Electric arc ion plating apparatus

A technology of arc ion plating and equipment, which is applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., and can solve the problem of protection and modification of the inner surface of long tubes and inner walls of deep hole devices and modified films or coatings Uniformity and poor binding force, etc., to reduce the content of large particles and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

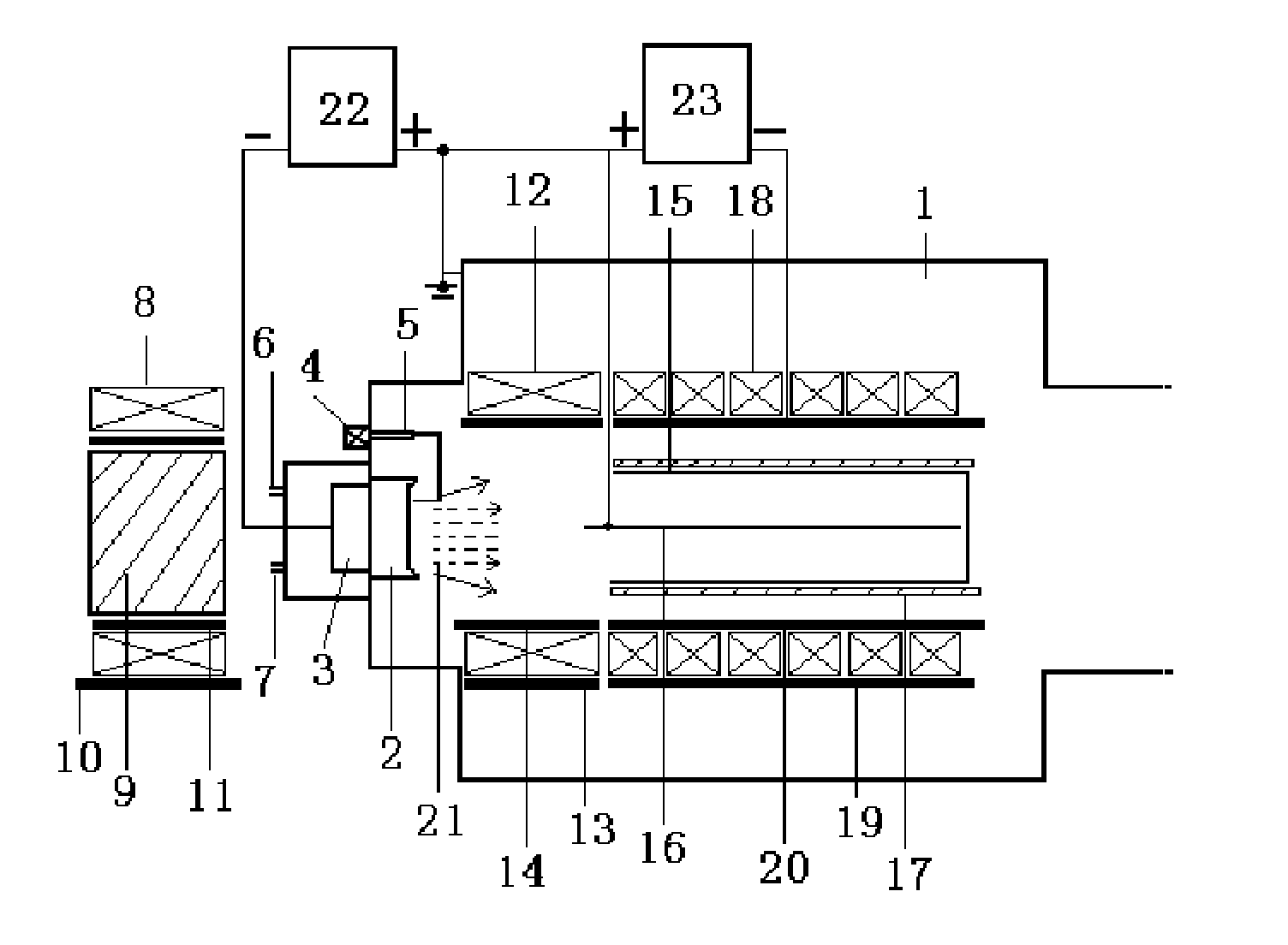

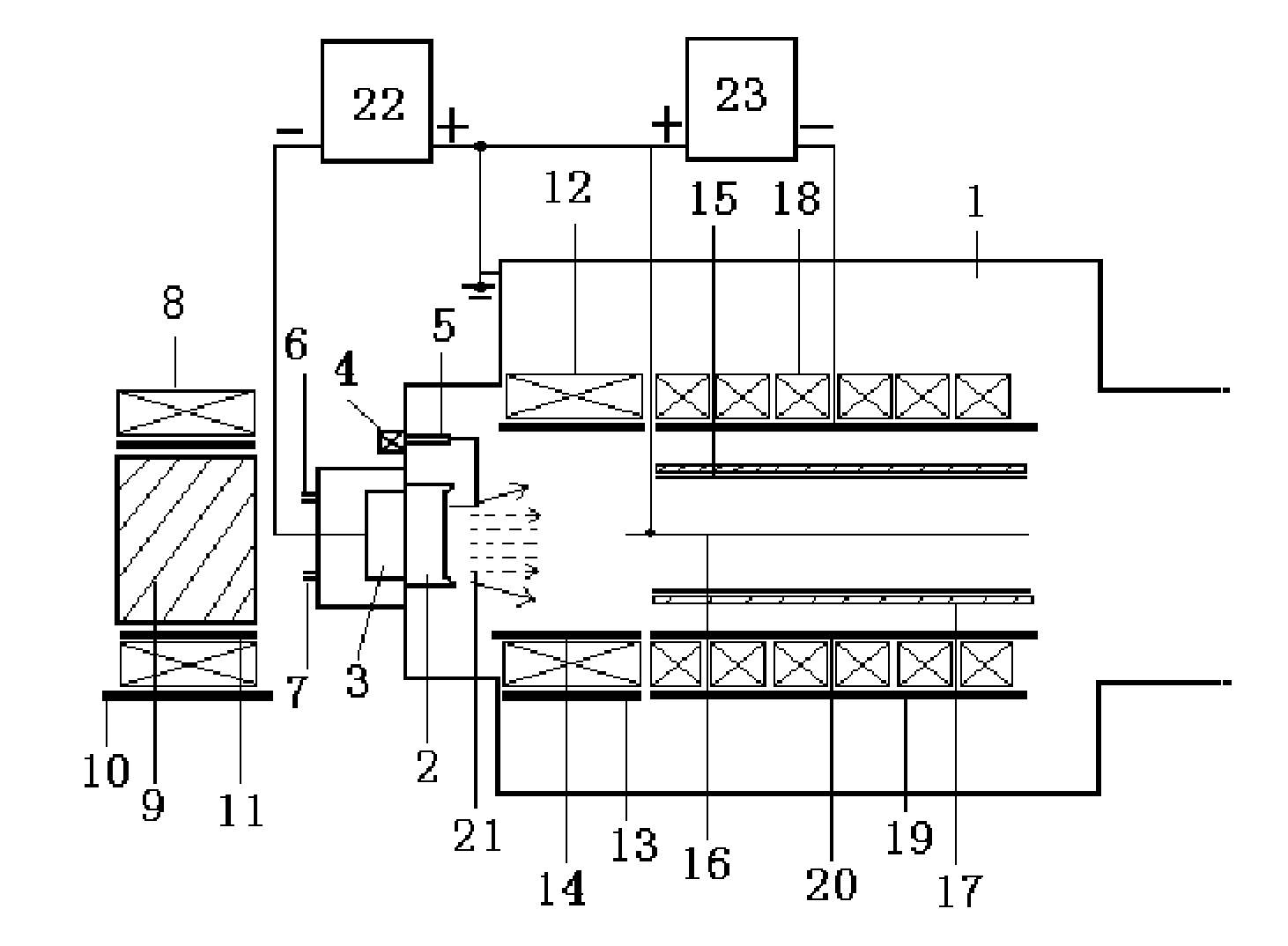

[0041] Such as figure 1 As shown, an arc ion plating equipment is provided with three sets of magnetic field generating devices, including: a first magnetic field generating device for focusing the metal ion flow emitted by the cathode target, which is arranged outside the vacuum chamber 1 The position corresponding to the back of the cathode target 2; the first magnetic field generator is the first electromagnetic coil 8 or annular permanent magnet with nickel-plated pure iron 9 installed in the middle, and the first electromagnetic coil 8 or annular permanent magnet passes through the first support cylinder 11 Or use a support frame structure to fix on the movable first workbench 10 connected to the equipment shell, the central axis of the first magnetic field generating device coincides with the central axis of the cathode target 2, and the generated magnetic induction intensity is 1000-5000Gauss, the first The inner diameter of the support tube 11 or the side length of the...

Embodiment 2

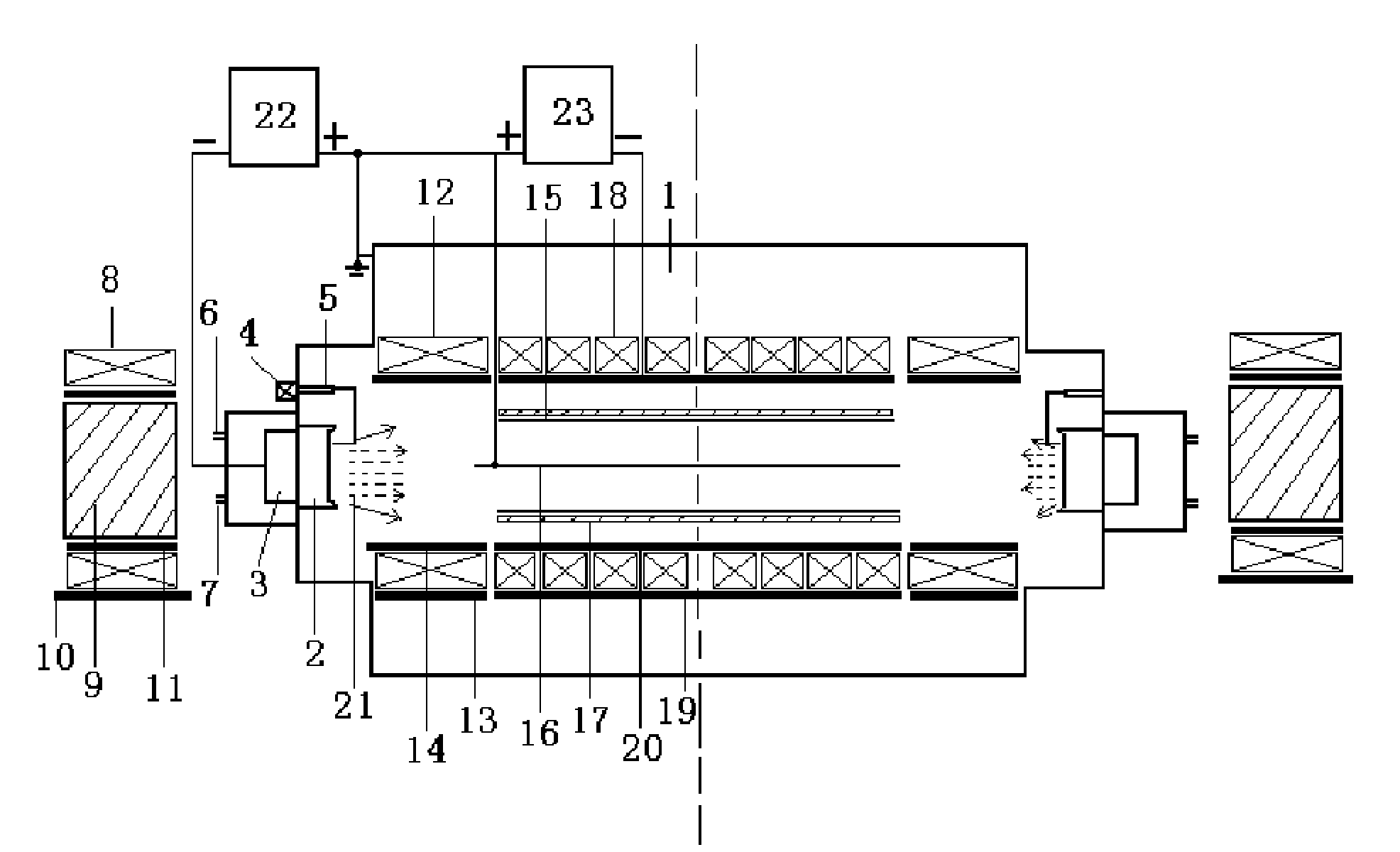

[0049] Such as image 3 As shown, the difference from Example 1 is that for through-hole long tubes or deep hole devices, a symmetrical magnetic field device structure and a cathode target structure are used to simultaneously protect the inner surface of the tube and modify the film or coating from both ends of the hole. layer, so that the length of the processed long tube can be doubled, three sets of magnetic field generators and cathode targets of the arc ion plating equipment in embodiment 1 are symmetrically provided with another three sets of magnetic field generators and cathode targets, and its structure The structure is the same as that of the three sets of magnetic field generating devices in Example 1, symmetrical structure, the symmetrical plane is the surface where the end of the third magnetic field generating device is located and is perpendicular to the workpiece, the symmetrical magnetic field structure and the cathode target structure are simultaneously carrie...

example 1

[0051] Example 1: Deposition of titanium nitride coating on the inner surface of stainless steel pipe

[0052] Adopt the equipment of embodiment 1, select the stainless steel pipe of Φ 14 * 300mm that the wall thickness is 3mm, put into the protective overcoat after dilute phosphoric acid cleaning, dehydrated alcohol ultrasonic cleaning, drying, put into the workpiece platform, make the stainless steel pipe The centerline coincides with the axis of the cathode target. The vacuum chamber is evacuated to 3×10 -3 After Pa, argon was introduced and the gas pressure in the vacuum chamber was maintained at 2.0Pa. Adjust the electromagnetic coil current of the first magnetic field generating device outside the vacuum chamber to 3.7A (corresponding to a magnetic induction of 3000Gauss); adjust the current of the bunching electromagnetic coil in the vacuum chamber, that is, the second magnetic field generating device to 2.1A (corresponding to a magnetic induction of 1000Gauss); adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com