Forklift motor stator processing tool and operation method thereof

A motor stator and forklift technology, which is applied in the field of forklift motor stator processing tooling, can solve the problems of complexity, many processes, and the inability to guarantee the roundness and concentricity of the motor stator core, so as to achieve fewer processing steps, improve coaxiality, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

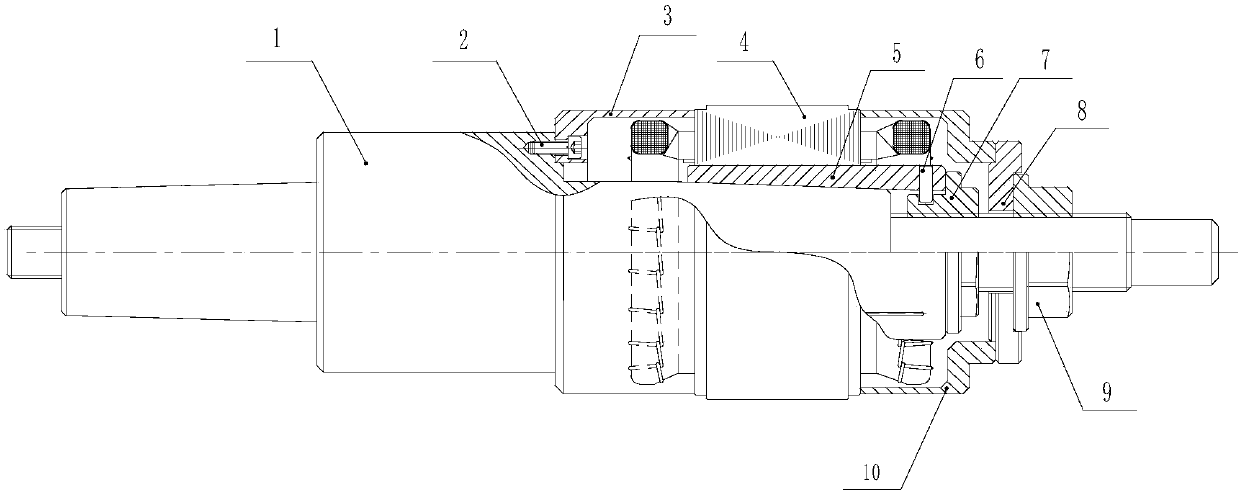

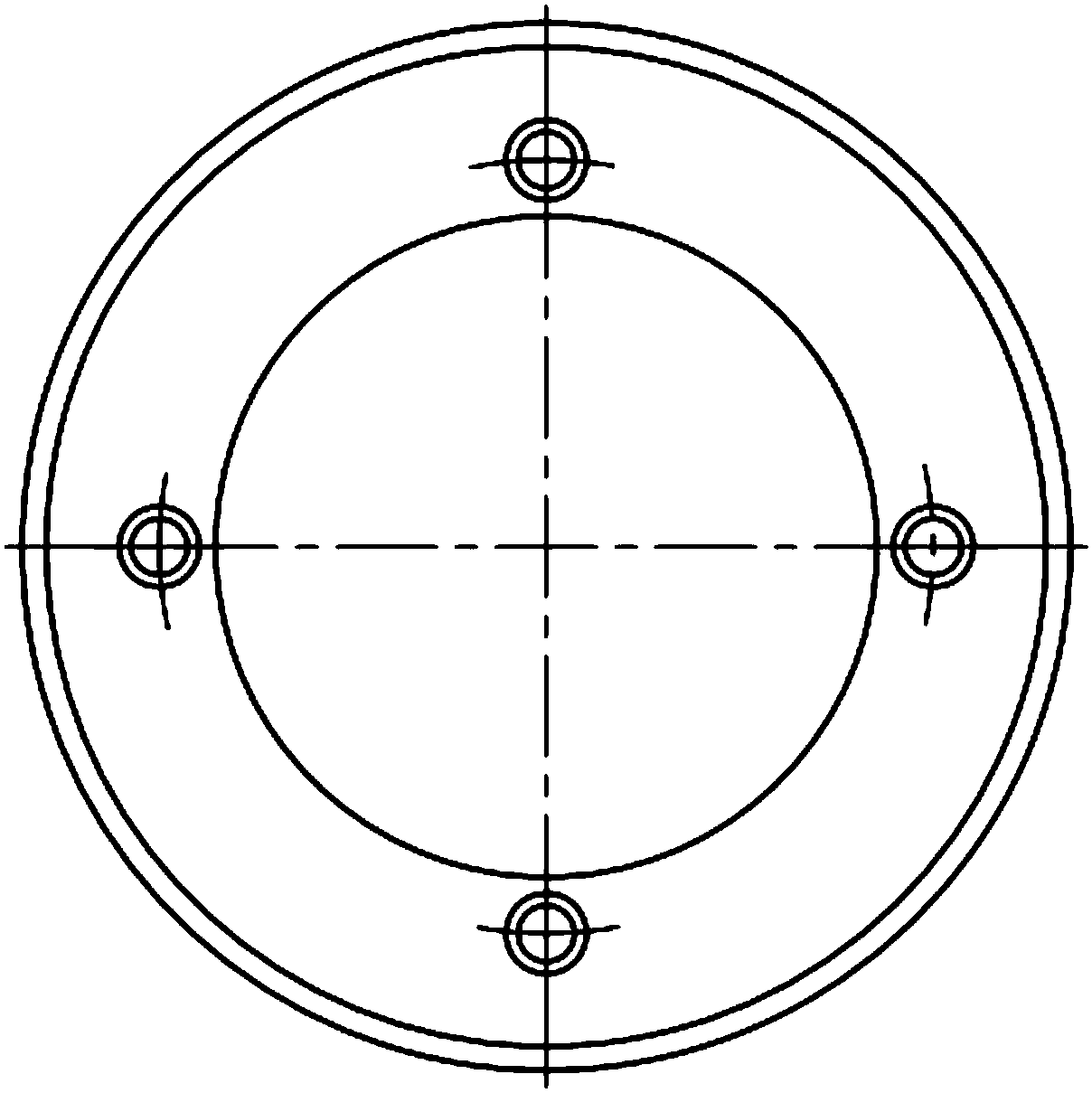

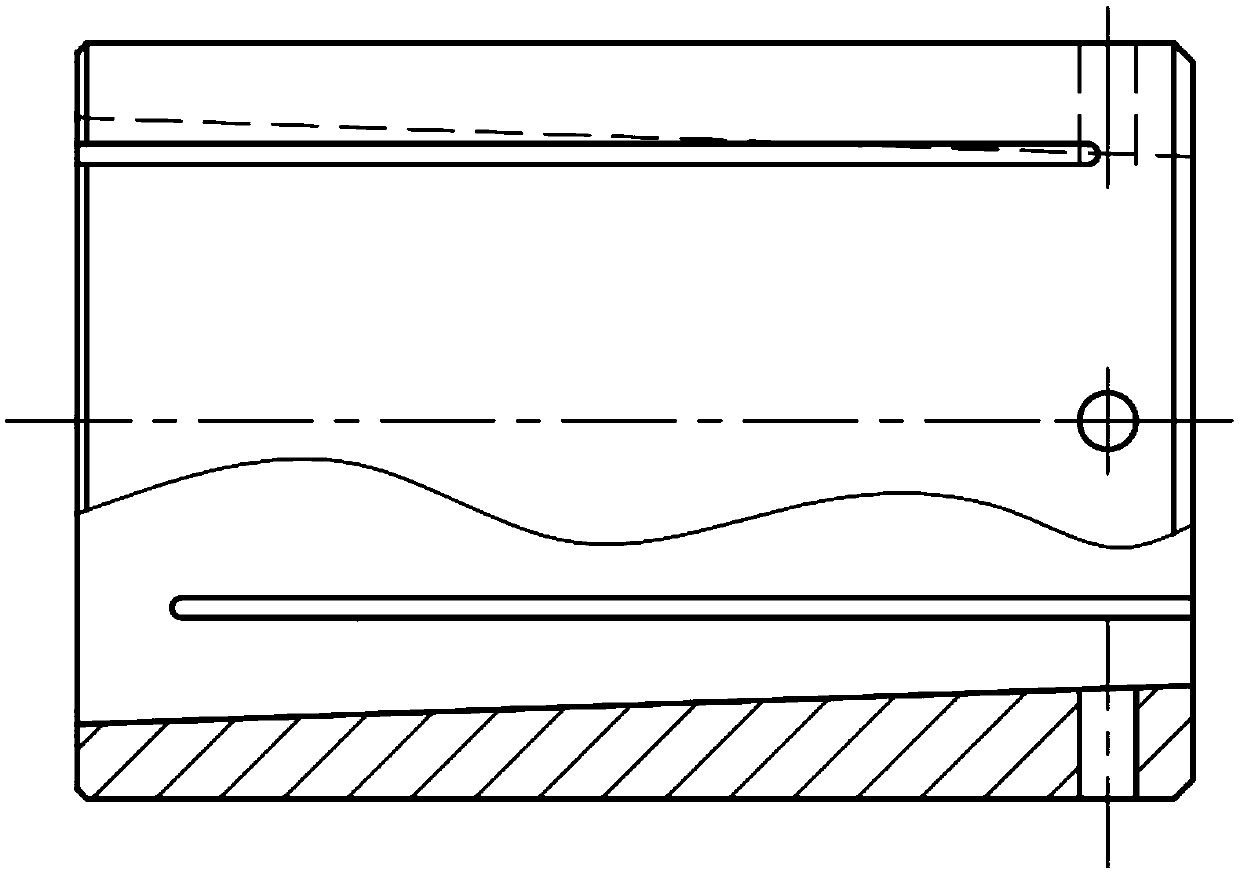

[0030] Figure 1 to Figure 8 It shows a specific embodiment of the present invention, a forklift motor stator processing tool and its operation method, including a mandrel 1, a hexagon socket head cap screw 2, a mold doubler plate 3, a winding stator core 4, an expansion sleeve 5, Cylindrical pin 6, left lock nut 7, mold backing plate 8, right lock nut 9 and mold pressure plate 10, the mold doubler plate 3 is a cylindrical structure and the mold doubler plate 3 passes through the inner hexagon The cylindrical head screw 2 is fixedly installed on the cylindrical positioning boss on the mandrel 1, the stator core 4 with winding is installed on the expansion sleeve 5 and the left end surface of the stator core 4 with winding is pushed against the right end surface of the mold doubler plate 3 , the expansion sleeve 5 is made of 40Cr material and the center of the expansion sleeve 5 is provided with a conical hole. There are two groups of rectangular strip cutting grooves evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com