Patents

Literature

94 results about "Electrolysis - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

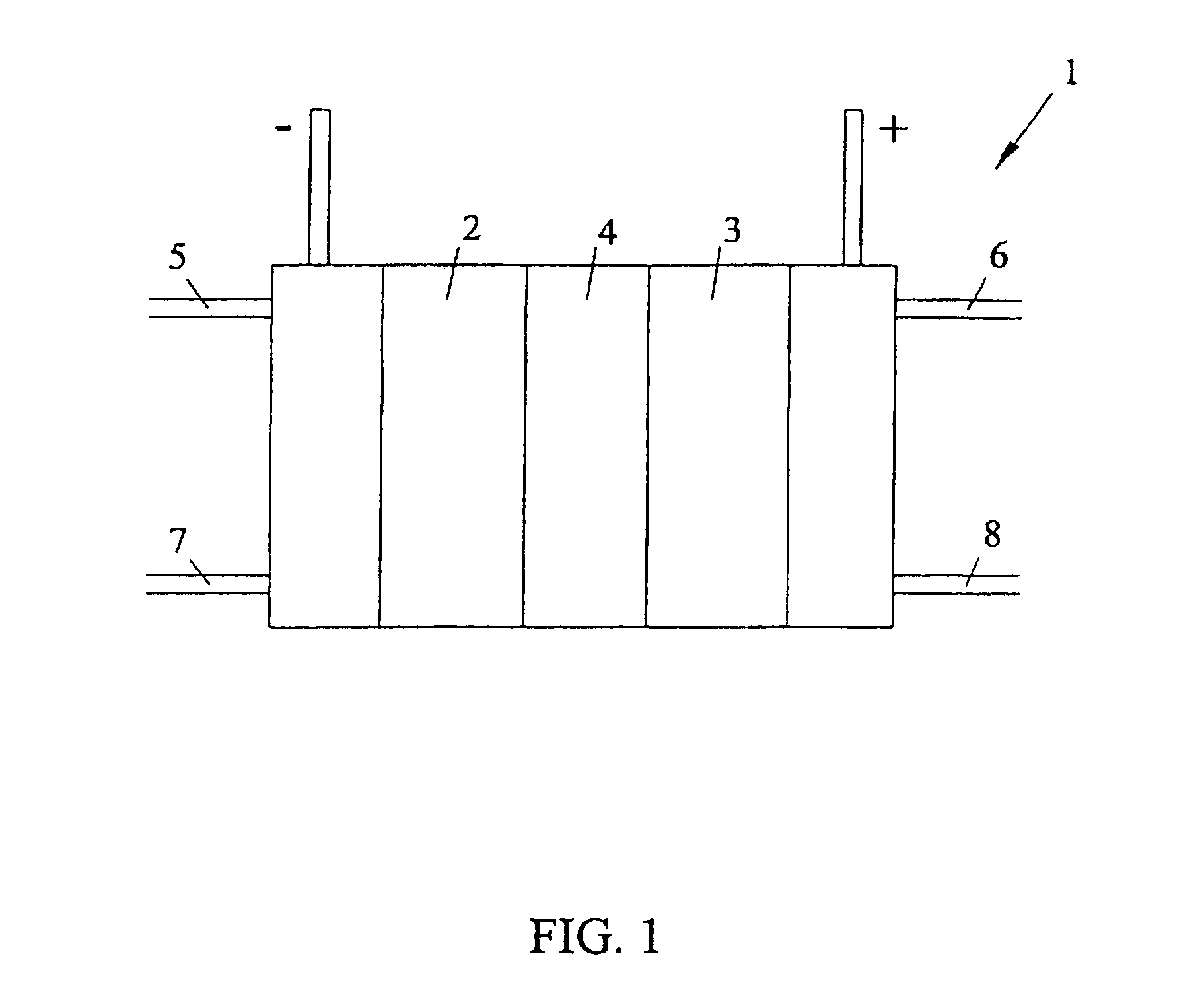

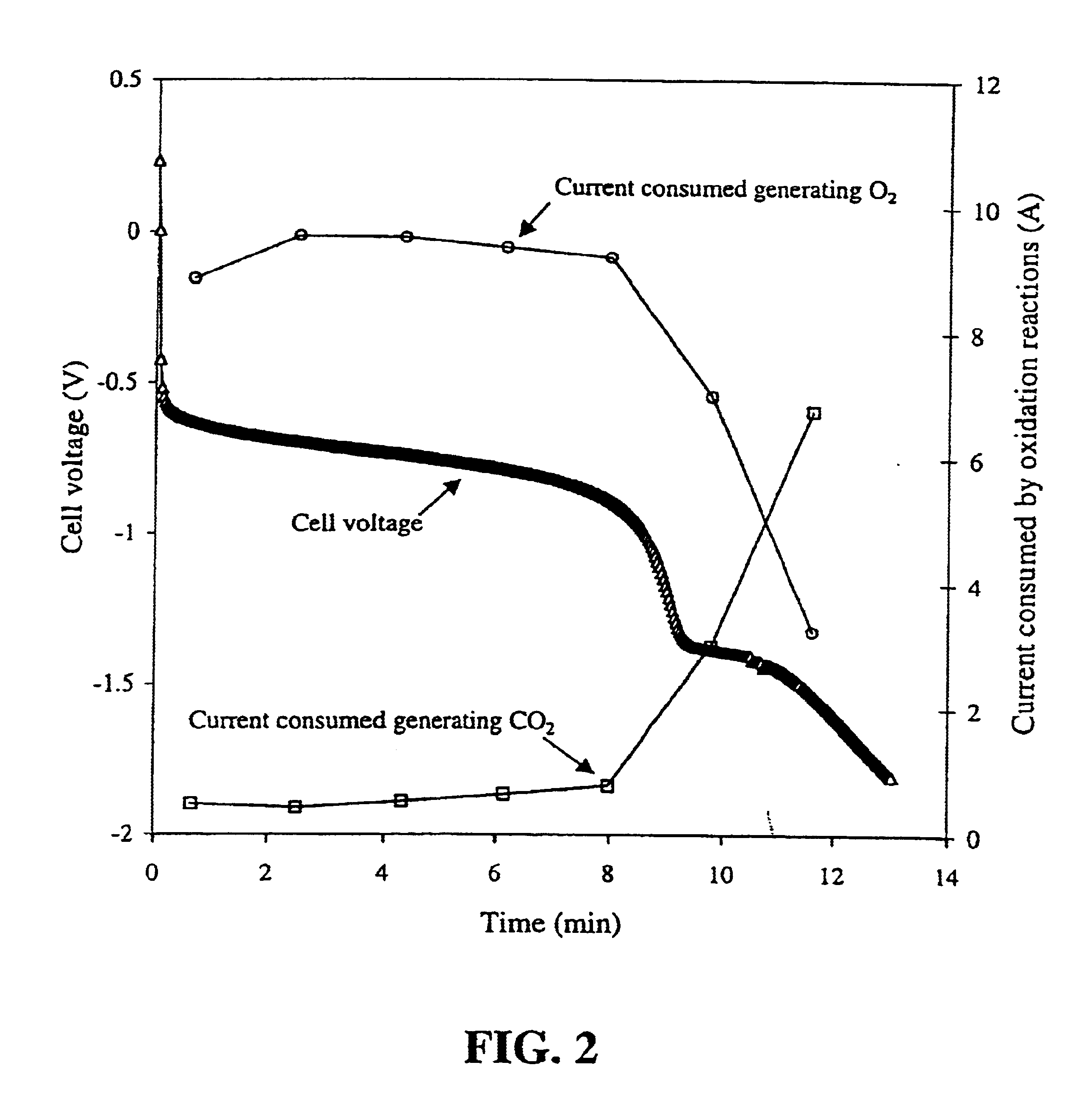

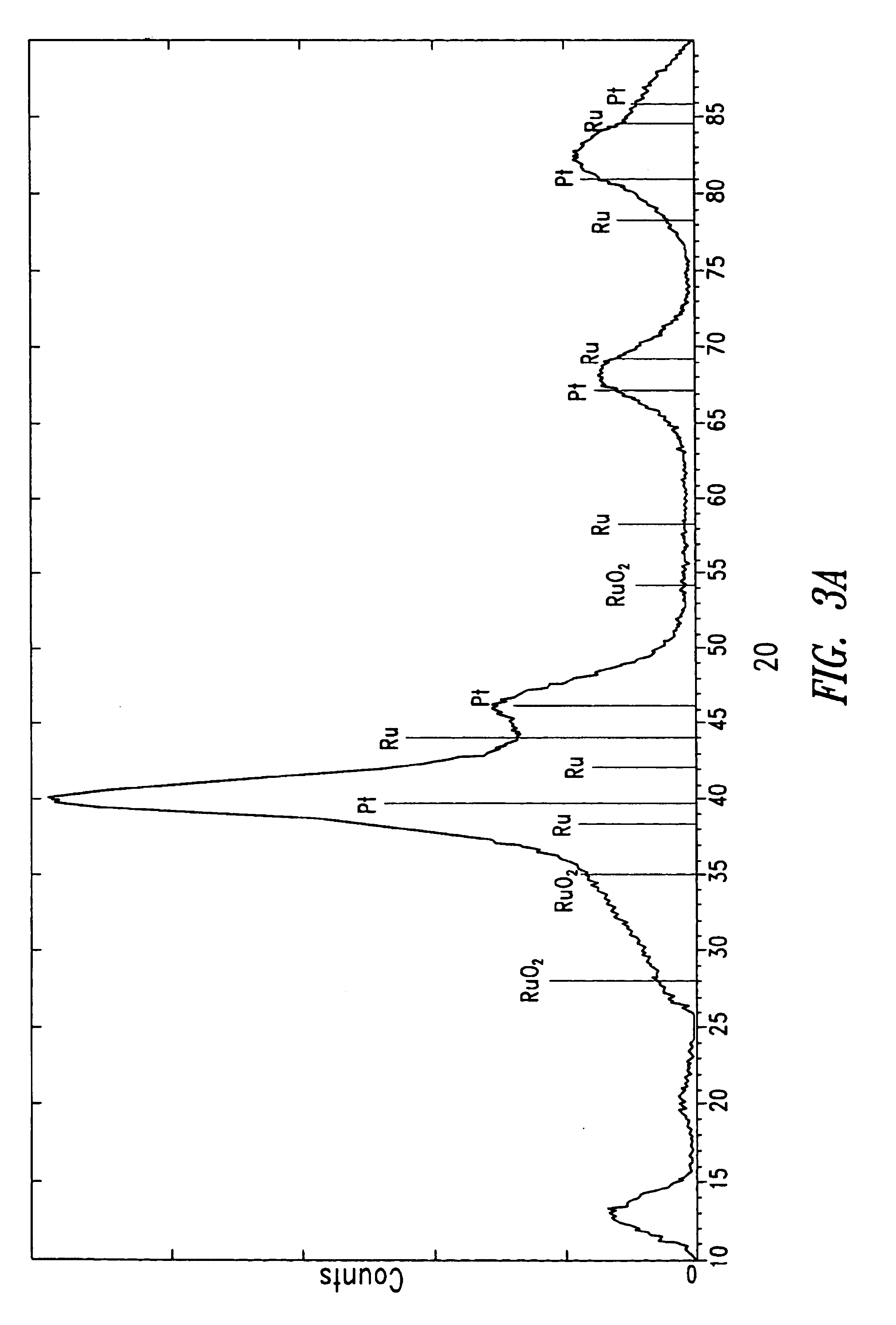

Solid polymer fuel cell with improved voltage reversal tolerance

In a solid polymer fuel cell series, various circumstances can result in the fuel cell being driven into voltage reversal. For instance, cell voltage reversal can occur if that cell receives an inadequate supply of fuel (for example, fuel starvation). In order to pass current during fuel starvation, reactions other than fuel oxidation may take place at the fuel cell anode, including water electrolysis and oxidation of anode components. The latter may result in significant degradation of the anode. Such fuel cells can be made more tolerant to cell reversal by promoting water electrolysis over anode component oxidation at the anode. This can be accomplished by incorporating a catalyst composition at the anode to promote the water electrolysis reaction, in addition to the typical anode electrocatalyst for promoting fuel oxidation.

Owner:BALLARD POWER SYSTEMS +1

Integrated electrolysis nitrogen and phosphorus removal wastewater treatment method

InactiveCN101549896AGood conditionEfficient removalWater/sewage treatmentElectrode polaritySmall footprint

The invention relates to an integrated electrolysis nitrogen and phosphorus removal wastewater treatment method, which realizes to remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater in same electrolytic tank. The invention adopts graphite and iron plate as electrodes, alternates electrolysis phosphorus removal and electrolysis nitrogen removal process by alternating the electrode polarities to remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater. The invention performs optimization and integration according to the change characteristics of the parameters including electrolysis time, current density, pH value, pollutants removal rate in the electrolysis phosphorus removal and electrolysis nitrogen removal process, can remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater in high efficiency in short time without adding any medicament in the process, achieves the advantages of small occupation area, short treatment time and high pollutants removal efficiency.

Owner:SHANGHAI JIAO TONG UNIV

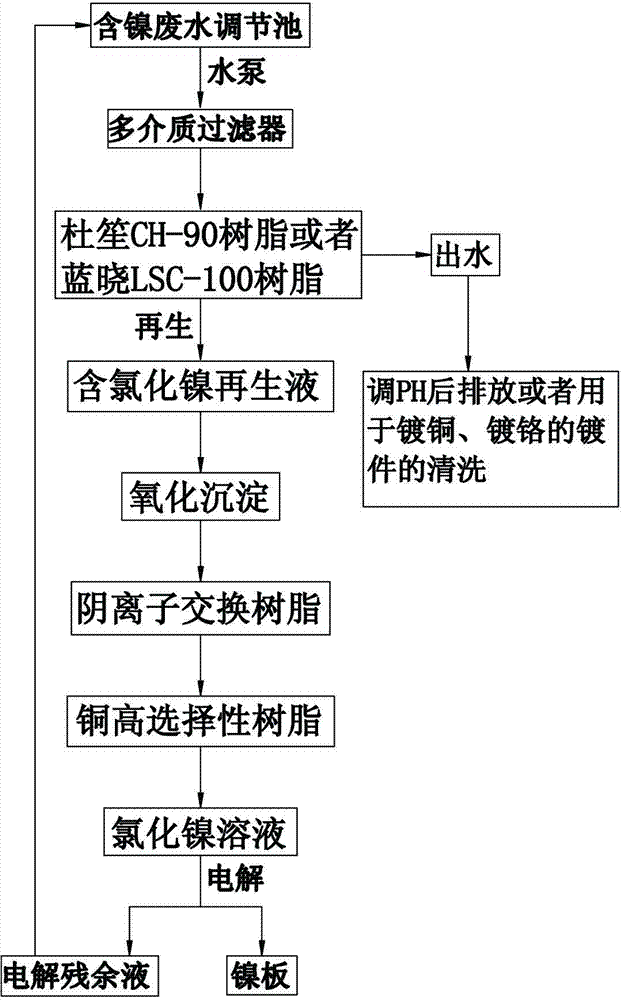

Method for recovering nickel from electroplating centralized control wastewater

InactiveCN103572319AAvoid removalSolve the removal problemPhotography auxillary processesWaste water treatment from metallurgical processHigh concentrationSludge

The invention relates to a method for recovering nickel from electroplating centralized control wastewater. The method comprises the following steps in sequence: a, collecting; b, filtering; c, adsorbing, i.e., enabling filtrate obtained in the step b to pass through an adsorption device filled with nickel high-selectivity resin; d, regeneration, i.e., washing out nickel ions adsorbed on the resin by acid liquid to obtain regenerated liquid; e, impurity removal, i.e., sequentially carrying out oxidation sedimentation and resin adsorption processing on the regenerated liquid; f, electrolysis, i.e., using a rhodanized titanium plate as an anode, using a titanium plate as a cathode and carrying out electrolysis under the current density of 150 to 300A / m<2> to obtain a nickel plate. According to the invention, due to adoption of Tulsion CH-90 resin, nickel solution with relatively high concentration can be obtained; the method is beneficial for reducing electrolysis cost of subsequent electrolysis; interference ions with serious influence on nickel electrolysis are removed by three impurity removal processes; the method also improves the electrolysis rate of nickel ions and improves the recovery rate of nickel by selecting the suitable anode and cathode, does not generate sludge and not only is environmental-friendly, but also effectively reduces treatment cost.

Owner:NANAN XUFAN METAL RECYCLING CO LTD

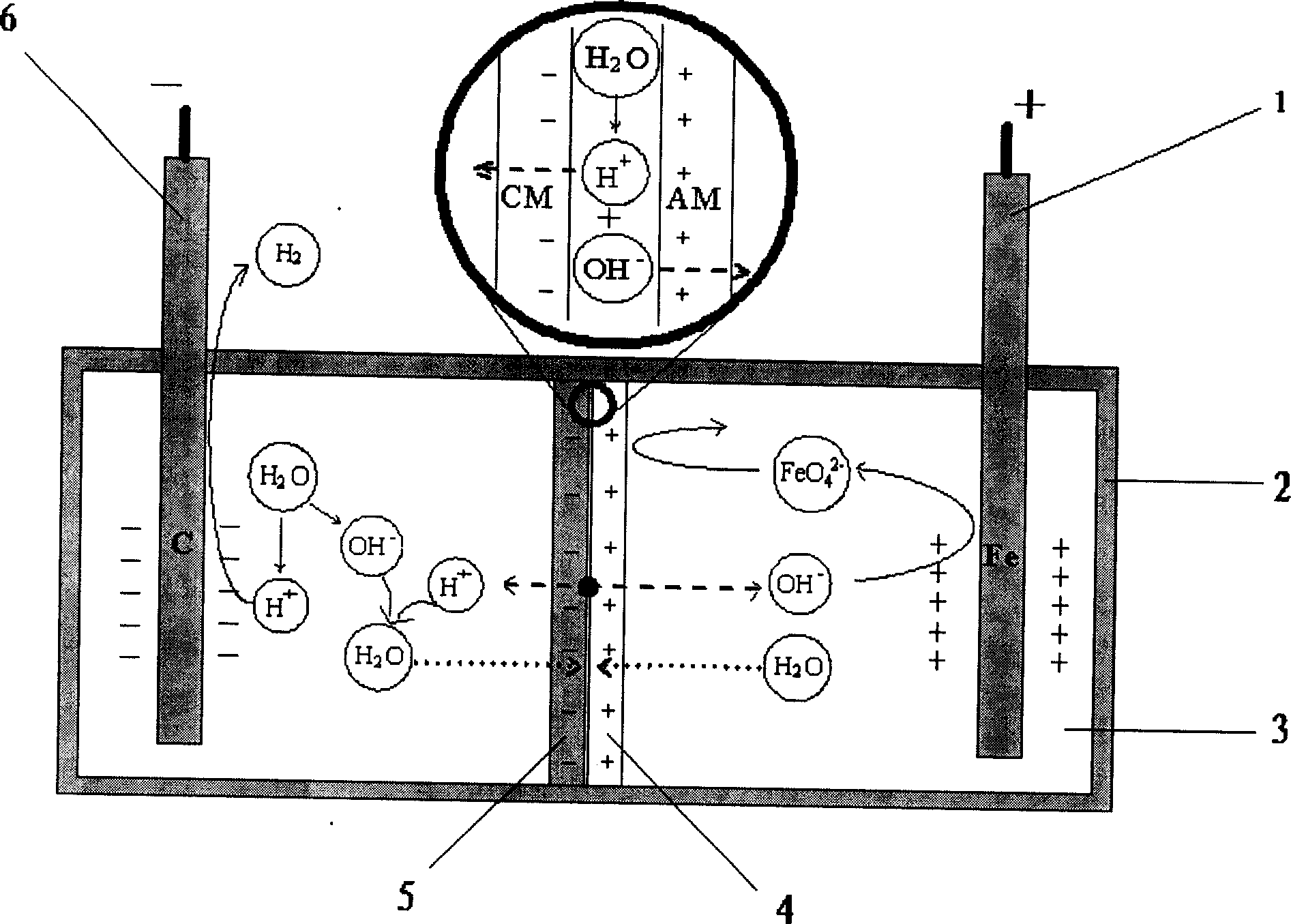

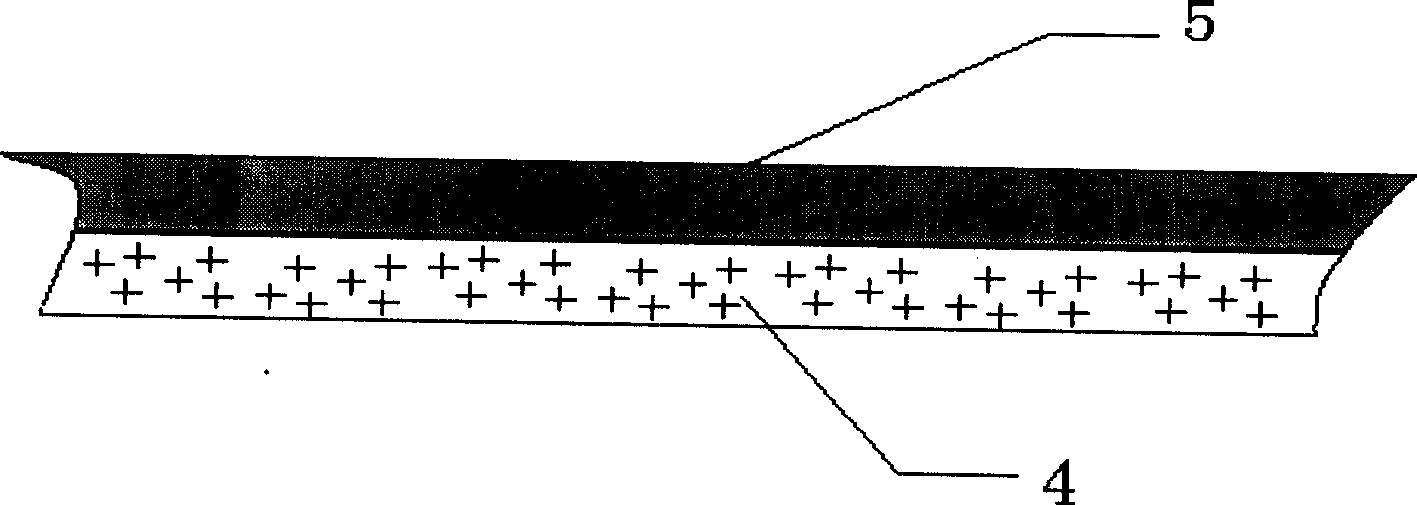

Novel dipolar membrane and use thereof in electrolysis preparation of ferrate

InactiveCN1865509AFlat current efficiencySpeed up electrolysisSemi-permeable membranesOrganic diaphragmsHigh current densityElectricity

The invention discloses a new bipolar film and utility in the ferrate, which comprises the following steps: adopting 3 percent sodium carboxymethylcellulose aqueous solution; stirring; heating; decompressing; decolouring; proceeding doctor-blade casting process on the glass board; drying to form film; immersing in the FeCl3 solution for several min; drying to produce positive electrode film; dissolving chitose through 2 percent acetate aqueous solution to prepare chitose acetate aqueous solution; stirring; decompressing; decolouring; proceeding doctor-blade casting process on the glass board; drying to form CS-CMC polymeric bipolar film of negative and positive electrode; utilizing the prepared CS-CMC polymeric bipolar film as negative and positive electrode to electrolyze ferrate at 30-40mA .cm-2 condition. The invention modifies chitose into insoluble negative ion exchanging film, which satisfies high-current density working need.

Owner:FUJIAN NORMAL UNIV

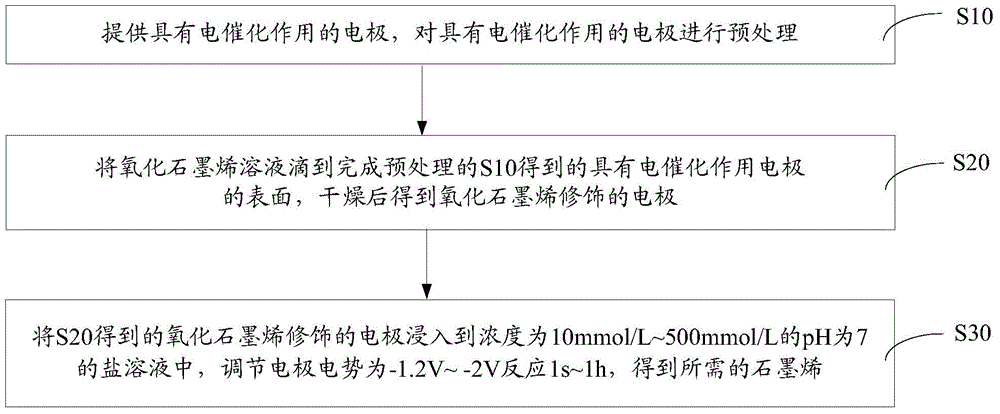

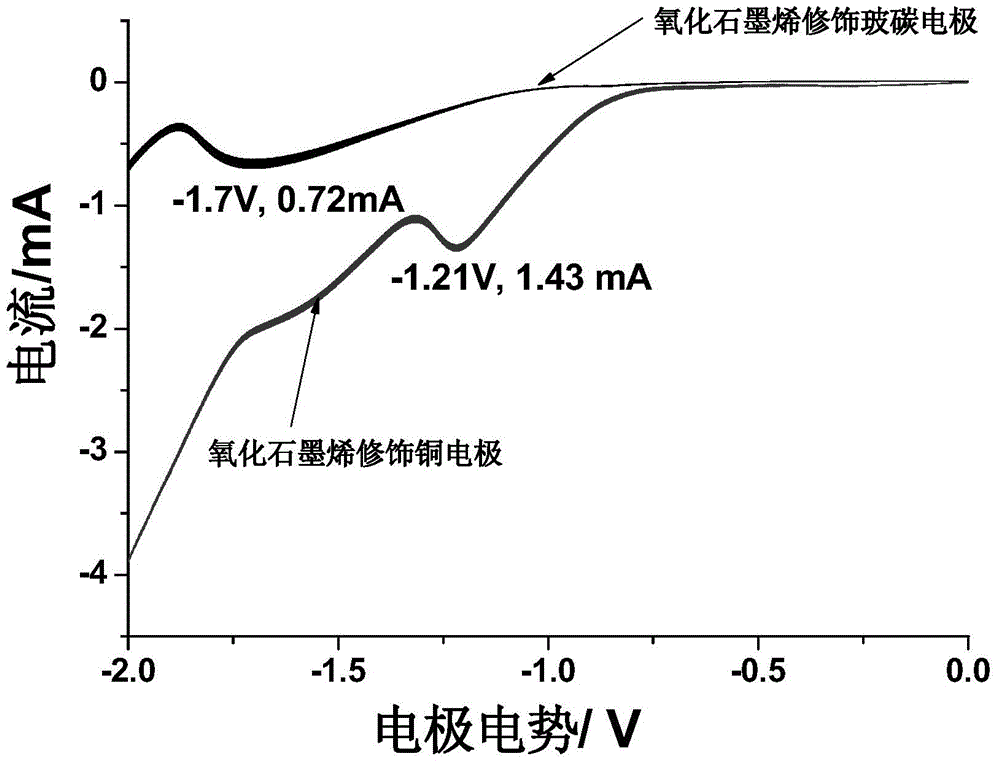

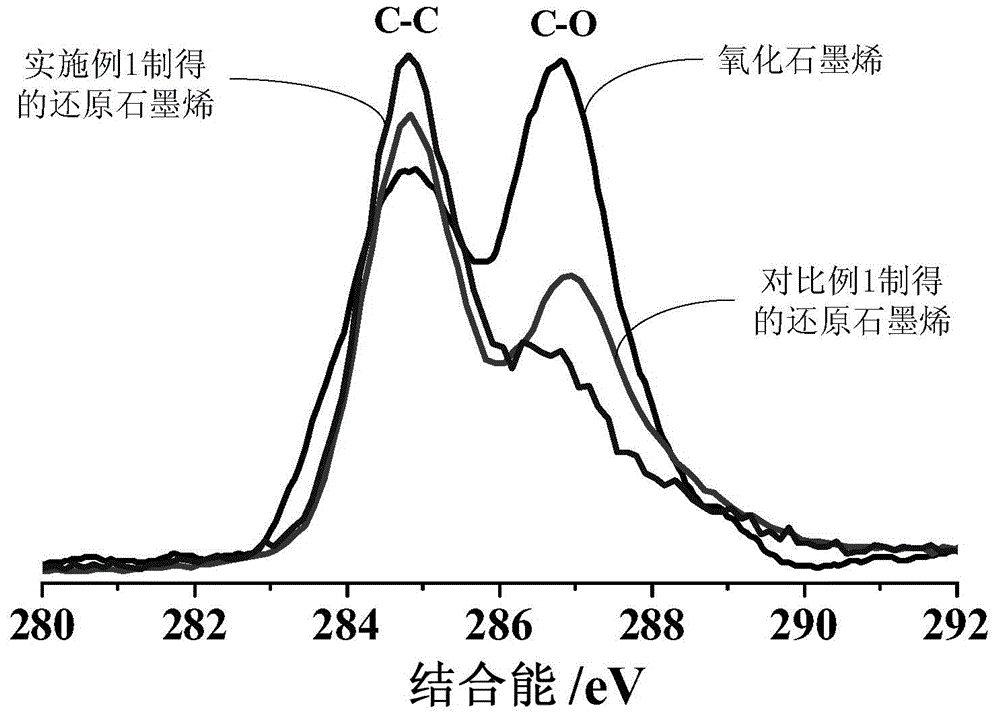

Electrochemical preparation method of graphene

ActiveCN104593802AReduce manufacturing costReduce manufacturing difficultyElectrolysis componentsEnvironmental resistanceLow voltage

The invention discloses an electrochemical preparation method of graphene. The preparation method comprises the following steps: providing an electrode with the electrolysis action, and pretreating the electrode with the electrocatalysis action; dropping a graphene oxide solution onto the surface of the pretreated electrode with the electrocatalysis action, and drying to obtain a graphene oxide modified electrode; and soaking the graphene oxide modified electrode into a 10mmol / L-500mmol / L salt solution with the pH value of 7, regulating the potential of the electrode to be -1.2V to -2V and reacting for 1s to 1h, so as to obtain needed graphene. According to the electrochemical preparation method of the graphene, by matching the electrode with the electrocatalysis action with the salt solution with the pH value of 7 for use, the reduction action of graphene oxide can be activated with relatively low voltage, the neutral salt solution is green, simple to prepare, and low in price. Compared with a traditional electrochemical preparation method of the graphene, the electrochemical preparation method of the graphene is lower in preparation cost and difficulty.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

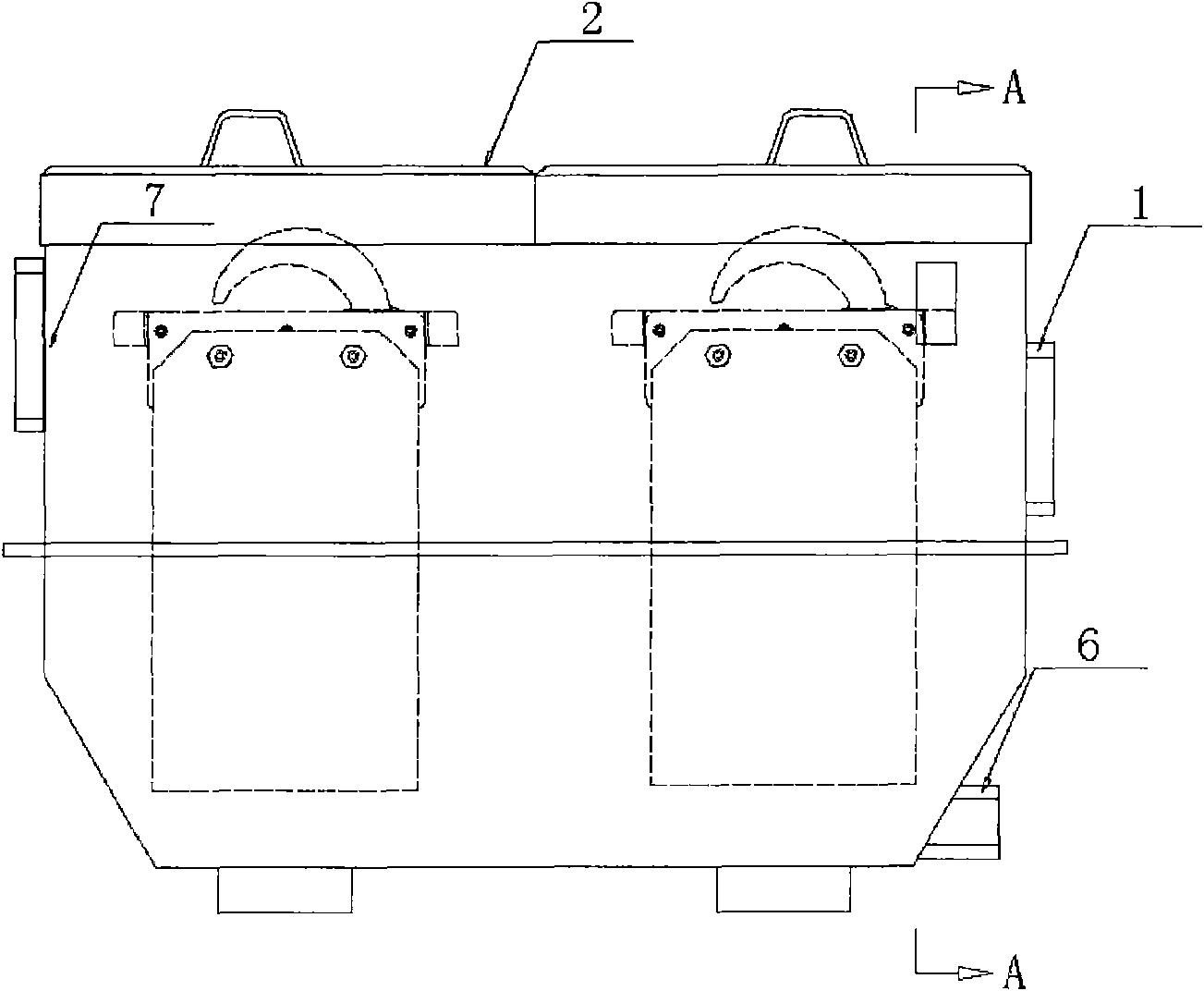

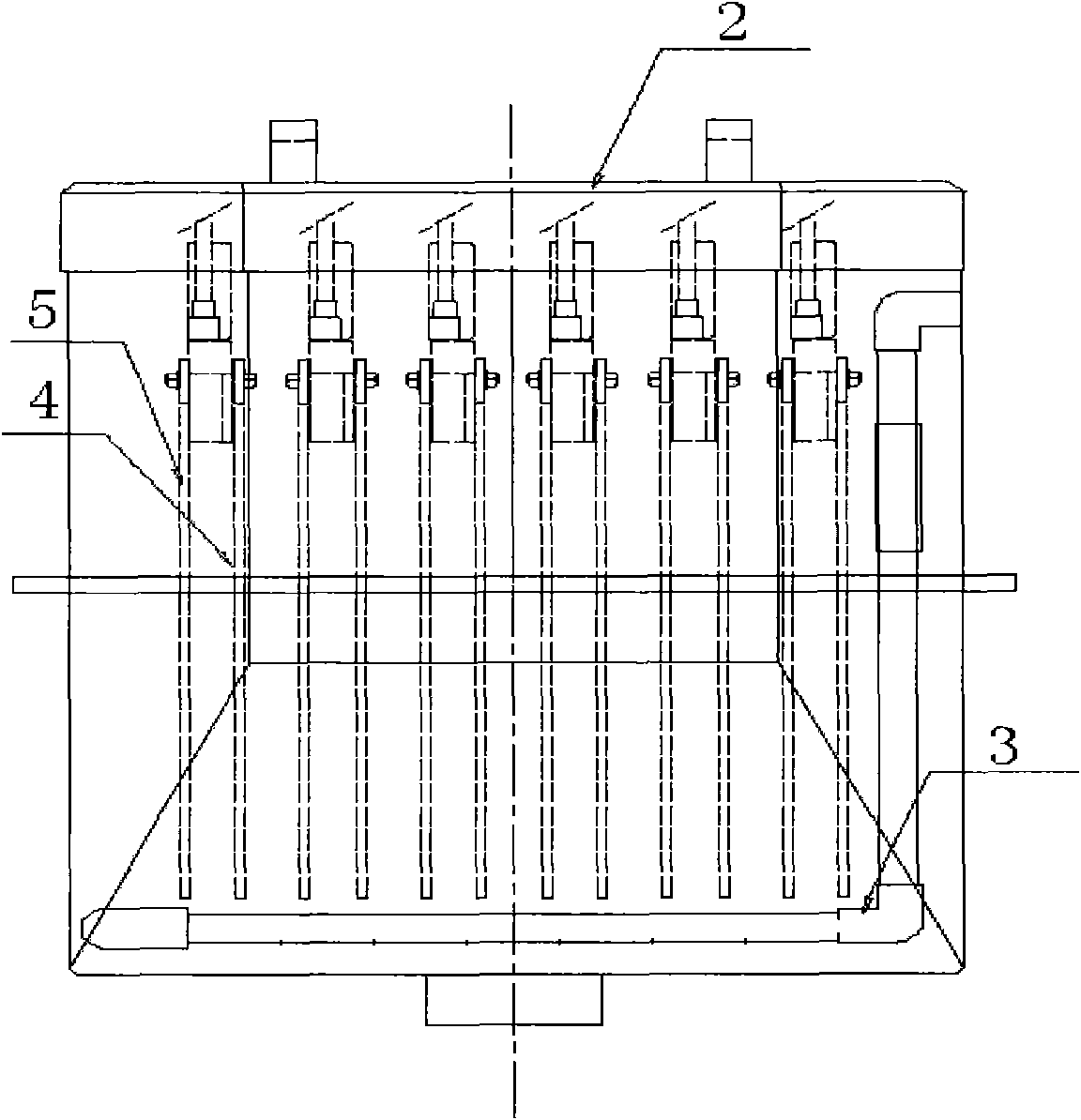

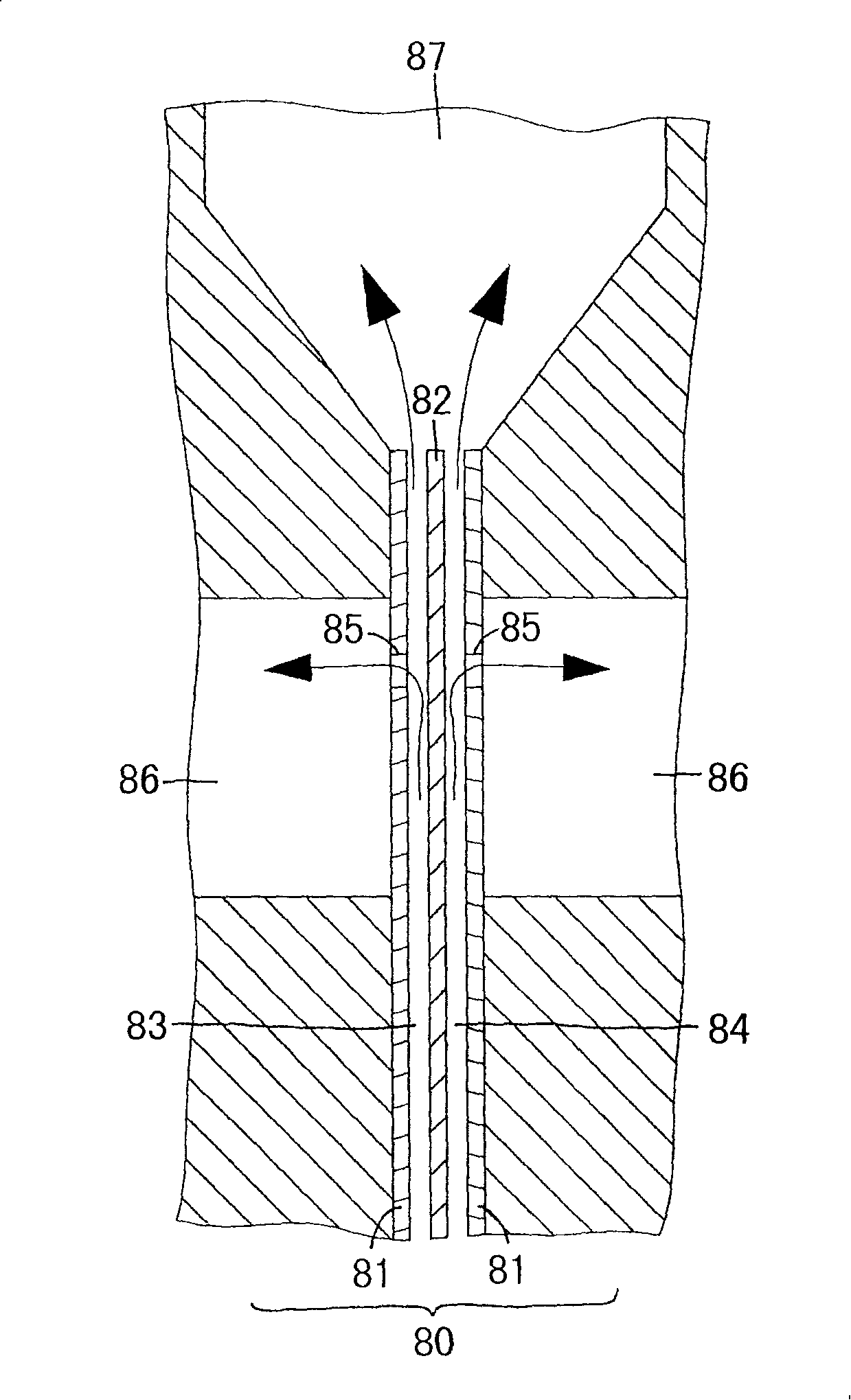

Granular active carbon circulating micro-electrolysis reactor

InactiveCN101648737ASignificant progressSignificant positive effectWater/sewage treatmentMicro bubbleEngineering

The invention relates to a granular active carbon circulating micro-electrolysis reactor, comprising a micropore aeration pipe, a granular active carbon separating chamber, wherein the micropore aeration pipe is connected with a total aeration pipe and positioned at the bottom of the reactor; positive poles of a plurality of scrap iron plates are uniformly distributed on the upper middle of the reactor at equal intervals; a support beam I and a support beam II which are fixed on the inner lateral wall of the reactor and processed with corrosion resisting materials are provided with a fixed clamping groove I and a fixed clamping groove II, and the left end, the right end, the upper end and the lower end of the positive poles of the scrap iron plates are vertically fixed in the fixed clamping groove I and the fixed clamping groove II; waste water enters in the reactor through a water inlet pipe; micro-bubbles generated by the micropore aeration pipe provide rising power for granular active carbon so that the granular active carbon rises among the positive poles of the scrap iron plates so as to form a granular active carbon rising area; the gravity of the granular active carbon is reduced in a non-aeration area so as to realize the granular active carbon circulating in the reactor; and the water enters in the granular active carbon separating chamber through an overflow weir after being processed and is discharged by a water outflow pipe. The invention solves the problems of scrap iron hardening, waste water channeling, micro-electrolysis positive pole inactivating which is puzzled for a long time and the problem that redox sediments are attached to positive and negative poles.

Owner:NORTHEAST DIANLI UNIVERSITY

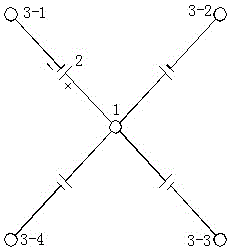

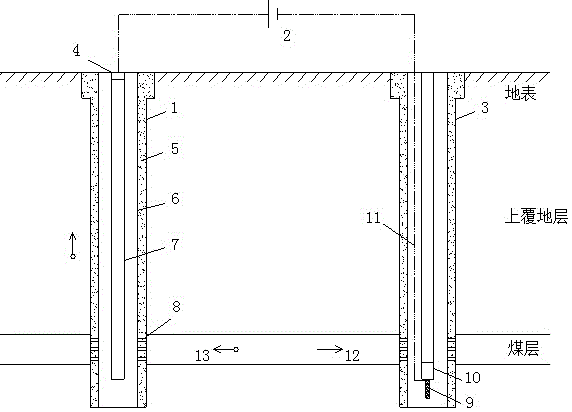

Method for improving coal bed gas recovery efficiency by electrochemistry

ActiveCN106437638AEnhanced overall recoveryImprove drainage and gas production capacityFluid removalElectrolytic agentCalcite

A method for improving coal bed gas recovery efficiency by electrochemistry is characterized in that a vertical well is drilled, a well net is formed, an anode electrode is placed at a wellhead of a liquid injection well, a cathode electrode is fixed at the bottom of a gas recovery well, fracturing liquid with electrolyte is used for fracturing a coal bed, the electric osmosis direction of an electrochemically modified area points to the bottom of the gas recovery well from the wellhead of the liquid injection well after a direct-current power supply is turned on, water is drained to the gas recovery well, and coal bed gas is displaced. The electrophoretic direction points to the wellhead of the liquid injection well from the bottom of the gas recovery well, solid particles such as pulverized coal and rock powder in coal reservoir pore fractures migrate towards the wellhead of the liquid injection well, and a methane migration channel is dredged. Filling minerals such as calcite and pyrite in the coal reservoir pore fractures are corroded by electrolysis, the number of the fractures is increased, and permeability of the coal bed is improved. The temperature of a coal reservoir and the electrolyte is increased by electric heating action, and desorption-diffusion characteristics of methane are improved. Under the combined action of electric drive, electric plug removal, electric permeability increase, electric heating and the like, the desorption and seepage capacity of the coal reservoir is effectively enhanced, gas production is improved by 3-10 times, and the recovery efficiency is improved to 60-90%.

Owner:TAIYUAN UNIV OF TECH

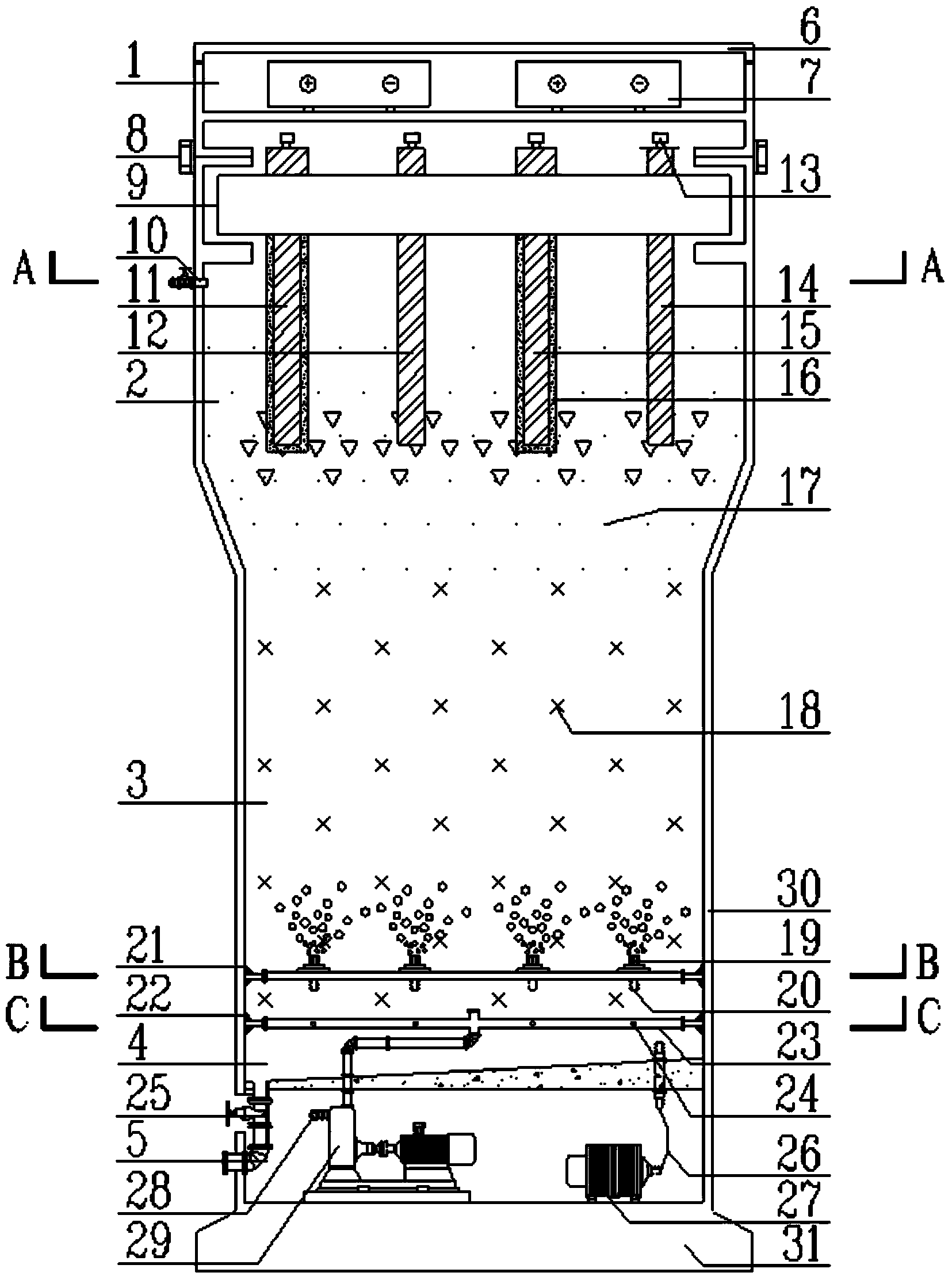

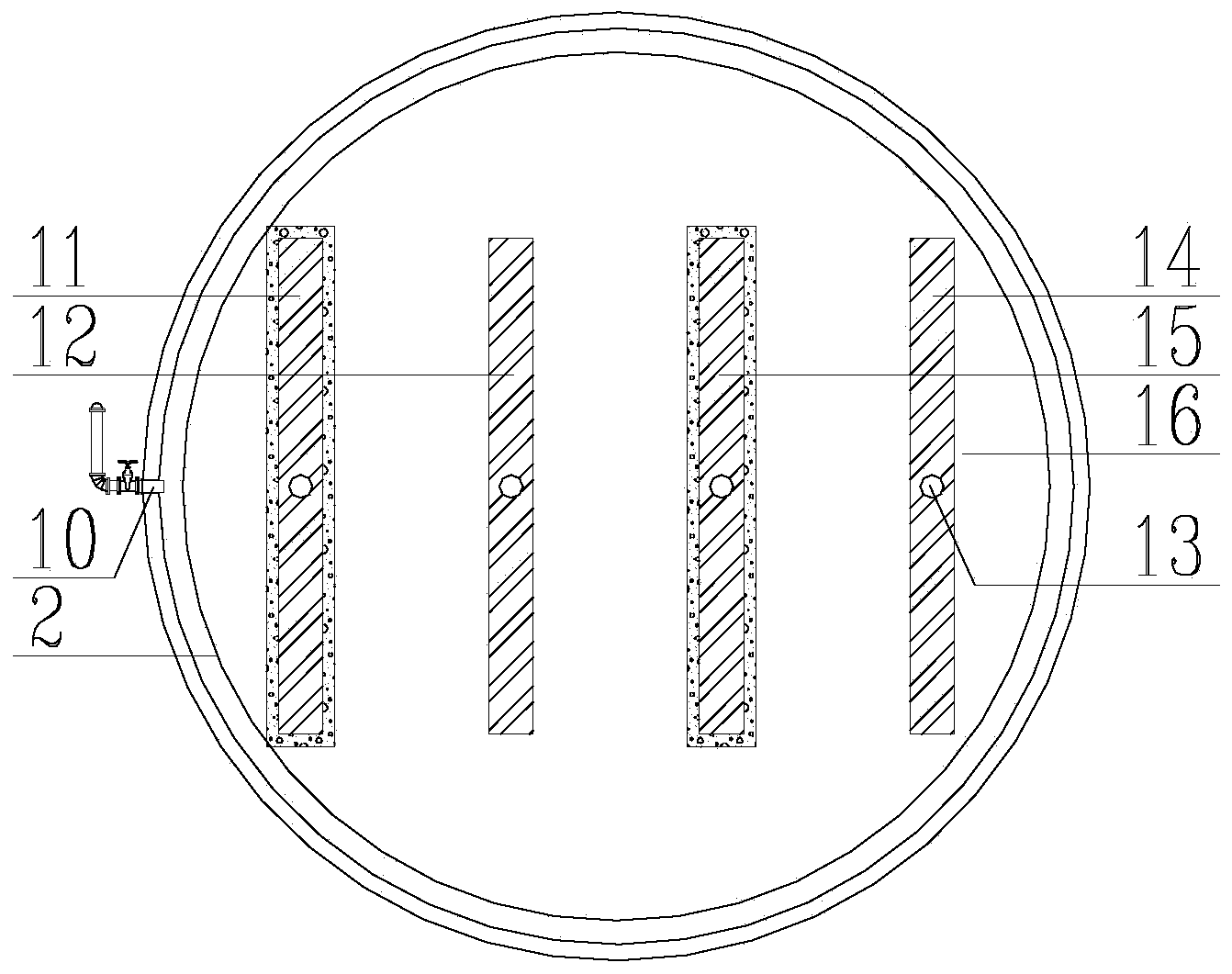

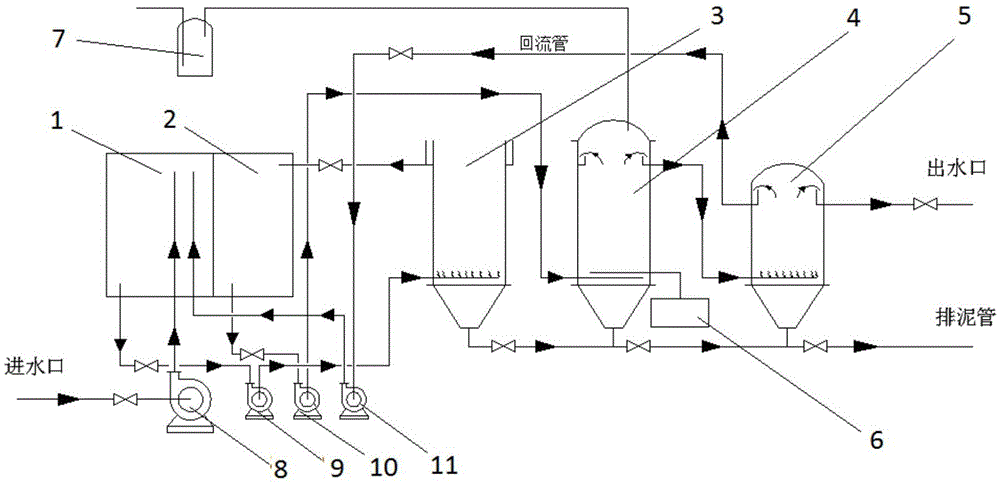

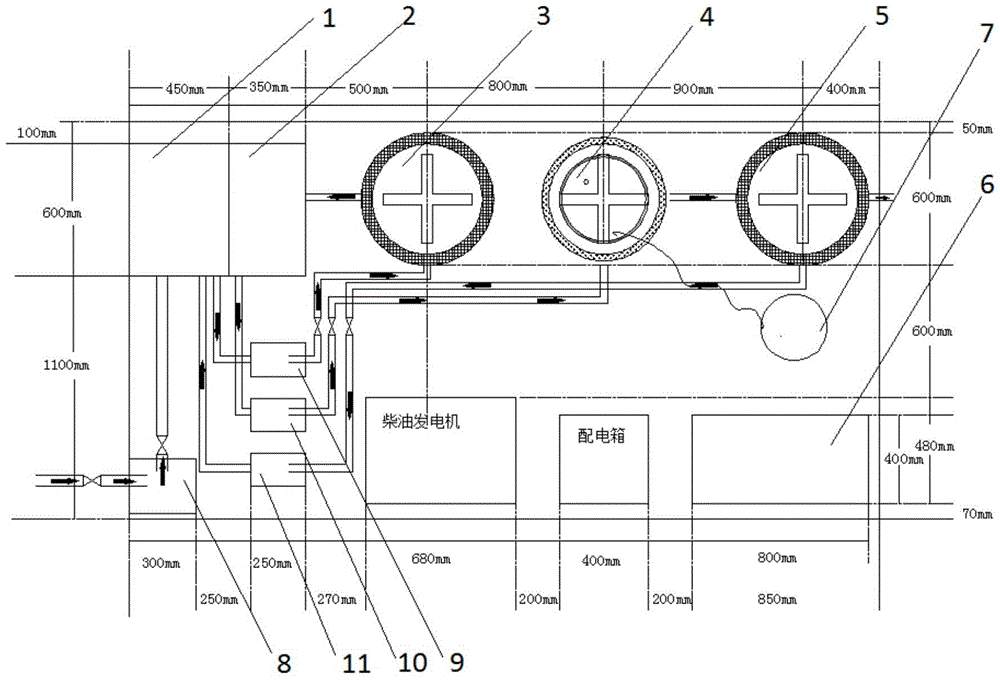

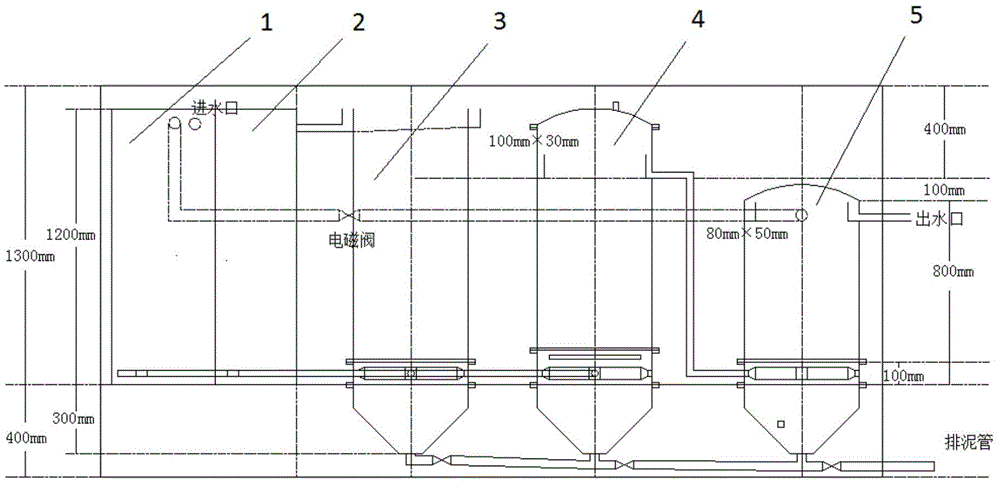

Combined electrolysis reactor and waste water treatment method thereof

ActiveCN103910414AReduce consumptionLow working voltageWater/sewage treatmentElectricityPower controller

The invention discloses a combined electrolysis reactor and a waste water treatment method thereof, belonging to the technical field of waste water treatment. The combined electrolysis reactor comprises a reactor and a reactor base, wherein a power supply chamber, a multidimensional electrode chamber, an iron-carbon micro-electrolysis chamber, a water distribution aeration chamber and an equipment chamber are sequentially inside the reactor from top to bottom; the power supply chamber is arranged in the top cover of the reactor and is provided with two power supply controllers; the multidimensional electrode chamber is arranged below the top cover of the reactor and consists of four electrode plates which are sequentially electrode plates a, b, d and c from left to right, wherein the electrode plates a and d are main anodes, the electrode plates b and c are main cathodes, and carbon packing fills in the gaps among the electrode plates; the iron-carbon micro-electrolysis chamber is positioned at the lower part of the multidimensional electrode chamber and is internally filled with iron-carbon packing; the water distribution aeration chamber is positioned at the lower part of the iron-carbon micro-electrolysis chamber and respectively carries out water distribution and aeration through a water distribution pump and an aeration pump in the equipment chamber. According to the combined electrolysis reactor, the treatment efficiency can be effectively improved, and the occurrence of passivation and hardening can be reduced.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

Microwave plasma oxidation water treatment method and its application

InactiveCN1785855AQuick and effective removalLow running costMultistage water/sewage treatmentWater/sewage treatment by sorptionActivated carbonMicrowave

The present invention relates to a microwave plasma oxidation water treatment method and its application. Said invention includes the following steps: feeding industrial waste water, utilizing mixture of iron discharge body and active carbon to adsorb organics in the waste water; utilizing plasma produced by using microwave to excite iron discharge body to oxidate organics adsorbed on the surface of active carbon, at the same time internal electrolysis action produced between iron discharge body, active carbon and organics can be used for degrading organics, after the organics are oxidated and degraded, making the waste water be reached to reuse and discharge standard.

Owner:WUHAN TEXTILE UNIV

Air purification device and purification method

InactiveCN104633783AAchieve the purpose of purificationPermanent releaseMechanical apparatusLighting and heating apparatusParticulatesEnvironmental resistance

The invention discloses an air purification device and a purification method, and belongs to the technical field of air purification. By the aid of the electrolytic action, the piezoelectric effect and the pyroelectric effect of tourmaline, particularly, by the aid of the piezoelectric effect and the pyroelectric effect of the tourmaline, the tourmaline can release a large number of negative ions by the piezoelectric effect and the pyroelectric effect generated under flow of constant temperature water, so that air is purified. Compared with a pure tourmaline material air purification method, the method has the advantages of high air purification efficiency, wide application scope, fine effect and the like. Besides, PM2.5 (particulate matters 2.5) can be degraded, harmful gas and undesirable odor are eliminated, bacteria are resisted, humidification is realized, human metabolism is promoted, human immunity is improved, physical and psychological health of humans is protected, and the air purification device has the advantages of safety, environmental protection, non-toxicity, no odor, no radiation, long service life, convenience in use and the like.

Owner:华生康泰(北京)环保科技有限公司

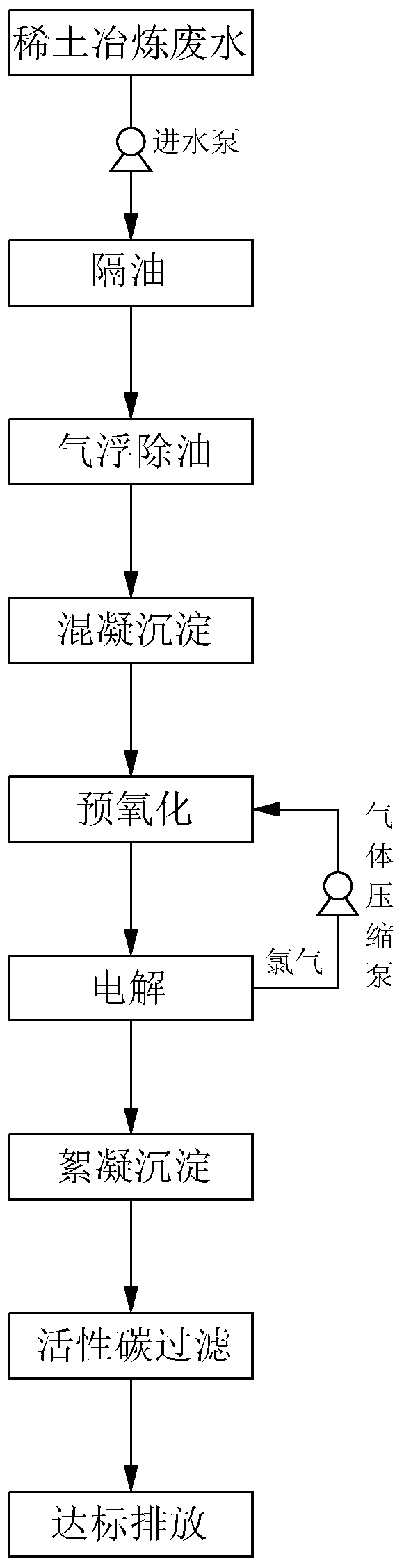

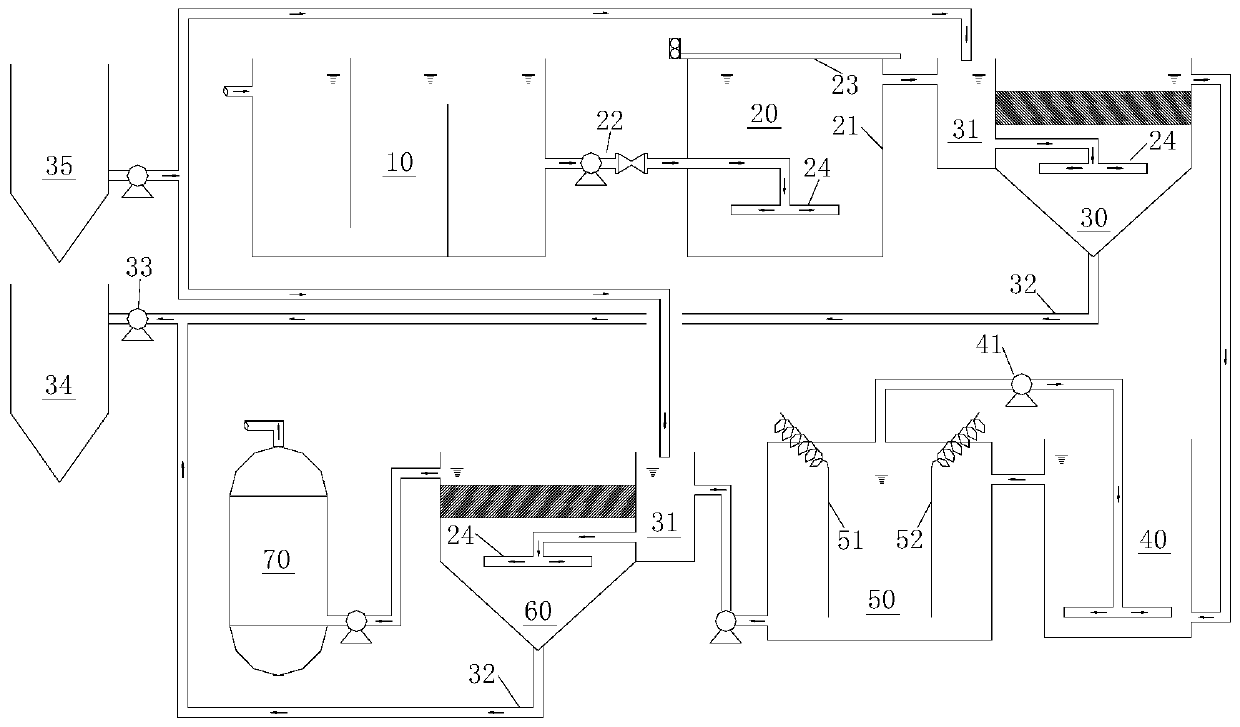

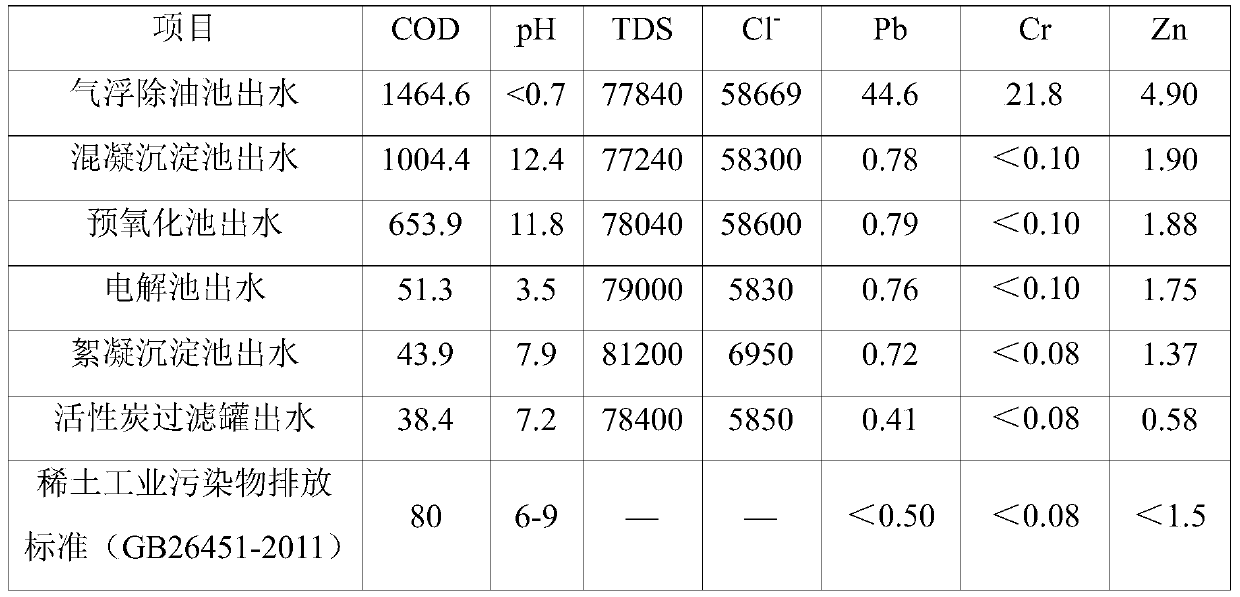

Electrolysis treatment process and device for low-content organic pollutants in high-salinity rare earth wet smelting wastewater

InactiveCN109761412AMeet emission requirementsImprove processing efficiencyWater contaminantsWaste water treatment from metallurgical processActivated carbon filtrationPh regulation

The invention discloses an electrolysis treatment process and device for low-content organic pollutants in high-salinity rare earth wet smelting wastewater. The electrolysis treatment process comprises the following main steps: (1) oil removal of the wastewater; (2) pH regulation and coagulating sedimentation for heavy metal removal of the wastewater; (3) chlorine peroxidation treatment of the wastewater; (4) electrolysis treatment of the wastewater; (5) reduction, flocculation and sedimentation of the wastewater; (6) activated carbon filtration treatment of the wastewater. According to the electrolysis treatment process and device, aiming at the refractory characteristic of organic matter in the high-salinity rare earth wet smelting wastewater, the organic matter is decomposed and mineralized under the electrolysis action and the strong oxidation action of produced chlorine, and up-to-standard discharge of the wastewater is realized.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

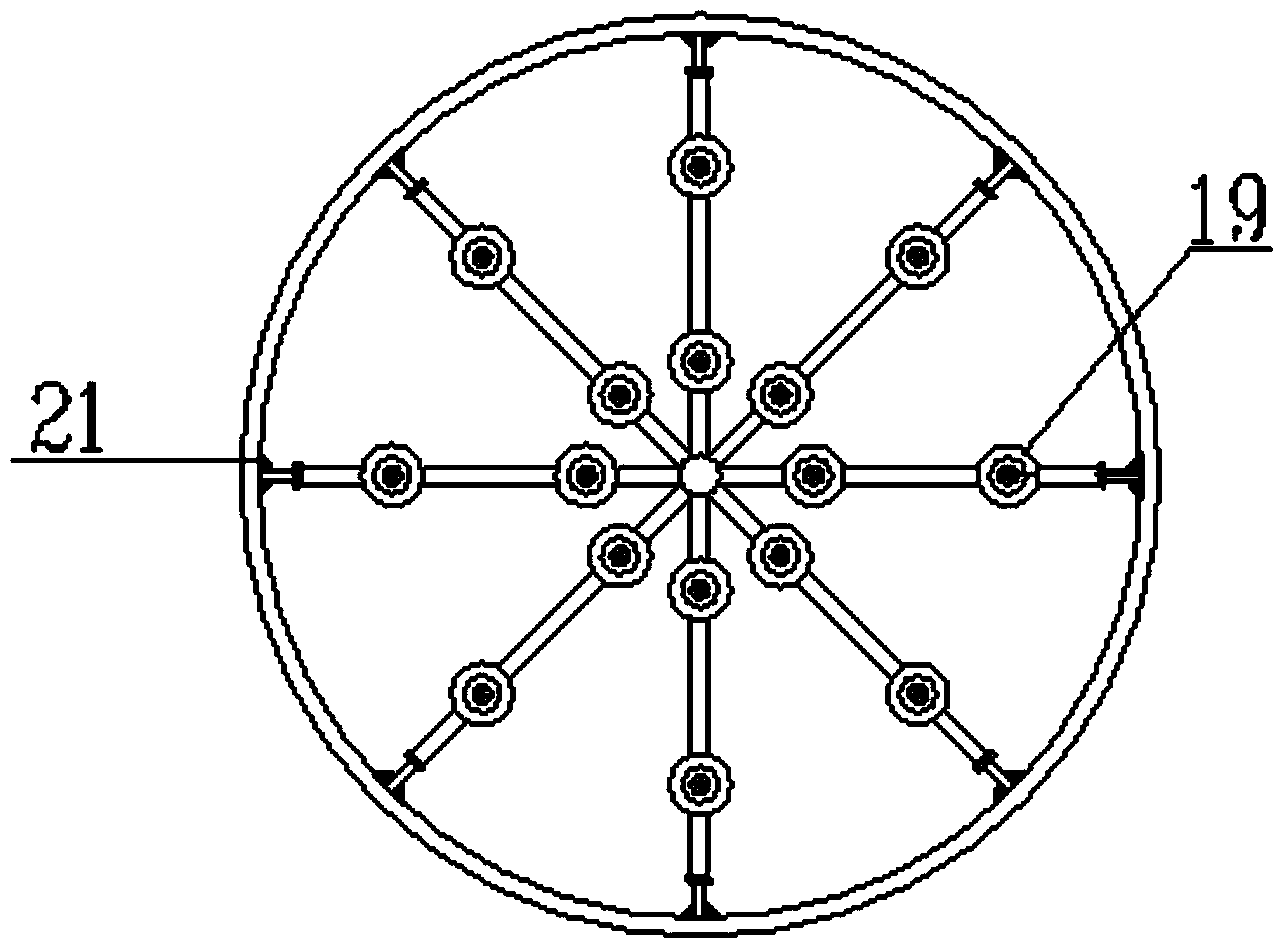

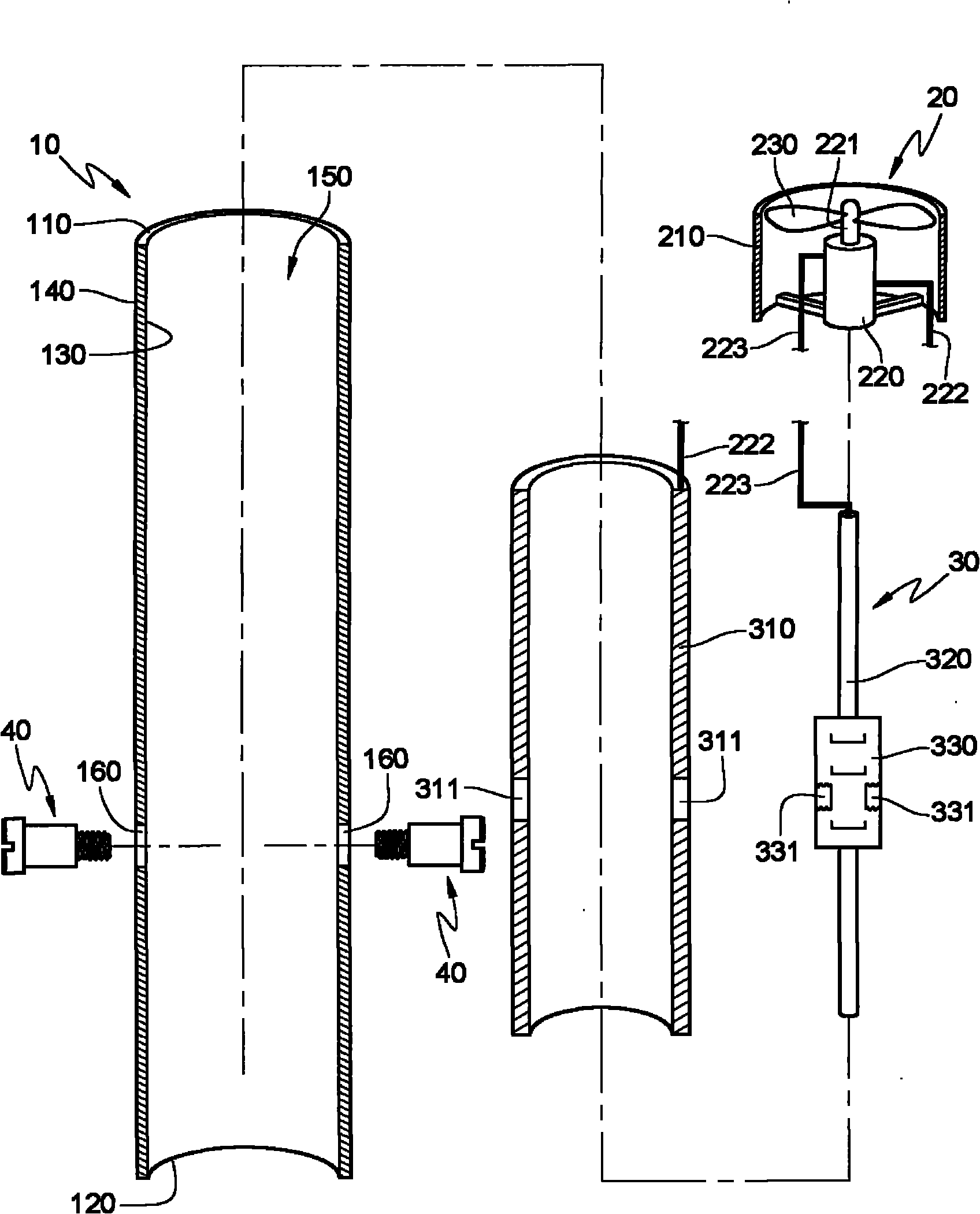

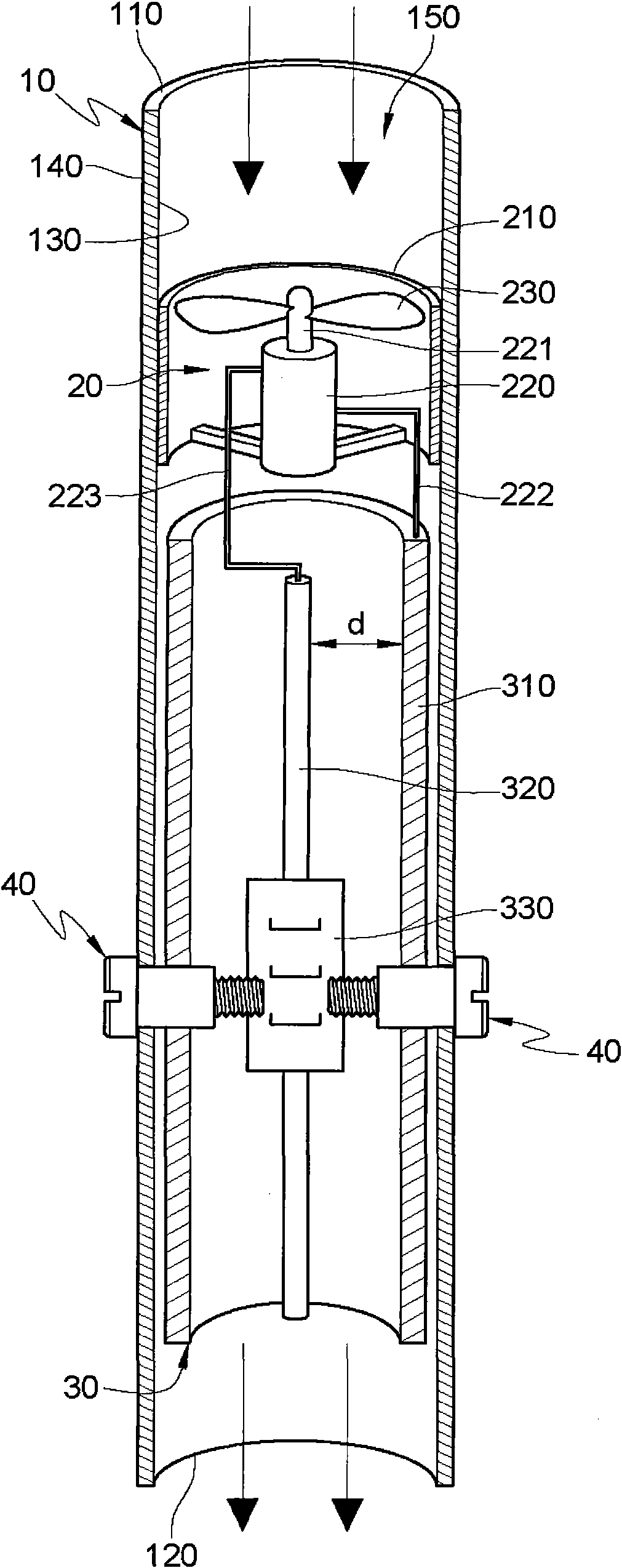

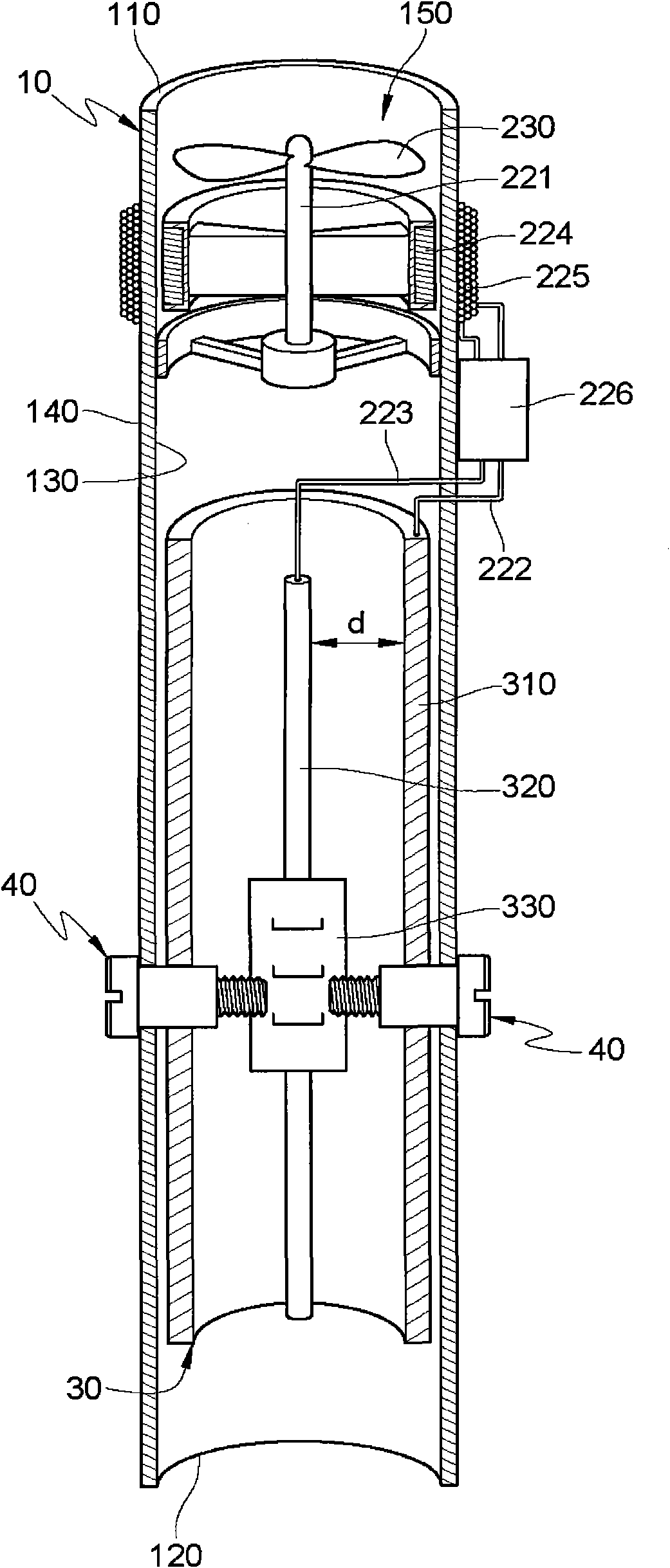

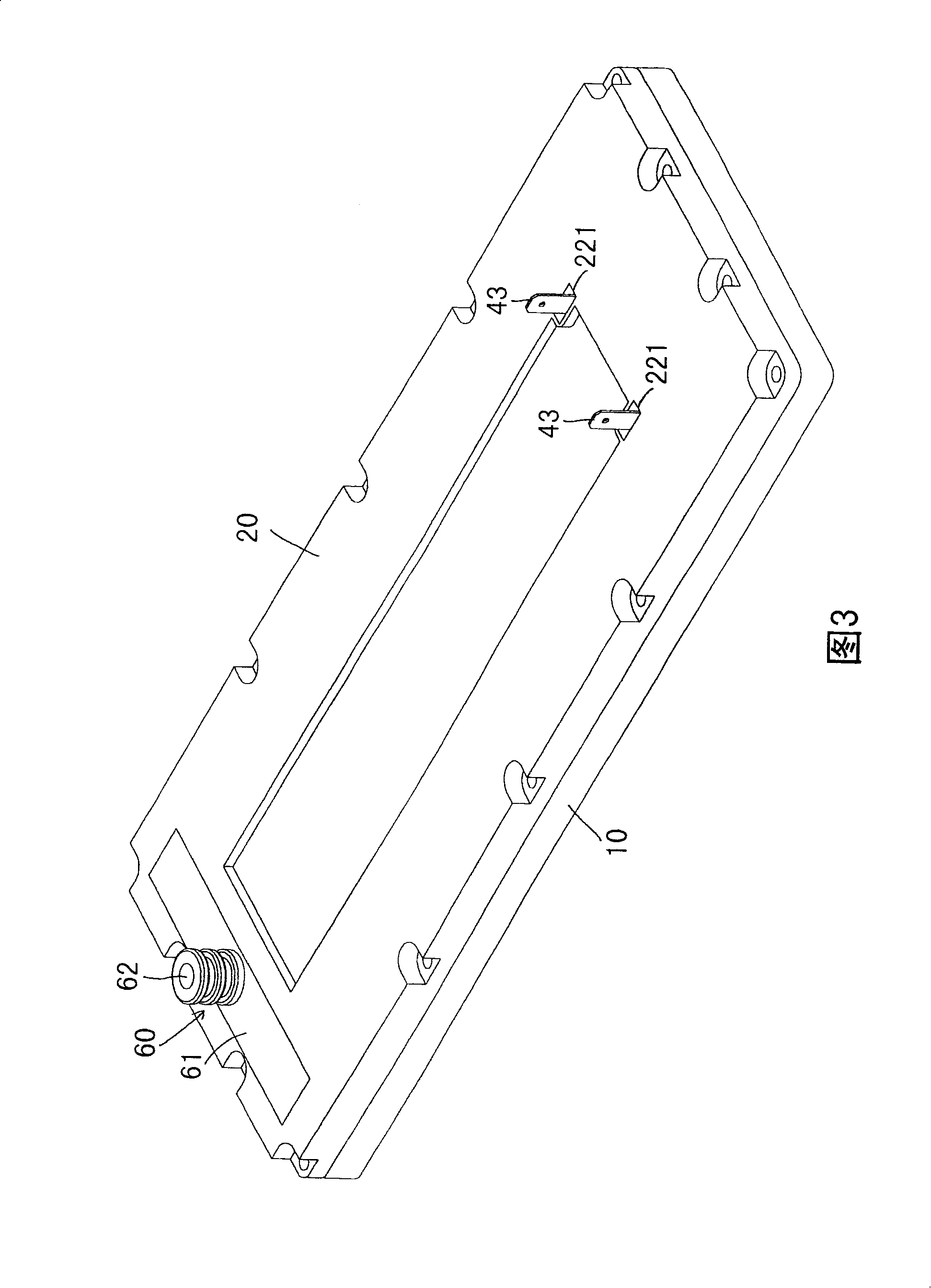

Self-generating water body electroreduction module

ActiveCN102115232ASimple structureImprove convenienceWater/sewage treatmentMachines/enginesEnvironmental engineeringElectric power

The invention discloses a self-generating water body electroreduction module, applied to a water body containing oxidizing substances. The self-generating water body electroreduction module comprises a hollow tube, a self-generating unit and an electrolysis unit, wherein the self-generating unit is arranged in the hollow tube and coupled to the electrolysis unit. When the water body circulates in the hollow tube, the water body drives the self-generating unit to generate electric power and transmit the electric power to the electrolysis unit which receives the electric power and performs an electrolysis action on the water body circulating to the electrolysis unit, so that the oxidizing substances in the water body are subjected to a reduction reaction.

Owner:IND TECH RES INST

Micro-electrolysis device capable producing active oxygen

ActiveCN101786752AEfficient degradationImprove and purify water qualityWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentWater qualityOxygen

The invention belongs to the technical field of water treatment, in particular to a micro-electrolysis device capable of producing active oxygen. The device comprises a water injector, an ultrasonic generator, a dissolved oxygen and ultrasonic reactor, a micro-electrolysis generator, a micro-electrolysis reactor and a micro-electrolysis controller. The ultrasonic wave produced by the ultrasonic generator plays a role in the dissolved oxygen and ultrasonic reactor, activates and produces active oxygen substance; and the micro-electrolysis generator produces the active oxygen substance in the micro-electrolysis reactor through the action of an electric field between electrodes under the control of the micro-electrolysis controller. The device uses the interaction of the ultrasonic wave and a micro-electrolysis battery, can kill bacteria and degrade organic matter, and finally achieves the purpose of purifying water quality.

Owner:上海赛一环保设备有限公司

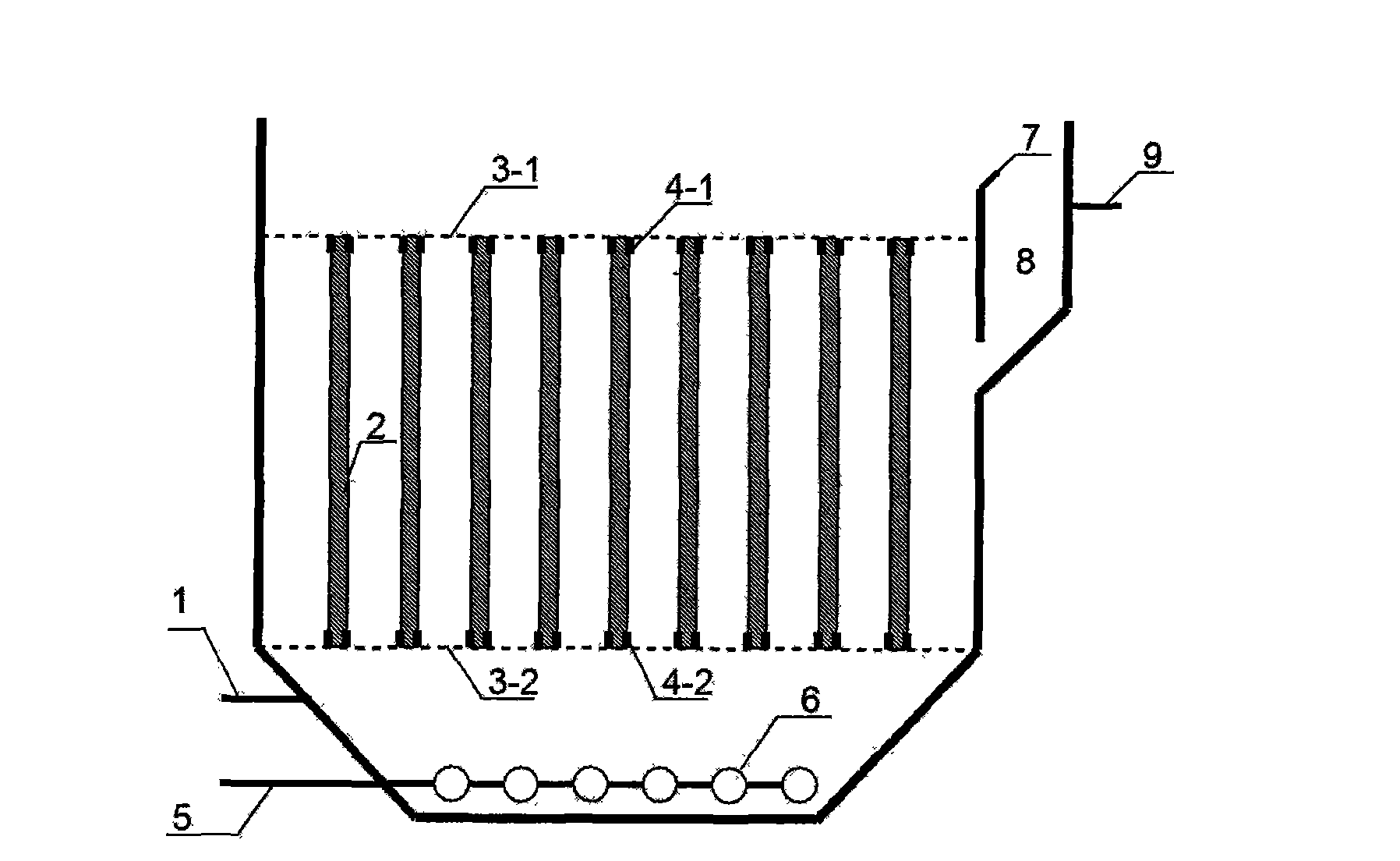

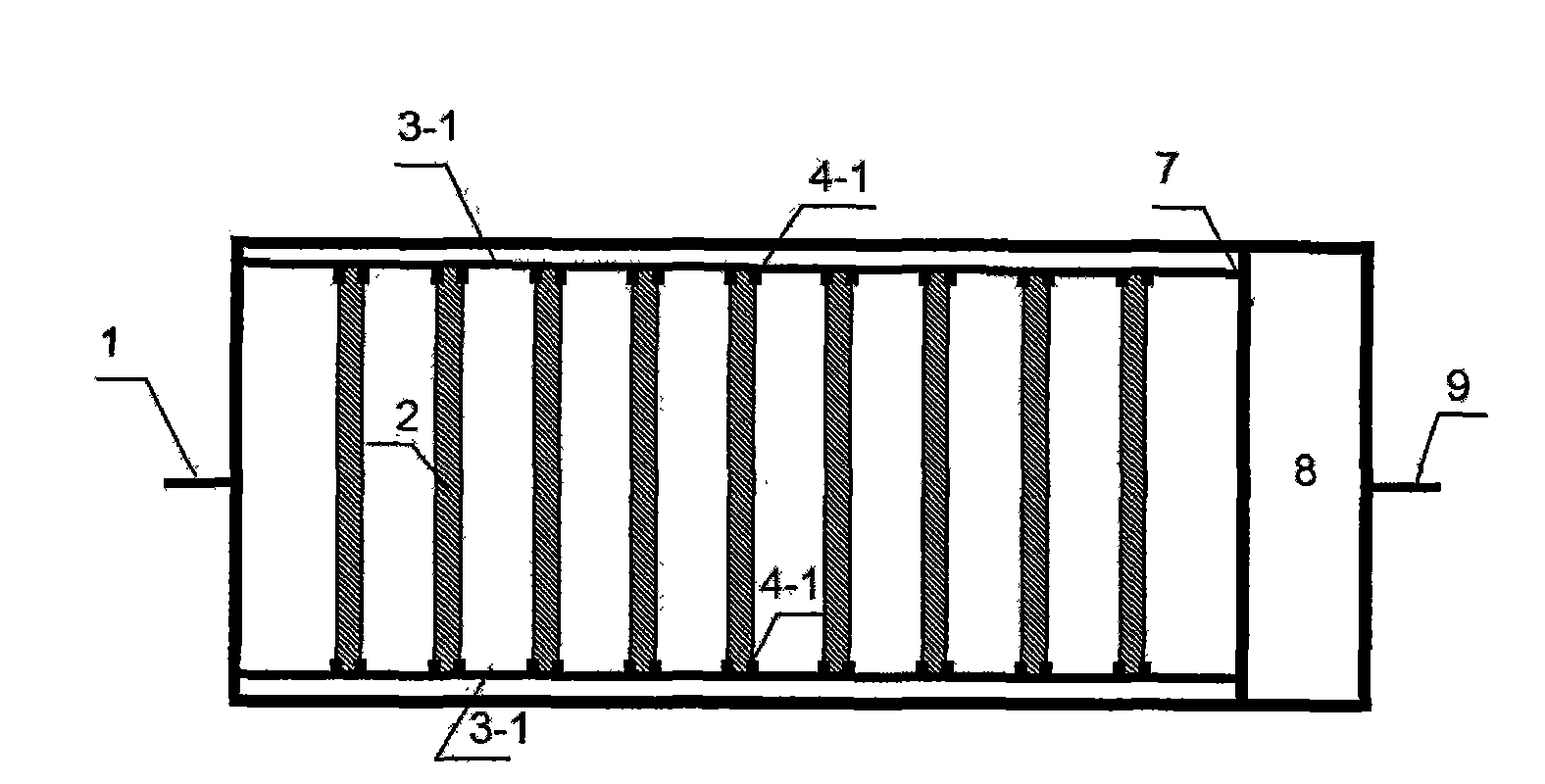

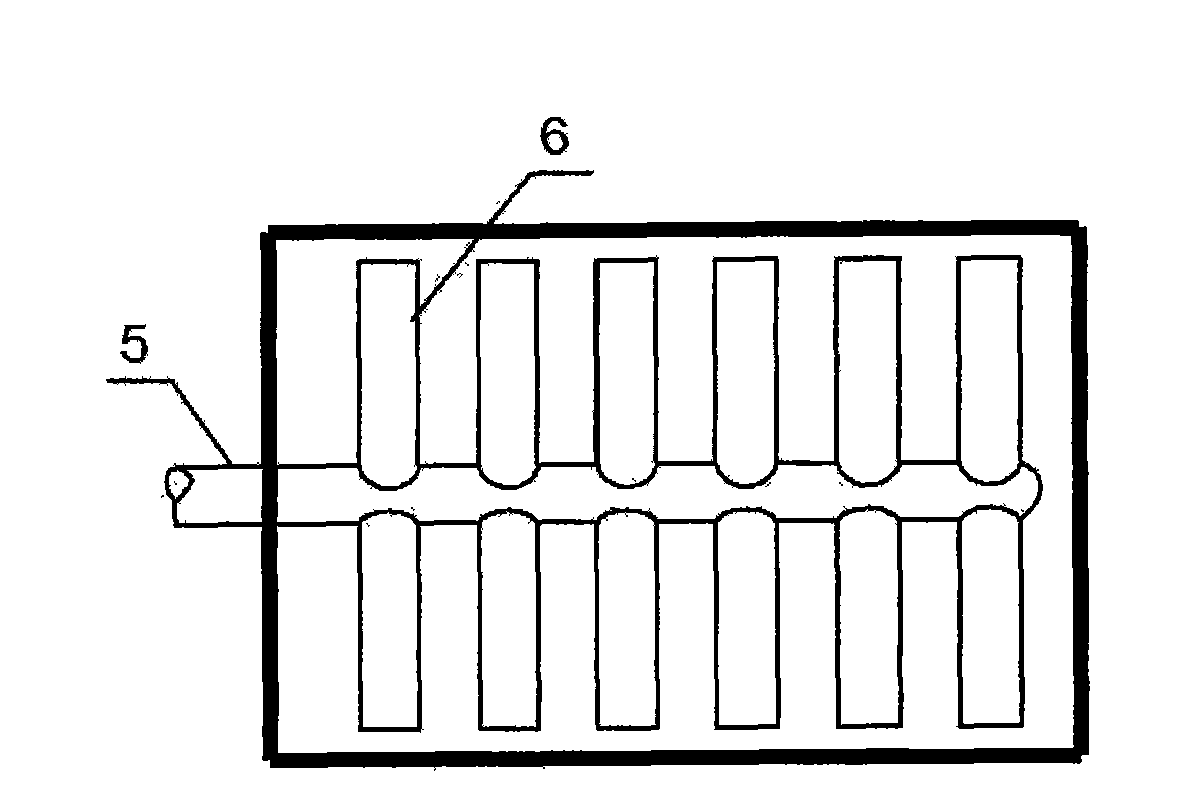

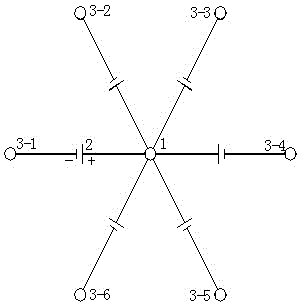

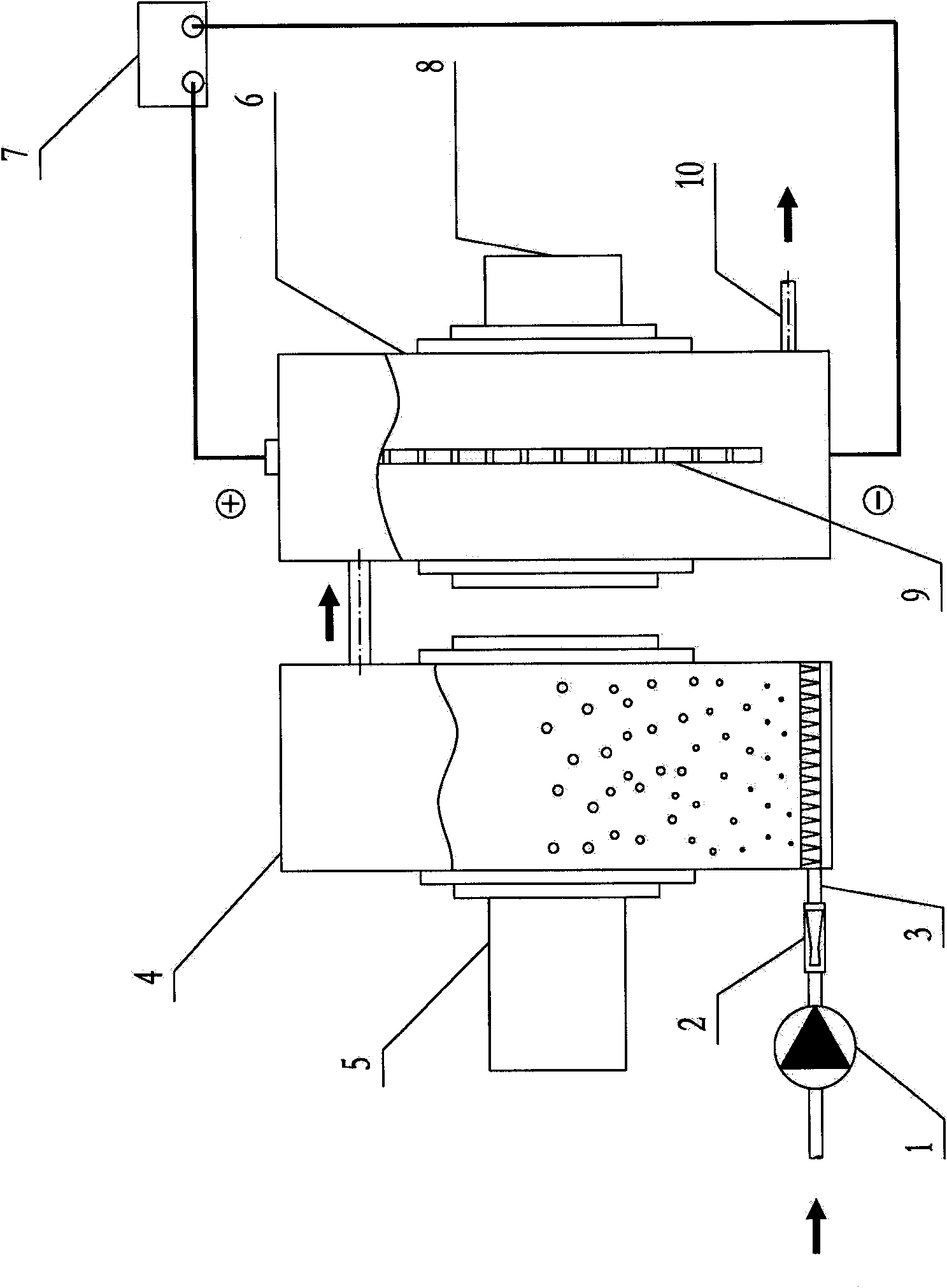

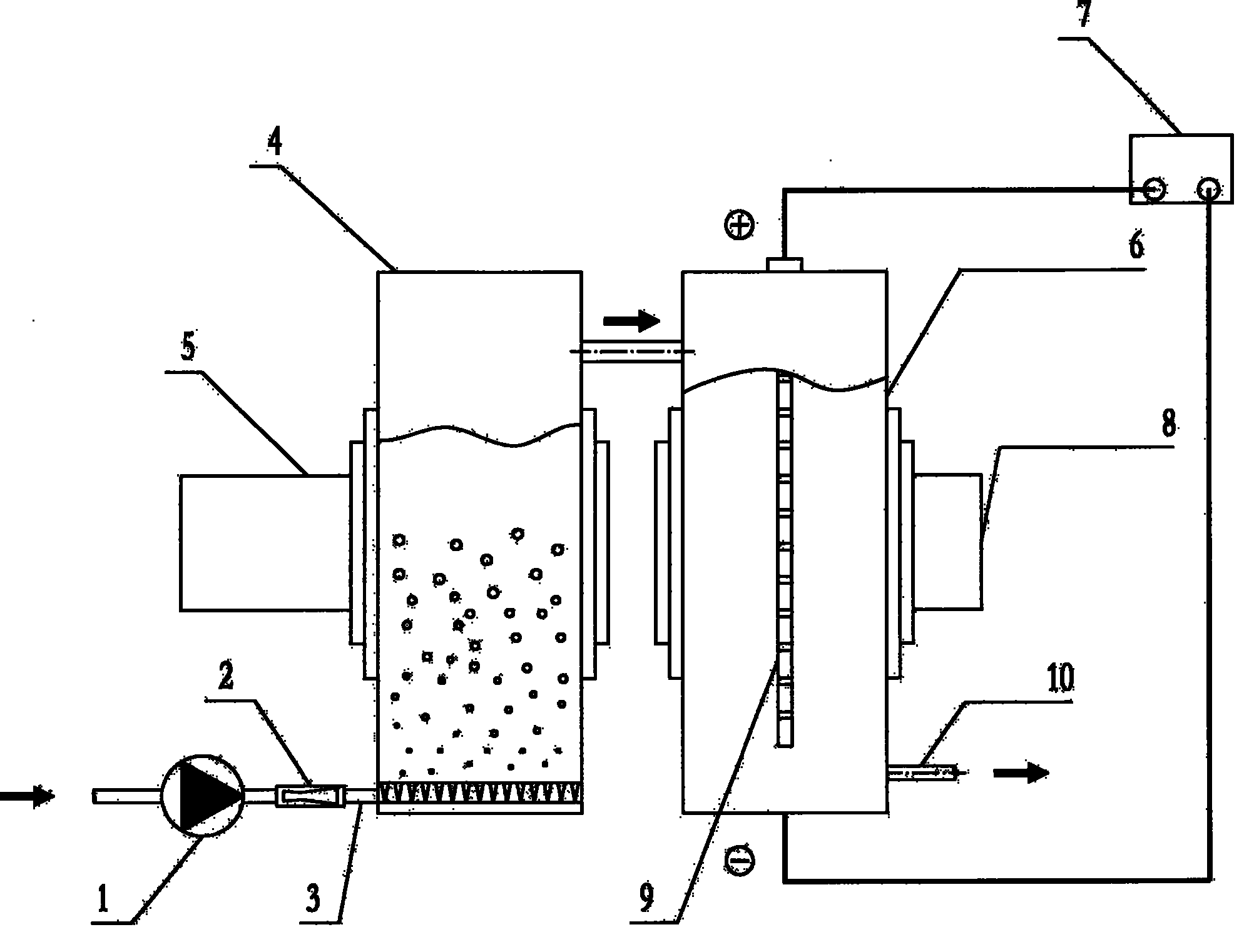

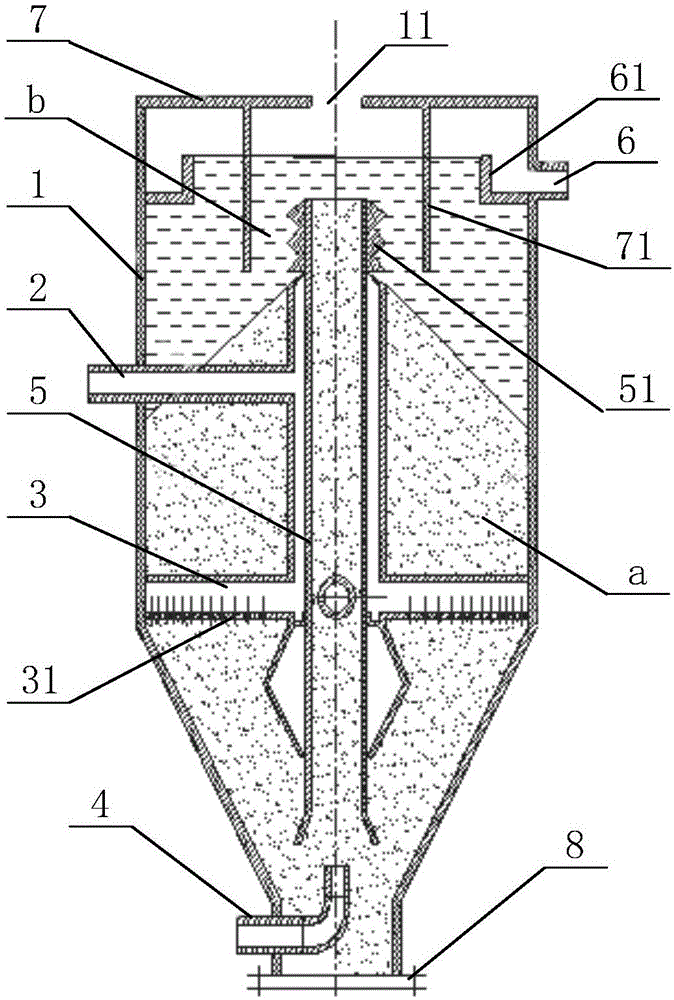

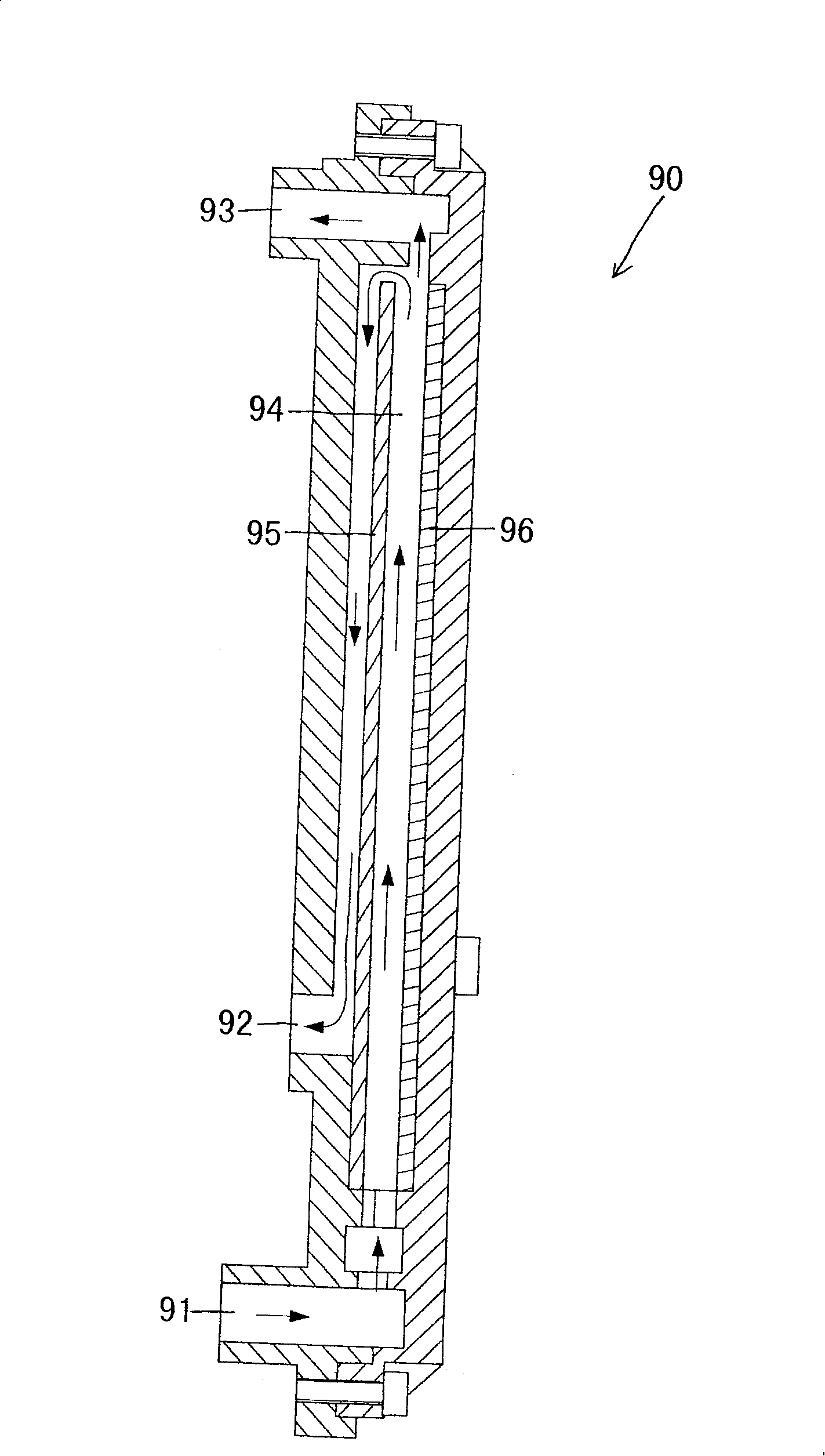

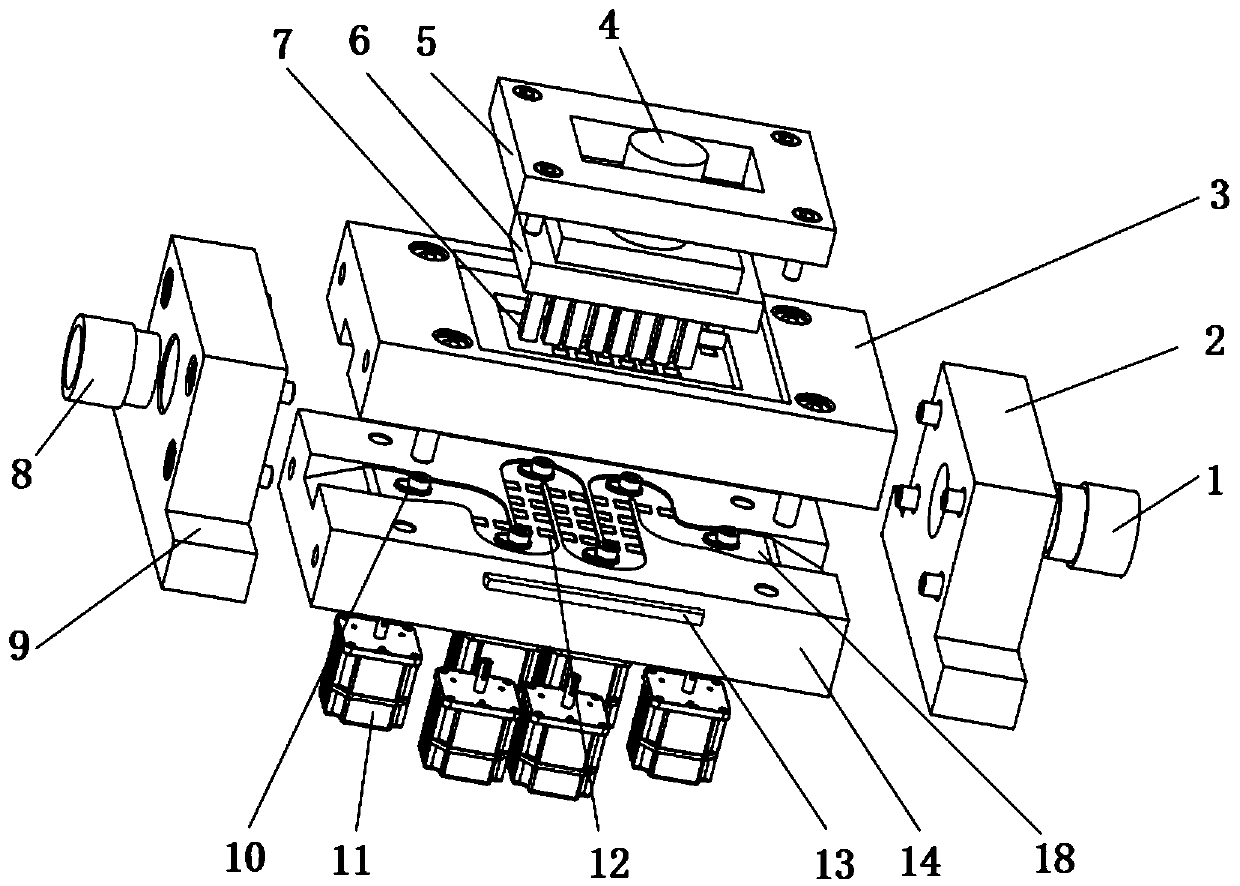

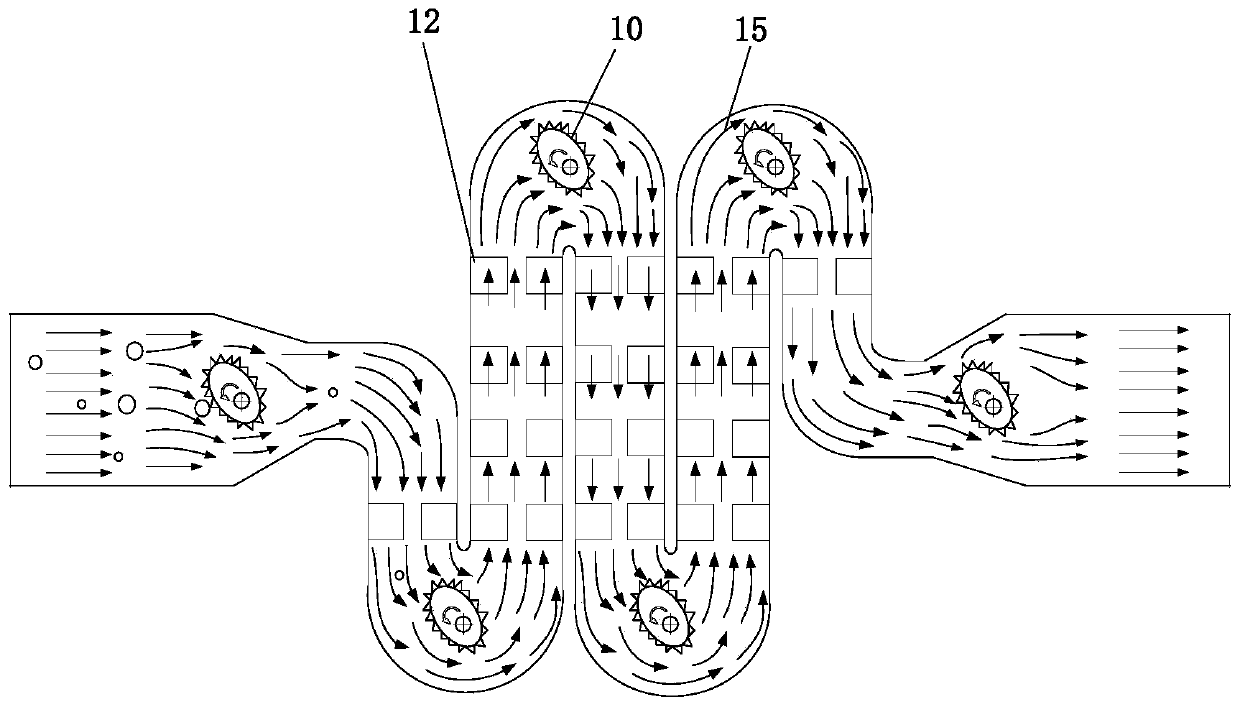

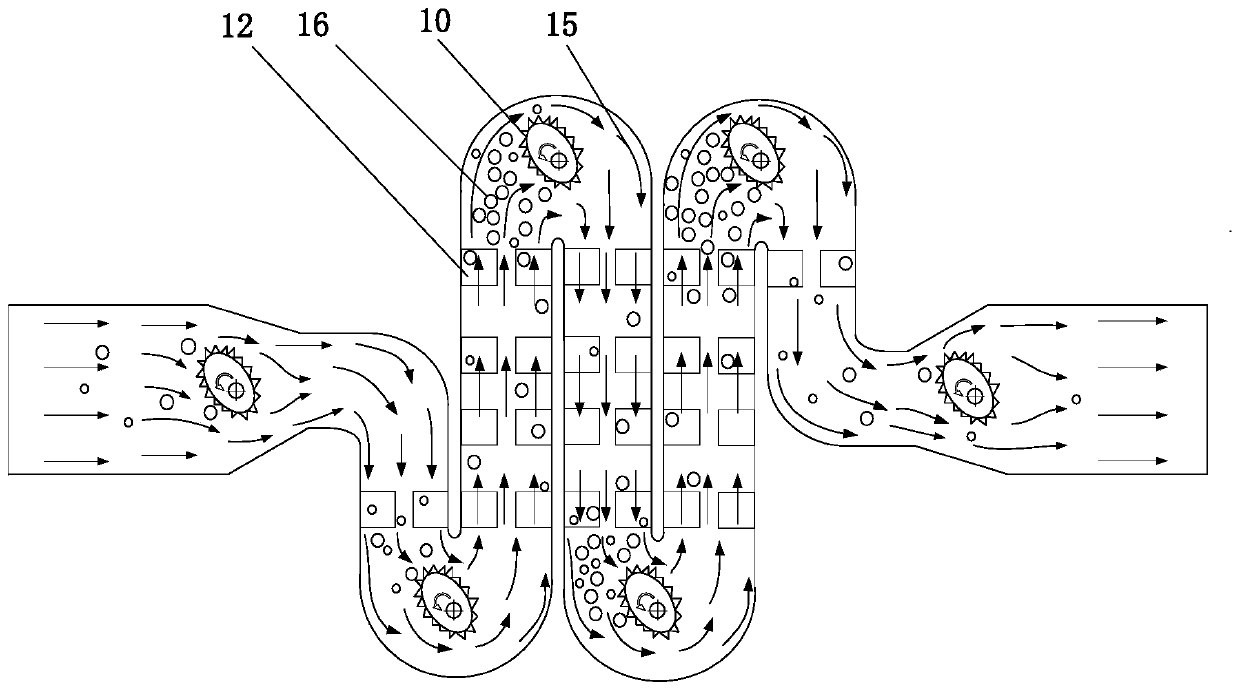

Internal-circulation type iron-carbon micro-electrolysis reactor

ActiveCN105036261AReduce energy consumptionReduce wearWater/sewage treatment using germicide/oligodynamic-processWater flowSewage

The invention discloses an internal-circulation type iron-carbon micro-electrolysis reactor. The reactor structurally comprises a cylinder body (1), a water inlet pipe (2), a water distributor (3), an air inlet pipe (4) and an internal circulation pipe (5); waste water flows through the water inlet pipe (2) and the water distributor (3) in sequence and is dispersed into iron-carbon filler (a) which is located on the lower portion of the cylinder body (1), and in the process of being in contact with the iron-carbon filler (a), the waste water is purified unceasingly till post-purification water is formed and drained out of a water outlet (6) of the cylinder body; air enters the iron-carbon filler (a) at the bottom of the cylinder body (1) through the air inlet pipe (4), and aeration bubbles moving upward are formed; the aeration bubbles drive the iron-carbon filler (a) to pass through the internal circulation pipe (5) and be discharged into the post-purification water; the iron-carbon filler (a) keeps on being sedimentated till falling back to an accumulation bed of the iron-carbon filler (a), thereby an aeration cycle of the iron-carbon filler (a) is formed. It is thus clear that by means of the internal-circulation type iron-carbon micro-electrolysis reactor, the energy consumption is low, the abrasion is little, the operation is simple, and the waste water can be disposed in a continuous and highly-efficient mode.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

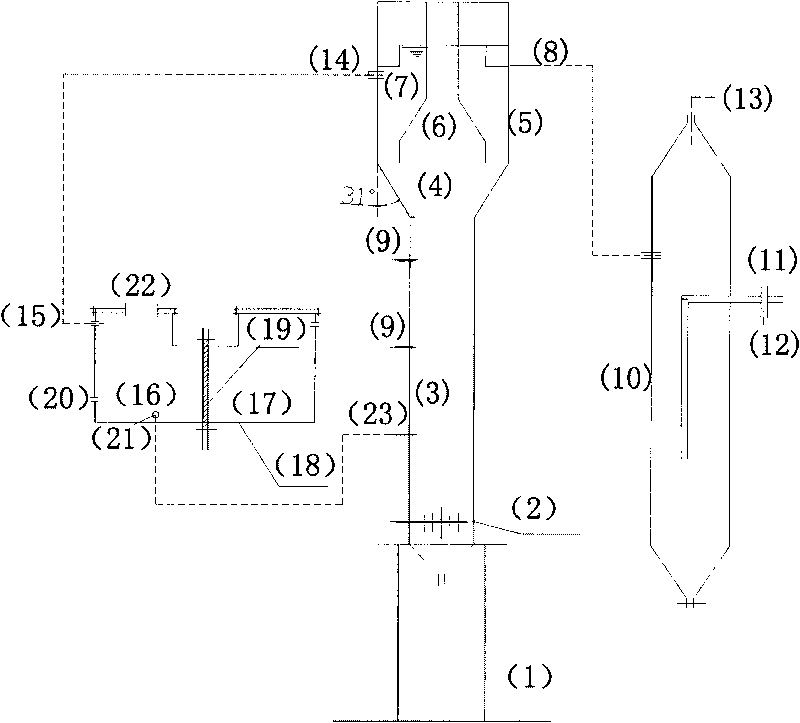

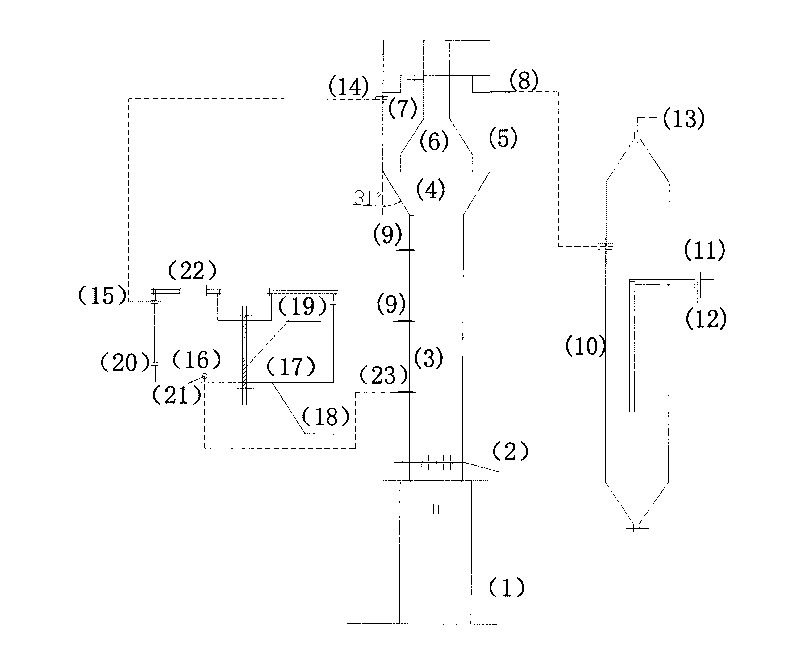

Electrolytic-biological anaerobic reactor and technique thereof

InactiveCN101693577AGuaranteed uptimeDisinhibition effectWater/sewage treatmentTreatment with anaerobic digestion processesNuclear engineeringAnaerobic reactor

The invention discloses an electrolytic-biological anaerobic reactor and a technique thereof. The electrolytic-biological anaerobic reactor comprises a reactor body and support legs, wherein the reactor body is orderly provided with a mud settling chamber, a gradual expansion chamber and an upflow reaction chamber from top to bottom; the outer side on the bottom of the reactor body is provided with a water inlet pipe and an external circulation pipe outlet; the upper part of the gradual expansion chamber is provided with an overflowing conical baffle; a three-phase separator is arranged in the mud settling chamber; the side wall on the upper part of the mud settling chamber is provided with an overflow weir, an overflow weir water outlet pipe and a gas-liquid separator; the upper part of the reactor body is provided with a backflow external circulation outlet; the outflow water flows into an external circulation inlet from the external circulation outlet through an external electrolysis bath; and the cathode and the anode of the electrolysis bath are separated by a cation exchange membrane. Through the electrolysis action of the external circulation, the invention can promote sulfides to be converted and oxidized, relieve the toxicity inhibition of the sulfides to the biological treatment, ensure the efficiency of the reactor for treating anaerobes and relieve the stroma inhibition. The reactor has large potential and strong impact resistance for treating waste water with low carbon-sulfur ratio.

Owner:ZHEJIANG UNIV

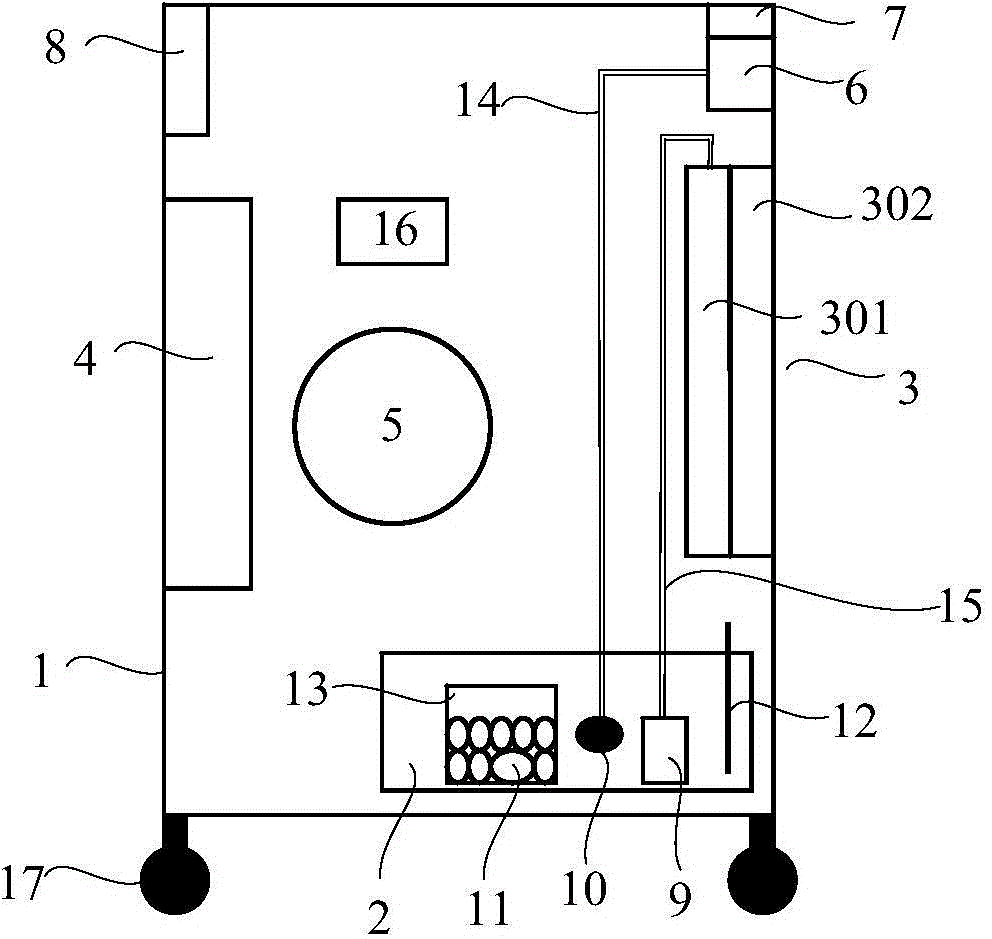

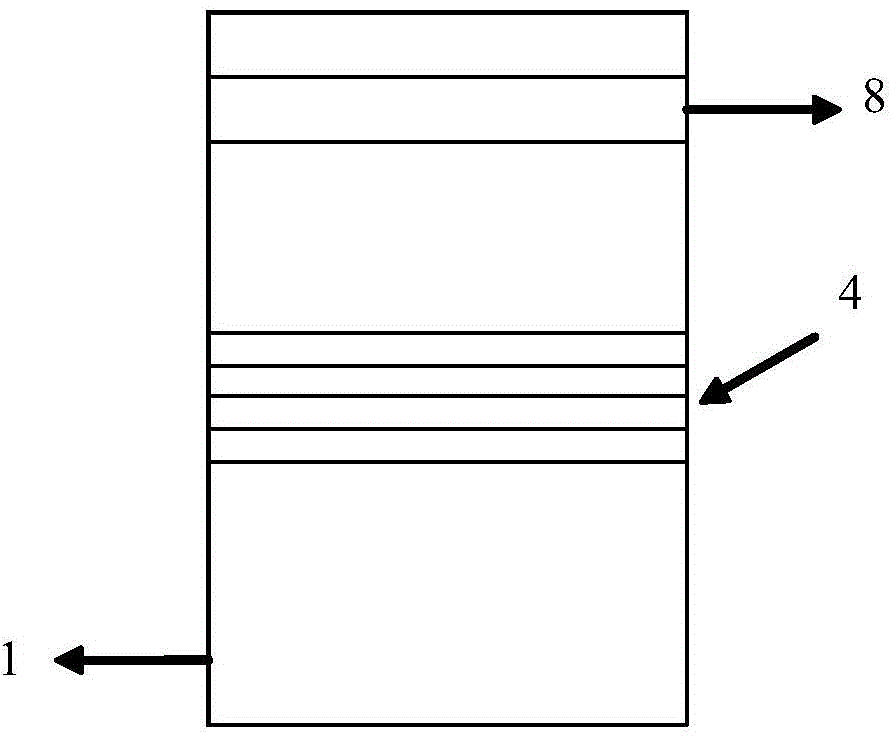

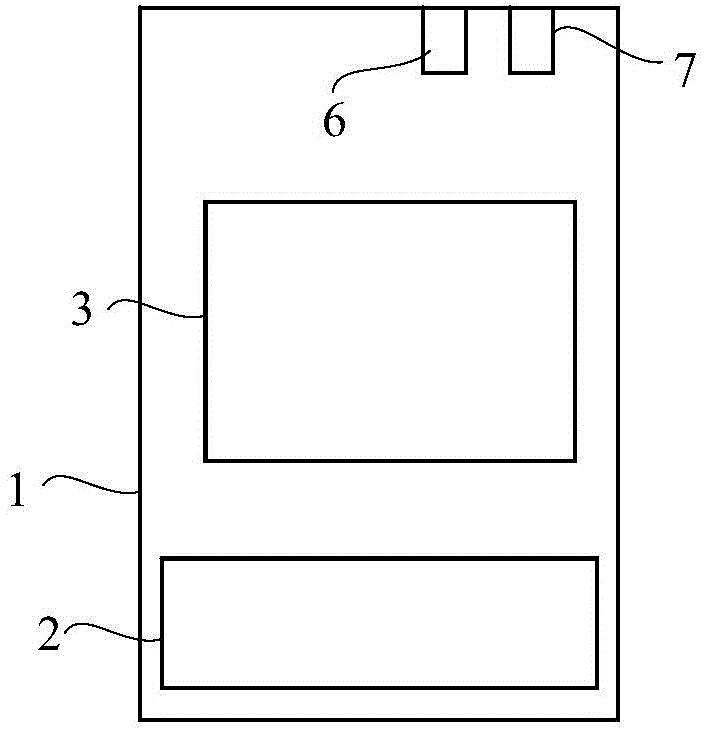

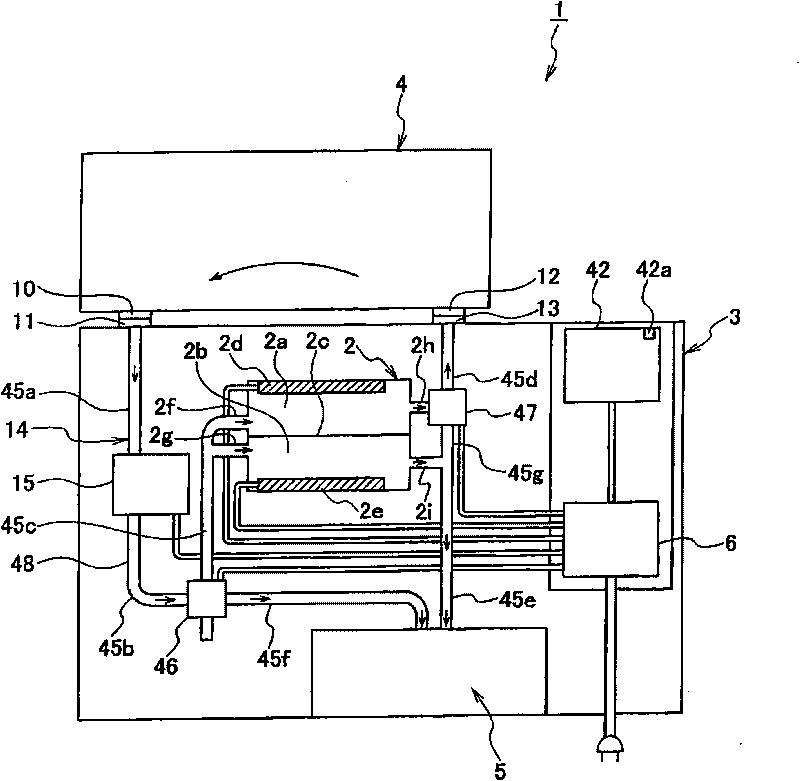

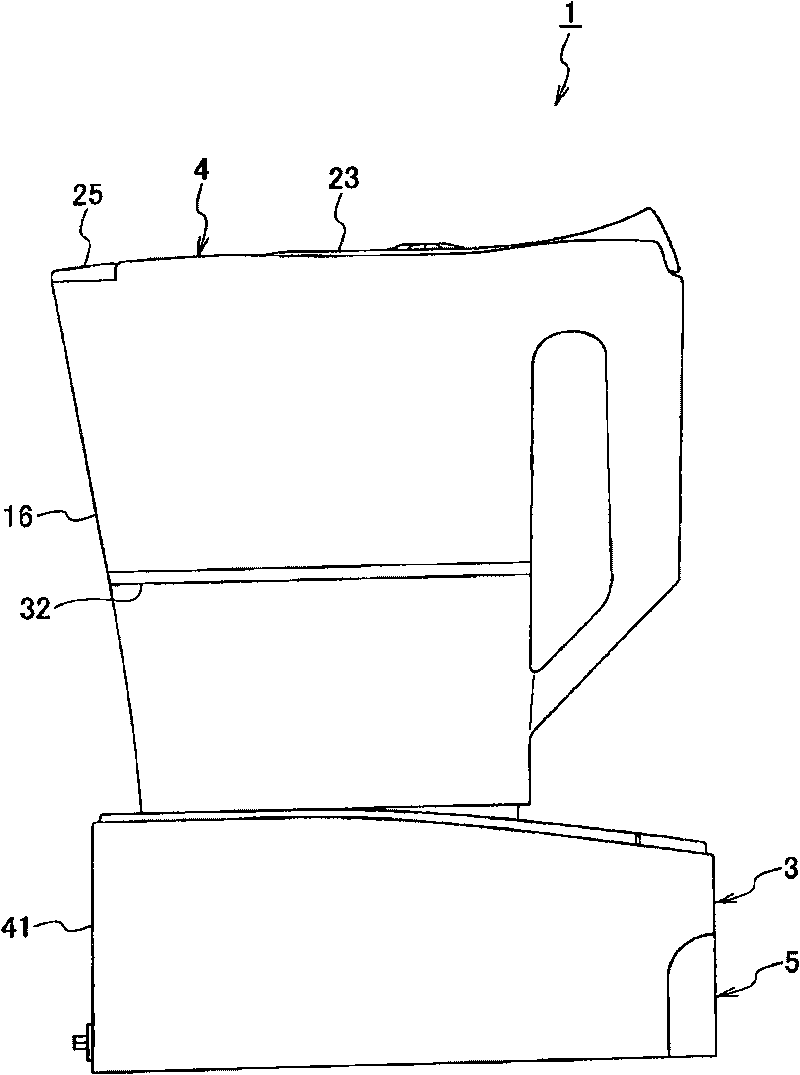

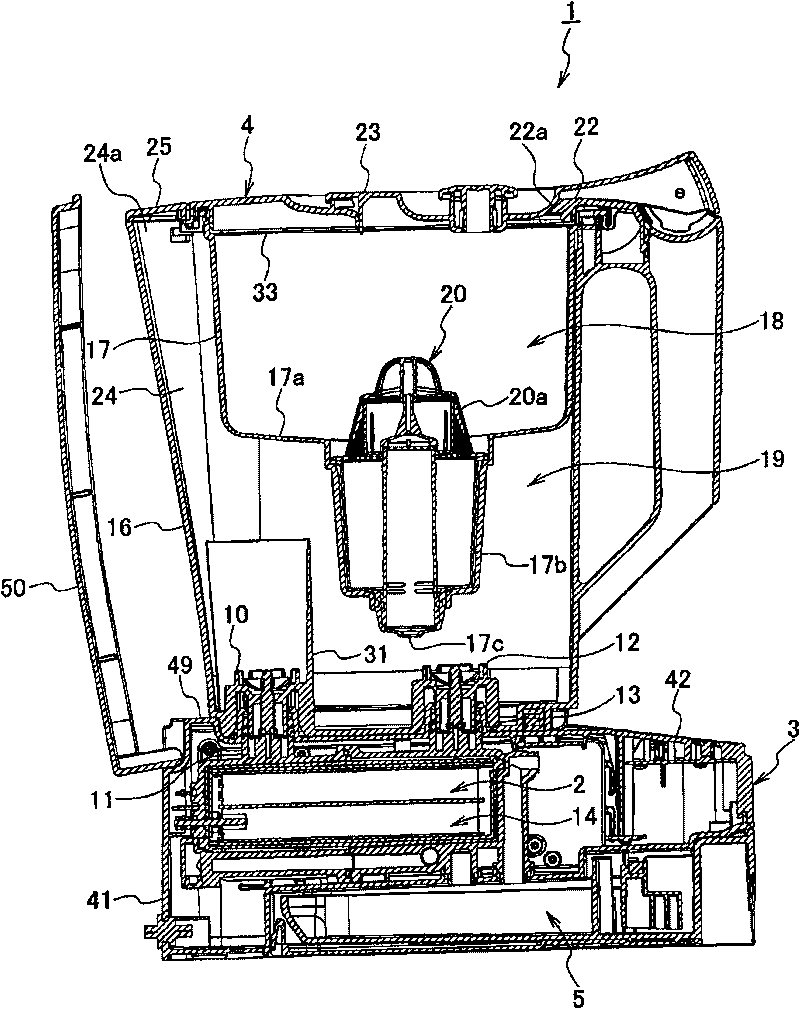

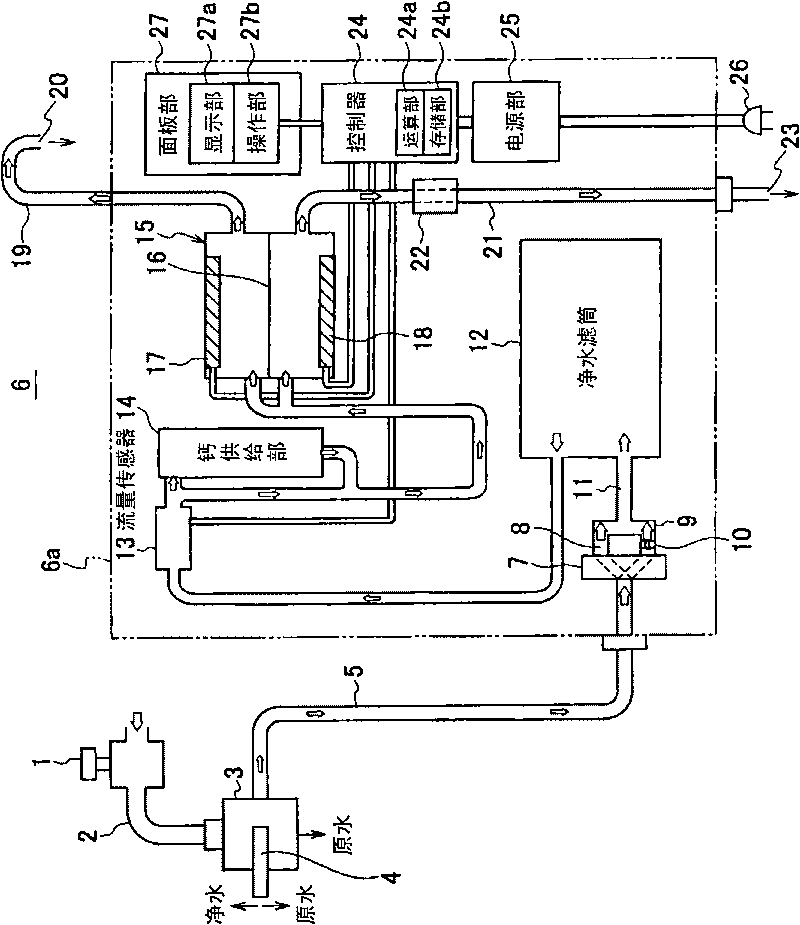

Electrolyzed water generation apparatus

The present invention provides an electrolyzed water generation apparatus which can realize miniaturization of an electrolysis tank. The electrolyzed water generation apparatus (1) comprises the following components: a water storing part (4); a body part (3) which is provided with an electrolysis tank (2); a circulation flow path (14) which passes through the water storing part and the electrolysis tank (2); and a circulation device (15) for circulating the water in the circulation flow path (14). The electrolyzed water is generated while the water circulates between the water storing part (4) and the electrolysis tank (2). Furthermore the generated electrolysis water is stored in the water storing part (4).

Owner:PANASONIC CORP

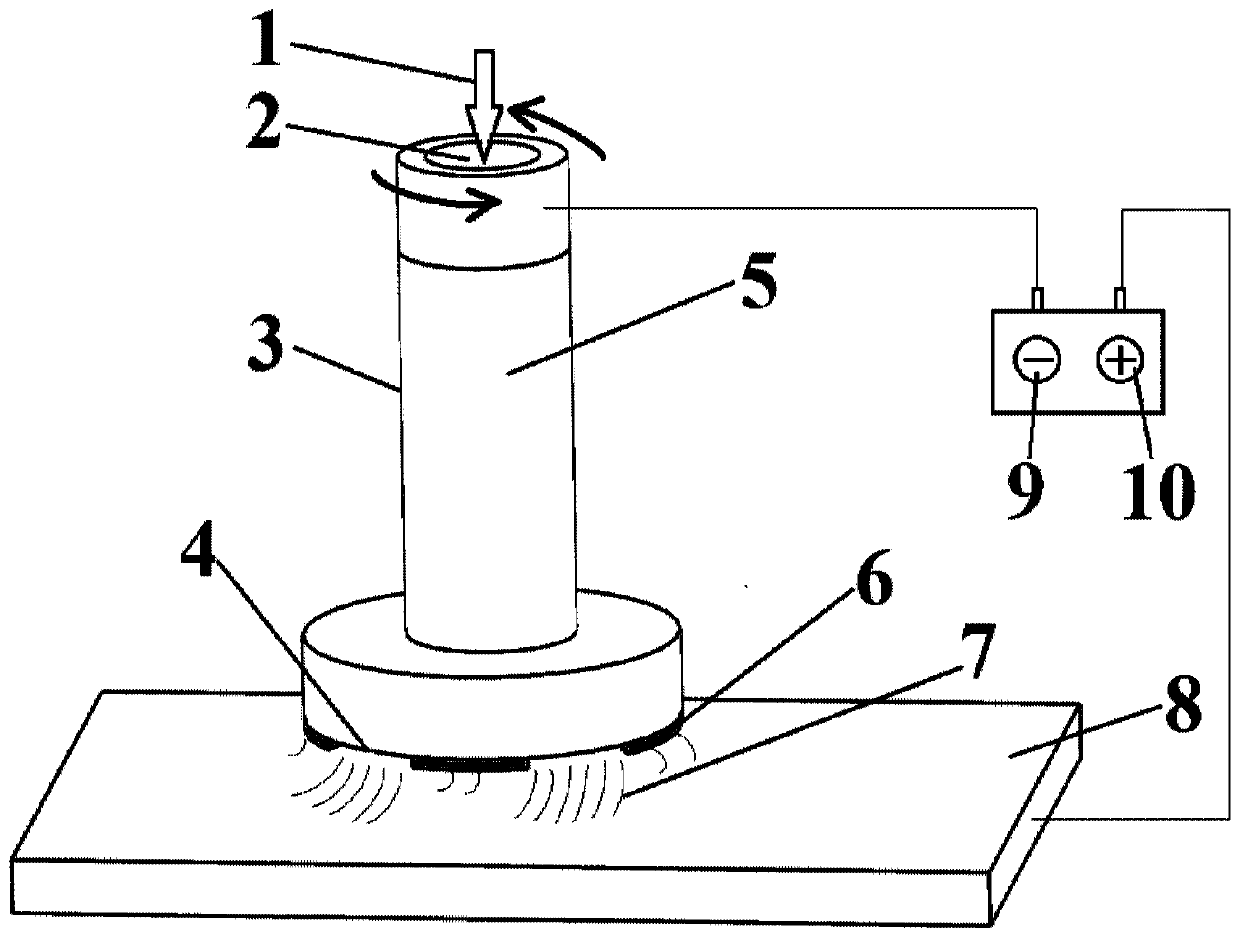

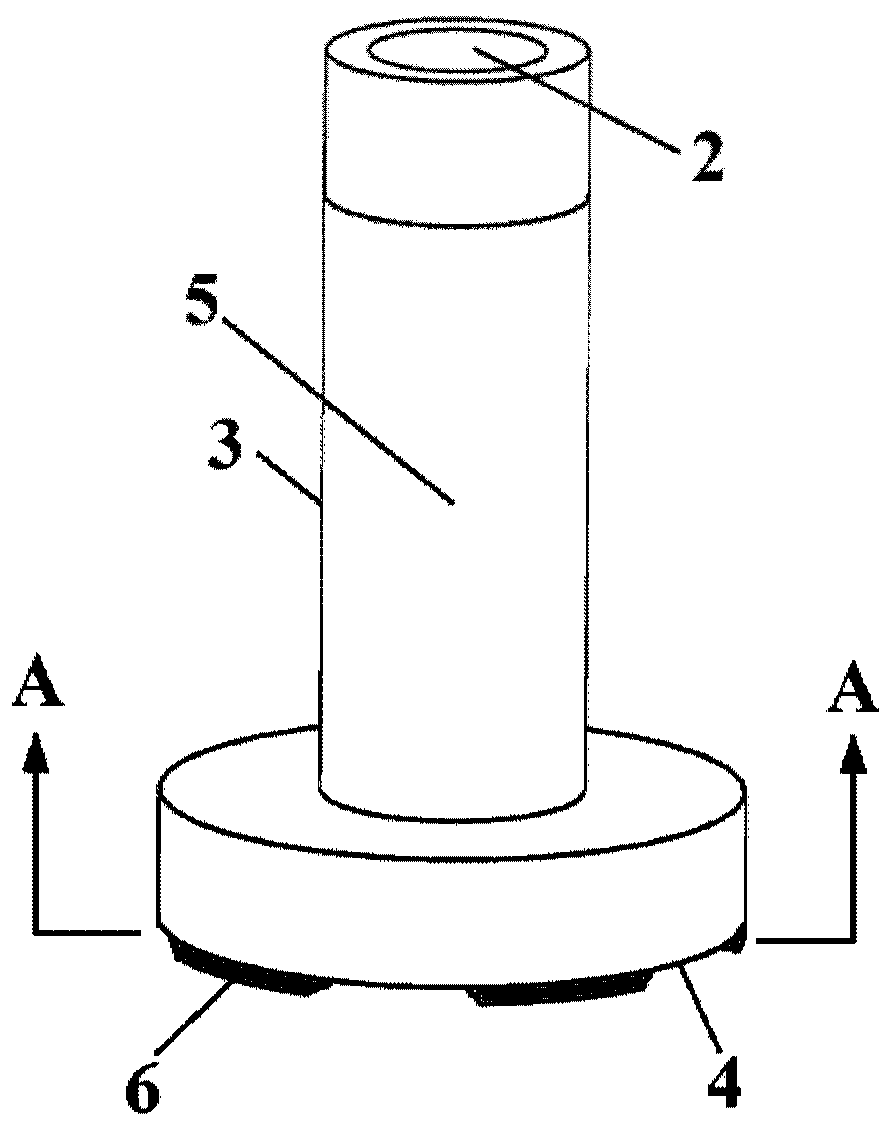

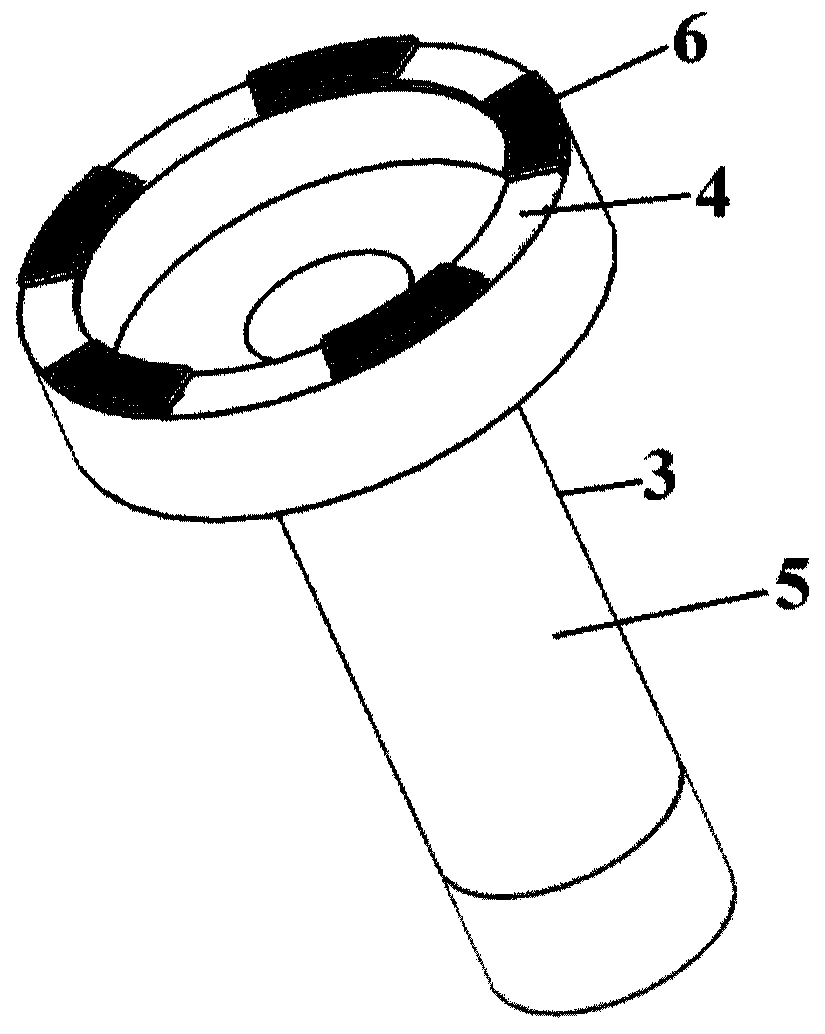

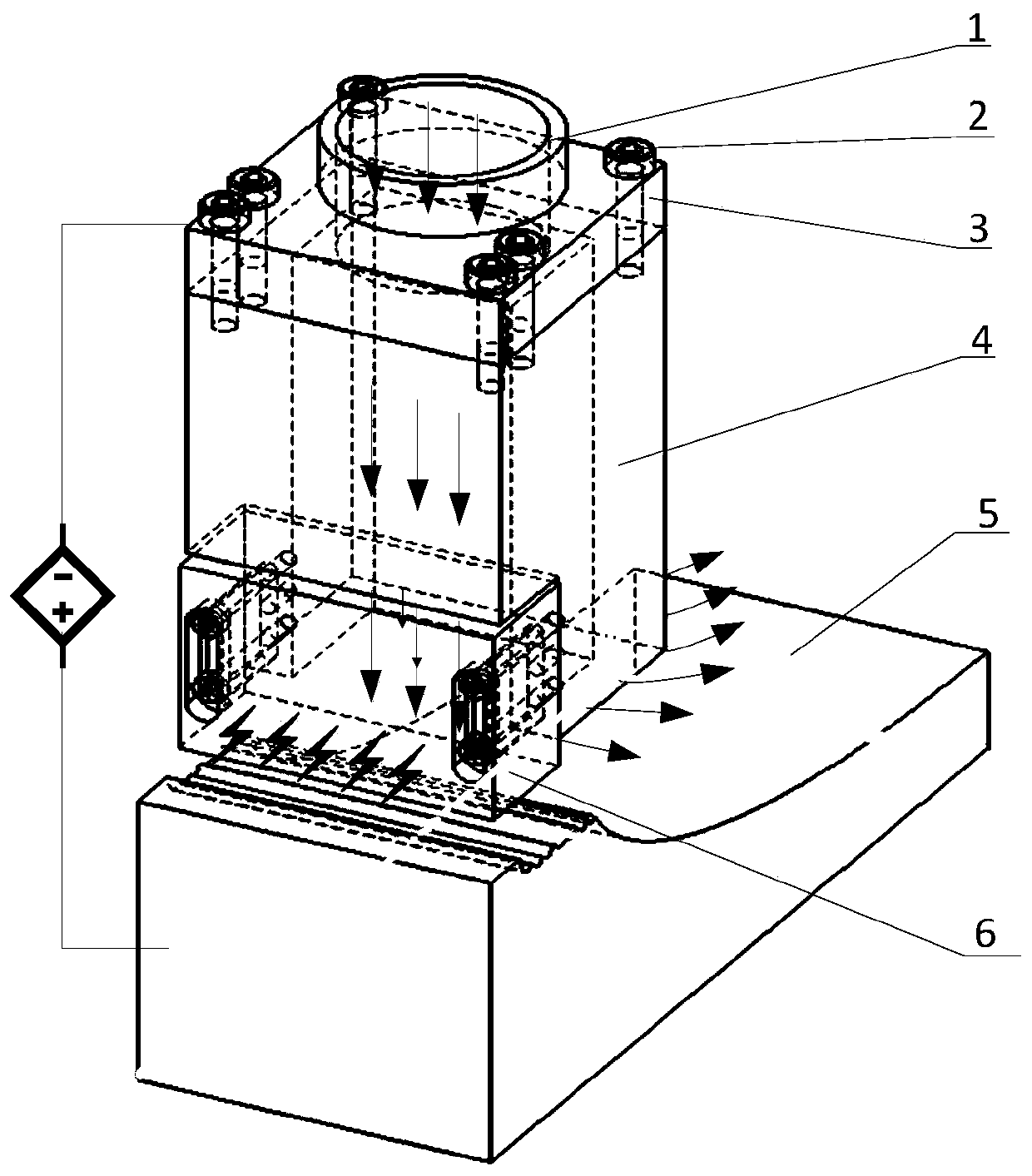

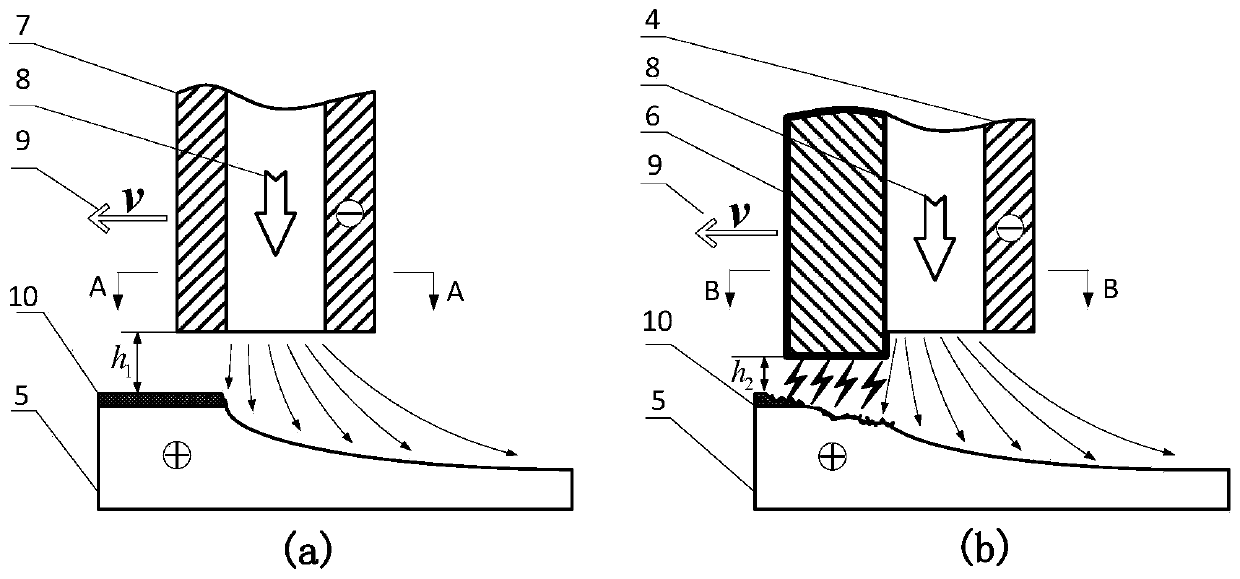

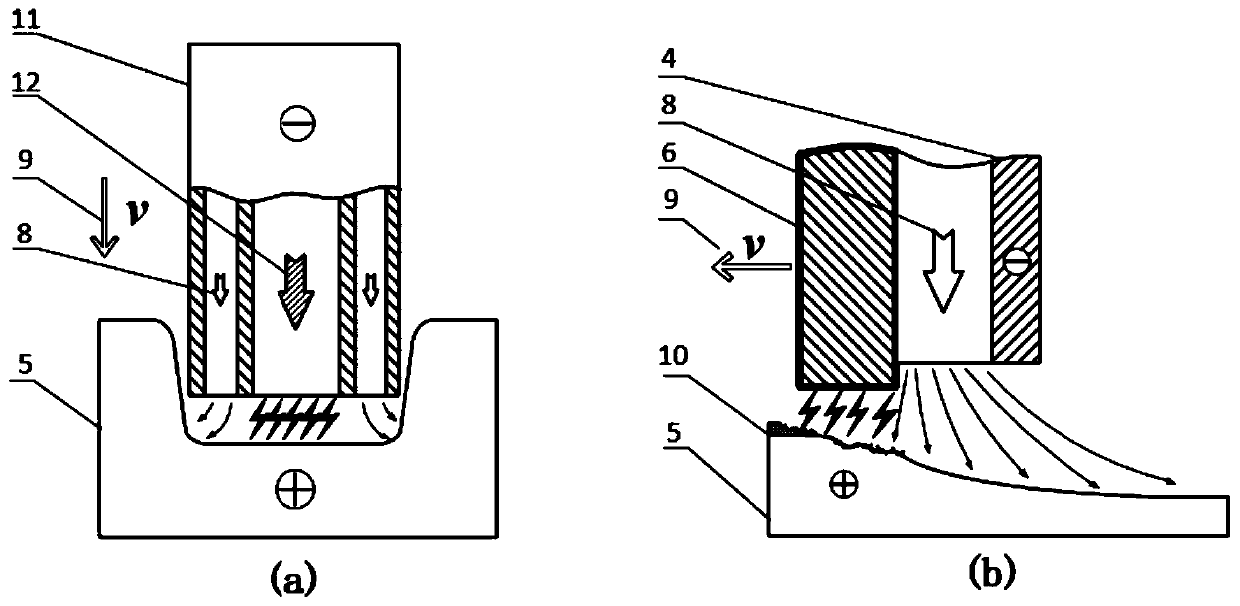

Surface grinding and electrolytic composite processing device, system and method

PendingCN110560807AReduce surface roughnessReduce surface roughness requirementsSurface roughnessHardness

The invention discloses a surface grinding and electrolytic composite processing device, a system and a method, and belongs to the field of grinding and electrolytic composite processing. The surfacegrinding and electrolytic composite processing device comprises a grinding main body and a plurality of grinding blocks, wherein the grinding main body can be accessed into a negative electrode of a power source as an electrolytic processing cathode, a penetrating liquid through hole is formed in the grinding main body so as to access electrolyte, the grinding blocks are arranged at the end of thegrinding main body at interval to form a grinding zone, the exposed areas in the middles of adjacent grinding blocks form an electrolytic action zone, and the electrolyte can flow out from the electrolytic action zone. According to the invention, the grinding main body with the central liquid through hole is adopted to perform grinding and electrolytic composite processing on a workpiece, so theprocessing device can meet the requirements for processing high-strength and high-hardness materials, and the requirements for improving the processing precision and reducing the surface roughness ofthe workpiece.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Industrial wastewater treatment method by internal electrolysis intensified by microwave plasma oxidation technology

InactiveCN1629087AQuick and effective removalSimple and easy water treatment technologyMultistage water/sewage treatmentActivated carbonIndustrial effluent

The invention provides an industrial wastewater treatment method by internal electrolysis intensified by microwave plasma oxidation technology comprising the steps of, absorbing the organic contaminant in industrial sewage by using the mixture of irony electric discharging body and activated charcoal, oxygenizing the adsorbed organic contaminant under the internal electrolysis action produced by the mixture, the microwave energizing the irony electric discharging body to produce plasma under wet state, thus degrading the absorbed organic contaminant and regenerating activated charcoal rapidly, finally discharging the cleaned industrial sewage.

Owner:WUHAN TEXTILE UNIV

Electric spark and electrolytic continuous machining method and tool for efficient plane milling

The invention relates to an electric spark and electrolytic continuous machining method and tool for efficient plane milling, and belongs to the field of electric spark and electrolytic machining. A cathode of the tool is mainly formed by combining a copper-tungsten alloy electric spark electrode and a stainless steel electrolytic electrode. The initial machining gap of the copper-tungsten alloy electric spark electrode and the to-be-machined surface of a workpiece is set to be a small value, when a large voltage is applied, air in the machining gap is subjected to breakdown, generated electric sparks rapidly remove an oxidation layer and a large number of metal bodies on the surface of the alloy workpiece in a corrosion manner, and the time needed for oxidization layer removal in subsequent electrolytic machining is saved; and then materials are further efficiently removed by the electrolytic electrode through the electrolytic function, and the uneven surface subjected to electric spark machining is subjected to electrolytic machining to be level and smooth. Through electric spark and electrolytic continuous machining, titanium alloy materials can be efficiently removed, and the significance on improving the titanium alloy machining efficiency is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

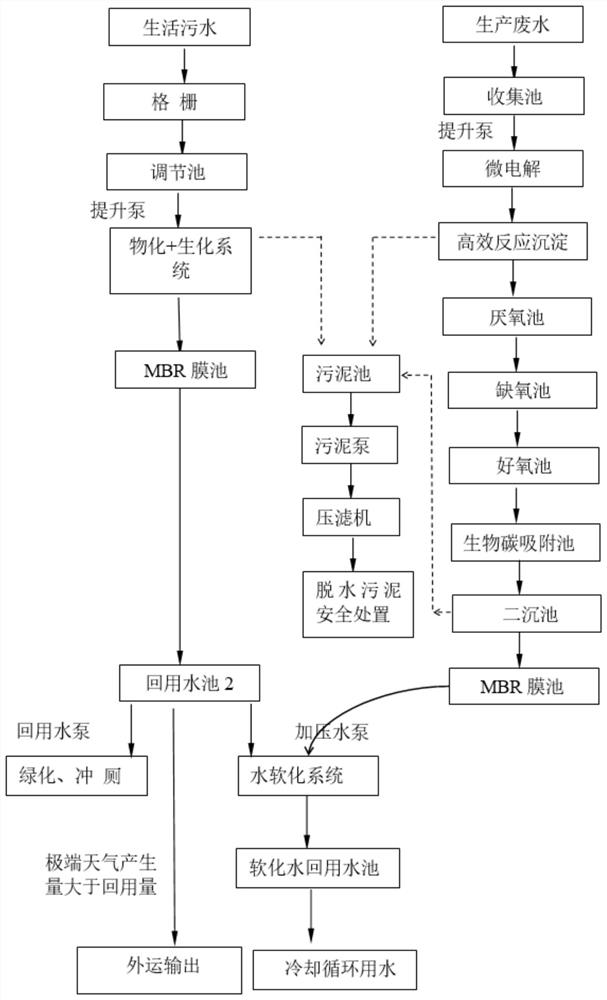

Industrial park domestic sewage and industrial wastewater treatment and recycling process

InactiveCN113429084AStabilizationGuaranteed uptimeWater contaminantsTreatment with aerobic and anaerobic processesIndustrial waste waterMunicipal sewage

The invention discloses an industrial park domestic sewage and industrial wastewater treatment and recycling process, and relates to the technical field of wastewater treatment. The industrial park domestic sewage and industrial wastewater treatment and recycling process comprises the steps of collecting wastewater to be treated in advance, and determining the type of the wastewater; and carrying out wastewater treatment based on wastewater categories, wherein the domestic sewage wastewater treatment comprises the steps of pre-collecting domestic sewage, pretreating the domestic sewage through a septic tank, and enabling the pretreated domestic sewage to flow into an adjusting tank; and the industrial wastewater treatment comprises the steps of collecting industrial wastewater in advance, and carrying out balance adjustment on water quality, water quantity and water temperature in a collecting tank; and pumping the industrial wastewater into a micro-electrolysis tank by a lifting pump, and destroying macromolecules of the wastewater through electrolysis. In allusion to a water treatment scheme that an industrial park is not provided with a matched municipal sewage pipe network and the current situation of surface water exceeds the standard, the process has the advantages of stable and efficient sewage treatment and low cost, ensures the stable operation of the process under the severe sewage condition, ensures the up-to-standard discharge of effluent, and is better and more stable in water quality and more beneficial to the natural environment.

Owner:广州茂绿环保科技有限公司

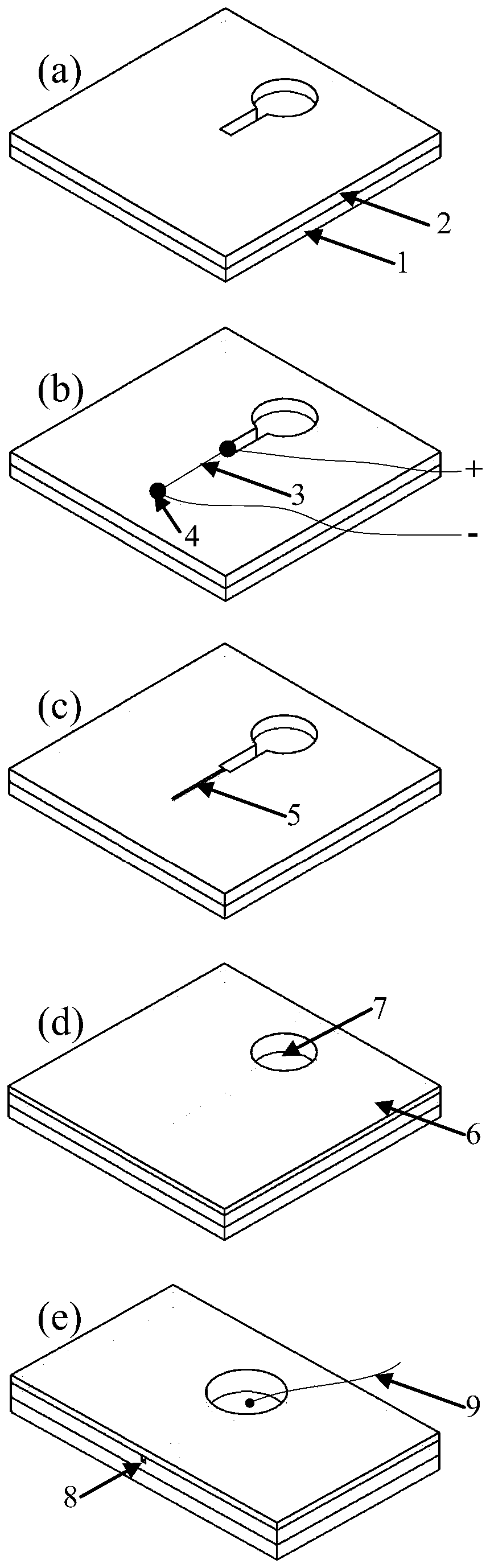

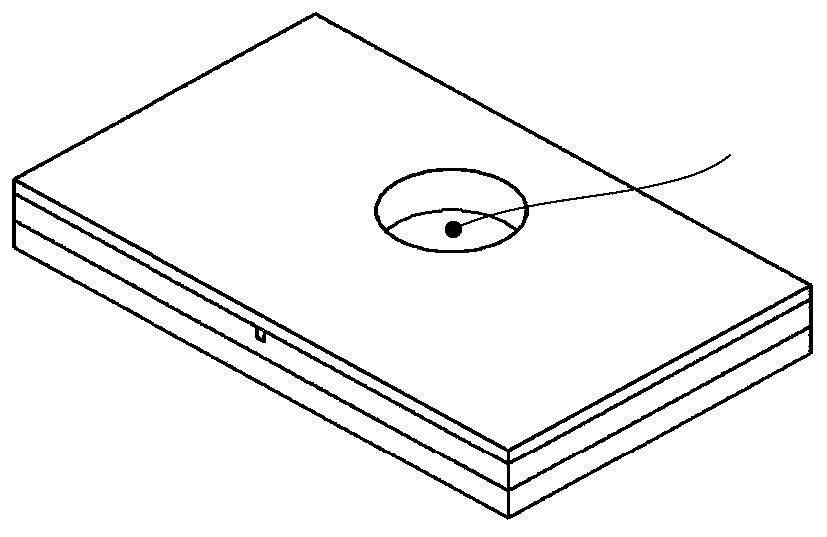

Method for manufacturing nano-scale electric jet-flow spray head based on SU-8 glue electrolytic process

The invention relates to nano-scale electric jet-flow spray head equipment, in particular to a method for manufacturing a nano-scale electric jet-flow spray head based on a SU-8 glue electrolytic process. The method is characterized by comprising the following steps: adopting SU-8 glue as an electric jet-flow spray needle material, and creating necessary conditions for forming nano cracks throughan incomplete drying and over-exposure way; taking a graphene straight line as an induced graph, and forming a linear nano channel with a relatively uniform dimension below the induced graph under electrolytic action of high-voltage electricity; and forming the final nano-scale electric jet-flow spray head through steps of thermo-compression bonding, ultra-violet lithography and electrode manufacturing.

Owner:JILIN UNIV

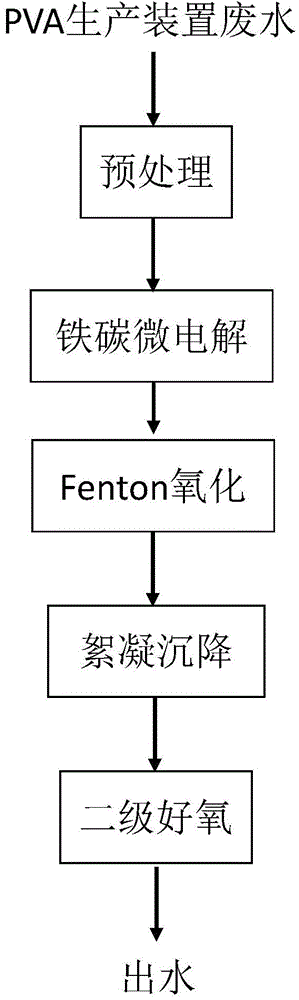

PVA production apparatus wastewater treatment method

ActiveCN105692967AAchieve emission standardsGood processing effectMultistage water/sewage treatmentNature of treatment waterTreatment effectOxygen

The invention relates to a PVA production apparatus wastewater treatment method. The method comprises the following steps: 1, adjusting the pH value of production apparatus wastewater to 2-4; 2, allowing the production apparatus wastewater to enter an iron-carbon micro-electrolysis reaction tank and to react; 3, allowing the production apparatus wastewater to enter a Fenton oxidation reaction tank and to react; 4, adding an alkali to yielding water discharged from the Fenton oxidation reaction tank to flocculate and settle iron ions in the yielding water; 5, allowing the yielding water discharged from the Fenton oxidation reaction tank to enter a primary aerobic reaction tank and to react; and 6, allowing yielding water discharged from the primary aerobic reaction tank to enter a secondary aerobic reaction tank and to react, settling yielding water discharged from the secondary aerobic reaction tank through a secondary sedimentation tank, and discharging standard reaching water. The treatment method adopts a combination technology to solve the defect of incomplete removal of COD from the PVA production apparatus wastewater by adopting single technologies, finally realizes standard reaching discharge of the PVA production apparatus wastewater through advanced treatment of the PVA production apparatus wastewater, and has the advantages of substantial treatment effect, simple maintenance, less investment and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Subcritical or supercritical water electrochemistry reinforced liquid phase catalytic biomass pyrolysis method

ActiveCN105441103AReduce oxygen contentReduce generationLiquid hydrocarbon mixture productionHydrocarbon oils treatmentLiquid fuelElectrochemistry

The invention discloses a subcritical or supercritical water electrochemistry reinforced liquid phase catalytic biomass pyrolysis method. The method takes subcritical or supercritical water as a medium to process the biomass in presence of a catalyst, by electrolyzing water to produce hydrogen, the biomass is pyrolyzed and dissolved, and the solid biomass is decomposed and converted to low molecular weight biological oil; on one hand, the subcritical or supercritical water transfers heat to the biomass, on the other hand, free hydrogen is released under an electrolysis function, free radical chain reaction is timely blocked, yield of liquid fuel is effectively increased and quality is improved; the biomass is uniformly heated, a chemical bond of lignocellulose is ruptured, an ion pair intermediate is generated and is stimulated by an electric field, a pyrolysis rate is quickened, efficiency is high, a process is easy to control and a use rate of the biomass is improved.

Owner:坤育环境发展(云南)有限公司

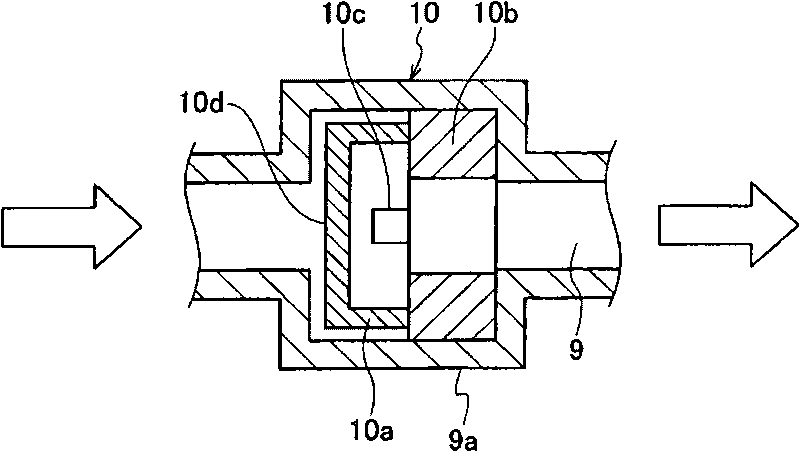

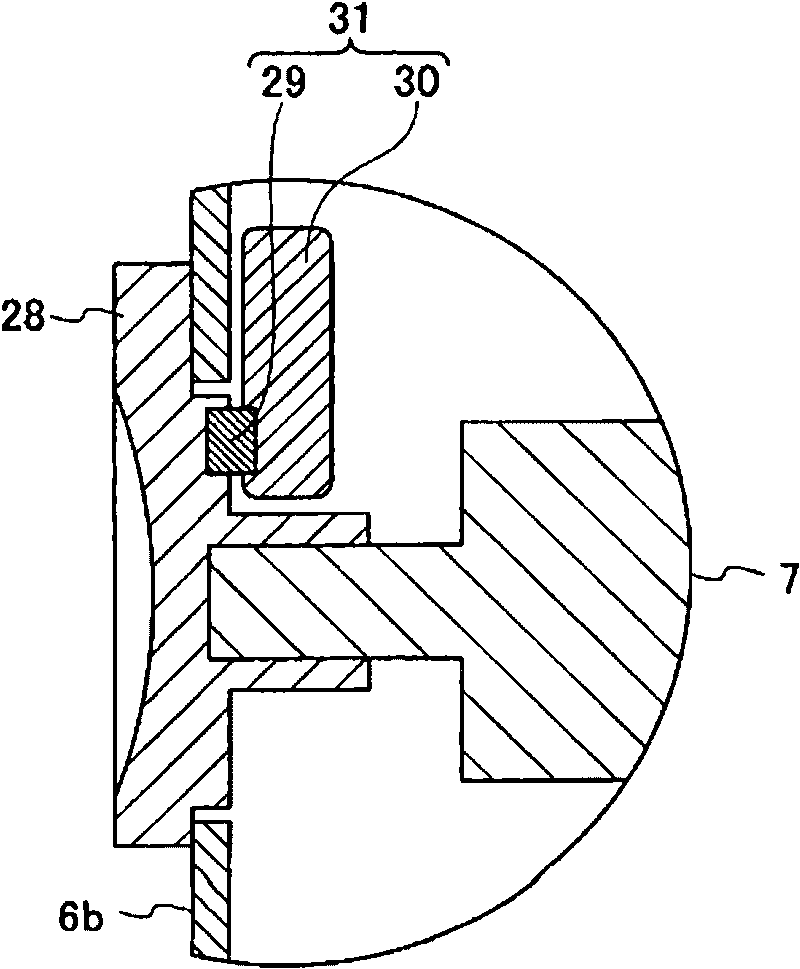

Water treatment apparatus

InactiveCN101746853AMiniaturizationIncrease the number ofCellsWater/sewage treatment apparatusMiniaturizationWater flow

The present invention provides a water treatment apparatus which can realize miniaturization and can restrain the reduction of clean water flow. The water treatment apparatus (6) of the invention comprises the following components: an apparatus body (6a) which is provided with a clean water filtering cartridge (12) for purifying raw water and an electrolysis tank (15) for electrolyzing raw water or clean water; and a water path (5) which is provided with a clean water path (8) for water flowing when the clean water is discharged and an electrolysis water path (9) for water flowing when the electrolysis water is discharged. The water treatment apparatus (6) is characterized in that: the water path (5) is provided with a water path conversion unit (7) for selecting a certain path selected from the clean water path (8) and the electrolysis water path (9); and furthermore the electrolysis water path (9) is provided with a flow adjustment unit (10) which adjusts the flow of water that flows in the electrolysis water path (9).

Owner:PANASONIC CORP

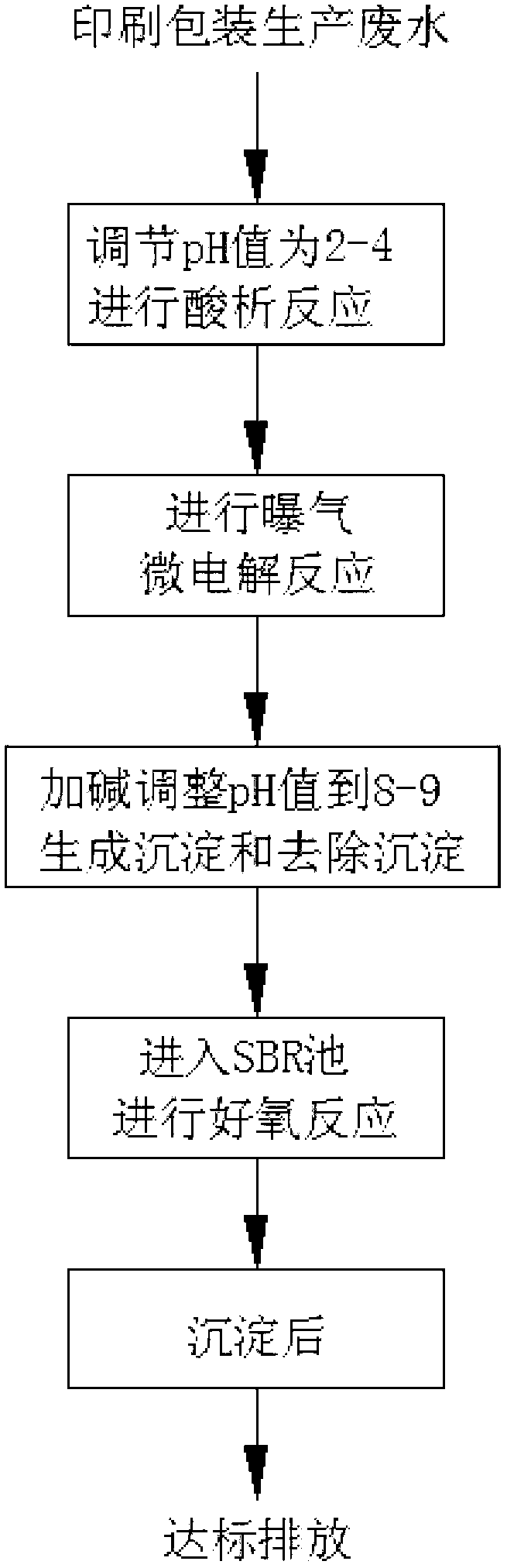

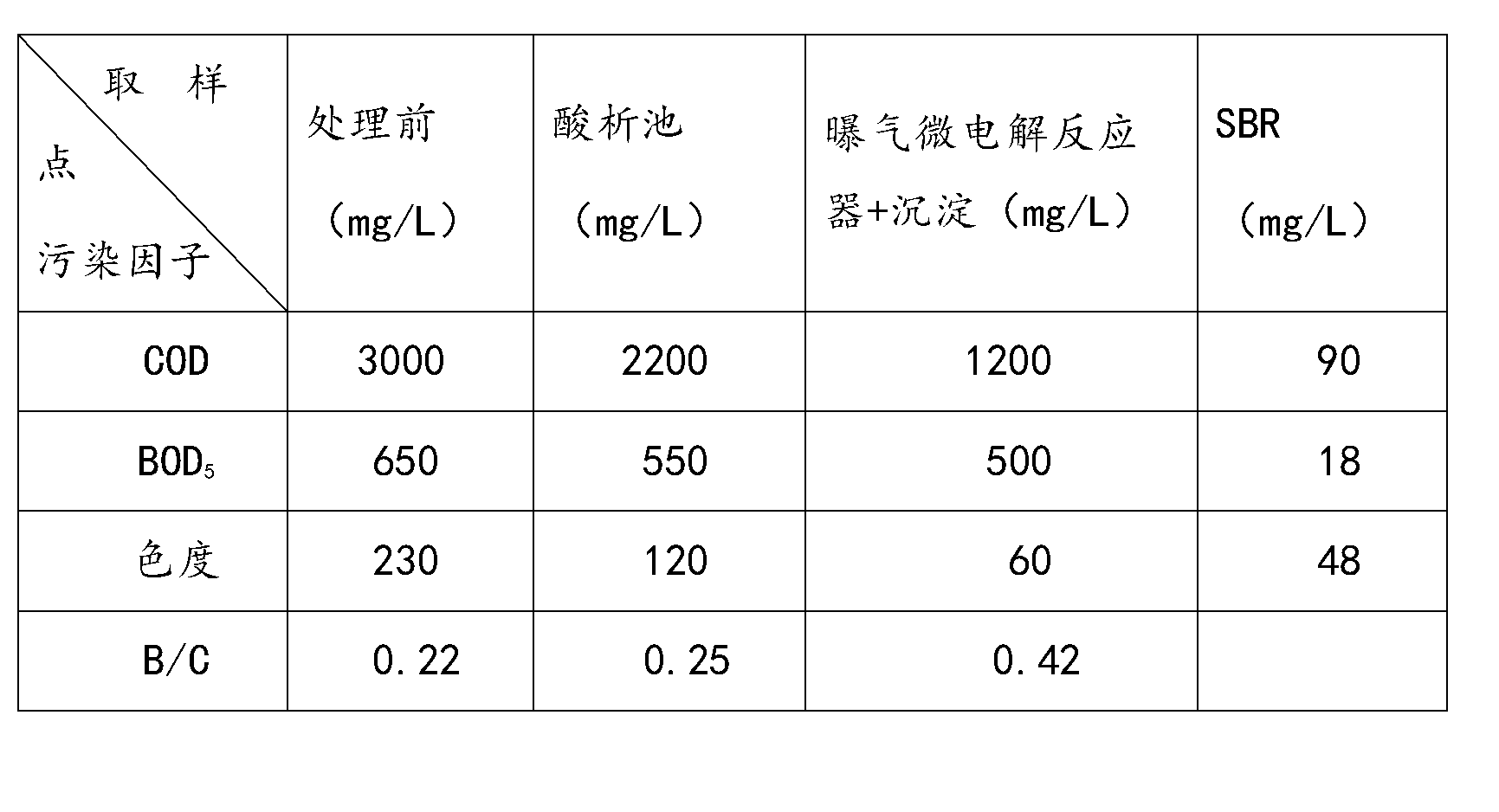

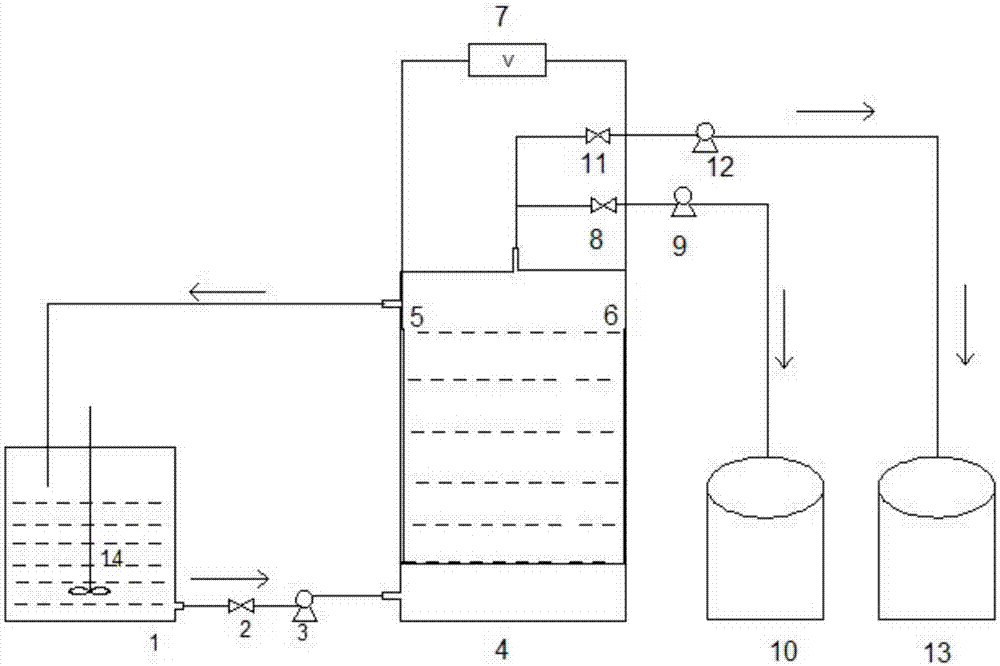

Treatment method for carton packaging and printing production wastewater

InactiveCN103159385AImprove biodegradabilityPrevent sludge bulkingMultistage water/sewage treatmentSequencing batch reactorOxygen

The invention discloses a treatment method for carton packaging and printing production wastewater. The treatment method comprises the following steps of: a, adjusting the pH value of the carton packaging and printing production wastewater to be between 2 to 4, performing acid precipitation reaction, and eliminating floating dross; b, performing aeration micro-electrolysis reaction on the wastewater after acid precipitation; c, adding alkali in the wastewater after micro-electrolysis, adjusting the pH value to be between 8 to 9 and generating a precipitate, and removing the precipitate generated by the reaction; d, conveying the wastewater after precipitation in an aerobiotic treatment pond and performing biochemical treatment; and e, precipitating the wastewater after the biochemical treatment and then draining to the outside, wherein the aeration micro-electrolysis reaction performs a strong oxidation reaction in an aeration micro-electrolysis reactor; fillers in the aeration micro-electrolysis reactor are waste iron scraps and active carbon; the mass ratio of the waste iron scraps to the active carbon is (1 to 3): 1; and the wastewater after the biochemical treatment is precipitated in an SBR (sequencing batch reactor) pond, and the supernatant is drained after reaching the standard. The treatment method disclosed by the invention is low in construction and use costs, and capable of preventing the sludge bulking of an SBR system and guaranteeing the stable running of the system.

Owner:HEFEI ZHONGDA ENVIRONMENT SCI & TECH

System and method for producing pure hydrogen and oxygen by adopting electrolysis brine

The invention relates to a system and method for producing pure hydrogen and oxygen by adopting electrolysis brine. The system comprises a water storage device, a water inlet valve, a water inlet pump, an electrolytic cell, the anode, the cathode, a pulsed power supply, a first valve, a first vacuum pump, a second valve, a second vacuum pump, a hydrogen collecting device and an oxygen collecting device. The method is characterized in that an operation mode of supplying power by adopting the pulsed power supply is adopted; when the pulsed power supply is turned on, only oxygen is generated and hydrogen ions accumulate at the liquid phase; after the pulsed power supply is turned off, only hydrogen is generated; the two gases: namely hydrogen and oxygen are collected and enter the gas collecting devices separately through the control of the valves and the vacuum pumps; and the turn on / off operation is carried out continuously, so that a lot of pure hydrogen and oxygen are prepared. Compared with the conventional water-electrolytic hydrogen making equipment and process, the system and method for producing pure hydrogen and oxygen by adopting electrolysis brine has the advantages as follows: the pulsed power supply method is adopted, the two gases: namely hydrogen and oxygen are separated and purified on the premise of not needing gas separation equipment, the loss of voltage of the conventional equipment due to membrane pollution and polarization is effectively reduced, and both the hydrogen production power consumption and equipment cost are greatly reduced.

Owner:CHINA UNIV OF MINING & TECH

Method for slowing electrolysis bath anion and cation thin film laminar flow and device

InactiveCN101191234AReduce flow ratePromote formationCellsWater/sewage treatmentAlkaline waterMixed flow

The invention provides a method for slowing electrolyte tank anion and cation membrane laminar flow and a device thereof, wherein, corresponding inner faces of two shells are provided with pole plates on which cathodes and anodes are correspondingly arranged, center positions on shells or pole plates are provided with water intake flow passages by which two electrolytic spaces are divided into, the raw water flows in through water inlets of the water intake flow passages and is electrolyzed directing to both sides, thereby slowing down the water velocity during the electrolytic process of the alkaline water and the acidic water, helping the split flow of the alkaline water and the acidic water and avoiding the mixed flow phenomenon.

Owner:徐文星

Electrolytic machining tool enabling flow field period fluctuation and method

ActiveCN110802288AEasy dischargeImprove stabilityMachining working media supply/regenerationElectrolytic agentProcess engineering

The invention discloses an electrolytic machining tool enabling flow field period fluctuation and a method, and belongs to the technical field of electrolytic machining. Due to the arrangement of a barbed cam mechanism in a device flow channel, the flow and the flow rate of an electrolyte in a machining flow channel fluctuate periodically, the electrolyte is promoted to flush the surface of a workpiece in a wave manner, a machining product is taken away quickly, and the surface quality of electrolytic machining is improved. In addition, spikes distributed throughout the surface of a barbed camcan pierce bubbles generated in the electrolytic action of the workpiece, the influence of the bubbles on later workpiece electrolytic machining is reduced, and the stability and the uniformity of electrolytic machining are improved. The electrolytic machining tool enabling flow field period fluctuation and the method have important significance in improving the electrolytic machining surface quality, machining stability and uniformity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Removable rapid waste water treatment equipment

InactiveCN105481151AEasy to handleEfficient processing effectMultistage water/sewage treatmentWater treatment multistage treatmentsHigh concentrationTreatment effect

The invention relates to removable rapid waste water treatment equipment, and belongs to the technical field of waste water treatment equipment. The removable rapid waste water treatment equipment is characterized in that the structure comprises a regulating tank (1), a middle water tank (2), a micro-electrolysis reaction column (3), a catalytic ozonation reaction column (4), and an activated carbon adsorption column (5). The micro-electrolysis reaction column (3) is filled with a regularized micro-electrolysis filter, the catalytic ozonation reaction column (4) is filled with a ferro-manganese-loaded silica-gel carrier as a catalyst, the catalytic ozonation reaction column is connected with an ozonator (6) and an ozone adsorption tank (7), and the activated carbon adsorption column (5) is provided with a return pipe connected with the regulating tank (1). The removable rapid waste water treatment equipment is designed to arrange on a bearing plate with wheels, and is powered by using a diesel generator, has the advantages of high maneuverability, cheap fillers, simple structure, good treatment effects and the like, can effectively remove COD and organic matters in high-concentration waste water, and has higher utilization value when a sudden environmental pollution event of the high-concentration waste water occurs.

Owner:JILIN UNIV

Preparation method of multifunctional composite micro-electrolysis filling material

InactiveCN106044959AImprove biodegradabilityEasy to installWater/sewage treatmentMixed materialsWaste treatment

The invention relates to a preparation method of a multifunctional composite micro-electrolytic filler, which comprises the following steps: the first step: mixing iron ore powder, carbon powder and binder in proportion to form a semi-finished product; the second step: mixing the mixed semi-finished product with Add water into the reaction kettle to heat once and stir evenly to form a mixture; the third step: put the mixture into a fully enclosed briquette machine and compress it to form a briquette filler; the fourth step: put the briquette filler into a high-temperature reactor for secondary heating to realize the honeycomb briquette Overmolding of fillers. The method of the present invention not only changes the shape of the micro-electrolysis material, but also increases the contact area with the waste water when it treats the waste water, which greatly increases the treatment efficiency. A large number of microporous structures are formed inside, and the problems of fillers being broken and blocking pipes during use can be avoided by adding adhesives, and the problem of loose fillers can be avoided by using the secondary heating reaction of the reactor.

Owner:江苏林格环境工程集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com