Treatment method for carton packaging and printing production wastewater

A technology for production wastewater and a treatment method, which is applied to the treatment of printing production wastewater and carton packaging, can solve the problems of difficult discharge of effluent, swelling of sludge in aerobic systems, and difficulty in meeting discharge requirements, and achieves improved biodegradability, The effect of preventing sludge bulking and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

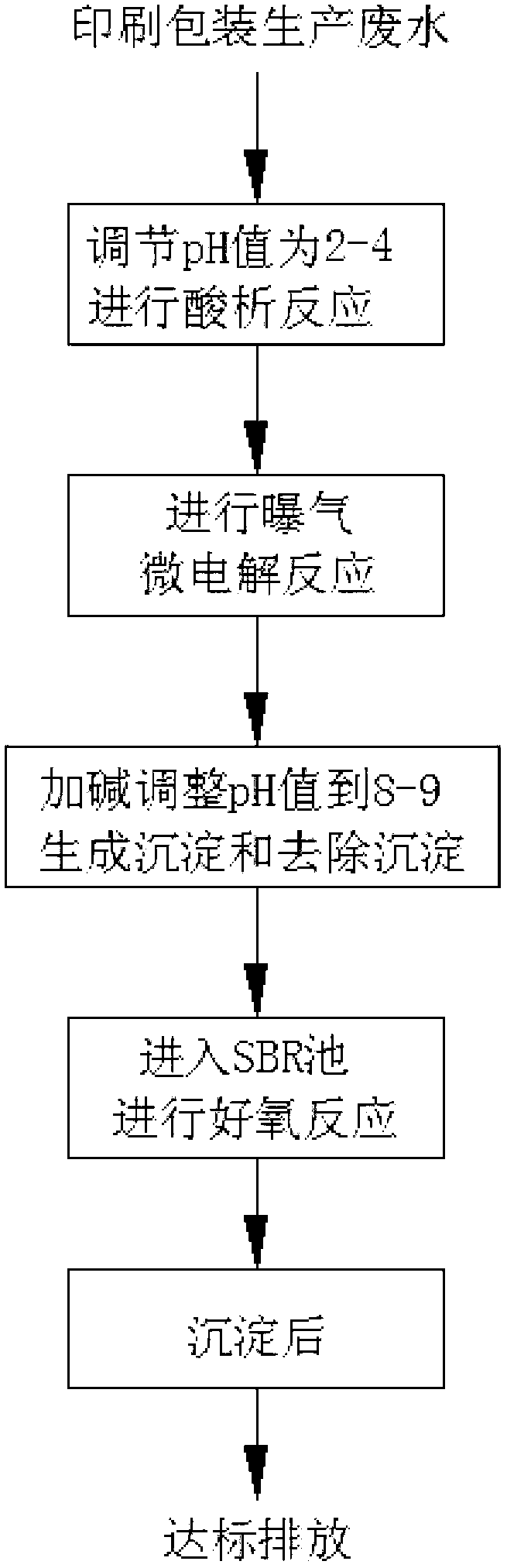

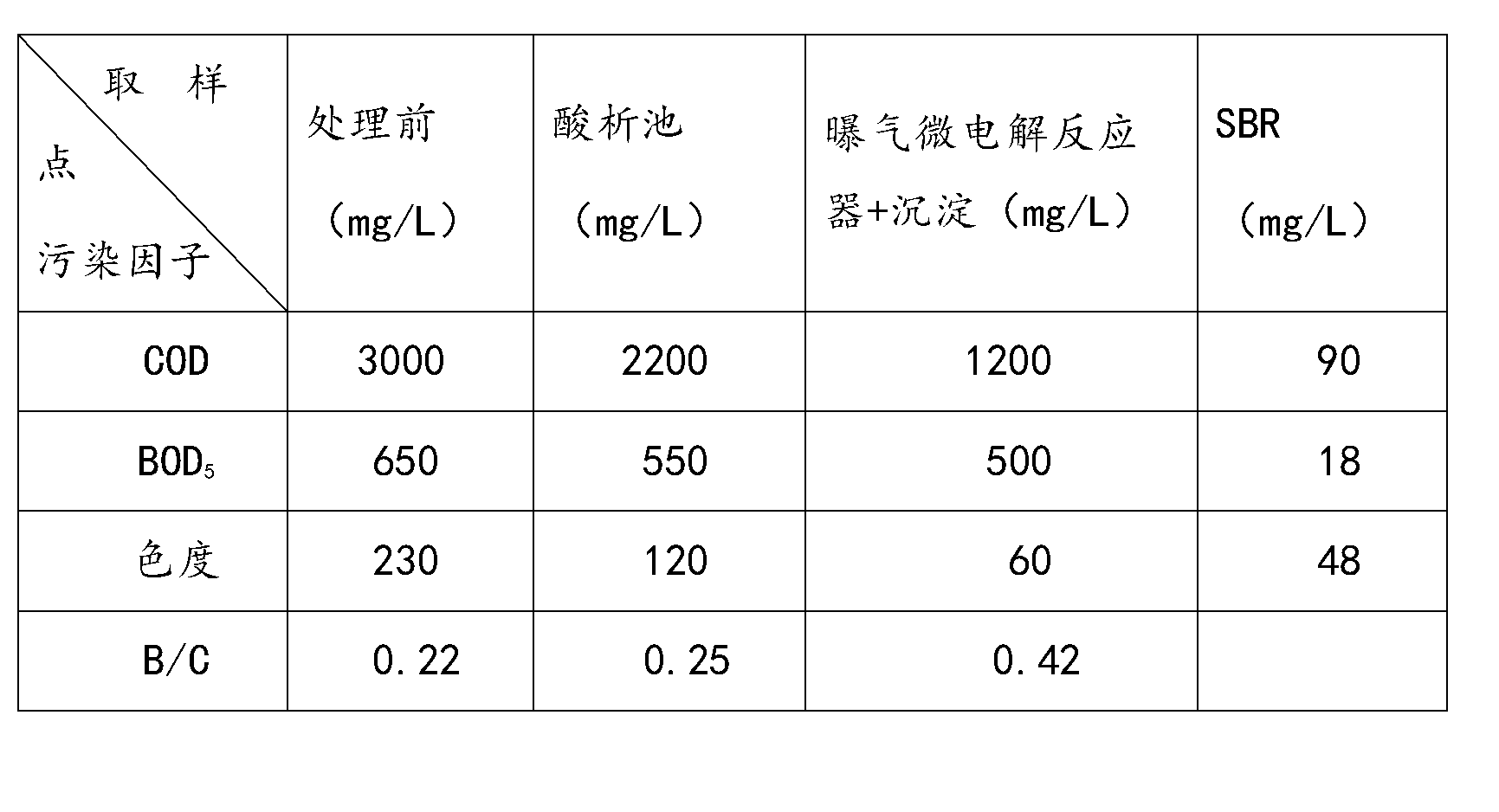

[0020] like figure 1 Shown, a kind of carton packaging and printing production wastewater treatment method, its steps are:

[0021] a. Adjust the pH value of the printing and packaging production wastewater to about 3 in the pH adjustment pool, so that the resin pollutants (such as water-soluble ink) dissolved in the wastewater can be separated from the water;

[0022] b. Separating the floating scum after acid analysis from the waste water;

[0023] c. Wastewater enters the aerated micro-electrolysis reactor for aerated micro-electrolysis reaction, and the macromolecules, long chains, and ring-shaped refractory organic substances in the wastewater are opened and broken;

[0024] d. The wastewater after micro-electrolysis flows into the chemical reaction tank to add alkali (such as NaOH), adjust the pH value to 8-9 to form precipitates or flocs; the alkali can also be Ca(OH) 2 , it is preferred to add NaOH here, because the solid waste generated by adding NaOH is less, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com