Patents

Literature

39results about How to "Speed up electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

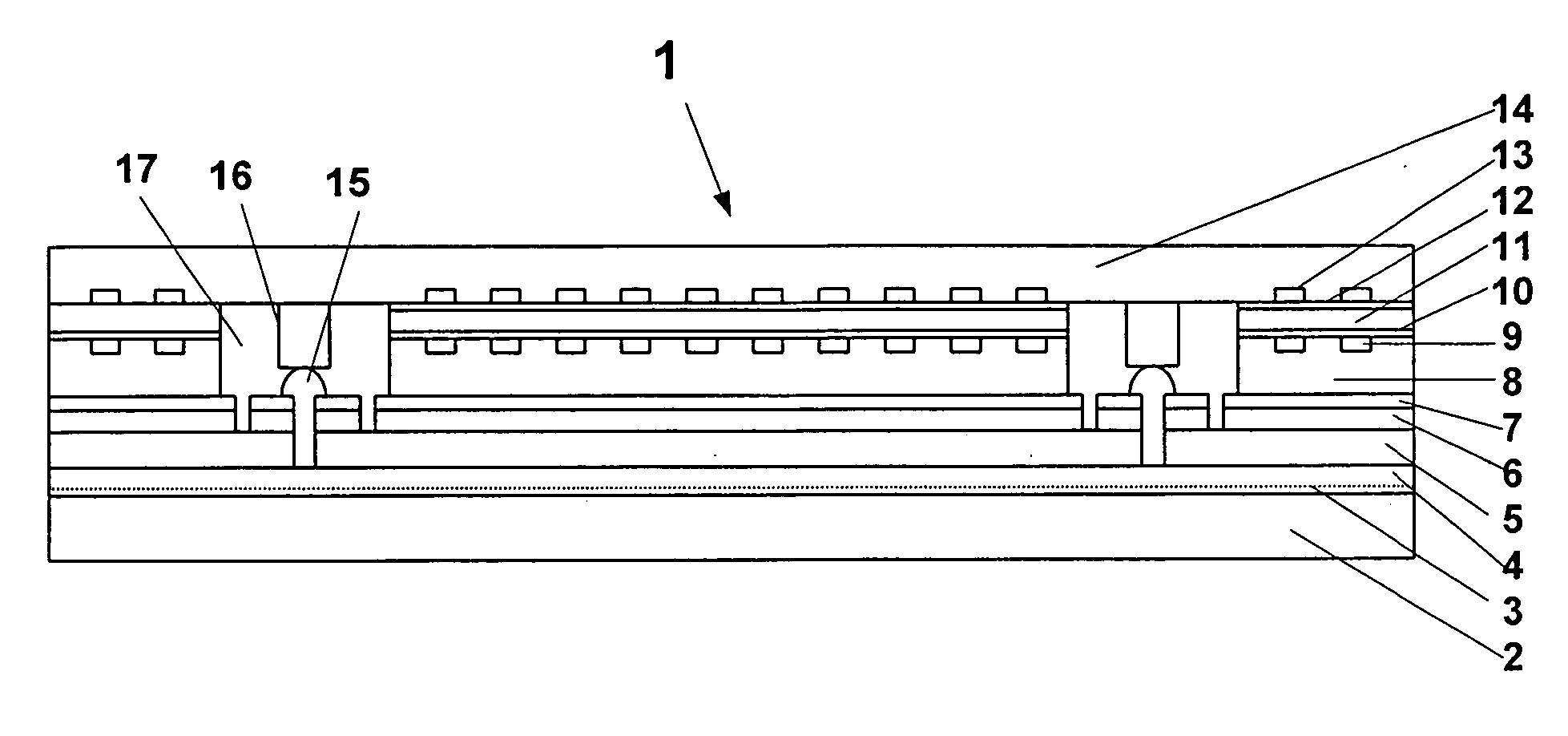

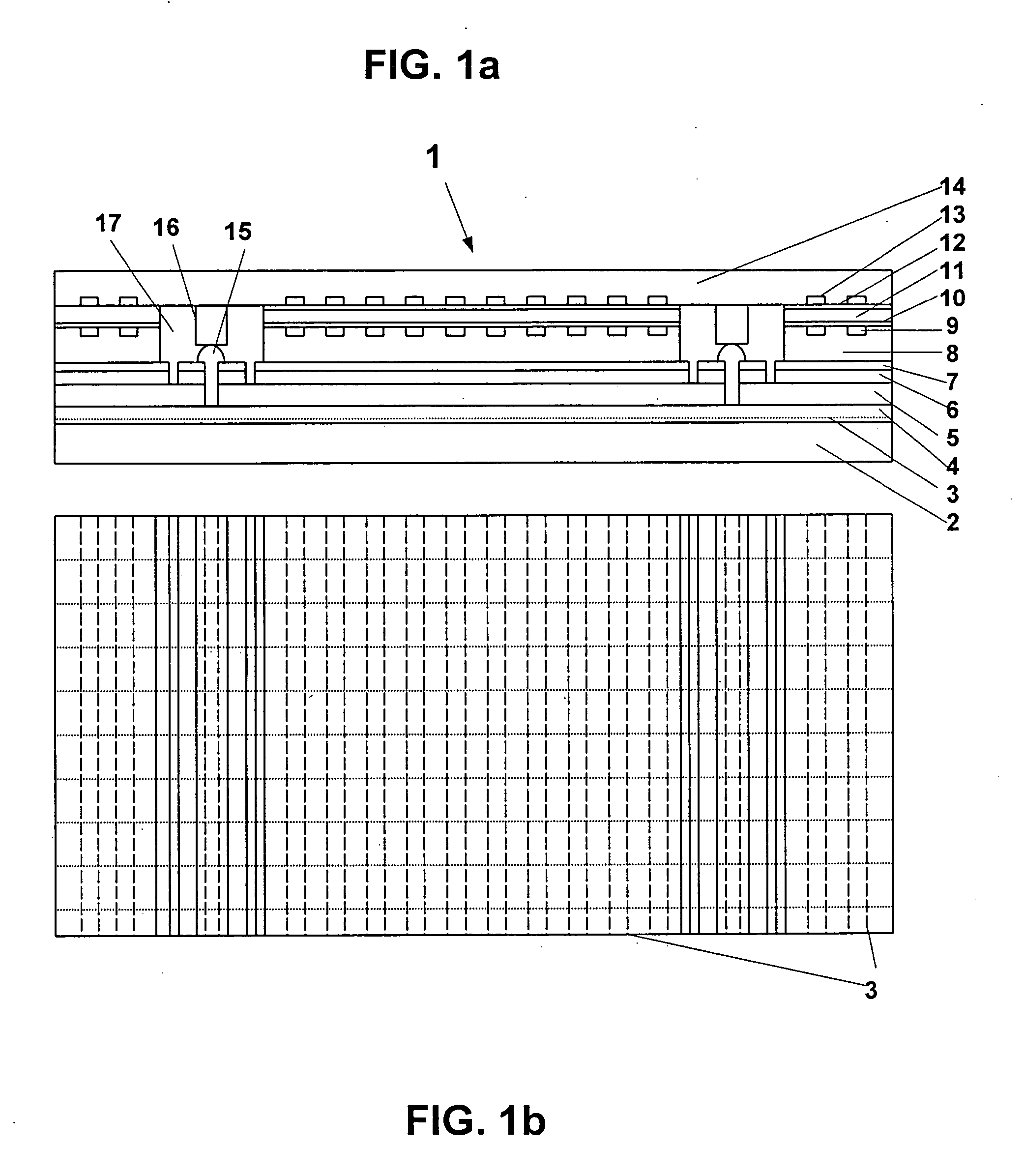

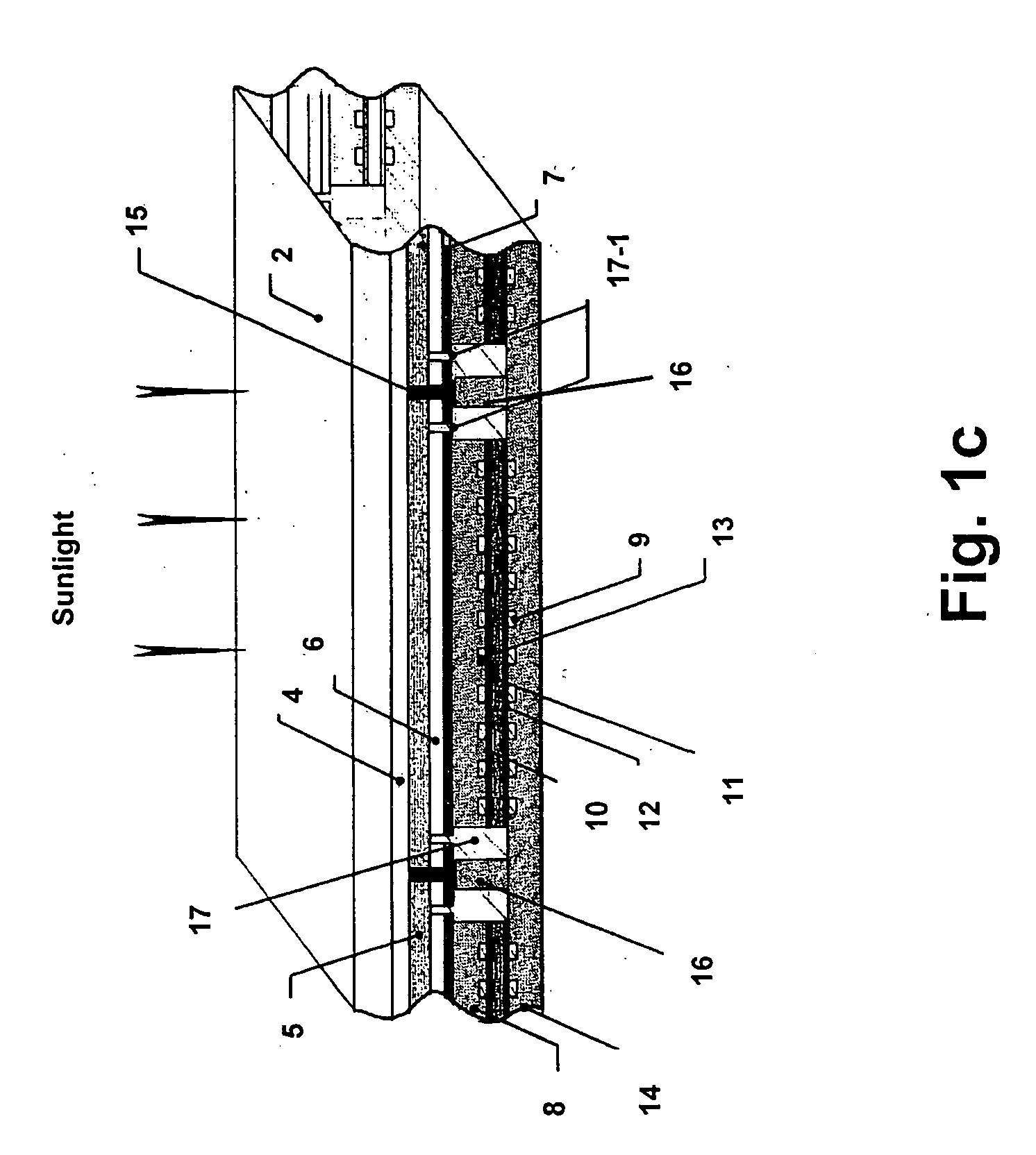

Integrated photoelectrochemical cell and system having a solid polymer electrolyte

InactiveUS20050205128A1Improve conversion efficiencyLow costElectrode manufacturing processesElectrolysis componentsPolymer electrolytesPhotoelectrochemical cell

A photoelectrochemical (PEC) cell includes a photovoltaic electrode that generates voltage under radiation; a solid membrane electrode assembly that includes at least one solid polymer electrolyte and first and second electrodes; a mechanism that collect gases from oxidation and reduction reactions; and an electrical connection between the photovoltaic electrode and the solid membrane electrode assembly. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

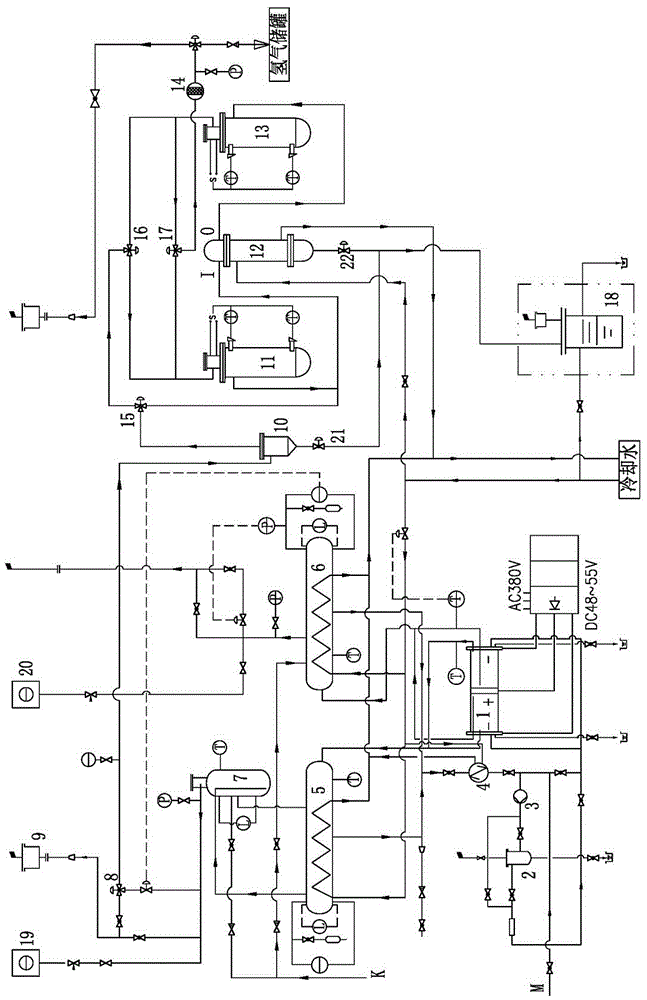

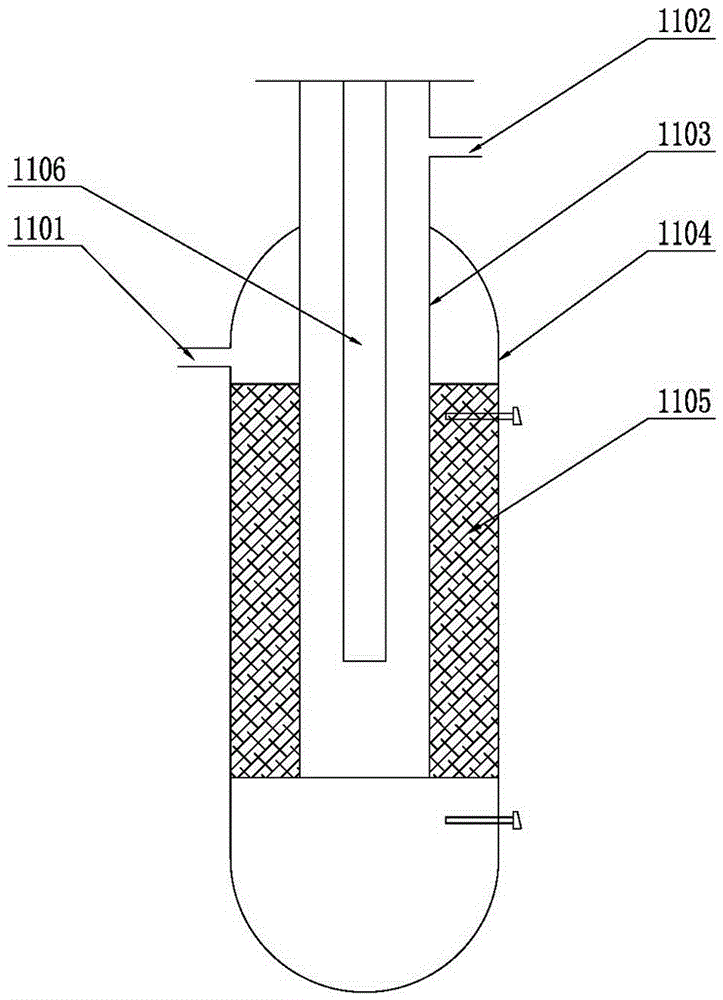

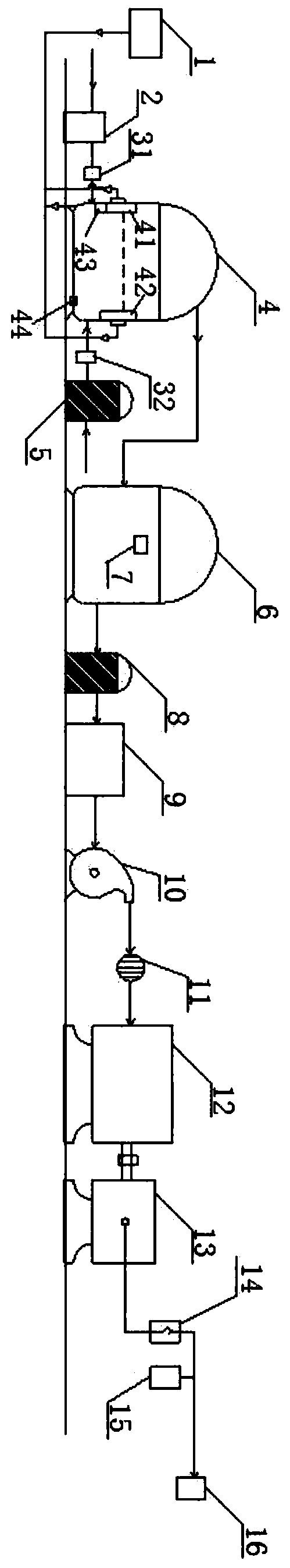

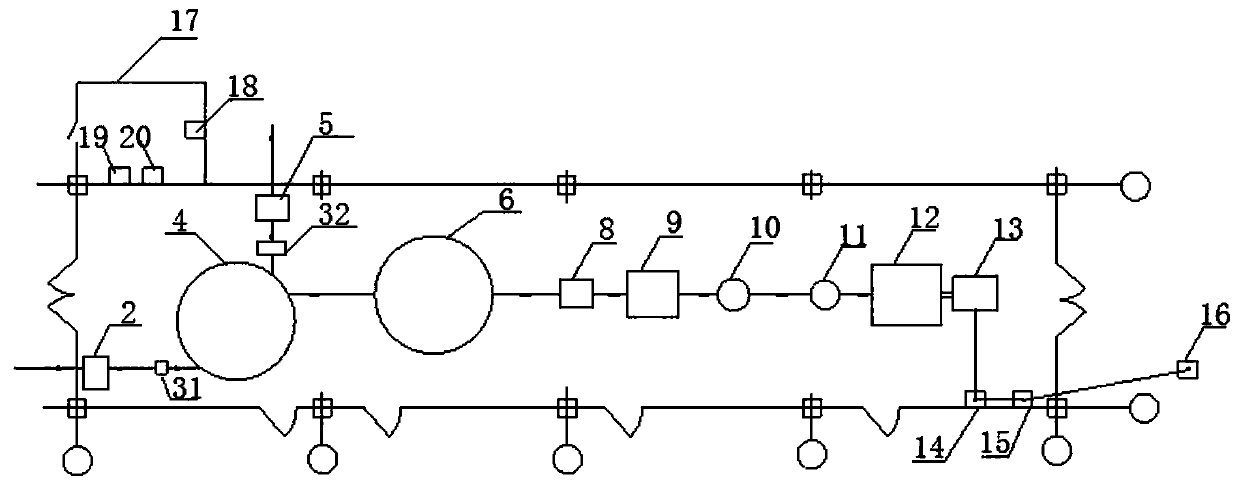

Alkaline solution electrolytic hydrogen production device and hydrogen production method

ActiveCN106119885AIncrease ionization rateSpeed up electrolysisCellsDispersed particle separationGas phaseOxygen

The invention discloses an alkaline solution electrolytic hydrogen production device in the field of hydrogen production devices. The alkaline solution electrolytic hydrogen production device comprises a direct current power supply, an electrolytic cell, a hydrogen separator and an oxygen separator, wherein the bottom of the electrolytic cell is provided with an alkaline solution inlet; the upper part of an anode zone of the electrolytic cell communicates with a circulating liquid inlet of the oxygen separator, and a gas phase outlet at the top of the oxygen separator communicates with the atmosphere through a valve; the upper part of a cathode zone of the electrolytic cell communicates with a circulating liquid inlet of the hydrogen separator, a gas phase outlet at the top of the hydrogen separator is connected to a hydrogen washing device, and the hydrogen washing device communicates with an inlet of a gas-water separator through a three-way valve I; circulating liquid outlets at the bottoms of the hydrogen separator and the oxygen separator communicate with the alkaline solution inlet sequentially via an alkaline solution cooler, an alkaline solution circulating pump and an alkaline solution filter; and a gas outlet of the gas-water separator is connected to a hydrogen storing tank through a three-way valve II and a drying system. A KOH or NaOH solution with a 25-30% mass concentration is used as an electrolyte. The device can safely produce hydrogen and is high in hydrogen producing efficiency, low in equipment investment and great in production continuity.

Owner:YANGZHOU CHUNGDEAN HYDROGEN EQUIP

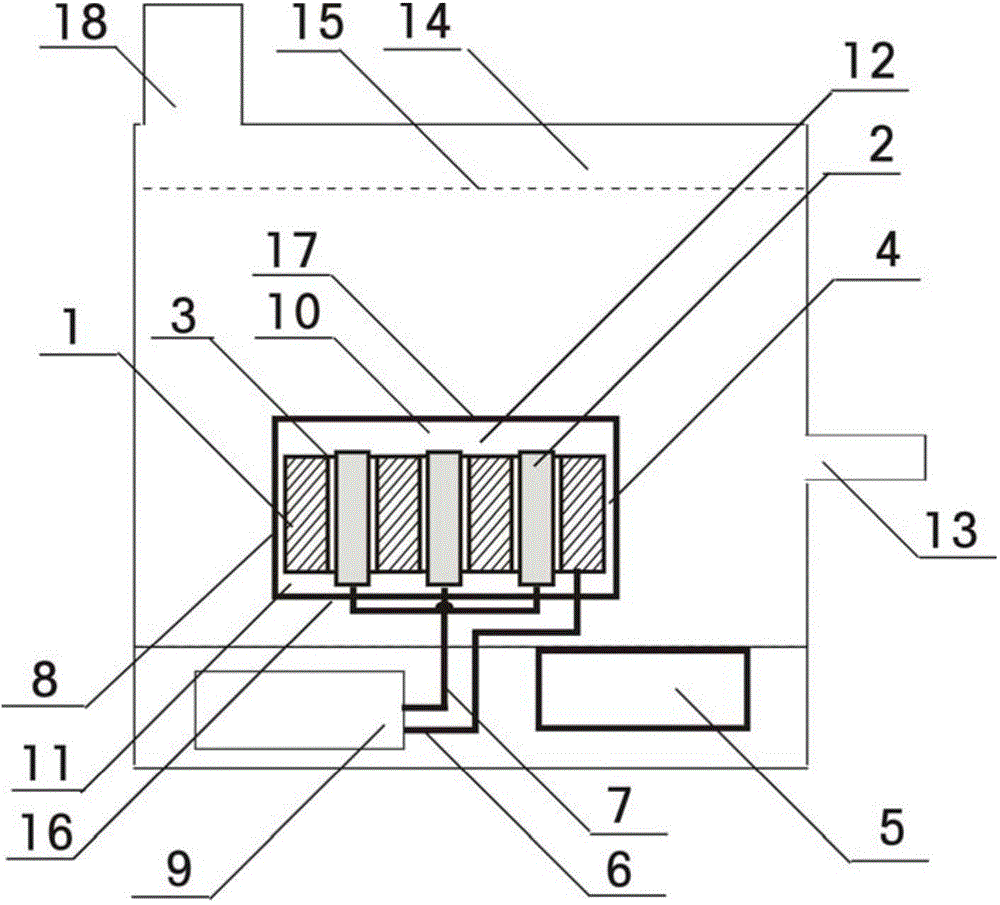

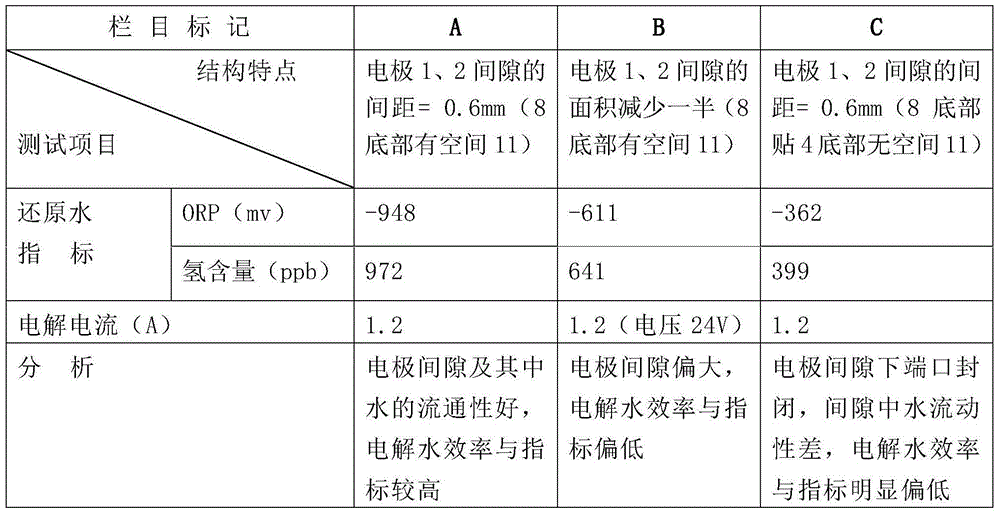

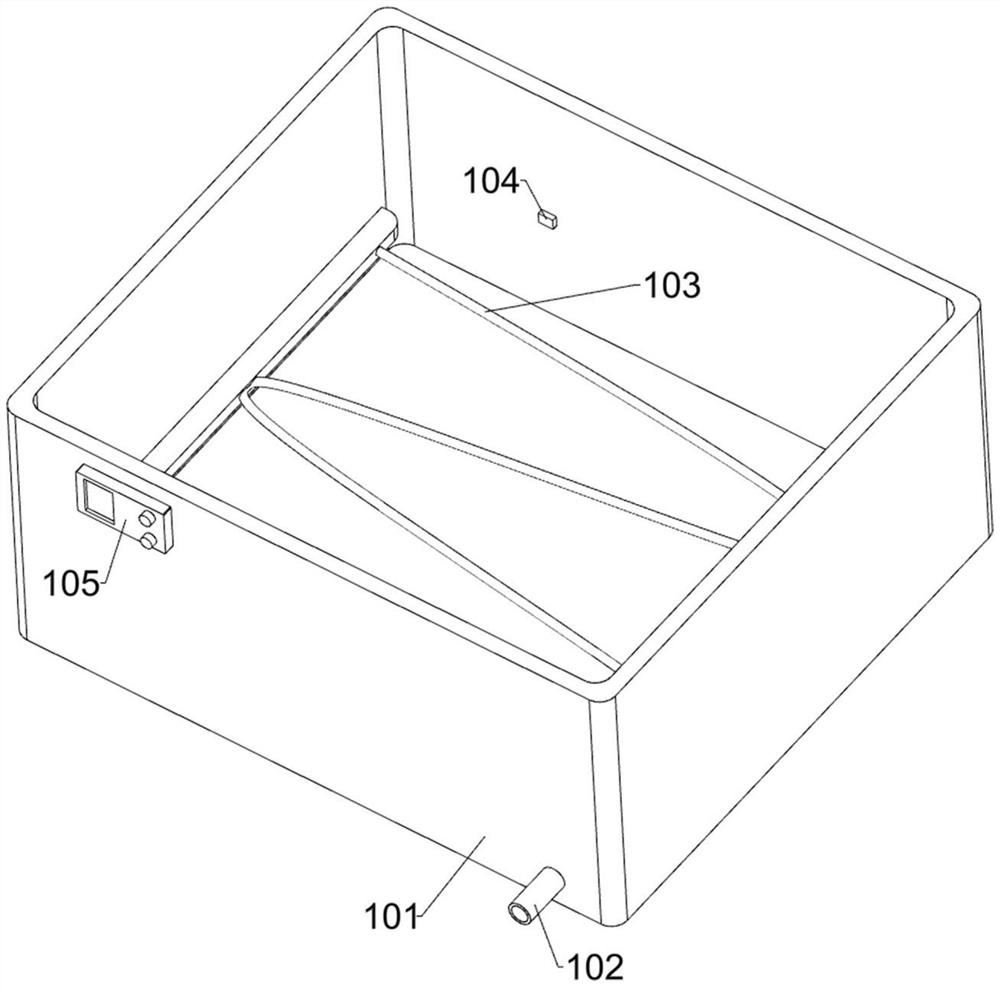

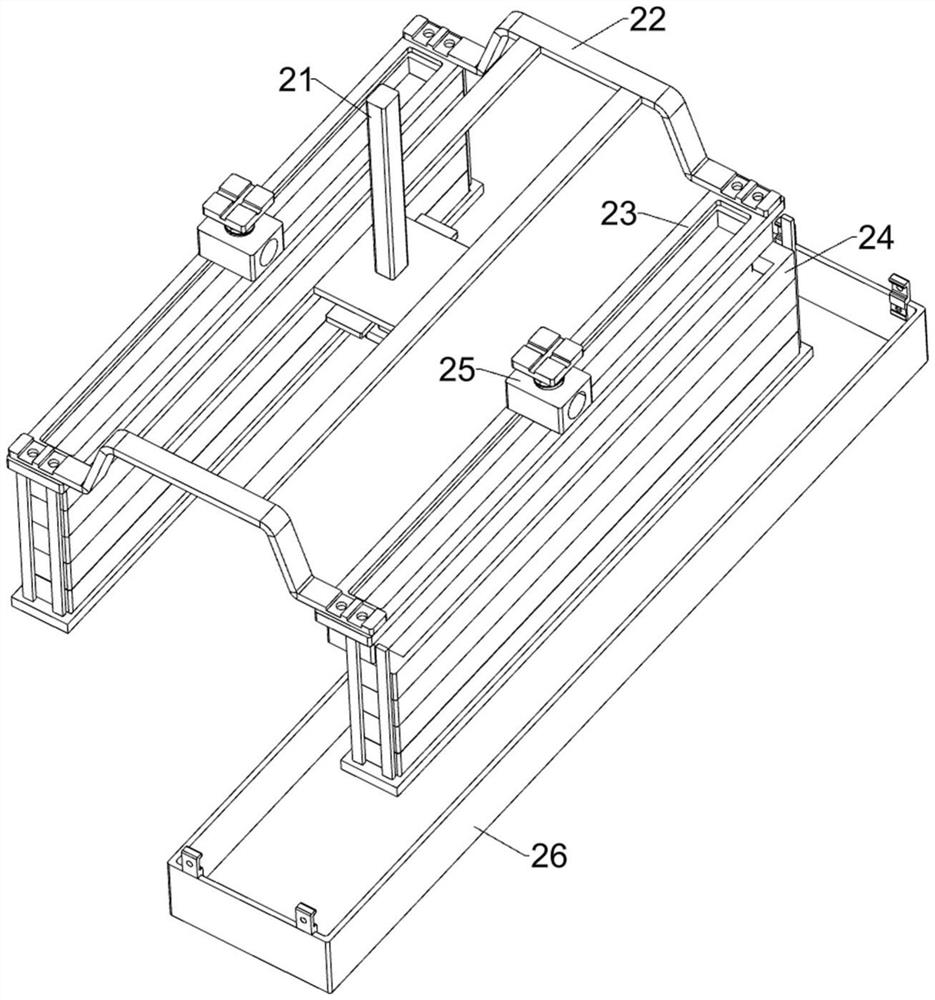

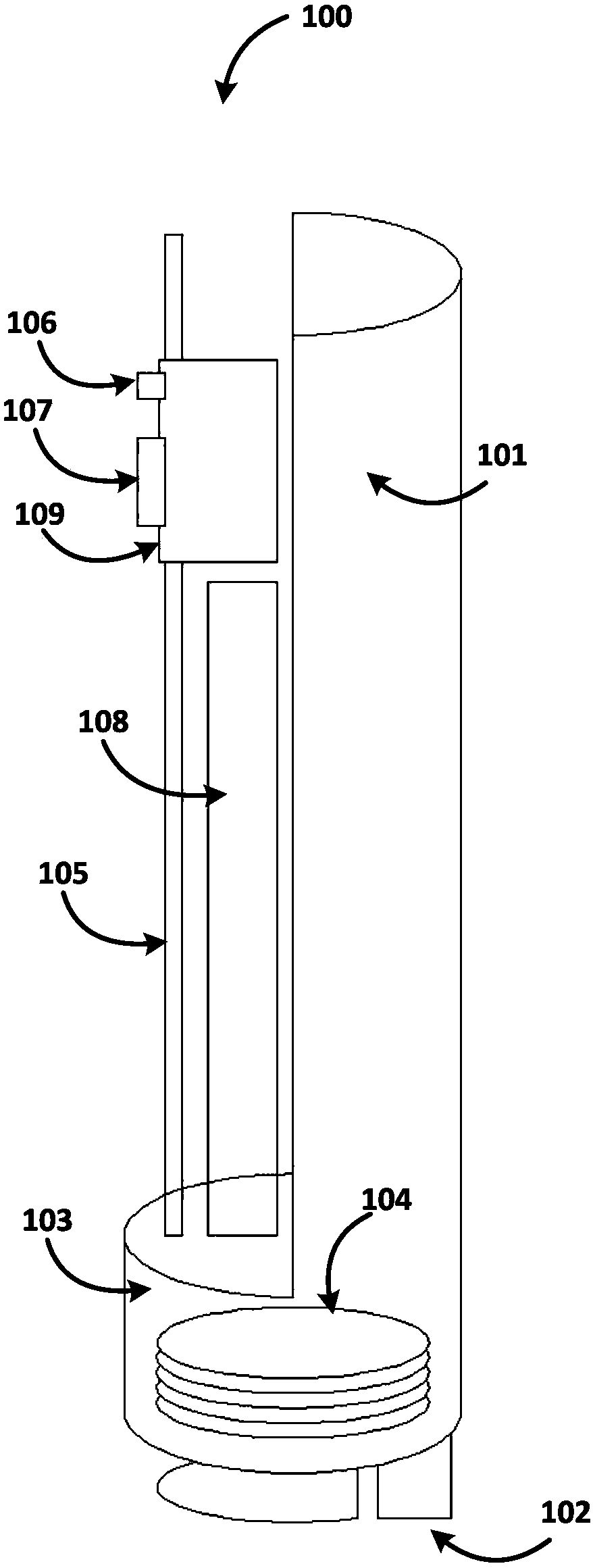

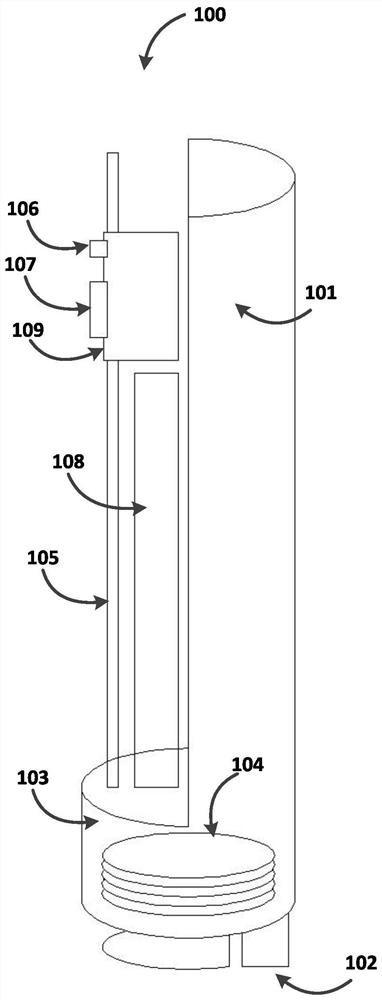

Water storage type electric water heater capable of draining electrolyzed water

InactiveCN104633912AElectrolysis is good for strengtheningImprove electrolysis efficiencyWater/sewage treatmentWater heatersWater storagePower flow

A water storage type electric water heater capable of draining electrolyzed water comprises a water storage container, an electric water heater electronic control system, a controllable electrolysis power supply and a membraneless electrolysis electrode subassembly, and is characterized in that a water inlet and a water outlet are formed in the water storage container; raw water enters the water storage container from the water inlet of the water storage container; the electric water heater electronic control system controls heating of the water in the water storage container; the controllable electrolysis power supply provides current for the membraneless electrolysis electrode subassembly; the membraneless electrolysis electrode subassembly is used for electrolyzing the water in the water storage container; and electrolyzed water is drained from the water outlet of the water storage container. A high-efficiency membraneless water electrolyzing technology is used in the membraneless electrolysis electrode subassembly, the water stored in the water storage container can be electrolyzed effectively in a required temperature range, characteristics that reasonable distances of gaps of electrodes with different polarities are small, reasonable area of the gaps of the electrodes with the different polarities is large and water can properly flow in the gaps of the electrodes in a water electrolyzing process are considered in the design of the membraneless electrolysis electrode subassembly, the electrolyzed probability and the electrolyzed amount of impurities in the water and water molecules are improved, and the water electrolyzing efficiency is improved.

Owner:罗民雄 +1

Nano composite cathode as well as preparation and application thereof

ActiveCN111244470AStable structureImprove redox abilityCell electrodesFuel cellsPtru catalystComposite cathode

The invention discloses a nano composite cathode for a high-temperature solid oxide electrolytic tank as well as a preparation method and application thereof. The structure of the nano composite cathode is a YSZ skeleton which is prepared by adopting PMMA as a pore forming agent and has micro-pores, an LSFM-GDC (M = Mn, Fe, Ni) composite nano electrode catalyst is prepared by adopting a co-impregnation method, and the nano composite cathode for the high-temperature solid oxide electrolytic tank is prepared after roasting. The high-temperature solid oxide nano composite cathode prepared by theinvention is suitable for high-temperature CO2 electrolysis and CO2-H2O co-electrolysis; good electrochemical performance is achieved on high-temperature CO2 electrolysis and Co2-H2O co-electrolysis,the performance and the operation stability of the solid oxide electrolytic tank can be remarkably improved, and good development prospects are achieved. The method is suitable for the field of high-temperature carbon dioxide reduction, the field of clean carbon fuel preparation and the technical field of energy and fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

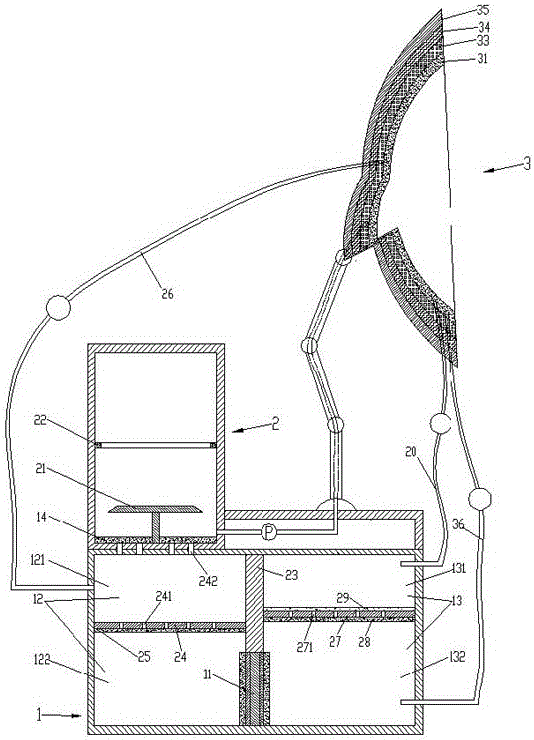

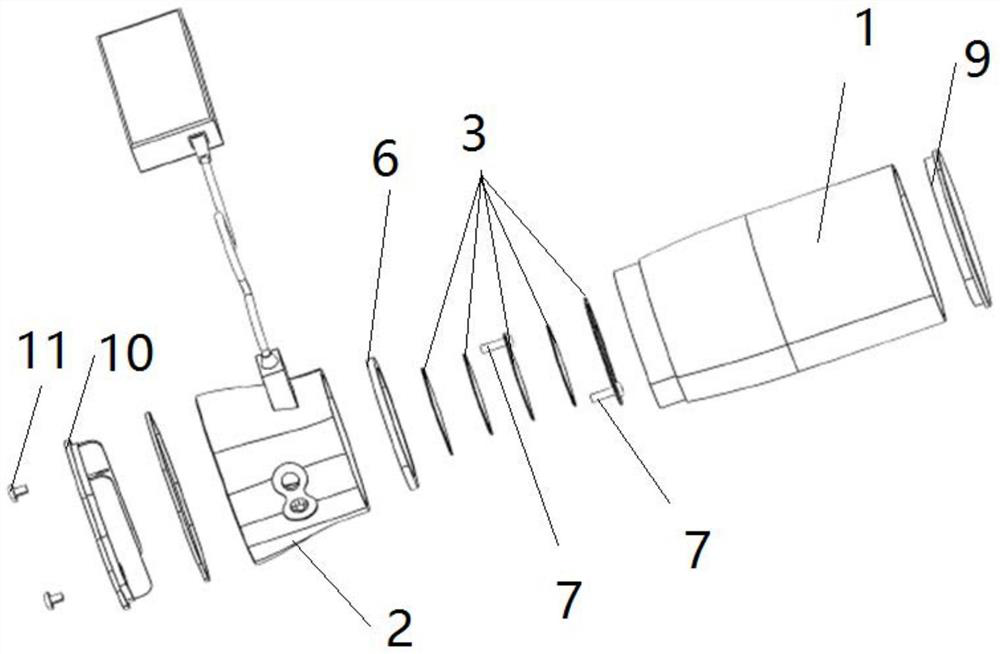

Facial mask machine and use method thereof

ActiveCN106389181ARealize self-disinfectionGuaranteed freshnessCosmetic preparationsToilet preparationsElectrolysisPower flow

The invention relates to a facial mask machine and a use method thereof. The facial mask machine comprises an electrolytic cavity, a juice squeezing cavity and a facemask for pasting a facial mask, wherein the electrolytic cavity is divided into a cathode cavity and an anode cavity by a PEM (proton exchange membrane) electrolysis electrode; a control circuits controls the magnitude of current and / or voltage of the PEM electrolysis electrode; a sponge liquid absorbing layer, a vibration sponge liquid absorbing layer, a vibration diffusion layer enabling juice therein to diffuse to a face, a cold-hot temperature adjusting layer for adjusting the temperature of the facemask for pasting the facial mask, and a shell are arranged by laminating in the facemask for pasting the facial mask in sequence from an outer layer to an inner layer; one surface, facing to a human face, of the sponge liquid absorbing layer is provided with a plurality of liquid outlet holes in cooperation with a human face curve; the sponge liquid absorbing layer communicates with the anode cavity by virtue of an ozone tube which can be opened and closed; a first waterproof air-permeable film is arranged between the cathode cavity and the juice squeezing cavity; and the juice squeezing cavity communicates with the sponge liquid absorbing layer.

Owner:FUZHOU PINXING TECH DEV

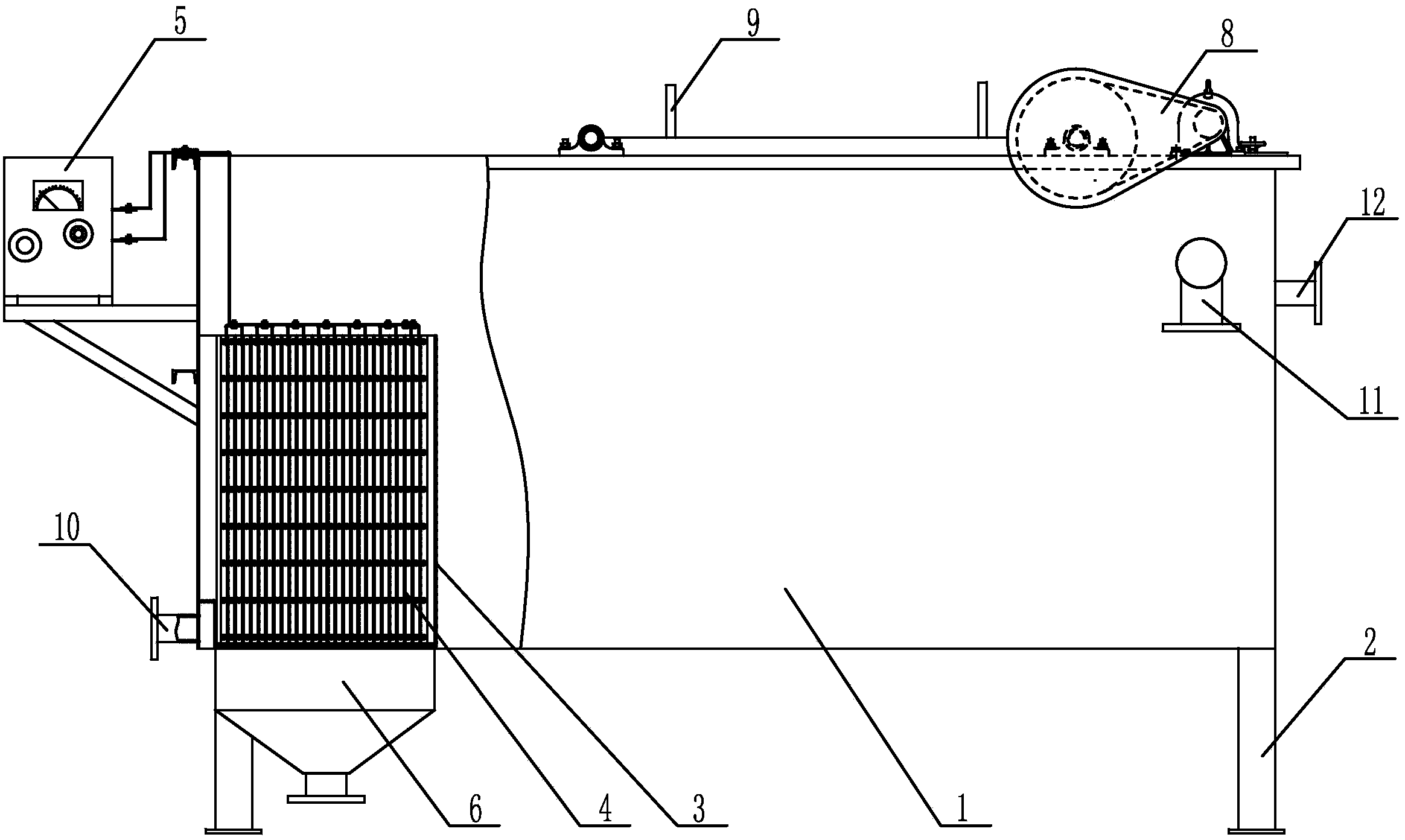

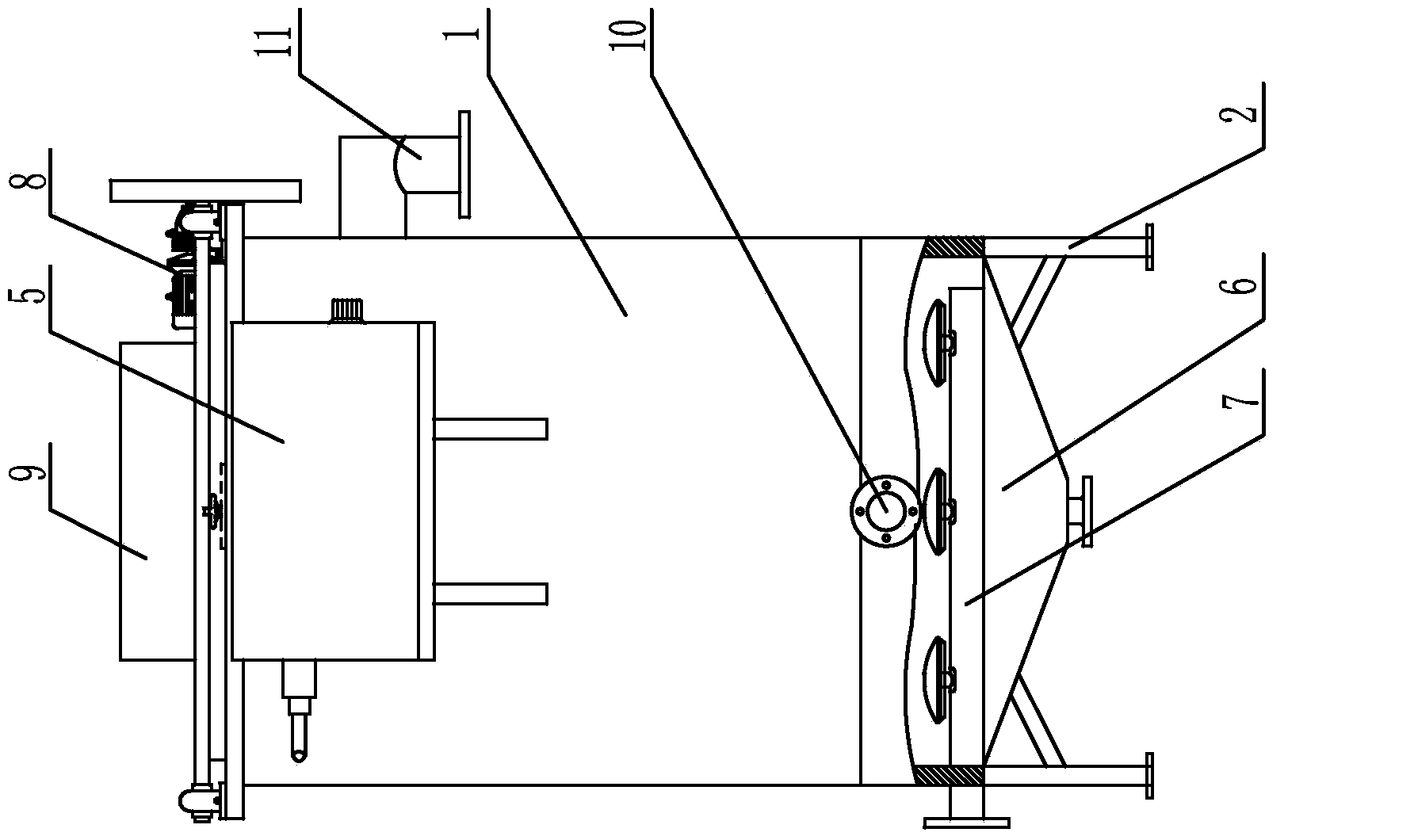

Electric flocculation air floatation machine with aeration device

InactiveCN103910416AMeet oxygen demandClean up thoroughlyWater/sewage treatment by flotationElectrolysisMicro bubble

The invention discloses an electric flocculation air floatation machine with an aeration device. The electric flocculation air floatation machine is characterized in that landing legs for supporting are respectively arranged at the bottom of a tank body; an electrolytic tank with an opening at the upper end is arranged on the left lateral wall inside the tank body; electrolytic plates are evenly arranged inside the electrolytic tank; a current adjuster is connected with the electrolytic plates through electrode plate binding posts; an electrolytic tank slag removal bucket is welded at the external part of the tank body below the electrolytic tank; the aeration device is arranged inside the electrolytic tank slag removal bucket; a dross scraper is arranged above the tank body through a scraper power device; a water intake pipe is arranged on the tank body below the electrolytic tank and communicated with the electrolytic tank; a dress discharge pipe and a clean water output pipe are respectively arranged above the tank body. The added aeration device can effectively meet the oxygen demand of sewage, electrolysis is quickened, suspending dirt in the sewage can be effectively taken to the water level by micro-bubbles generated by oxygenation, the suspending dirt in the sewage can be more thoroughly cleaned, and pollution to the environment is reduced.

Owner:山东金昊三扬环保机械有限公司

Method for preparing 4-amidogen-3,6-dichloropyridine-2-formic acid by means of catalytic electrolysis

ActiveCN105803481AMild reaction conditionsSpeed up electrolysisOrganic chemistryElectrolysis componentsChemistryFormic acid

The invention discloses a method for preparing 4-amidogen-3,6-dichloropyridine-2-formic acid by means of catalytic electrolysis, and belongs to the field of production of chemical products. The technical problems that when 4-amidogen-3,5,6-trichloropyridine-2-formic acid is used for preparing the 4-amidogen-3,6-dichloropyridine-2-formic acid by means of electrolysis, the electrolysis time is long, the energy consumption is high, and selectivity is poor are solved. According to the scheme for solving the above technical problems, during electrolysis of the 4-amidogen-3,5,6-trichloropyridine-2-formic acid, a catalyst is added, the specific temperature, the PH value and other conditions are combined, chlorine on a pyridine ring is desorbed, a final product is the 4-amidogen-3,6-dichloropyridine-2-formic acid, and the catalyst is filtered and washed in the aftertreatment procedure to be recycled and reused. On the basis of electrolysis, low input is increased, the content and yield of the product are increased, and the energy consumption is reduced.

Owner:ZHEJIANG AVILIVE CHEM CO LTD

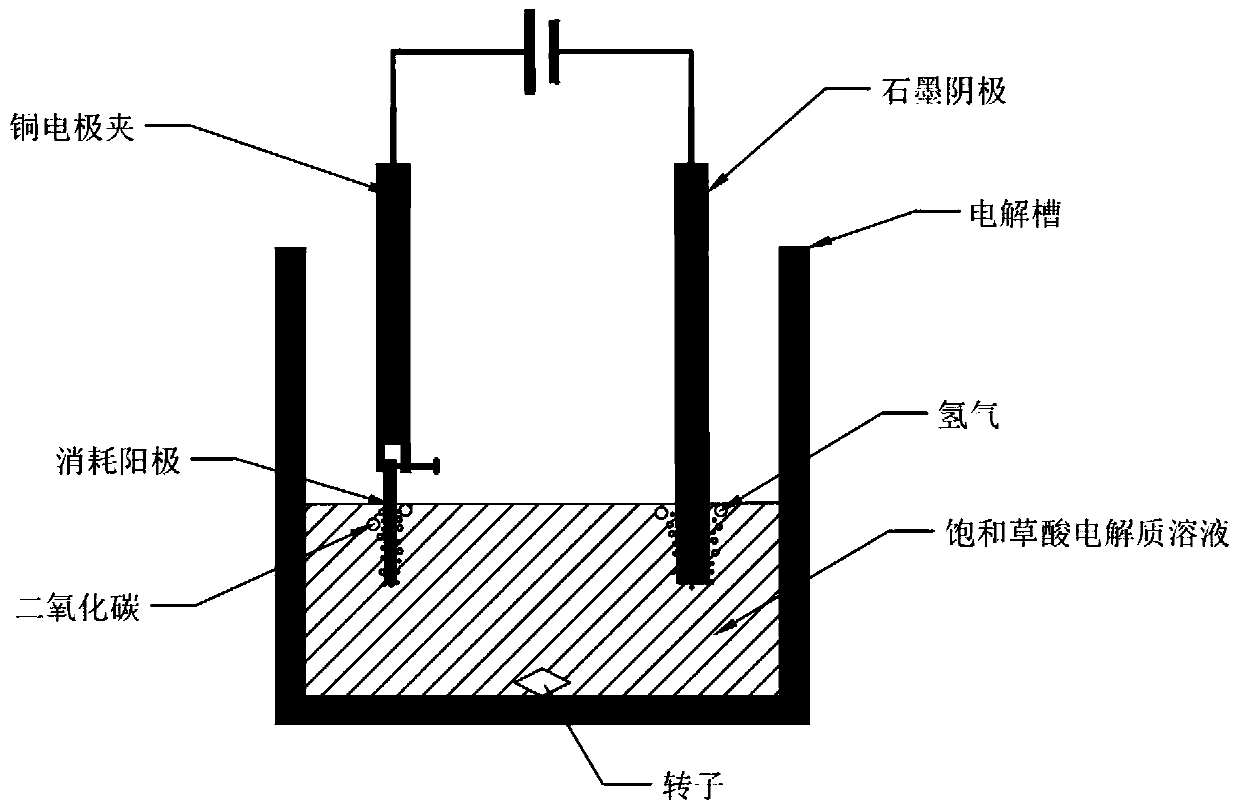

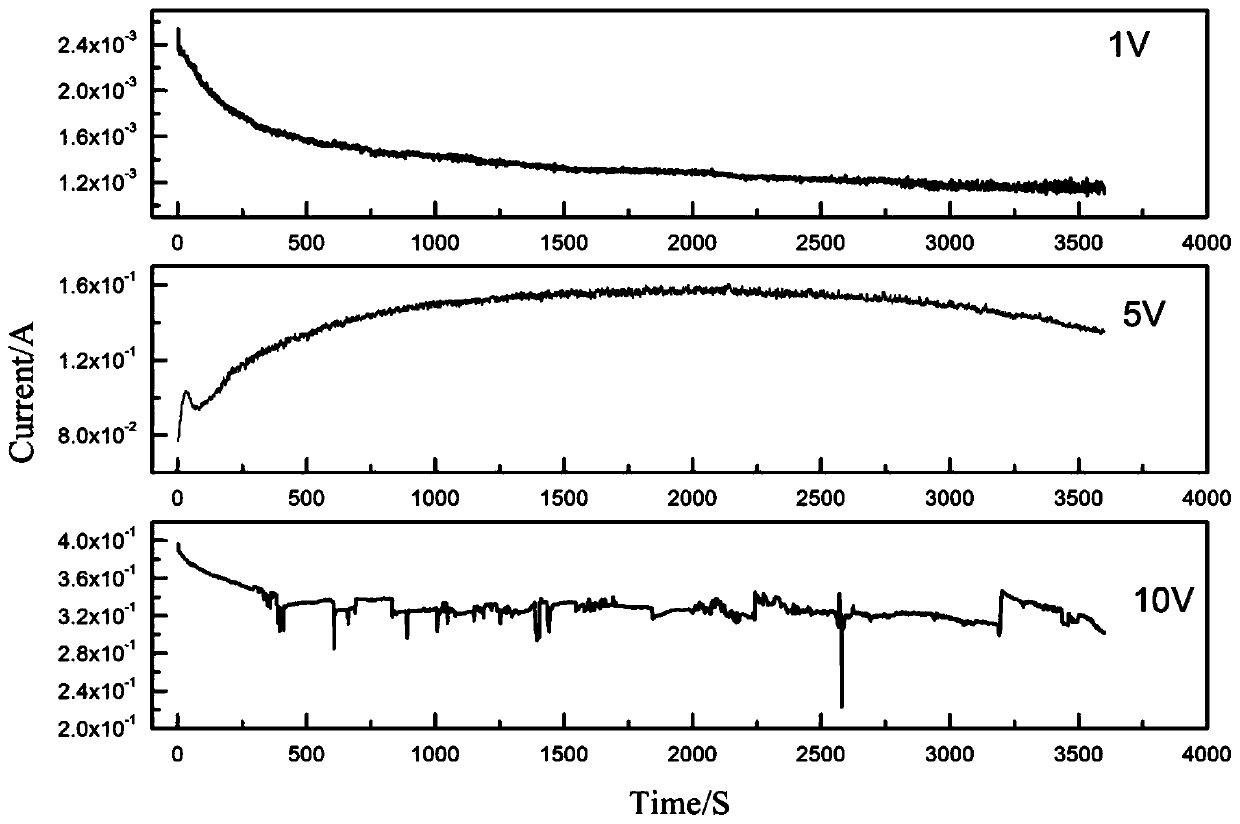

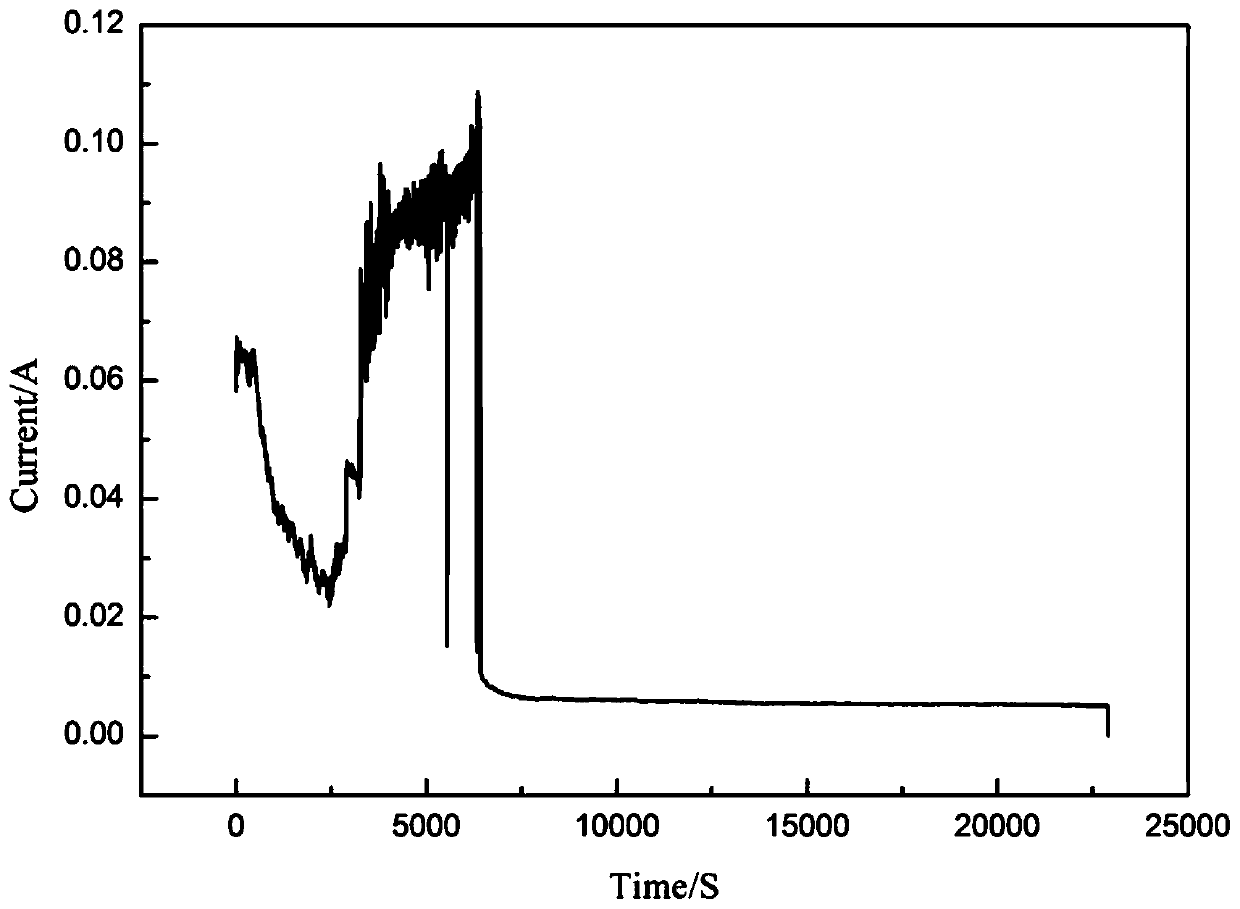

Method of electrolyzing anode to leach vanadium in normal temperature saturated oxalic acid solution

ActiveCN110117714APromote leachingSpeed up electrolysisProcess efficiency improvementGas emission reductionIonCarbon dioxide

The invention relates to a method of electrolyzing an anode to leach vanadium in a normal temperature saturated oxalic acid solution. The method comprises the following steps: adding an adhesive intoferrovanadium spinel vanadium concentrate as an initial raw material to be mixed and carrying out pressing and forming and reducing roasting to prepare the anode; carrying out an electrolytic reactionby taking the saturated oxalic acid solution as an electrolyte, wherein in the electrolytic process, ferrum and vanadium in the anode are oxidized to high valence ions to carry out a complex reactionwith oxalate and enter the solution finally in forms of [Fe(C2O4)3]3<->, VO2<+> or / and [VO(C2O4)2]3<->, [Fe(C2O4)3]3<-> and [VO(C2O4)2]3<-> promote leaching of vanadium in the vanadium concentrate, and meanwhile, pollution-free carbon dioxide gas is separated out on the surface of the anode and hydrogen is separated out on a cathode; and after the electrolytic reaction, carrying out solid-liquidseparation to obtain a vanadium containing lixivium. According to the method, by preparing the anode according to electrical conductivity of the ferrovanadium spinel, carrying out electrolysis by taking the oxalic acid as the electrolyte and forming a complex by combining the oxalate ions with ferrum and vanadium, the vanadium concentration is promoted to dissolve and vanadium is oxidized and leached efficiently. The method is mild in operating condition, can be carried out at constant temperature and constant pressure, and is simple in process, pollution-free and low in cost.

Owner:UNIV OF SCI & TECH BEIJING

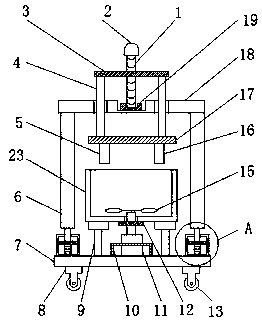

Electroplating device for faucet production and manufacturing

The invention relates to an electroplating device, in particular to an electroplating device for faucet production and manufacturing. According to the electroplating device for faucet production and manufacturing, a faucet can be uniformly and quickly electroplated. The electroplating device for faucet production and manufacturing comprises an electroplating container; an electroplating material providing assembly which is mounted on the electroplating container; and a carrying assembly which is mounted on the electroplating container. The electroplating device is provided with an accelerationassembly, so that the water flowing speed can be increased, the electroplating process is further accelerated, time is saved, and the production efficiency is improved; the electroplating device is provided with a heater, so that water can be heated to accelerate electrolysis of a chromium plate, and the electroplating effect is better; and a temperature sensor and a temperature controller are further arranged, and therefore the situation that the electroplating effect is affected by overhigh temperature can be prevented.

Owner:FUZHOU YINSHENGWANG SANITARY WARE

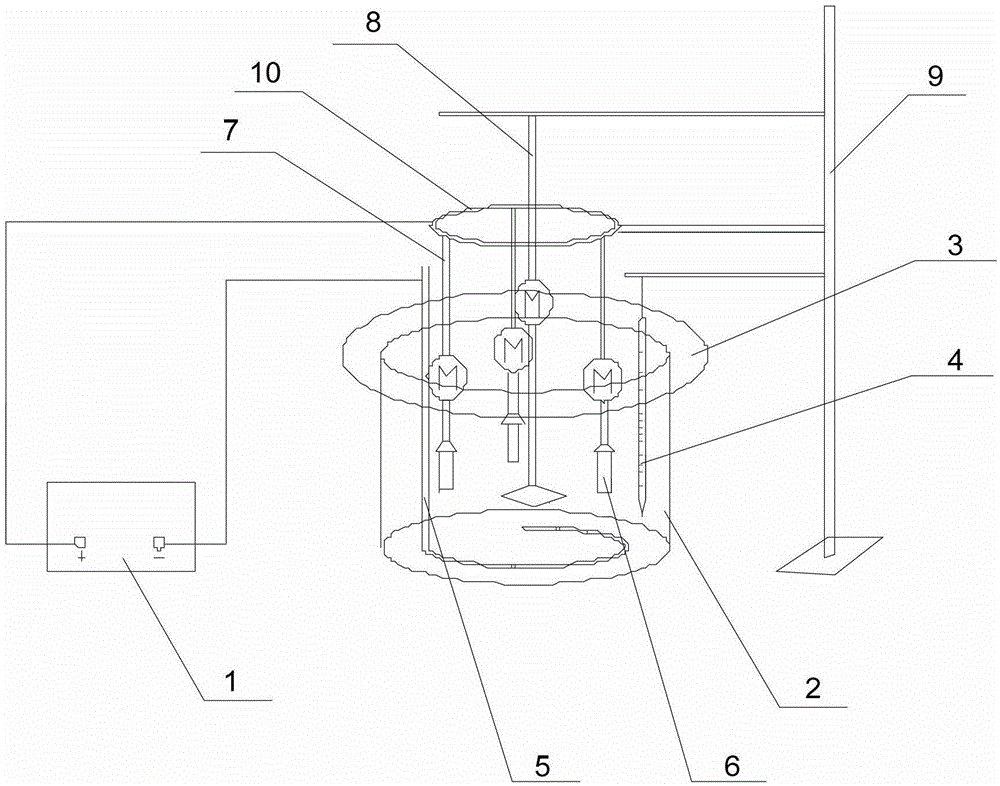

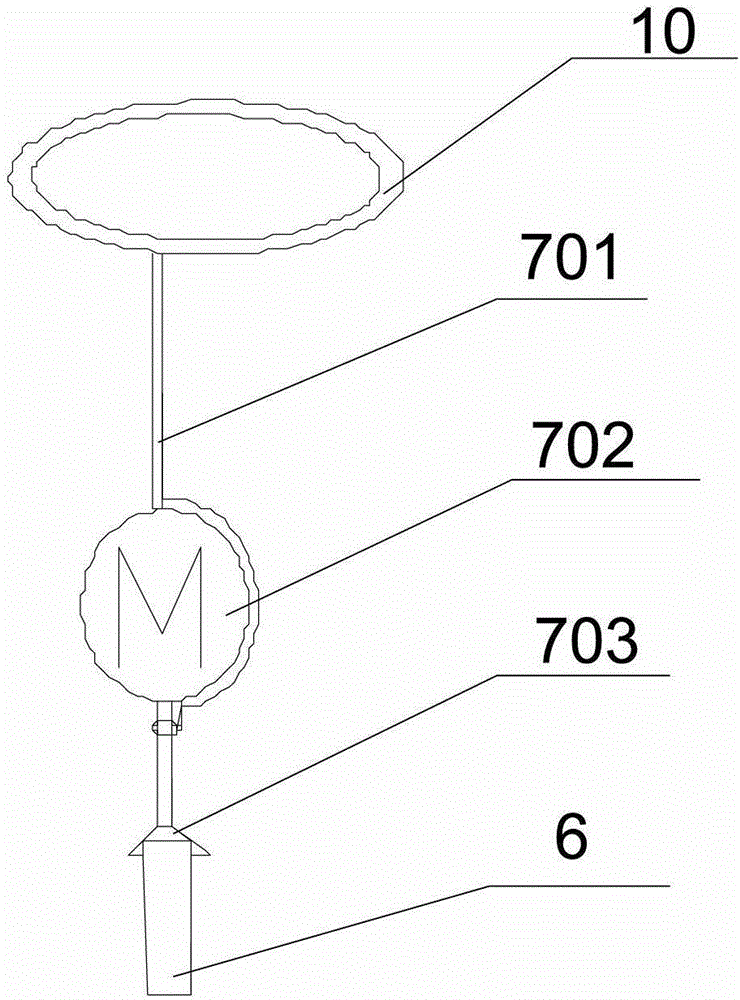

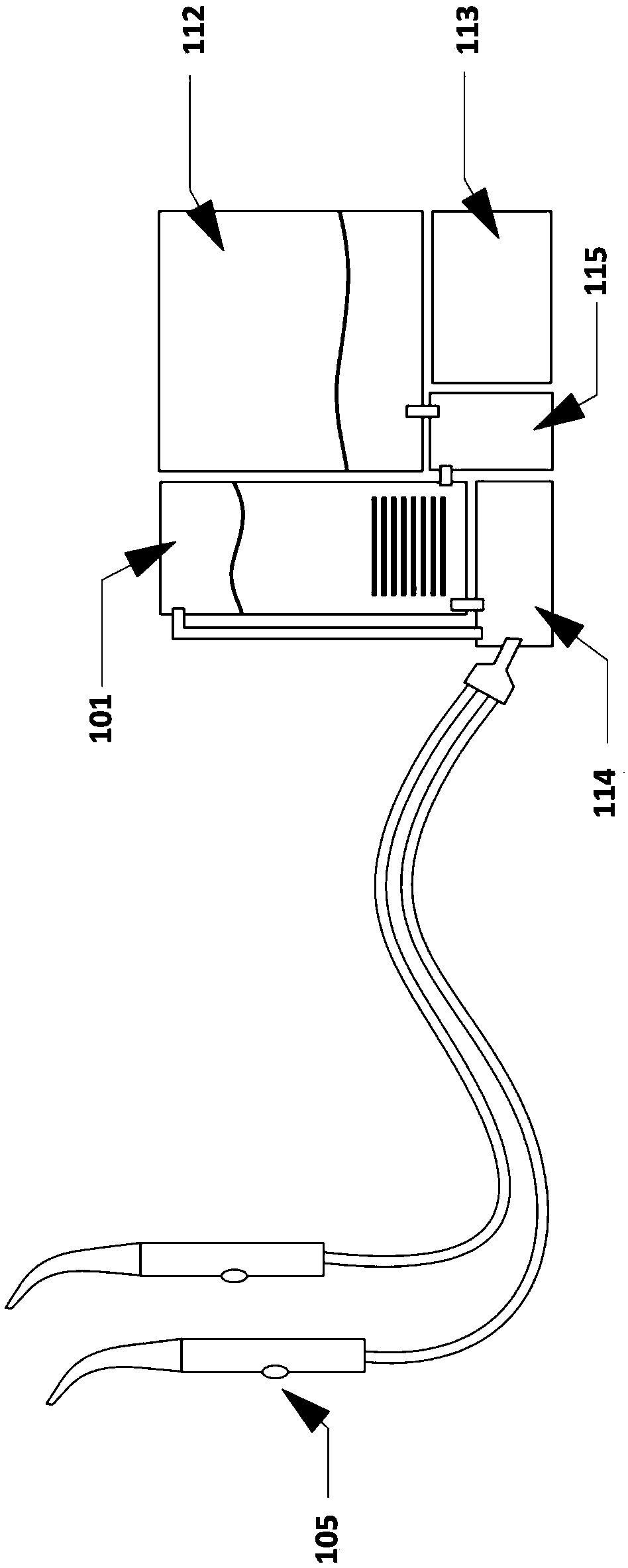

Electrolysis device and method for efficiently extracting slag inclusion in steel

InactiveCN103060885BImprove the mixing effectPrevent oxidationElectrolysis componentsPreparing sample for investigationElectrolysisSlag

The invention discloses an electrolysis device and method for efficiently extracting slag inclusion in steel, and belongs to the technical field of metallurgical engineering. The device comprises a power supply, an electrolytic bath, a seal cover and a temperature gauge and further comprises a cathode, at least two anodes, at least two anode rotating devices, a center rotator, an insulating support and an anode connecting frame. The electrolytic reaction area is increased through increasing anode sample number and adopting a sample parallel connection mode, and at the same time, the electrolysis is accelerated through sample rotating; same or opposite rotation direction between the anode and a center stirrer is guaranteed, and the slag inclusion in partial electrolyzed steel sample is rapidly separated from the steel sample and mass transfer by a molten pool is accelerated through controlling the rotating speed of the anode and controlling the rotating speed of the center stirrer, so that the nodulation of the sample surface is avoided, and the electrolytic efficiency is improved; a conductive metal gas-guide tube in which air holes are formed is adopted by the cathode, and argon is introduced and enters the electrolyte through the air holes, so that the stirring effect is improved; and at the same time, inert gas guarantees that the electrolyte is in an oxygen-free state, so that the anodes are prevented from being oxidized by oxygen in air.

Owner:XUZHOU YIZHONG STAINLESS STEEL CO LTD

Treatment method of EDTA complexing nickel wastewater

ActiveCN112358095AReduce processing operating costsStable removalWater contaminantsTreatment involving filtrationChelating resinChemical agent

The invention discloses a treatment method of EDTA (Ethylene Diamine Tetraacetic Acid) complexing nickel wastewater. The treatment method specifically comprises the following steps: step 1, carrying out acid precipitation separation on organic matters; step 2, carrying out first-time decomplexing; step 3, carrying out second-time decomplexing; the invention belongs to the technical field of complex heavy metal wastewater treatment. Firstly, organic matters are acidified and separated to reduce the energy consumption and medicament consumption of subsequent treatment; by adding ferrous ions, the conductivity of complexing wastewater is improved, the generation rate of hydroxyl radicals is increased by adding hydrogen peroxide, the treatment efficiency is improved, chemicals such as sodium hypochlorite, ferrous sulfate and hydrogen peroxide are common chemicals, the price of the chemicals is low, and the operation cost of wastewater treatment can be reduced; according to the treatment method, complex nickel is stably removed through three times of complex breaking treatment, the nickel emission concentration of treated effluent is 0.2 mg / L or below, and the nickel removal rate reaches up to 99%.

Owner:中新联科环境科技(安徽)有限公司

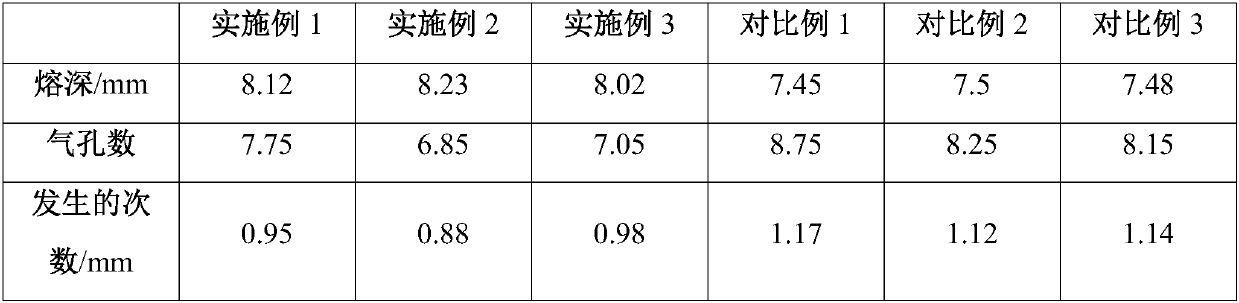

4-series aluminum alloy welding method

InactiveCN110193656AWelding inhibitionGood seam welding effectWelding/cutting auxillary devicesAuxillary welding devicesElectrolysisCleansing Agents

The invention belongs to the technical field of metal welding, and relates to a 4-series aluminum alloy welding method. The 4-series aluminum alloy welding method comprises the steps that the surfacesof to-be-welded aluminum profiles are subjected to alkaline electrolysis ionized water cleaning, drying and clamping, and welded seams are formed through electron beam welding, wherein the PH value of the electrolysis ionized water is 9-10, the concentration of C1<-> in the electrolysis ionized water is smaller than 0.1mg / L, the concentration of SO4<2+> is smaller than 0.1mg / L, the concentrationof Ca<2+> is smaller than 0.1mg / L, the water temperature is 30-40 DEG C, the injection pressure of a nozzle is 0.4MPa, and injection lasts for 20-30s. The problems that after the surface of 4-series aluminum alloy is cleaned through an existing cleaning agent, the welding defects that greasy dirt on the surfaces of the aluminum profiles is not thoroughly removed, and the surfaces of the profiles after welding have bubbles are prone to occurring to the surface of the aluminum alloy are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

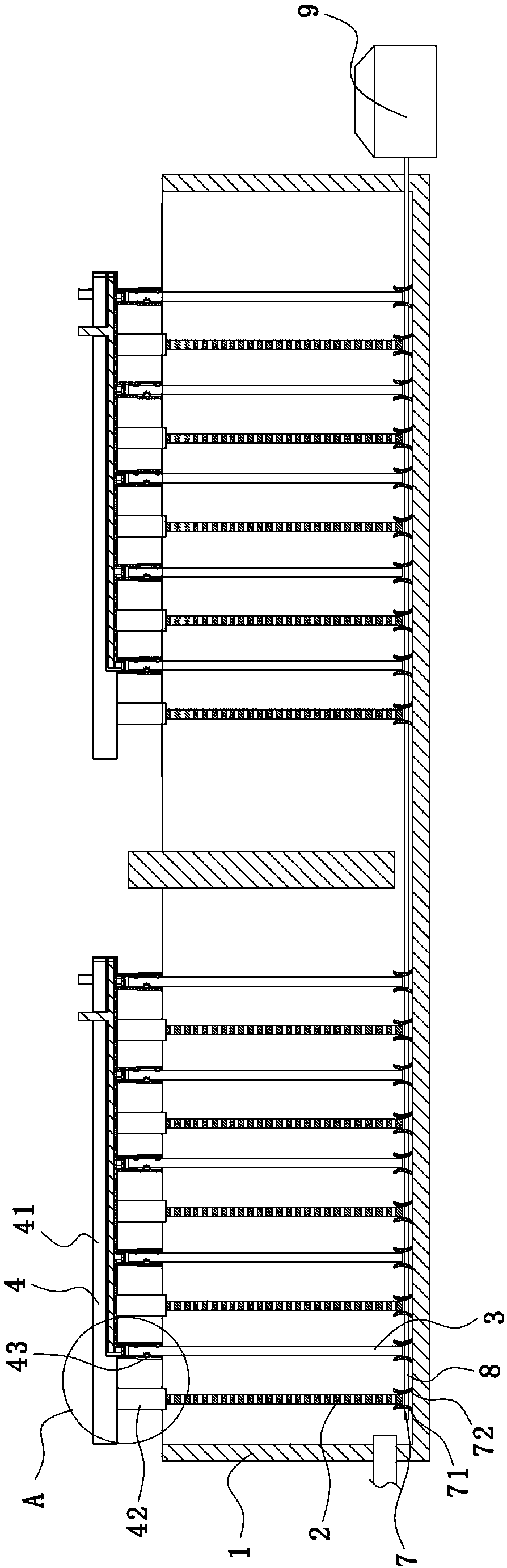

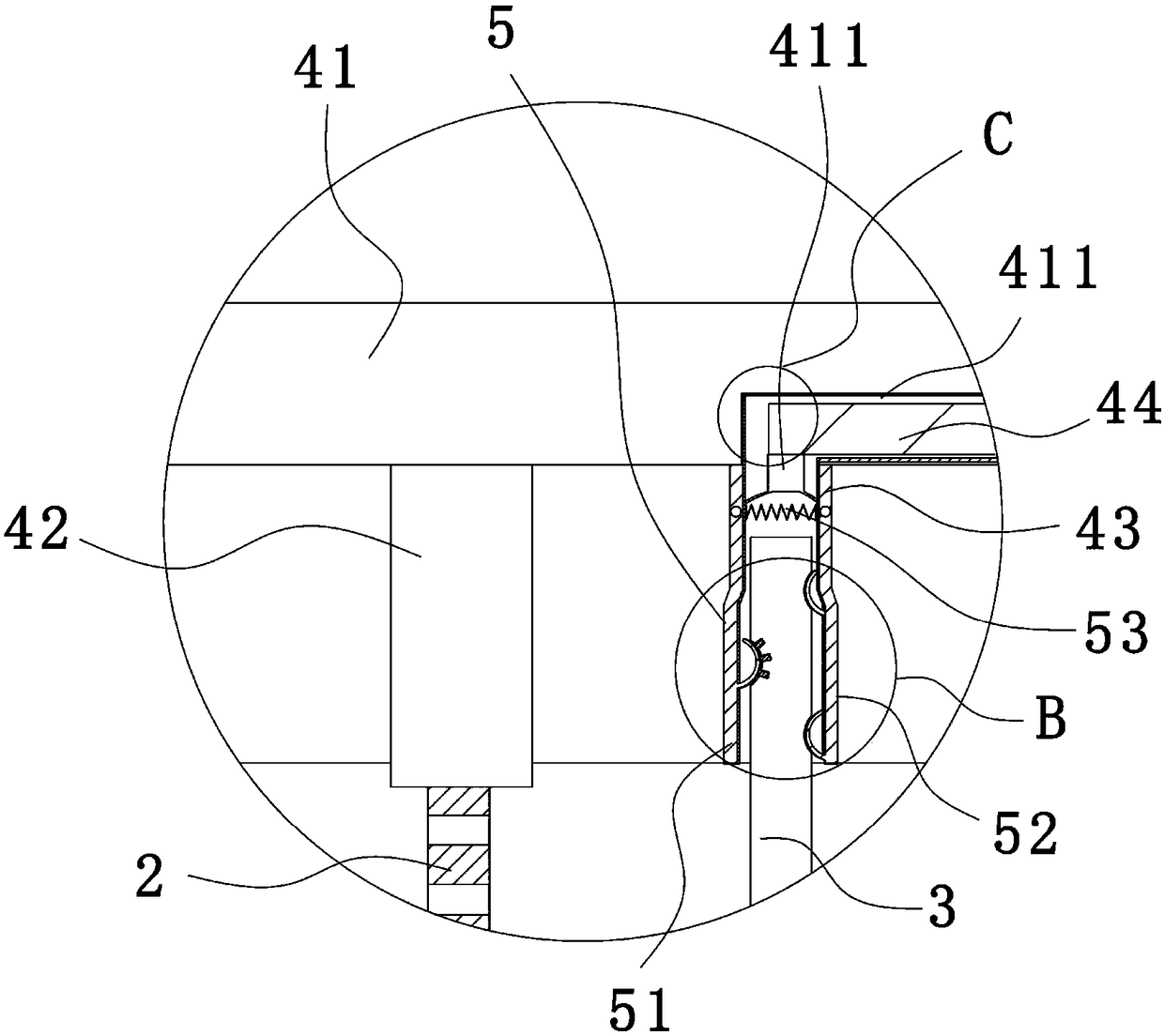

Continuous anode electrolytic cell prepared from multiferroic material

The invention relates to the technical field of electrolytic cells, and discloses a continuous anode electrolytic cell prepared from a multiferroic material. Thecontinuous anode electrolytic cell comprises an electrolytic cell main body, an anode cell and a cathode cell which are through are arranged in the electrolytic cell main body, a clamping assembly is fixedly installed on the inner wall of one side of the anode cell, a partition plate structure is arranged between the anode cell and the cathode cell, a mud scraping structure is arranged at one side of the electrolytic bath body, and a filtering assembly is arranged at the bottom of the electrolytic bath body. An anode needing to be electrolyzed is placed between the side plate and the sliding plate, the pressing plate and the side plate can clamp the anode and can make contact with an anode guide rod, overall clamping is convenient, a net rack is arranged on a vertical plate, anode mud can be filtered, collection and utilization are convenient, the vertical plate can be tightly pressed by rotating a rotating block, the sealing performance between the anode cell and the cathode cell is high, due to the fact that the sealing performance is high, an inserting plate needs to be pulled up or pushed down by a pulling block, and a solution in the cathode groove can be discharged from a water discharging opening through a round hole.

Owner:XIANYANG NORMAL UNIV

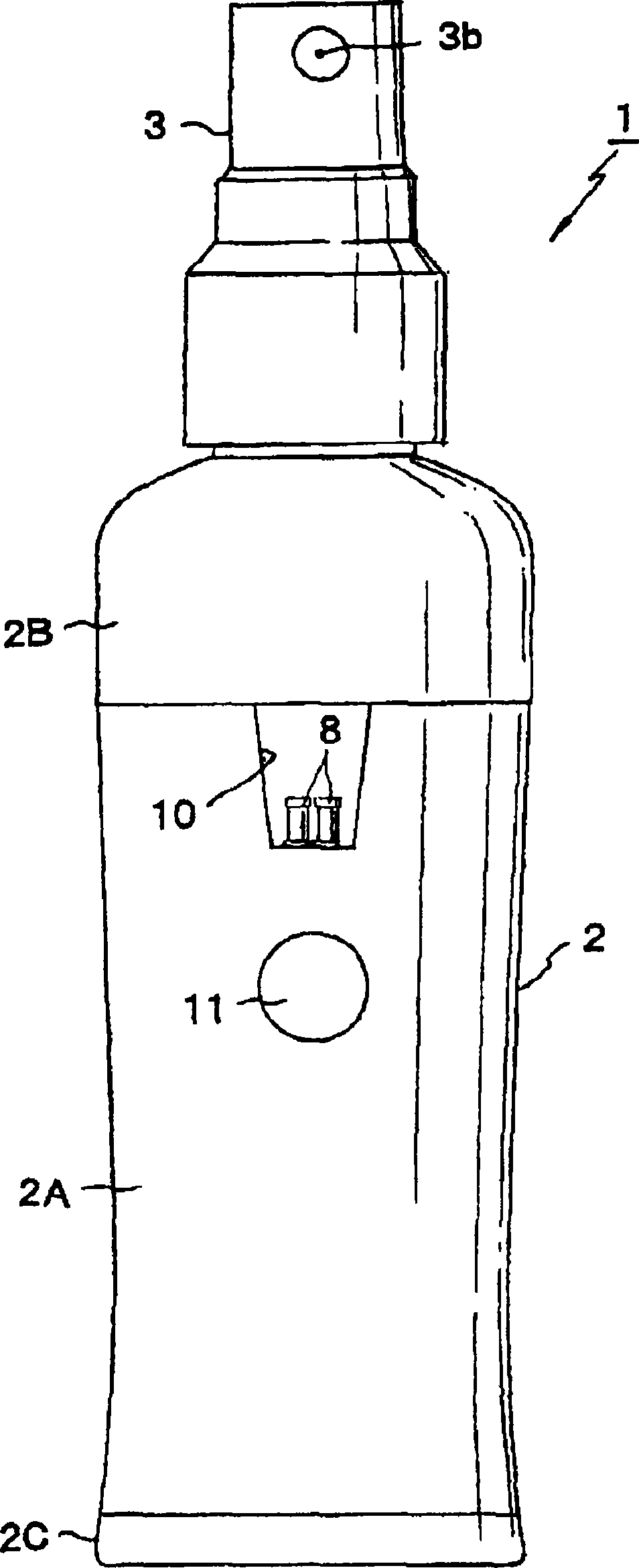

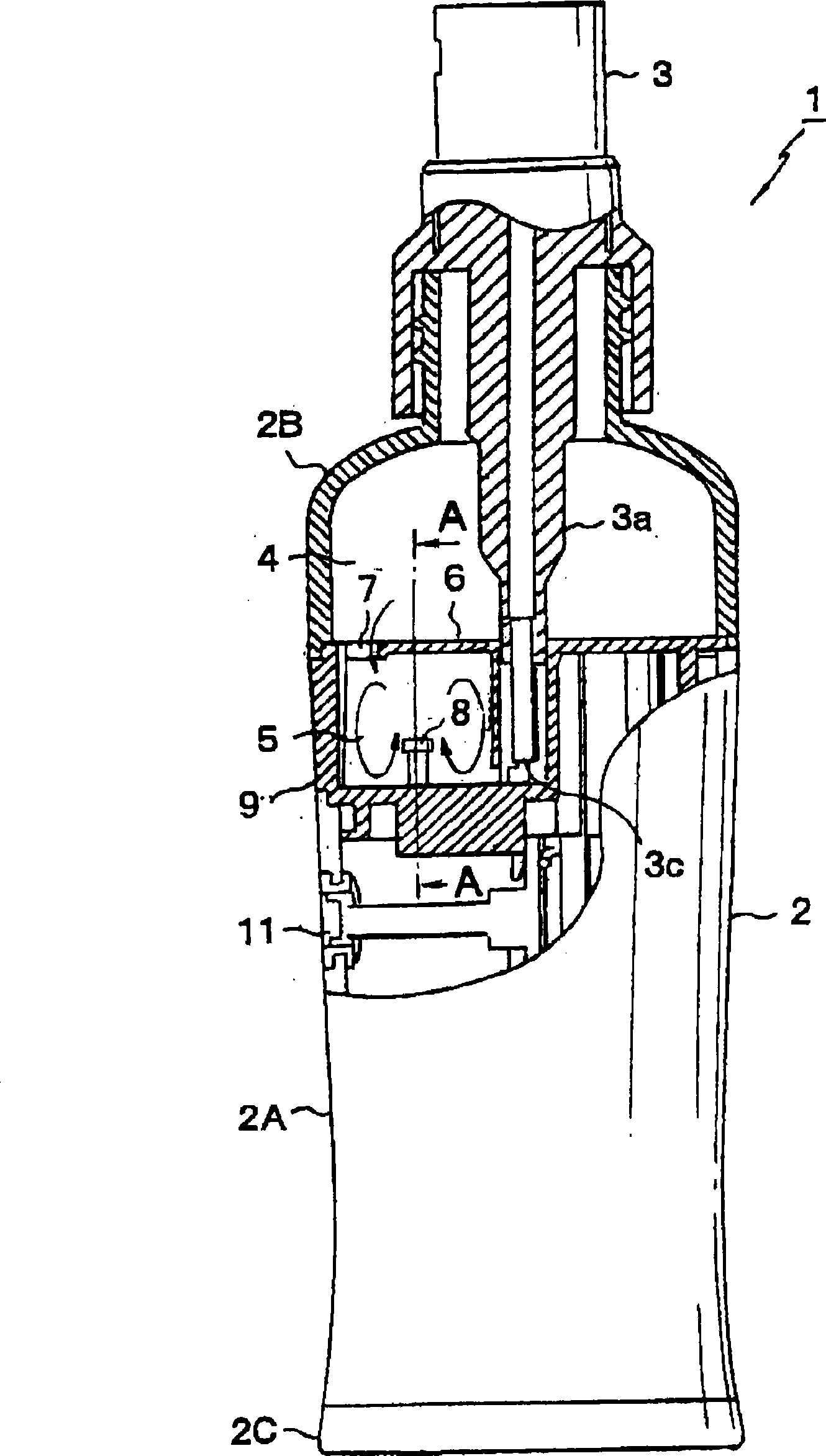

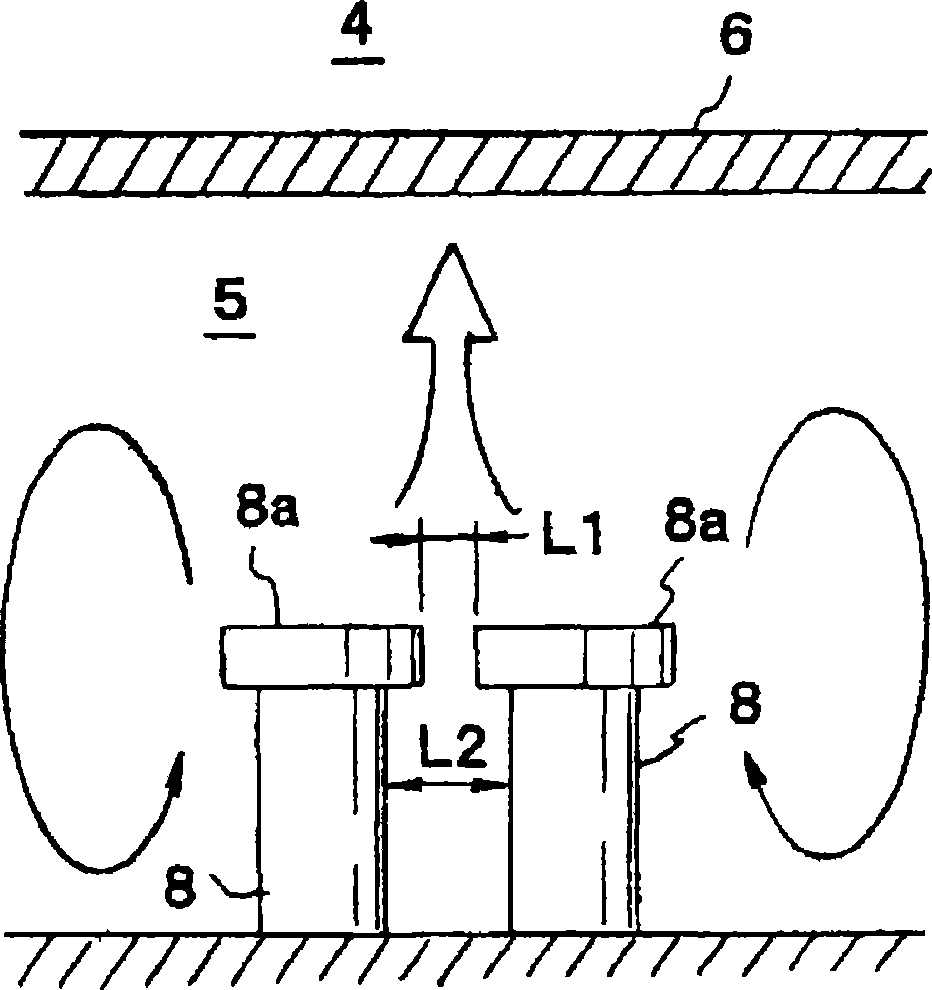

Electrolyzed water generating and spraying device

InactiveCN101468831AConfirm the status of electrolysisAvoid smallDispensing apparatusWater/sewage treatment by electrochemical methodsElectrolysed waterWaste management

Owner:MIKUNI CORP

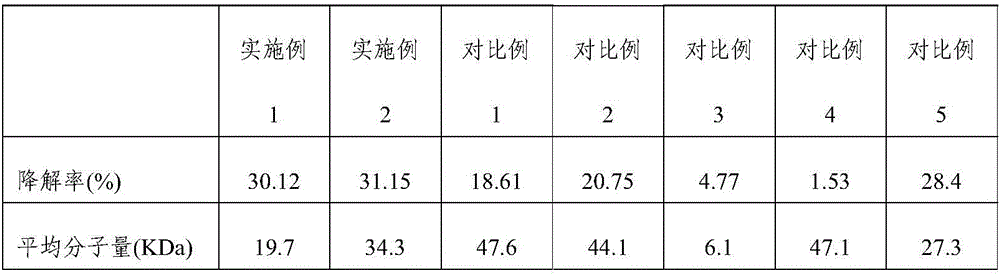

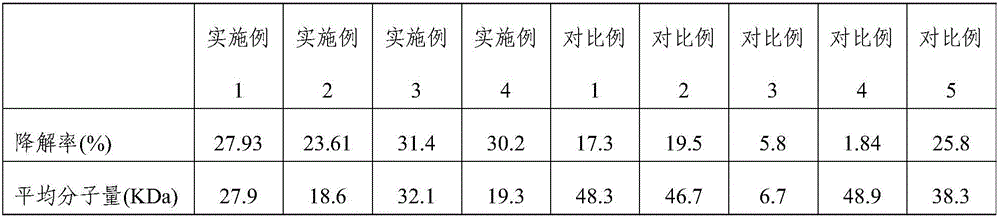

Method for degrading beta-1,4-glycosidic-bond-containing high-molecular-weight polysaccharides

ActiveCN106188327AEvenly dispersedSpeed up electrolysisElectrolysis componentsElectrolytic organic productionElectrolysisHydrogen peroxide degradation

The invention relates to a method for degrading beta-1,4-glycosidic-bond-containing high-molecular-weight polysaccharides. The method comprises the following steps: introducing an 80-180 mg / mL beta-1,4-glycosidic-bond-containing high-molecular-weight polysaccharide solution into an electrolyzer provided with a cathode and an anode, regulating the solution to acidity, introducing 4.0-6.0L of oxygen to the cathode for every liter of the polysaccharide solution, and introducing a direct current while controlling the current density of the cathode at 10-13 mA / cm<2>; and under such conditions, carrying out degradation, and collecting the electrolyte. The method has favorable selectivity for beta-1,4-glycosidic-bond-containing polysaccharides, has the advantages of simple technical operation, time saving, high efficiency, mild reaction conditions and low environmental pollution, and is beneficial to scale-up production. More importantly, compared with the acid-process degradation and hydrogen peroxide degradation, the electro-Fenton process has higher degradation rate for polysaccharides, and the molecular weight range of the obtained low-molecular-weight polysaccharides is narrower.

Owner:北京颐方生物科技有限公司

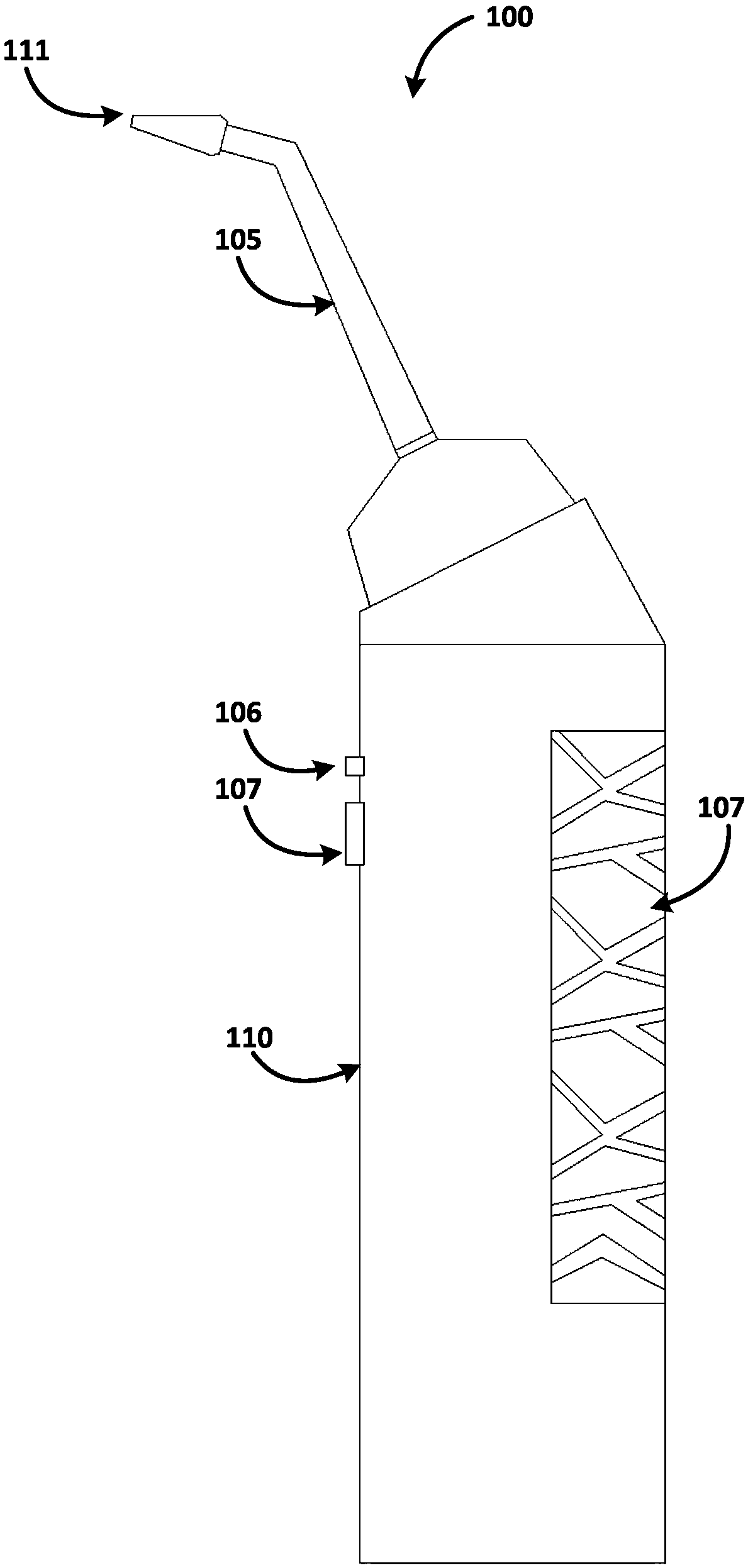

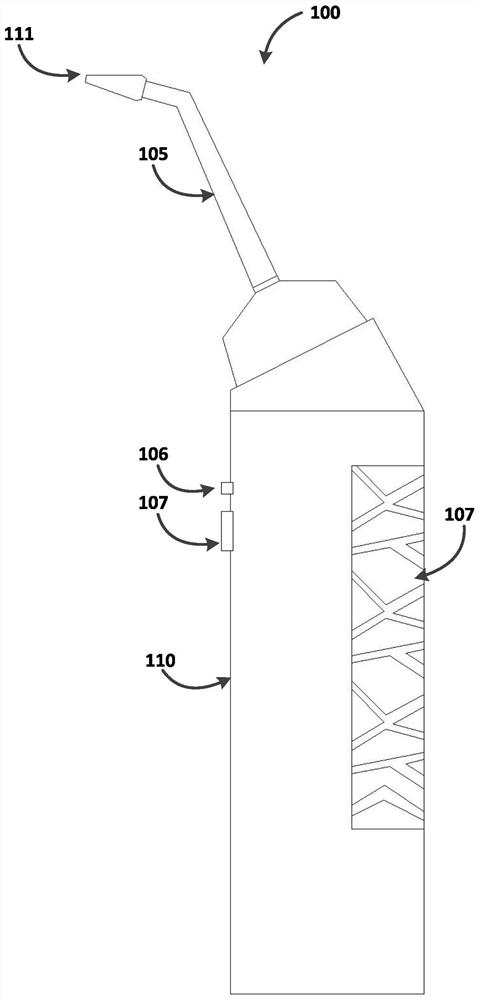

Electrolysis water toothpick

The invention relates to an electrolysis water toothpick. The electrolysis water toothpick comprises a water trough provided with a water inlet and a water outlet, a water electrolysis device and a water outlet pipe, wherein the bottom of the water outlet is close to the water trough, the water electrolysis device is arranged in the water trough to electrolyze water in the water trough into hydrogen and oxygen, and the water outlet pipe is connected with the water outlet. The invention also relates to a method for operating the electrolysis water toothpick. By adopting the electrolysis water toothpick or the method, water-draining mechanical parts such as motors can be omitted, and meanwhile a sterilization function is provided without additional sterilization preparations.

Owner:孙恒

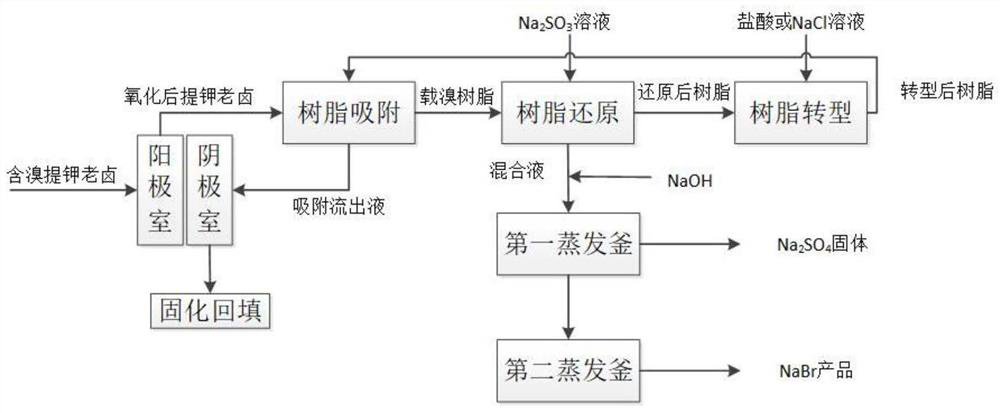

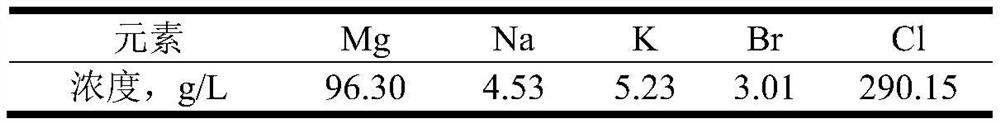

Method for extracting bromine from potassium extraction old brine and producing sodium bromide

PendingCN114875428AAvoid secondary oxidationSimple processElectrolysis componentsChemical industryElectrolysisBromine

The invention provides a method for extracting bromine from potassium extraction old brine and producing sodium bromide, which comprises the following steps of: introducing the potassium extraction old brine into an anode chamber of an electrolysis device, introducing resin adsorption effluent into a cathode chamber, and reacting through direct current and bromine ions in a constant current mode to generate elemental bromine; enabling the potassium extraction old brine in the anode chamber to pass through anion exchange resin, enabling the bromine simple substance to be adsorbed on the resin to form bromine-loaded resin, and enabling the potassium extraction old brine to pass through the resin to obtain resin adsorption effluent; introducing a reducing agent into the bromine-loaded resin, reducing the bromine simple substance adsorbed on the bromine-loaded resin into bromine ions, and adding sodium hydroxide to react to obtain a mixed solution of sodium sulfate and sodium bromide; and performing quality-divided crystallization on the mixed solution to obtain a sodium sulfate solid and a sodium bromide product. According to the method, the storage and transportation safety problem and the environmental pollution risk caused by traditional chlorine oxidation are avoided, meanwhile, the old brine obtained after bromine extraction is converted to be neutral, and the influence on the curing and backfilling process is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Treatment method of domestic sewage

ActiveCN108218053AReduce CODPromote oxidationWater contaminantsTreatment involving filtrationHypochloriteHydrogen

The invention discloses a treatment method of domestic sewage. The treatment method comprises the following steps of a), removing a solid substance in source water, detecting the potential of hydrogen(PH) of a water body, and then adding a PH regulator to regulate the PH to 6.5 to 7.5, so as to obtain a water body A; adding a flocculating agent into the water body A, filtering, then introducing chlorine, and afterwards, adding alkali liquor. According to the treatment method, the water body is regulated to be neutral; a hydroxide ion in the water body is prevented from prematurely reacting with the chlorine; the chlorine can be dissolved in the water body; a generated hypochlorite reacts with an ammonium ion in the water; the ammonium ion in the water body is removed; quick lime is addedinto the water; a microorganism and a germ in the water can be killed; the quick lime generates slaked lime in the water, and the slaked lime reacts with a phosphorus ion in the water, so that a phosphorus element in the water can be removed.

Owner:江西挺进环保科技股份有限公司

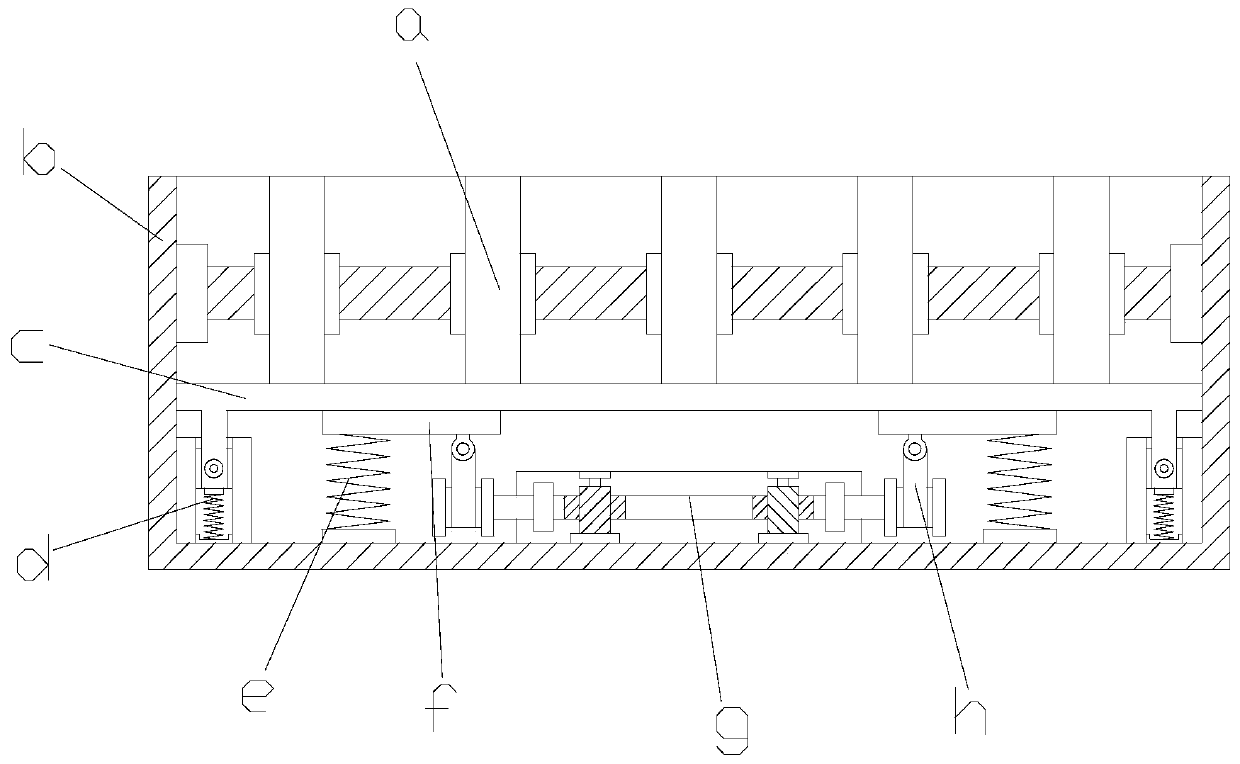

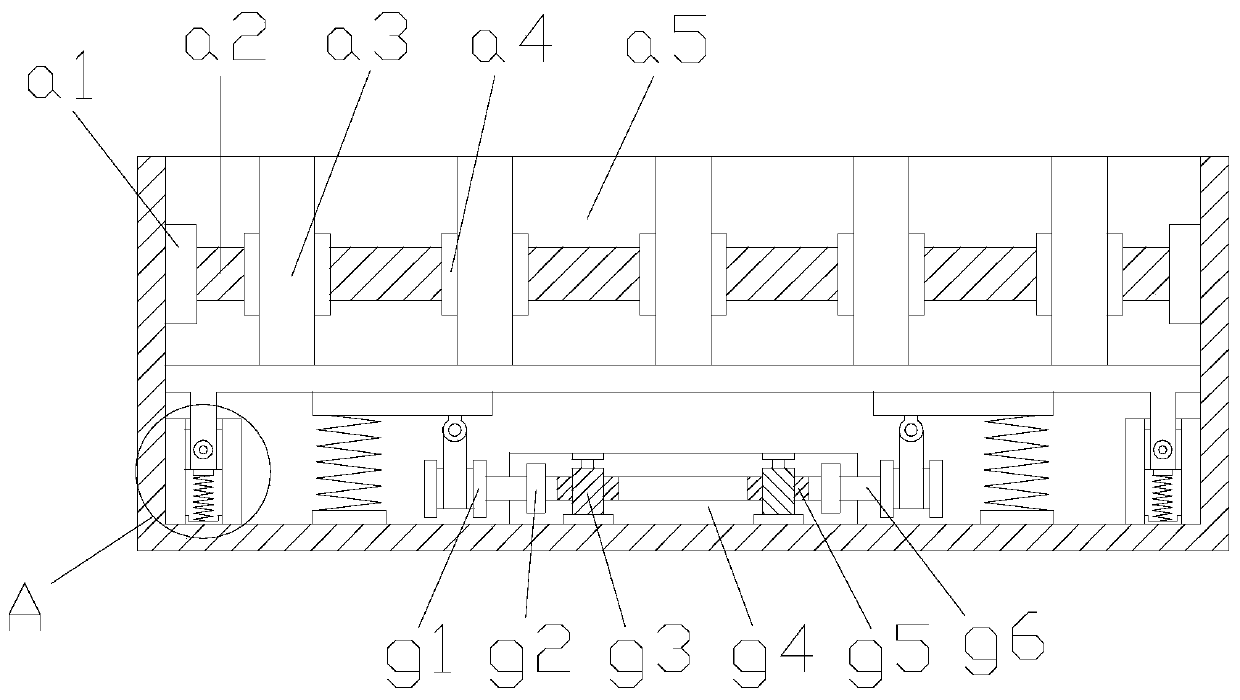

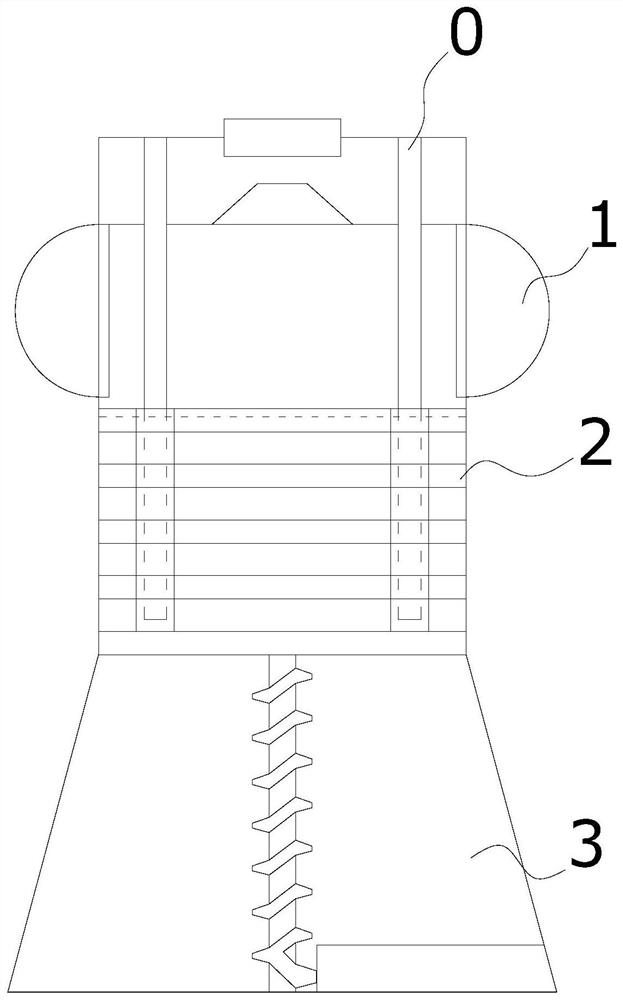

Piston type volume-adjustable rare earth electrolytic cell

The invention discloses a piston type volume-adjustable rare earth electrolytic cell which structurally comprises an electrolytic cell debugging device, two or more partition plates, two connecting columns, round shaft bases and a foot base. The front end and the rear end of the electrolytic cell debugging device are respectively provided with the round shaft bases correspondingly, the partition plates are located on the same plane, the partition plates are uniformly and equidistantly installed inside the electrolytic cell debugging device, the two connecting columns are parallel to each other, and the lower portions of the connecting columns are vertically welded to the middle portions above the round shaft bases correspondingly. Through the arrangement of the electrolytic cell debuggingdevice, when the piston type volume-adjustable rare earth electrolytic cell is in use, the size of the space charged on the electrolytic cell can be debugged through a lifting adjusting plate on the device, therefore, the containing capacity of rare earth can be improved, and the electrolytic process of the rare earth can be accelerated; due to the fact that a screw rod dragging device is arrangedinside the device, when the piston type volume-adjustable rare earth electrolytic cell is in use, the lifting adjusting plate on the device can be assisted in descending, high and low unevenness of the lifting adjusting plate is prevented from occurring when the lifting adjusting plate descends, and the containing capacity is improved.

Owner:黄祖班

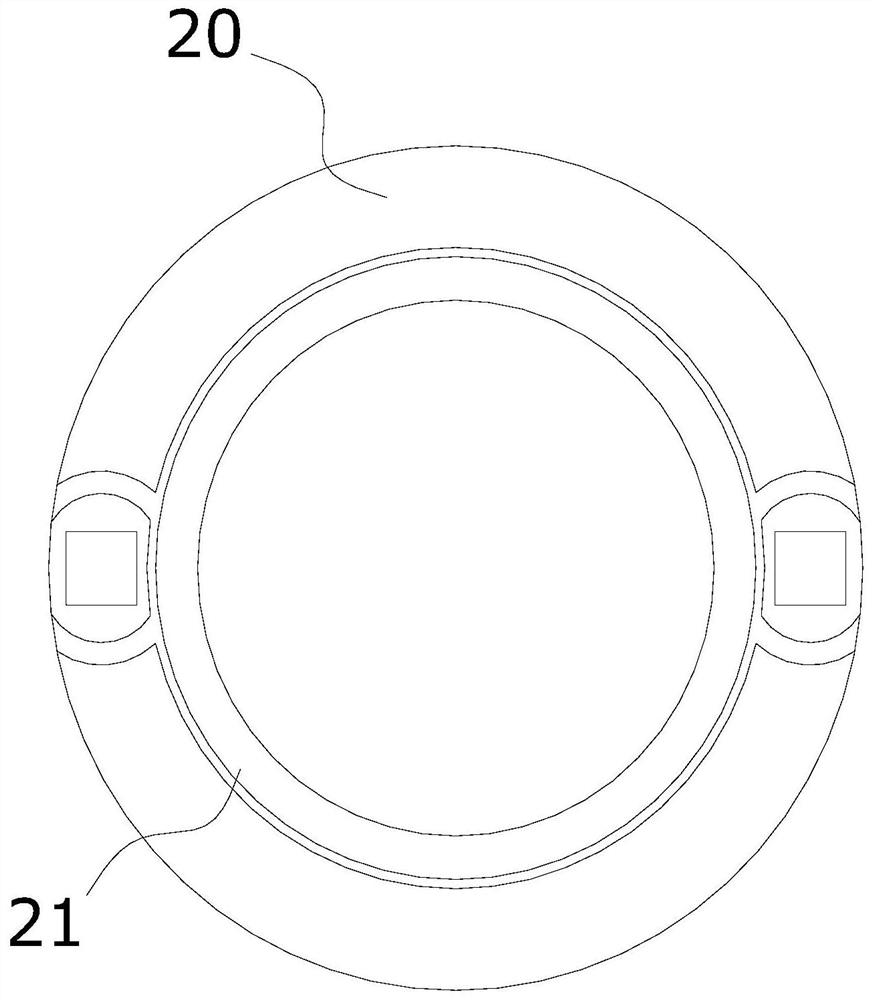

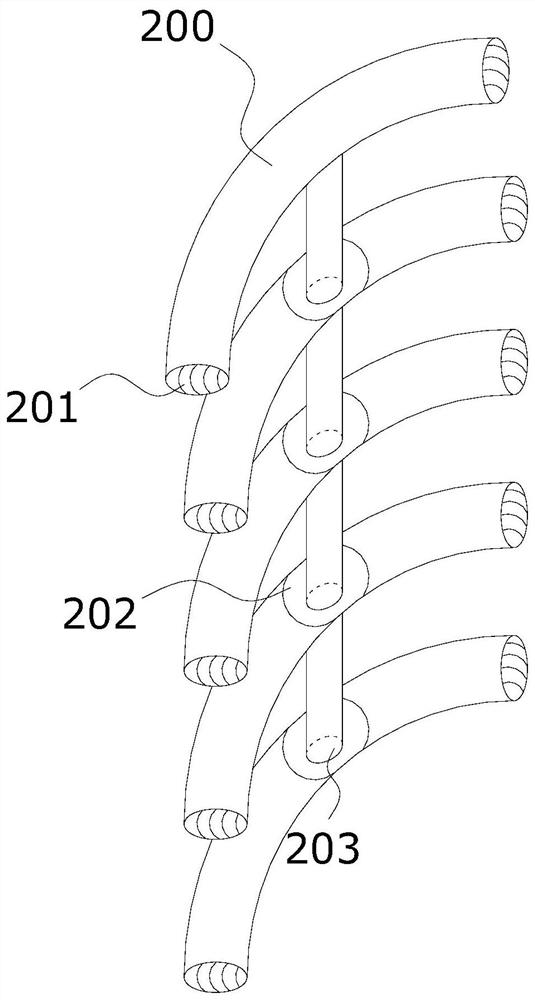

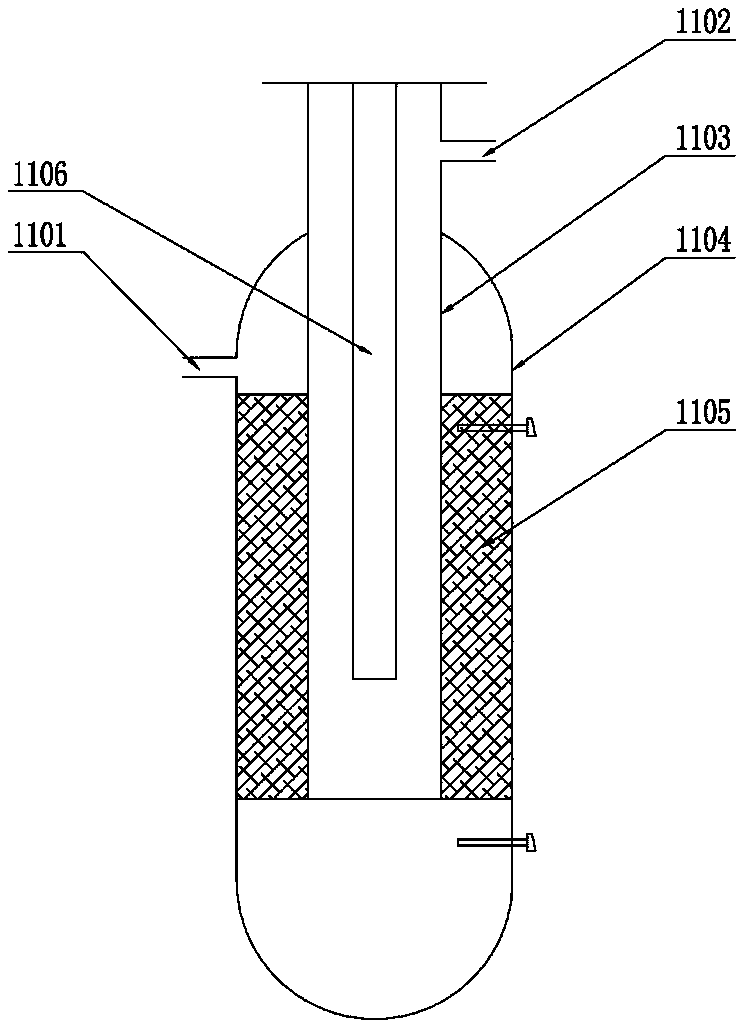

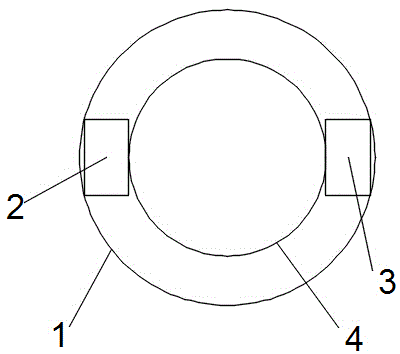

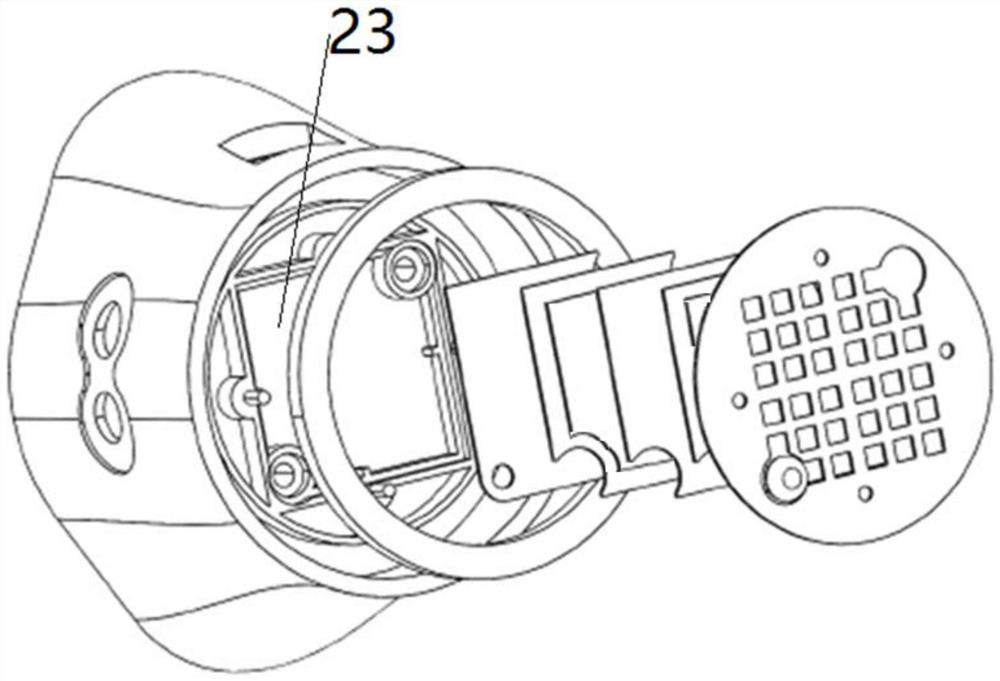

Electrolytic dehydration device of anhydrous hydrogen fluoride for hexafluorophosphate synthesis

PendingCN111847385ASpeed up electrolysisSpeed up circulationHydrogen fluorideHydrogen fluoridePhysical chemistry

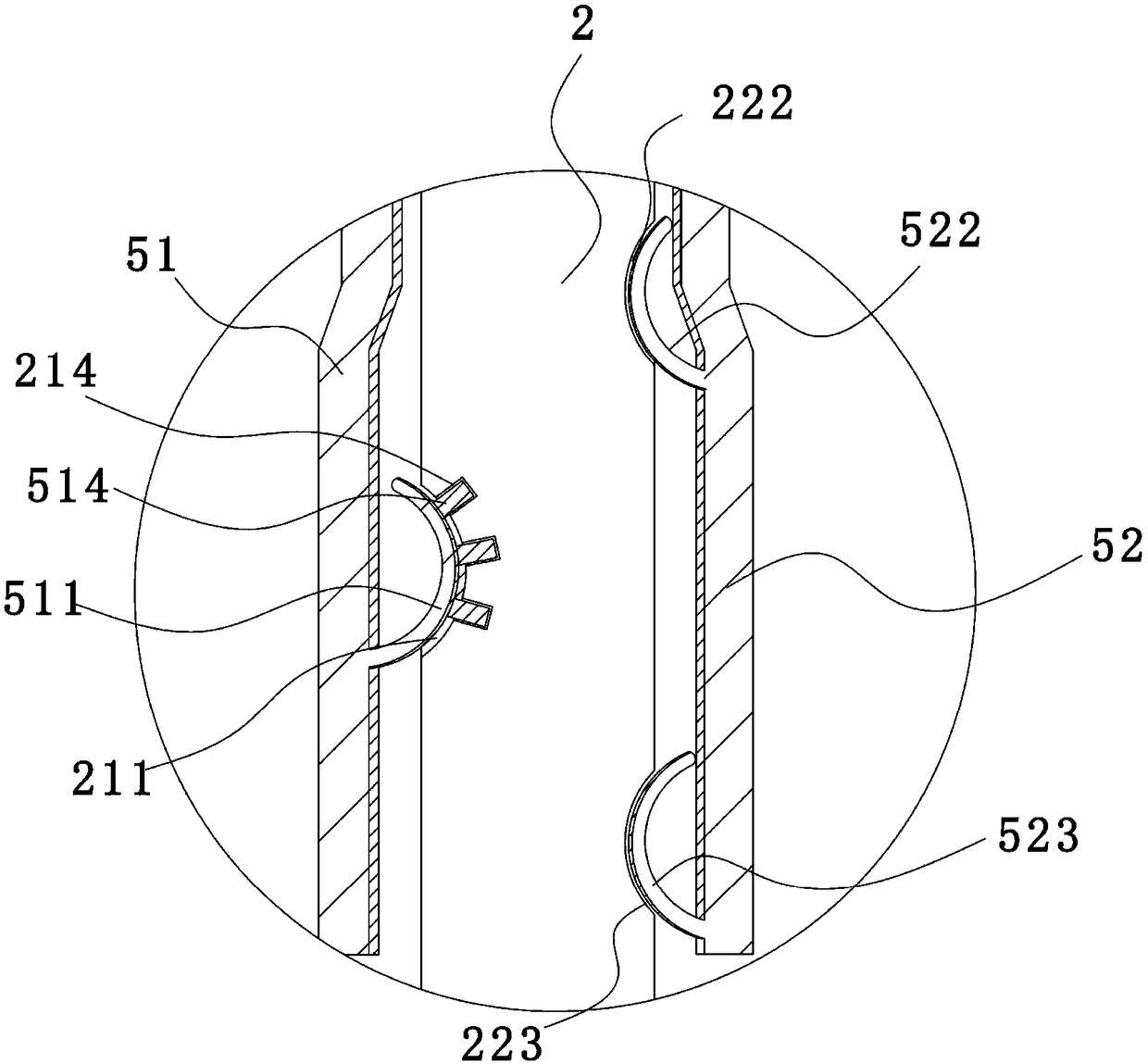

The invention discloses an electrolytic dehydration device of anhydrous hydrogen fluoride for hexafluorophosphate synthesis. The device comprises a guide cavity structure which is arranged in an electrolytic cell and surrounds and wraps the outer circumferential surfaces of positive and negative rods, and a suction structure which is movably opened and closed at the bottom of the electrolytic cell; an outlet of the suction structure is connected with an outer cavity sealing structure; the guide cavity structure comprises an outer ring and an inner ring; the positive and negative rods are vertically inserted and embedded at the joint of the outer ring and the inner ring; the guide cavity structure is arranged near the positive and negative rods of the electrolytic cell and in the hydrogen fluoride liquid circulating between the positive and negative rods, circulation of electrons in the liquid can be accelerated, the electrolysis effect between the positive electrode and the negative electrode is improved, water molecules in hydrogen fluoride can be ionized more completely, the water content in the hydrogen fluoride liquid is reduced to the minimum, and water in the hydrogen fluoride liquid is well removed.

Owner:福建省龙德新能源有限公司

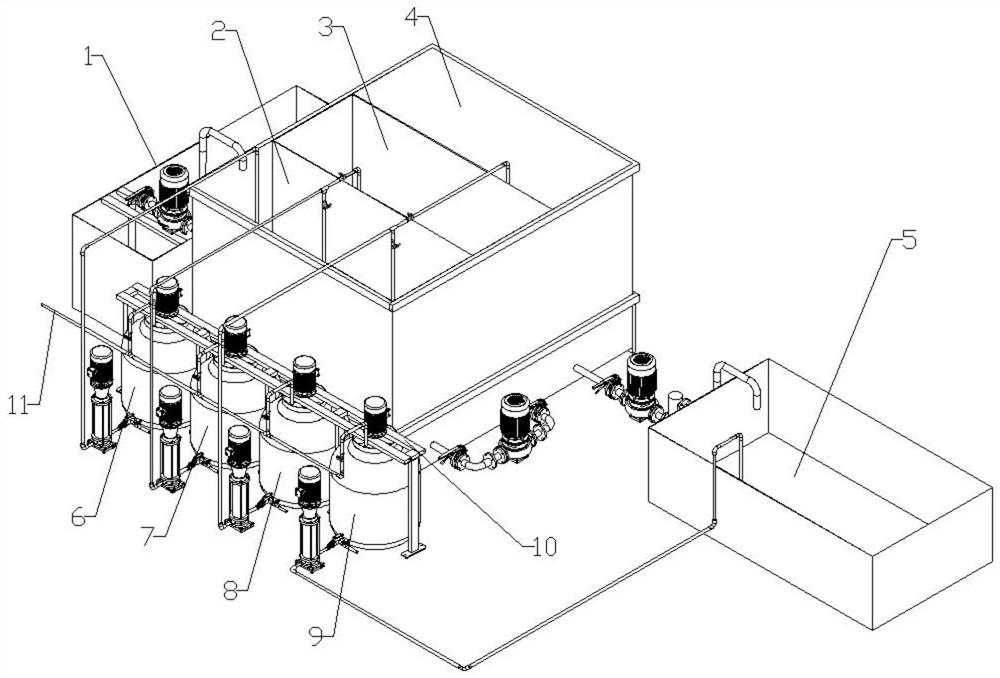

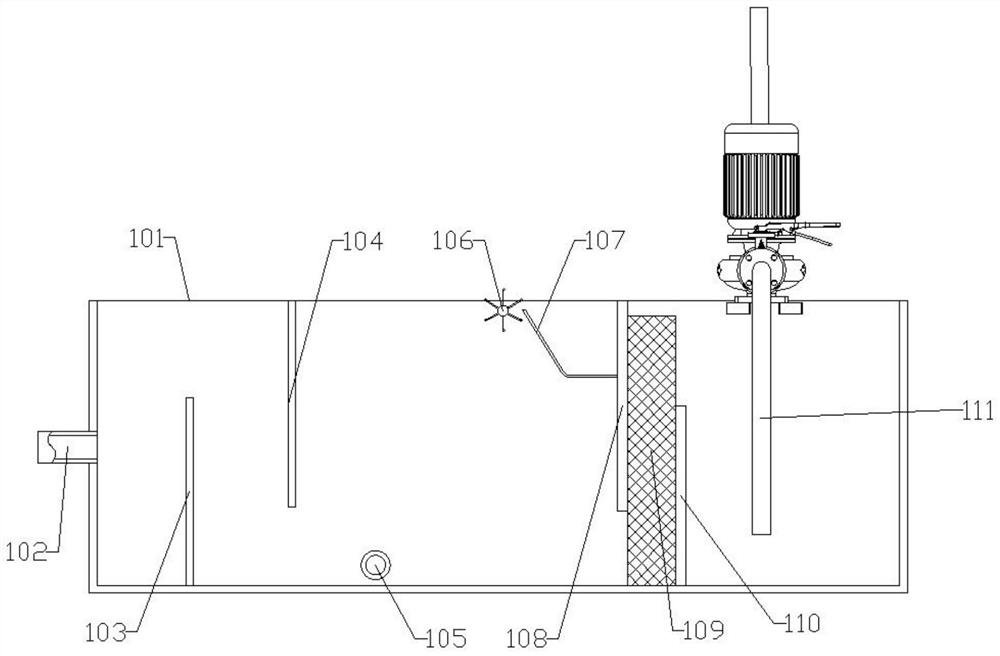

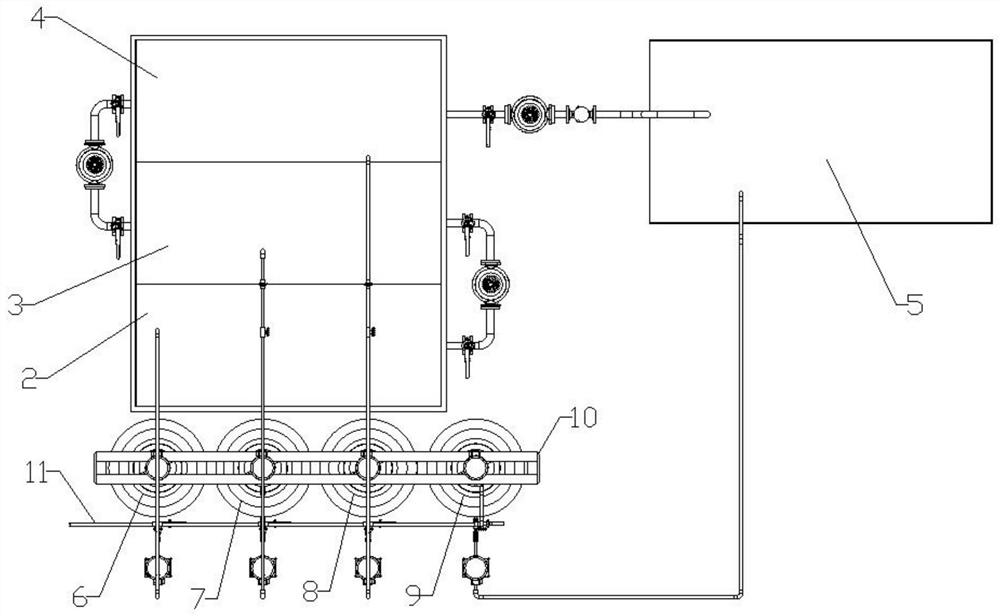

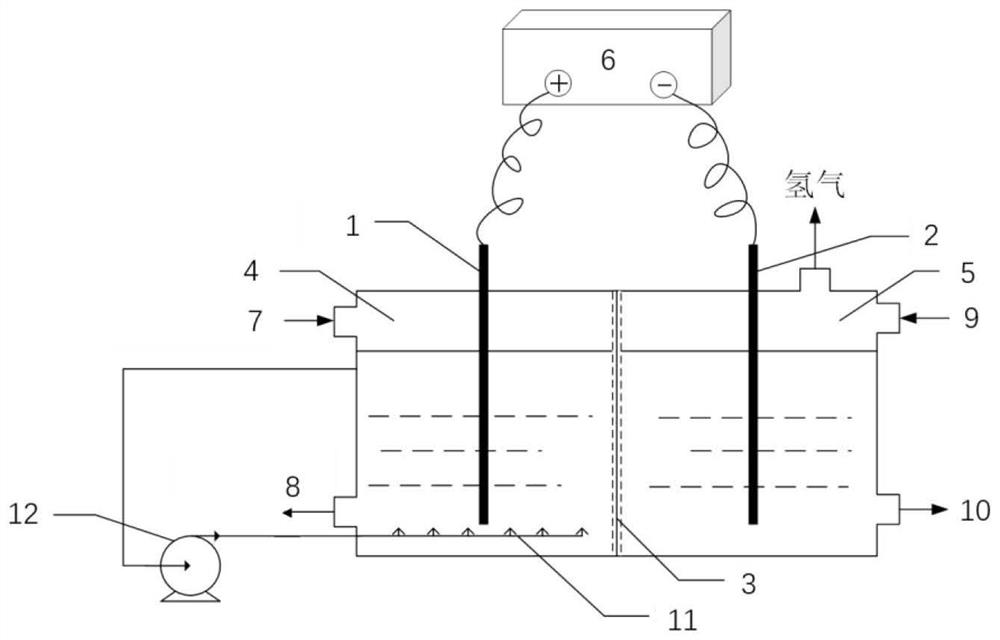

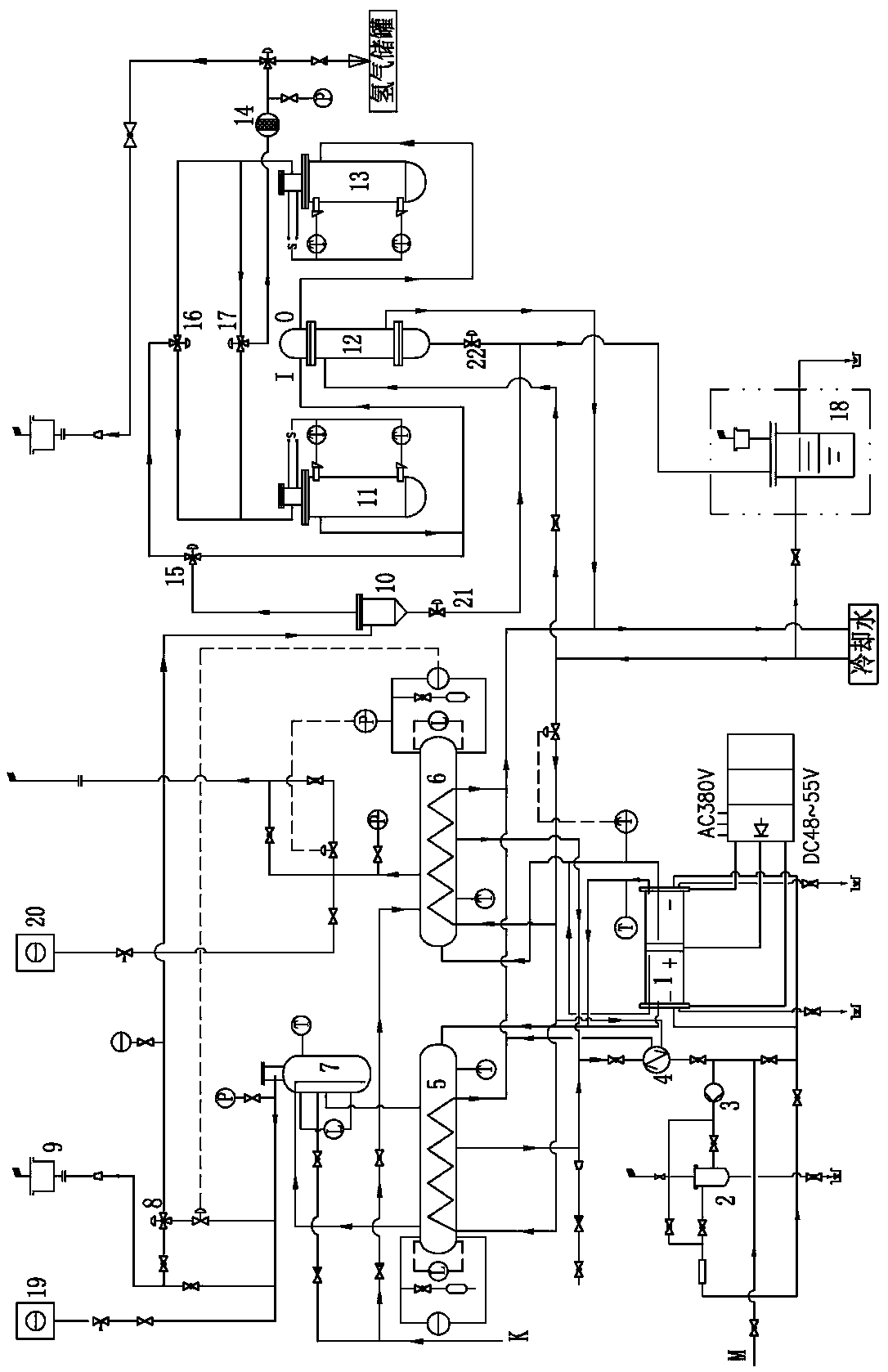

Alkaline solution electrolysis hydrogen production device and hydrogen production method

ActiveCN106119885BIncrease ionization rateSpeed up electrolysisCellsDispersed particle separationGas phaseOxygen

The invention discloses an alkaline solution electrolytic hydrogen production device in the field of hydrogen production devices. The alkaline solution electrolytic hydrogen production device comprises a direct current power supply, an electrolytic cell, a hydrogen separator and an oxygen separator, wherein the bottom of the electrolytic cell is provided with an alkaline solution inlet; the upper part of an anode zone of the electrolytic cell communicates with a circulating liquid inlet of the oxygen separator, and a gas phase outlet at the top of the oxygen separator communicates with the atmosphere through a valve; the upper part of a cathode zone of the electrolytic cell communicates with a circulating liquid inlet of the hydrogen separator, a gas phase outlet at the top of the hydrogen separator is connected to a hydrogen washing device, and the hydrogen washing device communicates with an inlet of a gas-water separator through a three-way valve I; circulating liquid outlets at the bottoms of the hydrogen separator and the oxygen separator communicate with the alkaline solution inlet sequentially via an alkaline solution cooler, an alkaline solution circulating pump and an alkaline solution filter; and a gas outlet of the gas-water separator is connected to a hydrogen storing tank through a three-way valve II and a drying system. A KOH or NaOH solution with a 25-30% mass concentration is used as an electrolyte. The device can safely produce hydrogen and is high in hydrogen producing efficiency, low in equipment investment and great in production continuity.

Owner:YANGZHOU CHUNGDEAN HYDROGEN EQUIP

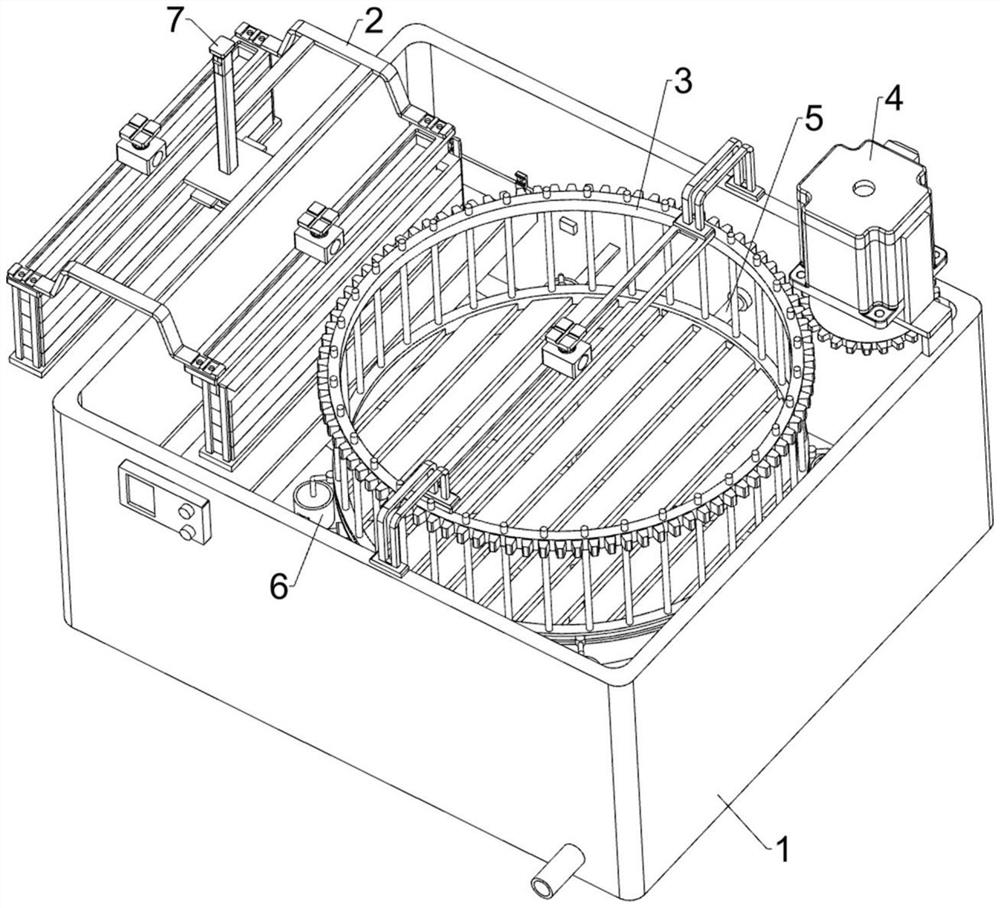

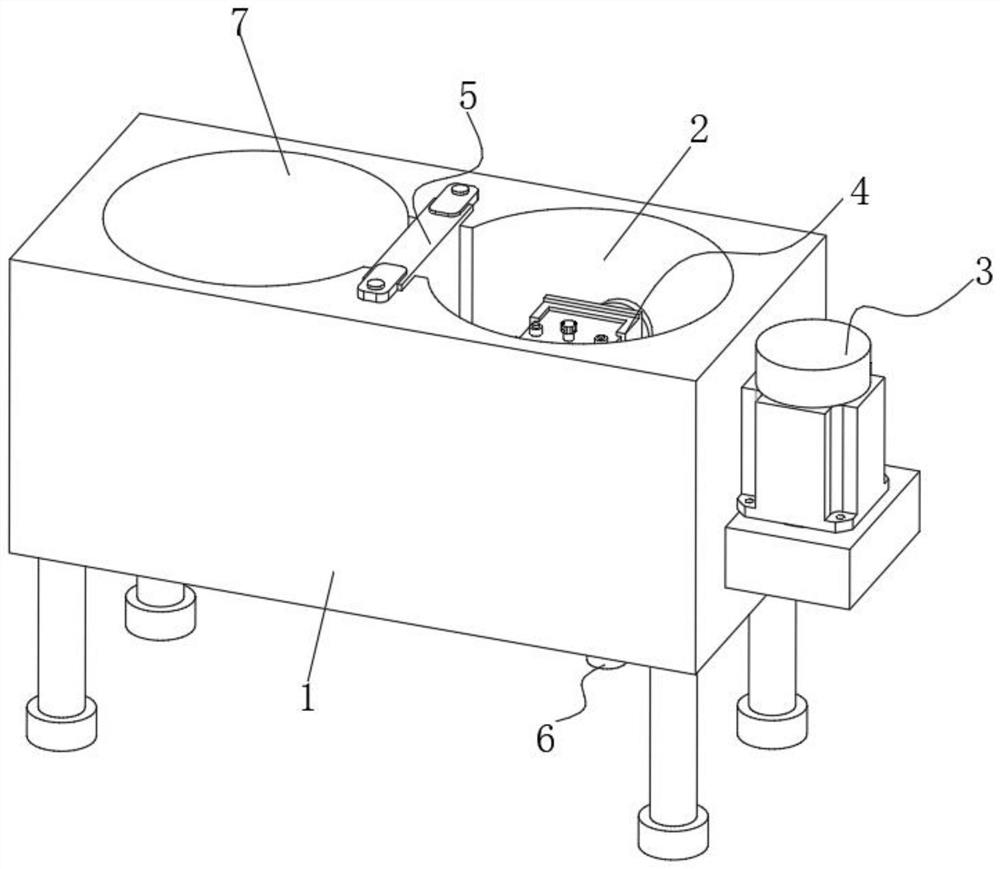

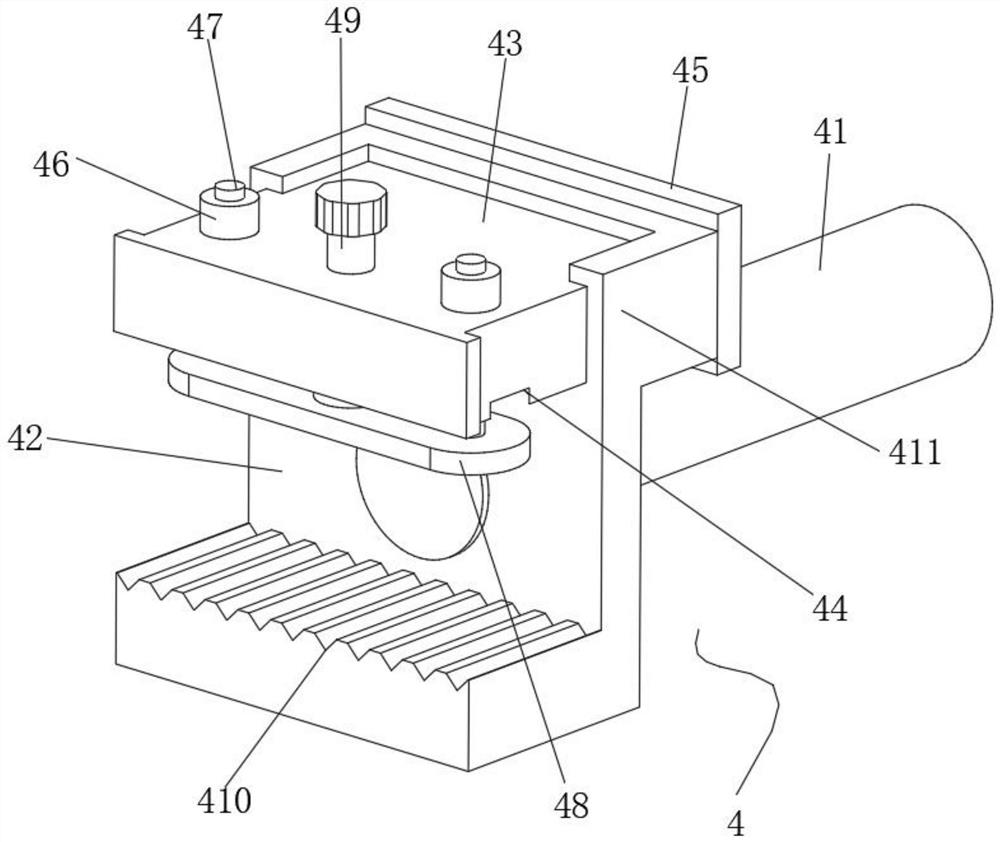

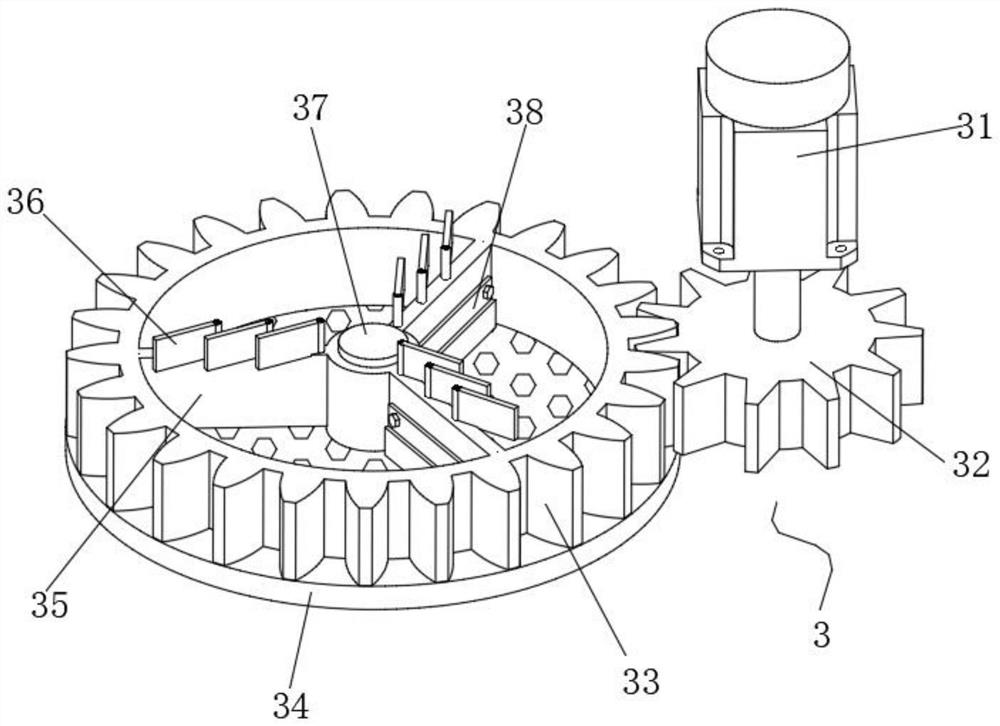

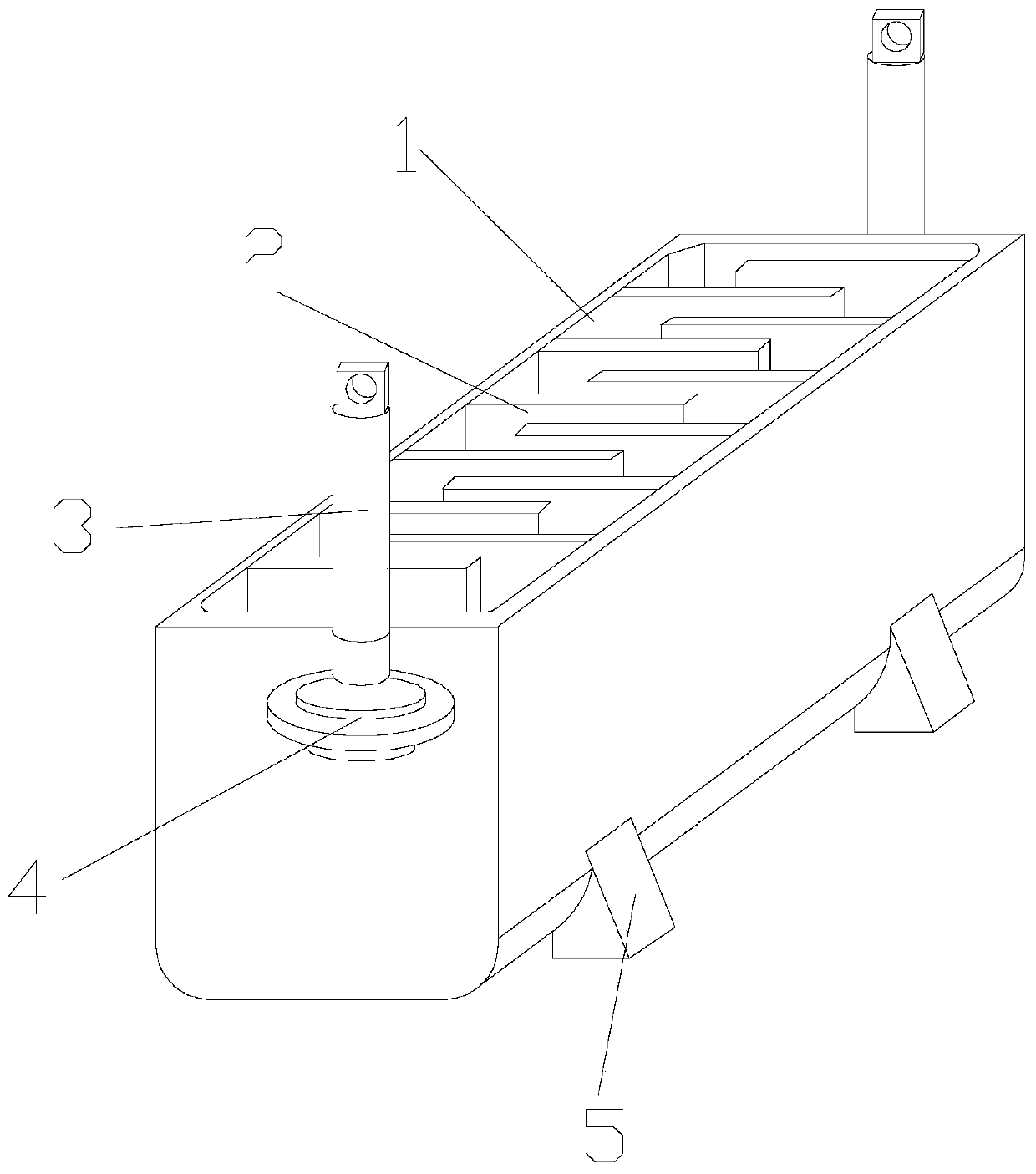

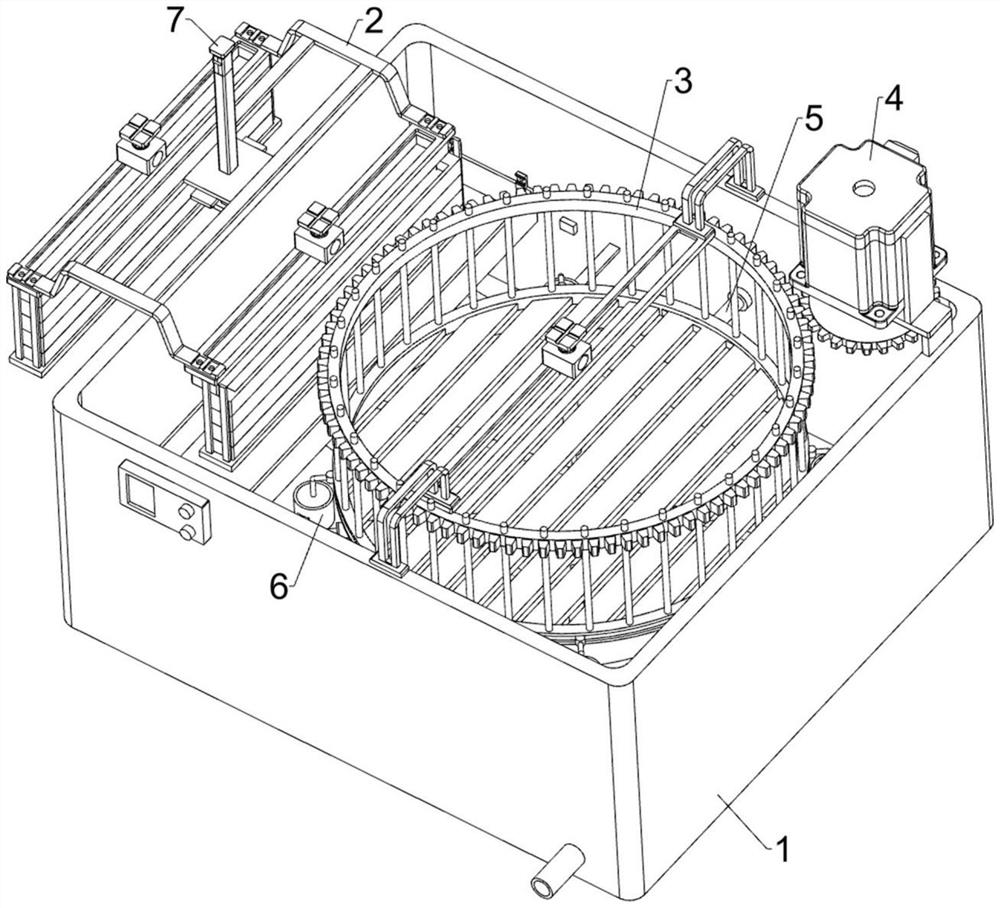

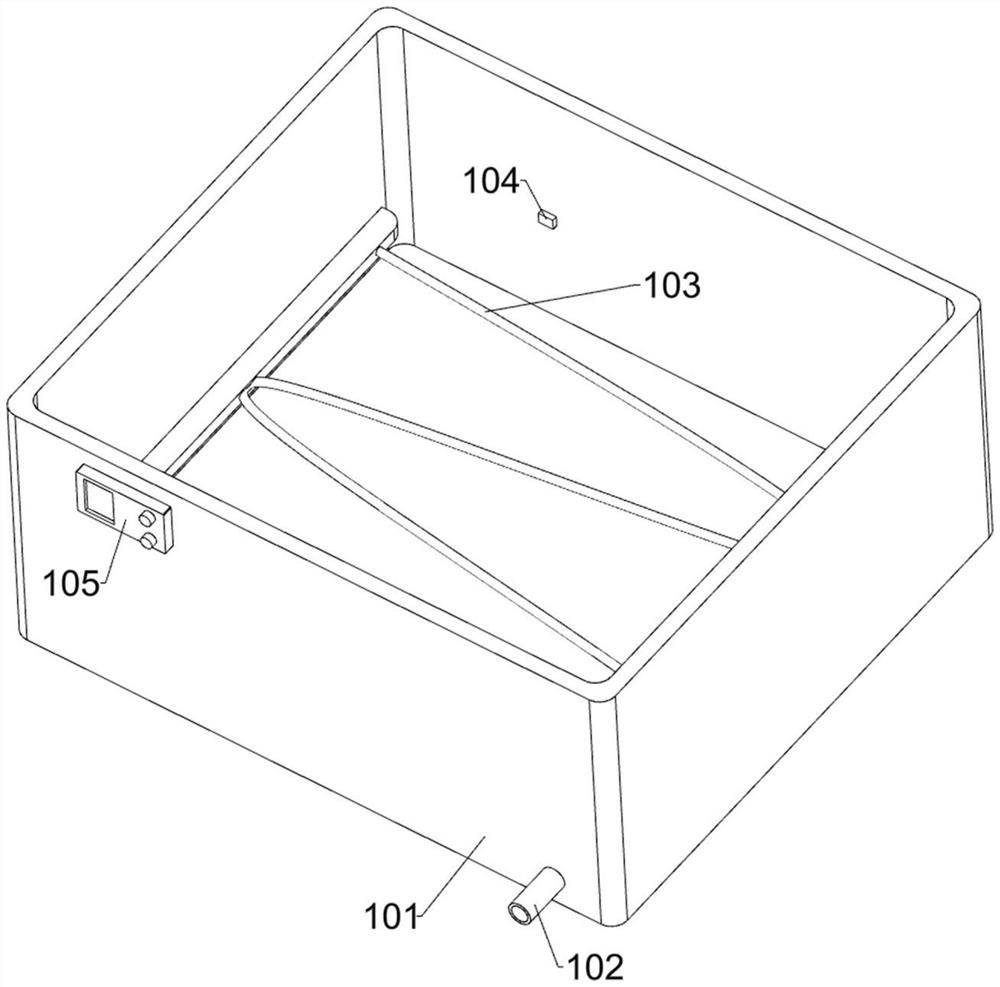

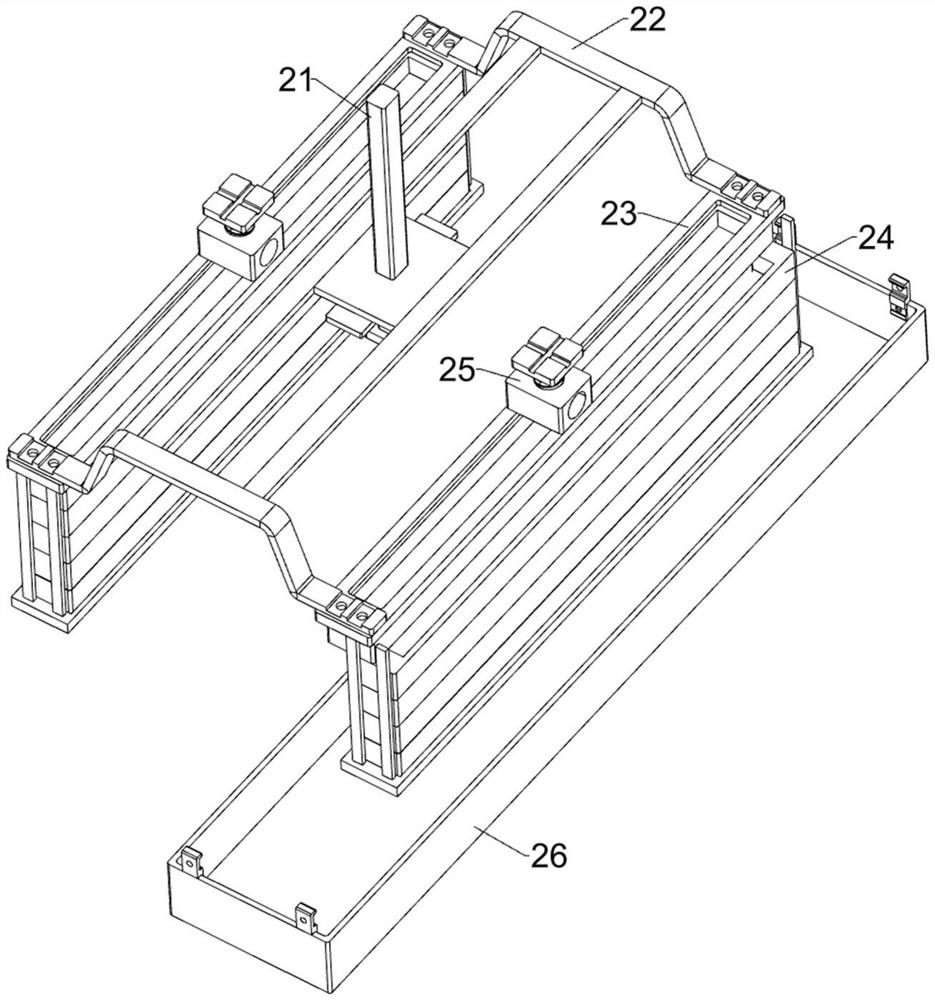

A kind of electroplating device for faucet manufacturing

ActiveCN112481682BShorten the timeSpeed up the plating processCellsTemperature controlElectrolysis

The invention relates to an electroplating device, in particular to an electroplating device for faucets. The object of the present invention is to provide an electroplating device for faucet manufacturing which can uniformly and quickly electroplate the faucet. An electroplating device for faucet production and manufacturing includes: an electroplating container; an electroplating material providing component installed on the electroplating container; and a placement component installed on the electroplating container. The invention has an acceleration component, which can speed up the flow of water, thereby further speeding up the electroplating process, saving time and improving production efficiency; the invention has a heater, which can heat the water, thereby accelerating the electrolysis of the chromium plate, and further making the electroplating The effect is better, and it also has a temperature sensor and a temperature controller, which can prevent the temperature from being too high and affect the plating effect.

Owner:FUZHOU YINSHENGWANG SANITARY WARE

A zinc electrolyzing device

InactiveCN106884186AIngenious ideaReasonable designPhotography auxillary processesProcess efficiency improvementElectrolysisLower grade

A zinc electrolyzing device is disclosed. The objective of the invention is to overcome the problem that zinc electrolyzing devices at present fail to meet requirements of zinc electrolyzing techniques of aqueous solutions of zinc ammonia complexes and are complex in structure. The device includes an electrolytic tank, a cathode, an anode, an electrode positioning element and a power supply apparatus. The cathode is a metal aluminum plate. The anode is a metal titanium plate. The cathode and the anode are separately connected to the power supply apparatus. The device can meet zinc electrolyzing requirements, the structure is simple, maintenance is convenient and a production cost is low. The device is ingenious in conception, reasonable in design, convenient to use and capable of achieving preparation of high-purity zinc and achieving clean environmentally friendly production of high-purity zinc through low-grade zinc ore extraction and separation. The device has important economic value and social value.

Owner:CHENGDU CHUANGWEIKAI TECH INFORMAITON CONSULTING CO LTD

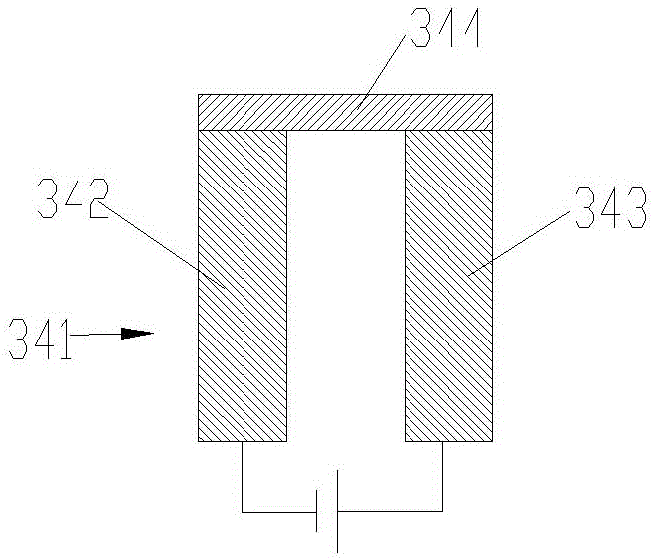

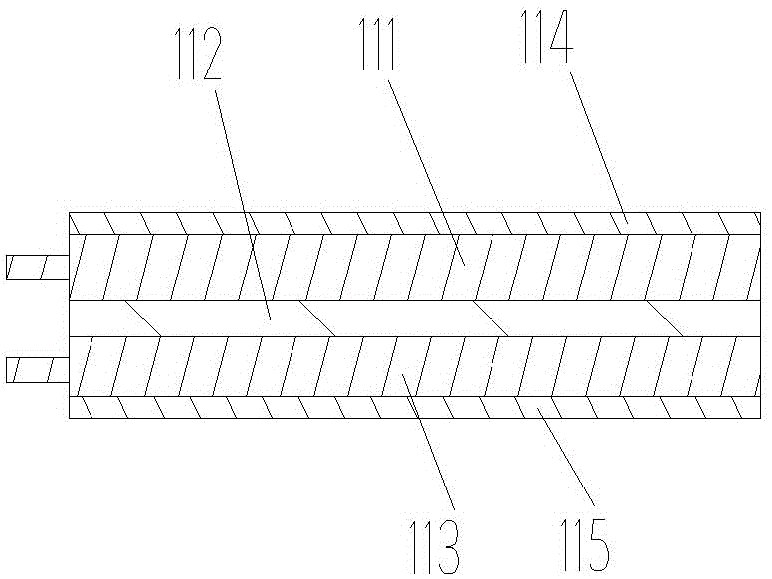

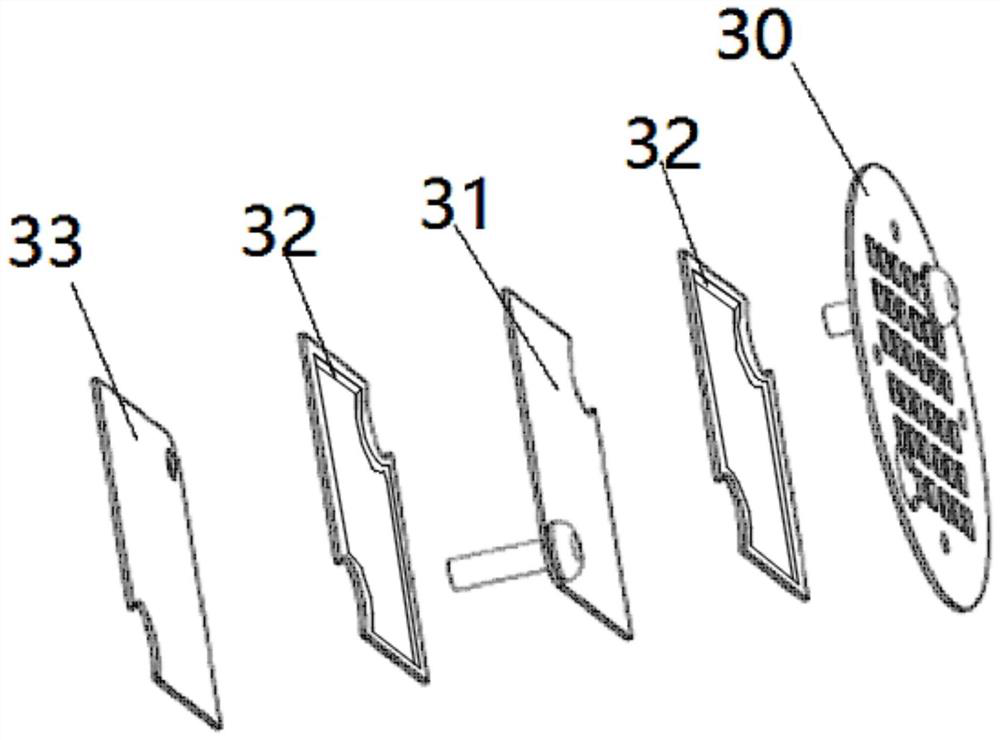

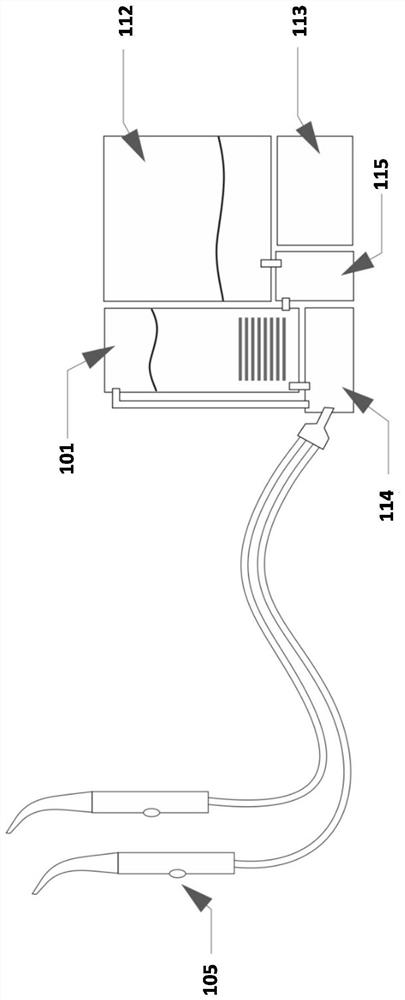

Improvement method and structure of ozone mouthwash instant generation device

PendingCN113388855AIncrease the ozone contentSpeed up electrolysisCellsCosmetic preparationsEngineeringElectrolysis of water

The invention provides an improvement method and structure of an ozone mouthwash instant generation device. The improvement method comprises the following steps that an electrode assembly protective cover of an original ozone mouthwash instant generation device is replaced with an element which can be used as a cathode; the element is paired with an anode plate of the original ozone mouthwash instant generation device, and an electrode separation device is arranged between the element and the anode plate; and a hydrogen release channel is formed by arranging electrode holes in the cathode plate, the anode plate and an element capable of being used as the cathode of the original ozone mouthwash instant generation device in a staggered manner. According to the invention, the element which can be used as the cathode is added, so that the electrode area is effectively increased, the catalytic efficiency is improved, rapid electrolysis of water molecules is promoted, and the purpose of increasing the ozone content in water is achieved. The electrode holes are distributed in a staggered manner, so that hydrogen is difficult to retain in water, the hydrogen is prompted to be quickly discharged, and the influence of hydrogen reduction on ozone generation is reduced.

Owner:SHANGHAI XIYUN ENVIRONMENTAL PROTECTION TECH CO LTD +1

A ceramic composite belt with high breakdown resistance, fire prevention and fire resistance and its preparation method

ActiveCN106349698BImprove flame retardant performanceImprove insulation performanceSynthetic resin layered productsRubber layered productsCeramic compositeVulcanization

The invention discloses ceramic fireproof and fire-resistant silicone rubber, a method for preparing the same, a ceramic compound belt with the ceramic fireproof and fire-resistant silicone rubber and a method for preparing the ceramic compound belt, and belongs to the technical field of ceramic compound belts. The ceramic fireproof and fire-resistant silicone rubber is made of, by weight, 100 parts of silicone rubber, 20-70 parts of silicon dioxide, 1-15 parts of dimethyldiethoxysilane, 20-60 parts of ceramic powder, 1-5 parts of stearic acid, 20-100 parts of flame retardants, 1-30 parts of magnesium oxide, 20-60 parts of magnesium hydroxide and 0.5-5 parts of silane coupling agents. The ceramic fireproof and fire-resistant silicone rubber and polyimide rubber belts are vulcanized and compounded with one another to obtain the ceramic compound belt with high breakdown resistance and fireproof and fire-resistant performance. The ceramic fireproof and fire-resistant silicone rubber, the methods and the ceramic compound belt have the advantages that the ceramic compound belt is excellent in breakdown-resistant performance, good in fireproof and fire-resistant performance and convenient to wind and coat, and has certain tensile properties.

Owner:东莞市裕天硅橡胶科技有限公司

Quick silver recovering machine

InactiveCN109183070AAchieve flowSpeed up electrolysisElectrolysis componentsPhotography auxillary processesElectrolyteBiochemical engineering

The invention belongs to the technical field of silver recovery, and particularly discloses a quick silver recovering machine. The machine comprises a bottom plate; two moving devices are symmetrically arranged at the bottom end of the bottom plate; an electrolytic tank is arranged above the bottom plate; a propeller is arranged inside the electrolytic tank; a servo motor is arranged between the bottom plate and the electrolytic tank; the tail end of an output shaft of the servo motor rises to penetrate through the electrolytic tank and is fixedly connected with the propeller; supporting columns are arranged at two side ends of the electrolytic tank; and shock absorbing devices are arranged between the bottom end of the supporting columns and the bottom plate through supports. The machineis novel in structure, the quick silver recovering machine is realized conveniently through the simple structure, flowing of an inside electrolyte can be realized conveniently, and then the recovery process of silver can be accelerated.

Owner:贵州融晟环保科技有限公司

Method for degrading large-molecular weight polysaccharide containing beta-1,3-glucosidic bonds

ActiveCN106146683AEvenly dispersedSpeed up electrolysisOrganic active ingredientsElectrolysis componentsHydrogen peroxide degradationOxygen

The invention relates to a method for degrading large-molecular weight polysaccharide containing beta-1,3-glucosidic bonds. The method comprises the specific steps that a large-molecular weight polysaccharide solution containing beta-1,3-glucosidic bonds with the concentration being 60-200 mg / mL is introduced into an electrolytic cell provided with cathodes and anodes, the solution is adjusted to be acid, oxygen is introduced into the cathode on the basis of the amount of the 4.0-8.0 L oxygen / L polysaccharide solution, direct current is introduced and controls the current density of the cathode to be 9-14 mA / cm<2>, on the condition, degradation is performed, and an electrolyte is collected. The method is simple technology and easy to implement, time is saved, the method is efficient, and large-scale production is promoted; reaction conditions are mild, and environment pollution is small; importantly, compared with acid process degradation and hydrogen peroxide degradation method, the polysaccharide degradation rate is high through the electric Fenton method, and the range of the obtained low-molecular-weight polysaccharide molecular weight is narrower on the condition that the polysaccharide of equivalent molecular weight is degraded.

Owner:北京颐方生物科技有限公司

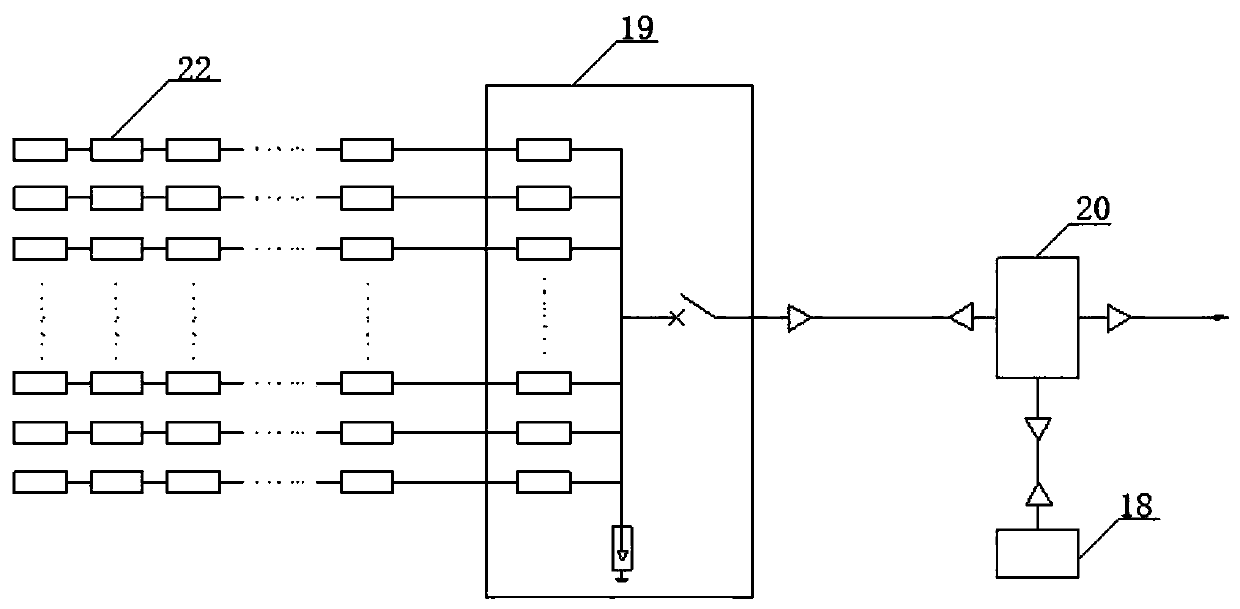

A system using biological urea to generate electricity

ActiveCN107237687BEasy to getGet fastElectrolysis componentsInternal combustion piston enginesElectrolysisPtru catalyst

The invention discloses a system for generating electricity by adopting biological urea. The system comprises a solar power, a gas storage cylinder and a generator, wherein the solar power is connected with a urea electrolysis cylinder through a three-core cable; the inlet end of the gas storage cylinder is connected with the top of the urea electrolysis cylinder through a pipeline, and the outlet end of the gas storage cylinder is connected with a gas engine through a pipeline; and the input end of the generator is connected with the gas engine, and the output end of the generator is connected with a local power distributing cabinet and a user power distributing cabinet. The system has the beneficial effects that a direct-current power which is obtained through solar photovoltaic power generation is utilized as an electrolysis power, so that energy is saved, and the system is safe and reliable; in the electrolysis state, sea water is introduced in the enable a urea solution to show alkali, so that hydrogen is generated more easily during performance of electrolysis, and the sea water is easily available; a nickel alloy is used as a catalyst which can accelerate electrolysis of the urea solution; urine of humans or animals is utilized, and is dehydrated to get the urea solution with certain concentration; the urea solution then is electrolyzed to generate hydrogen which serves as fuel for power generation; and the urine is convenient to get, so that comprehensive new-energy power generation is realized.

Owner:DATANG ENVIRONMENT IND GRP

Electrolyzed Water Scale

ActiveCN107669361BMaintain healthEasy to killTooth rinsingDental surgeryElectrolysed waterElectric machinery

The invention relates to an electrolysis water toothpick. The electrolysis water toothpick comprises a water trough provided with a water inlet and a water outlet, a water electrolysis device and a water outlet pipe, wherein the bottom of the water outlet is close to the water trough, the water electrolysis device is arranged in the water trough to electrolyze water in the water trough into hydrogen and oxygen, and the water outlet pipe is connected with the water outlet. The invention also relates to a method for operating the electrolysis water toothpick. By adopting the electrolysis water toothpick or the method, water-draining mechanical parts such as motors can be omitted, and meanwhile a sterilization function is provided without additional sterilization preparations.

Owner:孙恒

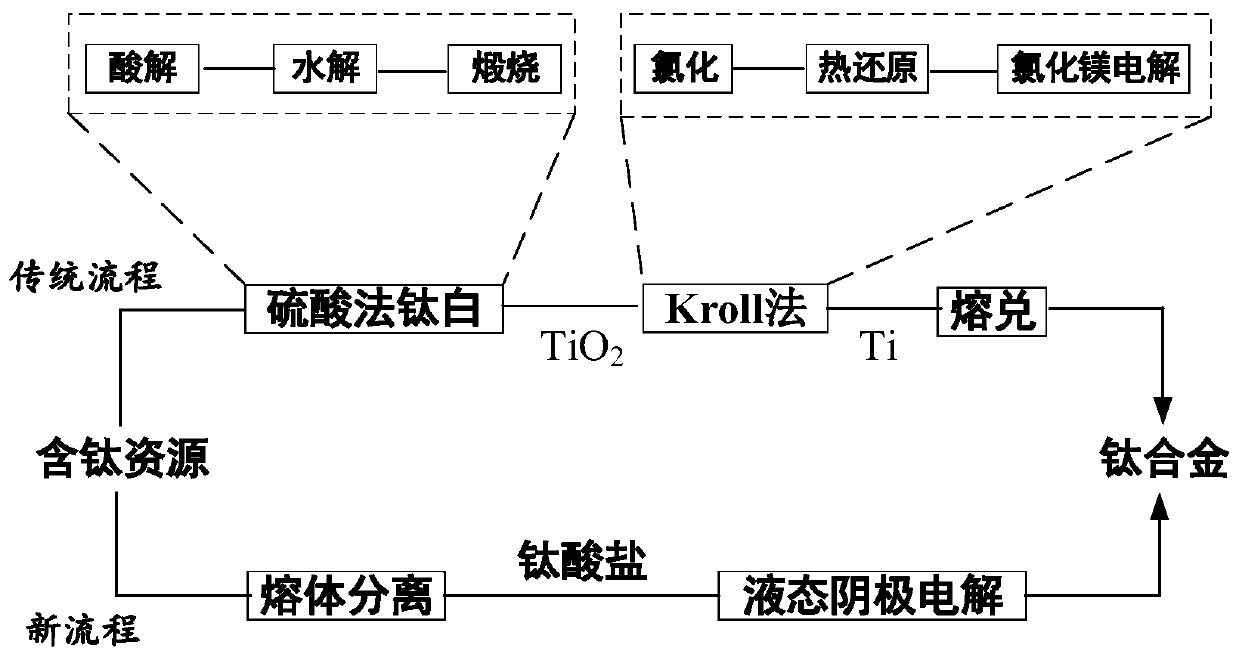

Method for preparing titanium alloy by carrying out molten salt electrolysis on soluble titanate through liquid metallic cathode

The invention discloses a method for preparing a titanium alloy by carrying out molten salt electrolysis on soluble titanate through a liquid metallic cathode. The method comprises the following stepsthat metal serving as the liquid cathode is contained in a silicon nitride crucible, the silicon nitride crucible is put in a graphite crucible, fluoride molten salt containing titanate with the masspercent ranging from 1% to 10% is added into the graphite crucible, the graphite crucible is put in a closed steel reactor, the temperature is increased to 300 DEG C under the argon atmosphere, constant-temperature operation is carried out for 24 h, and water in the molten salt is removed; the temperature is increased to range from 800 DEG C to 1000 DEG C, graphite is adopted as an anode, the liquid metal is adopted as the cathode, and constant-voltage electrolysis is carried out at the voltage ranging from 2.5 V to 4.5 V; and after electrolysis is finished, the silicon nitride crucible containing the liquid metallic cathode is lifted out from the molten salt, constant-temperature operation continues to be carried out for 0.5 h to 5 h, cooling is carried out to room temperature, cathode surface products are separated, and the titanium alloy is obtained. According to the method, the process is obviously shortened; application of concentrated sulfuric acid, chlorine and other corrosiveand contaminative chemical reagents is avoided, environment friendliness is achieved, the requirement for equipment materials is low, and operation is simple; and the liquid cathode has the function of depolarization on titanate reduction, and electrolysis and in-situ alloying of titanate can be enhanced.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com