Granular active carbon circulating micro-electrolysis reactor

A micro-electrolysis reactor, granular activated carbon technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of electrochemical corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

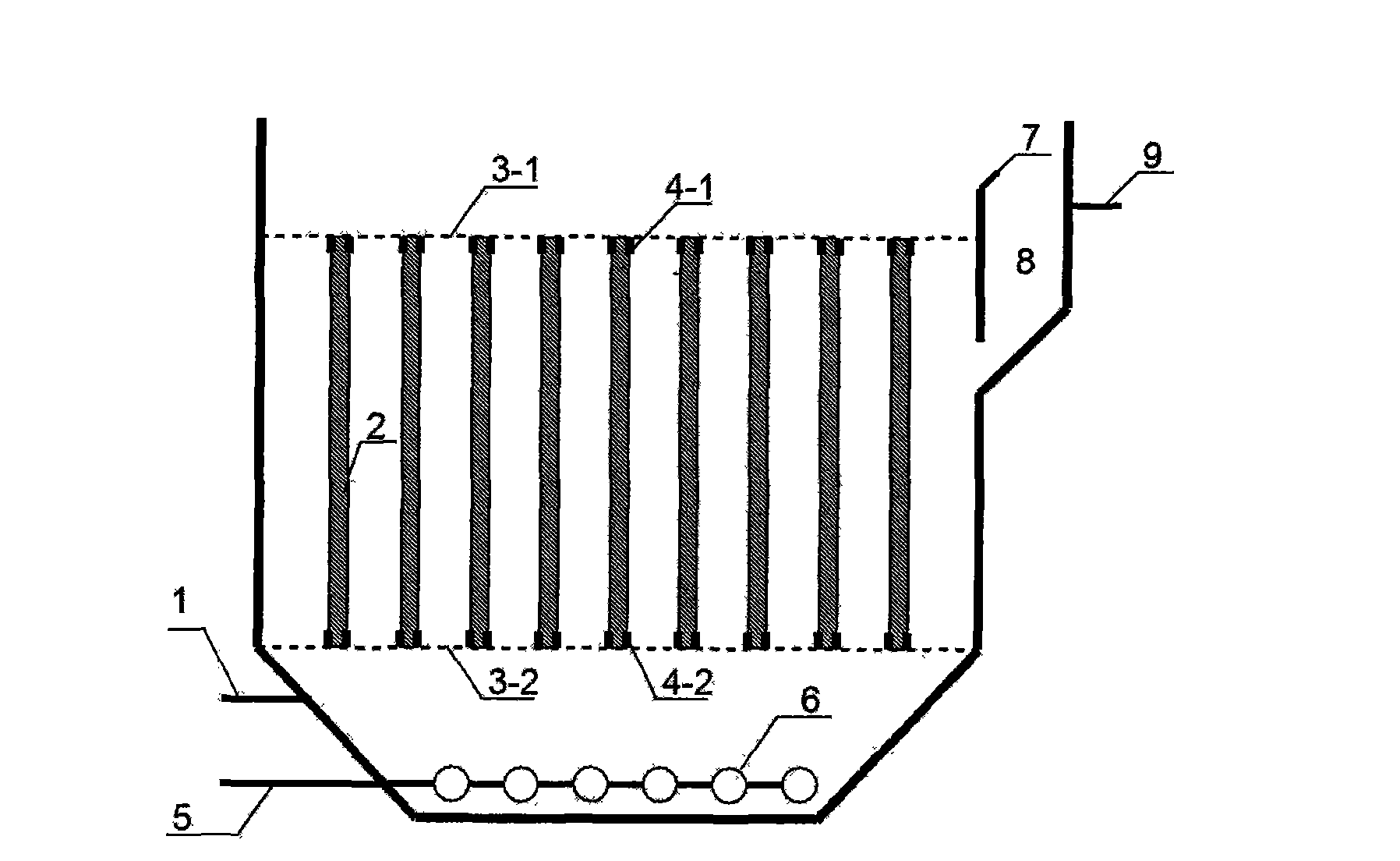

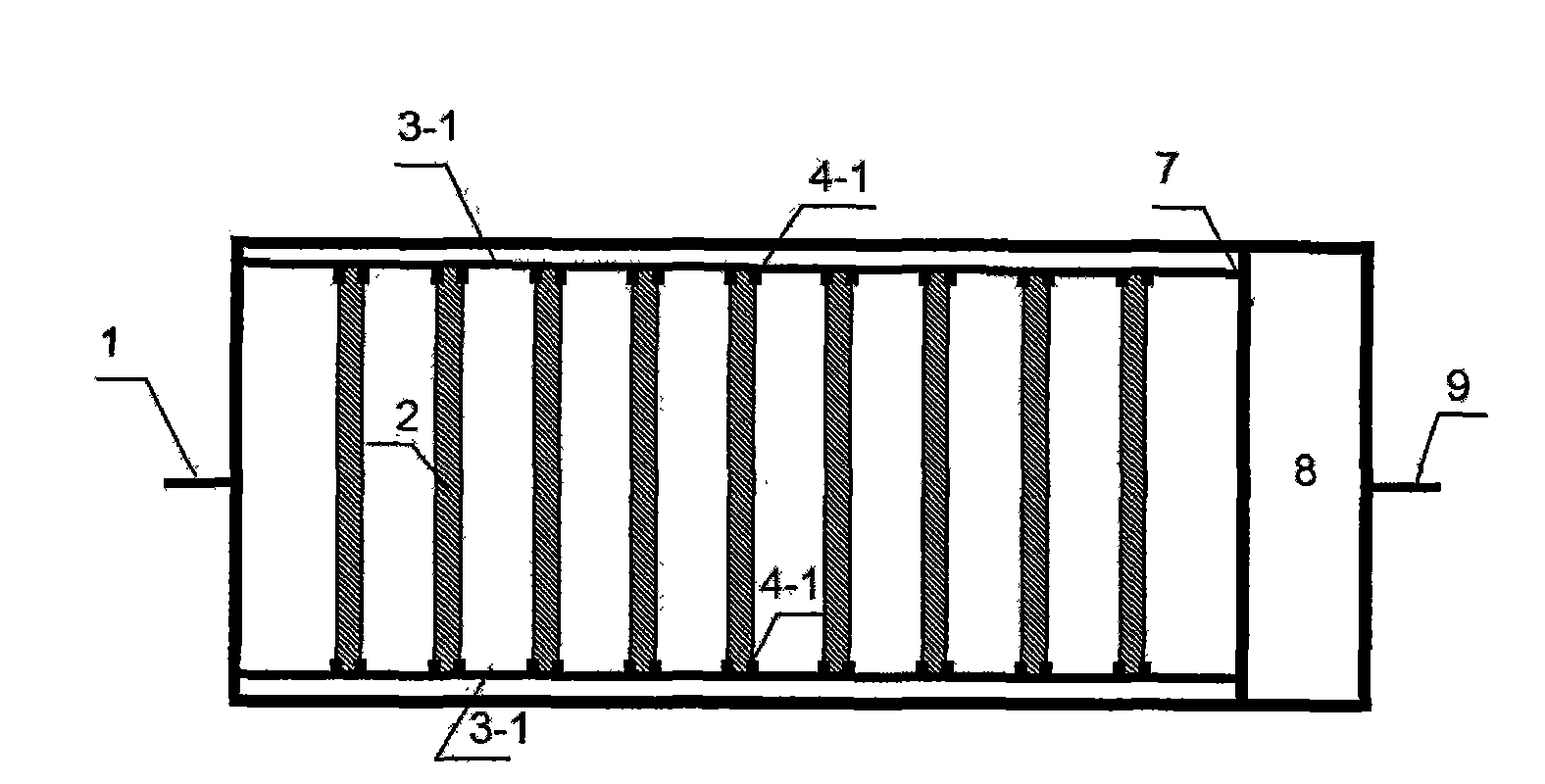

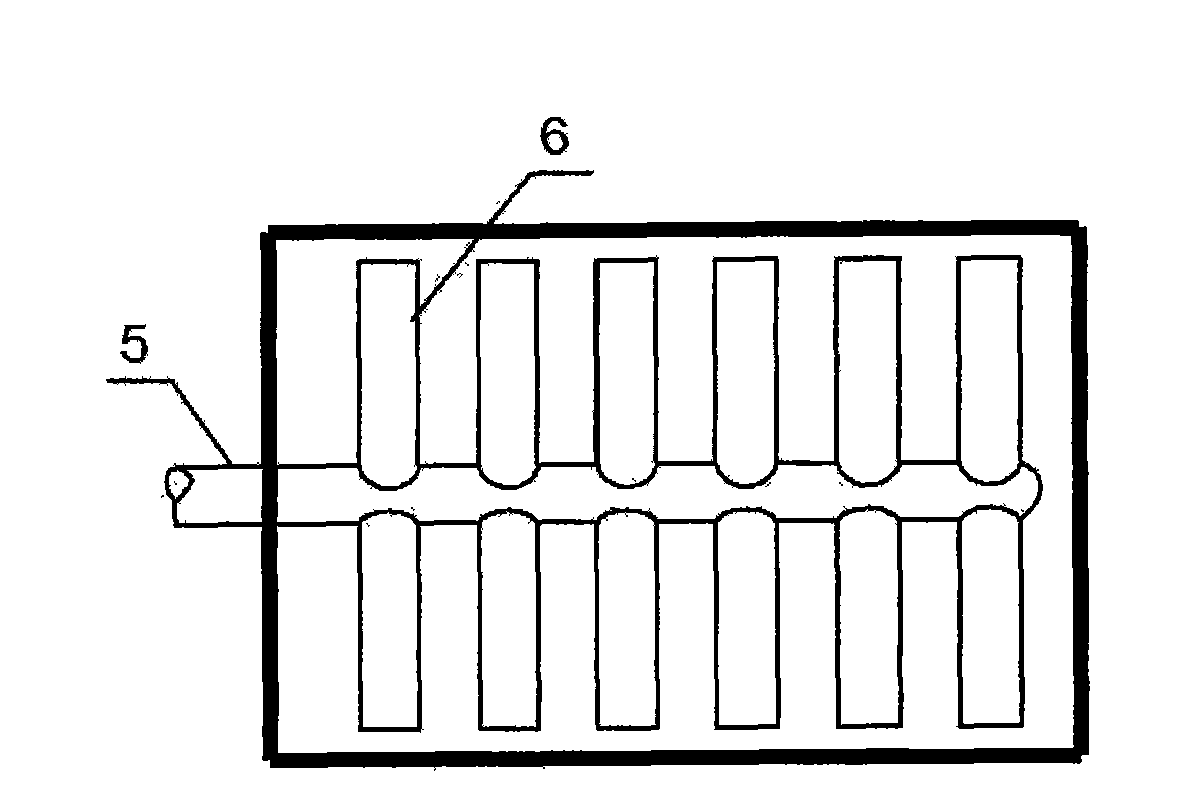

[0021] From figure 1 It can be seen that a granular activated carbon circulation micro-electrolysis reactor of the present invention mainly includes a microporous aeration pipe 6 and a granular activated carbon separation chamber 8, and is characterized in that: the microporous aeration pipe 6 is connected to the main aeration pipe 5 and is located at the bottom of the reactor. Nine pieces of iron filing board positive pole 2 are evenly equidistantly distributed with a spacing of 4 cm (see figure 2 ) In the middle and upper part of the reactor, the material of the supporting beam I3-1, the supporting beam II3-2 and the fixing slot I4-1 and the fixing slot II4-2 fixed on the inner wall of the reactor is hard polyvinyl chloride Material, fix the left and right, upper and lower ends of the positive electrode 2 of the iron chip board vertically in the fixed card slot I4-1 and the fixed card slot II4-2; the waste water enters the reactor through the water inlet pipe 1, and the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com