Metal support surface modification method

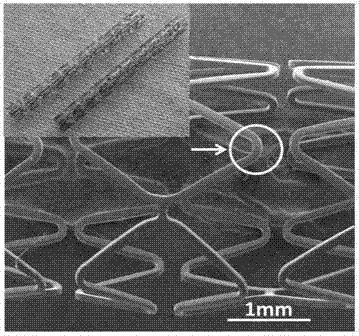

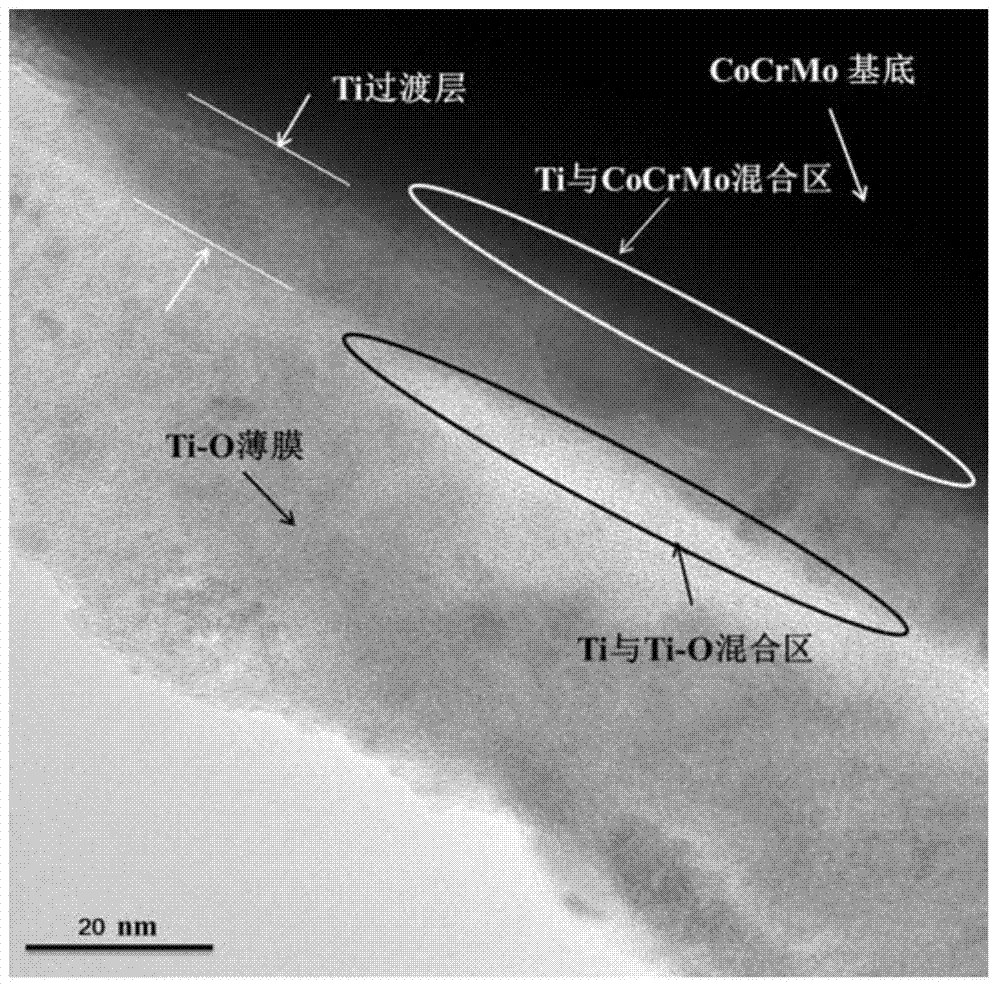

A metal stent and surface modification technology, which is applied in the direction of stent, metal material coating process, ion implantation plating, etc., can solve the problems of low film surface quality, easy sparking, and low bonding strength, so as to reduce restenosis rate and late thrombosis rate, high density and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A. Ultrasonic clean the cobalt alloy bracket in alcohol and distilled water for 20 minutes, take it out, and dry it for later use;

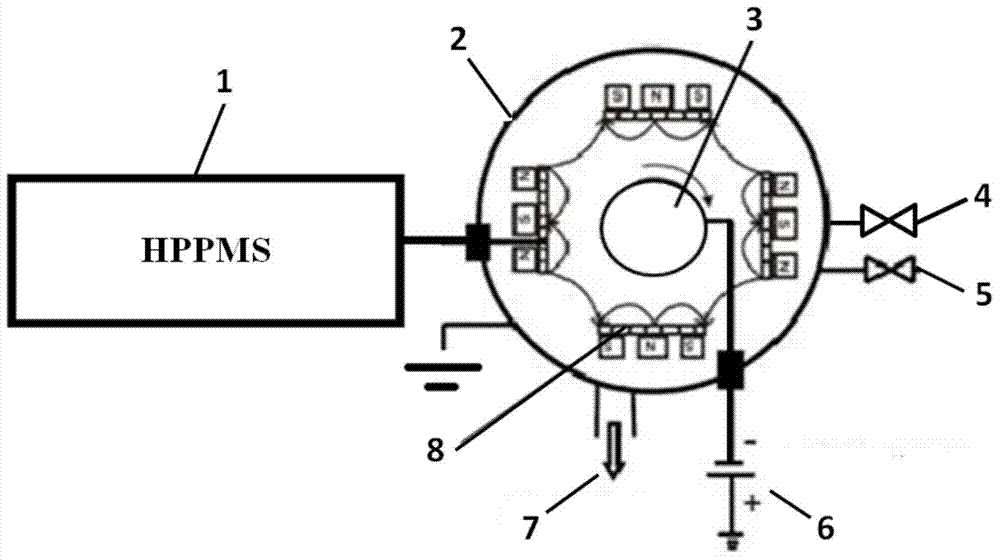

[0029] B. Open the vacuum chamber 2 of the high-power pulse magnetron sputtering device, install a sputtering titanium target 8 with a purity of 99.99%, put the cobalt alloy bracket into the vacuum chamber 2, close the vacuum chamber, and evacuate to 0.5×10 -3 Pa.

[0030] C. Open the gas valve 4, pass argon gas into the vacuum chamber 2 to a pressure of 0.5 Pa, turn on the sputter cleaning power supply, sputter clean the titanium target for 8 minutes, turn off the argon gas and the sputter cleaning power supply.

[0031] D. Open the gas valve 4, introduce argon gas into the vacuum chamber 2 to a pressure of 1 Pa, use radio frequency discharge to form argon plasma, turn on the bias power supply 6, and apply a -300V bias on the cobalt alloy stent to Perform sputter cleaning for twenty minutes, then turn off the argon gas and the bias power supply ...

Embodiment 2

[0037] A. The stainless steel bracket is ultrasonically cleaned in alcohol and distilled water for 20 minutes and taken out, dried for later use;

[0038] B. Open the vacuum chamber 2 of the high-power pulse magnetron sputtering device, install a sputtering titanium target 8 with a purity of 99.99%, put the stainless steel bracket into the vacuum chamber 2, close the vacuum chamber, and evacuate to 0.5×10 -3 Pa.

[0039] C. Open the gas valve 4, pass argon gas into the vacuum chamber 2 to a pressure of 0.5 Pa, turn on the sputter cleaning power supply, sputter clean the titanium target for 8 minutes, close the gas valve and the sputter cleaning power supply.

[0040] D. Open the gas valve 4, pass argon gas into the vacuum chamber 2 to a pressure of 0.5 Pa, use radio frequency discharge to form argon plasma, turn on the bias power supply 6, and apply a -50V bias on the stainless steel bracket to perform Sputter cleaning for 10 minutes, then close the gas valve 4 and the bias power sup...

Embodiment 3

[0044] A. Ultrasonic clean the titanium alloy bracket in alcohol and distilled water for 30 minutes, take it out, and dry it for later use;

[0045] B. Open the vacuum chamber 2 of the high-power pulse magnetron sputtering device, install a sputtering titanium target 8 with a purity of 99.99%, put the titanium alloy bracket into the vacuum chamber 2, close the vacuum chamber 2, and evacuate to 1×10 -3 Pa.

[0046] C. Open the gas valve 4, pass argon gas into the vacuum chamber 2 to a pressure of 1 Pa, turn on the sputter cleaning power supply, sputter clean the titanium target for 85 minutes, close the gas valve 4 and the sputter cleaning power supply.

[0047] D. Open the gas valve 4, inject argon gas into the vacuum chamber 2 to a pressure of 2Pa, use radio frequency discharge to form argon plasma, turn on the bias power supply 6, and apply a -500V bias on the titanium alloy stent. Perform sputtering cleaning for 20 minutes, and then close the gas valve 4 and the bias power supply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com