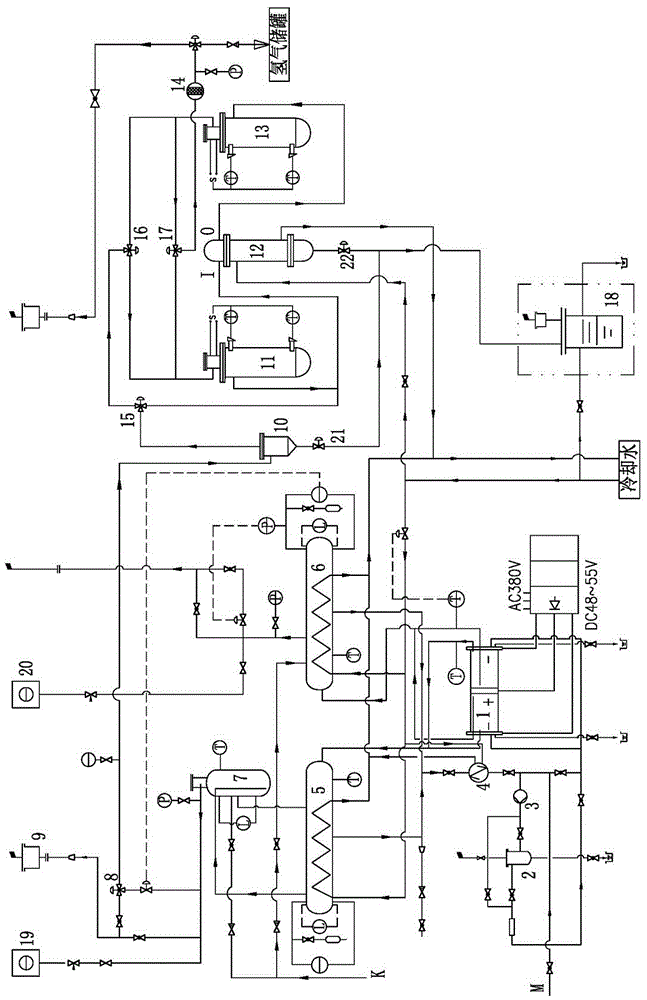

Alkaline solution electrolytic hydrogen production device and hydrogen production method

A hydrogen production device and alkaline solution technology, applied in the electrolysis process, electrolysis components, separation methods, etc., can solve the problems of low electrolysis efficiency, inconvenient control of the hydrogen production process, and unusable production practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

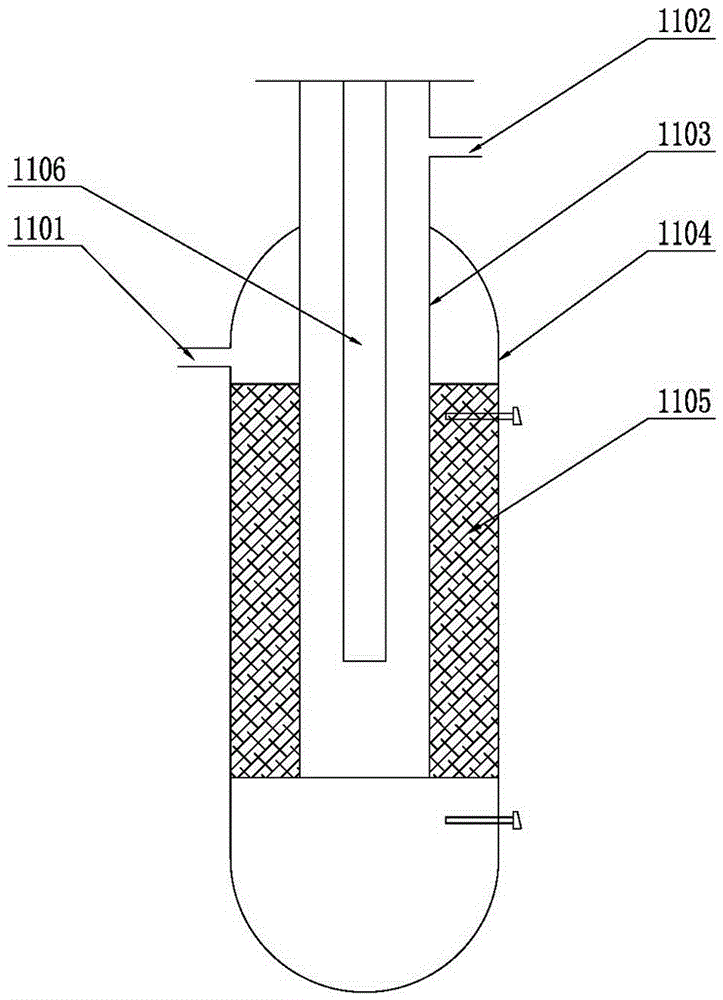

Method used

Image

Examples

Embodiment 2

[0031] A method for producing hydrogen by electrolysis using the above-mentioned device, which uses KOH lye as the electrolyte, the mass percentage concentration of alkali in the lye in the electrolytic cell 1 is 25%, the working temperature of the electrolytic cell 1 is 85-90°C, and the rated The current is 900A, the voltage is 48V; V with a mass concentration of 0.2% is added to the electrolyte 2 o 5 .

Embodiment 3

[0033] Another method for producing hydrogen by electrolysis using the above-mentioned device, which uses KOH lye as the electrolyte, the mass percentage concentration of alkali in the lye in the electrolytic cell 1 is 30%, the working temperature of the electrolytic cell 1 is 90°C, and the rated current 950A, voltage 55V; V with a mass concentration of 0.3% is added to the electrolyte 2 o 5 .

Embodiment 4

[0035] The third method utilizes the above-mentioned device to produce hydrogen by electrolysis, which uses NaOH lye as the electrolyte, the mass percentage concentration of alkali in the lye in the electrolytic cell 1 is 25 to 30%, and the working temperature of the electrolytic cell 1 is 85 to 90 ℃, rated current 900~950A, voltage 48~55V; V with a mass concentration of 0.2~0.3% is added to the electrolyte 2 o 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com