Treatment method of EDTA complexing nickel wastewater

A treatment method and technology for nickel wastewater, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that the total nickel in the effluent cannot meet the discharge standard, the wastewater treatment efficiency is low, and the network is broken. Insufficient and other problems, to achieve the effect of reducing electrolysis energy consumption and chemical consumption, reducing the amount, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

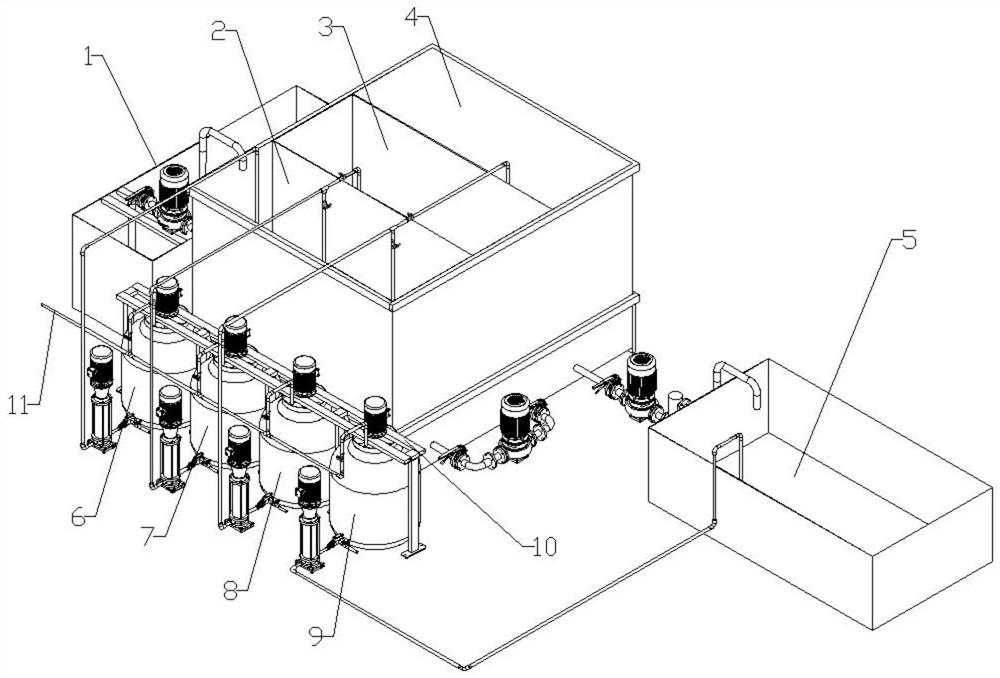

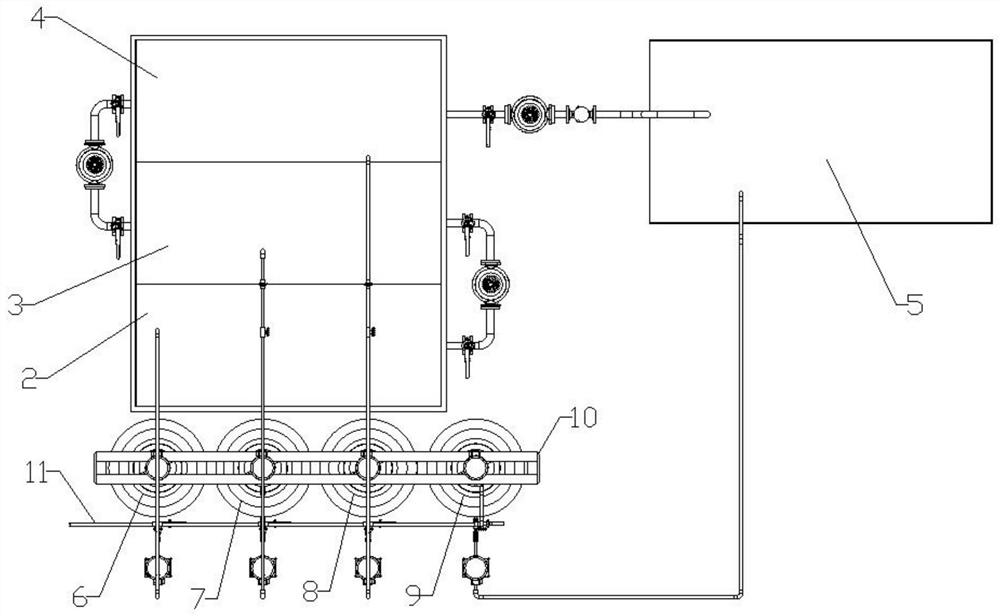

[0036] The processing method of EDTA complexed nickel waste water specifically comprises the steps:

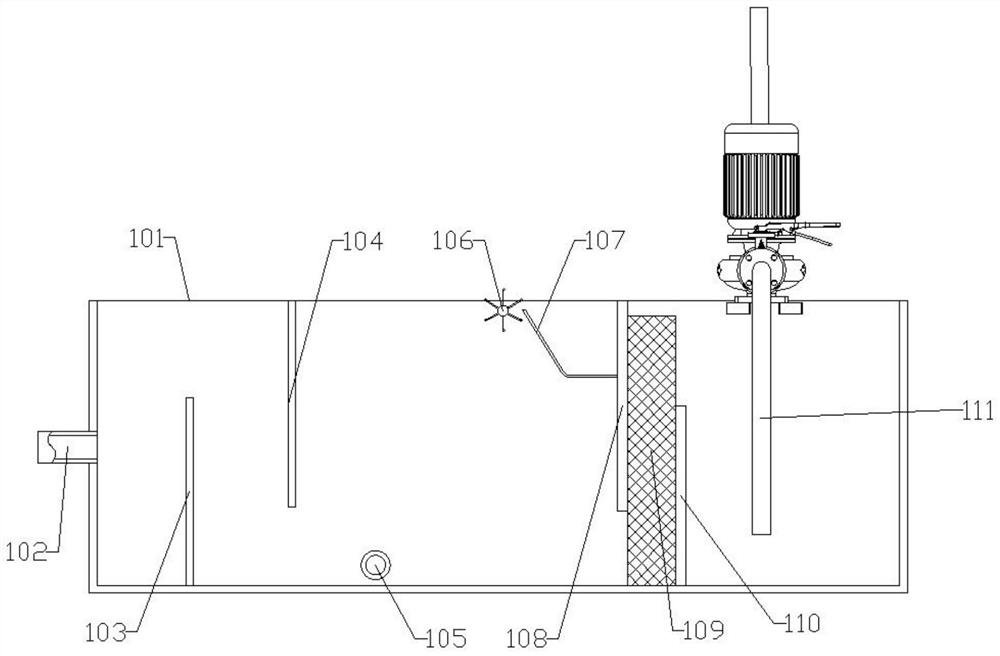

[0037] Step 1. Pretreat the EDTA-complexed nickel wastewater through an activated carbon filter, pump it into the acid analysis separation tank 1 of the complex nickel wastewater treatment device, adjust the pH value to 2, let it stand for 30 minutes, carry out acid analysis and separation of organic matter, and then filter Suspended solids are obtained for primary treatment of wastewater;

[0038] Step 2: Pump primary treated wastewater into the first electrolytic cell 2, pump ferrous sulfate solution into the first electrolytic cell 2 with a flow rate of 160L / h, and pump sodium hypochlorite solution into the first electrolytic cell 2 with a flow rate of 30L / h , pump hydrogen peroxide into the first electrolytic cell 2 with a flow rate of 18L / h, and set the current density of the titanium-based loaded lead dioxide electrode to be 10mA / cm 2 , control the oxidation-reduction p...

Embodiment 2

[0045] The processing method of EDTA complexed nickel waste water specifically comprises the steps:

[0046] Step 1. Pretreat the EDTA-complexed nickel wastewater through an activated carbon filter, pump it into the acid analysis and separation tank 1 of the complexed nickel wastewater treatment device, adjust the pH value to 3, let it stand for 30 minutes, carry out acid analysis and separation of organic matter, and then filter Suspended solids are obtained for primary treatment of wastewater;

[0047] Step 2: Pump primary treated wastewater into the first electrolytic cell 2, pump ferrous sulfate solution into the first electrolytic cell 2 with a flow rate of 170L / h, and pump sodium hypochlorite solution into the first electrolytic cell 2 with a flow rate of 35L / h , pump hydrogen peroxide into the first electrolytic cell 2 with a flow rate of 22L / h, and set the current density of the titanium-based loaded lead dioxide electrode to be 10mA / cm 2 , control the oxidation-reduc...

Embodiment 3

[0054] The processing method of EDTA complexed nickel waste water specifically comprises the steps:

[0055] Step 1. Pretreat the EDTA-complexed nickel wastewater through an activated carbon filter, pump it into the acid analysis and separation tank 1 of the complexed nickel wastewater treatment device, adjust the pH value to 4, let it stand for 30 minutes, carry out acid analysis and separation of organic matter, and then filter Suspended solids are obtained for primary treatment of wastewater;

[0056] Step 2: Pump primary treated wastewater into the first electrolytic cell 2, pump ferrous sulfate solution into the first electrolytic cell 2 with a flow rate of 180L / h, and pump sodium hypochlorite solution into the first electrolytic cell 2 with a flow rate of 40L / h , pump hydrogen peroxide into the first electrolytic cell 2 with a flow rate of 26L / h, and set the current density of the titanium-based loaded lead dioxide electrode to be 10mA / cm 2 , control the oxidation-reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com