A kind of electroplating device for faucet manufacturing

A technology for electroplating devices and faucets, which is applied in the direction of electrolytic components, electrolytic processes, cells, etc., can solve problems such as uneven electroplating and faucet movement, and achieve the effects of speeding up water flow, saving time, and speeding up the electroplating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

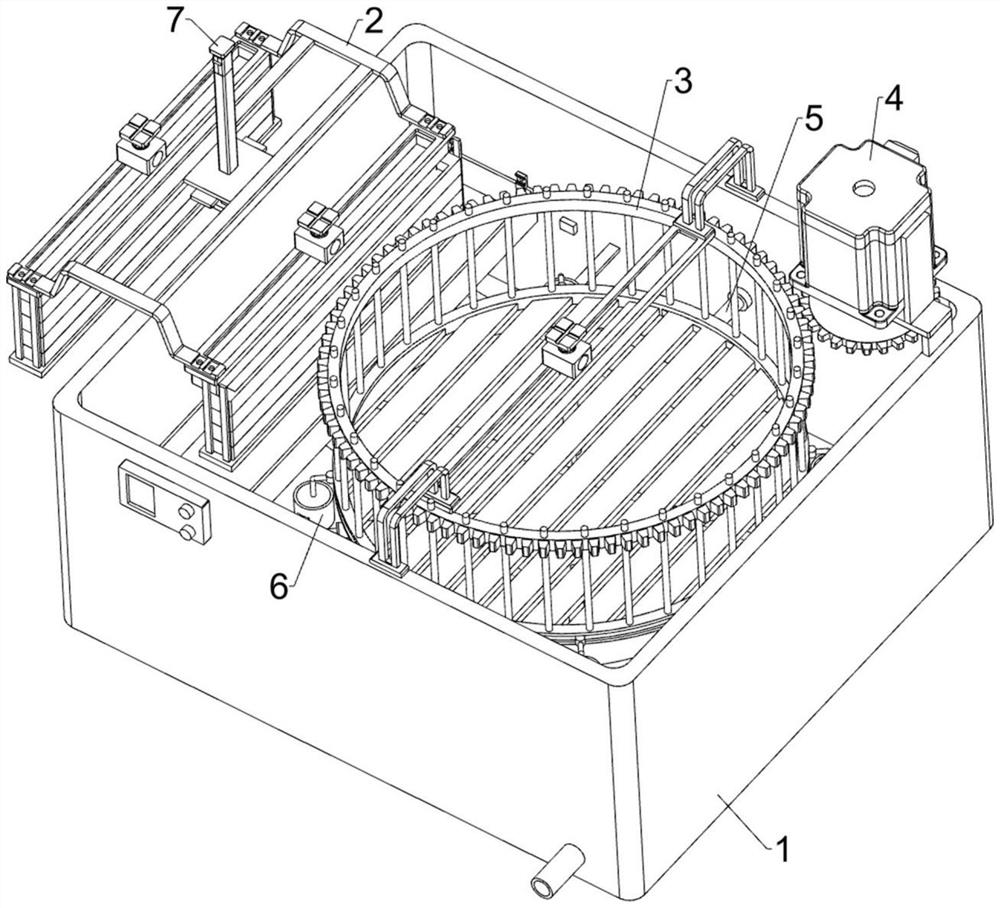

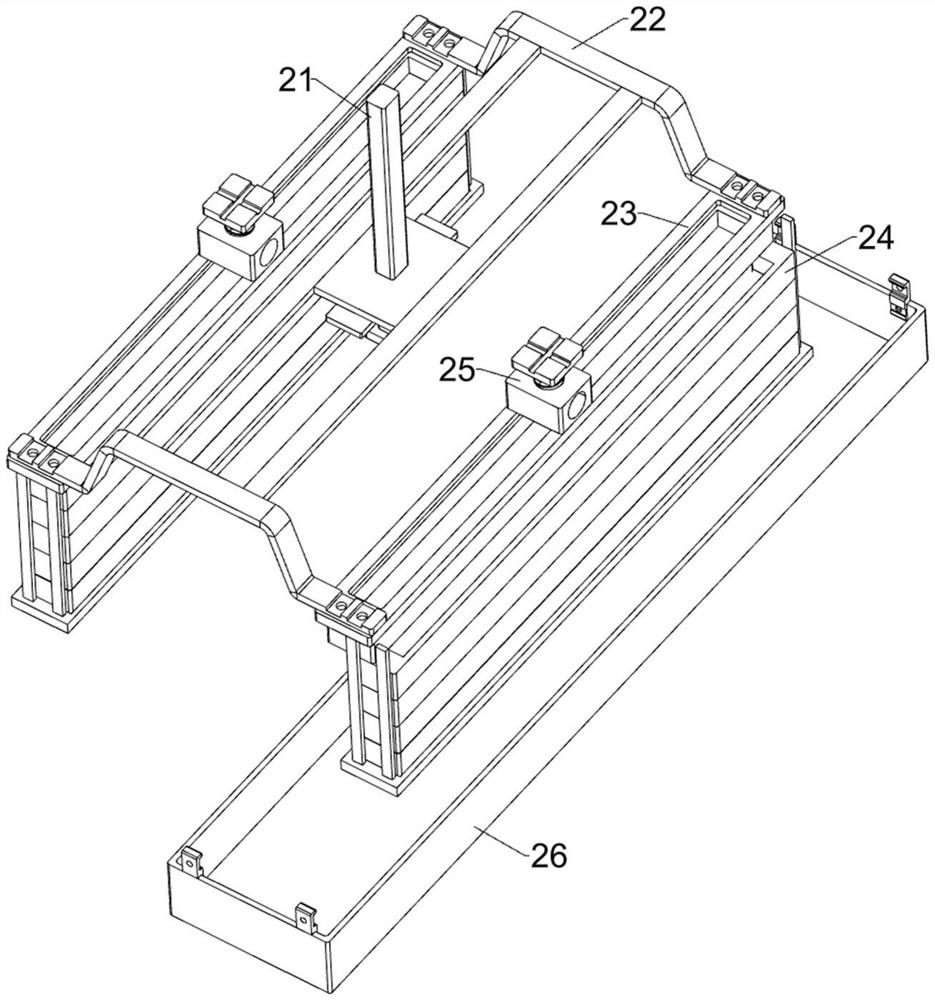

[0030] An electroplating device for faucet manufacturing, such as Figure 1-4 As shown, it includes an electroplating container 1 , an electroplating material supply component 2 and a placement component 3 , the electroplating material supply component 2 is arranged on the left side of the electroplating container 1 , and the placement component 3 is arranged inside the electroplating container 1 .

[0031] When the faucet needs to be electroplated, put the faucet into the placement component 3, then fill the electroplating container 1 with water, and then the electroplating material supply component 2 will cooperate with the placement component 3, so that the electroplating material supply component 2 is part The parts are dissolved, and then the faucet is electroplated. When the electroplating of the faucet is completed, the electroplating container 1 is controlled to discharge the water, thereby stopping the operation of the device.

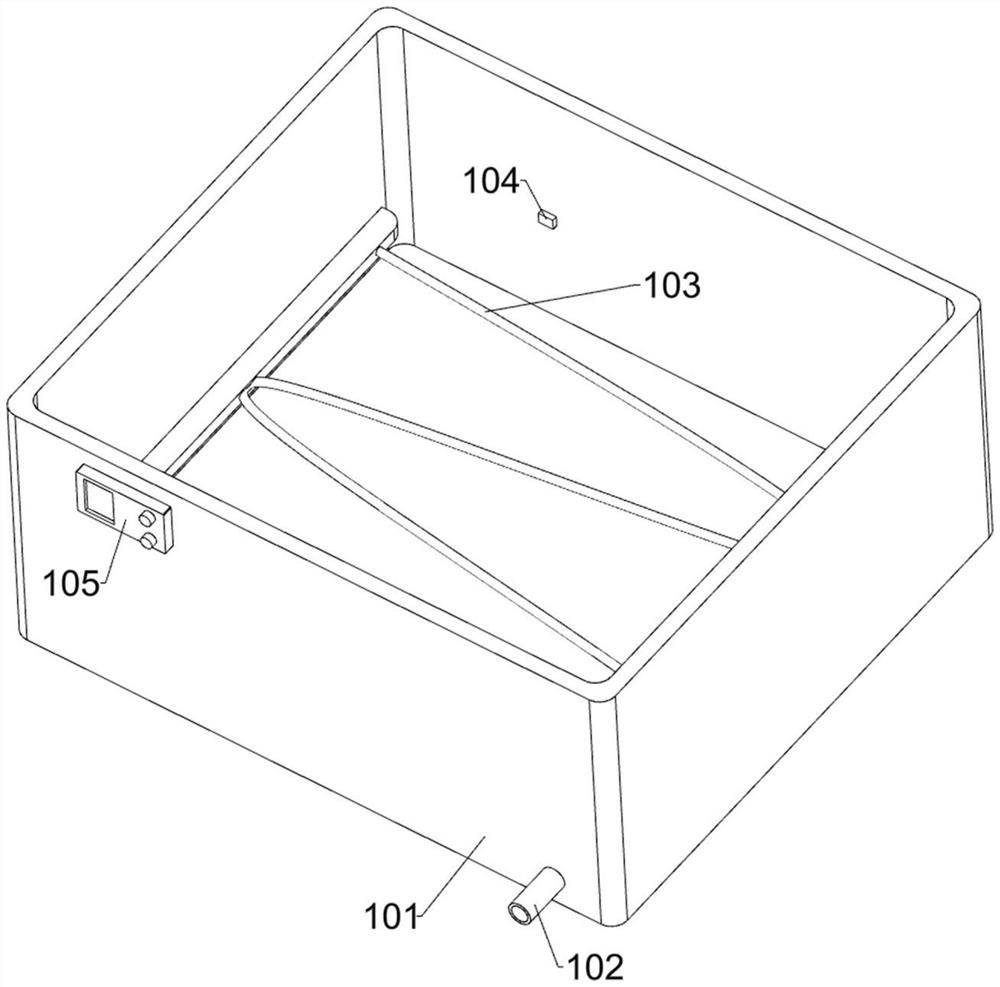

[0032] Electroplating container 1 compr...

Embodiment 2

[0039]On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a rotating assembly 4 is also included. The rotating assembly 4 includes a reduction motor 41, a gear 42 and a ring gear 43. A reduction motor 41 is installed on the upper right side of the electroplating tank 101, and a gear is arranged on the output shaft of the reduction motor 41. 42 , the outer side of the first ring 32 is provided with a ring gear 43 , and the ring gear 43 meshes with the gear 42 .

[0040] When the electroplating work starts, start the deceleration motor 41, the deceleration motor 41 will drive the gear 42 to rotate, and then drive the ring gear 43 to rotate, and then drive the first ring 32 to rotate, thereby driving the faucet to rotate, and then the faucet is electroplated. more evenly.

[0041] Also includes a lifting assembly 5, the lifting assembly 5 includes a support rod 51 and an arc-shaped sloping plate 52, the electroplating pool 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com