Synthetic ammonia organic wastewater divalent salt recycling and zero discharge process

An organic waste water and recycling technology, applied in inorganic chemistry, general water supply conservation, water pollutants, etc., can solve the problems of zero discharge treatment cost of waste water, frequent cleaning of fouling membranes, poor biodegradability, etc., and reduce operating costs. , avoid corrosion and scaling problems, avoid organic pollution and fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

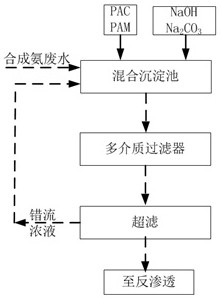

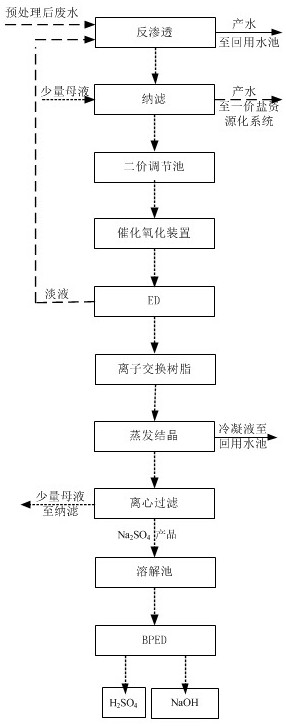

[0041] like figure 1 and 2 , the treated synthetic ammonia wastewater reverse osmosis concentrated water, the main water quality index contains 5.12g / L Na + , 0.67g / L of Cl - , 9.57g / L SO 4 2- , 142ppm Ca 2+ , 107ppm Mg 2+ , COD of 180ppm.

[0042] like figure 1 and 2 , a divalent salt resource and zero discharge process of synthetic ammonia organic waste water, the steps are as follows:

[0043] S1: Synthetic ammonia wastewater is biochemically treated in the pretreatment tank, and sodium carbonate and sodium hydroxide are added to the effluent to remove Ca in the water 2+ , Mg 2+ Reduce the hardness of concentrated water, add coagulant polyaluminum chloride (PAC) and coagulant polyacrylamide (PAM) at the same time, combine chemical precipitation principle, coagulation mechanism and high-density precipitation mechanism, and finally pass a series of reaction processes Adsorption removes suspended solids, colloids, bacteria, fluoride, alkalinity and hardness in raw w...

Embodiment example 2

[0055] In the present invention, the treated synthetic ammonia waste water reverse osmosis concentrated water, the main water quality index contains 4.1g / L Na + , 0.53g / L of Cl - , 9.12g / L of SO 4 2- , 130ppm Ca 2+ , 95ppm Mg 2+ , 160ppm of COD.

[0056] like figure 1 and 2 , a divalent salt resource and zero discharge process of synthetic ammonia organic waste water, the steps are as follows:

[0057] S1: Synthetic ammonia wastewater is biochemically treated in the pretreatment tank, and sodium carbonate and sodium hydroxide are added to the effluent to remove Ca in the water 2+ , Mg 2+ Reduce the hardness of concentrated water, add coagulant polyaluminum chloride (PAC) and coagulant polyacrylamide (PAM) at the same time, combine chemical precipitation principle, coagulation mechanism and high-density precipitation mechanism, and finally pass a series of reaction processes Adsorption removes suspended solids, colloids, bacteria, fluoride, alkalinity and hardness in r...

Embodiment example 3

[0069] In the present invention, the treated synthetic ammonia waste water reverse osmosis concentrated water, the main water quality index contains 6.4g / L Na + , 1.3g / L Cl - , 11.6g / L SO 4 2- , 168ppm Ca 2+ , 80-121ppm of Mg 2+ , COD of 210ppm.

[0070] like figure 1 and 2 , a divalent salt resource and zero discharge process of synthetic ammonia organic waste water, the steps are as follows:

[0071] S1: Synthetic ammonia wastewater is biochemically treated in the pretreatment tank, and sodium carbonate and sodium hydroxide are added to the effluent to remove Ca in the water 2+ , Mg 2+ Reduce the hardness of concentrated water, add coagulant polyaluminum chloride (PAC) and coagulant polyacrylamide (PAM) at the same time, combine chemical precipitation principle, coagulation mechanism and high-density precipitation mechanism, and finally pass a series of reaction processes Adsorption removes suspended solids, colloids, bacteria, fluoride, alkalinity and hardness in r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com