Method for treating recycling of coking wastewater

A coking wastewater and treatment method technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems that have not been practically applied, achieve stable treatment effects, and low production and operation costs , The effect of easy operation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

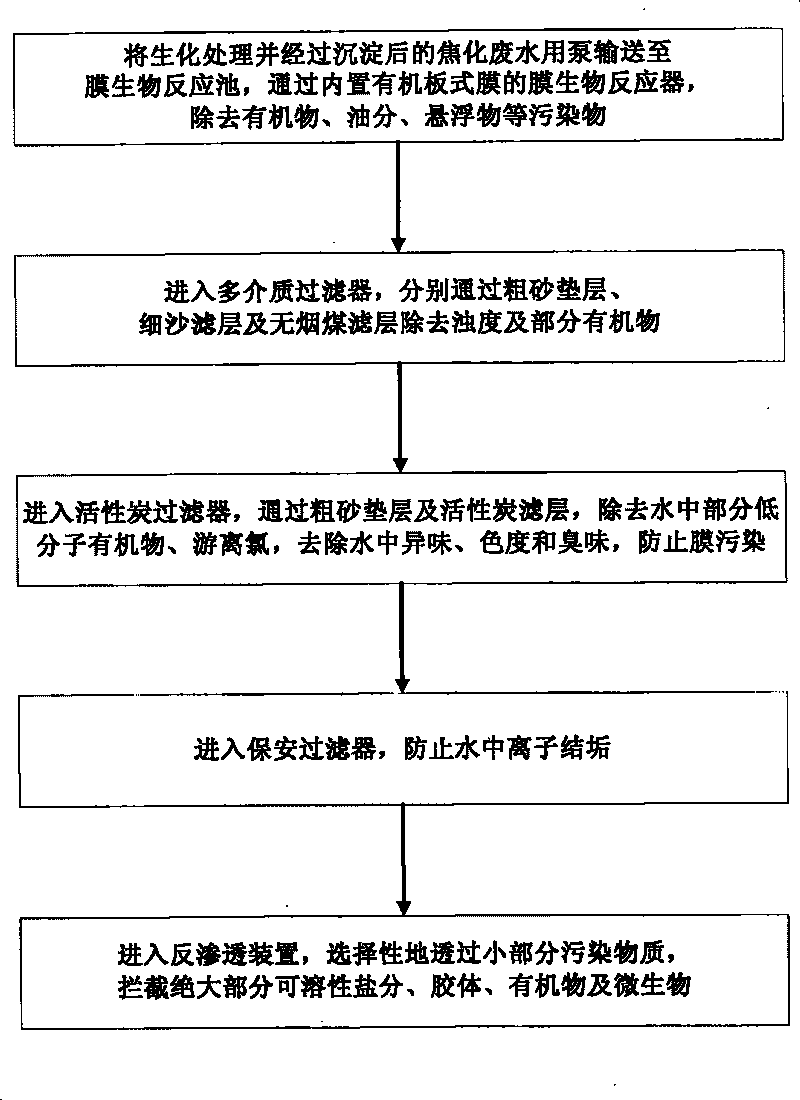

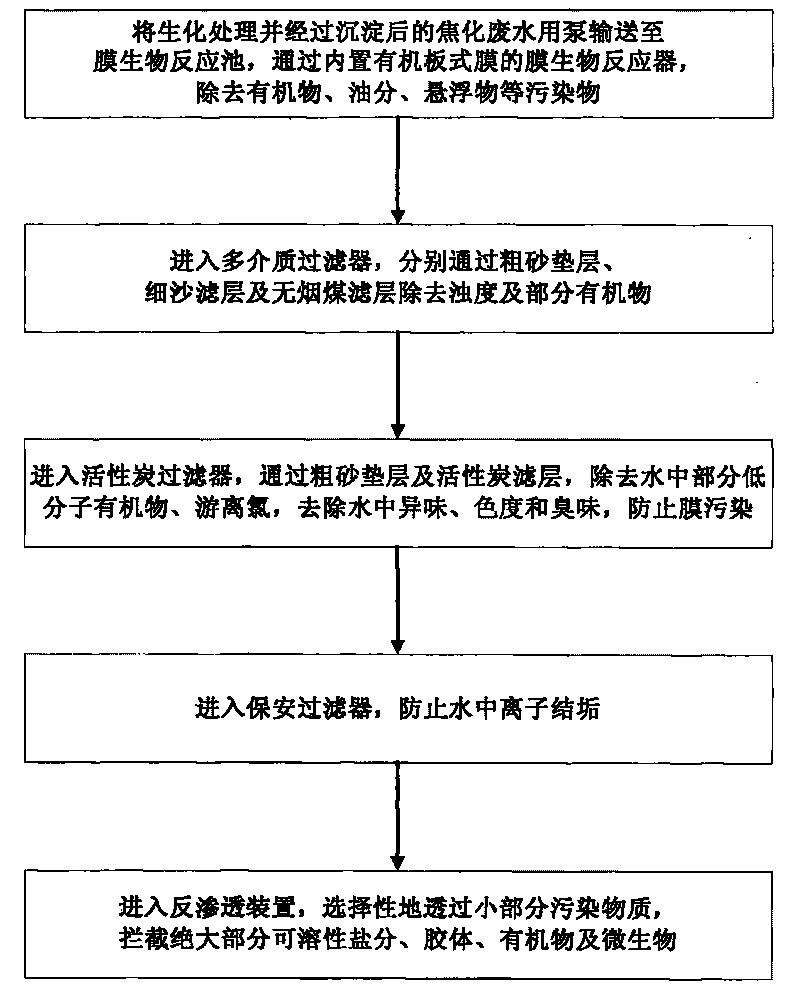

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] Referring to accompanying drawing, according to a kind of processing method of coking waste water reuse of the present invention, process flow is carried out according to the following steps:

[0032] A. Pump the biochemically treated and precipitated coking wastewater to the membrane bioreactor, and pass through the membrane bioreactor. The membrane bioreactor adopts the form of a built-in organic plate membrane to remove organic matter, oil, suspended matter and other pollutants.

[0033] B. Enter the multi-media filter, and remove turbidity and some organic matter through the coarse sand cushion, fine sand filter layer and anthracite filter layer.

[0034] C. Enter the activated carbon filter, pass through the coarse sand cushion and activated carbon filter layer, remove part of the low-molecular organic matter and free chlorine in the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com