; (5) carrying out qualitative judgment: when the Raman spectrum of the sample has an obvious characteristic Raman peak, judging that the chili powder contains the Sudan red I; and (6) calculating the content of the Sudan red I in the sample according to the Sudan red I standard curve and the Raman spectrum of the normalized sample. According to the laser-Raman spectrum method, the qualification is accurate, the operation is simple, and strong professional backgrounds are not needed; readings are visual, the detection speed is high, the sensitivity is high, and the detection limit can be up to 5mg / kg-50mg / kg; and the cost is low, unqualified foods can be effectively identified, and thus the rights and interests of consumers are protected.

Owner:河北省食品检验研究院 +1

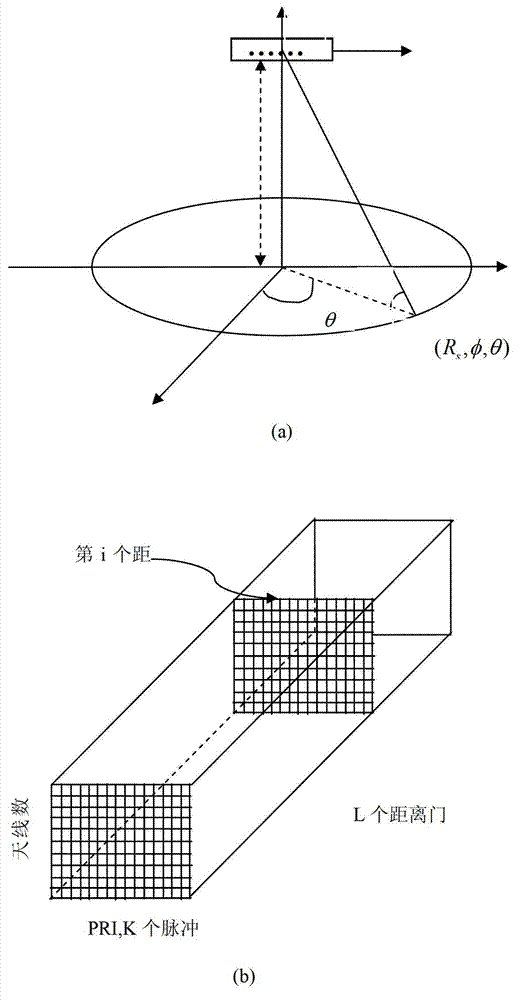

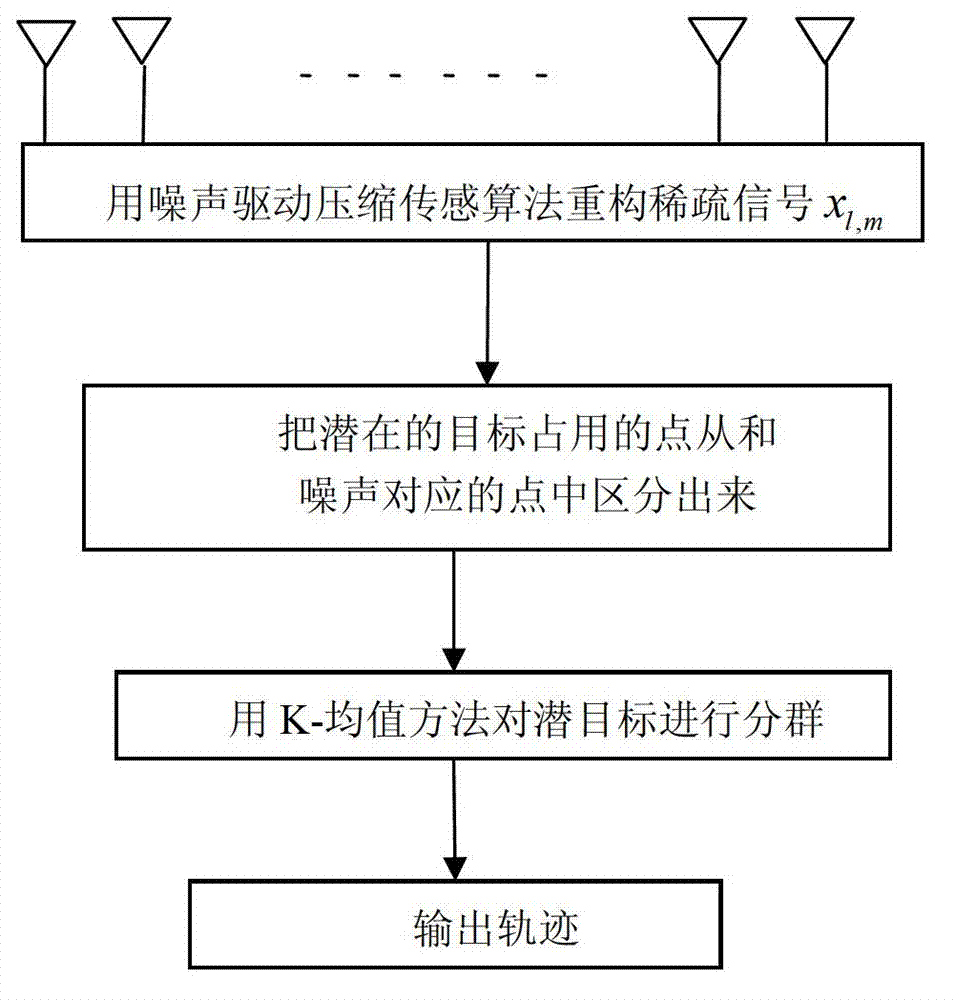

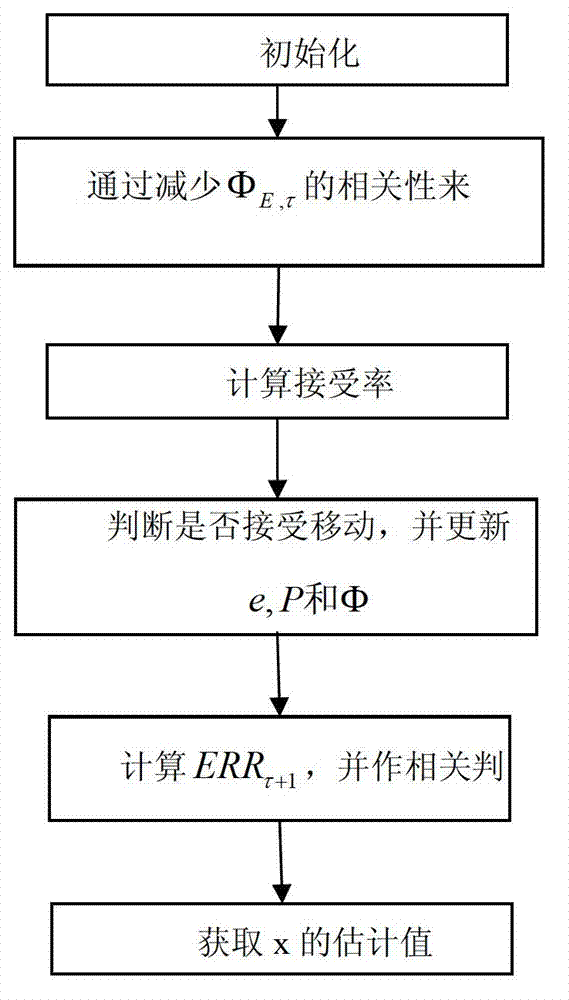

Compressed sensing-before testingtracking method based on phased array radar system

InactiveCN103091673AEffective trackingEfficient discriminationRadio wave reradiation/reflectionContinuous scanningIlluminance

The invention discloses a compressed sensing-before testing tracking method based on a phased array radar system. The compressed sensing-before testingtracking method based on the phased array radar system comprises the following steps: (1) using noise-driving compressed sensing algorithm to reform and characterize sparse signals of a sparse scenario, (2) separating points occupied by potential objectives from points corresponding to noise, (3) hiving off the potential objectives through a k-means clustering method, (4) and outputting tracks of the test objectives. The compressed sensing-before testingtracking method based on the phased array radar system adopts compressed sensing technology and reforms the whole radar scenario for each distance door in a series of continuous scanning. The compressed sensing-before testingtracking method based on the phased array radar system can not only track in real time in the continuous scanning, but also track in each scanning in real time on the basis of information acquired from multiple illumination intensity. The noise-driving compressed sensing algorithm can effectively reform the radar sparse scenario without changing the existing hardware system due to the optimization of transmission waveform. On the other hand, timely tracking in each scanning can acquire information based on the multiple illumination intensity, and therefore a real objective is effectively identified from false objectives and the clutters.

Owner:XI AN JIAOTONG UNIV

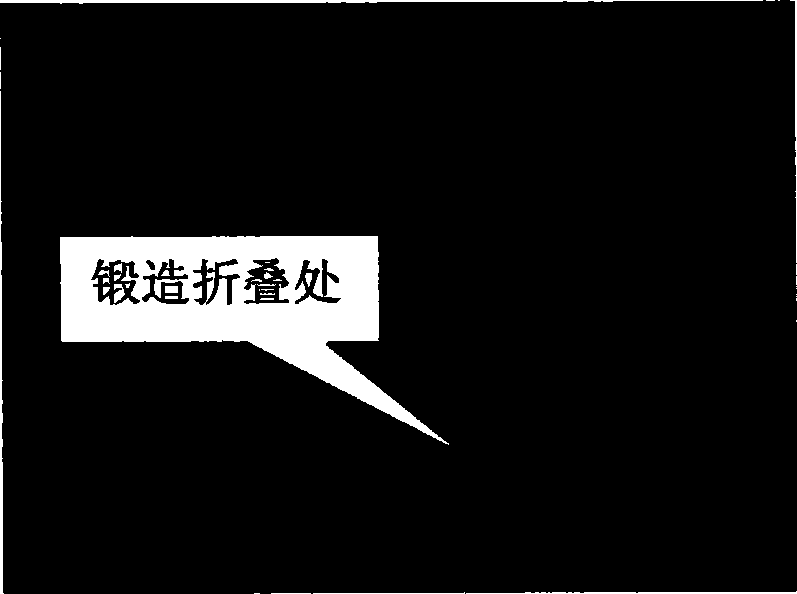

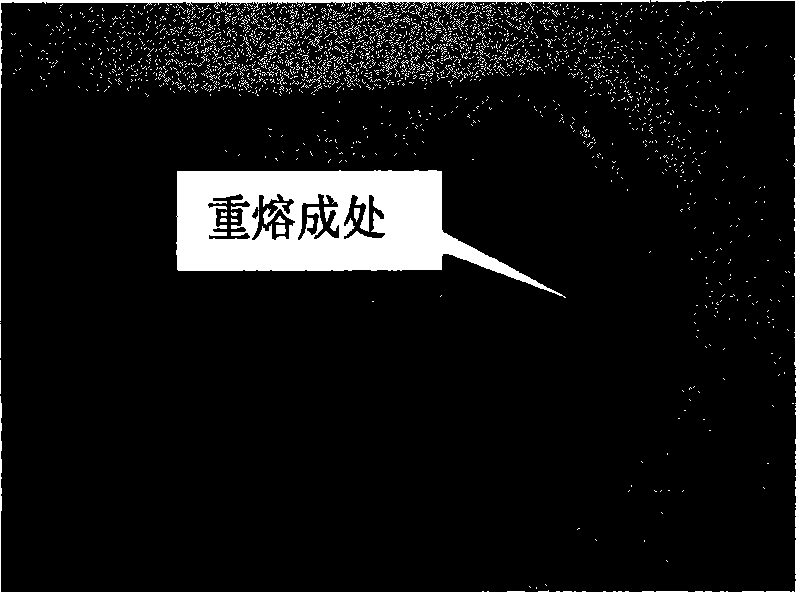

Blue anodic oxidation process for titanium alloy

InactiveCN101413140AIdentify quickEffective discriminationSurface reaction electrolytic coatingLayer removalBiological activation

The invention relates to a process for oxidizing a titanium alloy blue anode, which comprises the following steps: deoiling, cold water washing, hardened layer removal, cold water washing, activation, cold water washing, titanium alloy anodization, cold water washing, deionized water washing, transflective displaying, deionized water washing, hot water washing, drying, and inspection. The process has the advantage of distinguishing the alloy defect and processing defect on the surface of a titanium alloy part fast and effectively. The main representation comprises that after finishing the processes of the anodization and the transflective displaying, the surface of the part has a steel gray background, and the parts where defects exist present different colors; compared with a defect picture, the defects of forging fold, inclusion, overheating, partial supercooling, partial alpha phenomenon, beta concentration area, grinding ablation and the like of the parts due to metallurgy or processing reasons can be judged more clearly and reliably. Through detection, the result shows that the process is stable and reliable and has the advantage that the process can not replaced by the prior process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

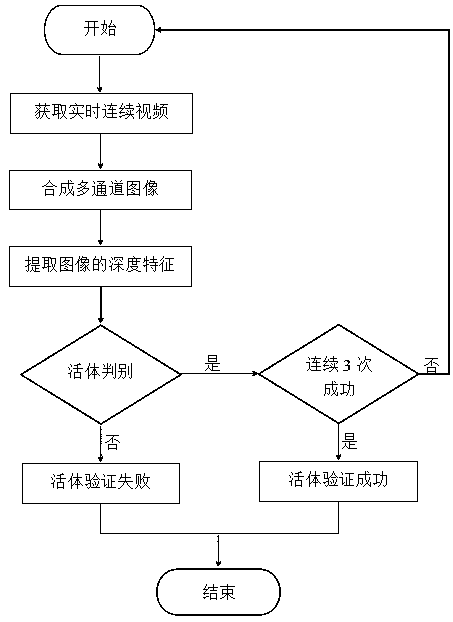

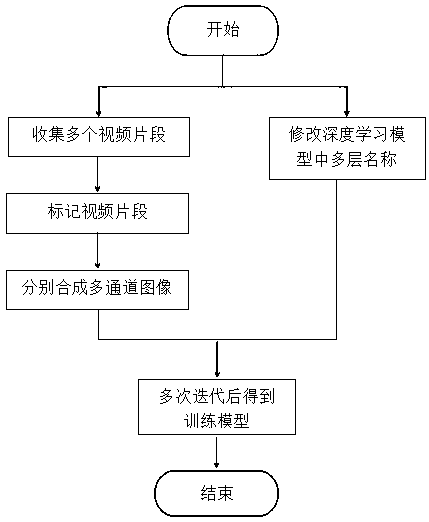

Real person verification method via videos

InactiveCN107944416AEfficient discriminationSolve the problem of fake facesSpoof detectionPattern recognitionIn vivo

The invention discloses a real person verification method via videos Videos are collected continuously, continuous video frames in a video stream are converted into single-channel images, the single-channel images are combined into one multi-channel image, a trained deep learning model is used to process the synthesized multi-channel image, depth characteristics are extracted, an in-vivo determination method is used to determine whether there is a real person in the image, and a determination result is output. Thus, the real person can be determined effectively. The in-vivo is detected onlinevia a deep learning manner, and the problem that the face is faked via a picture, video or 3D model can be solved effectively.

Owner:CHENGDU REMARK TECH CO LTD +1

Method and apparatus for gamma ray detection

InactiveUS6906559B2High sensitivityImprove spatial resolutionElectric analogue storesElectronic switchingHodoscopeRecoil electron

A high sensitivity, three-dimensional gamma ray detection and imaging system is provided. The system uses the Compton double scatter technique with recoil electron tracking. The system preferably includes two detector subassemblies; a silicon microstrip hodoscope and a calorimeter. In this system the incoming photon Compton scatters in the hodoscope. The second scatter layer is the calorimeter where the scattered gamma ray is totally absorbed. The recoil electron in the hodoscope is tracked through several detector planes until it stops. The x and y position signals from the first two planes of the electron track determine the direction of the recoil electron while the energy loss from all planes determines the energy of the recoil electron.

Owner:NOVA R&D

User authentication method and device

InactiveCN106919821AGuaranteed accuracyGuaranteed validityDigital data authenticationValidation methodsUser authentication

The invention discloses a user authentication method and device. The method comprises the following steps of: providing a video, audio or audio / video with emotional characteristics through a user interface; receiving feedback operation information, aiming at the video, audio or audio / video, of a user, wherein the feedback operation information represents operation information, for a discrimination result of the emotional characteristics in the video, audio or audio / video, of the user; judging whether the discrimination result represented by the feedback operation information is correct or not; and if the judging result is positive, indicating that the authentication passes. According to the method, the emotional characteristics which can be perceived and deduced by natural persons are used as basic differences for discriminating the natural persons and machines. The authentication in the method represents analysis and deduction for emotions displayed in the video, audio or audio / video, so that the real users can carry out thought analysis according to the displayed emotional characteristics so as to discriminate the correct options, and the machines cannot correctly discriminate the correct options. The authentication method is capable of ensuring the correctness and effectiveness of the authentication process.

Owner:ALIBABA GRP HLDG LTD

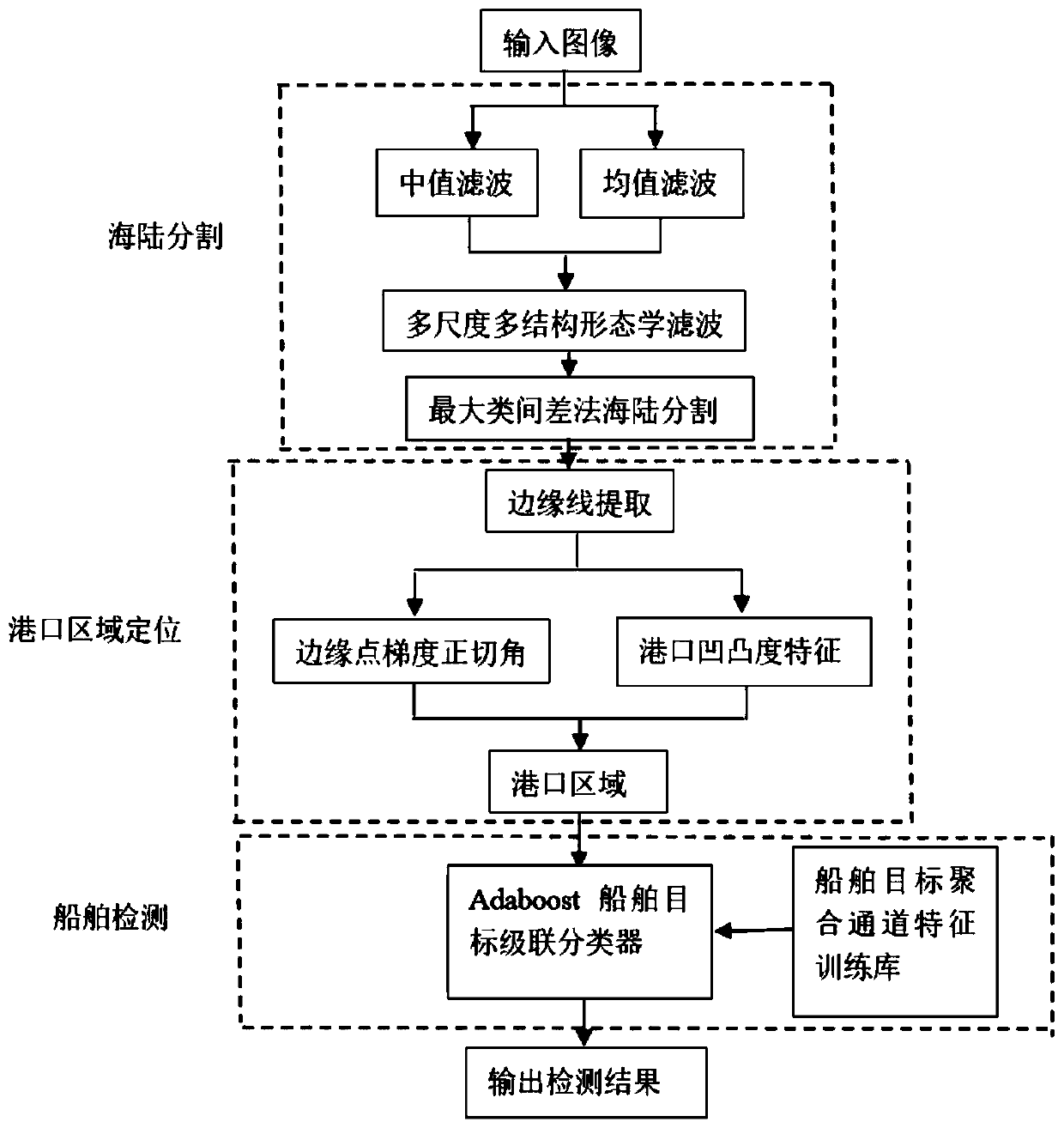

A docking ship detection method based on edge line analysis and aggregation channel characteristics

ActiveCN109815807AEfficient discriminationDetection speedCharacter and pattern recognitionPrior informationMorphological filtering

The invention provides a docking ship detection method based on edge line analysis and aggregation channel characteristics. The method comprises the following steps: firstly, realizing sea-land segmentation based on multi-scale multi-structure element morphological filtering, defining an edge point gradient tangent angle and port convexity characteristics by combining rectangular shape characteristics of a port in a remote sensing image to position the port, and obtaining a port region-of-interest set; and then, extracting aggregation channel characteristics of the ship target, constructing aship sample training library based on the aggregation channel characteristics, finishing training of a classifier by utilizing an AdaBoost algorithm, and finishing final judgment and confirmation of the ship target by utilizing the trained classifier. According to the invention, the port can be quickly positioned from the large-scale remote sensing image; port positioning does not need to acquiregeographic prior information and perform a large amount of feature matching calculation, ship features are fully reflected by utilizing aggregation channel features, the problem of serious interference of the backgrounds of ports on ship detection is solved, various types of ships can be detected, and the application range is wide.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com