Patents

Literature

146results about How to "Suitable for batch processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

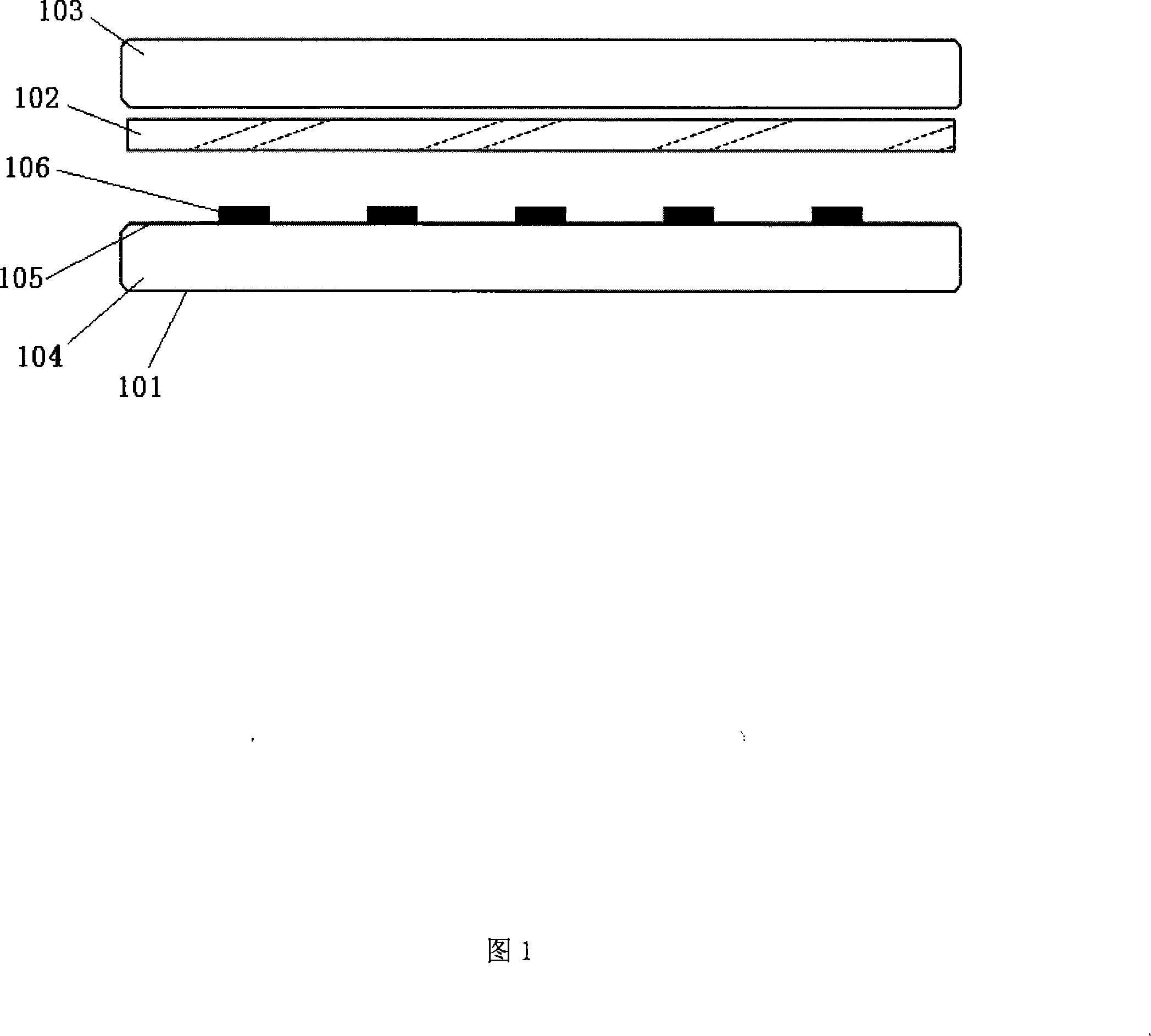

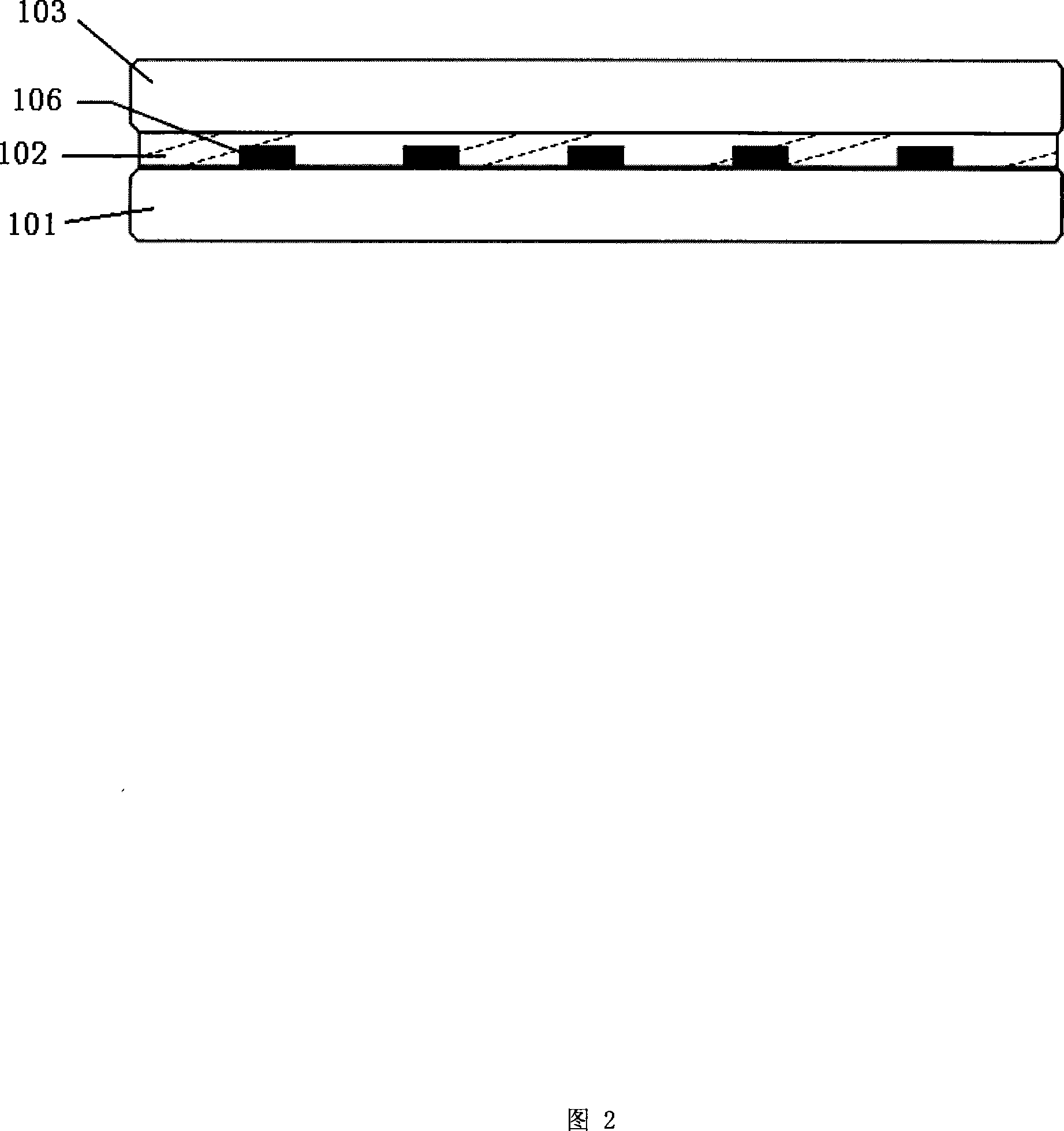

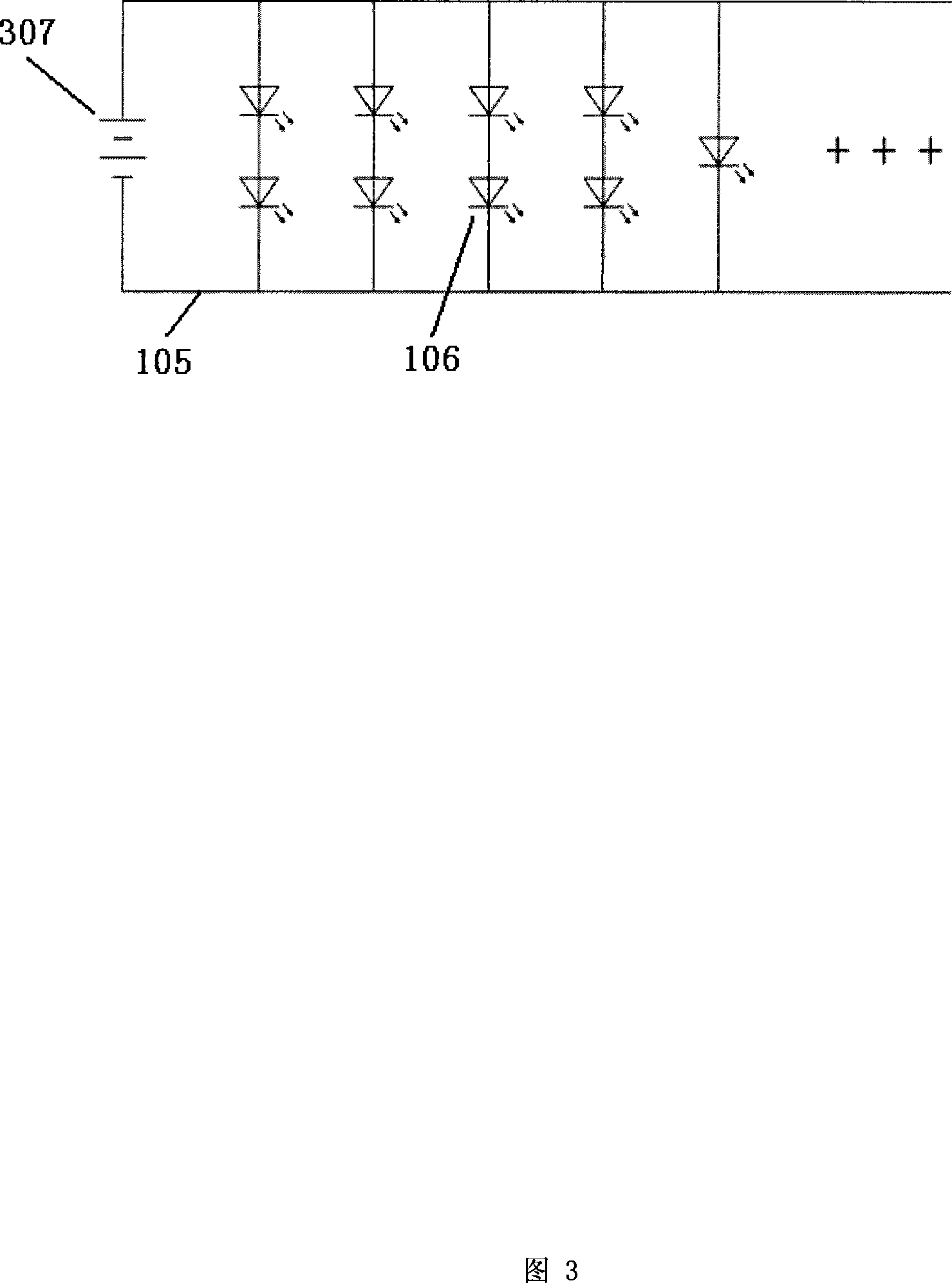

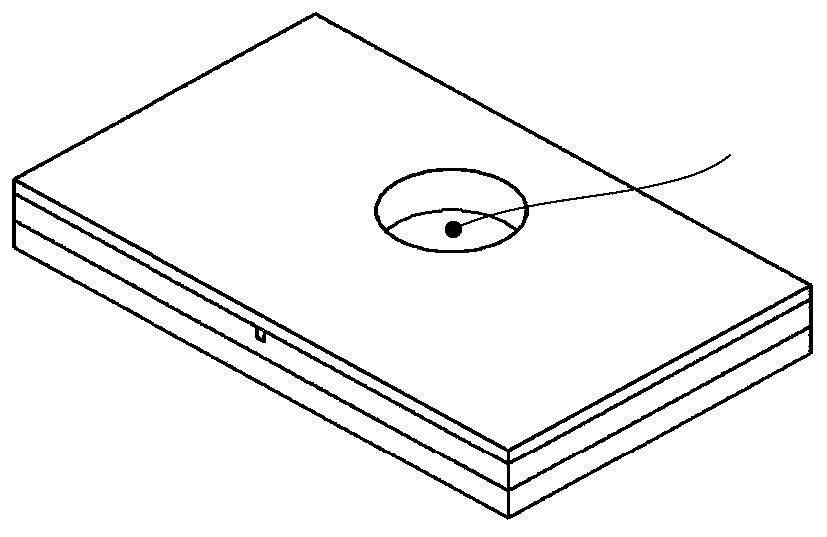

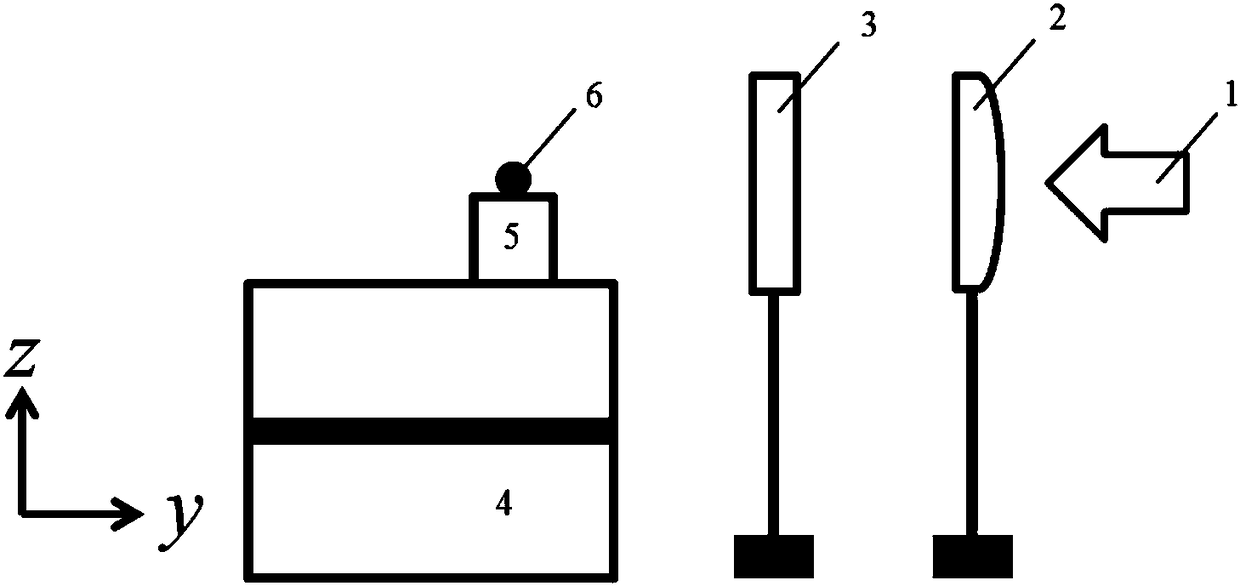

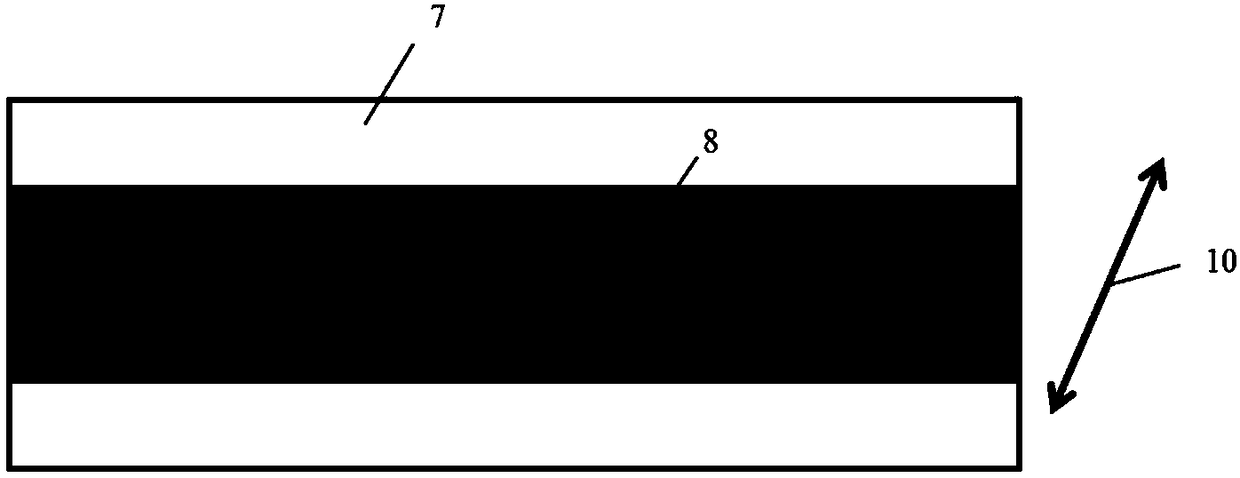

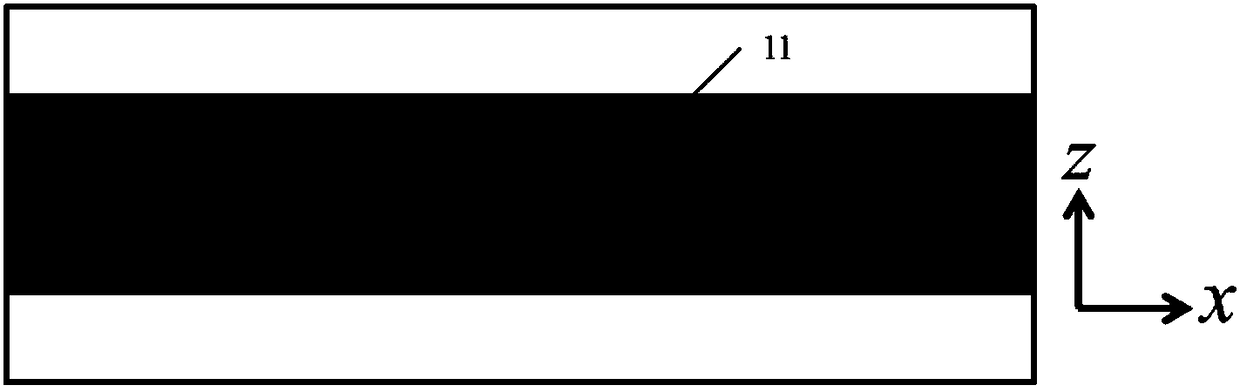

LED light-embedding artistic glass and method of manufacturing the same

InactiveCN101201152AGood light transmissionSuitable for outdoor usePoint-like light sourceElectric circuit arrangementsEngineeringHigh pressure

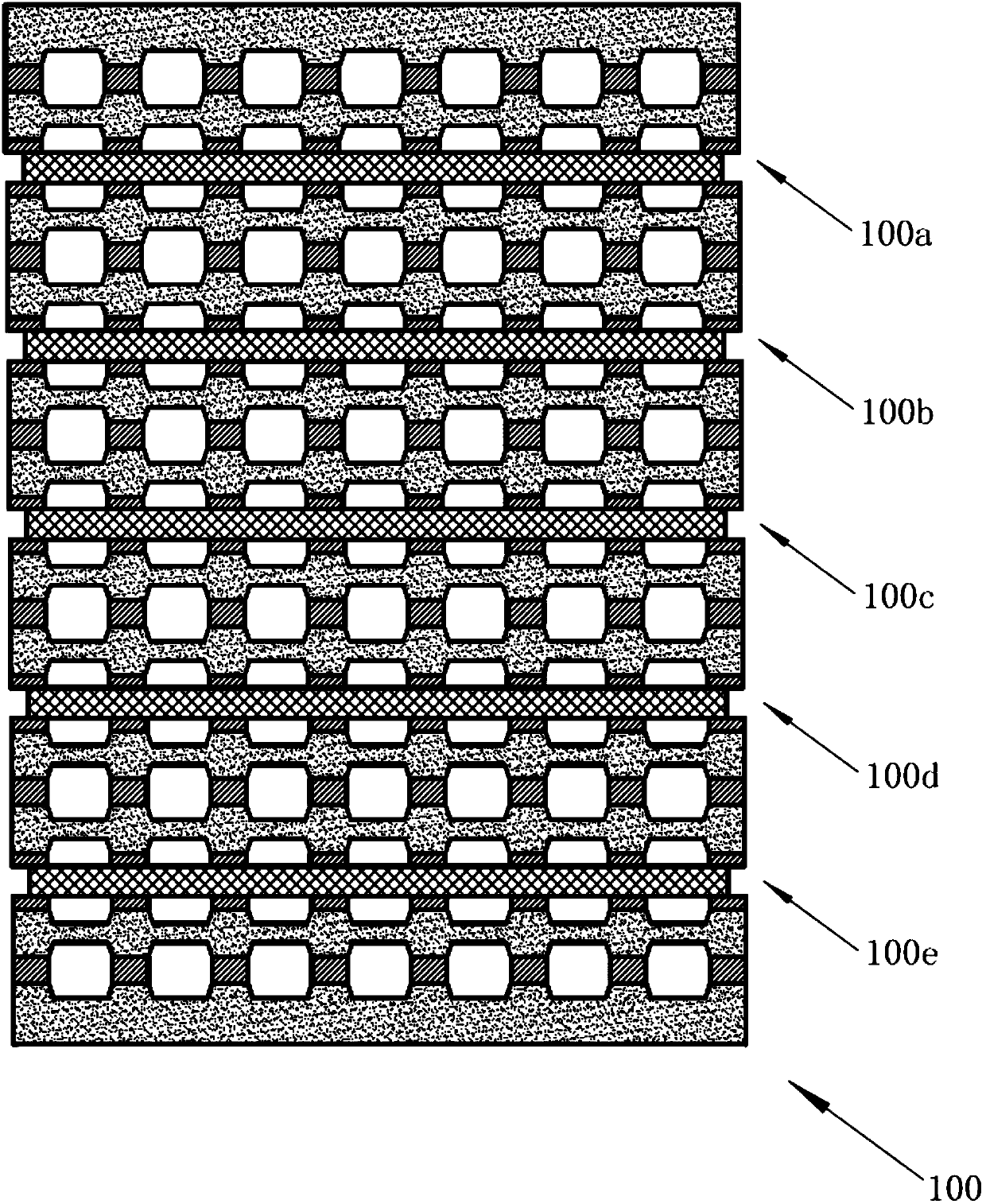

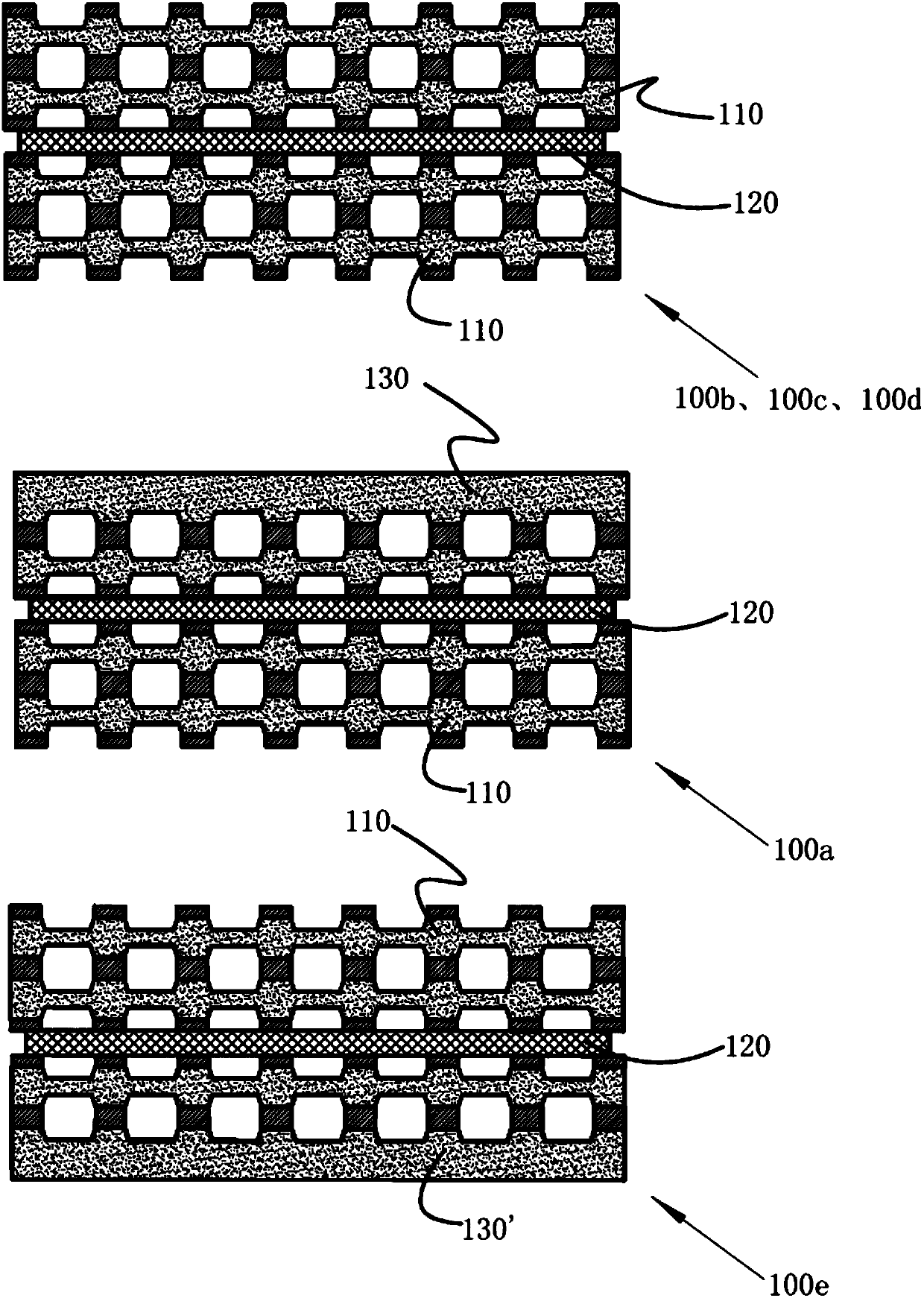

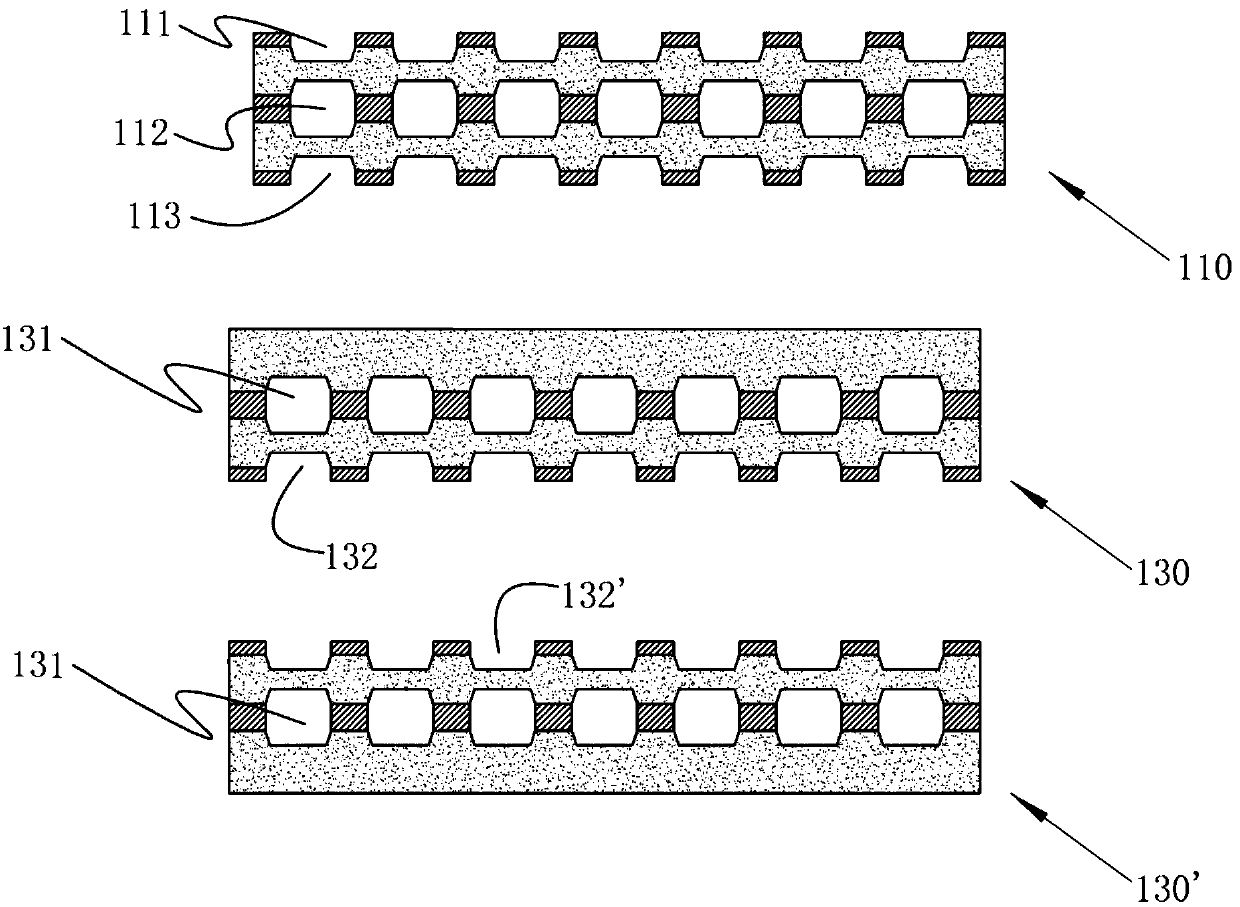

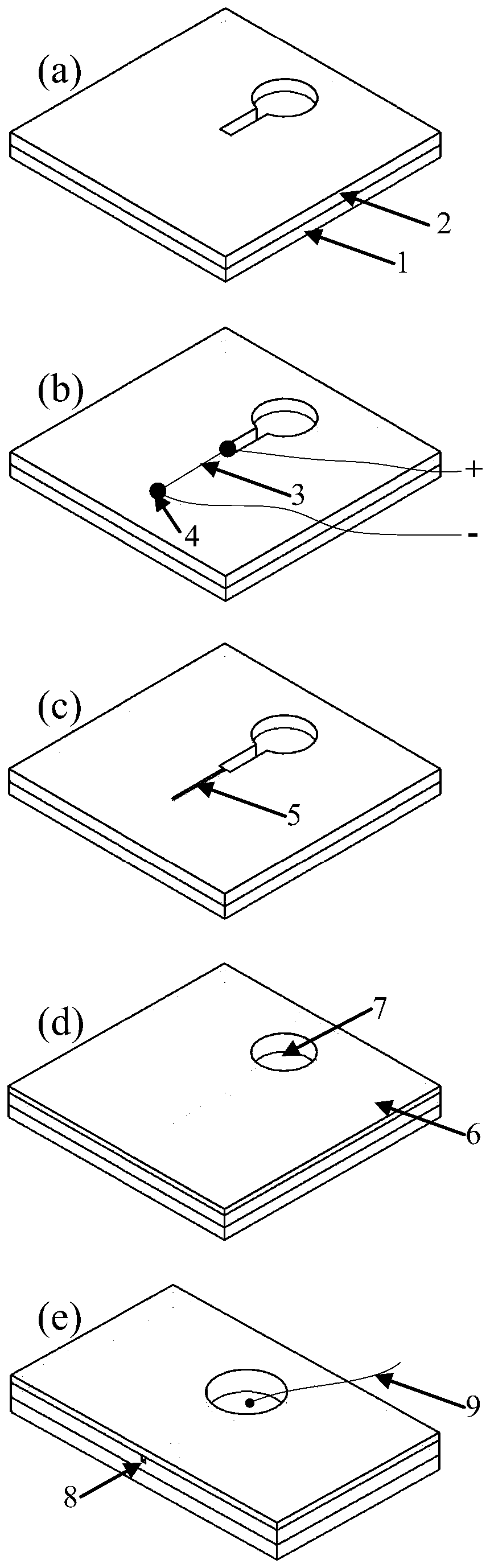

The invention discloses an LED light embedded art glass and a manufacture method for the art glass. The invention comprises a base layer, a middle layer and a covering layer. The base layer is a conductive glass and the conductive glass is provided with a conductive line and a power interface. An LED illuminant is arranged in the conductive line and is arranged according to the pattern and effect needed displaying. The middle layer is a PVB film arranged between the base layer and the covering layer. The base layer, the middle layer and the covering layer are agglutinated through the treatment of a high-pressure autoclave. The invention has the advantages of anti-explosion, endurance, attractive appearance, etc., and has a broad market prospect.

Owner:上海尊华电子工程有限公司

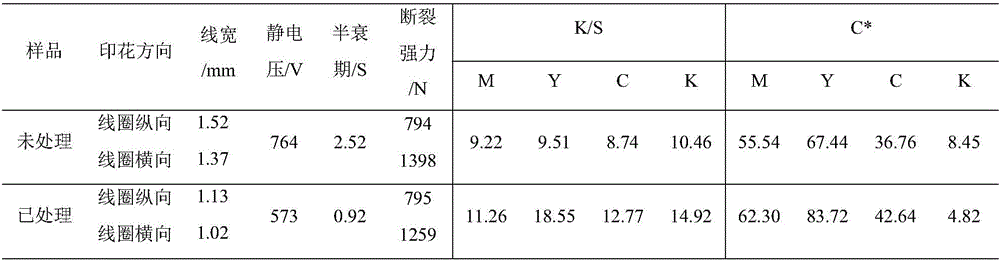

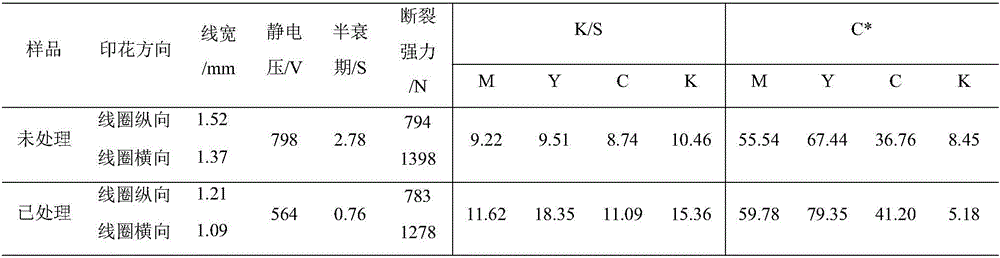

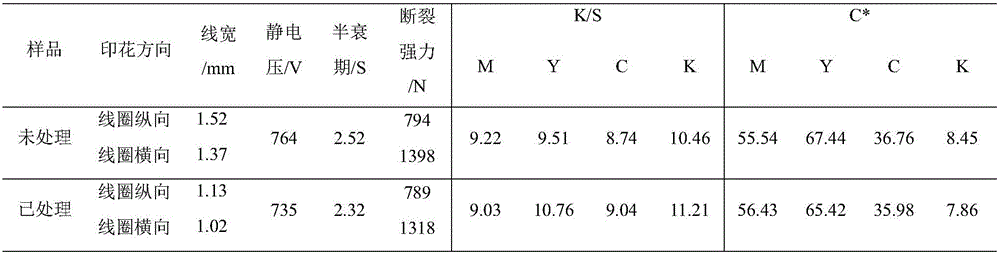

Pretreatment method for improving direct spray inkjet printing definition of polyester fabric

InactiveCN106758165ASuitable for batch processingImprove clarityFibre typesDyeing processPolyesterPre treatment

The invention discloses a pretreatment method for improving the direct spray inkjet printing definition of polyester fabric, and belongs to the field of digital inkjet printing of textiles. A method for improving the direct spray inkjet printing definition of the polyester fabric by adopting a nano porous material is provided for the problem of an indistinct printed pattern caused by static electricity in the direct spray inkjet printing of the polyester fabric. Compared with improvement of the inkjet printing performance, the definition, the color depth and obvious brightness effect of the pattern are improved. The method is simple in process, high in operability, friendly to environment and suitable for batch processing of the polyester fabric, and meets the modern industrial environmental protection requirements.

Owner:JIANGNAN UNIV

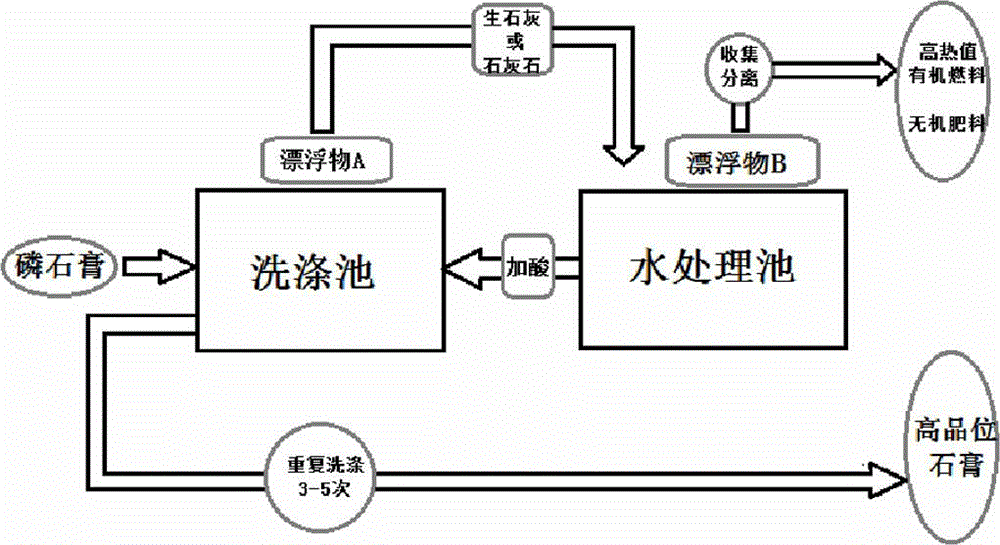

Comprehensive processing method for ardealite washing technology

InactiveCN104150796ALow impurity contentRealize closed recyclingO-Phosphoric AcidEnvironmental engineering

The invention relates to a comprehensive processing method for an ardealite washing technology. The method comprises the following steps: waster is added to ardealite of phosphoric acid by-products by a wet method, the ardealite and the water are mixed and placed still, lower-layer gypsum, upper-layer washing liquid and floaters A floating on filtrate are obtained, and the floaters A and the upper-layer washing liquid are respectively collected; the floaters A and quick lime are added into the upper-layer washing liquid, the floaters A, the quick lime and the upper-layer washing liquid are stirred and placed still, flocculent floaters B are obtained, and the floaters B and lower-layer aqueous solutions are respectively collected; after acid solutions are added into the lower-layer aqueous solutions for adjusting a pH value, the lower-layer aqueous solutions are used for circularly washing the ardealite. The ardealite which is processed can be used as excellent structural materials and auxiliary materials, and impurities in ardealite raw materials are translated into secondary resources, so that the effect of turning waste into wealth is realized.

Owner:湖北胜垒石膏技术有限公司 +1

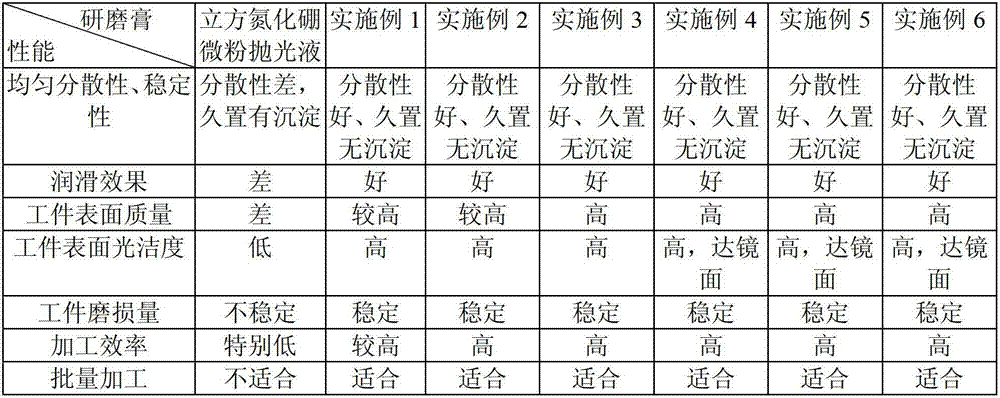

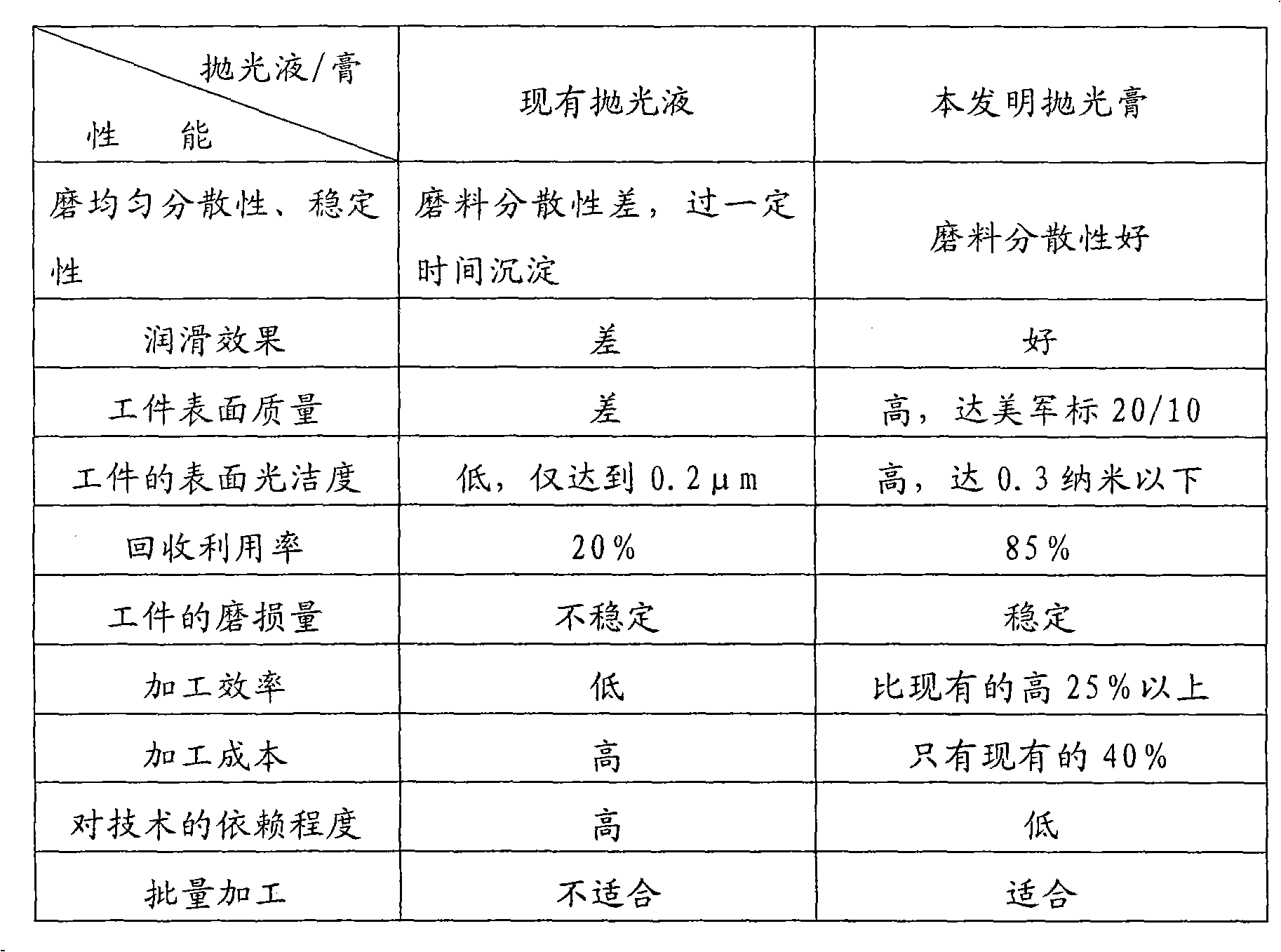

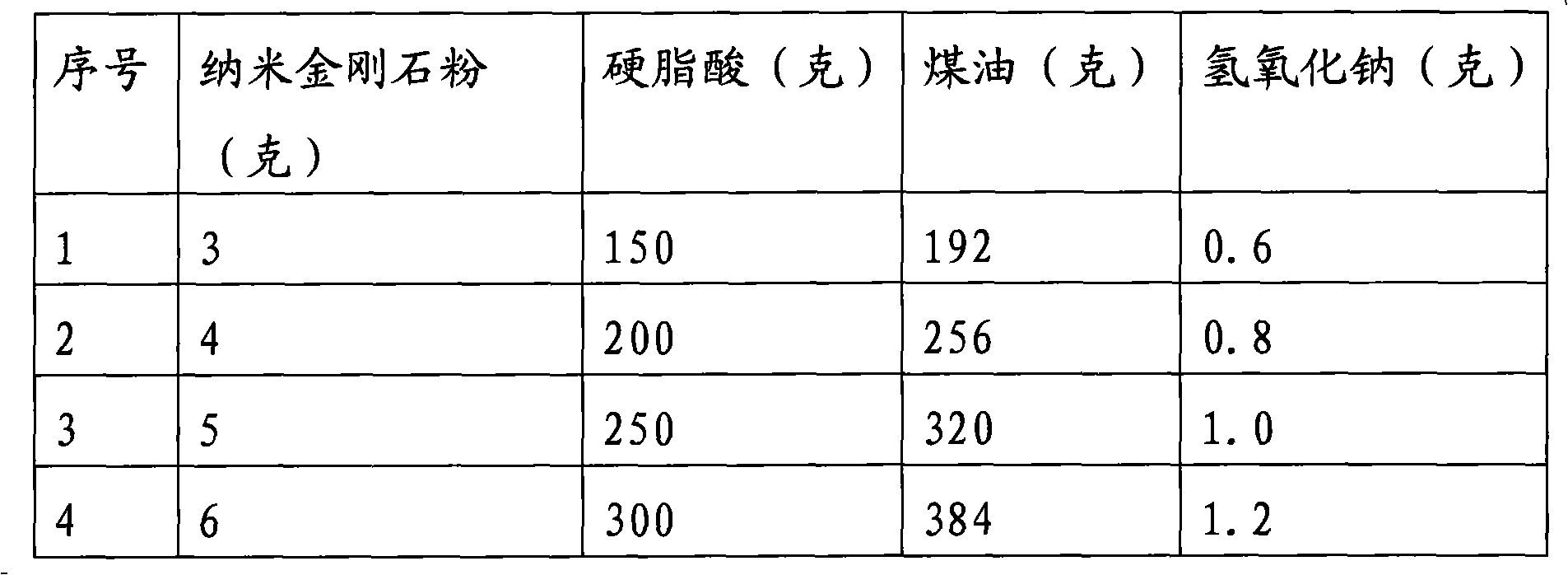

Man-made diamond grinding paste

InactiveCN103160208AActs as a lubricantQuality improvementPolishing compositions with abrasivesSurface finishBatch processing

The invention provides a man-made diamond grinding paste, and the problem that existing polishing solution is prone to generating scrape and damage on the surface of a precision mold. The man-made diamond grinding paste is composed of man-made diamond powder, mixed fat, oleic acid and lubricant. By weight, the man-made diamond grinding paste comprises 15-55 parts of the man-made diamond powder, 25-40 parts of the mixed fat, 20-30 parts of the oleic acid and 3-11 parts of the lubricant. The preparation method of the man-made diamond grinding paste includes the following steps: (1), each component is weighted according to the parts by weight; (2), all the components are mixed evenly under the temperature above 60 DEG C; and (3), the evenly mixed components are cooled to zero DEG C, and the man-made diamond grinding paste is prepared. The grinding paste is matched with a pneumatic polishing machine to be used for carrying out polishing treatment on the surface machining of the precision mold, the surface quality and the surface finish are high, experience and technological level of an operator are not required highly, the production efficiency can be greatly improved, the cost can be reduced and the method is suitable for batch processing.

Owner:QINGDAO HENGHUI MOLD TECH

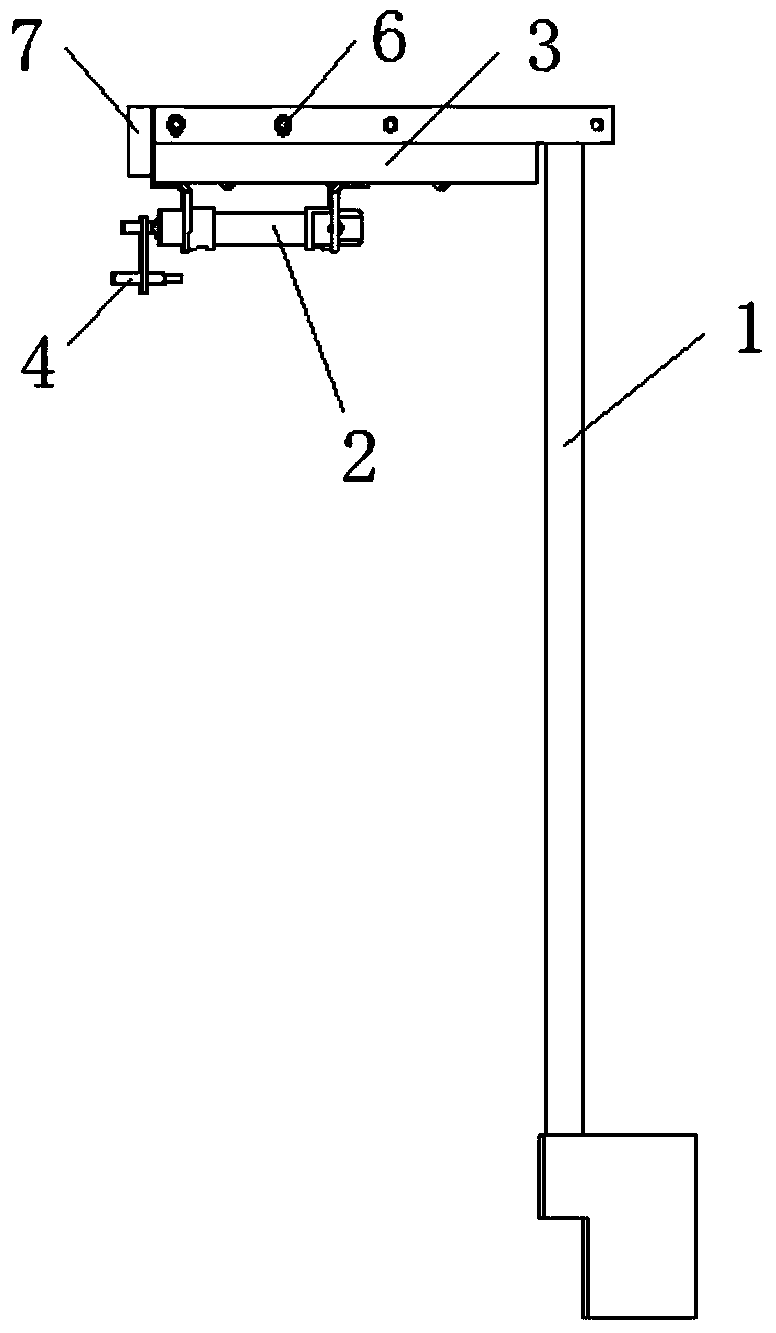

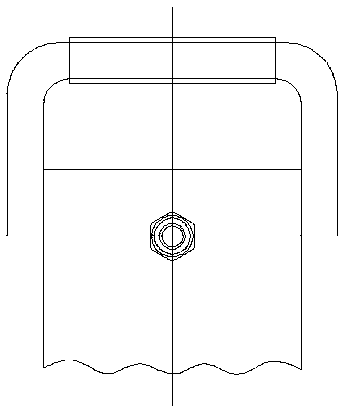

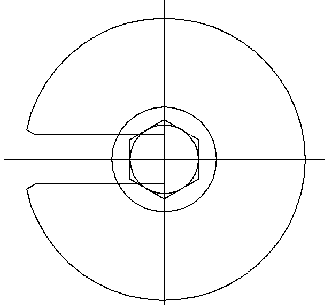

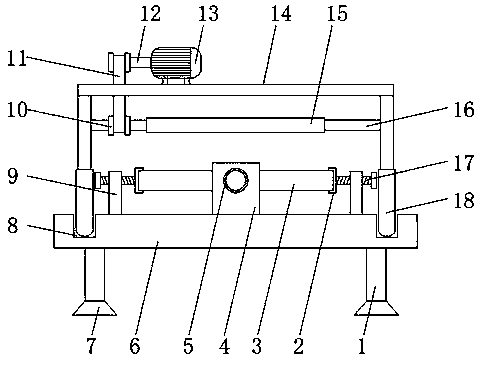

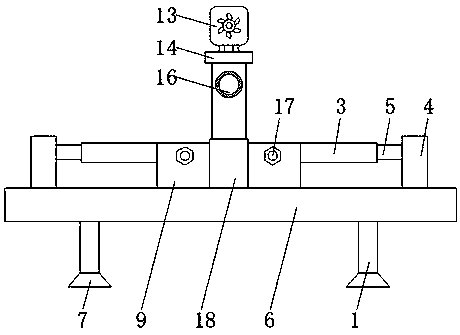

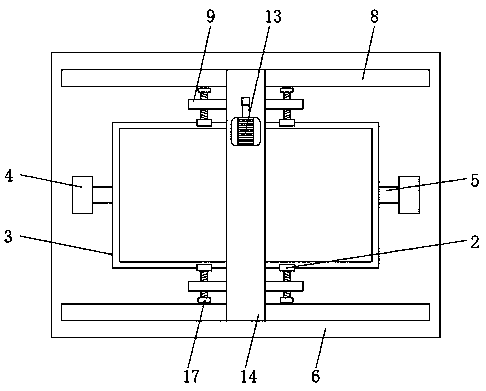

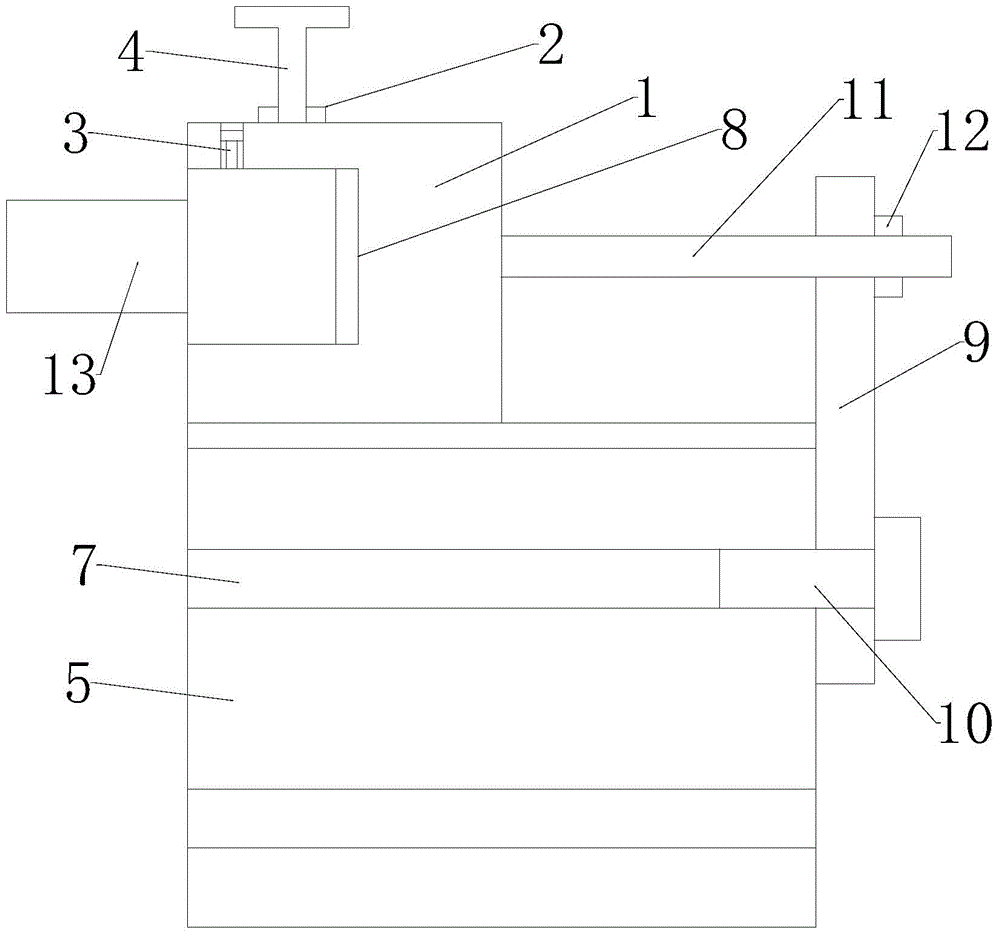

Welding tool

InactiveCN101972912ASuitable for batch processingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesMotor driveDrive shaft

The invention belongs to a processing process device, and particularly relates to a tool for welding circular parts. The tool has the working condition that: a speed regulating motor drives a rotating shaft arranged on a tool rack through a drive sprocket wheel, a drive shaft transfers power to a three-claw chuck connected with the drive shaft through a flange plate, and then the tool is assembled on the chuck. Ideal welding requirement is acquired by controlling the rotational speed of the speed regulating motor.

Owner:TIANJIN GENERAL PRINCIPLE MACHINERY NEW TECH

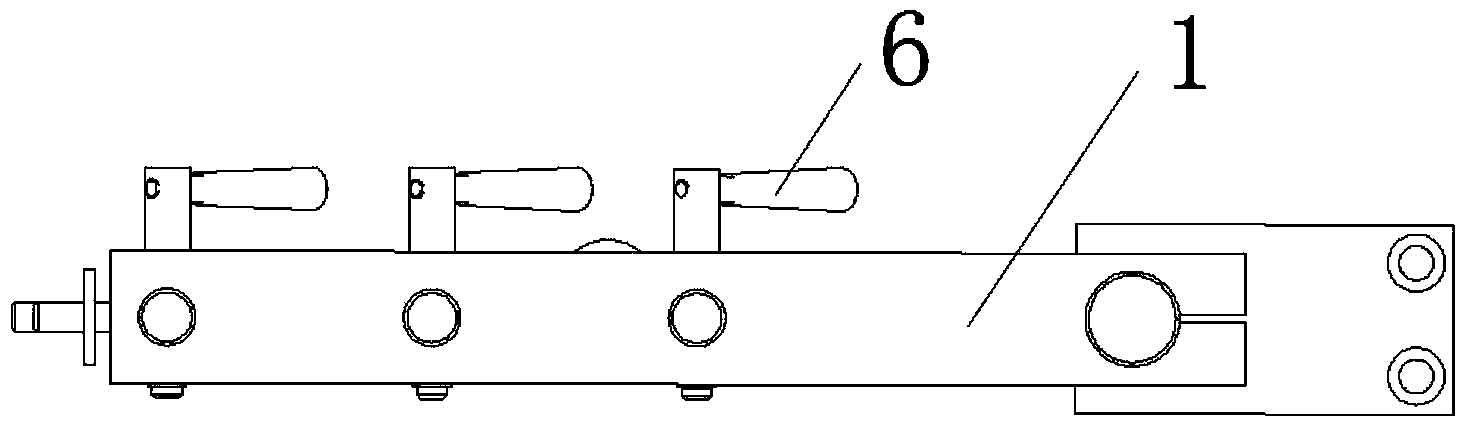

Cutting machine

InactiveCN102861946AEasy to operateOperational securityTube shearing machinesPipe fittingAgricultural engineering

The invention discloses a cutting machine, comprising a bottom plate, a fixing block, a positioning block, a push block, convex blocks, a connecting rod, a pressing block and cutters, wherein one end of the bottom plate is provided with the fixing block; one part of the bottom plate, which is close to the fixing block, is fixedly and sequentially provided with the positioning block and the push block which can slide on the bottom plate; the convex blocks are arranged at the two sides of the bottom plate; the convex blocks are located between the fixing block and the push block; the convex blocks are connected with the push block through a connecting piece; the positioning block is provided with the pressing block which can move up and down; the fixing block is provided with a plurality of first fixing circular holes; a plurality of fixing semicircular holes are correspondingly arranged on the positioning block and the pressing block; when the positioning block and the pressing block are close, a second fixing circular hole is formed by the two fixing semicircular holes; axes of the first fixing circular holes and the second fixing circular hole are on the same straight line; the pressing block is provided with the cutters which have the same quantity as the fixing semicircular holes; the cutters penetrate through the second fixing circular hole; and a mark groove is arranged at one side of the bottom plate. According to the cutting machine disclosed by the invention, the length precision of a machined pipe fitting can be guaranteed, the machining efficiency is high and the cutting machine is suitable for batch machining.

Owner:SUZHOU DONGLI MACHINERY

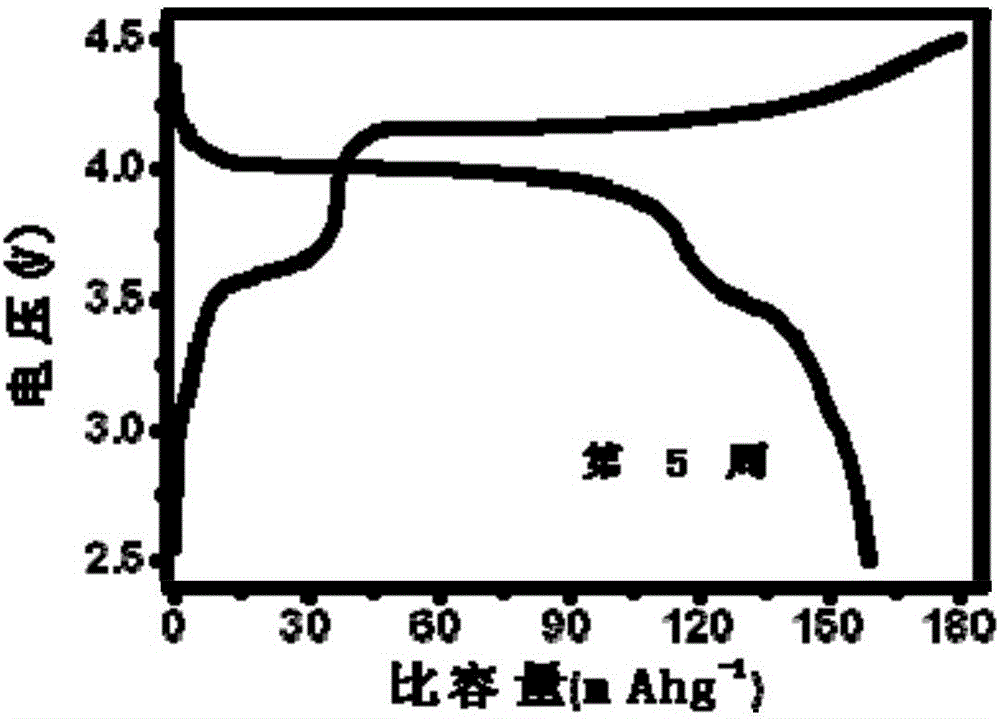

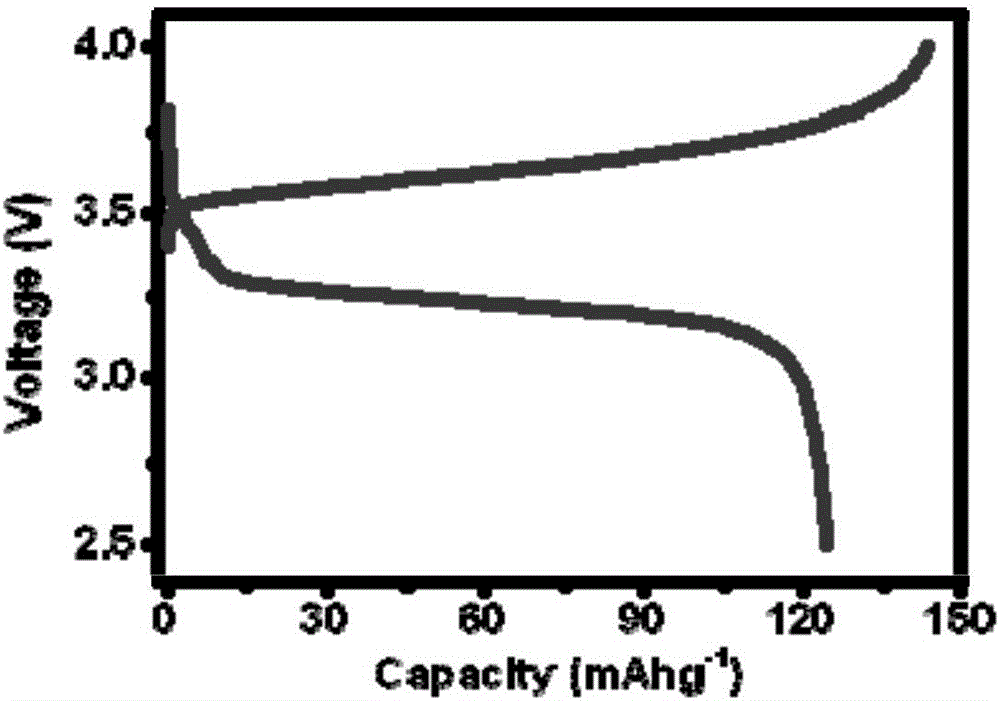

Method using iodine solution to treat lithium surface and application of method to solid-state battery

InactiveCN106784636AGood stability and compatibilityHas ion conductivityChemical electrode manufacturingLi-accumulatorsBatch processingIodine solutions

The invention relates to a method using an iodine solution to treat a lithium surface and application of the method to a solid-state battery and belongs to the technical field of chemical power supplies. The method is characterized in that cathode materials used during lithium electrode production are pure lithium or boron alloy sheets and are cut and pressed into an electrode plate; a solvent for dissolving iodine is tetrahydrofuran, and the weight percentage concentration of the iodine solution is 0.5-30%; the electrode plate is submerged into the iodine solution, and residual liquid is dried through drying to obtain the surface-treated lithium cathode plate. The application of the method to the solid-state battery is characterized in that solid-state battery assembling includes preparing the surface-treated lithium cathode, preparing composite solid electrolyte, preparing an anode and assembling the solid-state battery, and the surface-treated lithium cathode preparation uses the method. The method is simple, evident in effect, applicable to the large-scale and batch processing of lithium cathode surfaces, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

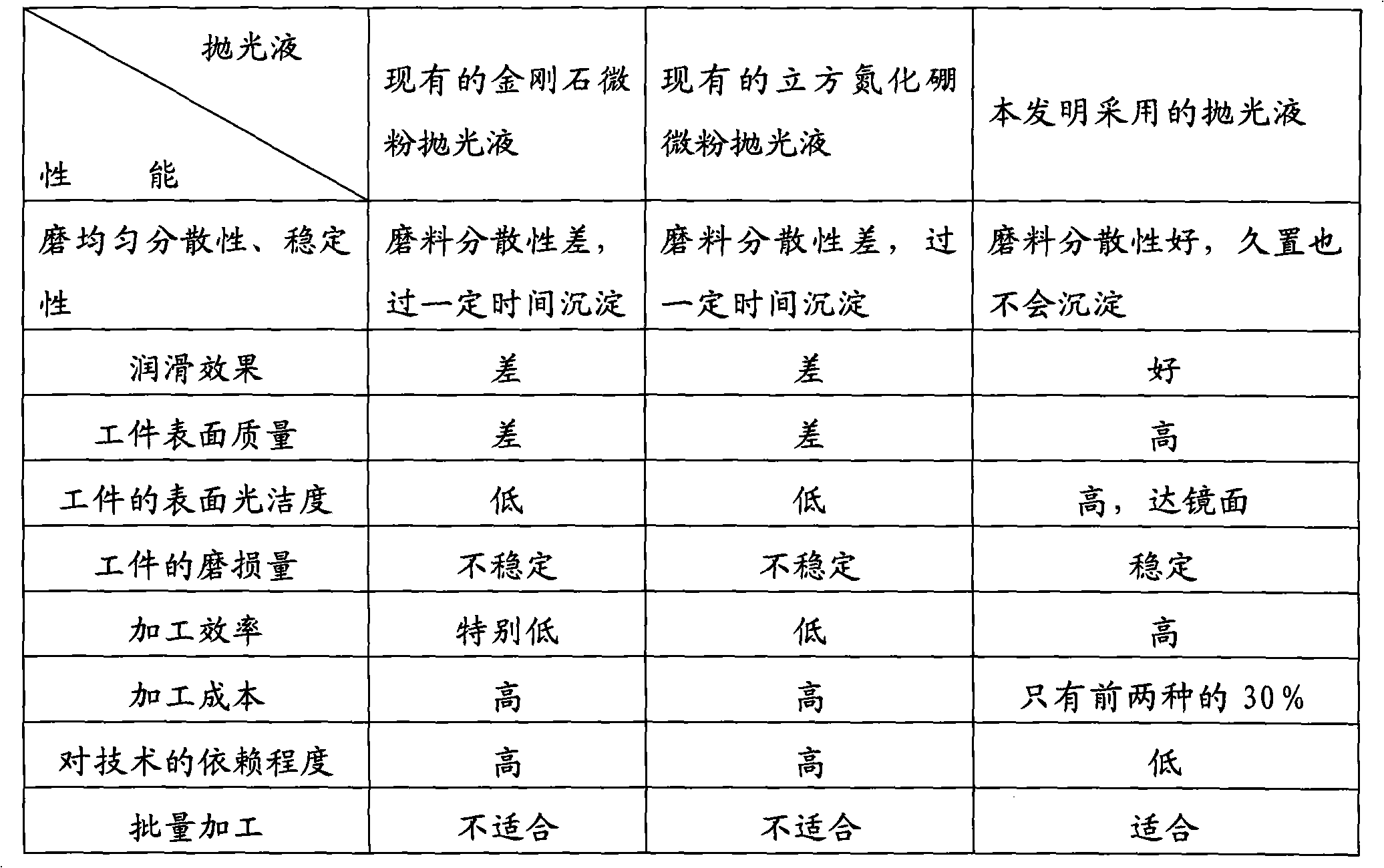

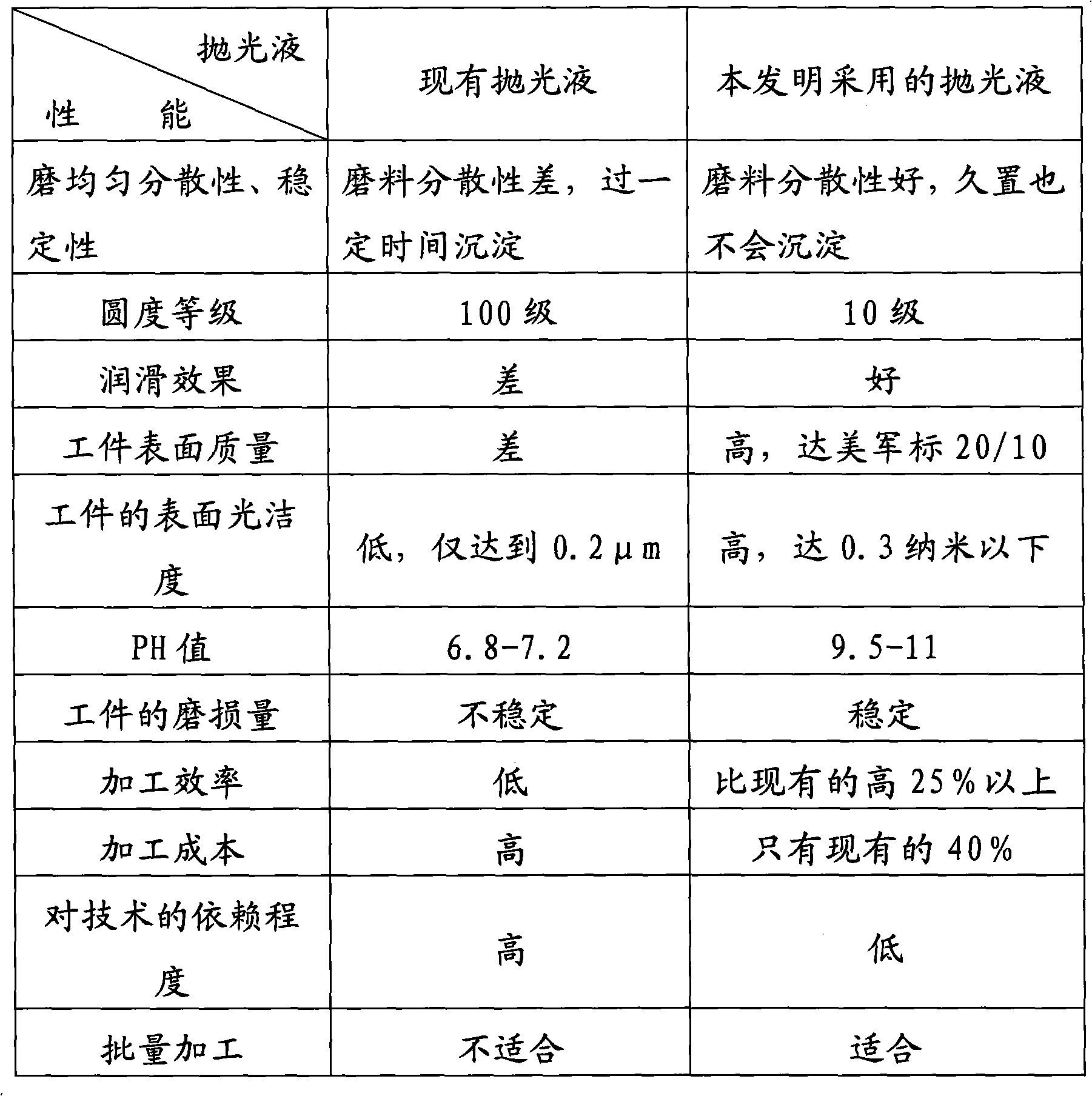

Polishing liquid used for stainless steel mirror surface and preparation method

ActiveCN101875818AImprove the finishEasy to operatePolishing compositions with abrasivesHigh volume manufacturingKerosene

The invention relates to polishing liquid used for a stainless steel mirror surface and a preparation method. The polishing liquid consists of the following components in part by weight: 3 to 6 parts of cubic boron nitride micropowder, 240 to 300 parts of stearic acid, and 320 to 480 parts of kerosene. The surface of a workpiece polished by using the polishing liquid of the invention has high surface finishment; an operation method is simple; technical requirements are low; and the polishing liquid is suitable for large-batch production. The polishing liquid prepared by adopting the method ofthe invention is permanent suspension without precipitate.

Owner:CHONGQING CHUANYI AUTOMATION

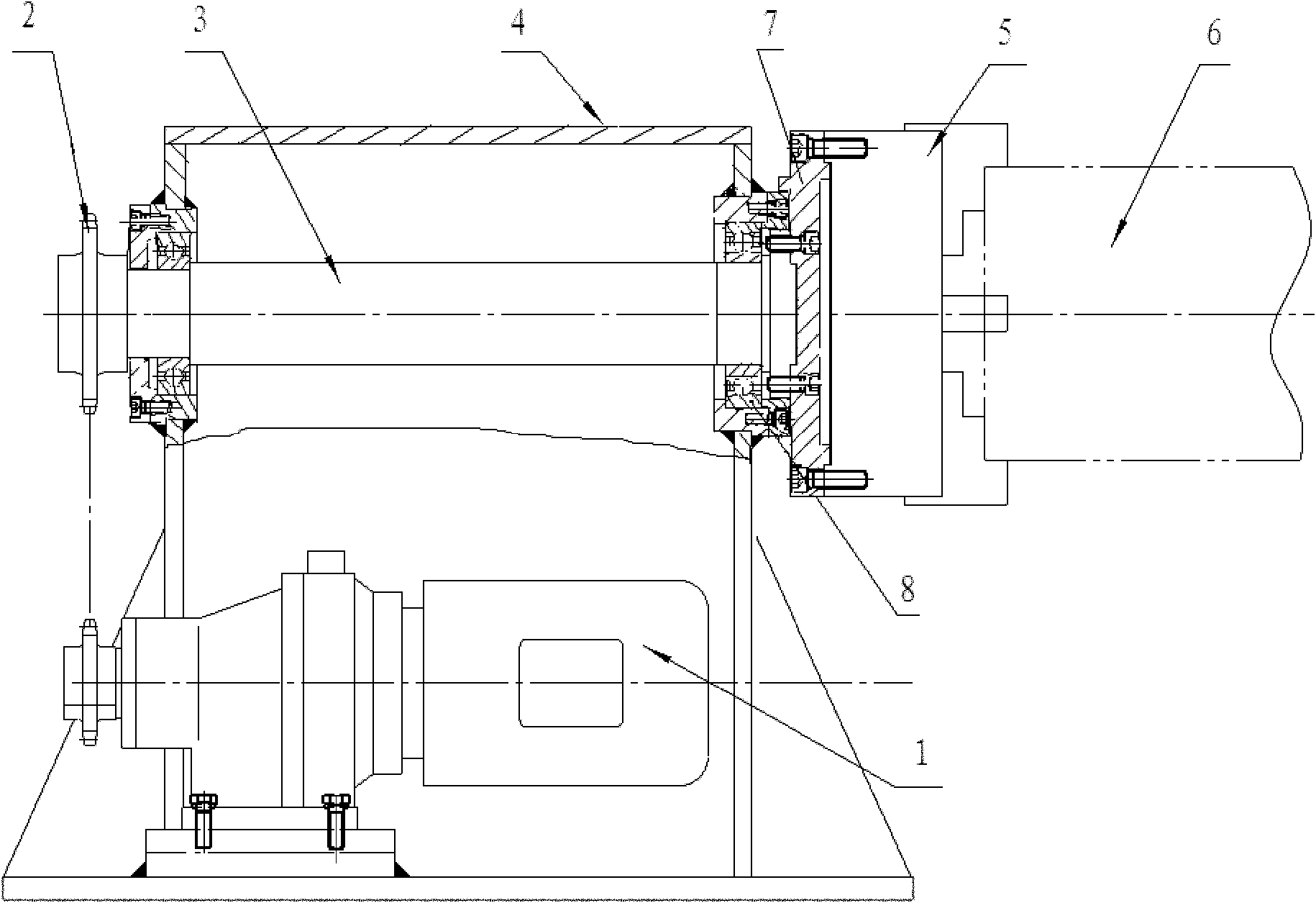

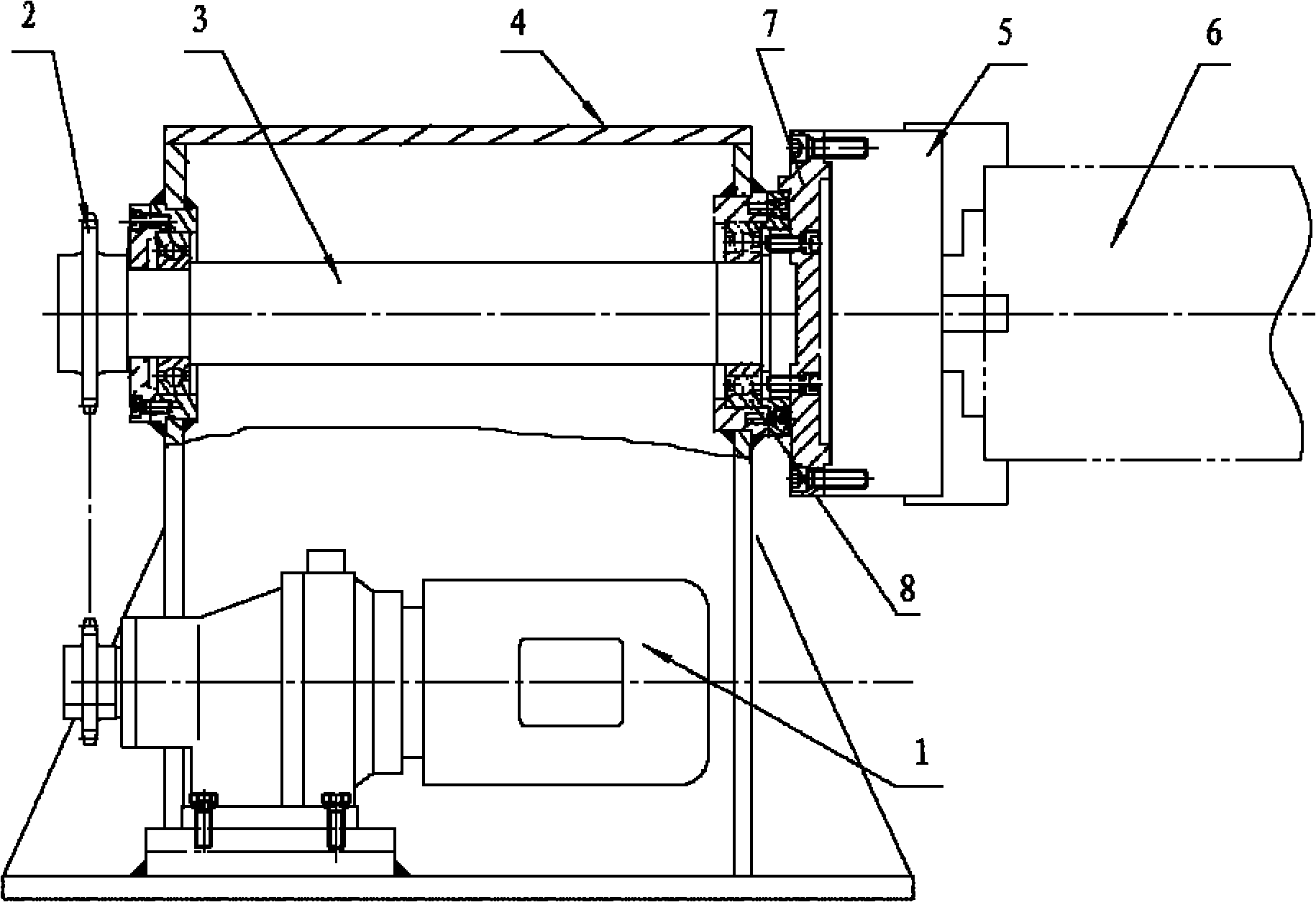

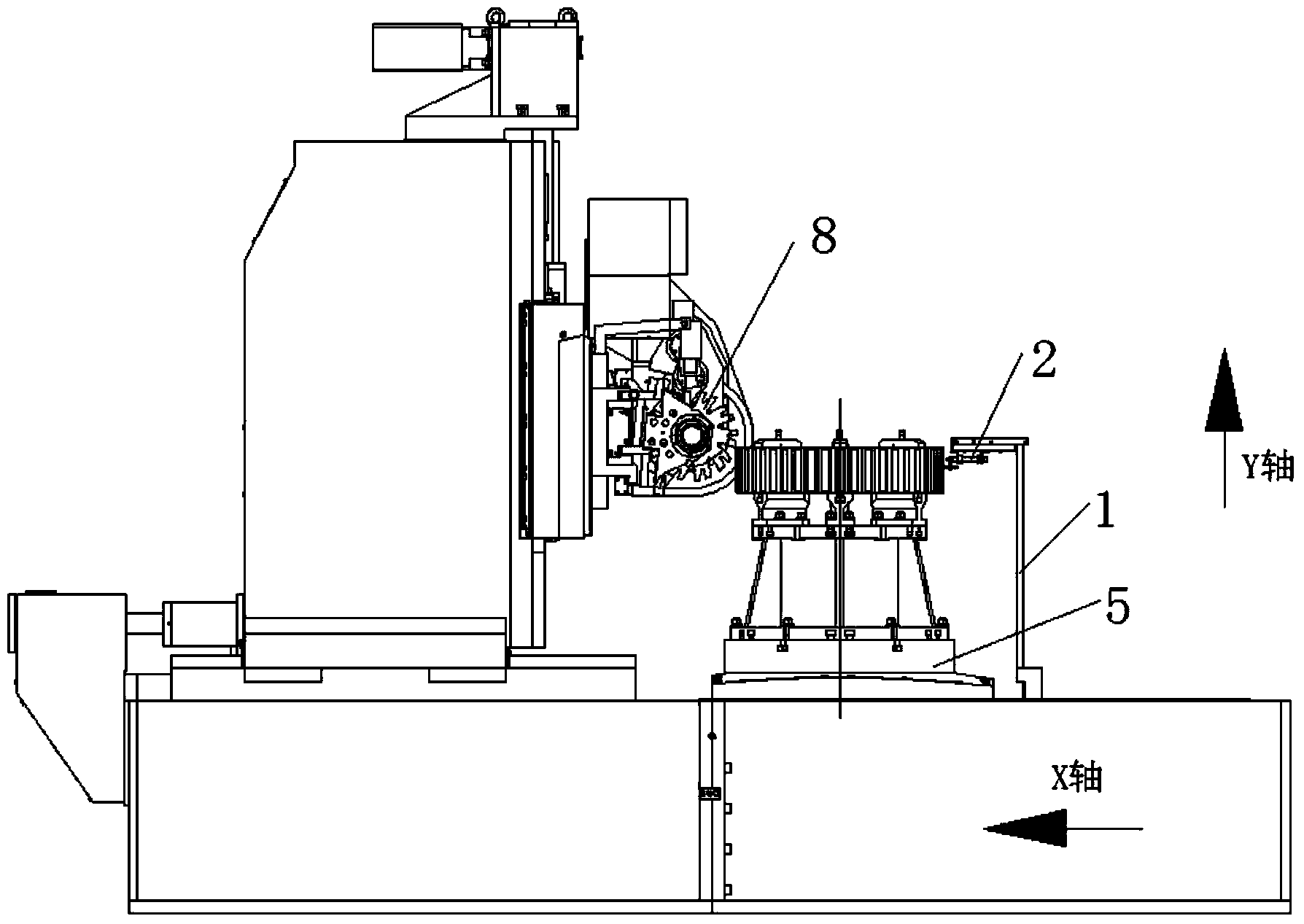

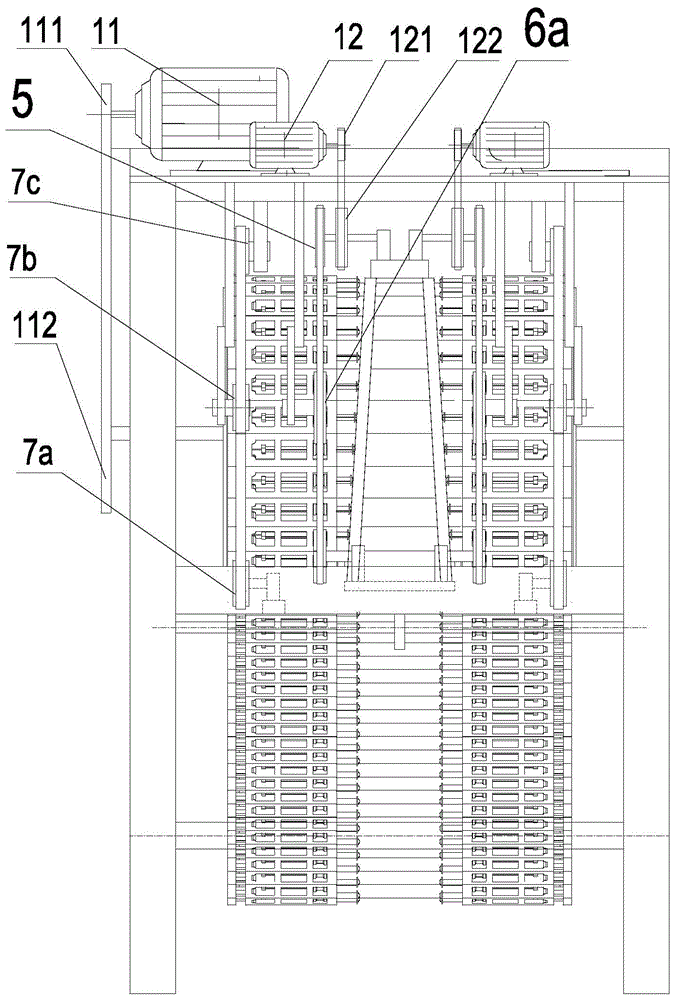

Automatic tooth aligning mechanism for large-sized gear hobbing machine and tooth aligning method thereof

ActiveCN104028850ABalance evenly distributedExtended service lifeAutomatic control devicesFeeding apparatusBatch processingHobbing

The invention discloses an automatic tooth aligning mechanism for a large-sized gear hobbing machine. The automatic tooth aligning mechanism comprises a support, a telescopic mechanism, and a PLC (programmable logic controller); the height of the support can be adjusted along an axis Y; a moving rack and a proximity switch are arranged on the telescopic mechanism; the moving rack is in sliding fit with the support along an axis X. The PLC is disposed on the large-sized gear hobbing machine and is connected with the telescopic mechanism and the proximity switch. The invention further discloses a tooth aligning method of the automatic tooth aligning mechanism. The tooth aligning method includes: manual tool setting, positioning of the tooth aligning mechanism, tooth aligning for a next gear and the like. The automatic tooth aligning mechanism and the tooth aligning method thereof have the advantages that the structure is simple, an operating method is simple and easy, the subsequent gear can be automatically aligned just by ensuring effectiveness of initial alignment, artificial error is reduced, uniformity is good, the precision is high, and the mechanism and the method are especially suitable for batch processing; meanwhile, hobbing allowance is uniformly distributed, and the service life of a hob is greatly prolonged.

Owner:CHONGQING MACHINE TOOL GROUP

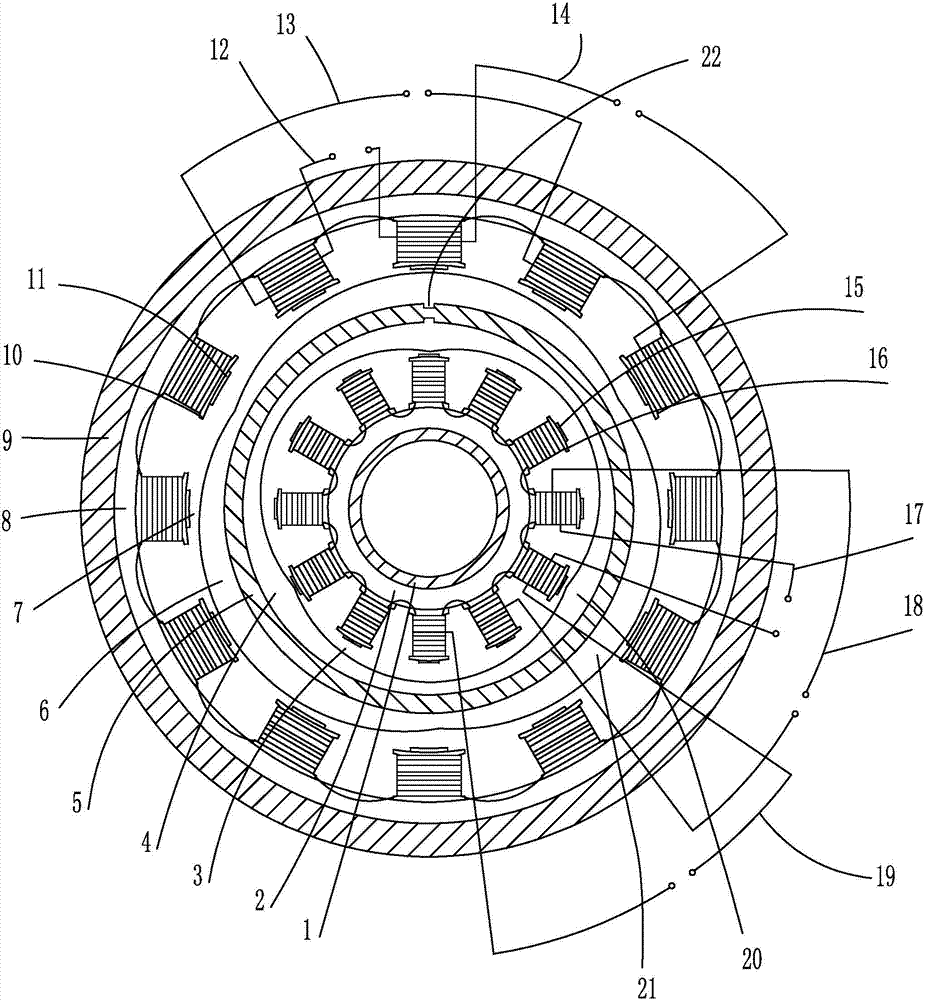

Double-stator magnetic resistance type angle sensor

InactiveCN104734440AIncrease effective spaceSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsSystem structureMagnetic loop

The invention discloses a double-stator magnetic resistance type angle sensor which comprises an inner stator and a rotor. A first sine air gap is formed between the inner stator and the rotor. The double-stator magnetic resistance type angle sensor further comprises an outer stator outside the rotor. A second sine air gap is formed between the outer stator and the rotor. The rotor comprises a magnetism isolating ring, an inner rotor portion arranged on the inner wall of the magnetism isolating ring and an outer rotor portion arranged on the outer wall of the magnetism isolating ring. Through the combination of an inner stator and rotor assembly and an outer stator and rotor assembly are arranged, the double-stator magnetic resistance type angle sensor is particularly suitable for a double-stator servo drive motor system, the system structure can be greatly simplified, the effective space of the motor is increased, and the double-stator magnetic resistance type angle sensor has the advantages of being simple in structure, high in reliability and the like. By changing the number of teeth of the rotor, the inner stator and the outer stator, the angle sensor with 1-8 pole pairs can be obtained, and the double-stator magnetic resistance type angle sensor is suitable for the servo motor system with different numbers of pole pairs, and has the advantages of being convenient to install and suitable for batch processing production.

Owner:JIANGMEN POLYTECHNIC

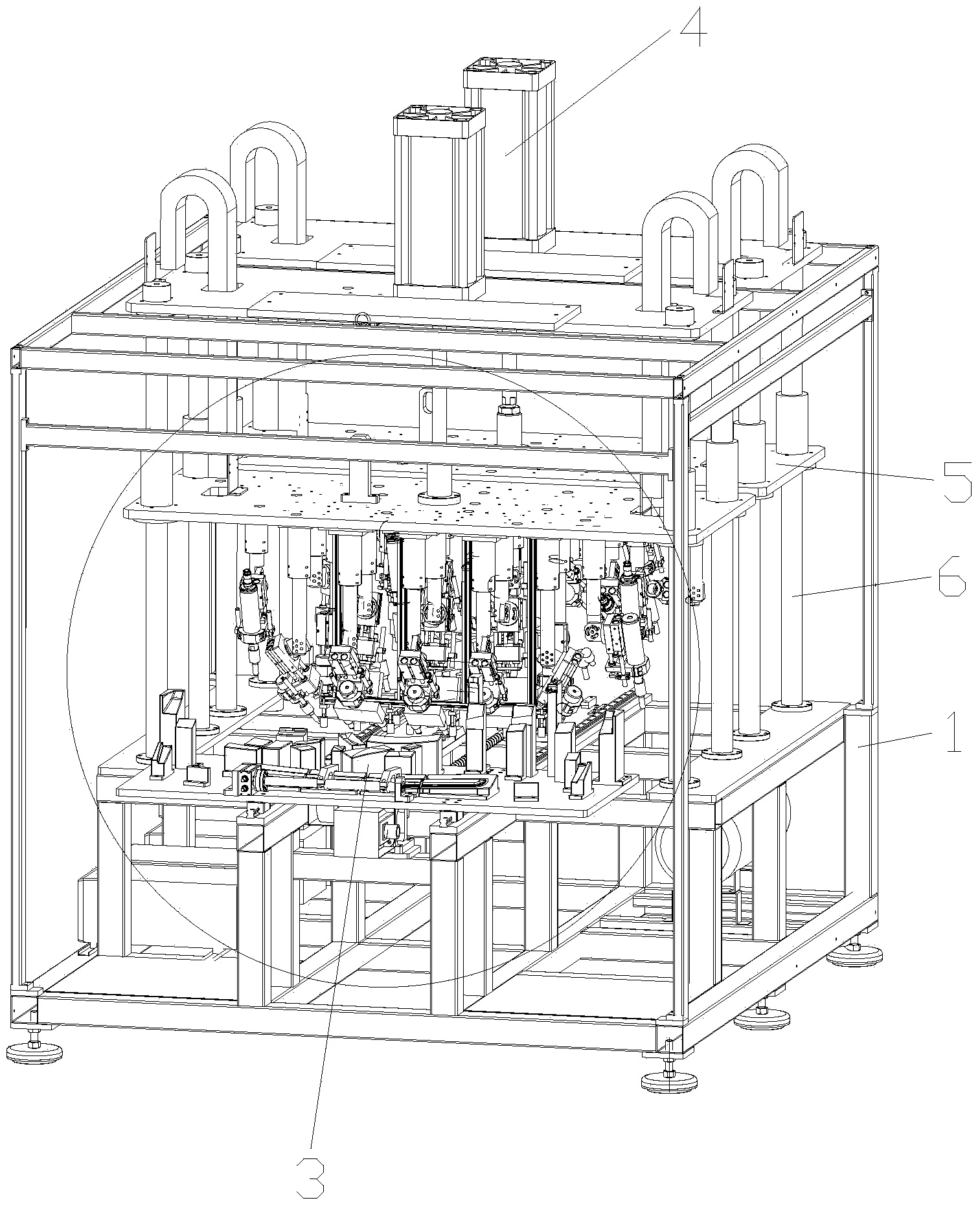

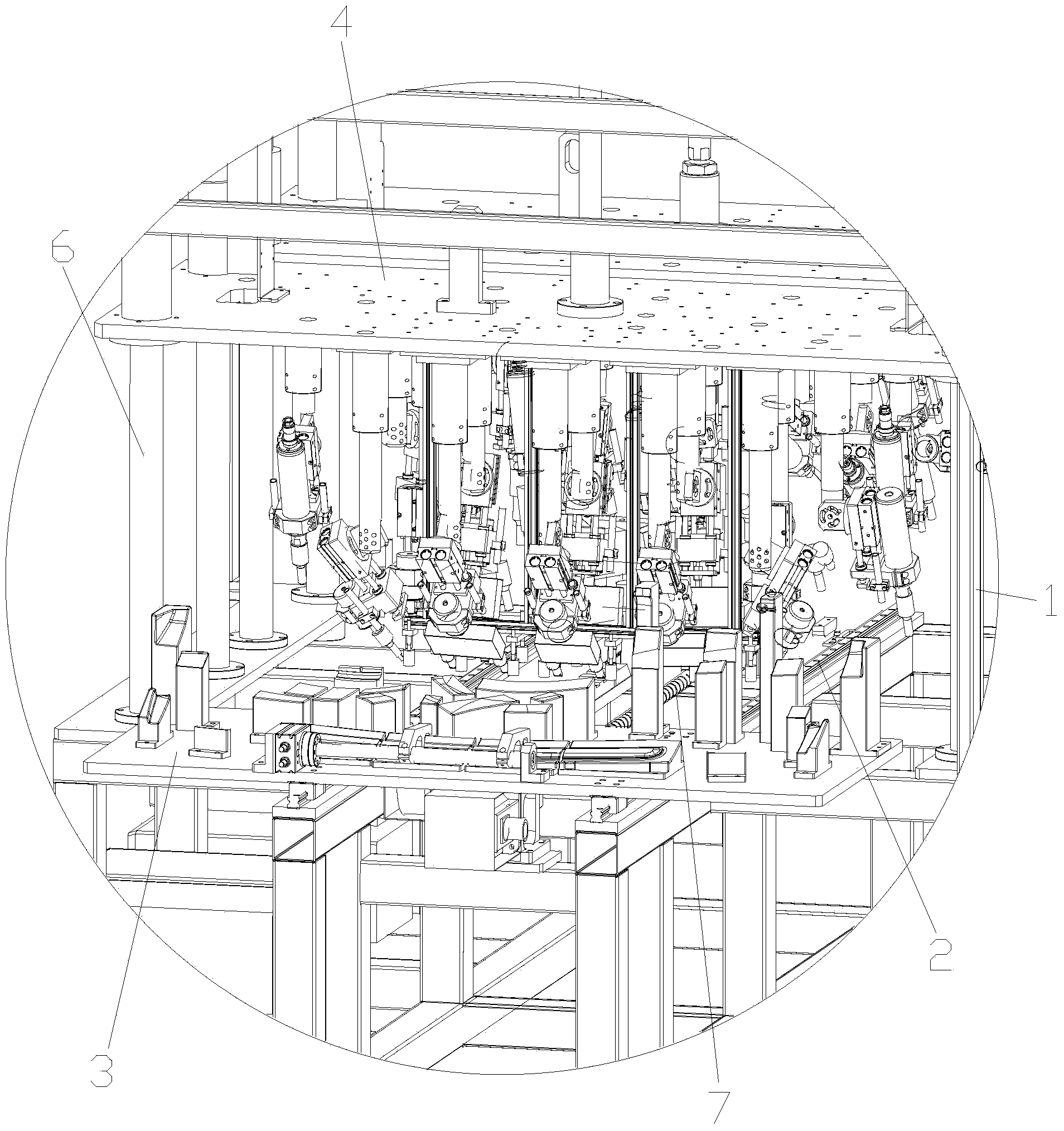

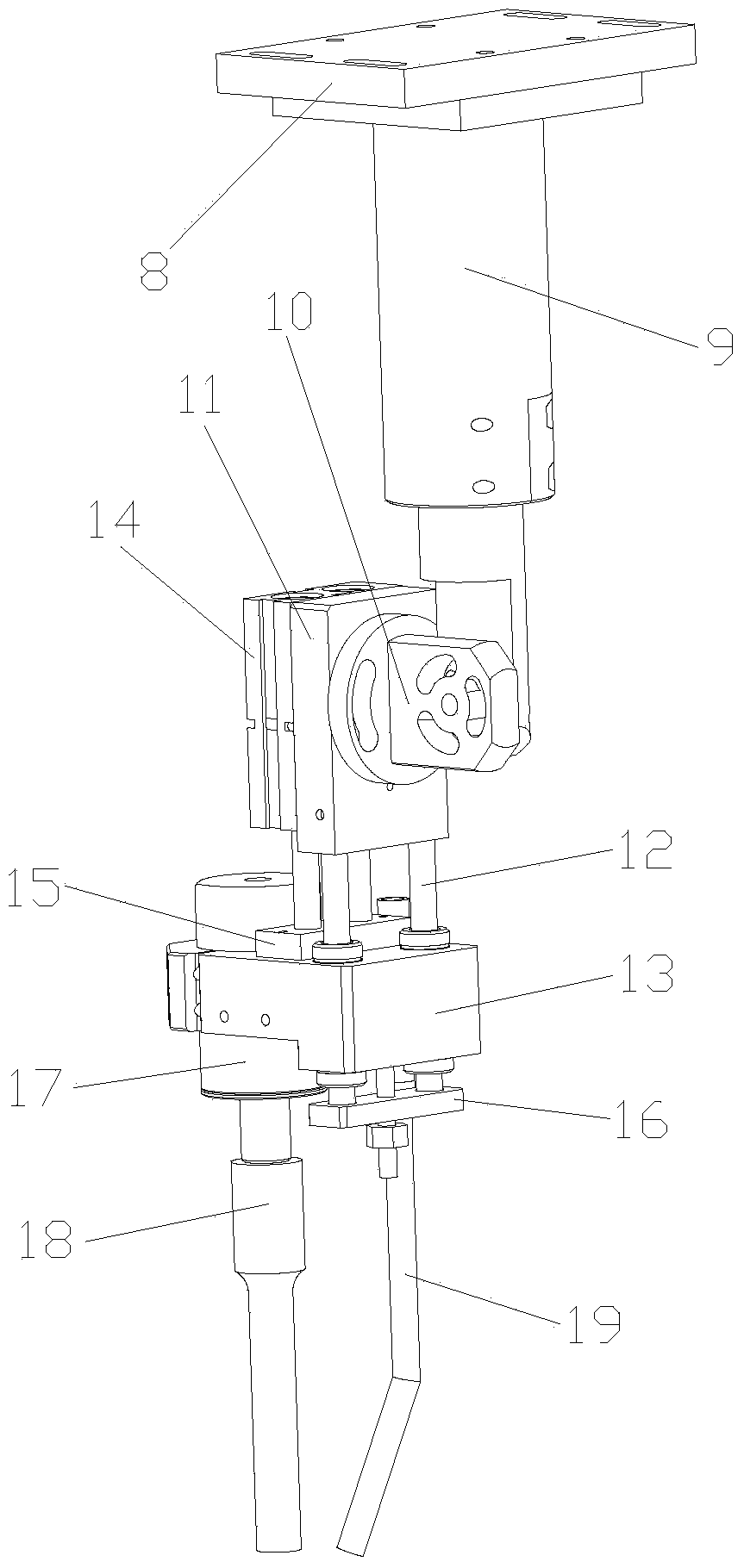

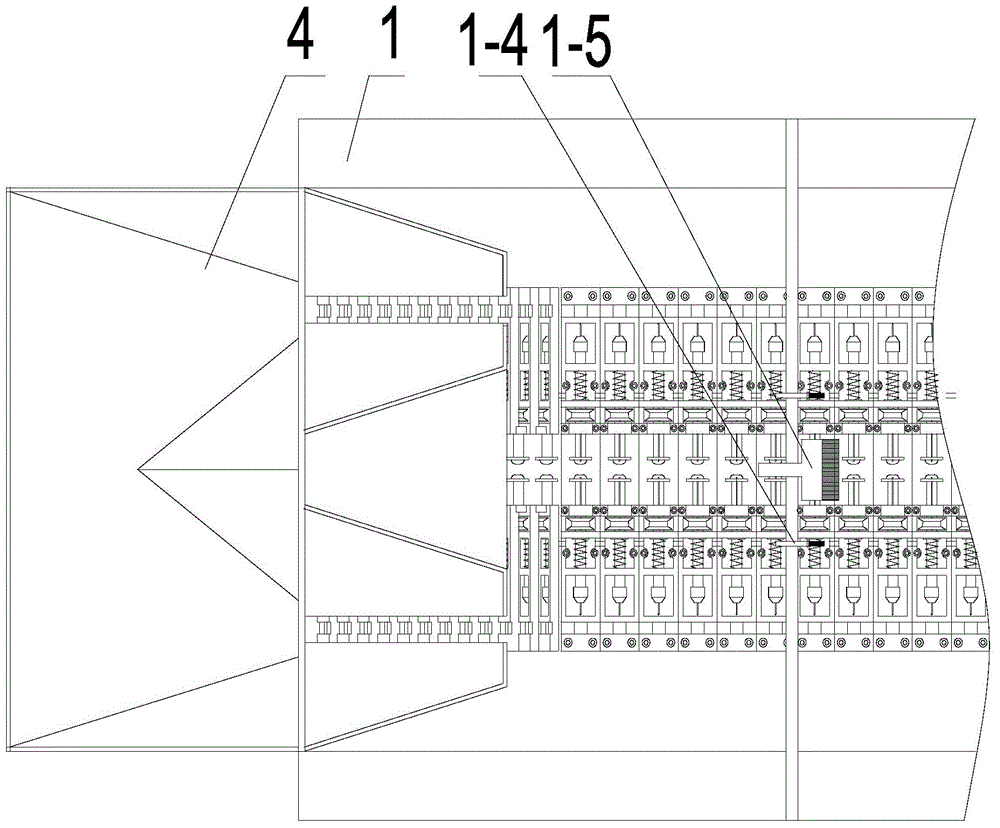

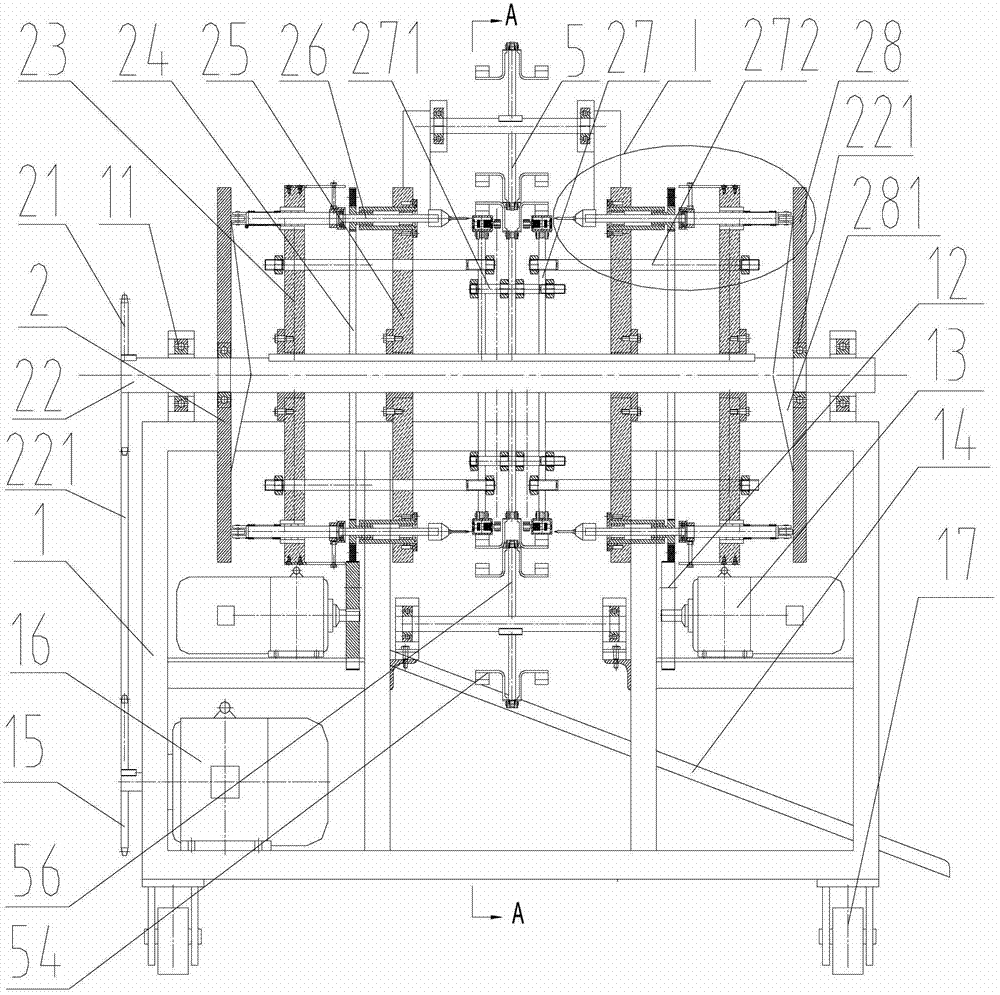

Ultrasonic welding machine of instrument desk

The invention discloses an ultrasonic welding machine of an instrument desk. The ultrasonic welding machine comprises a frame, movable sliding rails, a fixing device, a driving device, lifting cylinders, first fixing plates and universal welding units, wherein the plurality of movable sliding rails are arranged on the frame; the fixing device capable of moving along the sliding rails forwards and backwards is arranged on the movable sliding rails; the driving device is arranged on the frame to drive the fixing device to move along the sliding rails forwards and backwards; the plurality of lifting cylinders are arranged above the frame; the first fixing plates are arranged at the lower end parts of expansion links of the lifting cylinders; the plurality of universal welding units are arranged below the first fixing plates. The ultrasonic welding machine of the instrument desk can effectively save labor and improve machining efficiency and machining quality, and is suitable for batch machining.

Owner:SUZHOU KEBER PRECISION MACHINERY

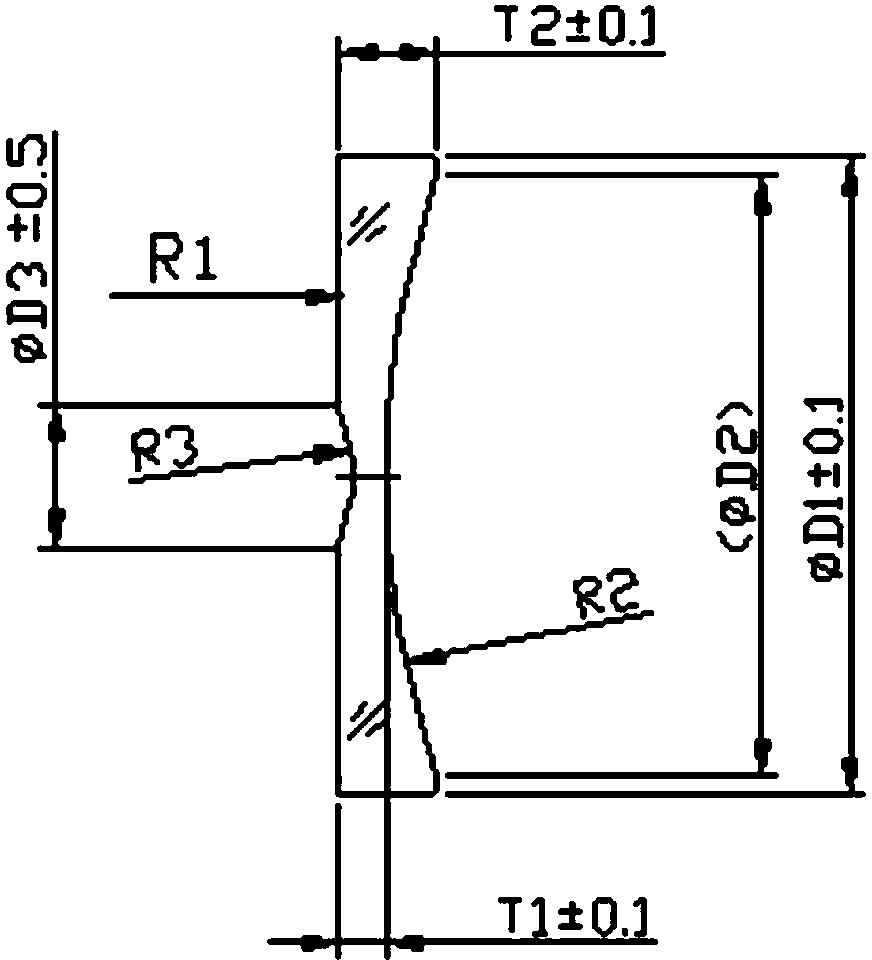

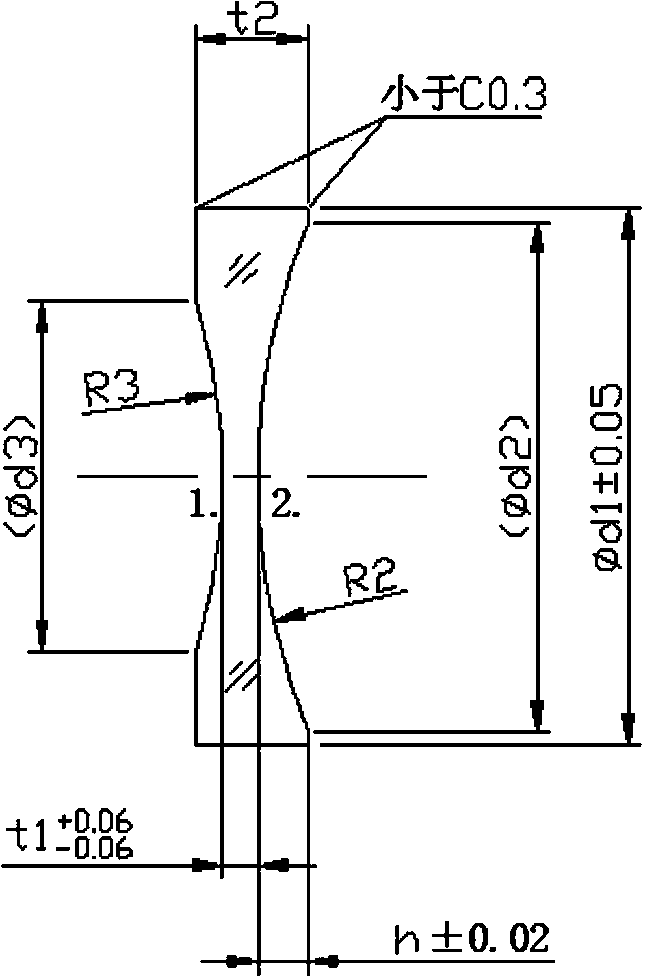

Method for machining optical lens with three radii

ActiveCN103506913AMeet optical parts requirementsSimple processOptical surface grinding machinesEngineeringMachining process

The invention discloses a method for machining an optical lens with three radii. The optical lens is machined through two machining steps according to the technology, and the specific technology includes the steps of milling, accurate grinding, edging, polishing, milling, accurate grinding, polishing and film coating. The first machining step includes the steps of reserving a central thickness tolerance and a rise tolerance which are required to be controlled in the first machining step, and enabling the opening diameter of an R3 face to be increased in the first machining step so as to be suitable for polishing and machining, and meanwhile reserving an arc height allowance which is larger than 0.7mm when secondary milling is carried out on an R1 face. The second machining step includes the technological steps of mainly achieving grinding on the R1 face, enabling the total height to be guaranteed, meanwhile, controlling the opening diameter of an R2 face to be within a required range, conducting accurate grinding and polishing, and then enabling the total height to meet drawing requirements of parts. The whole technological processes are easy and convenient to carry out, and the method is suitable for field control, machining requirements are met, and the optical lens is suitable for mass machining.

Owner:NANYANG LIDA PHOTOELECTRIC

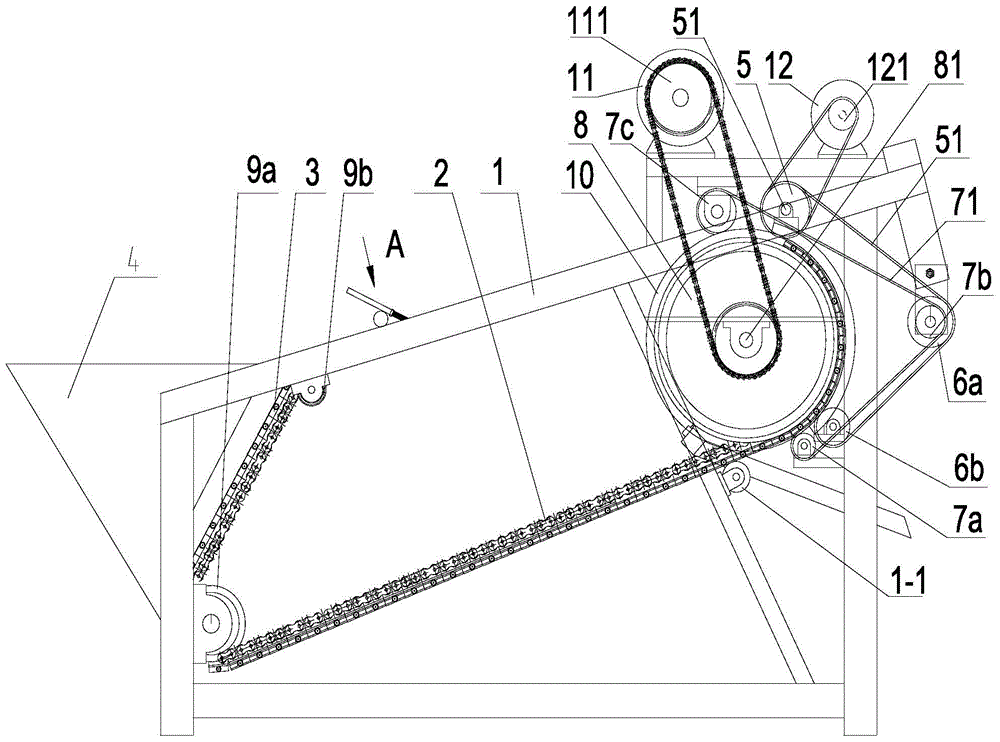

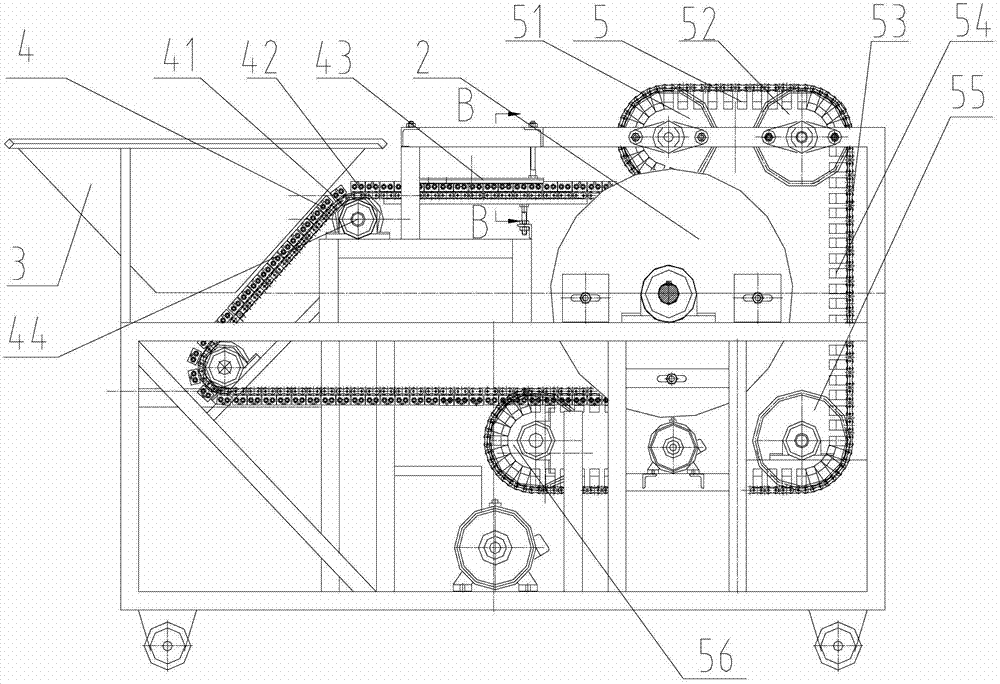

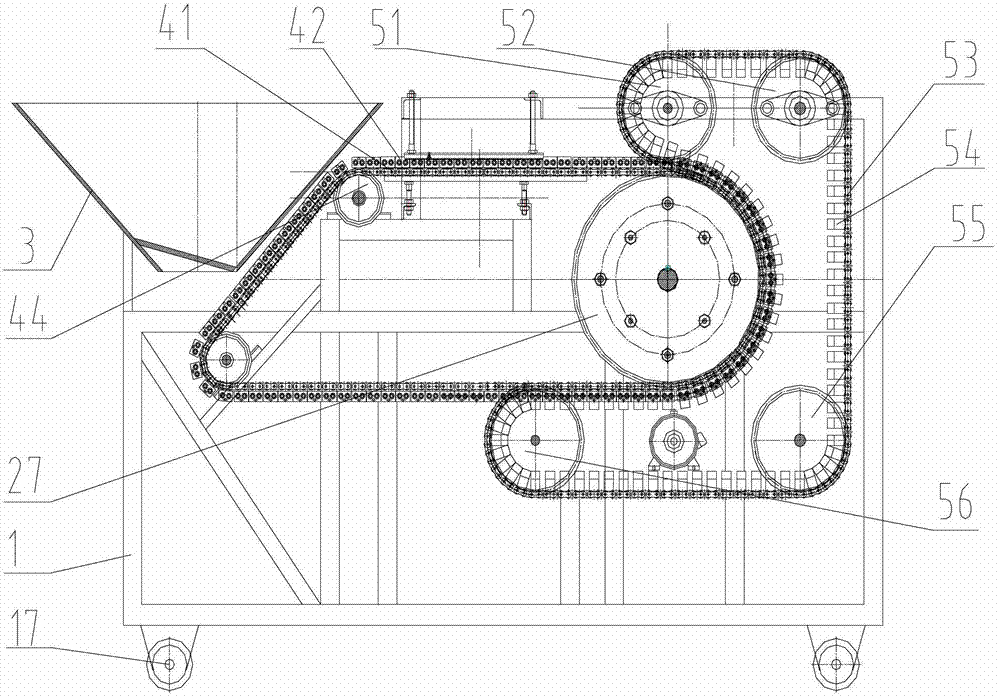

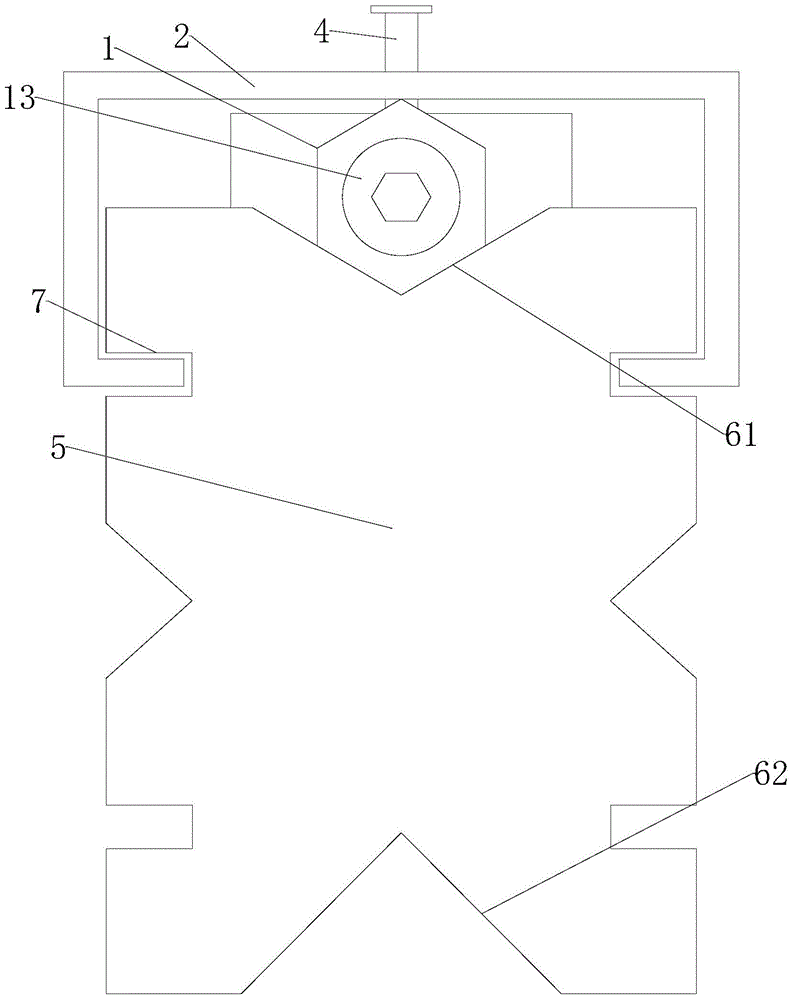

Lotus seed core drilling machine

ActiveCN104544485ASuitable for batch processingIncrease productivityFruit stoningTransmission beltEngineering

The invention discloses a lotus seed core drilling machine. The lotus seed core drilling machine is characterized by comprising a stand, a hopper, a plurality of core removing devices, a driving belt pulley, a driven belt pulley, a transmission belt, a material press belt, a material press belt pulley, a material conveying disc, a drive chain wheel, a driven chain wheel and a conveying chain; each core removing device comprises a substrate, a drill rod, a drill bit and a pulley wheel; the substrate is provided with lotus seed grooves and belt pulley holes, the drill rod is inserted in a drill rod hole and connected with the drill bit, and the belt pulley is connected with the drill rod; a spring is arranged between the drill rod and substrate; the core removing devices are arranged on the chain, and the material conveying disc is provided with a cam mechanism, the transmission belt and the material press belt; the transmission belt is compressed on the belt wheels of the core removing devices, and the material press belt is corresponding to aligning holes of the core removing devices. The lotus seed core drilling machine uses mechanical automatic work to automatically remove lotus seed cores, enables the production efficiency to be improved, and enables the labor force to be saved. The lotus seed core drilling machine is simple and compact in structure, is low in cost and overcomes the disadvantage of bad safety of manual work.

Owner:谭常勇

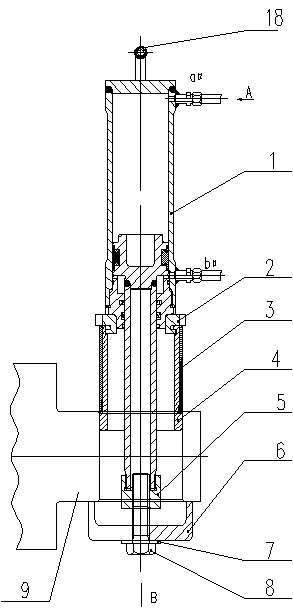

Hand-held hydraulic bushing press-mounting device

The invention discloses a hand-held hydraulic bushing press-mounting device, and belongs to the technical field of machining equipment. A circle of steps is arranged on the outer circumferential surface of the lower end of a steering tool, and the outer circumferential surfaces of the steps are matched with cylinder bottom hinged holes. An internal thread is arranged on the inner circumferential surface of the upper end of the steering tool. A bushing is sleeved on the steering tool, and the lower end of the bushing abuts against on the steps of the lower end of the steering tool. An externalthread matched with the internal thread of the upper end of the steering tool is arranged on the outer circumferential surface of the lower end of a positioning sleeve. A circle of steps is arranged on the outer circumferential surface of the upper end of the positioning sleeve, and the upper end of the bushing abuts against the lower end faces of the steps of the upper end of the positioning sleeve. The diameter of the steps of the positioning sleeve is larger than that of the cylinder bottom hinged holes. A outer seam allowance matched with the upper end of the positioning sleeve is formed in one end of a cylinder cover of a hydraulic oil cylinder. The piston rod end of the hydraulic oil cylinder is detachably connected with a quick-change sleeve with the diameter larger than the diameter of the cylinder bottom hinged holes. The hand-held hydraulic bushing press-mounting device has a compact and portable structure and can be lifted by hand. By adopting the quick-change structure, thehand-held hydraulic bushing press-mounting device is simple in operation and can be suitable for press-mounting of large workpiece bushings. For different specifications, only the tool needs to be replaced.

Owner:XCMG HYDRAULICS CO LTD

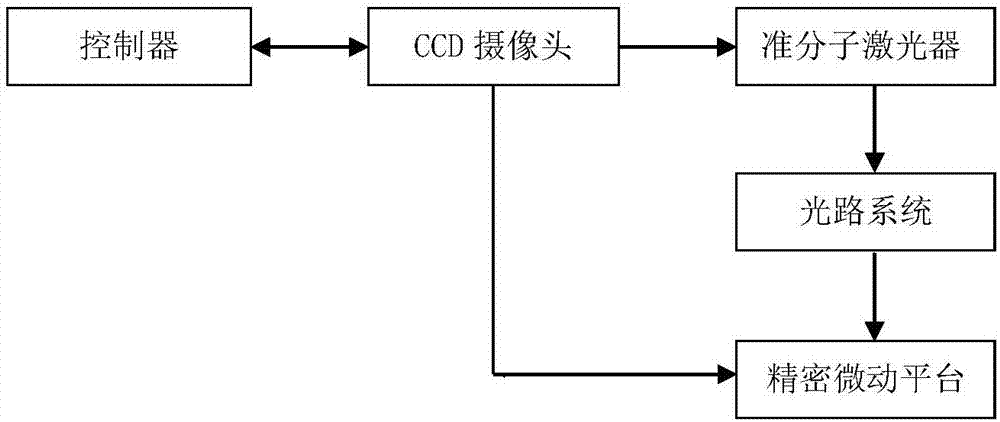

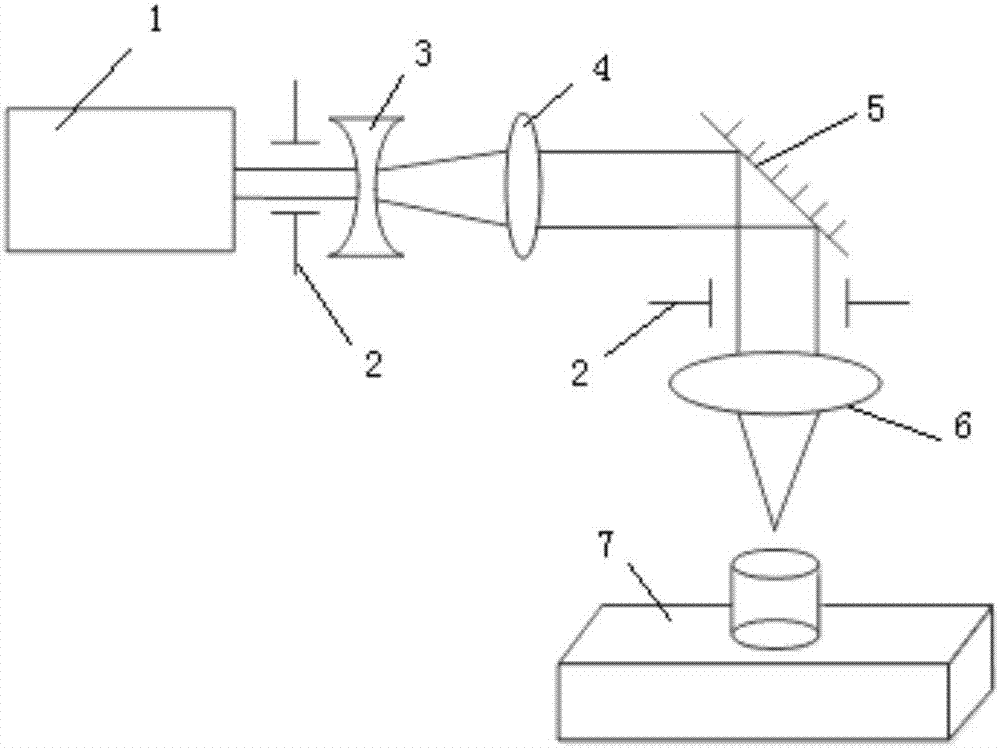

Optical fiber F-P filter and preparation method thereof

ActiveCN107247310ASolve end face offset misalignmentImprove filtering performanceOptical light guidesDislocationEngineering

The invention discloses an optical fiber F-P filter and a preparation method thereof, and solves the problems that translational dislocation and even inclined angle are liable to occur in the end surface processing course of the present optical fiber F-P cavity so that cascade spacing of the optical fiber F-P cavity can be reduced and miniaturization of the cascade filter can be realized. The adopted technical scheme is that two or more than two micron-scale holes are continuously carved on one optical fiber core in one step by using the excimer laser to manufacture a single optical fiber F-P filter or a cascade optical fiber F-P filter, the optical fiber end surface is replaced by the micron holes and the air medium is replaced by the optical fiber core so that transmission light is enabled to be reflected for multiple times between the micron holes to form interference, a pair of micron holes form the single optical fiber F-P filter, and multiple micron holes form the cascade optical fiber F-P filter.

Owner:菏泽市新世纪电子技术有限公司

Processing method of high-elasticity cloud flannelette

InactiveCN108660793AGood crepe effectGood shape retention for pleatsBiochemical fibre treatmentLiquid/gas/vapor removalProduct inspectionProcessing cost

The invention discloses a processing method of high-elasticity cloud flannelette, which comprises the following steps of: S1, preparing raw materials, and pretreating processing flannelette, S2, sufficiently dyeing the flannelette, S3, drying the dyed flannelette, S4, preparing an elasticity improvement solution, and spraying the solution onto the surface of the flannelette to improve elasticity,S5, gigging and sufficiently carding the soaked flannelette, and S6, conveying the gigged flannelette into a setting machine for setting, and then performing finished product inspection, rolling and package. The flannelette prepared by the method is soft, thick and breathable, keeps warm, has a good creping effect, an excellent pleat preservation effect, a good textile shape and structural stability, is easy to flatten, soft in hand feeling, bright in color and has a strong stereoscopic effect and perfect elasticity; in addition, the overall processing cost is low; a production procedure is simple; and the method is suitable for massive processing.

Owner:常熟市兆佳针纺织有限公司

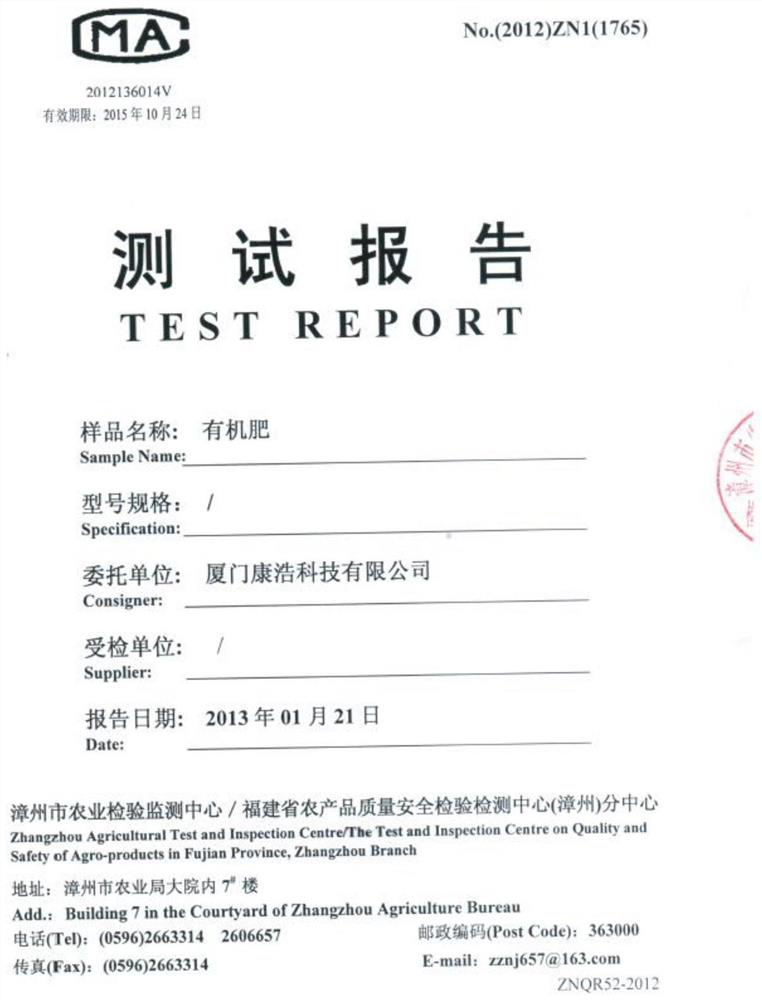

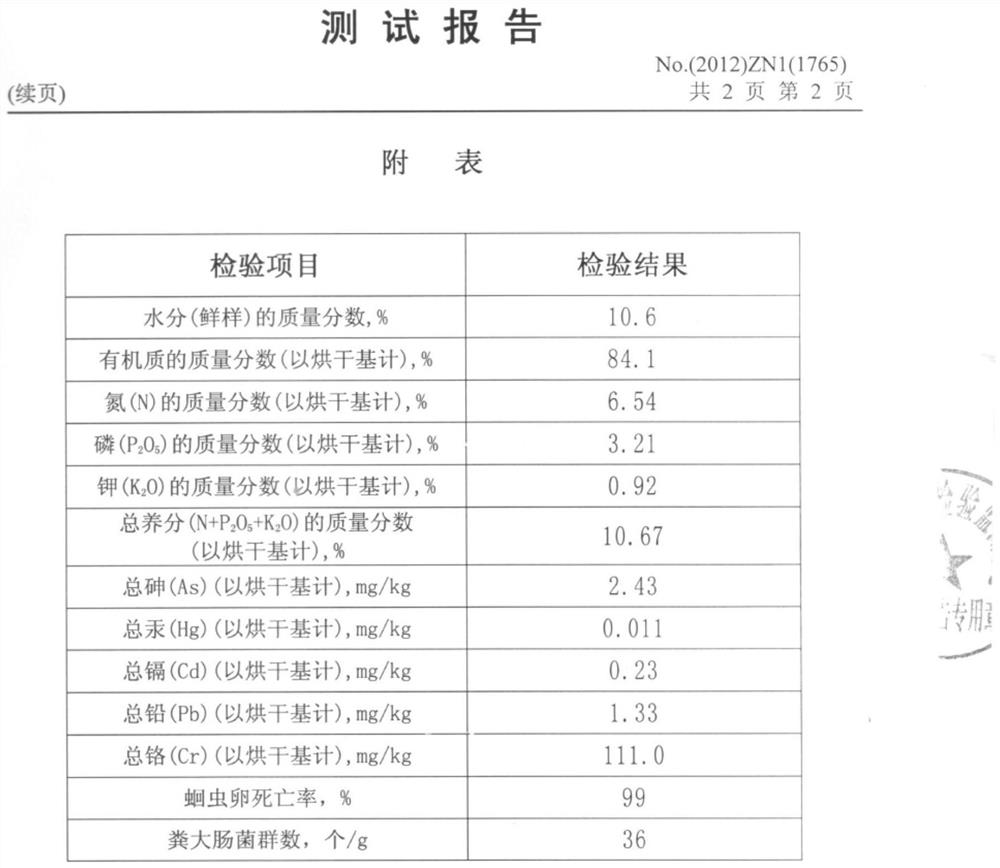

Pig manure organic fertilizer fermentation microbial inoculum and application method thereof

PendingCN111620724ARemove completelySuitable for batch processingFungiBio-organic fraction processingBacillus licheniformisAscaris

The invention discloses a pig manure organic fertilizer fermentation microbial inoculum, which comprises a microbial inoculum composed of bacillus licheniformis, bacillus subtilis, saccharomycetes, trichoderma viride, rhizopus oryzae, aspergillus niger, actinomycetes and acid protease. Compared with the prior art, harmful substances and ascaris in pig manure can be thoroughly removed for an organic fertilizer prepared from pig manure, the natural fermentation period is only about 20-25 days, and the microbial inoculum is suitable for batch treatment in large-scale farms.

Owner:SICHUAN HUIBANG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

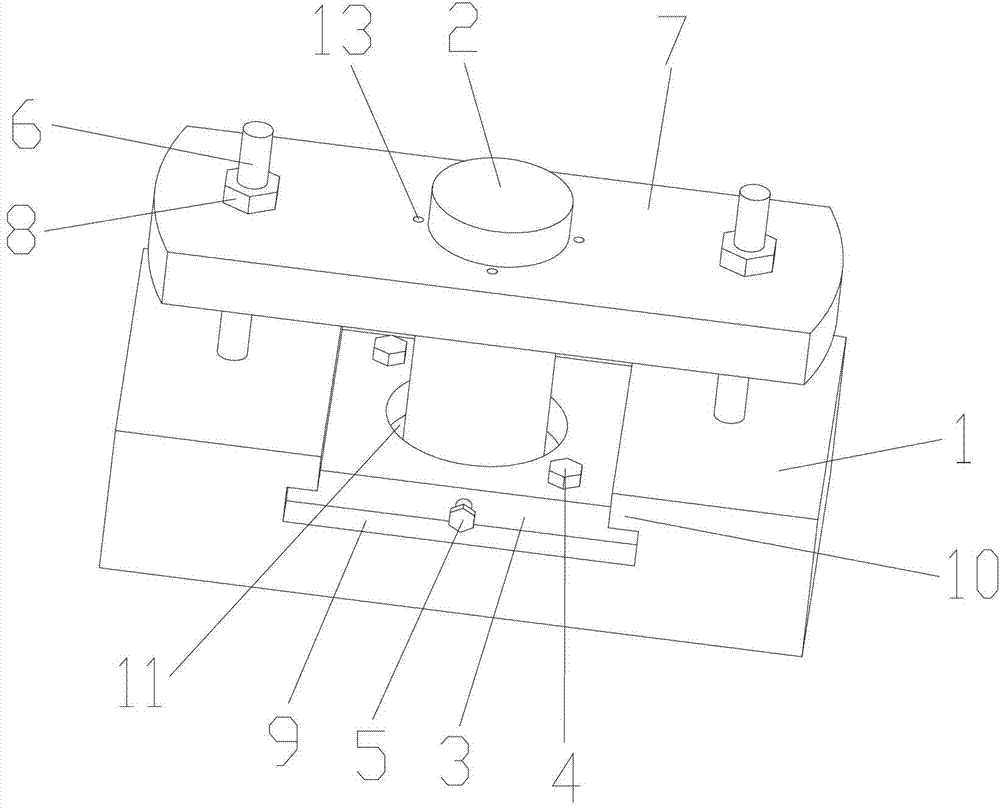

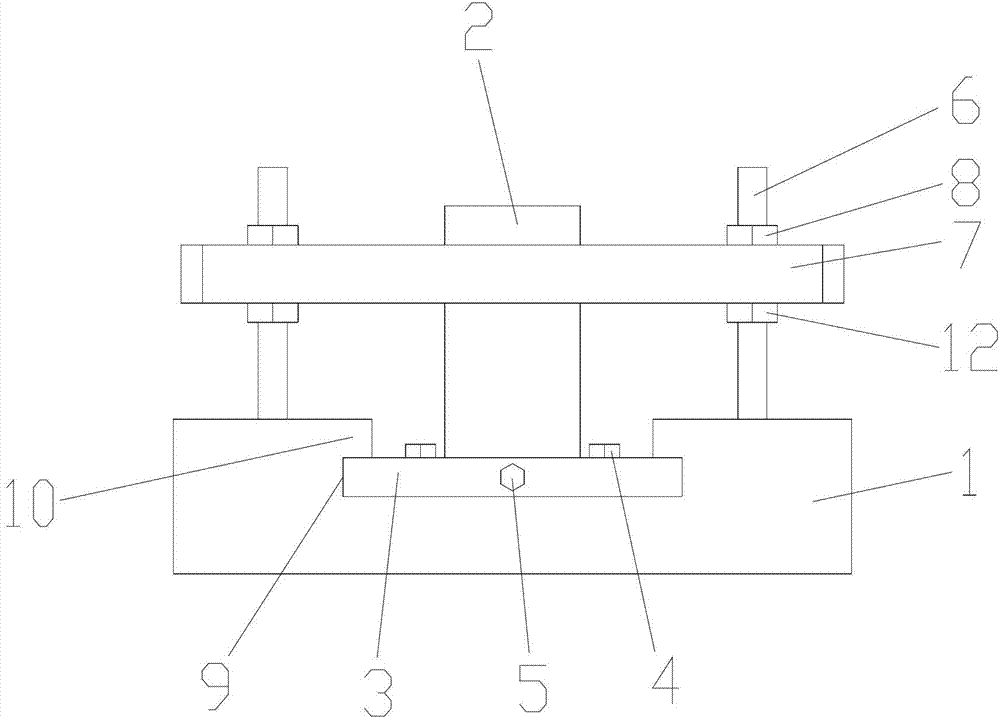

Fixture for machining of end face hole of sleeve

InactiveCN102873560AGuaranteed positioning accuracyEasy to operatePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a fixture for machining of an end face hole of a sleeve. The fixture comprises a base, a positioning cylinder, a positioning block, fixing bolts, a locking bolt, screws, a pressing plate and compression nuts. The base is provided with a square groove which is provided with the positioning cylinder. The positioning block is fixed in the square groove through the fixing bolts and is provided with a positioning round groove. Diameter of the positioning round groove is larger than that of the positioning cylinder. The pressing plate is arranged above the base through the screws and the positioning cylinder. The compression nuts are arranged above the screws located on the pressing plate. The pressing plate is provided with machining holes centering on the center of the positioning cylinder, which are arrayed circularly. The fixture for machining of the end face hole of the sleeve is simple to operate and widely applicable, guarantees positional precision of the hole, and is high in machining efficiency and suitable for batch machining.

Owner:SUZHOU DONGLI MACHINERY

Polishing paste used for sapphire round-rod bakelite wheel and preparation method thereof

ActiveCN101875817ANo precipitationNo splashPolishing compositions with abrasivesVegetable oilHigh volume manufacturing

The invention relates to polishing paste used for a sapphire round-rod bakelite wheel. The polishing paste consists the following components in part by weight: 3 to 6 parts of nano-diamond, 240 to 300 parts of vaseline and 135 to 200 parts of vegetable oil. The surface of a workpiece polished by adopting the polishing paste has high surface finishment; an operation method is simple; technical requirements are low; and the polishing paste is suitable for large-batch production. The polishing paste prepared by adopting a preparation method of the invention has the characteristics of uniform dispersion, stability and no precipitation.

Owner:CHONGQING CHUANYI AUTOMATION

Silicon pole plate and preparation method thereof

The invention discloses a silicon pole plate and a preparation method thereof. The silicon pole plate is made of a doped conductive crystalline silicon material and is provided with an internal cooling medium flow channel, a front reducing agent flow channel and / or a back oxidizing agent flow channel, wherein the internal cooling medium flow channel, the front reducing agent flow channel and / or the back oxidizing agent flow channel are / is respectively provided with a silicon pole plate inlet and outlet combination communicated with the internal cooling medium flow channel, the front reducing agent flow channel and / or the back oxidizing agent flow channel. Compared with a metal pole plate, a graphite pole plate or a composite material pole plate in the prior art, the silicon pole plate provided by the invention has better advantages in the aspects of service life, cost, efficiency and power density, and undoubtedly has great significance and a core promotion effect on the large-batch industrialization process of fuel cells.

Owner:SUNLAND SHANGHAI INVESTMENT CO LTD

Method for manufacturing nano-scale electric jet-flow spray head based on SU-8 glue electrolytic process

The invention relates to nano-scale electric jet-flow spray head equipment, in particular to a method for manufacturing a nano-scale electric jet-flow spray head based on a SU-8 glue electrolytic process. The method is characterized by comprising the following steps: adopting SU-8 glue as an electric jet-flow spray needle material, and creating necessary conditions for forming nano cracks throughan incomplete drying and over-exposure way; taking a graphene straight line as an induced graph, and forming a linear nano channel with a relatively uniform dimension below the induced graph under electrolytic action of high-voltage electricity; and forming the final nano-scale electric jet-flow spray head through steps of thermo-compression bonding, ultra-violet lithography and electrode manufacturing.

Owner:JILIN UNIV

Parallel multi-angle tilted fiber bragg grating and preparation method thereof

ActiveCN108318963AAccurate angleEasy to operateCladded optical fibreOptical waveguide light guideFiberGrating

The present invention provides a parallel multi-angle tilted fiber bragg grating. In the same position of a fiber, in a direction being perpendicular to the axial direction of the fiber, the internalportion of the fiber core of the fiber has a plurality of different portions, wherein one tilted fiber bragg grating structure is prepared in each portion, the extension directions of the grating periodic structures of each two adjacent portions are parallel, and the titled angles of the grating periodic structures are different. After experimental verification, compared to a corresponding single-angle title fiber bragg grating, the parallel multi-angle tilted fiber bragg grating can obtain cladding mode response with a wider range and can be applied to refractive index measurement with a wider range. The present invention further provides a preparation method of a parallel multi-angle tilted fiber bragg grating.

Owner:XI AN JIAOTONG UNIV

Efficient polishing device for wood board used for furniture processing

InactiveCN109986452AReduce processing timeImprove processing efficiencyPolishing machinesGrinding drivesDrive shaftArchitectural engineering

The invention discloses an efficient polishing device for a wood board used for furniture processing. The efficient polishing device comprises a placement frame, a hollow base, clamping plates and a cover plate, wherein fixed blocks are welded on the two sides of the upper end of the hollow base, two telescopic rods are symmetrically and movably mounted on the two sides, away from the fixed blocks, of the upper end of the hollow base through chutes, second rotating rods are rotationally mounted on the telescopic rods, a polishing shaft is welded between the two symmetrically distributed secondrotating rods, the cover plate is welded at the top ends of the two symmetrically distributed telescopic rods, a motor is mounted at the upper end of the cover plate, a driving shaft is mounted on one side of the motor, the two sides of the placement frame are rotationally mounted on the fixed blocks through first rotating rods, the clamping plates are mounted on the hollow base, first threaded rods are mounted on the clamping plates through threads, and a clamping blocks is mounted at one end of each first threaded rod. According to the efficient polishing device for the wood board used forthe furniture processing, the placement frame rotates through the first rotating rods after one surface of the wood board is polished, so that the unpolished surface of the wood board is turned over and is subjected to polishing work.

Owner:常鑫

Polishing liquid used for gem ball with 10-grade surface finish and preparation method

ActiveCN101875819AIndicates high quality and surface finishIncrease productivityPolishing compositionsKeroseneBatch production

The invention relates to polishing liquid used for a gem ball with 10-grade surface finish and a preparation method. The polishing liquid consists of the following components in part by weight: 3 to 6 parts of nano-diamond, 240 to 300 parts of stearic acid, 320 to 480 parts of kerosene, and 1 to 1.2 parts of sodium hydroxide. The surface of a workpiece polished by using the polishing liquid of the invention has high surface finishment; an operation method is simple; technical requirements are low; and the polishing liquid is suitable for large-batch production. The polishing liquid prepared by adopting the method of the invention is permanent suspension without precipitate.

Owner:CHONGQING CHUANYI AUTOMATION

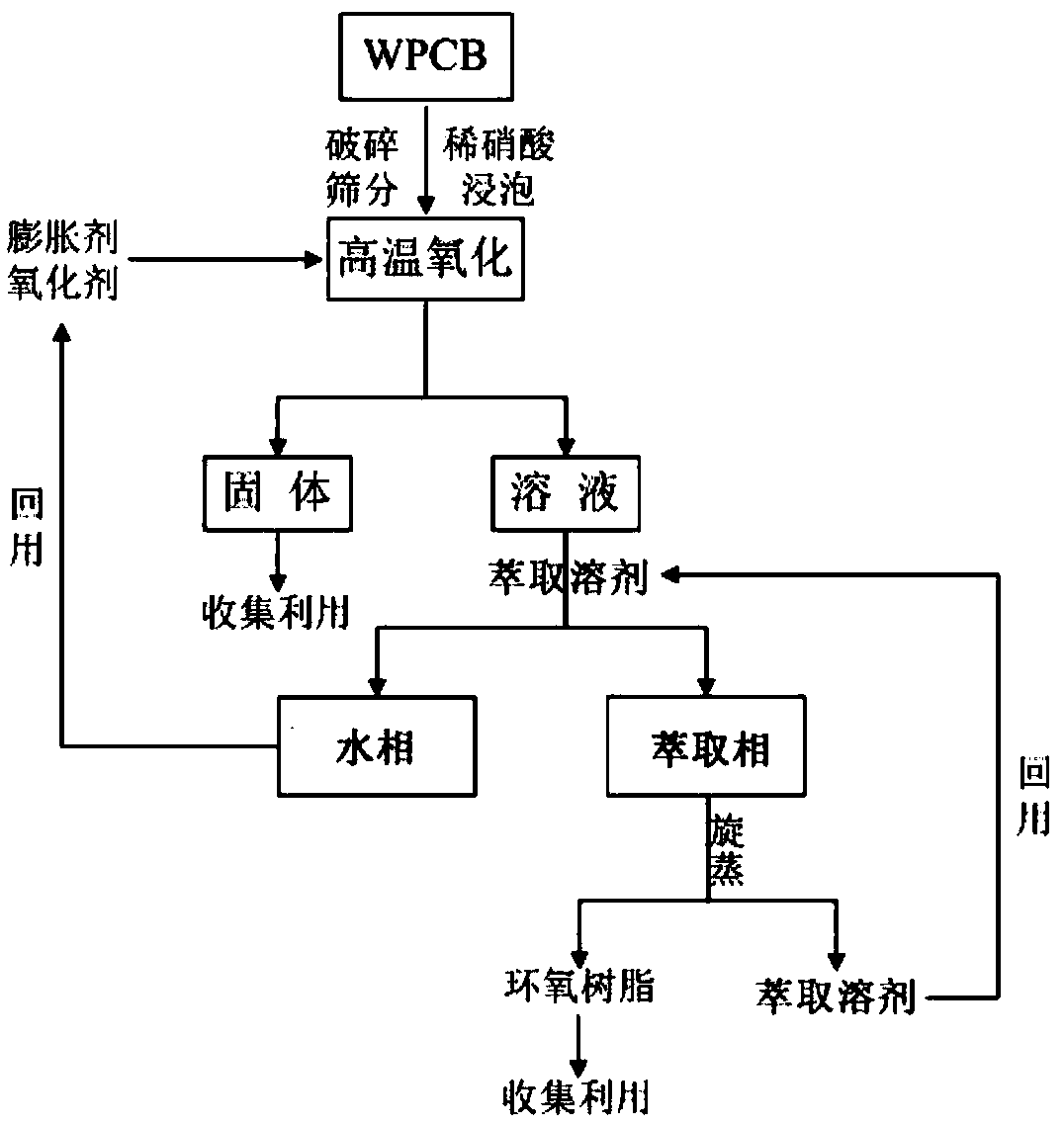

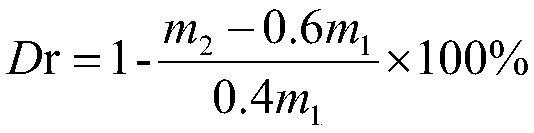

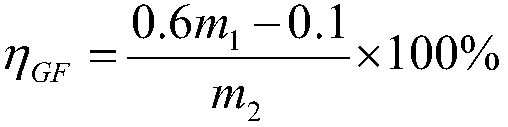

Method for wet oxidation separation of glass fiber and epoxy resin in WPCB non-metallic powder

PendingCN109651645APerformance improvement such as stretchingSkeletal structure is completePlastic recyclingEpoxyGlass fiber

Belonging to the technical field of resource recycling of electronic waste, the invention in particular relates to a method for wet oxidation separation of glass fiber and epoxy resin in WPCB non-metallic powder. The method includes: soaking non-metallic powder obtained by subjecting WPCB to mechanical crushing and sorting and metal recovery with a dilute nitric acid solution fully, conducting filtering and drying, then performing mixing with an expansion agent and an inorganic oxidant and carrying out wet high-temperature oxidation reaction, and subjecting the obtained product to follow-up treatment, thus obtaining high purity glass fiber and epoxy resin solid respectively. The molecular structure and characteristic functional group of the recovered epoxy resin do not change. The separated glass fiber (containing a small amount of organic ingredients) is employed to modify plastic, and the modified composite plastic shows performance superior to the original plastic, thus realizing the resource recycling value of WPCB non-metallic powder. The method mainly covers the chemical degradation separation method of WPCB non-metallic materials, the experimental scheme is environmentally friendly, and the separation effect is good.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY +1

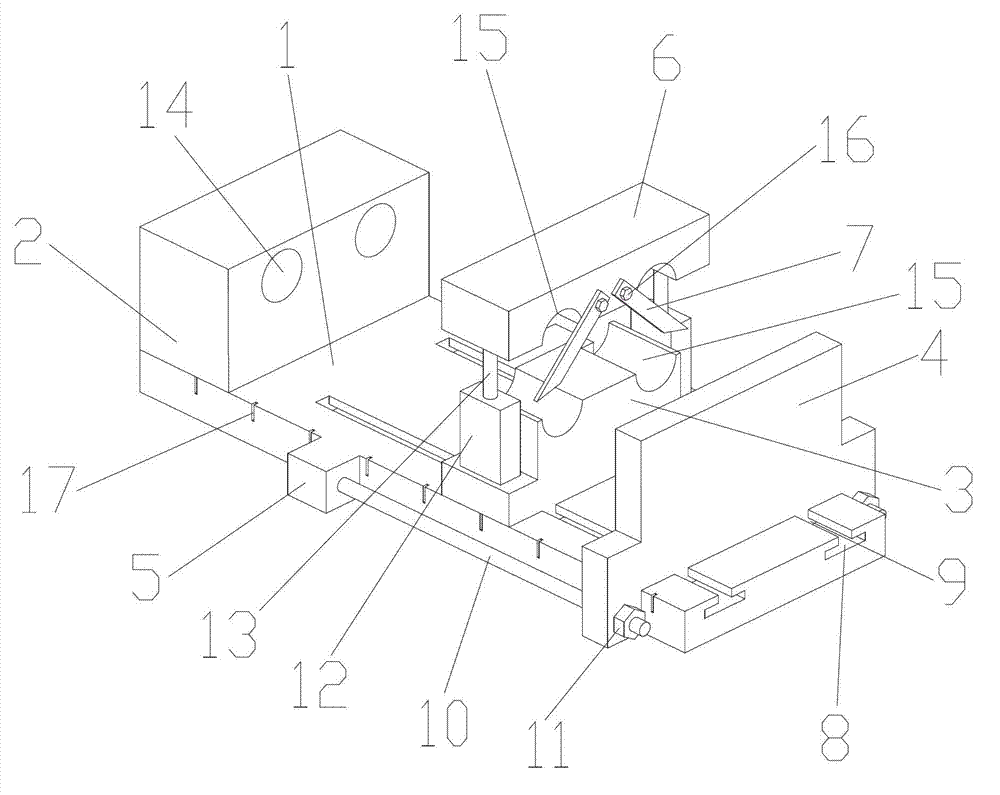

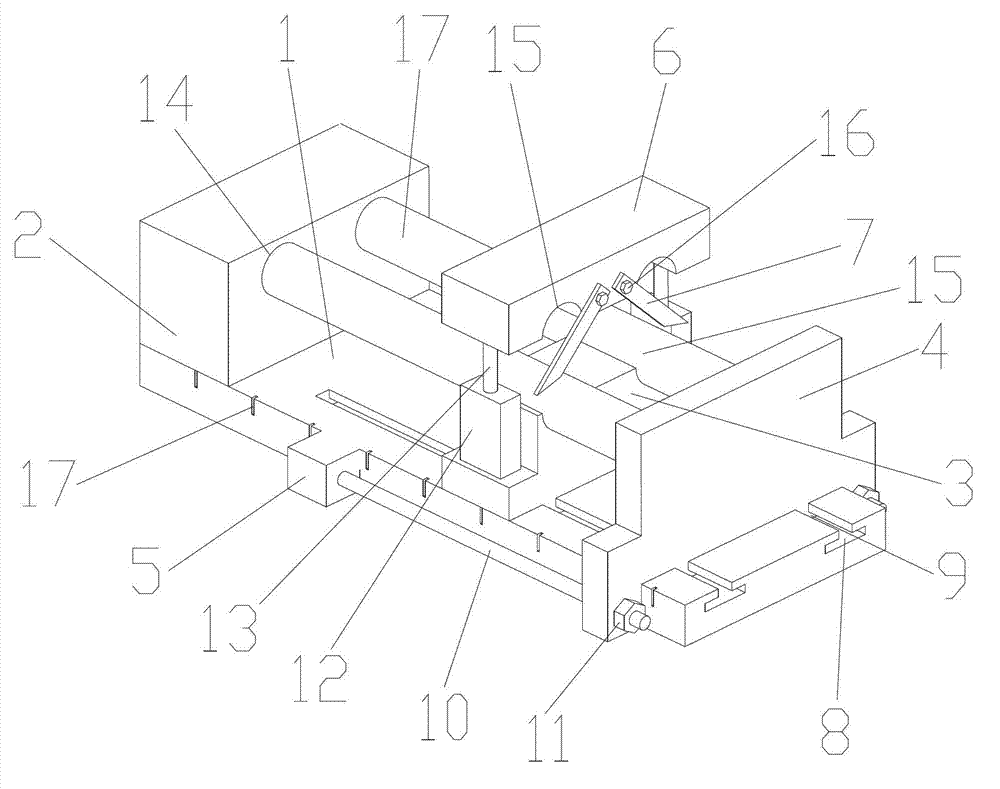

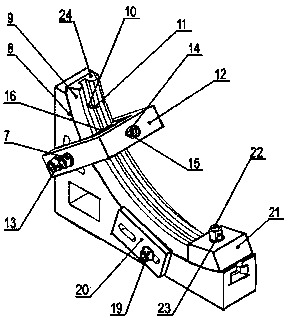

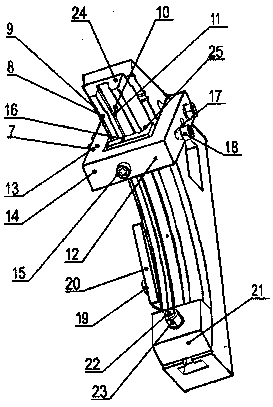

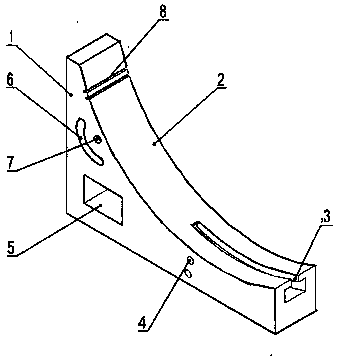

Milling cutting installing and clamping tooling for end surface of circular arc-shaped clamp hoop

PendingCN107662118APrecise positioningImprove general performancePositioning apparatusMetal-working holdersShaped beamClassical mechanics

The invention discloses a milling cutting installing and clamping tooling for the end surface of a circular arc-shaped clamp hoop. The problem of installing clamping fixation during the milling and cutting on the end surface of the circular arc-shaped clamp hoop is solved. The tooling comprises an installing and clamping base (1) and an arc-shaped workpiece (9) with concave grooves, wherein a door-shaped frame (12) is arranged at the left end of the installing and clamping base (1); an L-shaped workpiece top end pressing block (16) is arranged on the top beam of the door-shaped beam (12); a right lower end stop block (21) is arranged at the right end of the installing and clamping base (1); a right lower end baffle plate (20) is arranged at the side surface of the right lower end of the installing and clamping base (1); a workpiece upper end positioning pin (11) is inserted and connected between the workpiece positioning through hole (10) and the positioning long strip groove (8); thearc-shaped surface (2) arranged on the installing and clamping base (1) and the arc-shaped workpiece (9) with concave grooves have the completely identical radian, so that the arc-shaped bottom surface of the arc-shaped workpiece (9) with concave grooves and the arc-shaped surface (2) are completely attached. The universality of the tooling is high; the tooling is particularly suitable for mass processing.

Owner:SHANXI JIANGHUAI HEAVY IND

Lotus seed core drilling machine

ActiveCN103082385ASuitable for batch processingIncrease productivityFood treatmentGear wheelEngineering

Owner:广昌县正莲生物科技有限公司

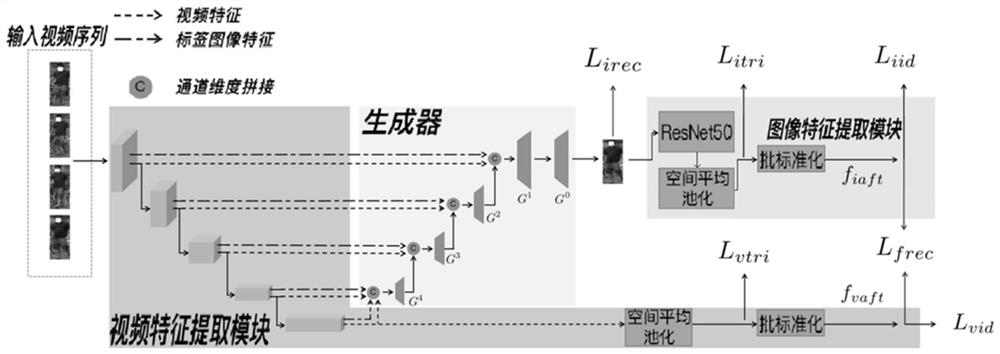

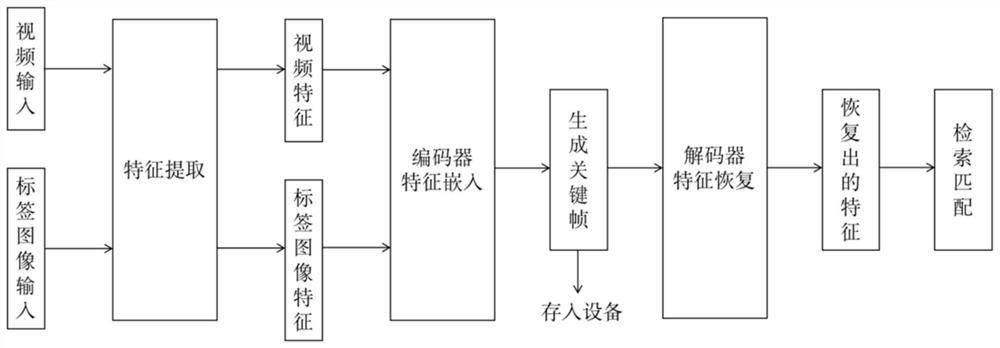

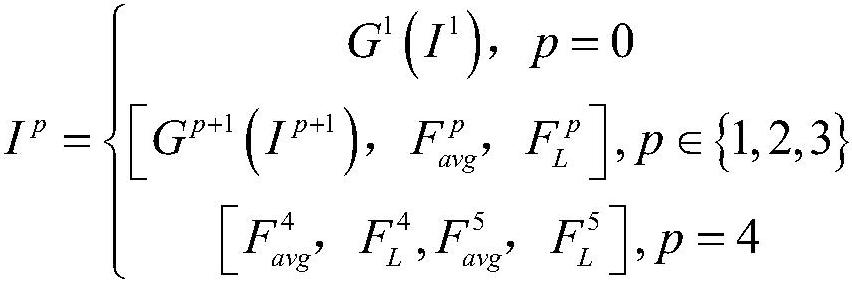

Video sequence encoding and decoding method for video pedestrian re-identification

ActiveCN112418127AReduce storage overheadVideo Feature PreservationCharacter and pattern recognitionNeural architecturesDecoding methodsEngineering

The invention discloses a video sequence coding and decoding method for video pedestrian re-identification, and the method comprises the following steps: in a training stage, fusing label picture features and video features, inputting the fused features into a generator, then employing a label picture as a reconstruction label, and restraining a key frame generated by the generator through image reconstruction loss; and then sending the generated key frame to an image feature extraction module for video feature recovery, and constraining the recovered video features through feature reconstruction loss, so that the video features are consistent with original video features in performance. In an application stage, K frames of pictures are selected by using an HSVTopK method to be used for generating key frames, and then the generated key frames are stored in equipment so as to reduce the storage overhead. When retrieval is needed, the image feature extraction module is used for carryingout video feature recovery on the generated key frame, and the recovered features reserve the performance of the video features and are used for retrieval matching of pedestrians.

Owner:ZHEJIANG UNIV

Linear cutting polygonal tool

InactiveCN104475896APlay the role of positioning indexingSimple processing and positioningPrecision positioning equipmentElectrical-based auxillary apparatusEngineeringMachining

The invention relates to a linear cutting polygonal tool which comprises an indexing module, a U-shaped pressing plate, a workpiece ejector screw, a module pressing screw and a V-shaped block. V-shaped grooves are formed in the upper end and the lower end of the V-shaped block, sliding rail grooves are formed in two sides of the V-shaped block, an opening end of the pressing plate extends into the sliding rail grooves, the pressing plate is slidably matched with the V-shaped block, the indexing module is placed in one V-shaped groove, the module pressing screw connected with the pressing plate in a threaded manner is arranged on the pressing plate, one end of the module pressing screw contacts with the indexing module, a workpiece groove is formed in the indexing module, the workpiece ejector screw is arranged in the workpiece groove, an adjusting baffle plate is arranged on the V-shaped block, a pressing screw is arranged at the lower end of the adjusting baffle plate, and a module positioning and adjusting screw is arranged at the upper end of the adjusting baffle plate. The linear cutting polygonal tool is simple in machining and positioning, high in positioning and indexing accuracy and suitable for batch machining, and indexing mistakes are not easily made.

Owner:CHANGZHOU CHANGSHENG MACHINERY

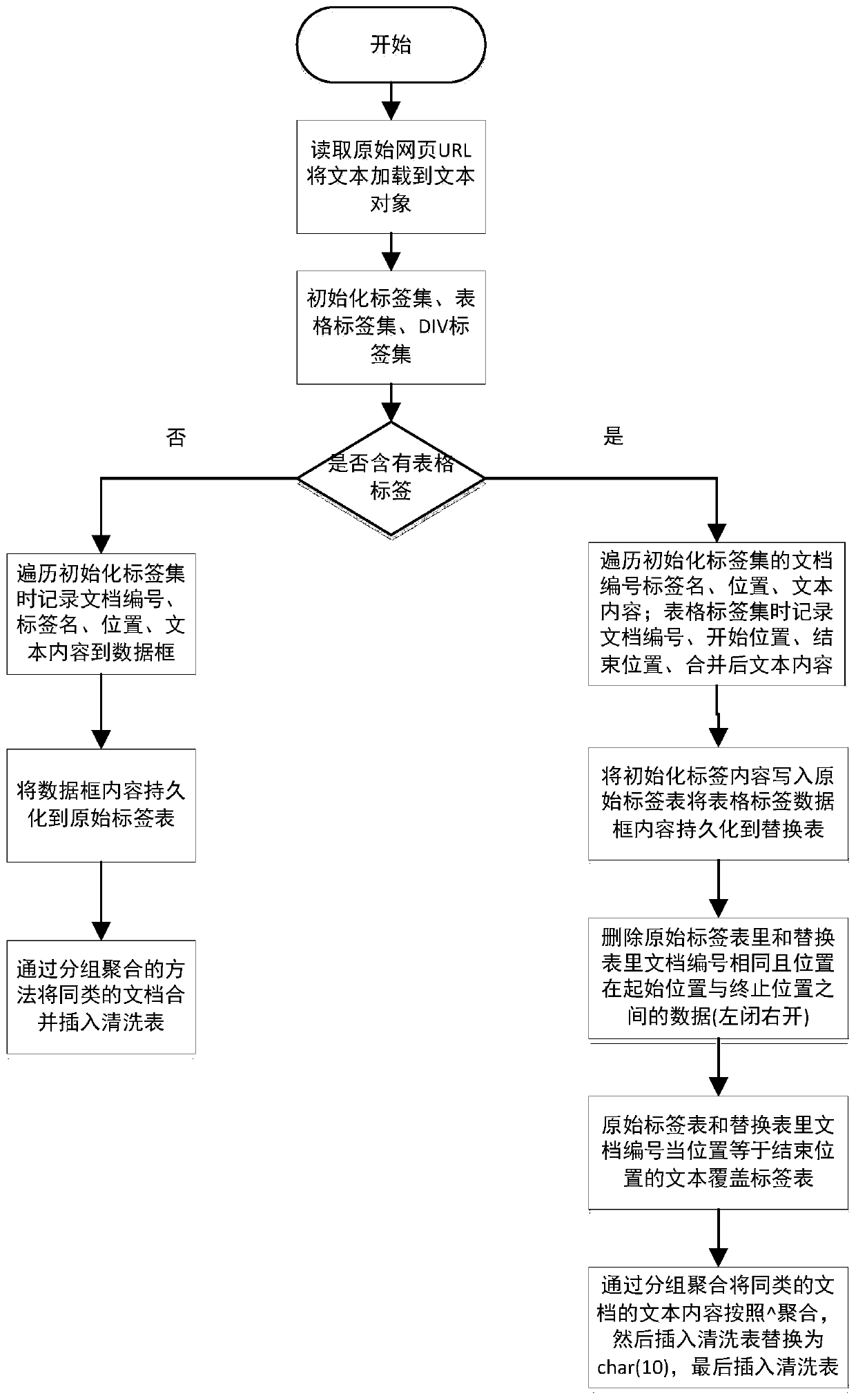

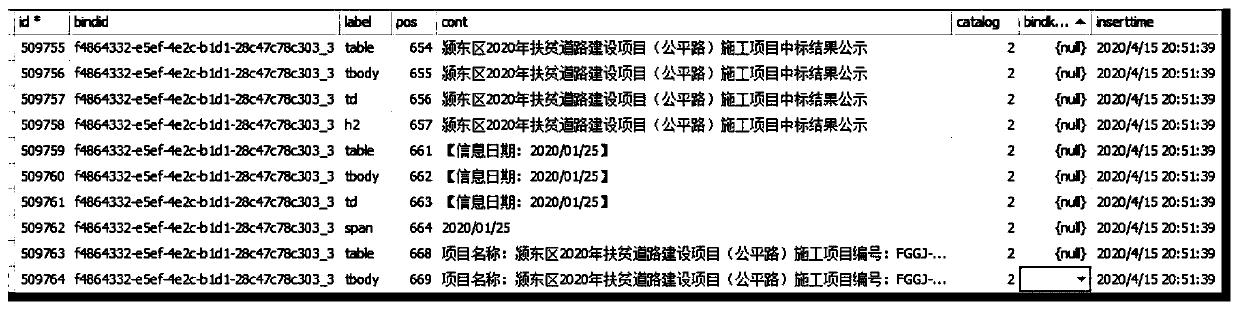

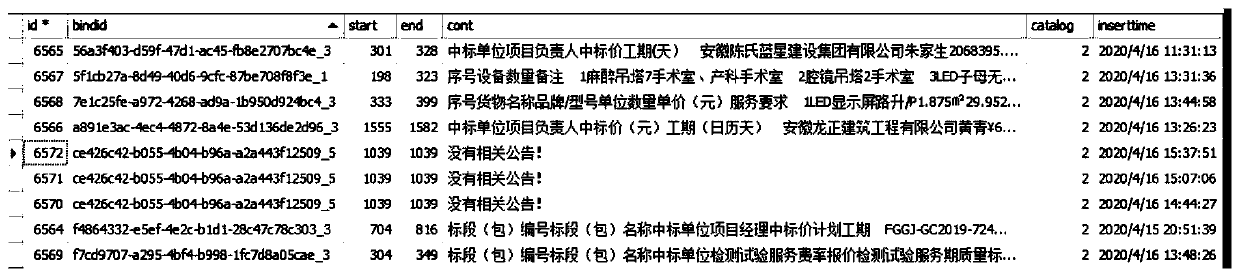

Webpage label position-based text formatting and cleaning method

PendingCN111597292AImprove accuracySupport full extractionText database indexingSpecial data processing applicationsData miningWeb page

The invention discloses a webpage label position-based text formatting and cleaning method, which comprises the following steps of: S1, traversing all labels of a whole webpage, and recording each label name, the position of each label, text content and a document number into an original table; s2, if the webpage contains the table data, dynamically traversing the table data in the webpage according to rows and columns, and extracting key information to obtain a replacement table; s3, matching the original table with the replacement table through document numbers, deleting or updating data information, related to the replacement table, of table positions in the original table, and outputting cleaned data to a cleaning table; and S4, if no table data exists in the webpage, extracting the text corresponding to the DIV in the webpage, extracting the document number and the text content to a data box, persisting the document number and the text content to an original table, and merging andinserting the similar documents into a cleaning table through a grouping aggregation method to complete cleaning of the webpage text. According to the invention, the accuracy of webpage text analysiscan be improved.

Owner:安徽慧医信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com