4-series aluminum alloy welding method

A welding method and aluminum alloy technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of incomplete cleaning of surface oil stains and welding pores, and achieve good welding effects, promote electrolysis, and increase penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

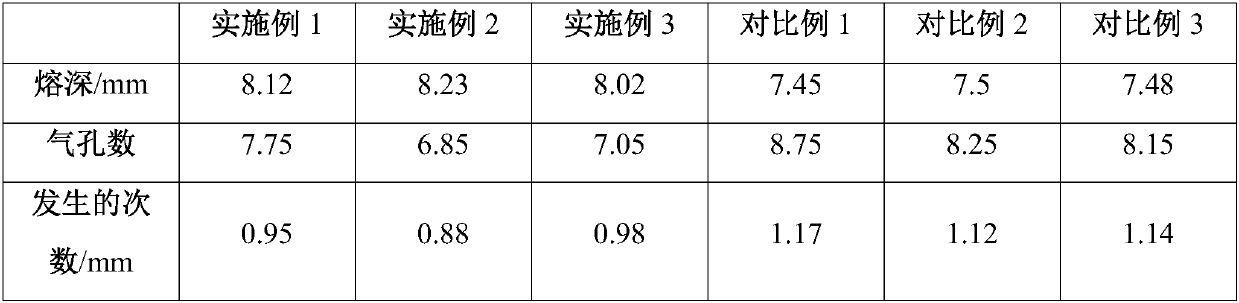

Examples

Embodiment 1

[0023] A kind of 4 series aluminum alloy welding method, comprises the following steps:

[0024] A. Put the aluminum profile to be welded on the belt conveyor and transport it at a transmission speed of 2m / min. During the transmission process, use an ionized water generator to spray the surface of the aluminum profile to be welded. The pH value of the ionized water is 9.35 , where C1-concentration in ionized water 4 2+ Concentration2+ The concentration is less than 0.1mg / L, the water temperature is 40°C, the nozzle is equipped with an injection pressure of 0.4MPa, and the injection time is 30s;

[0025] B. Blow cold air to the surface of the aluminum profile to remove water droplets on the surface of the aluminum profile, and blow hot air at 100°C to dry the surface of the aluminum profile;

[0026] C. Clamp and fix the dried two aluminum profiles with a specific welding tool;

[0027] D. The aluminum profile is welded by laser electron beam welding process, the electron bea...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is that the pH value of the ionized water in step A is 9.45.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is that the pH value of the ionized water in step A is 9.70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com