Method for manufacturing nano-scale electric jet-flow spray head based on SU-8 glue electrolytic process

A nano-scale, SU-8 technology, applied in coating devices, additive processing, etc., can solve the problems of high cost and complex process of nano-scale electrojet nozzles, and achieve low cost, simple preparation process and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

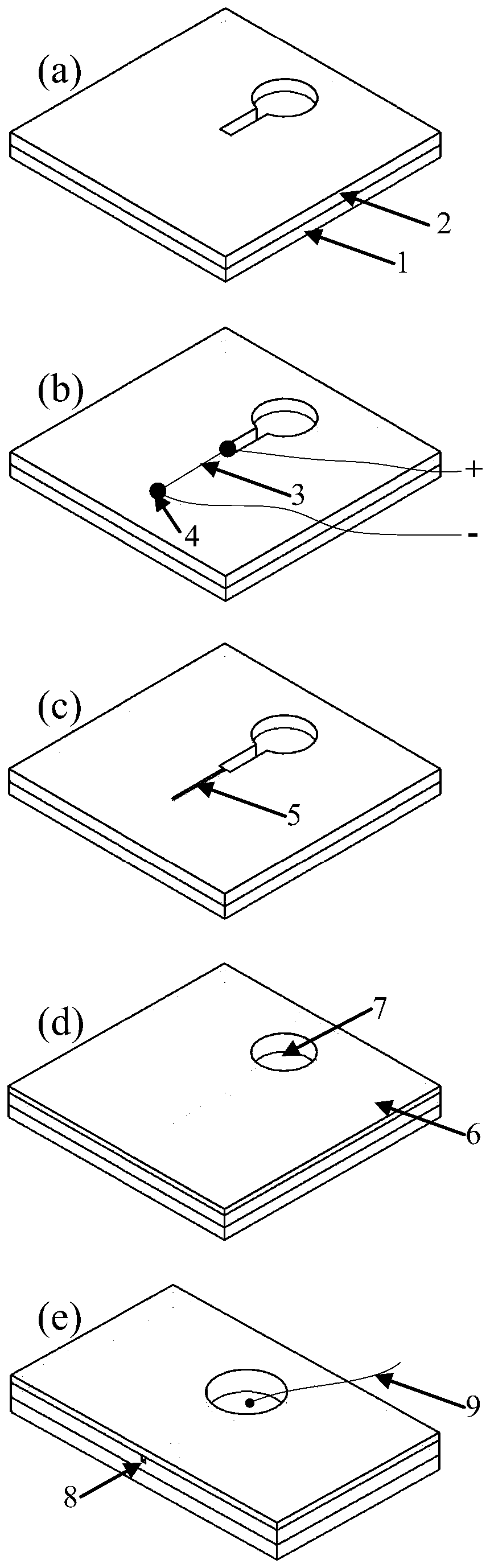

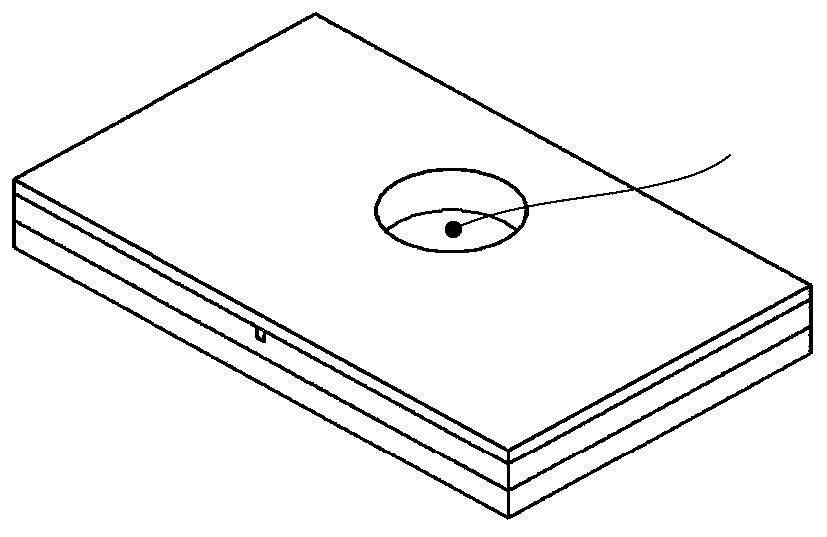

[0014] The specific implementation manner of the patent of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0015] 1. Microstructure fabrication of nanoscale electrofluidic nozzles

[0016] (1) Spin-coat a layer of SU-8 photoresist 2 with a thickness of about 20 microns on the silicon substrate 1, the spin-coating speed is 3000 rpm, and the spin-coating time is 30 seconds. Incomplete pre-baking of SU-8 glue, the pre-baking temperature is 70 degrees Celsius, and the time is 4-5 minutes. Incomplete pre-baking can increase the conductivity of SU-8, ensure that step 2 can form linear and uniform nano-cracks, and prevent the bifurcation of nano-cracks.

[0017] (2) Align the photolithographic mask plate with the SU-8 glue substrate, and overexpose the SU-8 glue, and the exposure time is 15 minutes. Overexposure can promote the embrittlement of SU-8 glue, which is a necessary condition for the formation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com