Quick silver recovering machine

A technology of recycling machine and silver, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of electrode polarization, low efficiency, and long extraction time of silver, so as to avoid electrode polarization, speed up the recovery process, and structure novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

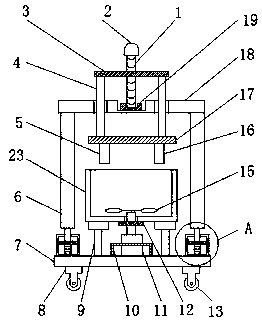

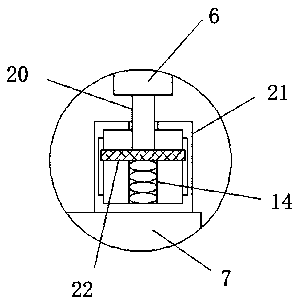

[0016] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, the fast silver recovery machine comprises a bottom plate 7, two moving devices are symmetrically arranged at the bottom of the bottom plate 7, an electrolytic cell 23 is arranged above the bottom plate 7, and a propeller 15 is arranged in the electrolytic cell 23, so that A servomotor 11 is arranged between the bottom plate 7 and the electrolytic tank 23, and the end of the output shaft of the servomotor 11 rises through the electrolytic tank 23 and is fixedly connected with the propeller 15. Columns 9 are arranged on both sides of the servomotor 11, The two ends of described column 9 are respectively fixedly connected with electrolytic cell 23 and base plate 7, and both sides of described electrolytic cell 23 are all provided with support column 6, and the support between the bottom end of described support column 6 and base plate 7 is provided with The shock absorbing device, the upper ends o...

Embodiment 2

[0017] Embodiment 2: as figure 1 and figure 2 As shown, the fast silver recovery machine comprises a bottom plate 7, two moving devices are symmetrically arranged at the bottom of the bottom plate 7, an electrolytic cell 23 is arranged above the bottom plate 7, and a propeller 15 is arranged in the electrolytic cell 23, so that A servomotor 11 is arranged between the bottom plate 7 and the electrolytic tank 23, and the end of the output shaft of the servomotor 11 rises through the electrolytic tank 23 and is fixedly connected with the propeller 15. Columns 9 are arranged on both sides of the servomotor 11, The two ends of described column 9 are respectively fixedly connected with electrolytic cell 23 and base plate 7, and both sides of described electrolytic cell 23 are all provided with support column 6, and the support between the bottom end of described support column 6 and base plate 7 is provided with The shock absorbing device, the upper ends of the two support columns...

Embodiment 3

[0018] Embodiment 3: as figure 1 and figure 2 As shown, a fast silver recovery machine includes a bottom plate 7, and the bottom of the bottom plate 7 is symmetrically provided with two mobile devices to facilitate the movement of the recovery machine. An electrolytic tank 23 is provided above the bottom plate 7 for holding and carrying out silver-containing solution. , and carry out electrolysis, the electrolytic tank 23 is provided with a propeller 15 to speed up the flow of the electrolyte and accelerate the electrolysis effect. A servo motor 11 is arranged between the bottom plate 7 and the electrolytic tank 23 to drive the propeller 15 to rotate, and the output of the servo motor 11 The end of the shaft rises through the electrolytic cell 23 and is fixedly connected with the propeller 15. Both sides of the servo motor 11 are provided with a column 9, and the two ends of the column 9 are respectively fixedly connected with the electrolytic cell 23 and the bottom plate 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com