Hand-held hydraulic bushing press-mounting device

A technology of hydraulic bushing and press-fitting device, which is applied in the directions of hand-held tools and manufacturing tools to achieve the effect of wide application range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

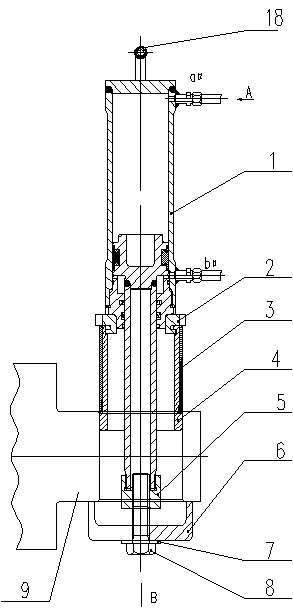

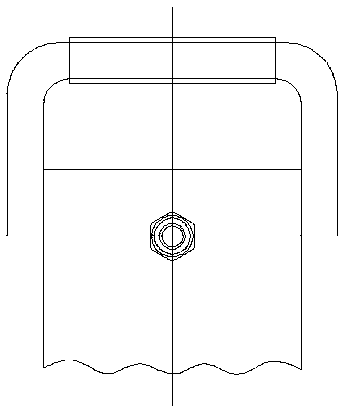

[0027] combine Figure 1 to Figure 4 Shown is a hand-held hydraulic bushing press-fitting device. One end of the cylinder bottom of hydraulic cylinder 1 is connected with handle 18;

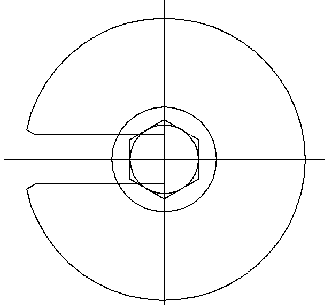

[0028] The guide tooling 4 is in the shape of a cylinder; there is a circle of steps on the outer peripheral surface of the lower end of the guide tooling 4, and the outer peripheral surface of the steps is matched with the hinged hole 9 in the cylinder bottom; the inner peripheral surface of the upper end of the guiding tooling 4 is provided with internal threads; On the frock 4, the lower end of the bushing 3 is against the step at the lower end of the guide frock 4. combine Figure 4 , the lower end of the guide tooling 4 has bullnose; the outer circumference of the guide tooling 4 near the steps of the guide tooling 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com