Corn threshing concave plate with adjustable grid intervals

A technology of corn threshing and grid spacing, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of bar round steel adjustment, high grain loss rate, high corn grain breakage rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

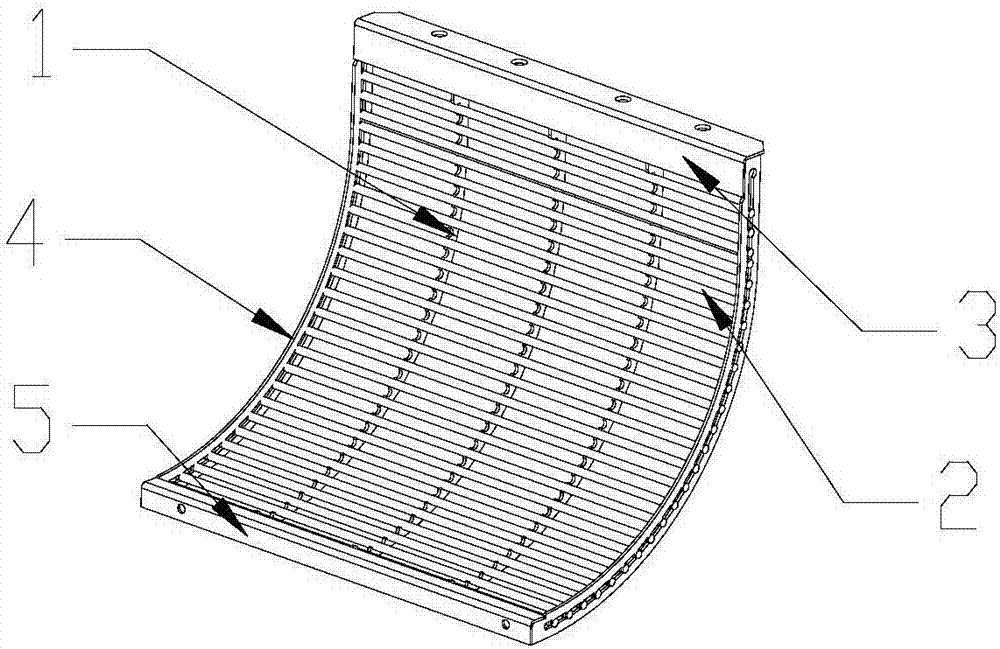

[0027] figure 1 Shown is an embodiment of the corn threshing concave plate with adjustable grid spacing in the present invention, the corn threshing concave plate with adjustable grid spacing includes grid round steel fixing mechanism 1, grid round steel 2, Upper connecting plate 3, two grid round steel chute plates 4 and lower connecting plate 5;

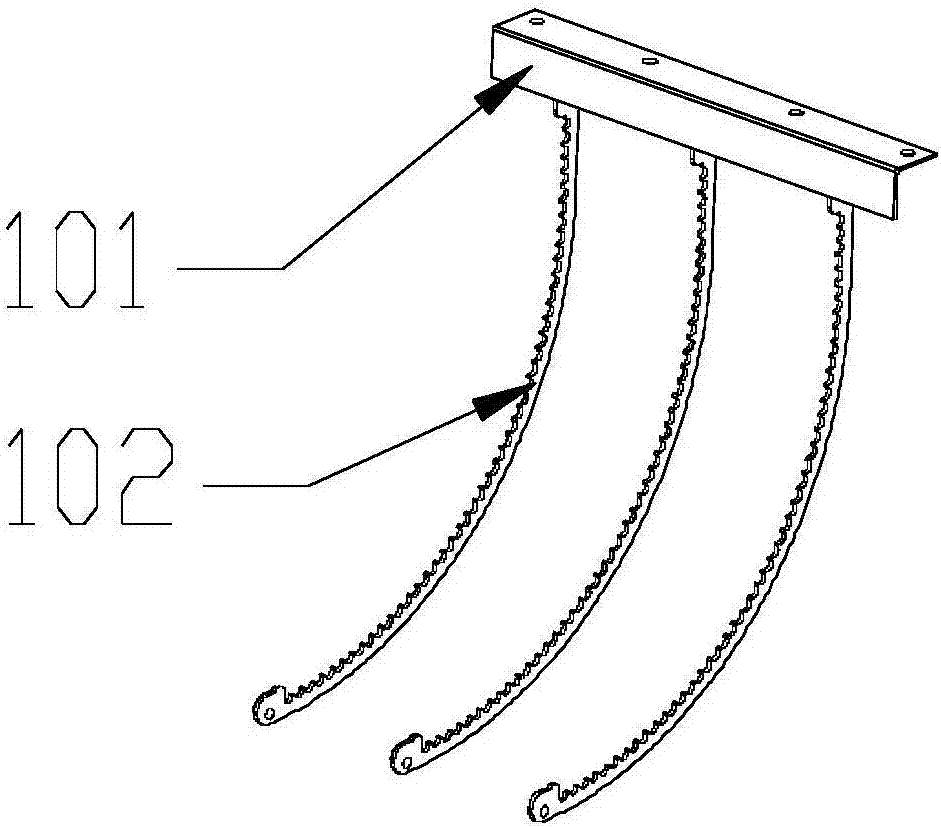

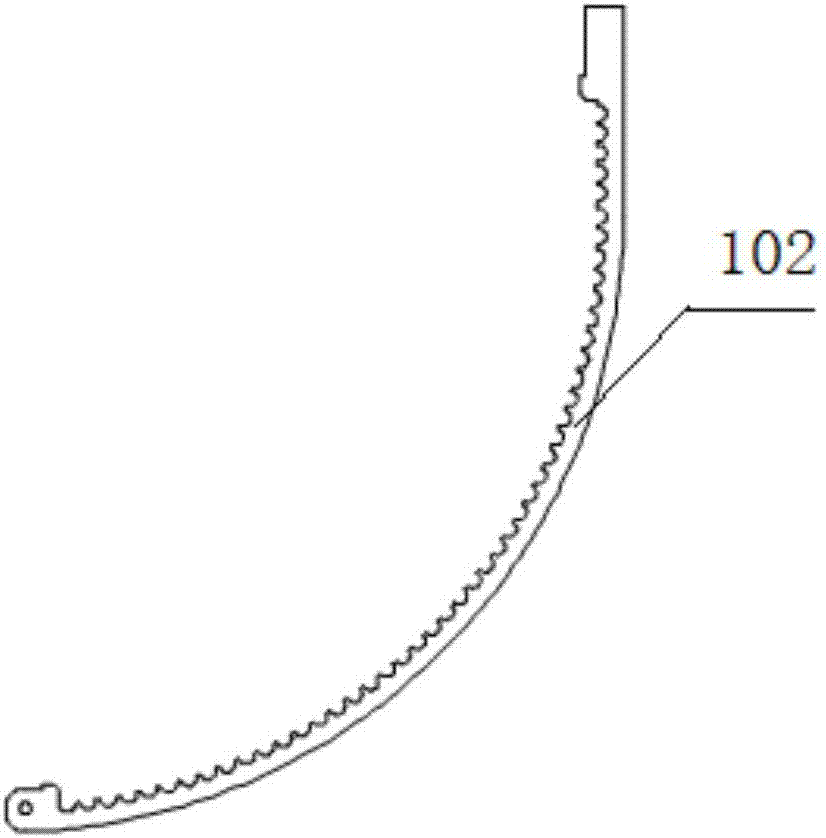

[0028] Such as figure 2 , 3 As shown in and 4, the grid round steel fixing mechanism 1 includes a connecting plate 101 and several fixing plates 102, and the upper end of the connecting plate 101 is detachably connected with the upper connecting plate 3; the upper end of the fixing plate 102 and the connecting plate 101 The lower end of the fixed plate 102 is fixedly connected, and the lower end of the fixed plate 102 has a hinge hole 103 to be hinged with the lower connecting plate 5, so that the grid round steel fixing mechanism 1 can rotate around the lower connecting plate 5; Shaped groove 104.

[0029] Such as Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com