Contour error on-line measuring device of non-circular pin-hole of piston

A contour error and detection device technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of piston special-shaped pin hole detection, etc., achieve high precision, wide application range, and meet the detection requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

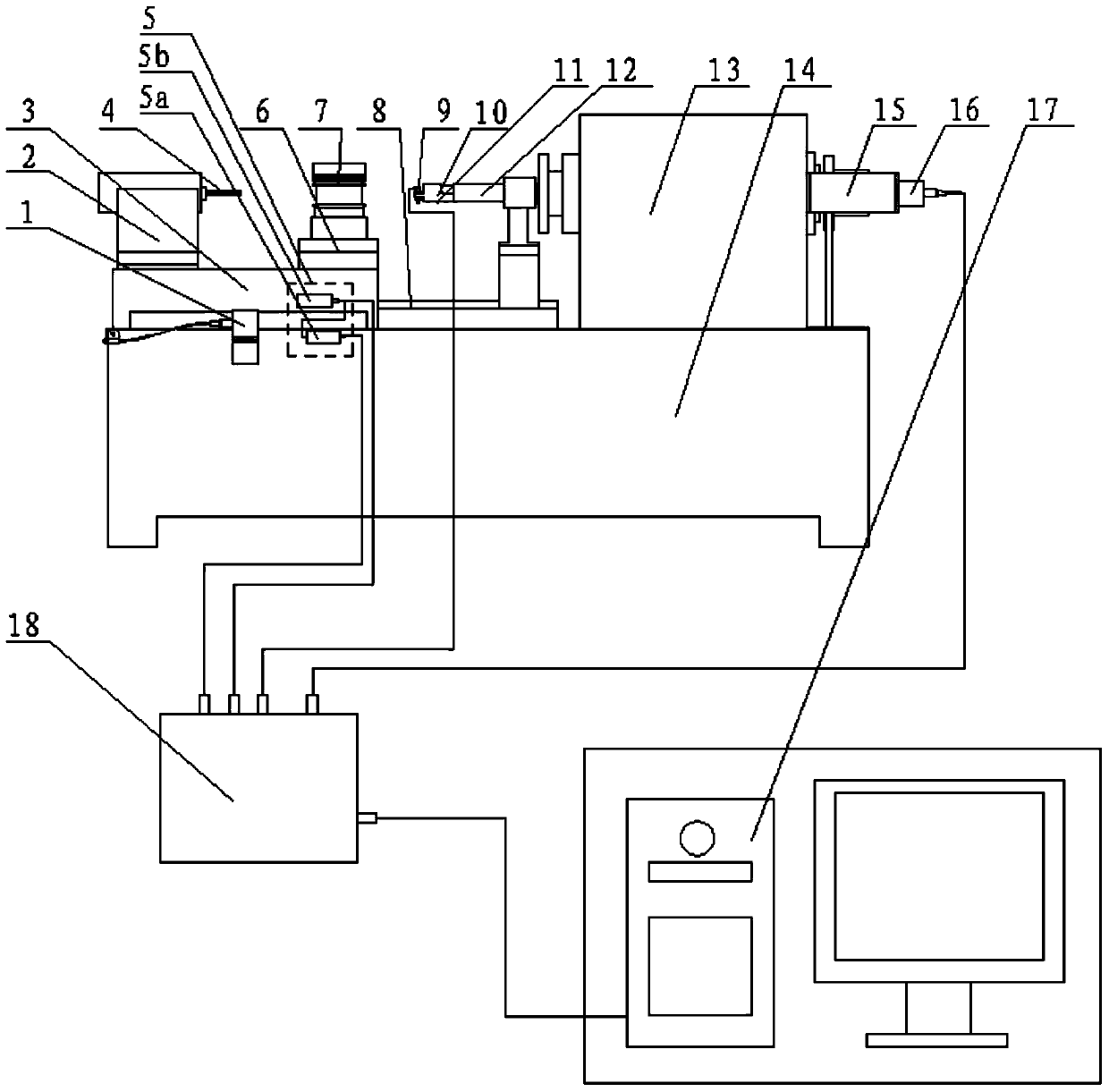

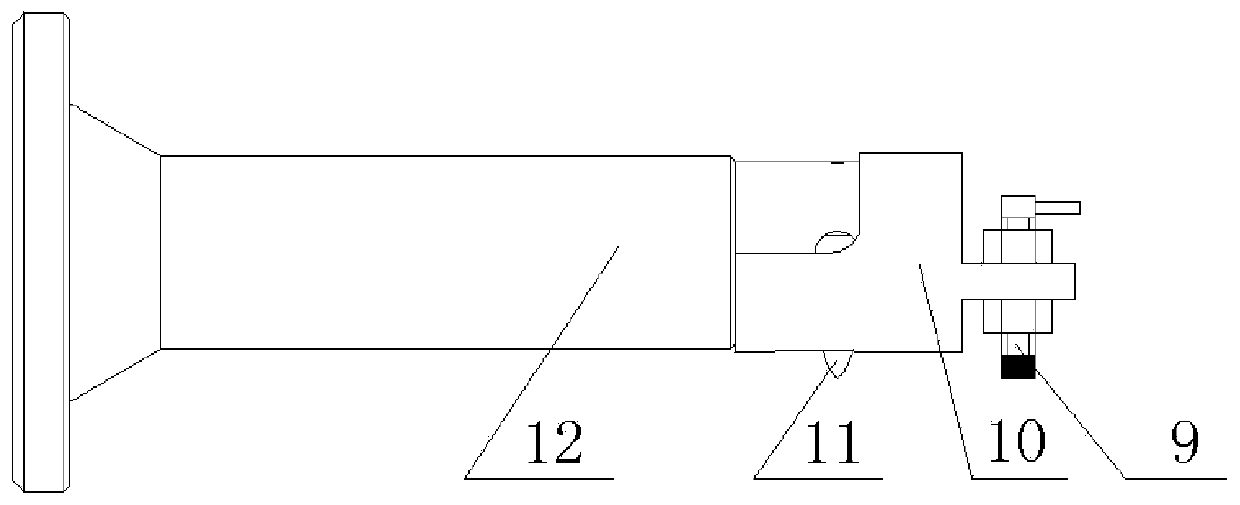

[0027] like figure 1 , figure 2 As shown, the device of the present invention includes a limit switch 1, a centering rod bracket 2, a supporting plate 3, a centering rod 4, an induction synchronizer 5, a clamping device 6, a guide rail 8, a measuring head 9, a measuring sleeve 10, and a measuring rod 12. Box body 13, machine tool base 14, encoder bracket 15, photoelectric encoder 16, computer 17, data acquisition card 18; guide rail 8 is horizontally fixed on one side of machine tool base 14, and supporting plate 3 is installed on guide rail 8 and can move horizontally along the guide rail 8, the centering rod 4 is installed on the side of the pallet 3 away from the box body 13 through the centering rod bracket 2, and the clamping device 6 is fixedly installed on the side of the pallet 3 close to the box body 13 On the top, the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com