Patents

Literature

47results about How to "Efficient electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

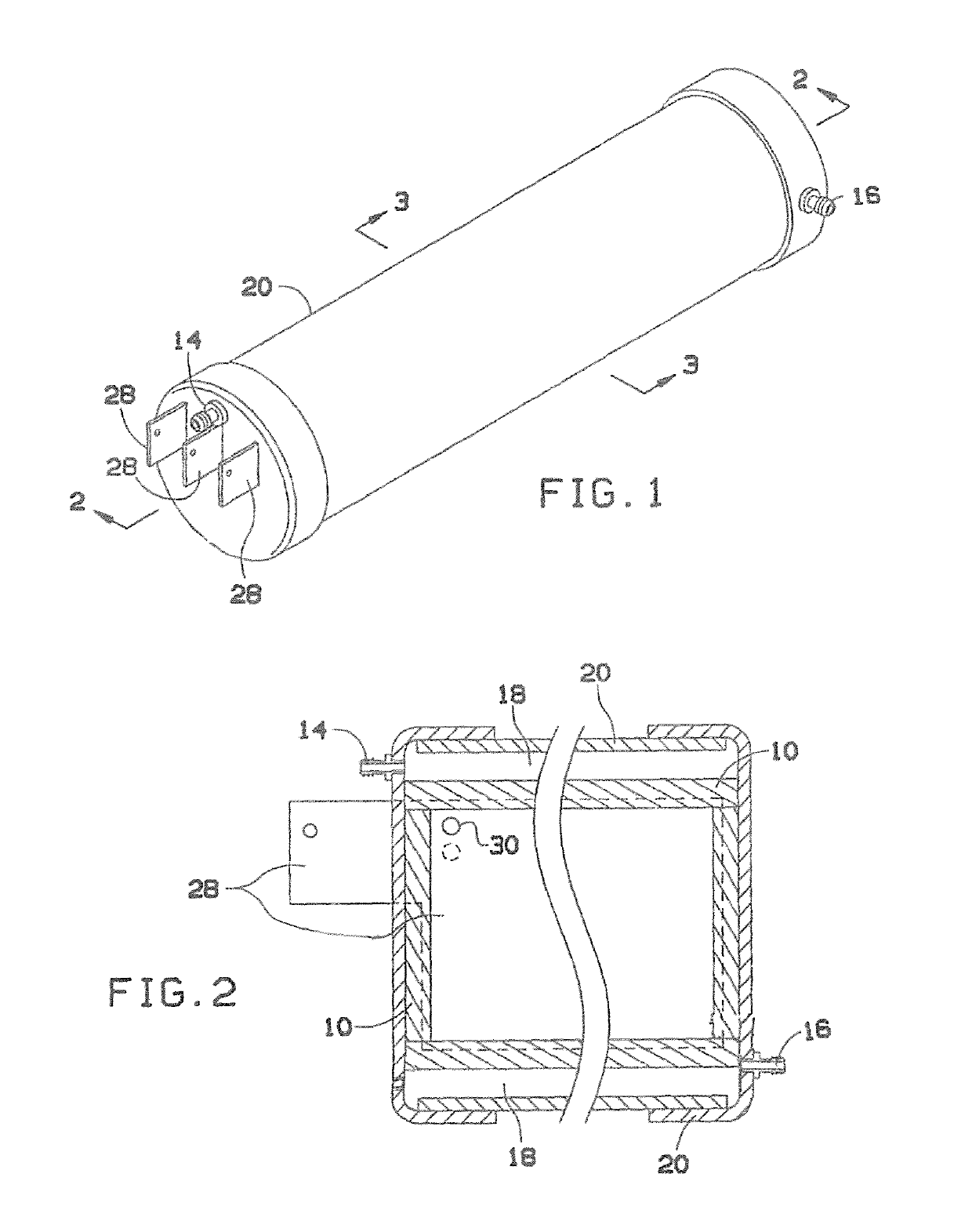

Integrated photoelectrochemical cell and system having a liquid electrolyte

InactiveUS20050211290A1Improve hydrogen efficiencyImprove oxygen production efficiencyCellsLight-sensitive devicesHydrogenPhotoelectrochemical cell

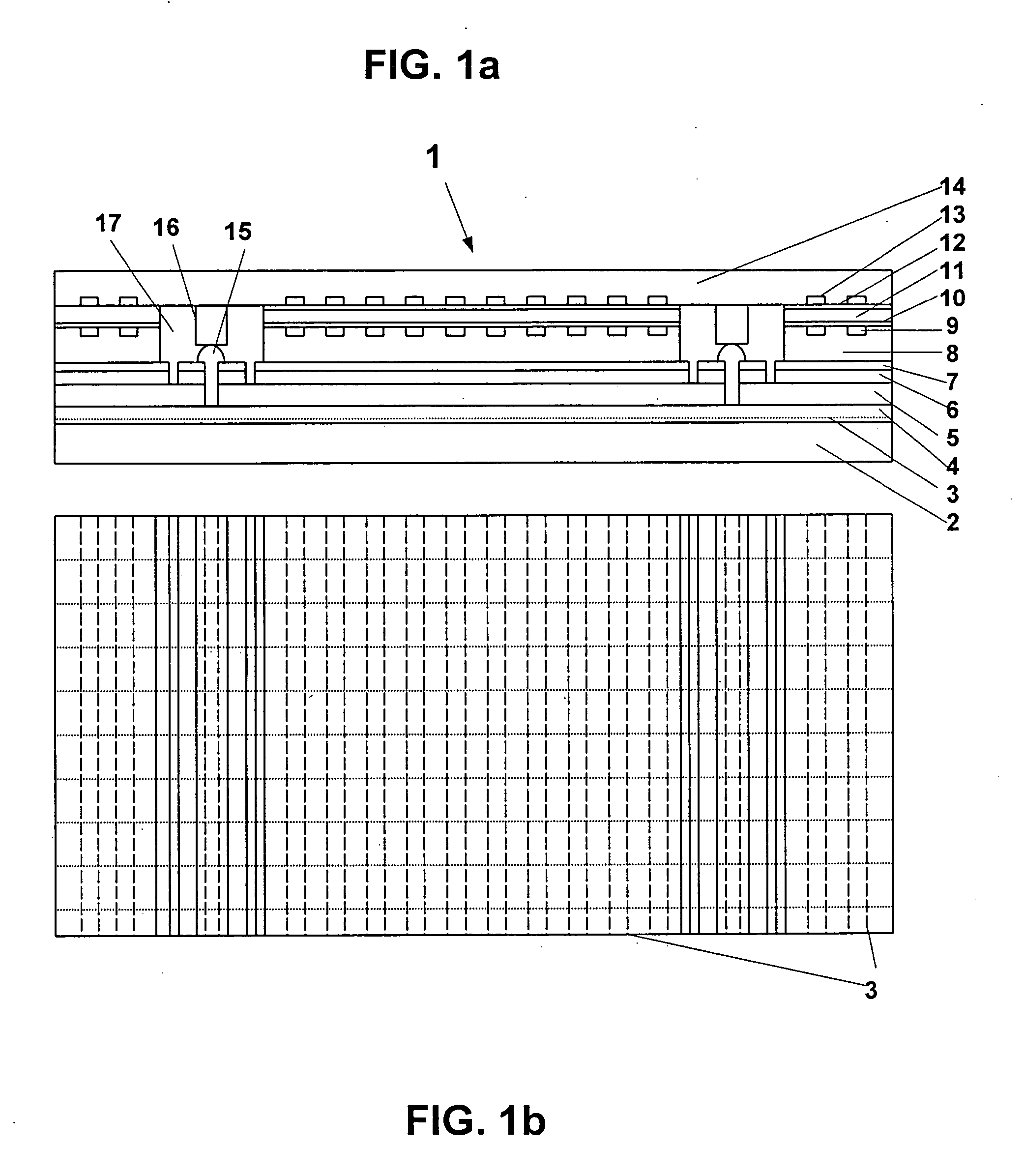

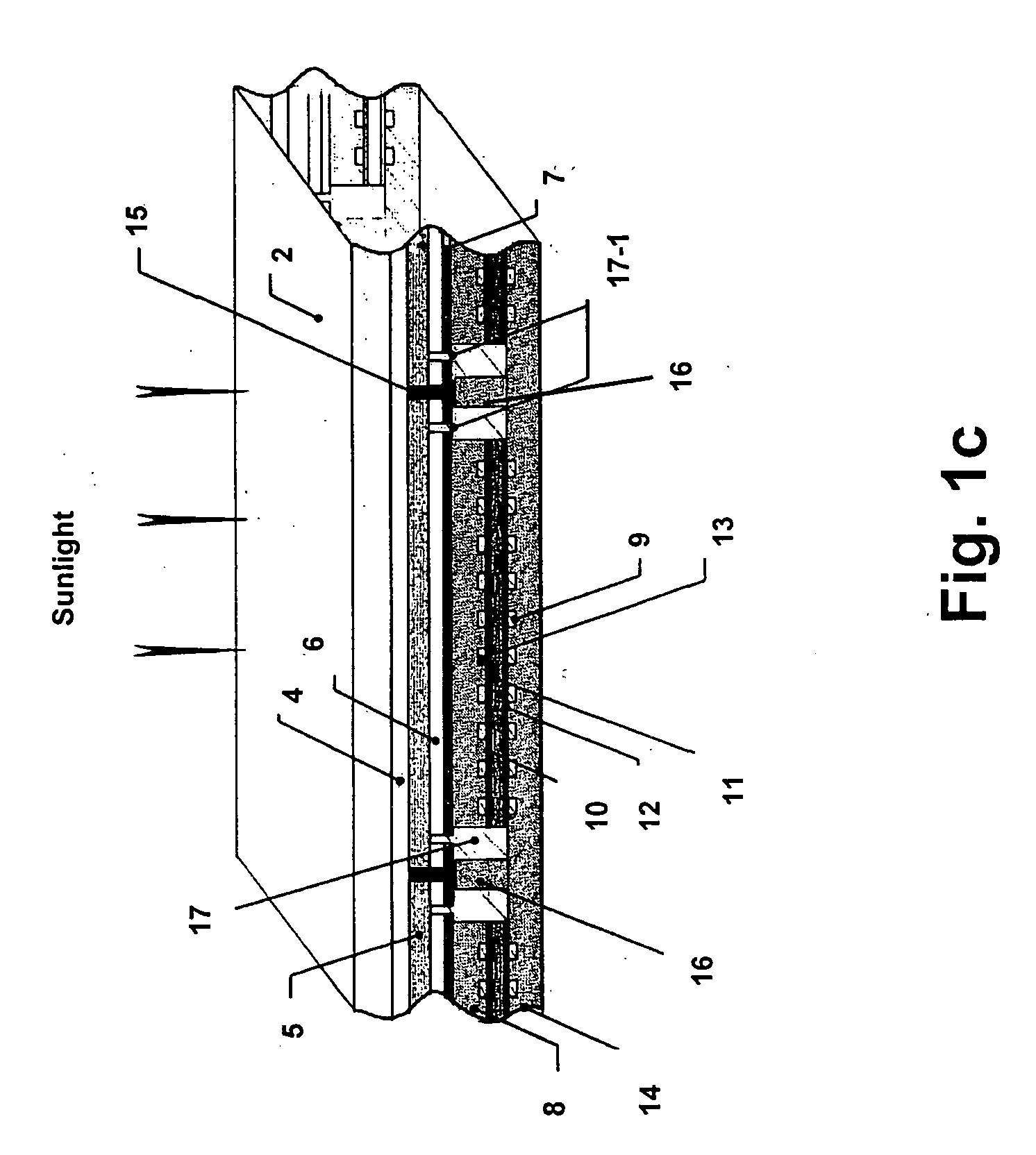

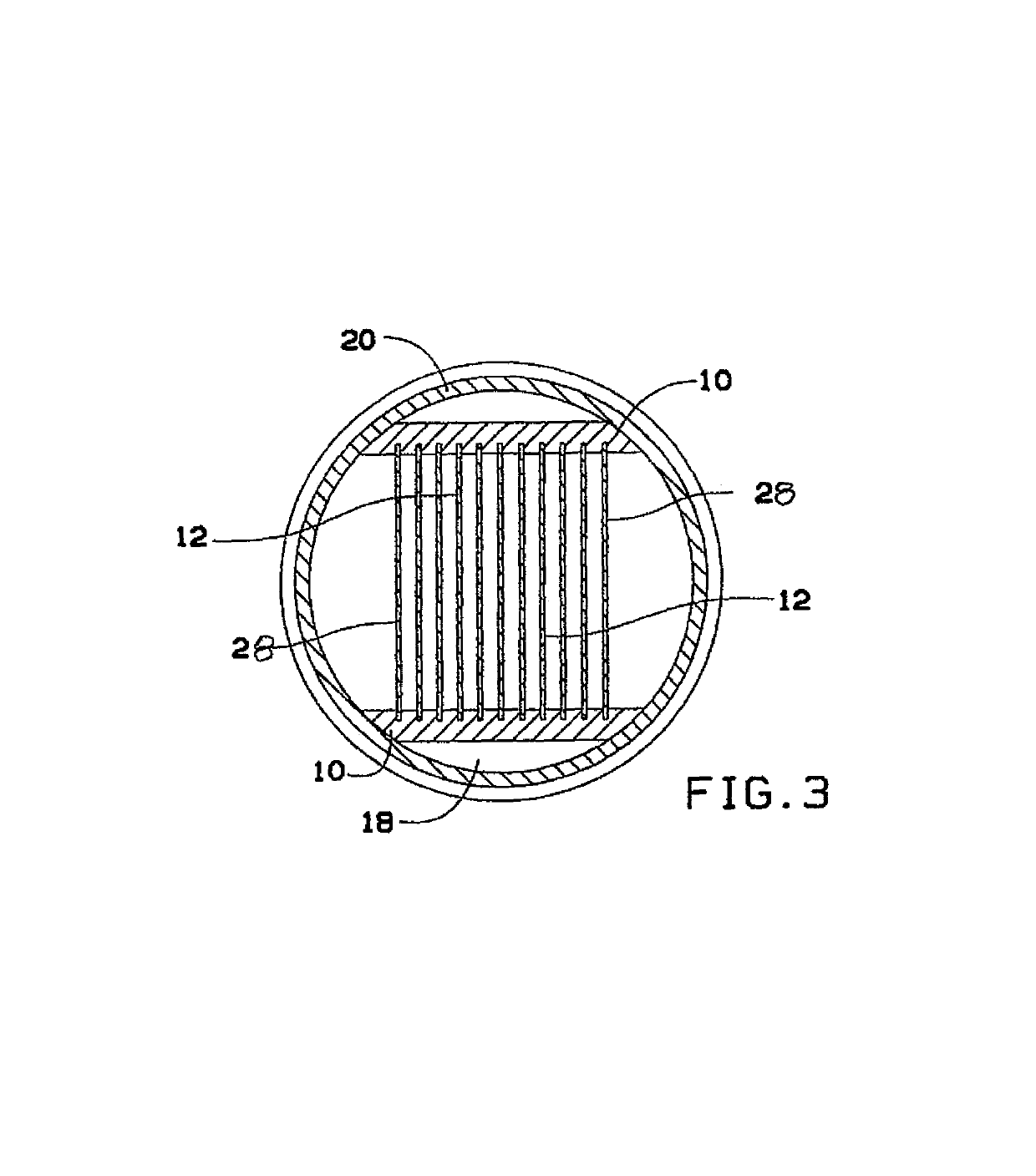

An integrated photoelectrochemical (PEC) cell generates hydrogen and oxygen from water while being illuminated with radiation. The PEC cell employs a liquid electrolyte, a multi-junction photovoltaic electrode, and a thin ion-exchange membrane. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

Integrated photoelectrochemical cell and system having a solid polymer electrolyte

InactiveUS20050205128A1Improve conversion efficiencyLow costElectrode manufacturing processesElectrolysis componentsPolymer electrolytesPhotoelectrochemical cell

A photoelectrochemical (PEC) cell includes a photovoltaic electrode that generates voltage under radiation; a solid membrane electrode assembly that includes at least one solid polymer electrolyte and first and second electrodes; a mechanism that collect gases from oxidation and reduction reactions; and an electrical connection between the photovoltaic electrode and the solid membrane electrode assembly. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

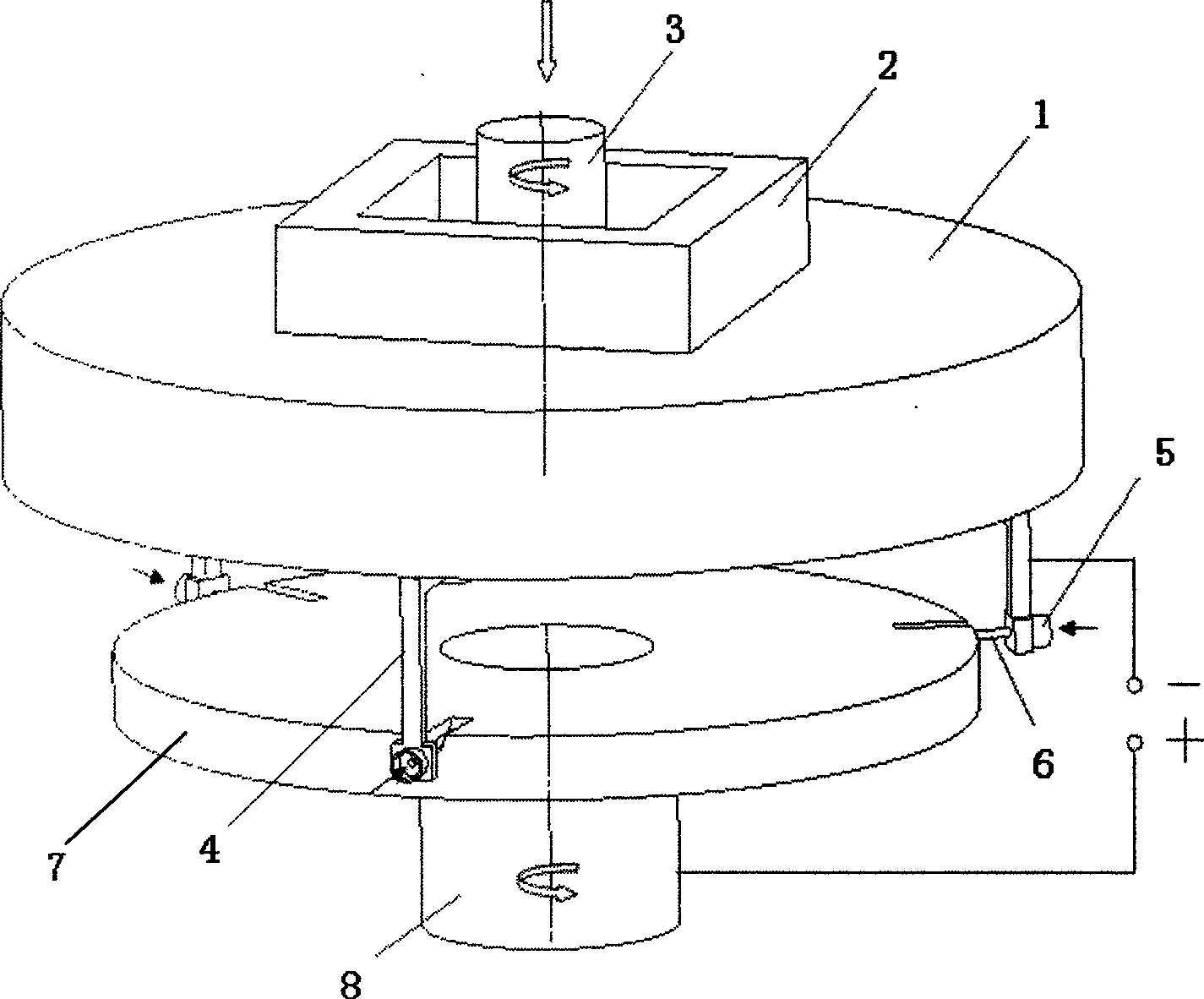

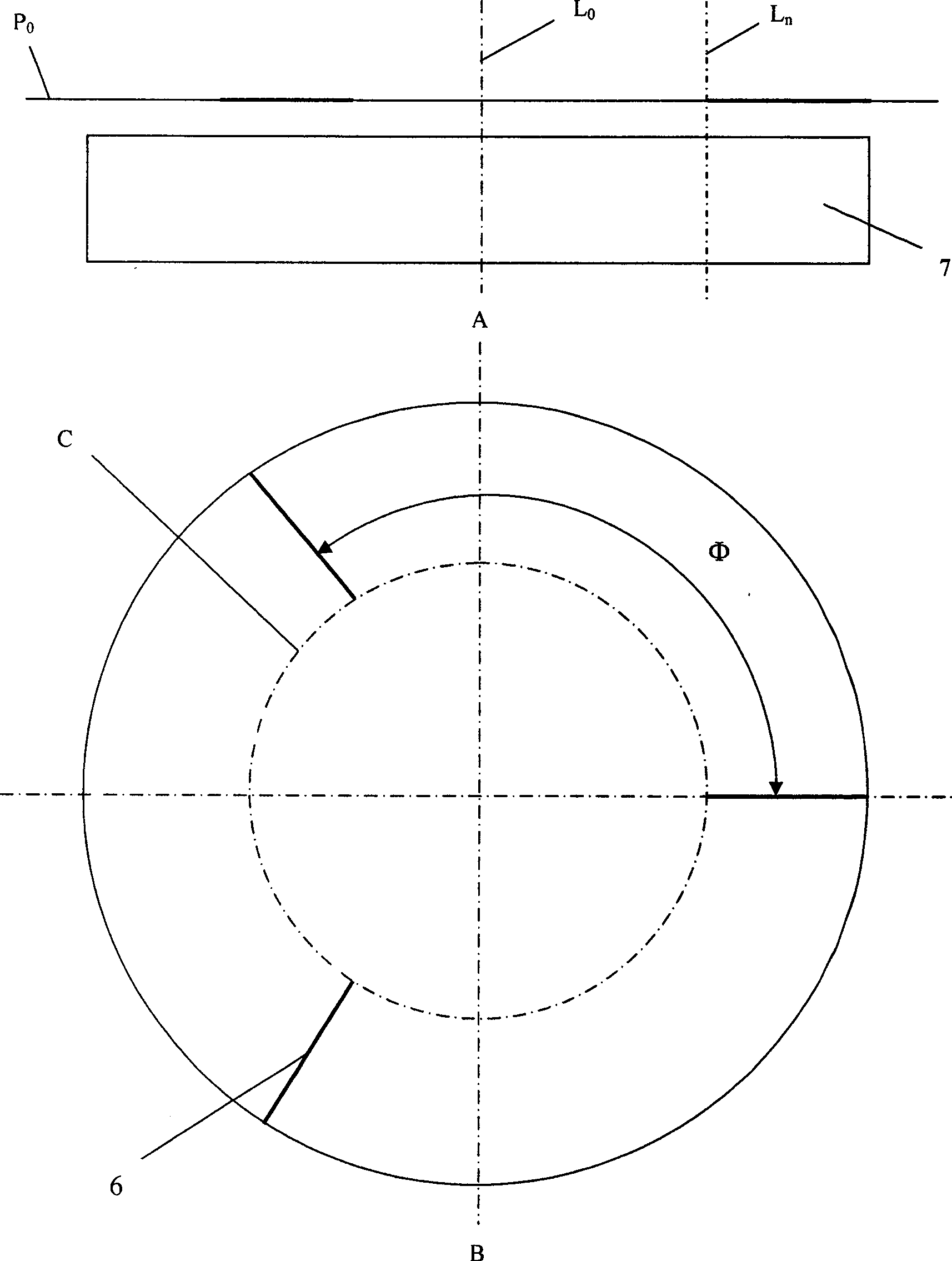

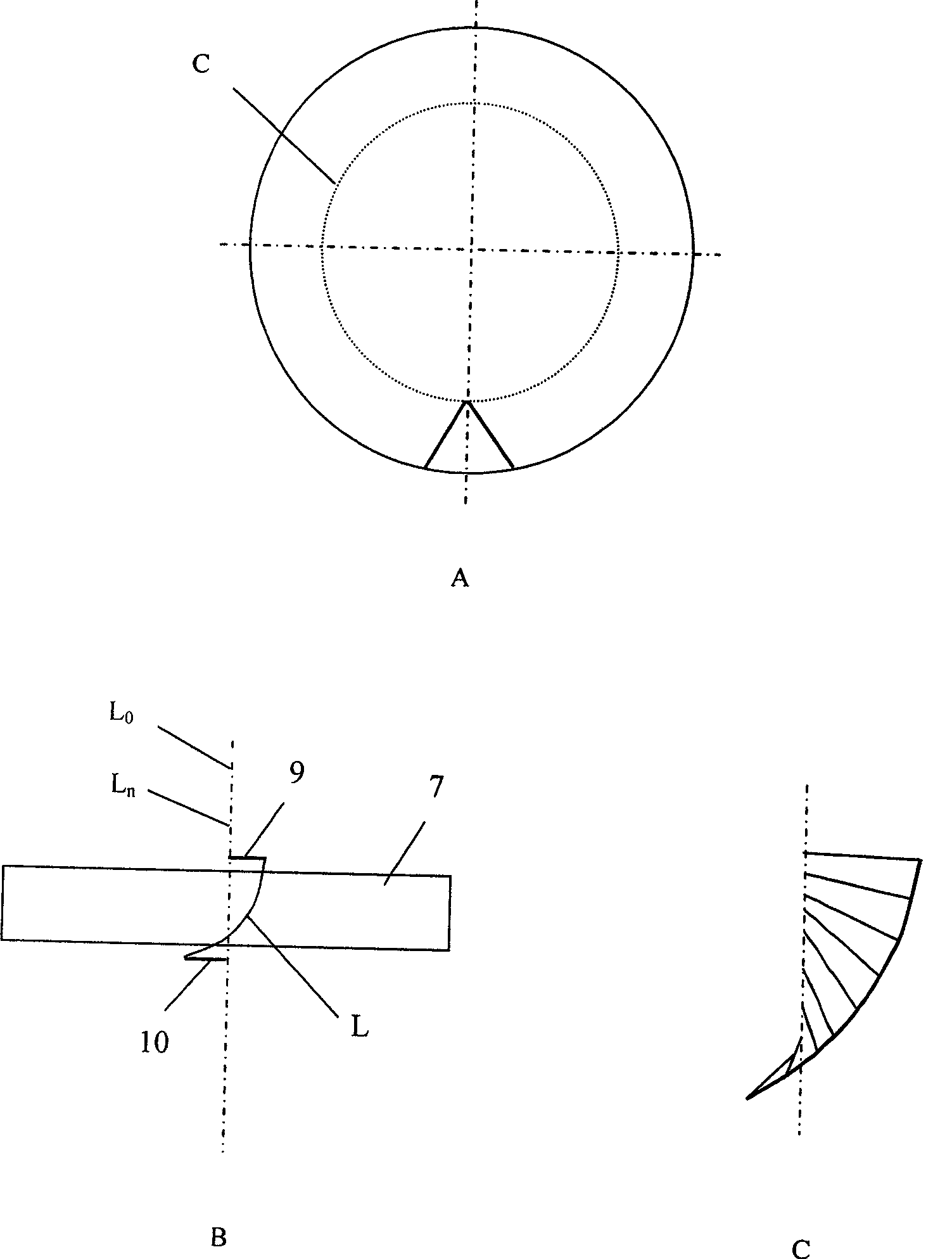

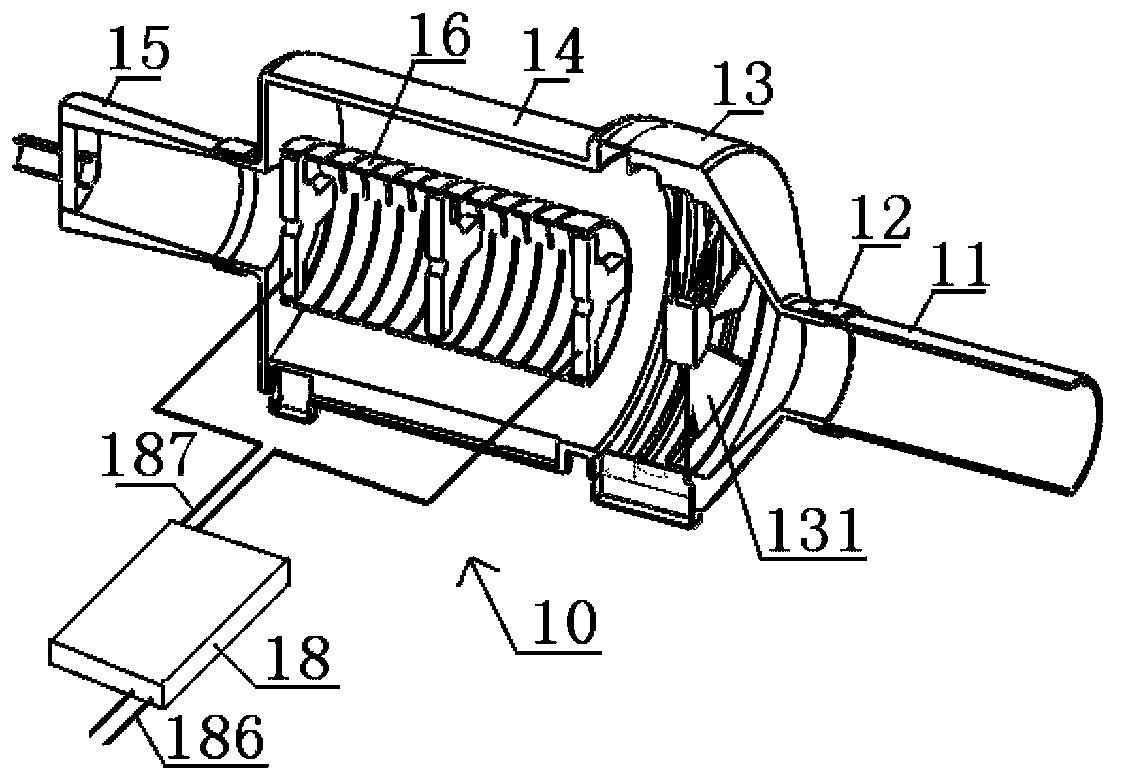

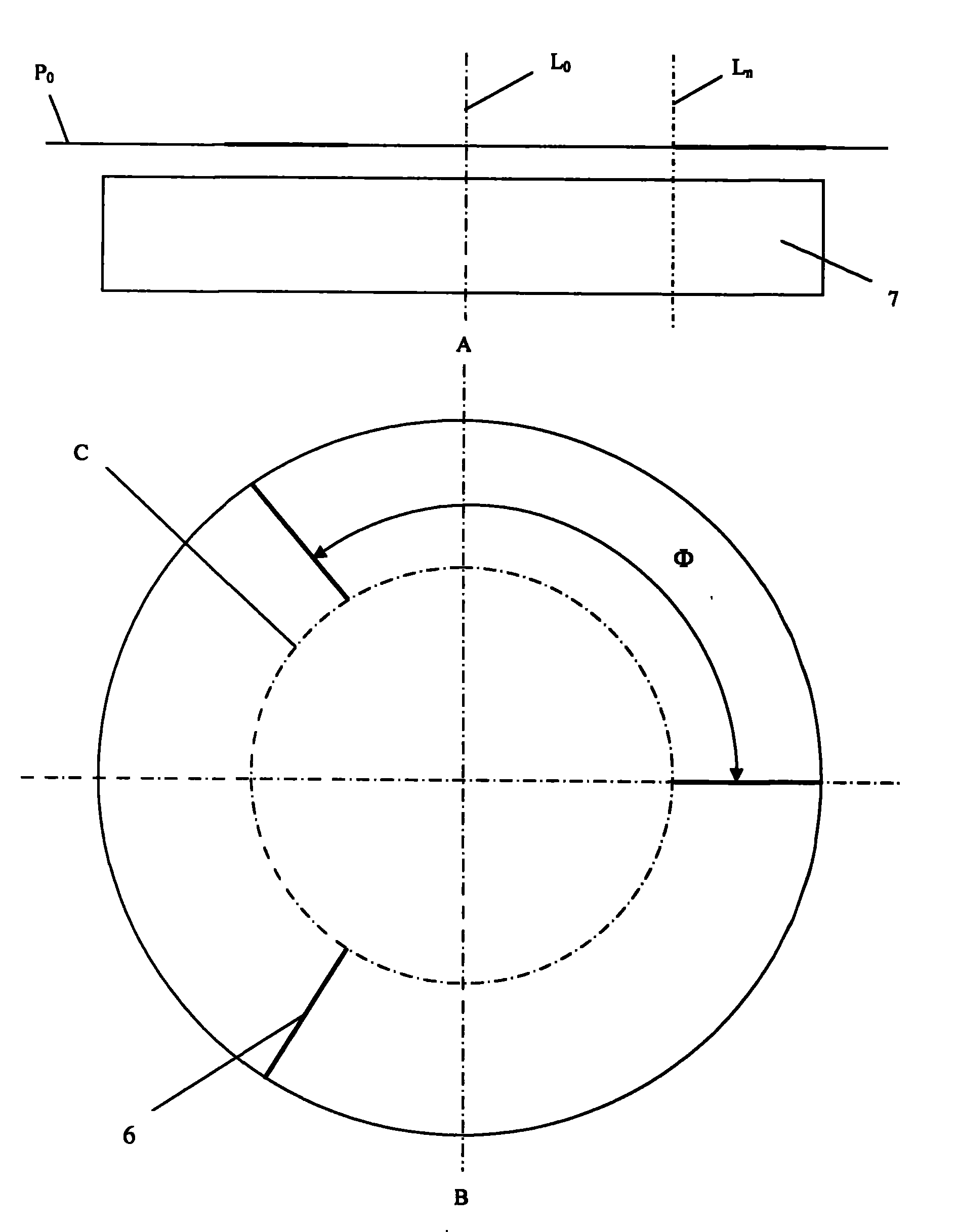

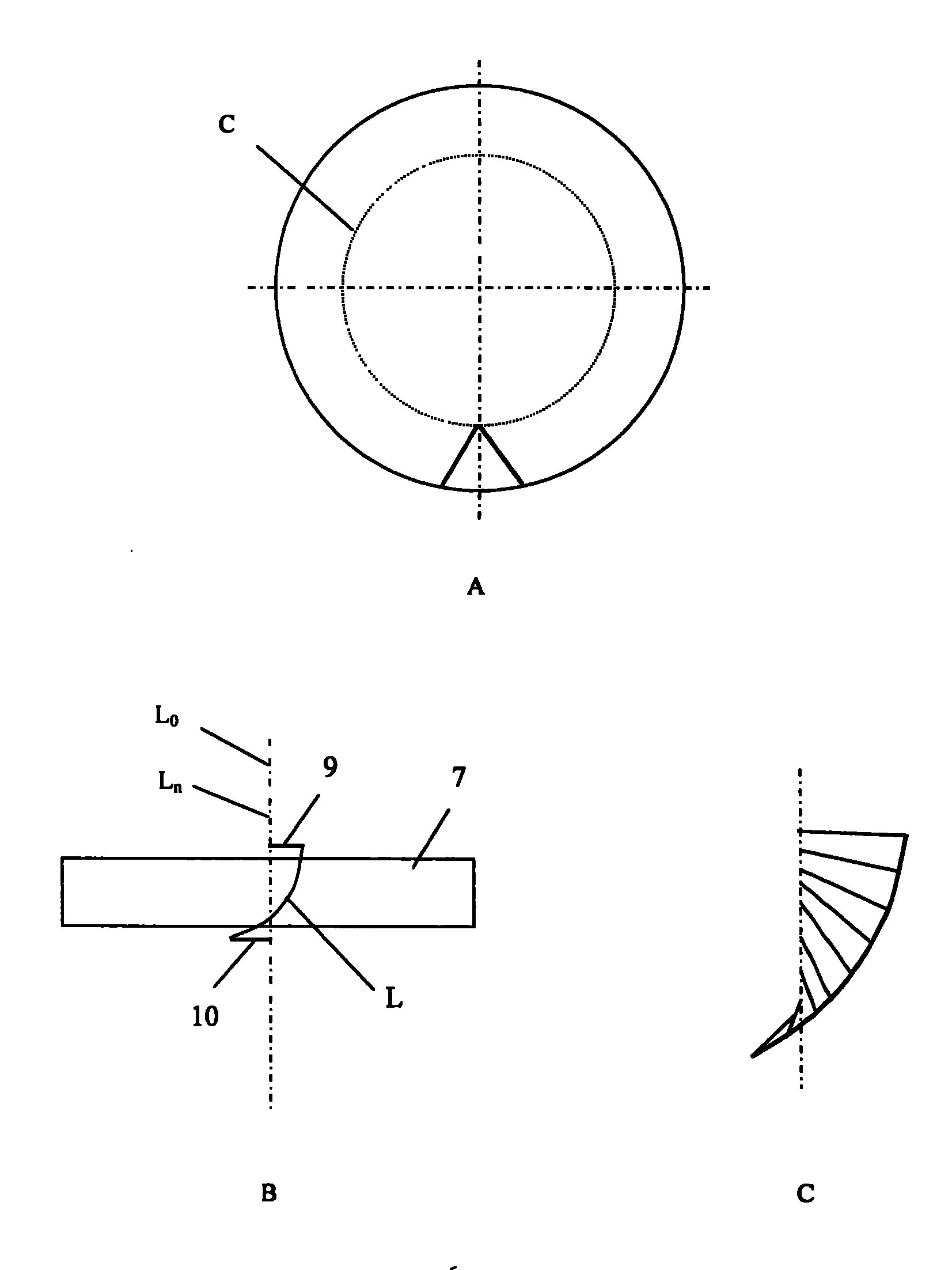

Multi-electrode spiral feeding integral blade wheel inter-blade passage electrolytic machining method

InactiveCN101508047AImprove processing efficiencyShorten the manufacturing cycleImpellerMachining process

The invention relates to an electrolytic machining method for multi-electrode screw feeding integral impeller flow passages, and belongs to the technical field of electrolytic machining. The method adopts a plurality of tool electrodes which are positioned on the same plane and arranged on an electrolytic machining clamp. In the machining process, a translation stage of a machine tool drives the plurality of the tool electrodes to simultaneously feed linearly along the axes direction of an impeller blank, and a turn table on the translation stage drives the plurality of the tool electrodes to rotate; meanwhile, the impeller blank rotates around the axes of the impeller blank, and the tool electrodes perform electrolytic machining along a motion trail determined by the resultant motion. The electrodes and the impeller blank keep a small clearance; electrolyte flows out at a high speed from gaps of the tool electrodes to continuously take away products of electrolysis; and a plurality of impeller flow passages are machined finally. The number and distribution positions of the tool electrodes can be adjusted to meet machining requirements of integral impellers in different types. Because the plurality of the electrodes are adopted to perform machining simultaneously, the machining efficiency for the integral impeller is greatly improved, and the rotation of the electrodes makes machining allowance more even at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Integrated photoelectrochemical cell and system having a liquid electrolyte

InactiveUS7750234B2Improve efficiencyLow costCellsLight-sensitive devicesPhotoelectrochemical cellIon-exchange membranes

An integrated photoelectrochemical (PEC) cell generates hydrogen and oxygen from water while being illuminated with radiation. The PEC cell employs a liquid electrolyte, a multi-junction photovoltaic electrode, and a thin ion-exchange membrane. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

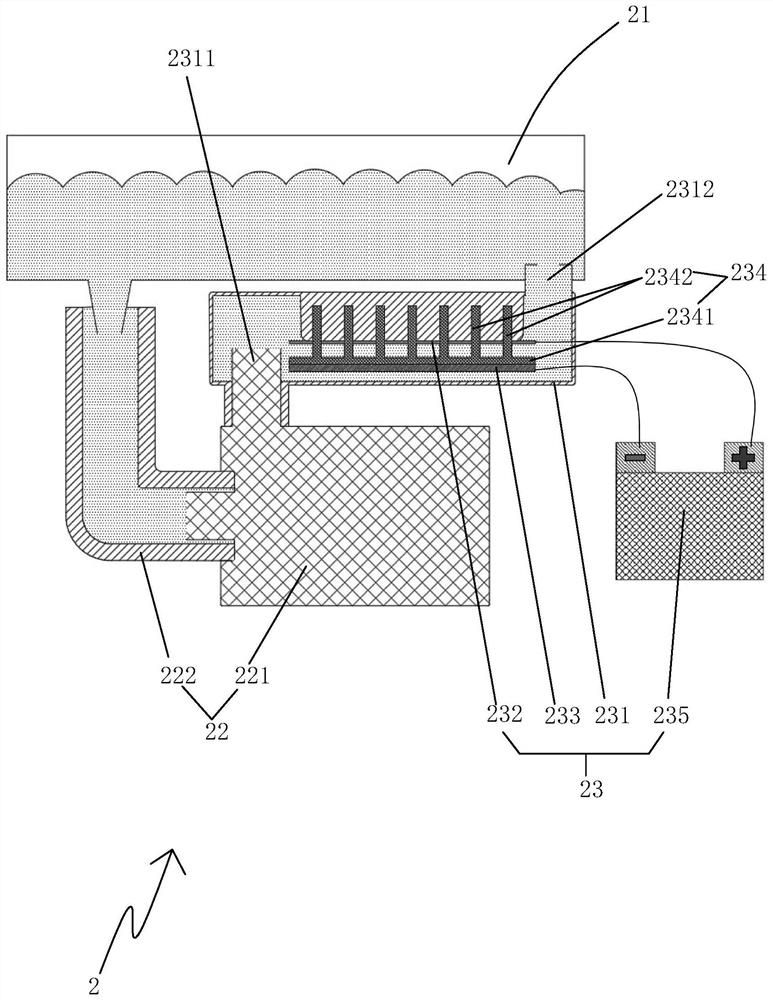

Electrolyzed water manufacturing device, electrolyzed water manufacturing method, and electrolyzed water

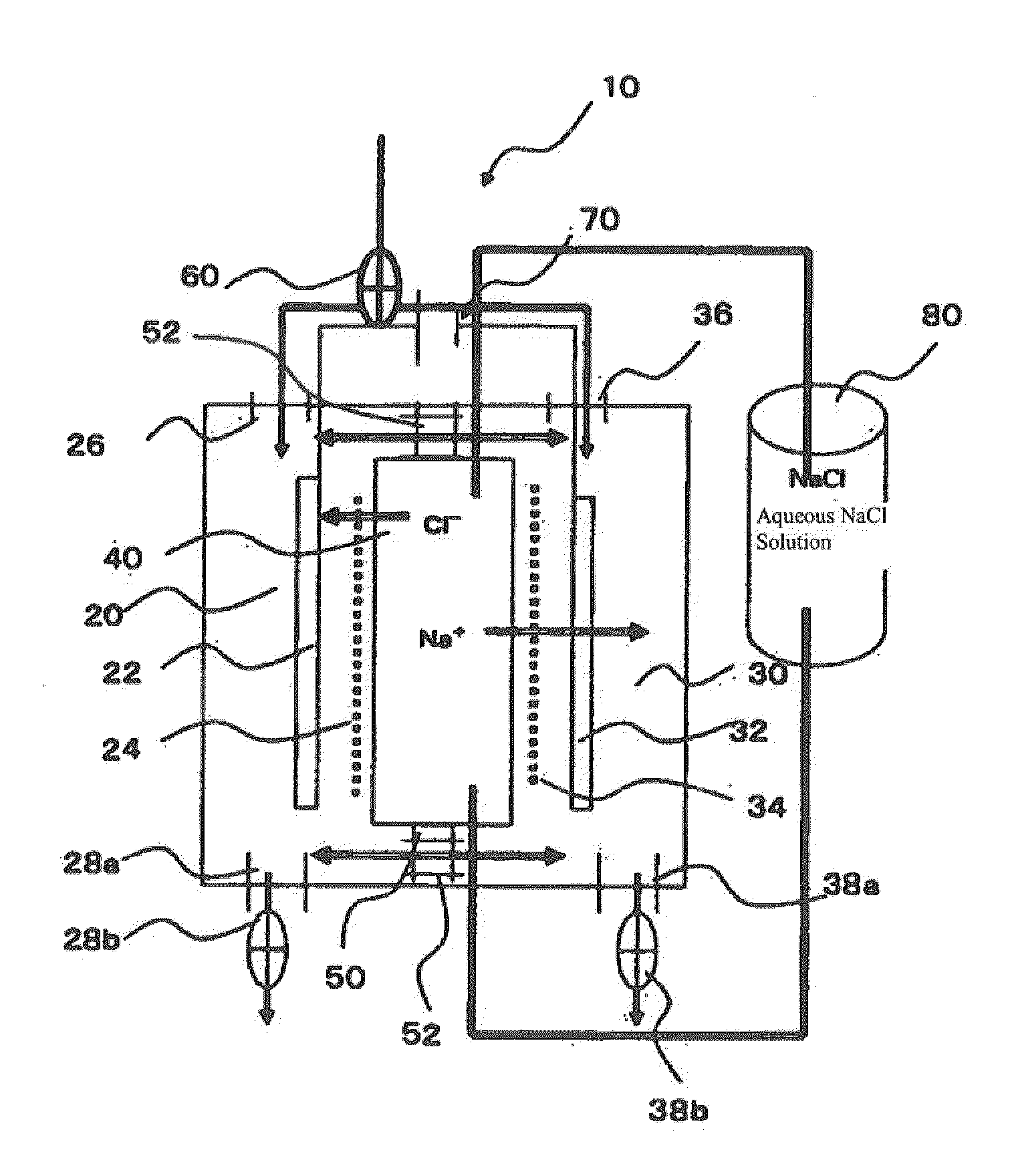

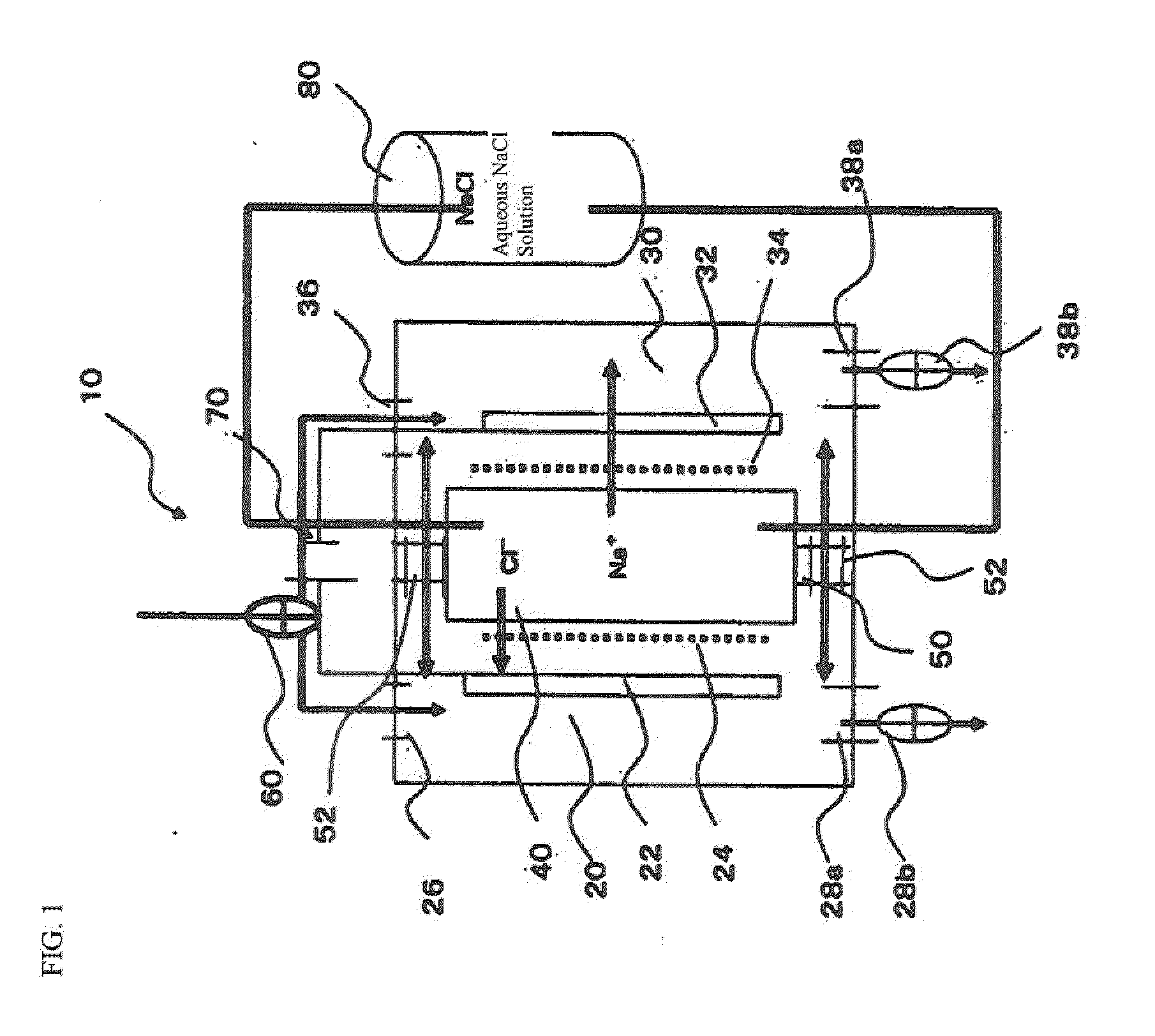

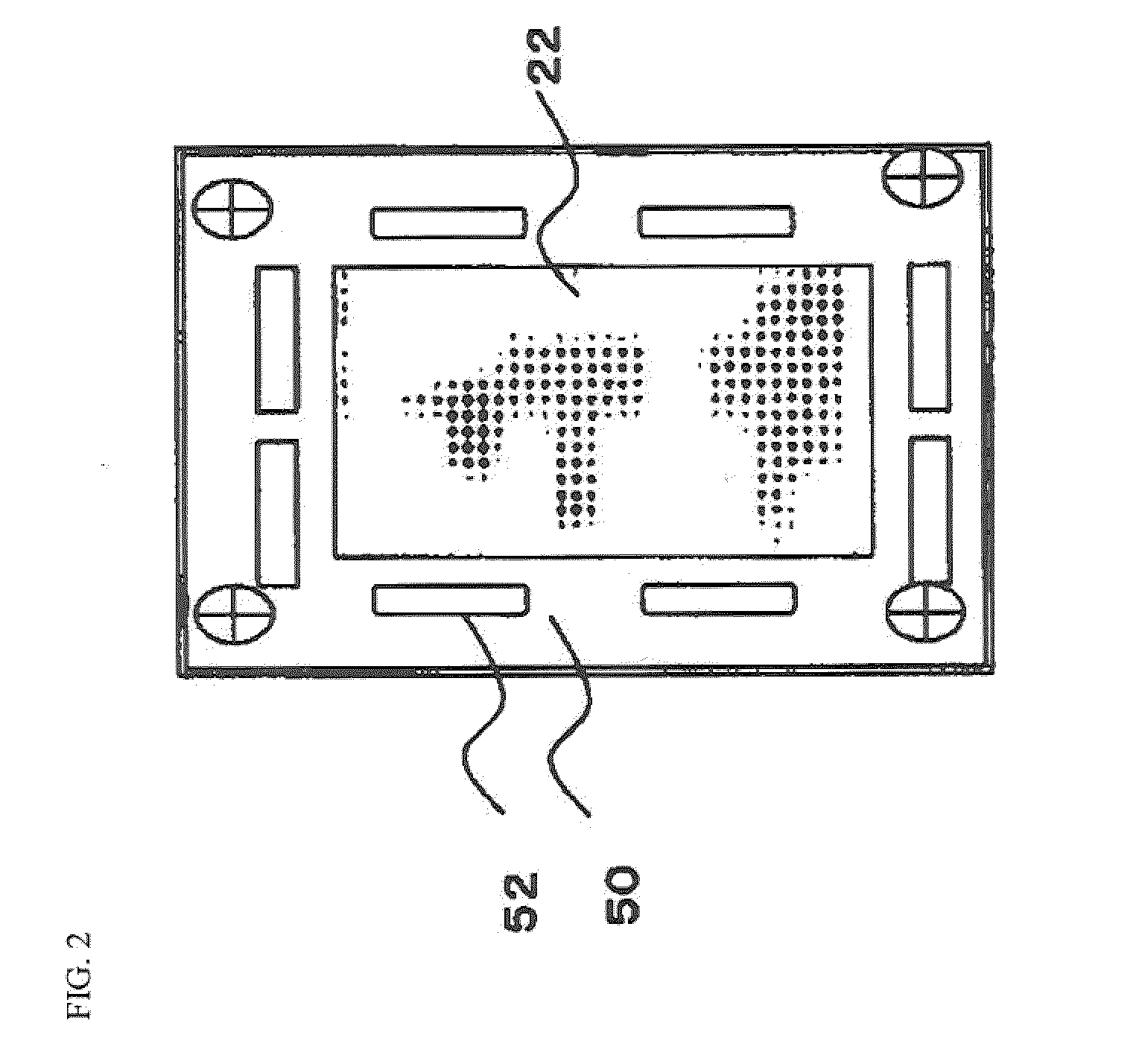

InactiveUS20100200425A1Suppress secondary electrolysisSuppress failureCellsMembranesElectrolysed waterIon-exchange membranes

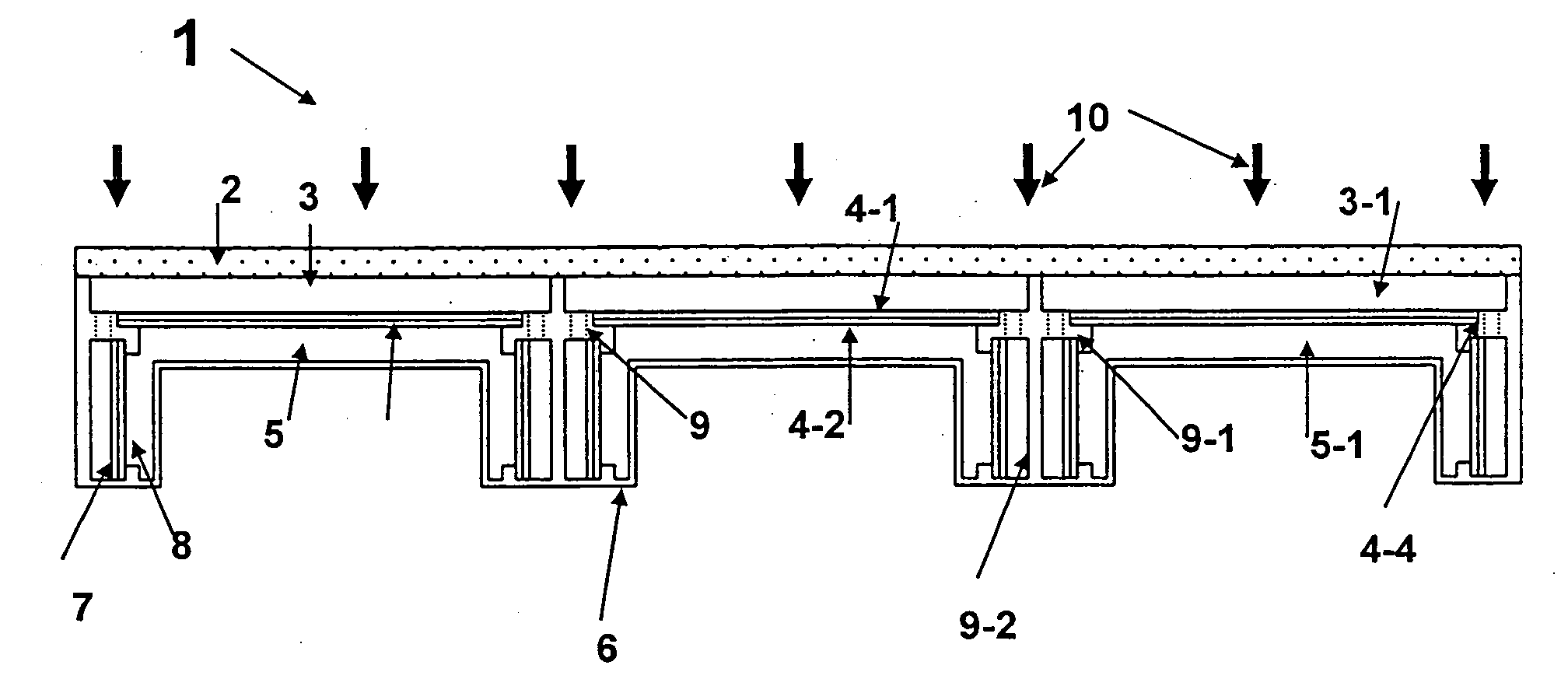

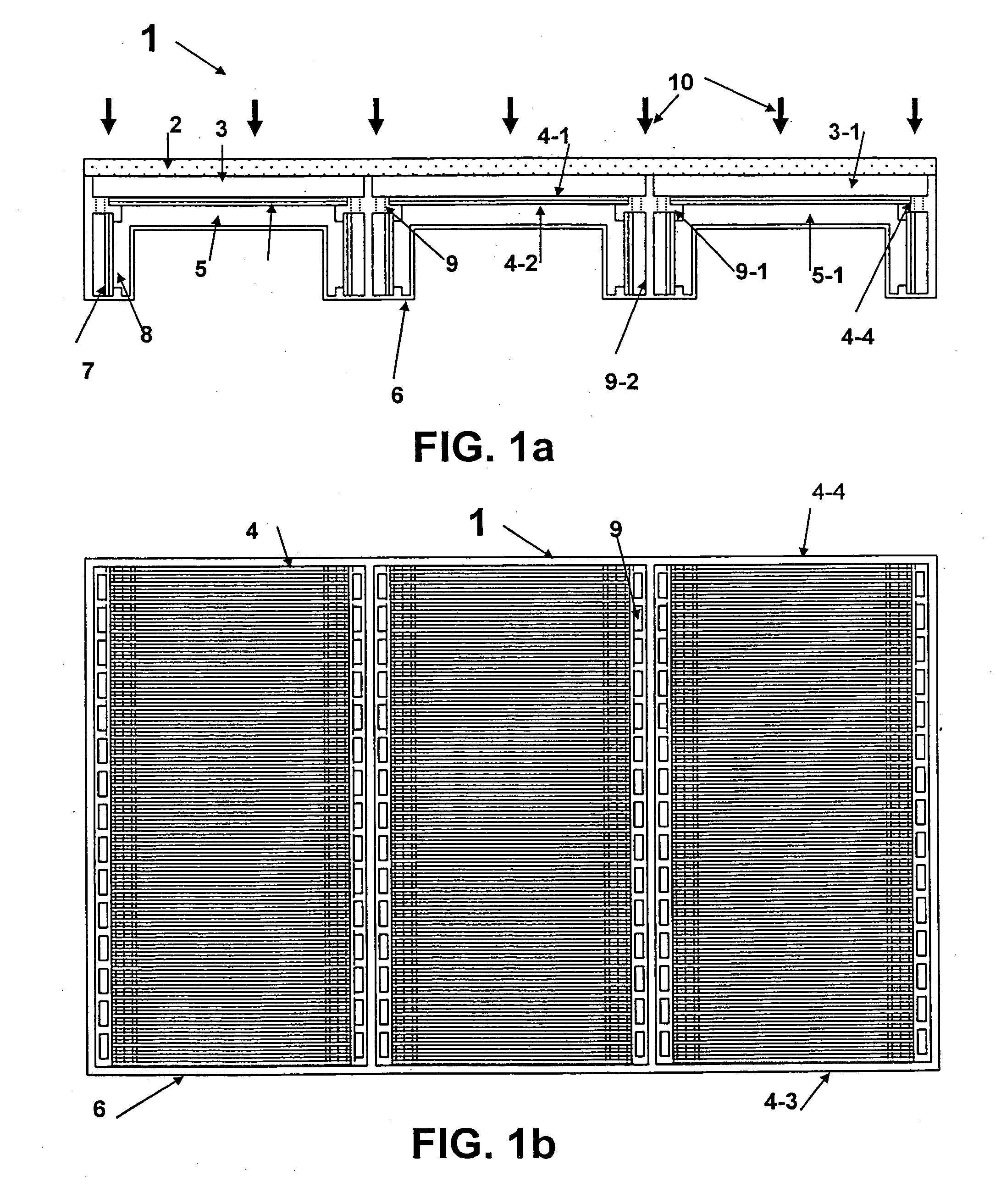

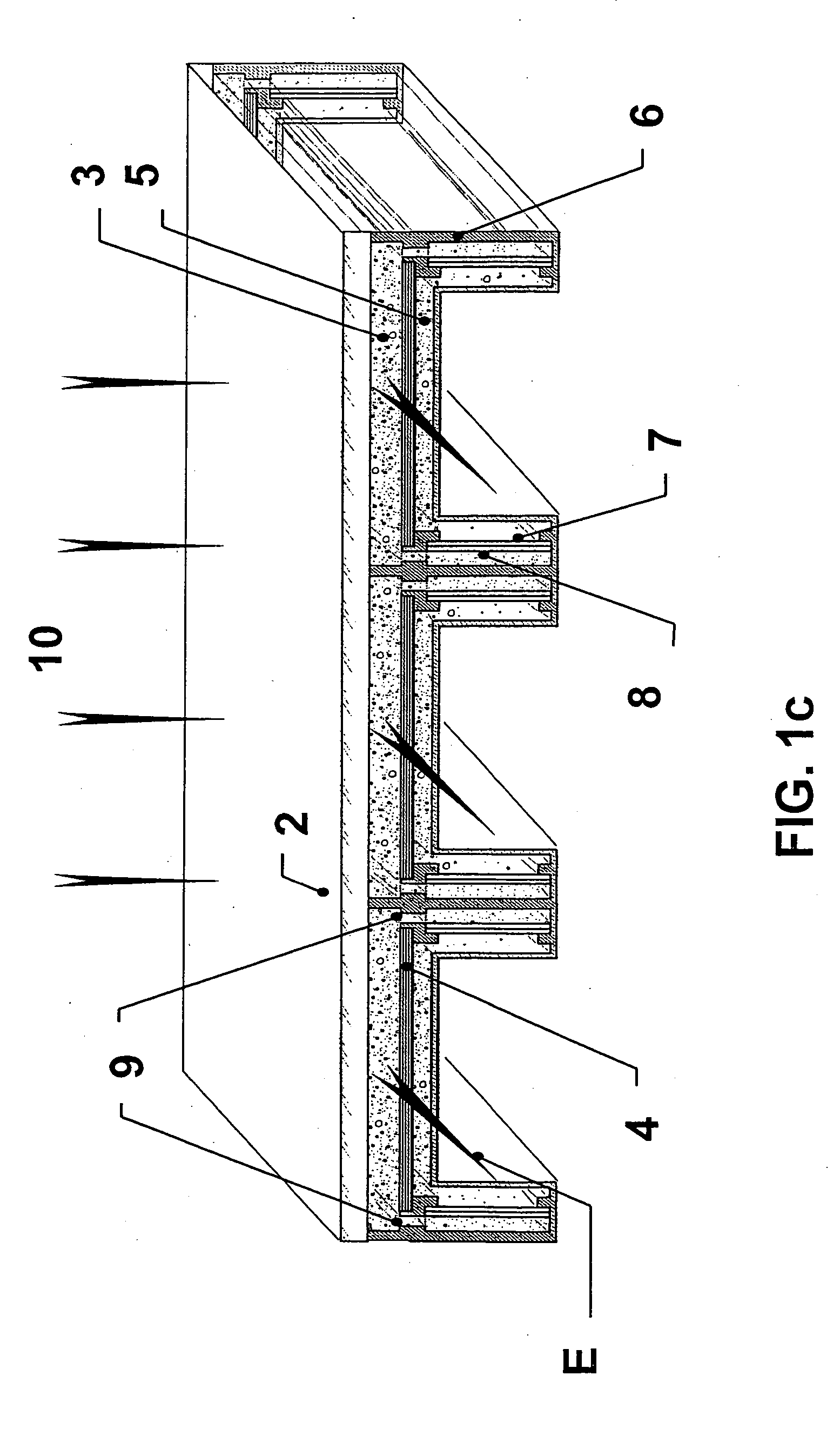

Disclosed is an electrolyzed water manufacturing method and electrolyzed water manufacturing device capable of producing efficiently weakly acidic through weakly alkaline electrolyzed water, and capable of producing said electrolyzed water on a large scale. The electrolyzed water manufacturing device 10 comprises: an anode chamber 20 that is provided with an anode electrode 22; a cathode chamber 30 that is provided with a cathode electrode 32; a middle chamber 40 for containing an aqueous electrolytic solution, disposed between the anode chamber 20 and the cathode chamber 30; an anion exchange membrane 24 for partitioning between the anode chamber 20 and the middle chamber 40; and a cation exchange membrane 34 for partitioning between the cathode chamber 30 and the middle chamber 40. The anode chamber 20 and the cathode chamber 30 are connected by a connecting hole 52 provided in a partitioning wall 50.

Owner:ARAI YUSHO

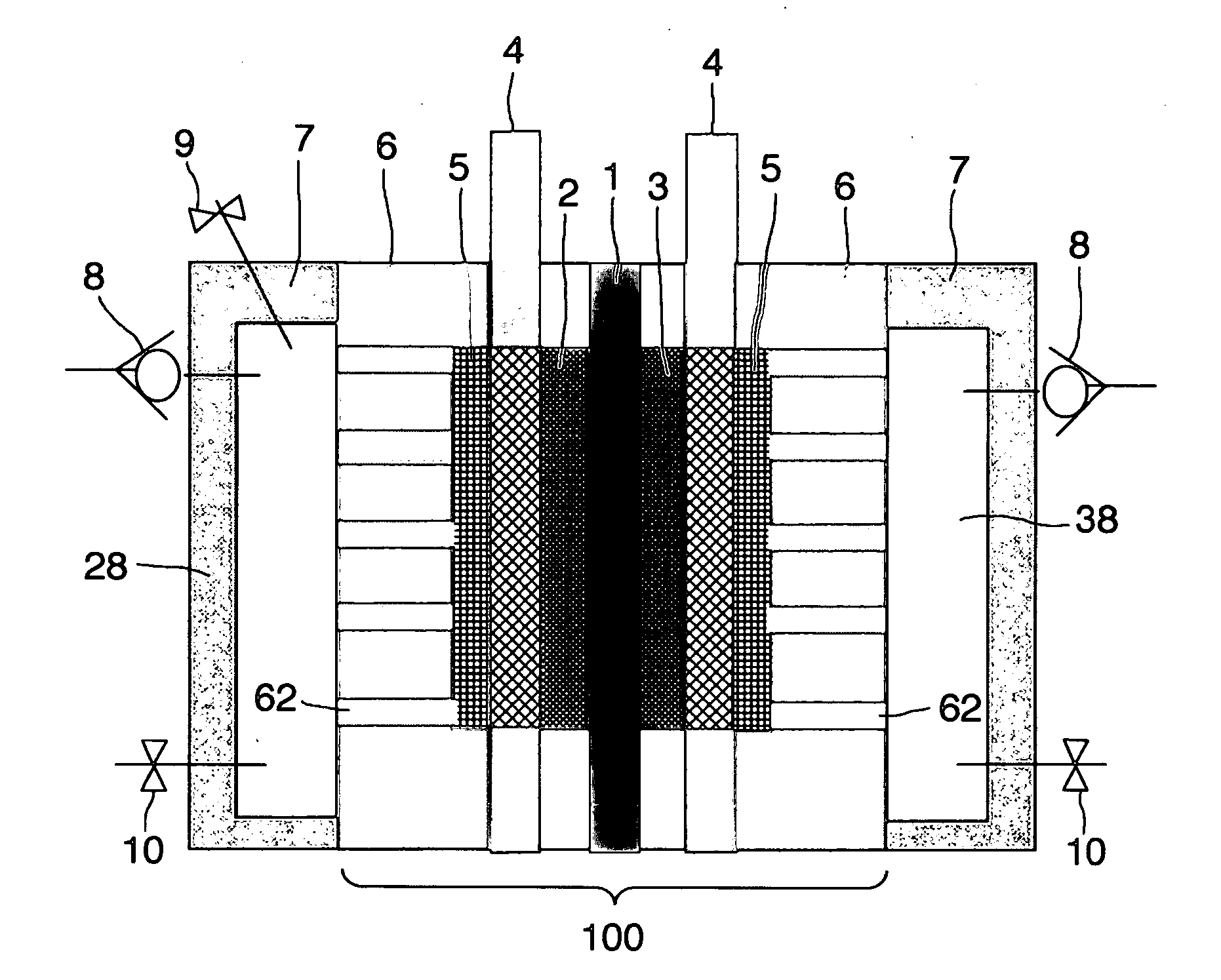

Solid polymer membrane-type water-electrolysis apparatus

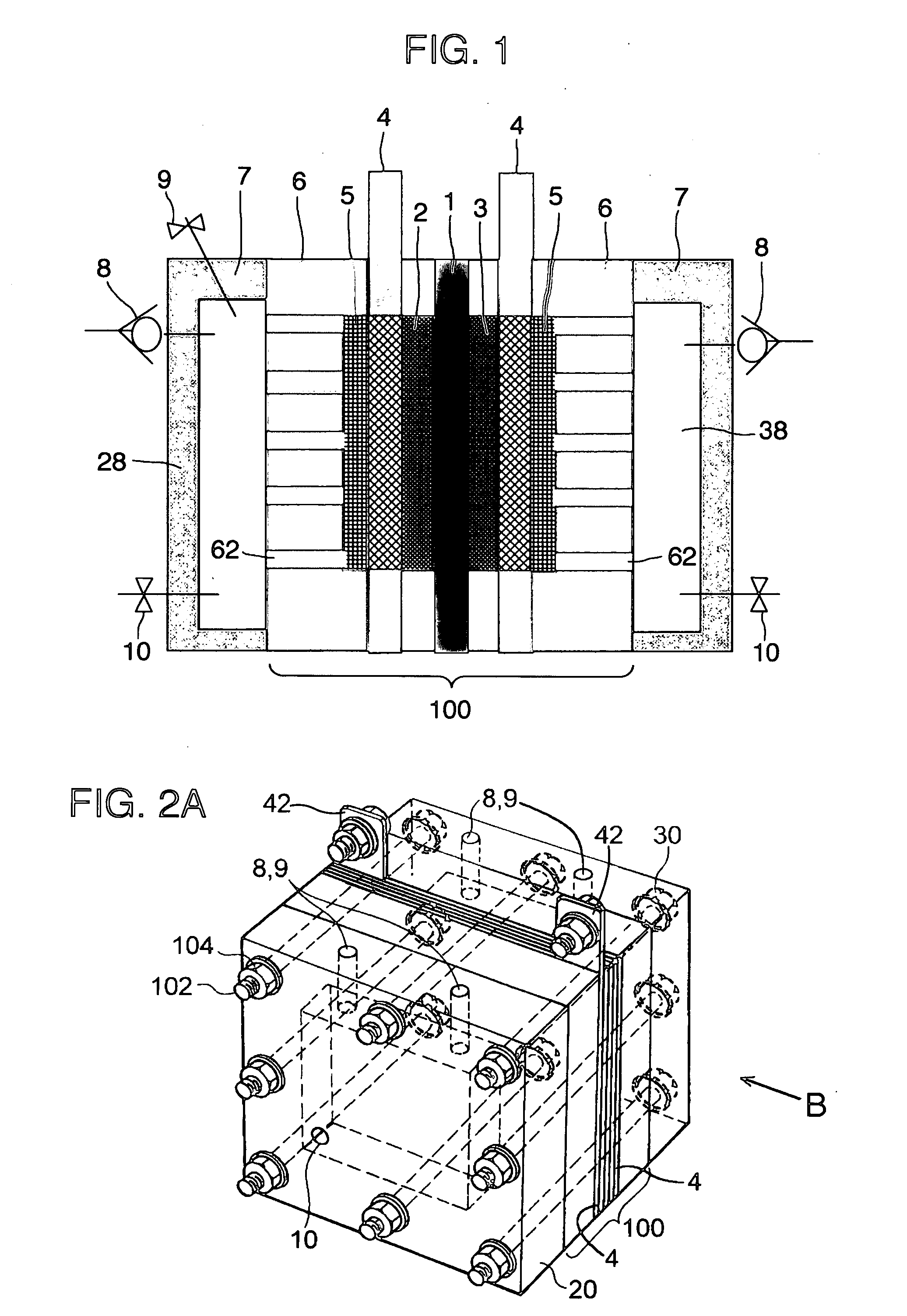

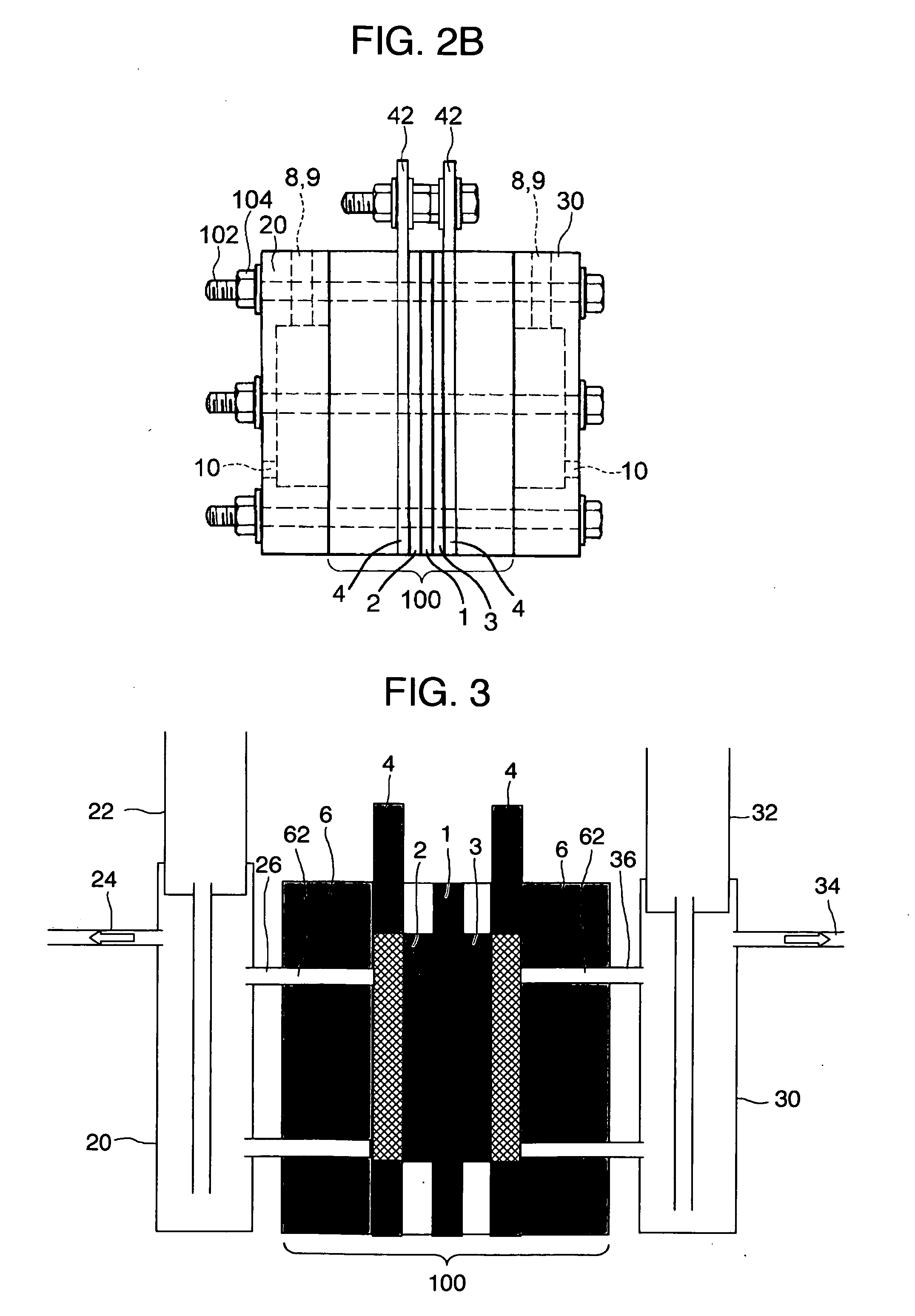

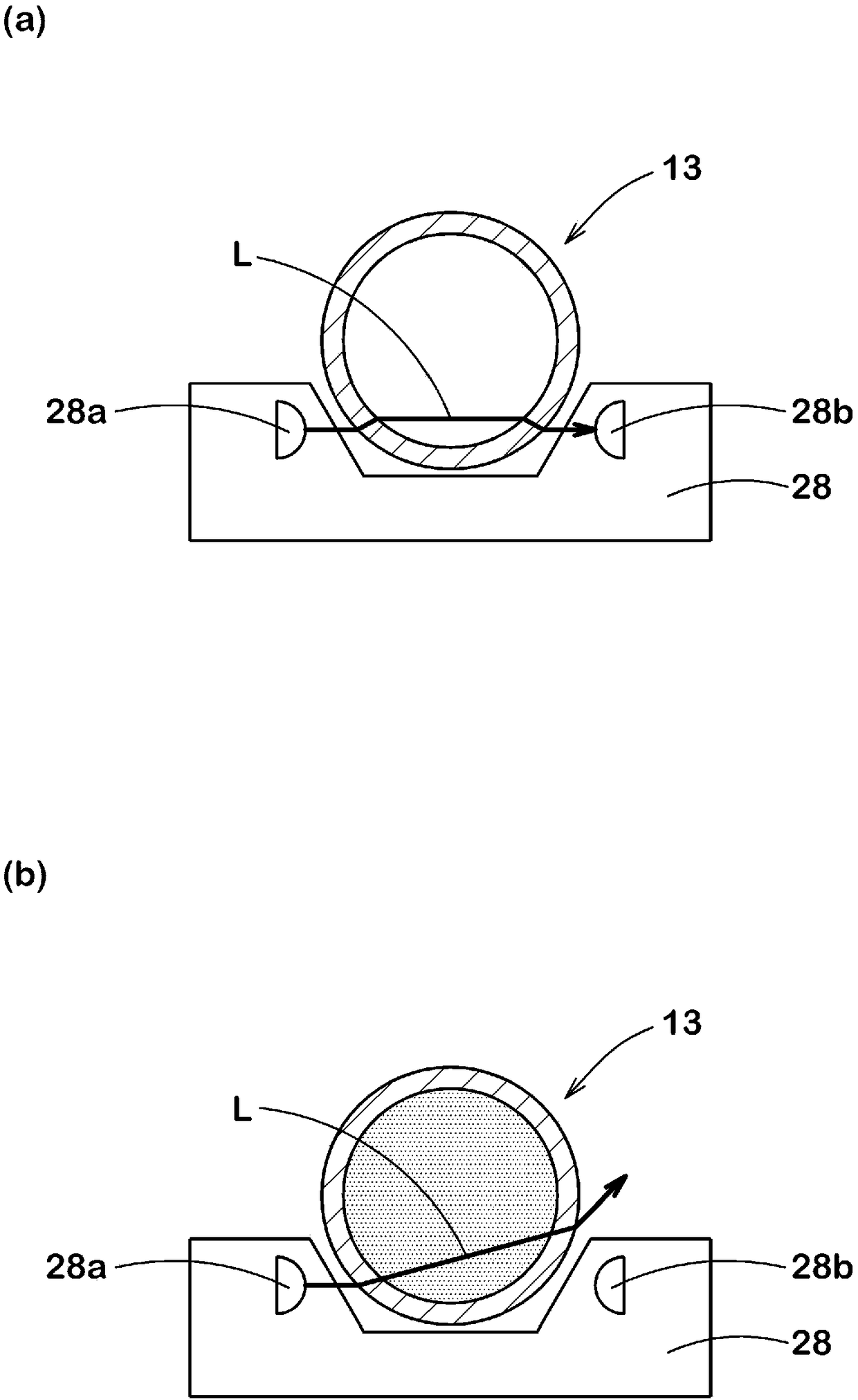

A solid polymer membrane-type water-electrolysis apparatus according to the present invention includes a solid polymer electrolyte membrane, an oxygen electrode mounted in contact with one side of the solid polymer electrolyte membrane, a hydrogen electrode mounted in contact with the other side of the solid polymer electrolyte membrane, separator plates mounted adjacent the outsides of the oxygen electrode and the hydrogen electrode and serving as current collector plates having passages for water and generated gasses, fixing plates disposed outside the separator plates and made of a non-conductive material, and reservoirs disposed outside said fixing plates for storing water and the generated gasses. The fixing plates include pressing members build therein for pressing the oxygen electrode and the hydrogen electrode against the solid polymer electrolyte membrane, and flow passages are included in the pressing members. The reservoirs are fixed integrally by tie bolts by clamping the solid polymer electrolyte membrane, the oxygen electrode, the hydrogen electrode, the separator plates and the fixing plates together from outside the fixing plates. Further, the reservoirs have water supply bores provided at locations higher in level than the position of the water electrolysis level, and discharge bores for discharging the generated gasses. In this apparatus, storage tanks for the produced oxygen and hydrogen gasses are formed integrally into a compact structure. Thus, the apparatus is convenient for movement and preservation, and the oxygen and hydrogen gasses stored can be brought into a pressure equal to or higher than the atmospheric pressure and supplied to a remote place.

Owner:DAIDO METAL CO LTD

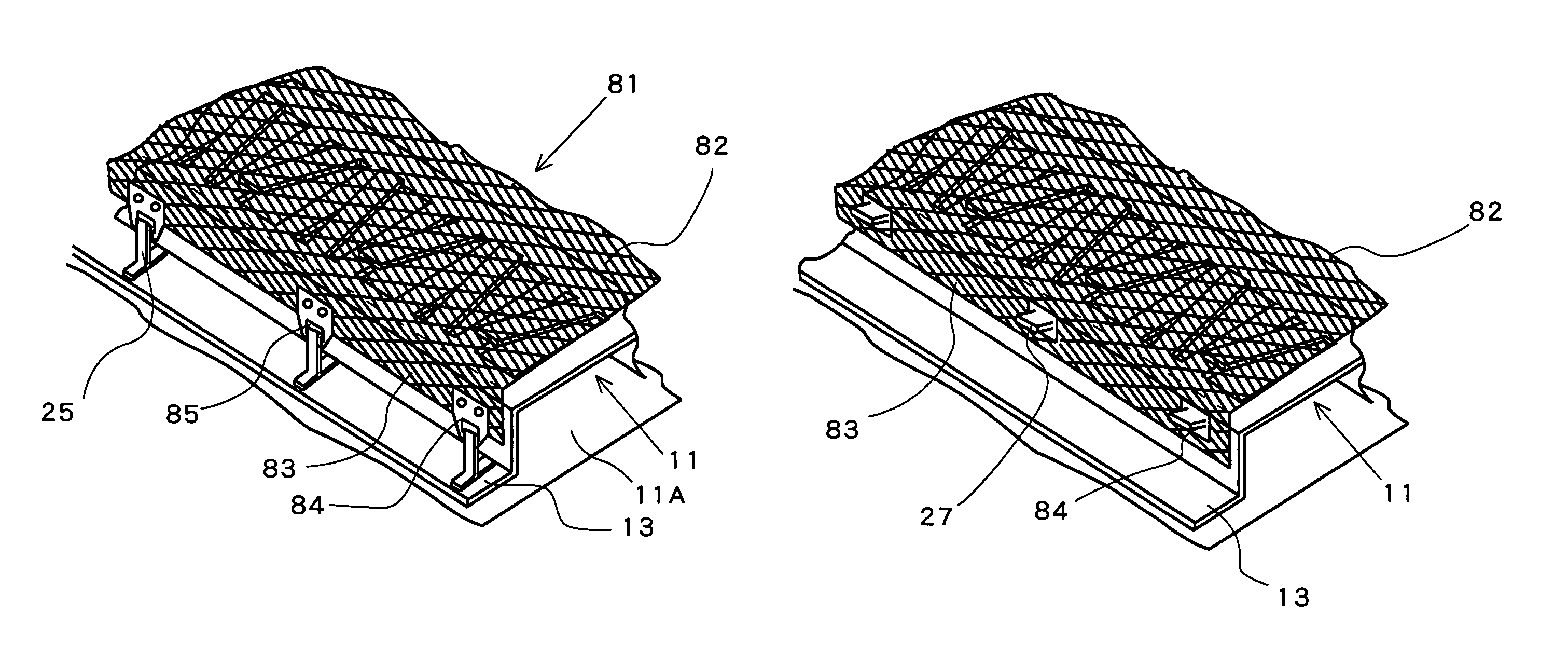

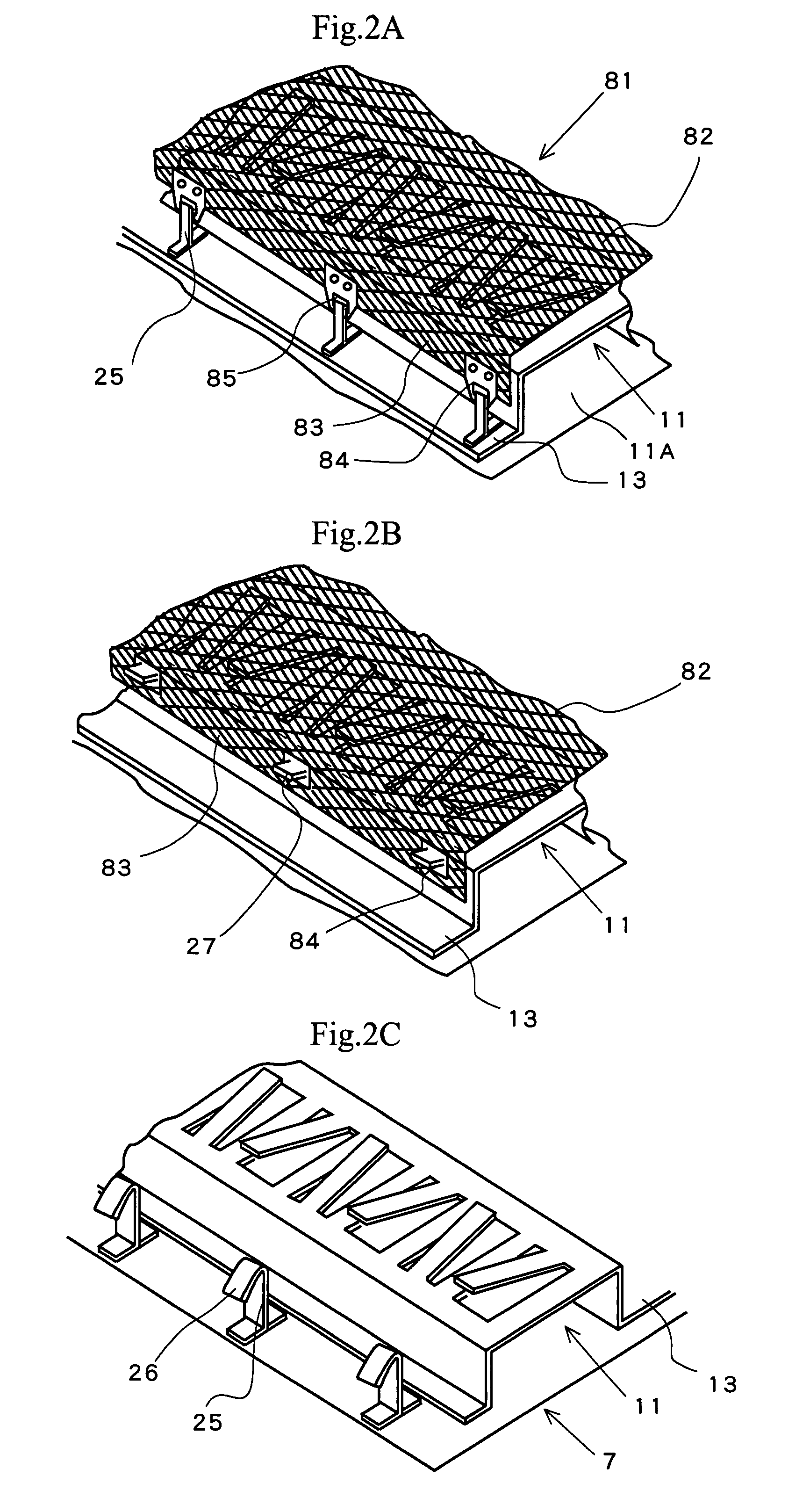

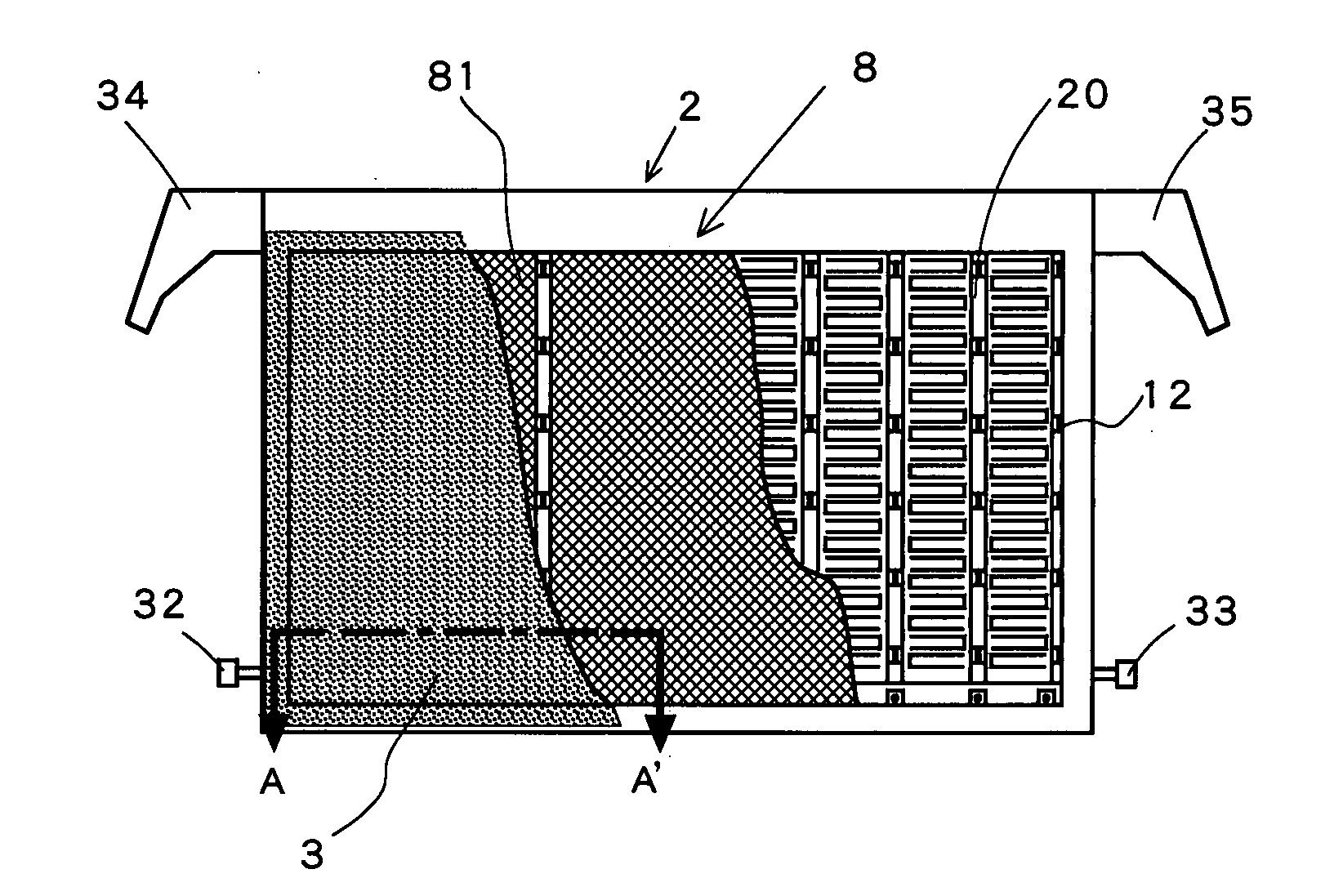

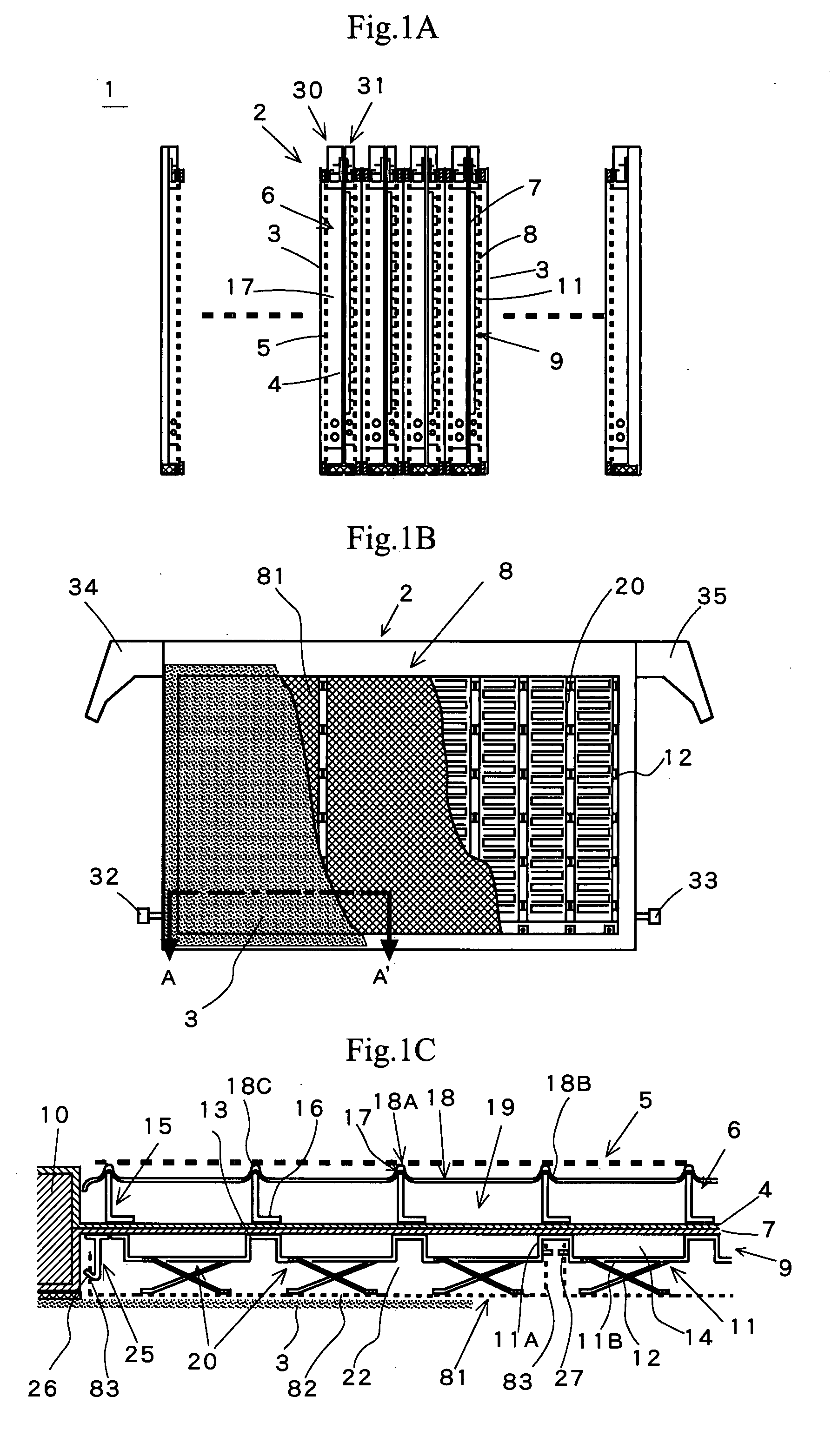

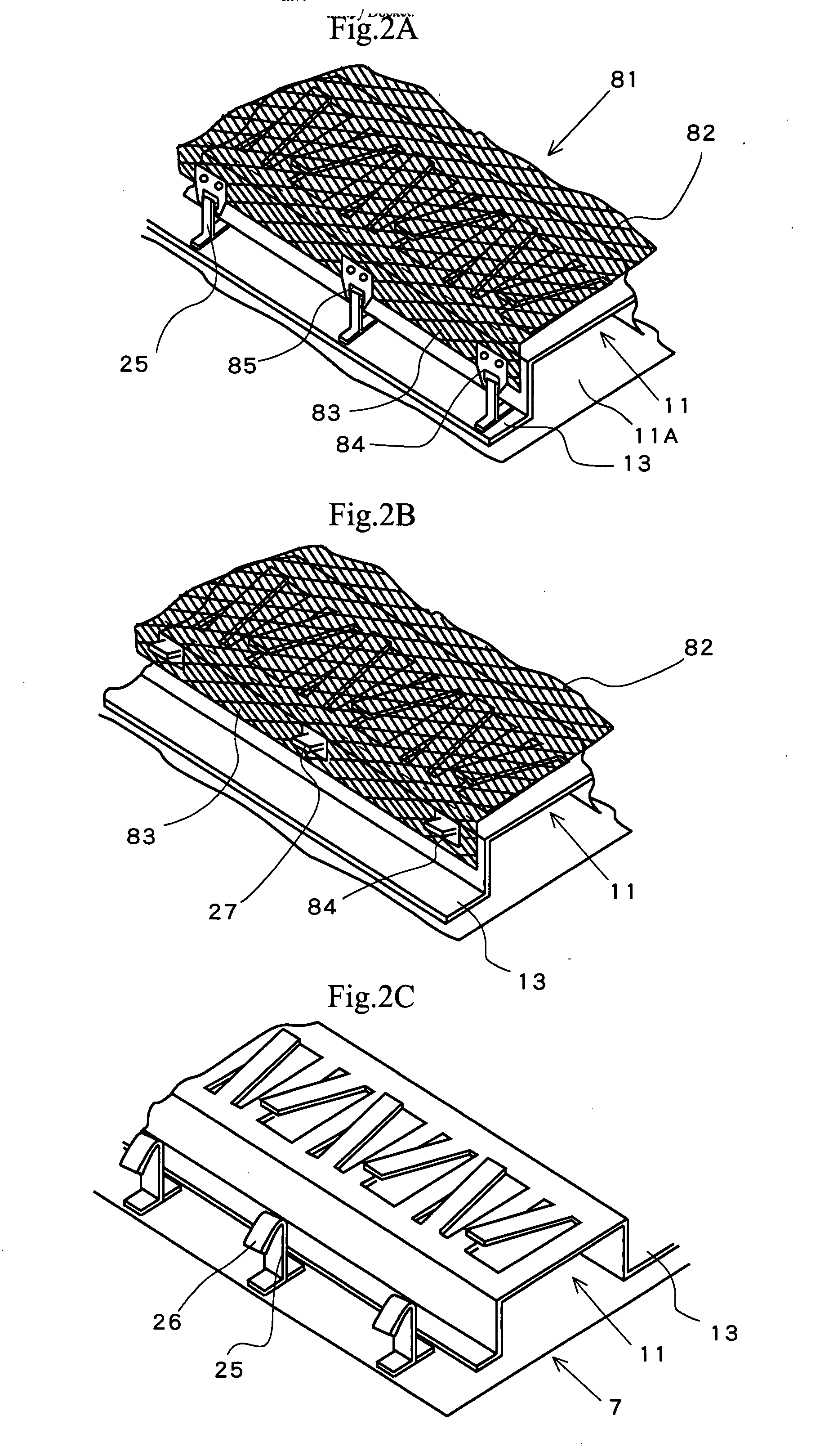

Ion exchange membrane electrolyzer

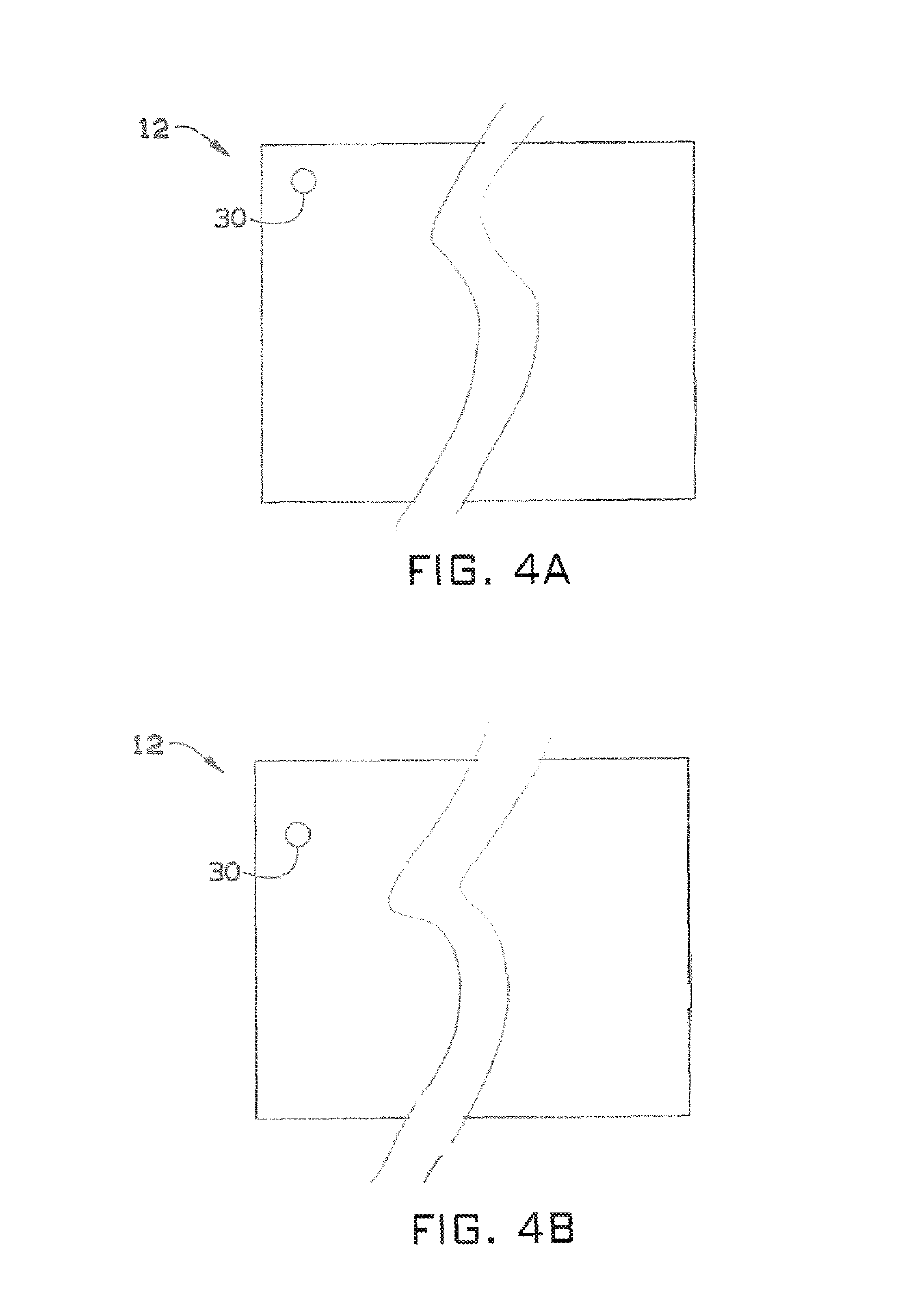

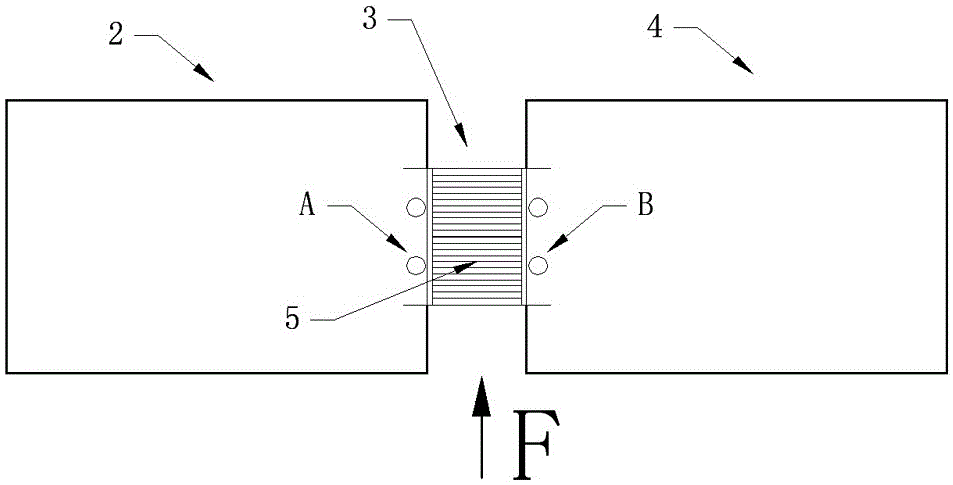

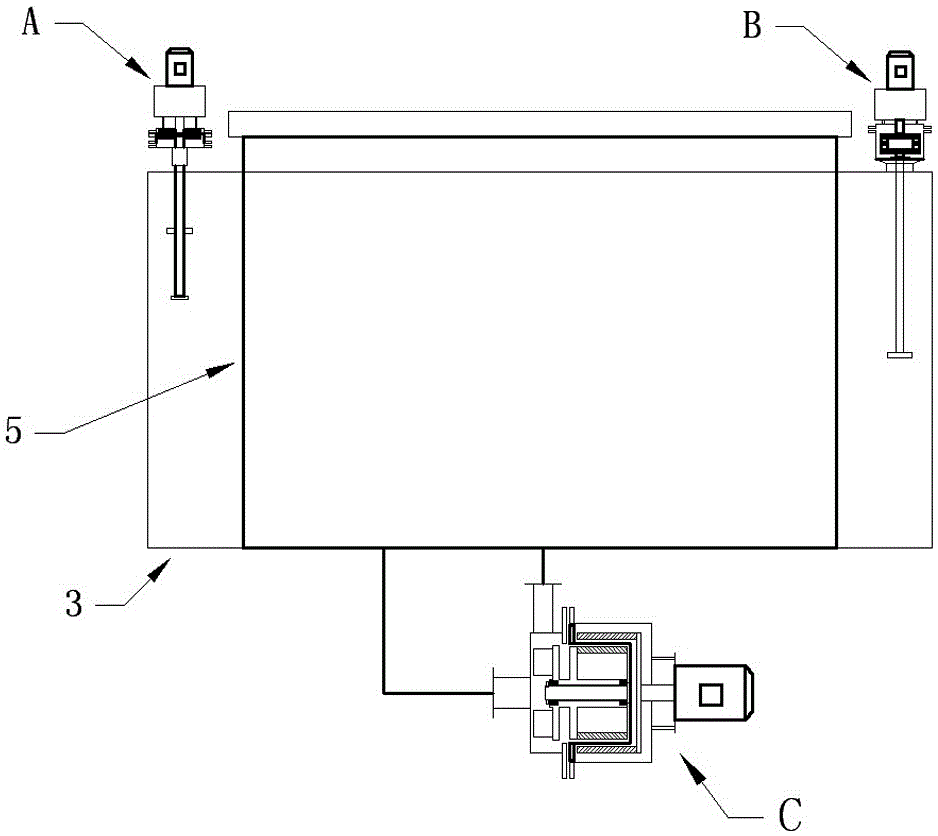

ActiveUS7763152B2Avoid displacementEfficient electrolysisCellsMachining electrodesEngineeringIon-exchange membranes

There is provided an ion exchange membrane electrolyzer, wherein at least one electrode is energized by coming into contact with plate spring bodies formed on the electrode side of an electrode holding member forming a space with an electrode chamber partition bonded to a plate-like electrode chamber partition by a strip-like bonded portion, the electrode has a connected portion extending from a plane parallel to the ion exchange membrane toward the electrode holding member side in a direction perpendicular to the electrode plane, the connected portion is provided with an engaging opening extending in a direction perpendicular to the electrode plane, and the engaging opening engages with an engaging member, permitting the electrode to move in a direction perpendicular to the electrode plane within the displacement range of the plate spring bodies.

Owner:TOSOH CORP

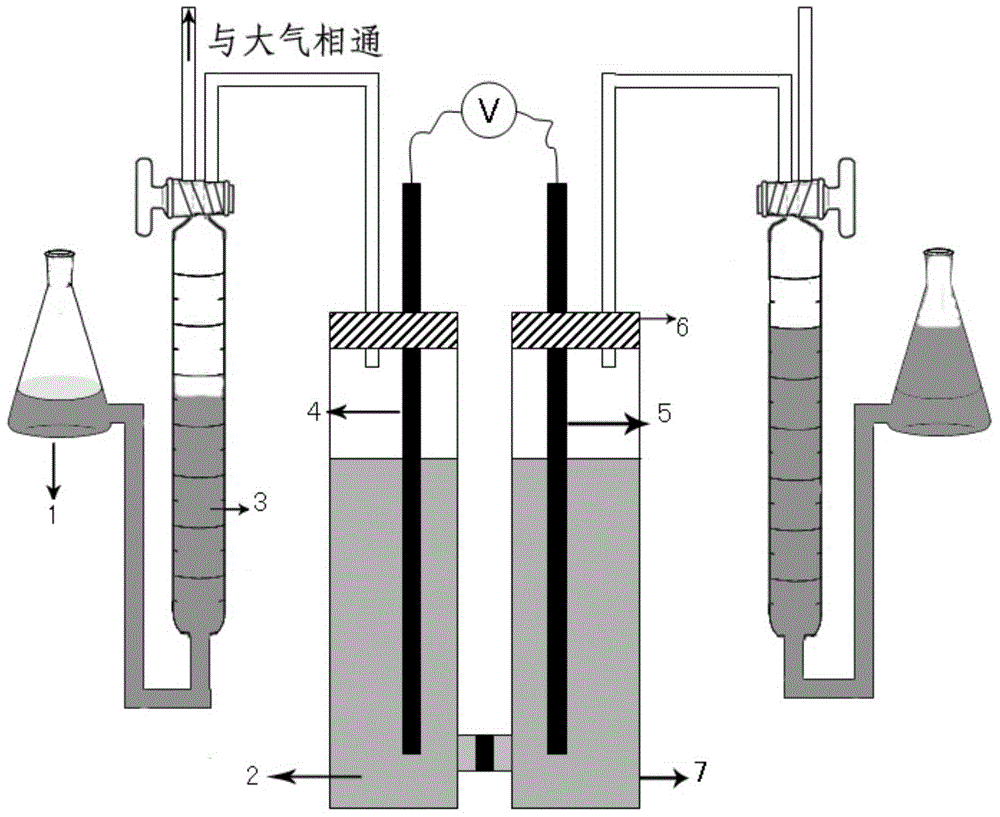

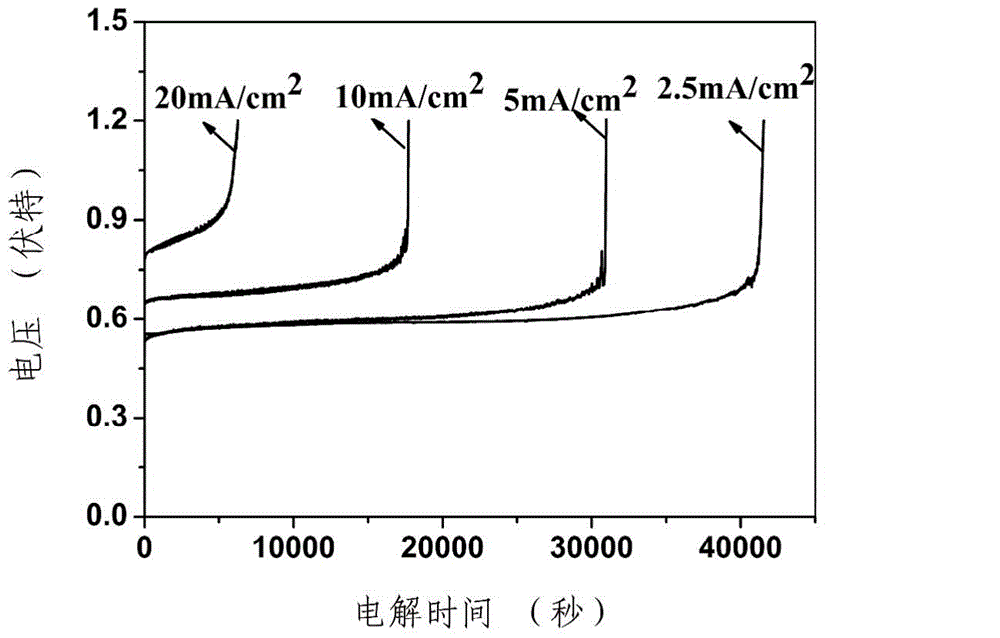

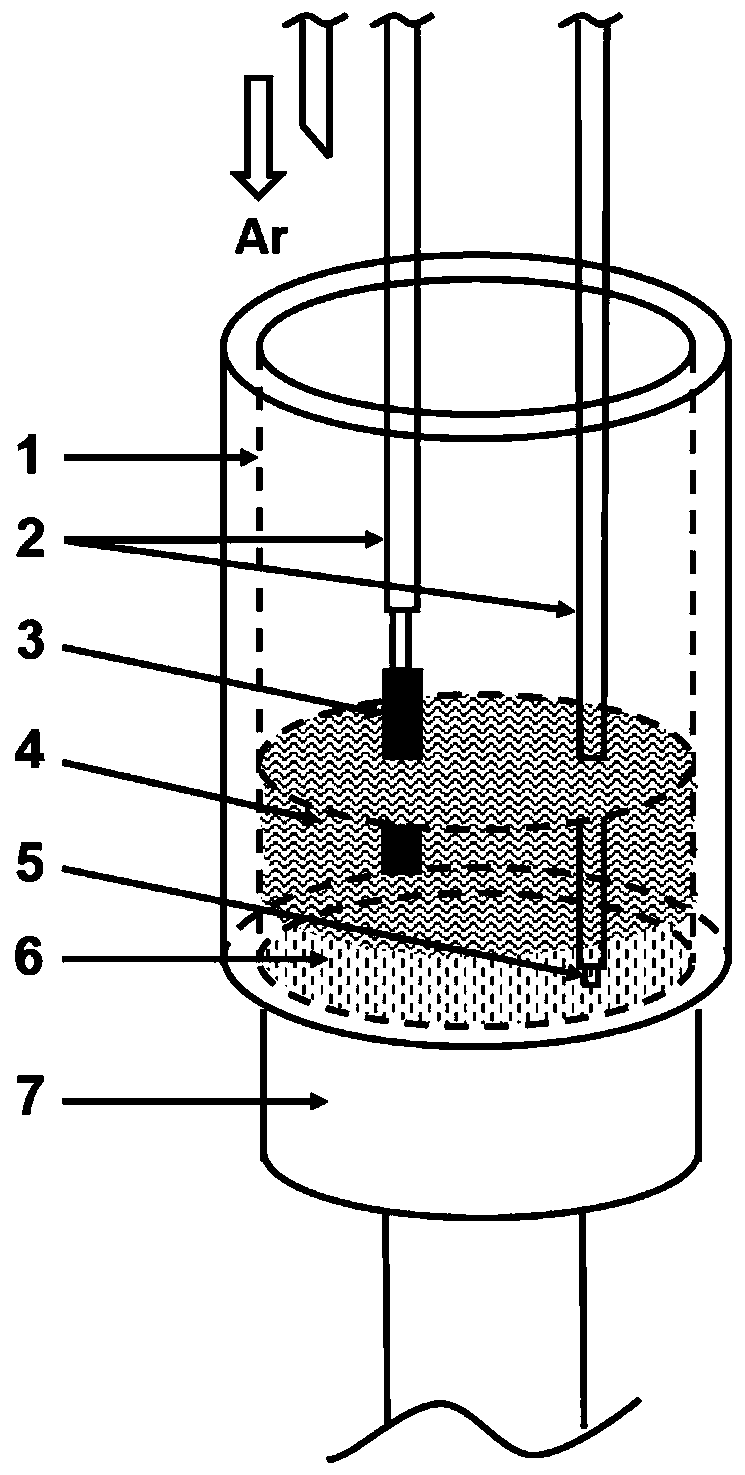

Method and device for preparing hydrogen by electrolyzing ammonia

InactiveCN104419945AReduce energy consumptionImprove efficiencyCellsElectrode shape/formsElectrolytic agentNitrogen gas

The invention belongs to a preparation method of hydrogen and specifically relates to a method and a device for preparing the hydrogen by electrolyzing ammonia. Ammonia is taken as a raw material and foamed nickel on which different noble metals are deposited is taken as an anode and a cathode for an electrolytic hydrogen production reaction; specifically, the cathode and the anode are simultaneously inserted into an ammonia-containing electrolyte, and the external voltage of 0.6-0.8V is applied between the cathode and the anode so that ammonia has an oxidizing reaction to generate nitrogen and water has a reduction reaction to generate hydrogen. The temperature of the electrolytic reaction is controlled between 50 and 60 DEG C. The method for preparing hydrogen by electrolyzing ammonia has the advantages that the electrolytic voltage can be controlled below 0.8V and hydrogen can be prepared economically and effectively.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

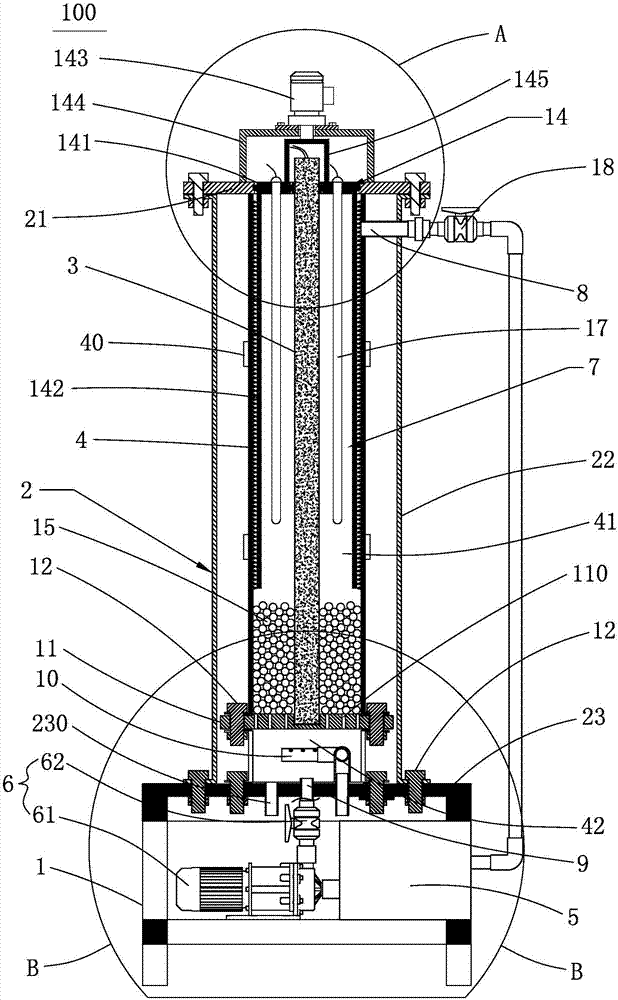

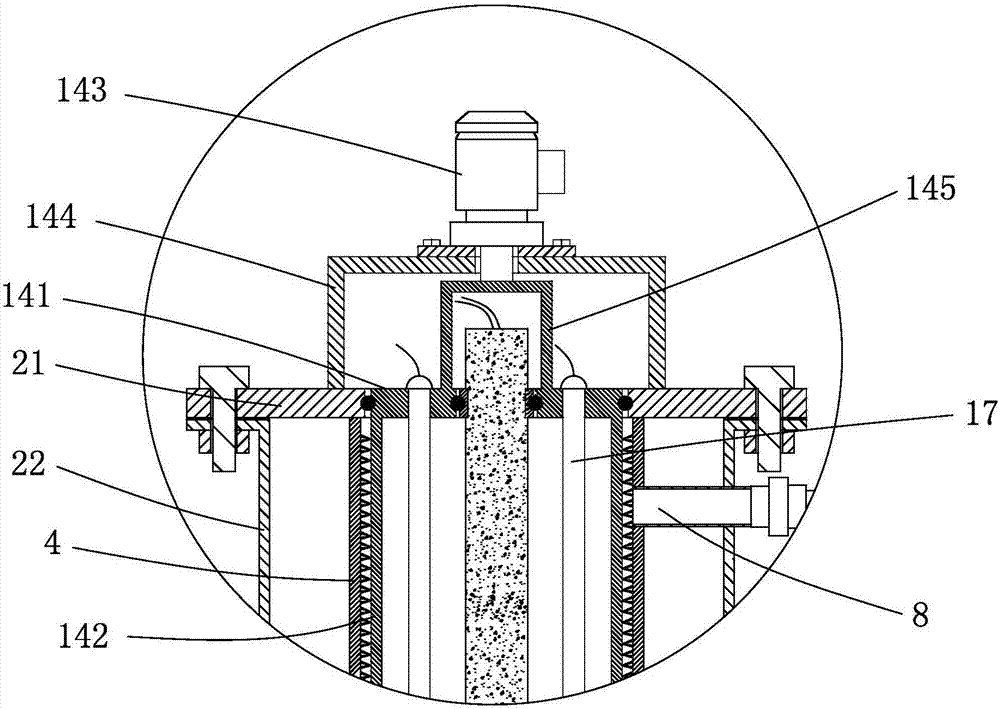

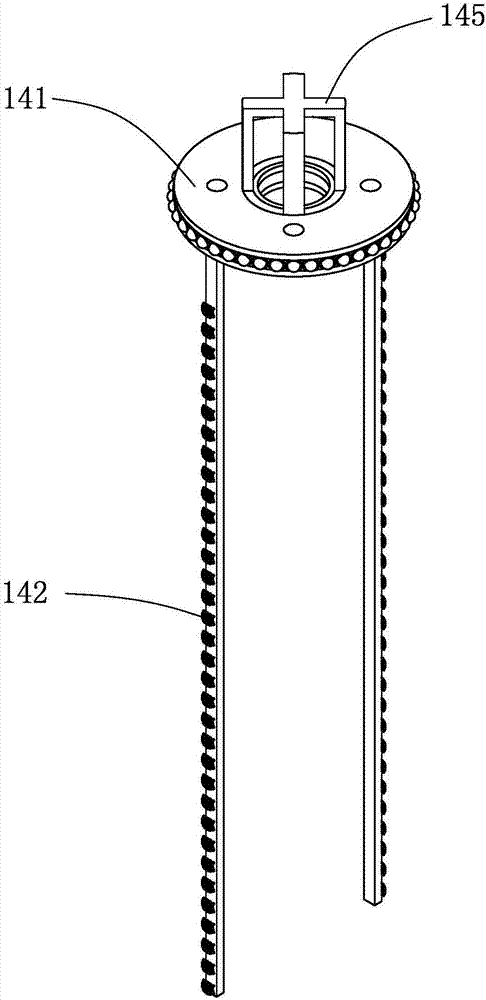

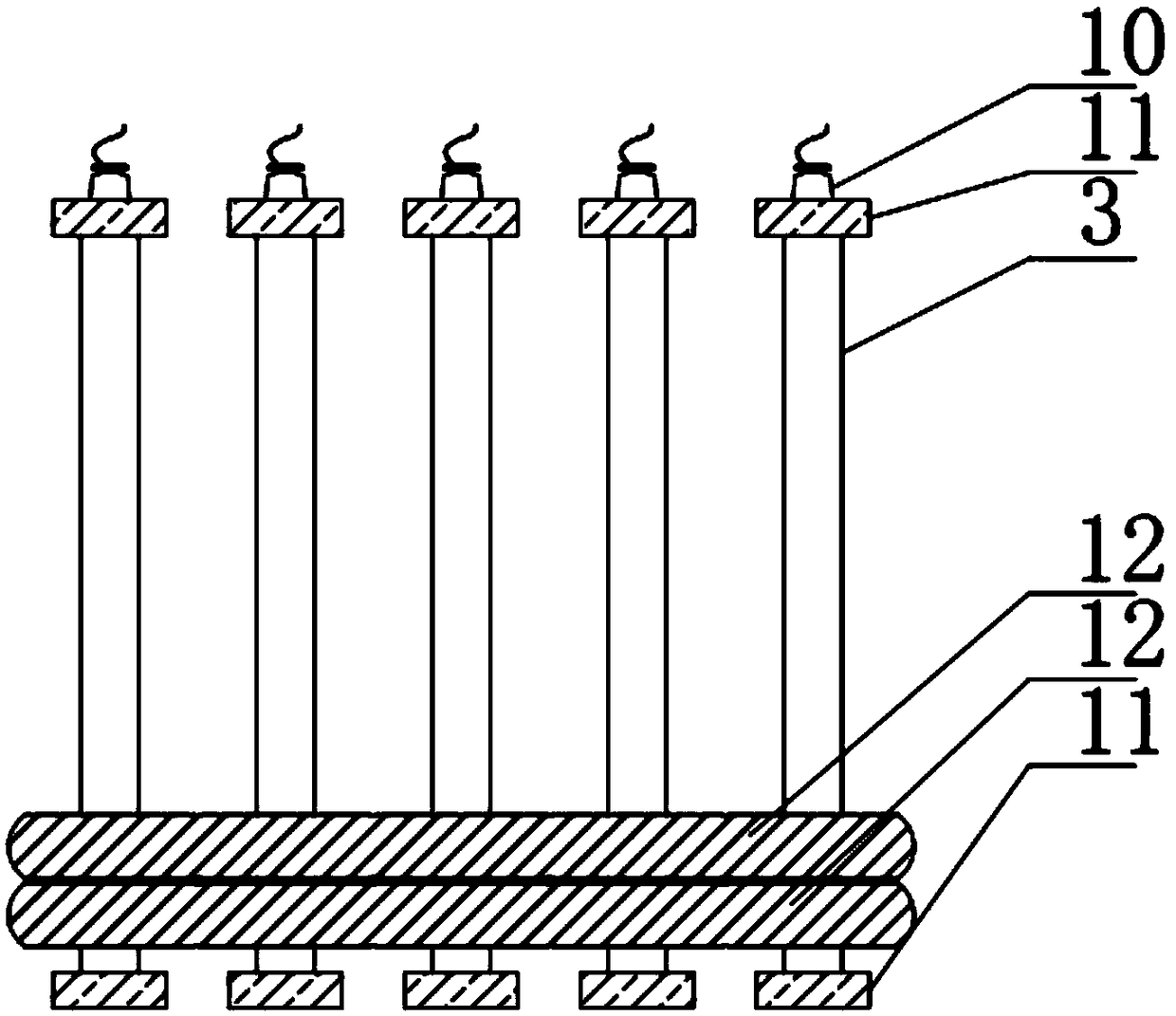

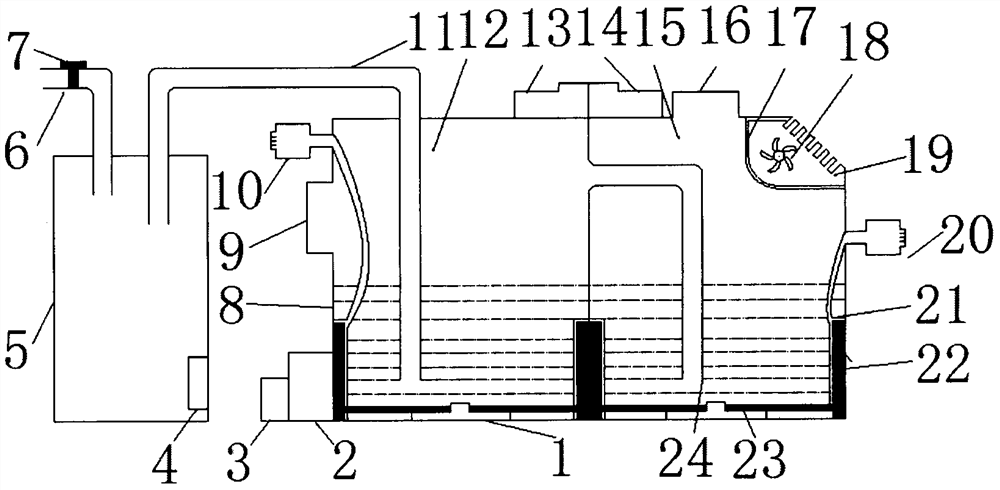

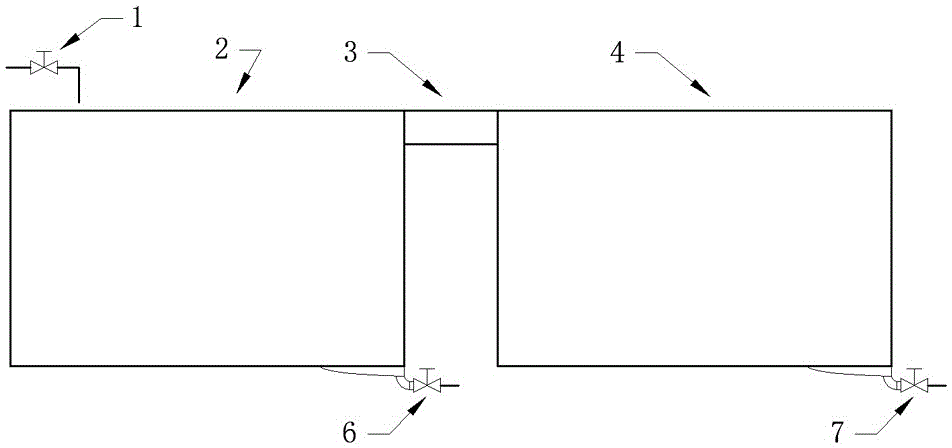

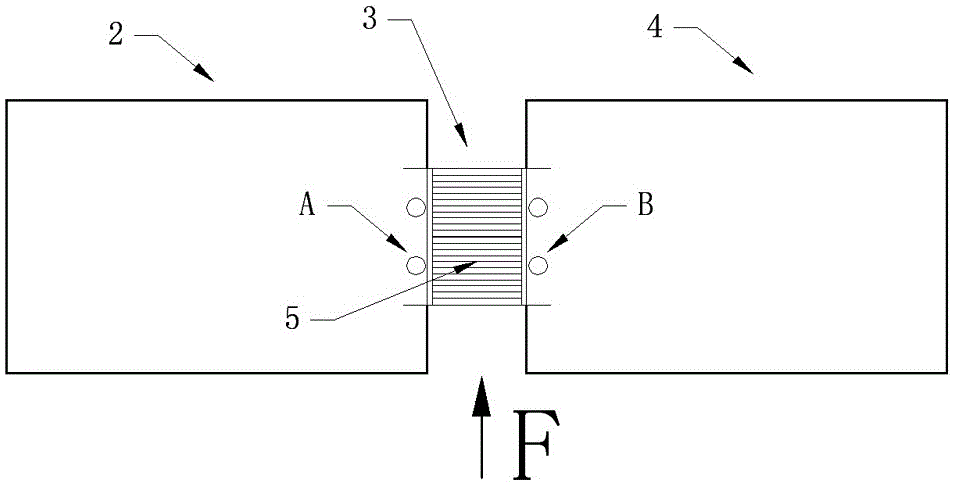

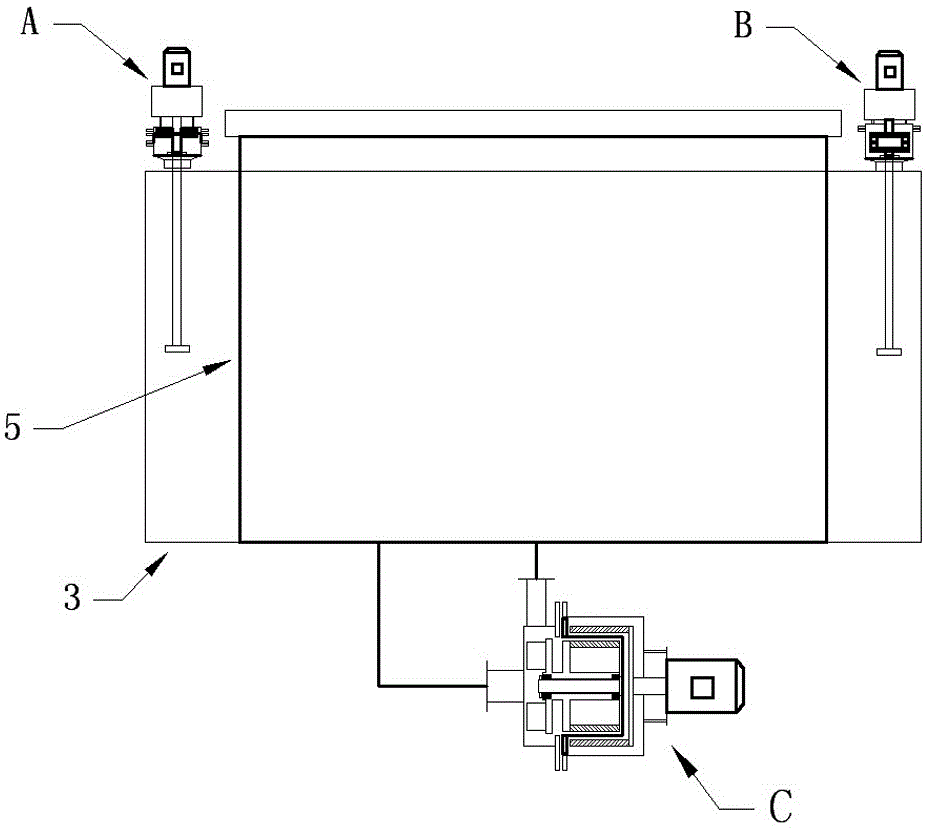

Electric flocculation unit, electric flocculation device and heavy metal wastewater treatment system

PendingCN107215929ATo achieve the purpose of removing pollutantsEfficient electrolysisWater treatment compoundsSpecific water treatment objectivesWater treatment systemElectro flocculation

The invention belongs to the field of heavy metal wastewater treatment and provides an electric flocculation unit, an electric flocculation device and a heavy metal wastewater treatment system. The electric flocculation unit comprises a shell, an anode bar, a cathode tube, iron carbon ball filler, a rotary type scraper device, an ultraviolet lamp, an aerating device, a power module and a liquid conveying mechanism, wherein the cathode tube is vertically arranged in the shell, the anode rod is vertically arranged in the cathode tube, the rotary type scraper device and the ultraviolet lamp are arranged in the cathode tube, the rotary type scraper device is movably connected with the shell through a bearing, the shell is detachably connected with the cathode tube and the anode bar, an insulating plate where a diffluence hole is formed is detachably connected to the cathode tube, and the iron carbon ball filler is stacked on the insulating plate. The electric flocculation device disclosed by the invention comprises a plurality of electric flocculation units, supports and liquid storage tanks, wherein the electric flocculation units, the supports and the liquid storage tanks are communicated through pipelines to be in parallel connection or serial connection. The heavy metal wastewater treatment system comprises the electric flocculation device, an air floating device and an ion exchange device, wherein are sequentially connected with each other. The heavy metal wastewater treatment system disclosed by the invention has a good heavy metal wastewater treatment effect and convenience in disassembling and cleaning.

Owner:SHENZHEN GAIA ENVIRONMENTAL ENG CO LTD

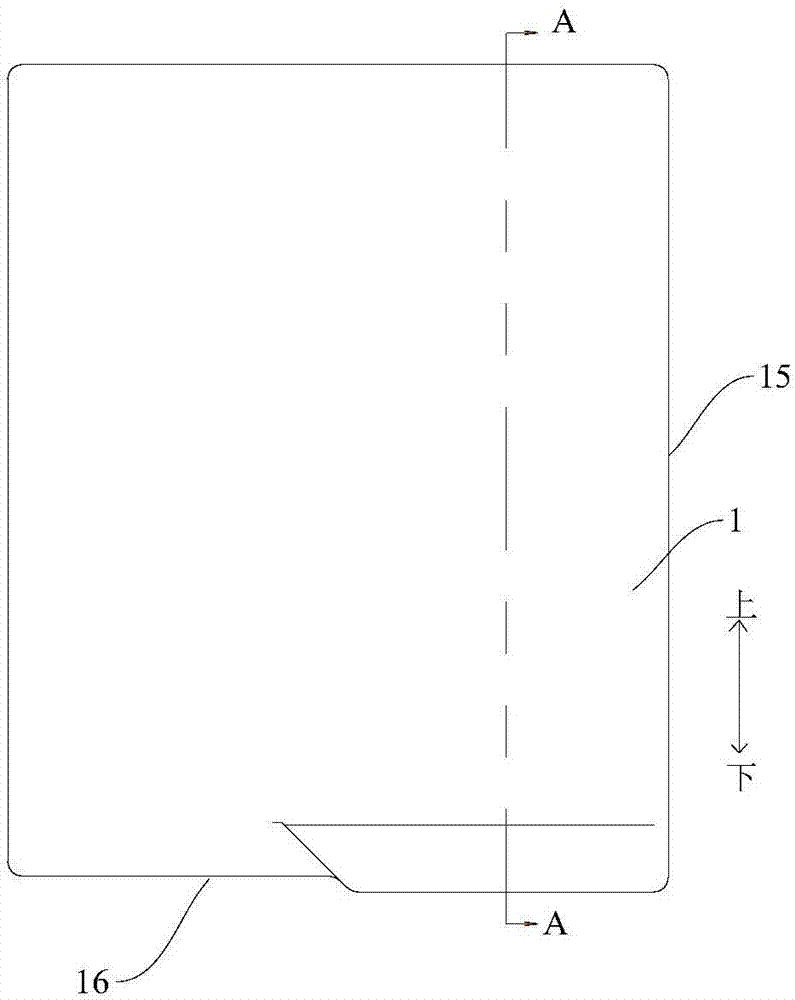

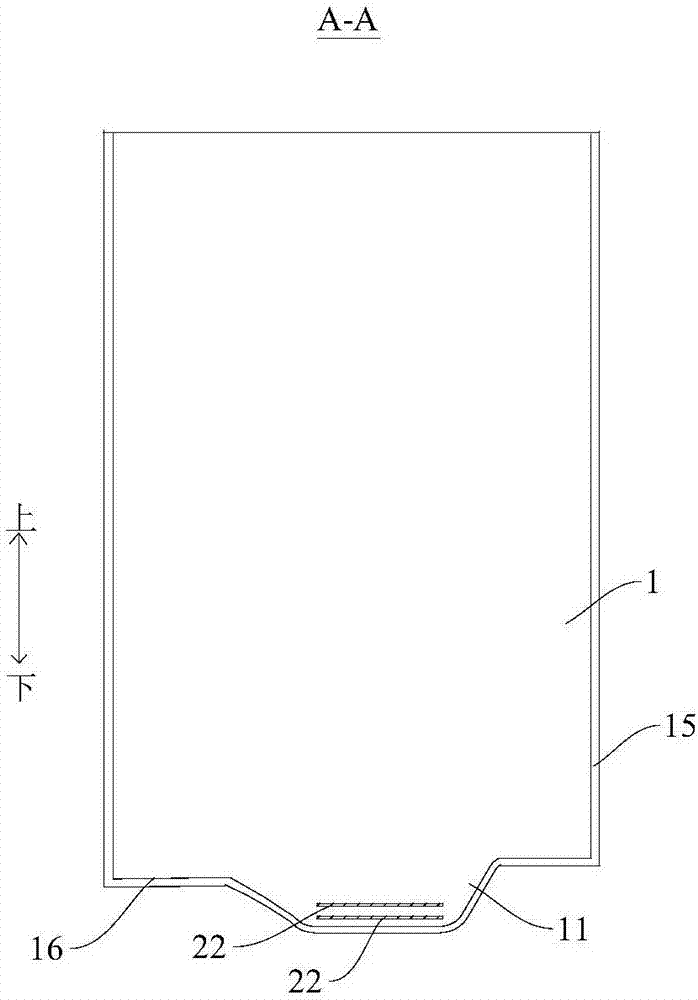

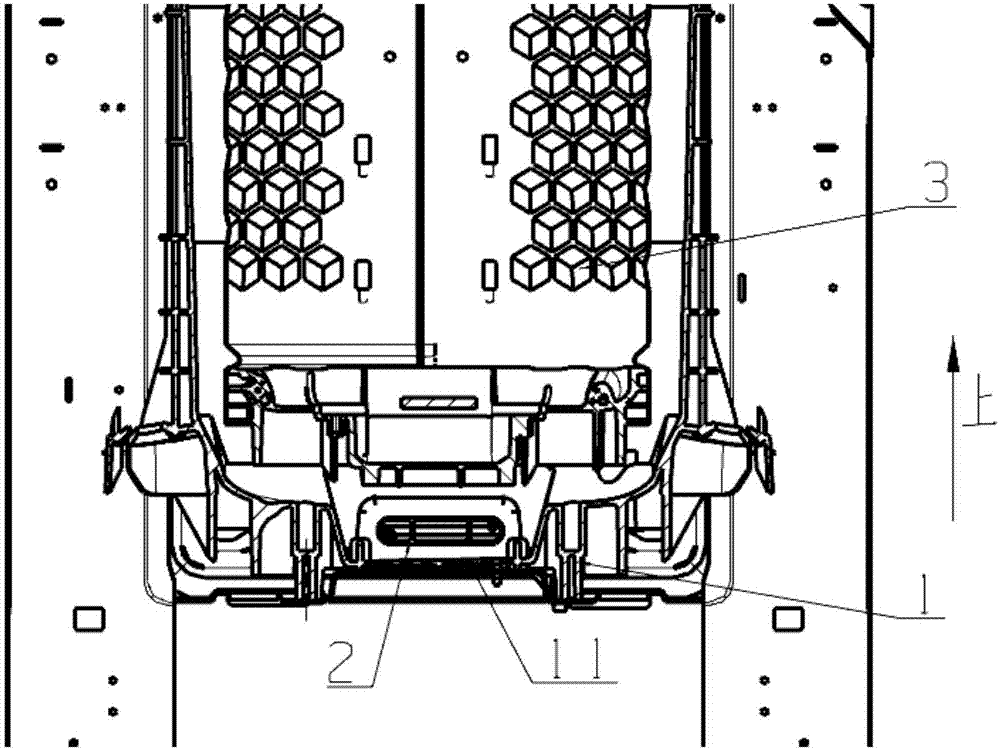

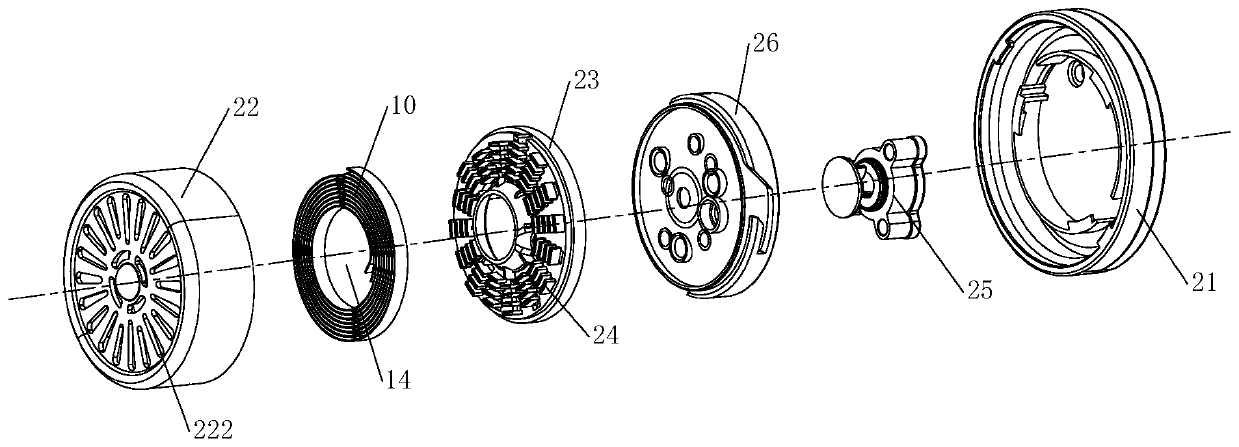

Impeller type washing machine

ActiveCN107488969AReasonable installationEfficient electrolysisOther washing machinesWater/sewage treatmentImpellerPulp and paper industry

The invention discloses an impeller type washing machine. The impeller type washing machine includes a water bucket, an inner bucket, an impeller and an electrolytic device, wherein the periphery of the water bucket is provided with an opening, the bottom wall of the water bucket is provided with an anticollision groove protruding outwardly, the inner bucket is arranged in the water bucket, the impeller is arranged on the bottom wall of the inner bucket, the electrolytic device includes an installation base and an electrode plate, the electrode plate is arranged on the installation base, the installation base is installed at the position of the opening and extends toward the anticollision groove, the electrode plate is arranged in the anticollision groove, and a wire leading hole is formed in the installation base, By arranging the electrode plate in the anticollision groove, interference between the electrode plate and original parts in the water bucket can be avoided, the space occupied by the impeller type washing machine is less, and the installation reliability of the electrolytic device can be guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Method for producing magnesium using bischofite as raw material

InactiveCN1663913AUniform particle sizeAvoid the dehydration processProcess efficiency improvementMagnesiaSolubilityMetallic materials

A method of preparing magnesium metal with bischofite, pertains to the field of metallic material. The invention is characterized in that it takes the bischofite as stock and prepare magnesium hydroxide with ammonia process under the following conditions: at the temperature between 45~55 DEG C for 20~30 minutes, with the proportion between magnesium and ammonia 1:1.2~1.5:2.2 and with the concentration of magnesium chloride about 35~55 g / L, calcinating the magnesium hydroxide under the temperature of 900~1000 DEG C for 3-4hours, getting the magnesia with the purity of more than 99.5%,in the molten salt electrolyte system of lanthanum chloride and magnesium chloride, the proportion between lanthanum chloride and magnesium chloride in moles is 10~30%, the solubility of magnesia is 5~10 mass%, thaw temperature is 700~750 DEG C, the tank voltage 4.5~6.5 volt, the current efficiency comes to 85~90%, the consumption of the direct current of magnesium is 11~12.5kWh per kilogram and the purity of magnesium is above 95%. The method avoids the dehydration process of bischofite and is characterized by the energy-saving and consumption-deducing, the highly effective and cleaning of electrolytic process, particularly for its not emitting chlorine and not polluting the environment.

Owner:UNIV OF SCI & TECH BEIJING

Method for recycling copper extracted from alkaline copper chloride etching waste liquid

InactiveCN106011929AImprove current efficiencyReduce power consumptionPhotography auxillary processesElectrodesCopper chlorideChemical substance

The invention relates to a method for recycling copper extracted from alkaline copper chloride etching waste liquid. Alkaline chloride system copper-contained etching waste liquid adopts a direct electrolytic copper removal and regeneration industrial method, and adopts a direct copper electrolysis mode; and liquid after removing copper is mixed with collected and absorbed ammonia and electrolysis copper washing water to form standard regenerated alkaline chloride system etching liquid. The method electrolytically deposits copper by independent circulating speed of a cathode plate and high current density, so that the current efficiency is high, the power consumption is low, the quality of a copper plate reaches national first standard cathode copper, the realization is easy, and the alkaline chloride system etching liquid recovers the etching activity; the all-closed replenishing, collection and absorption of ammonia volatilized from the internal are performed to replenish the alkalinity of the regenerated etching liquid; and effective salt attached on the copper plate is mixed in two circulating liquid by a reasonable ratio, so that all effective chemical substances in the internal are stably recycled.

Owner:无锡派乐科技有限公司

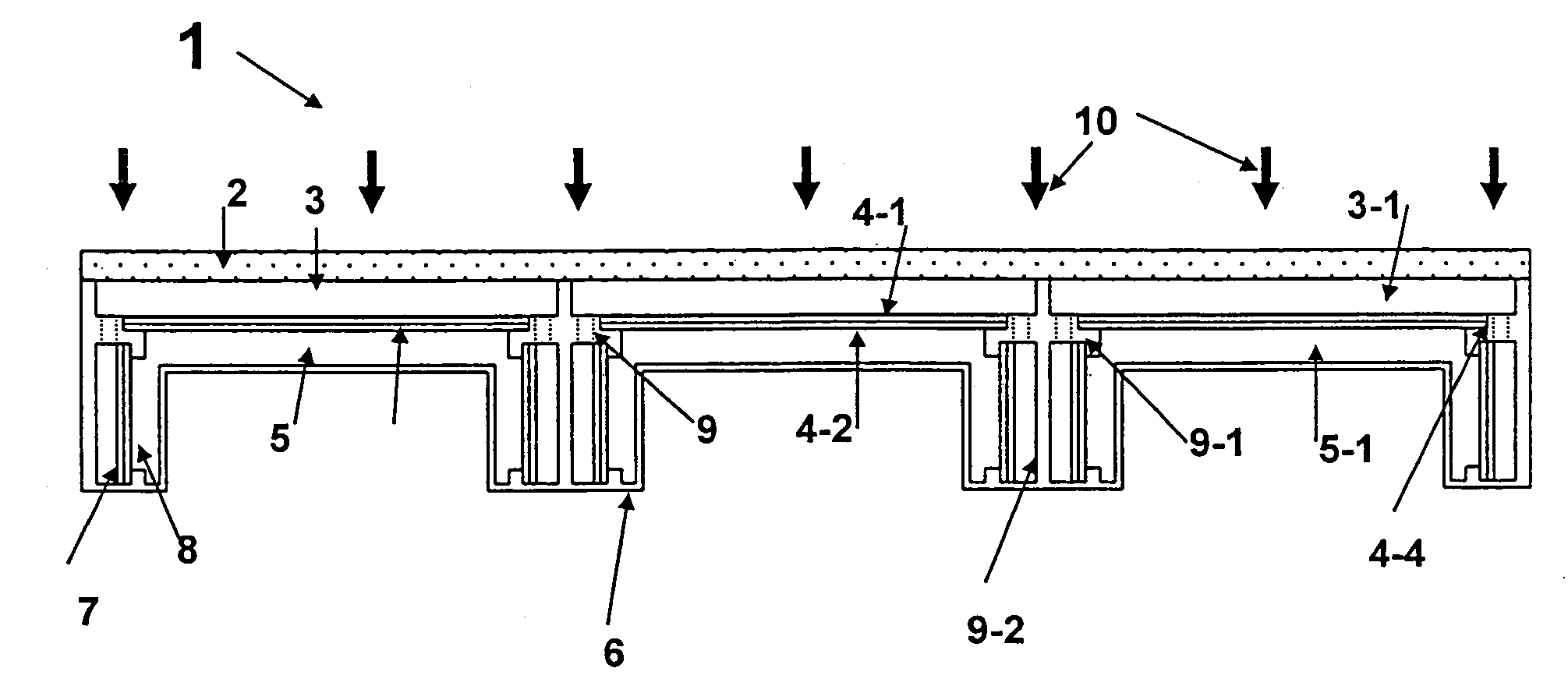

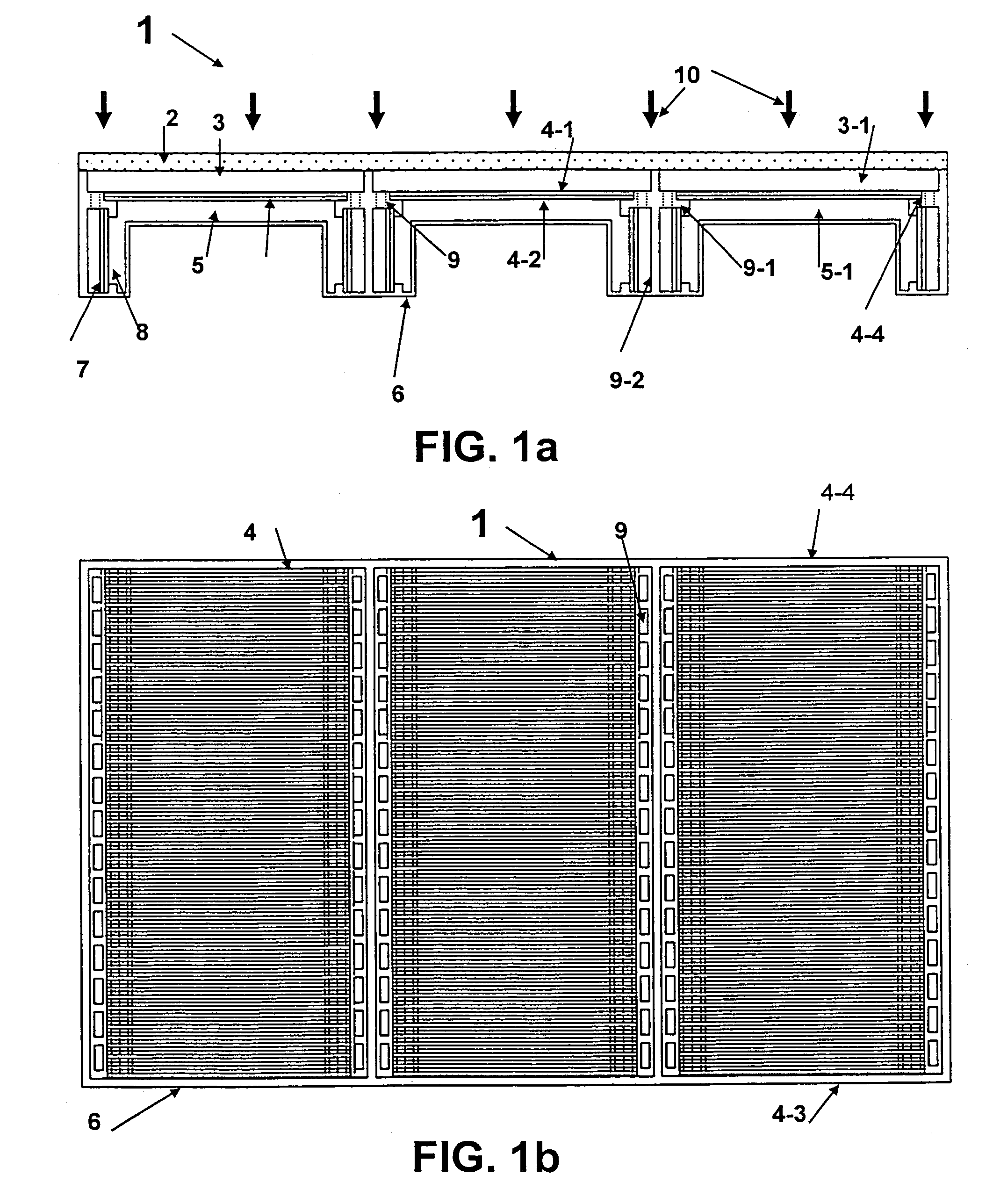

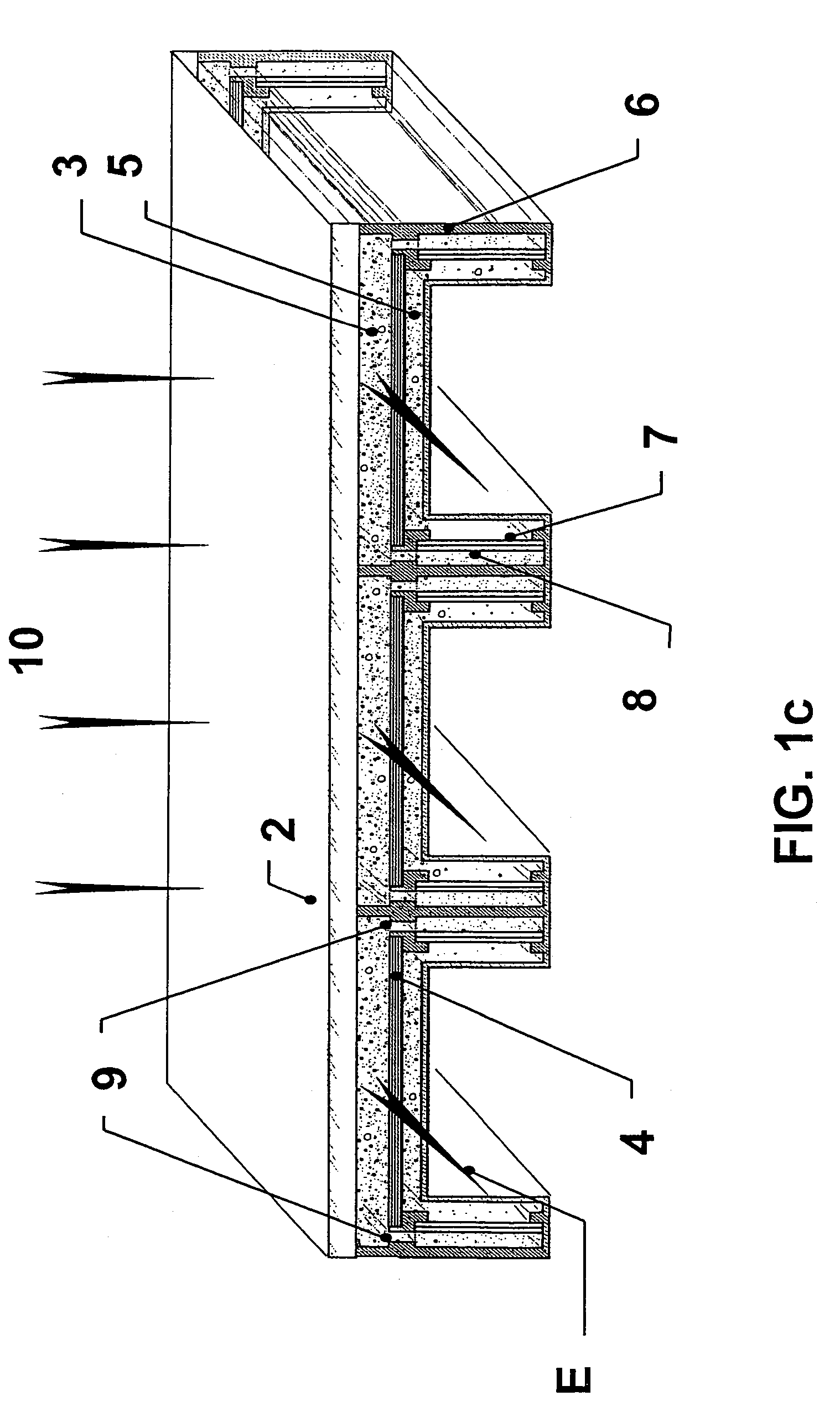

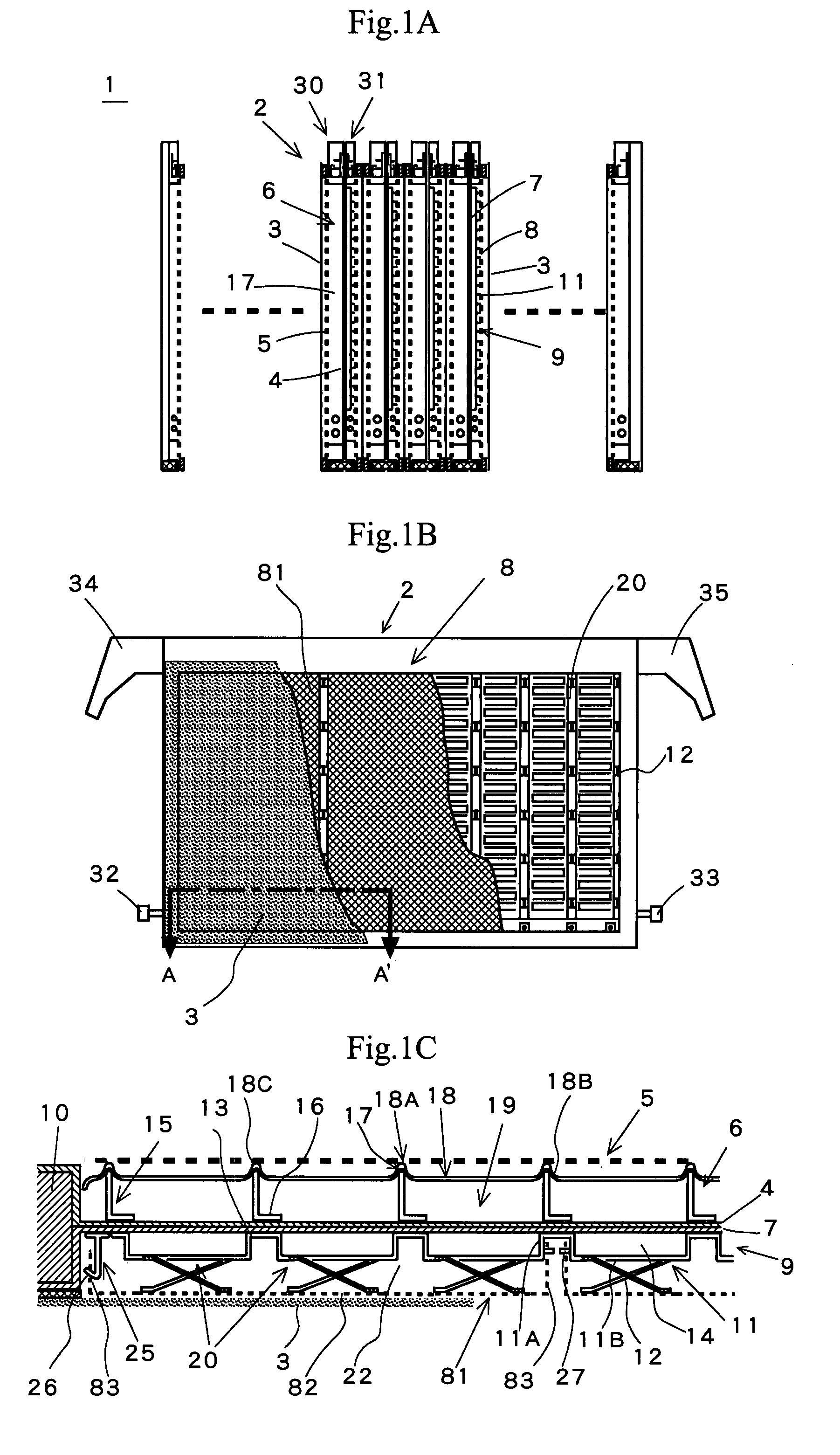

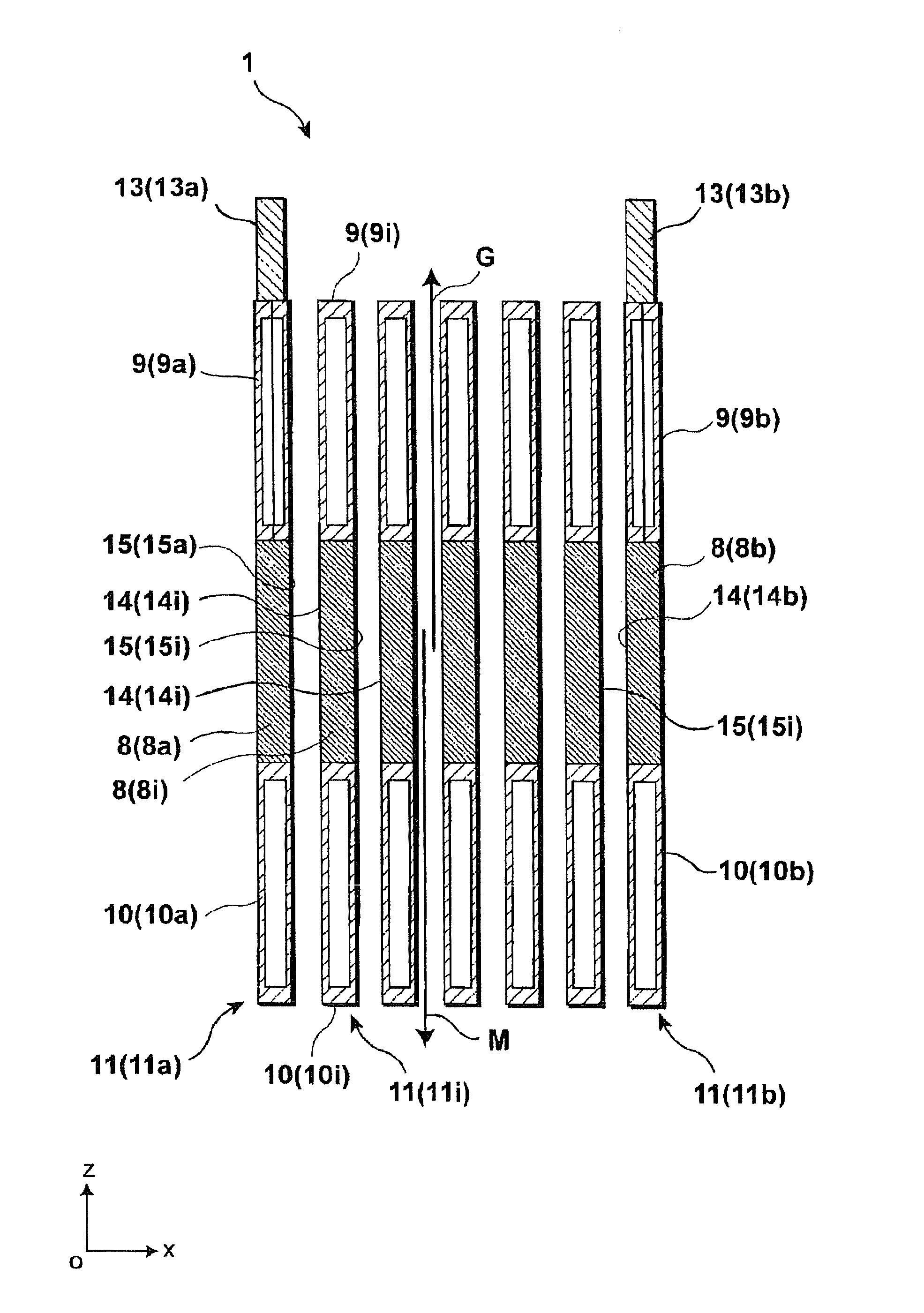

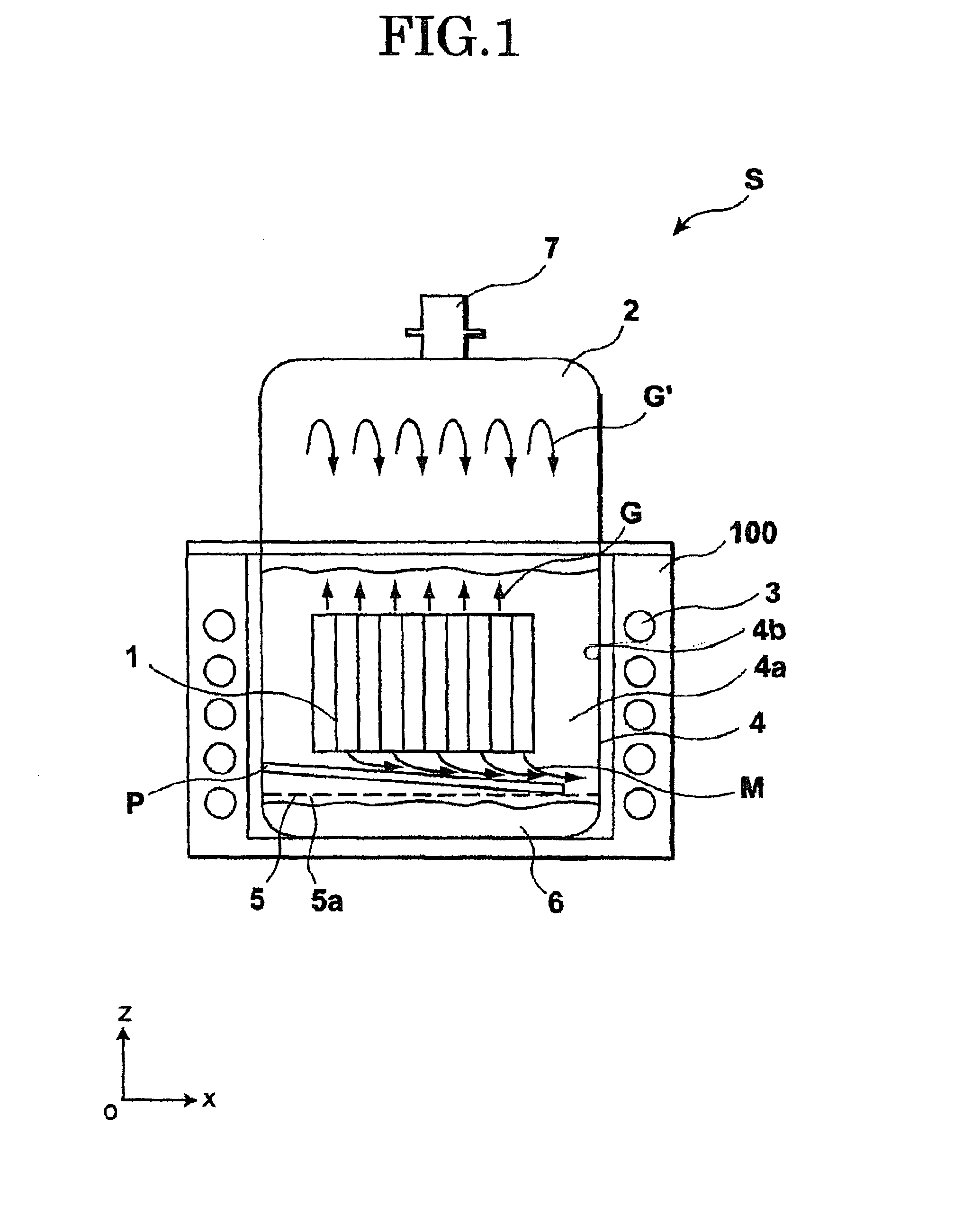

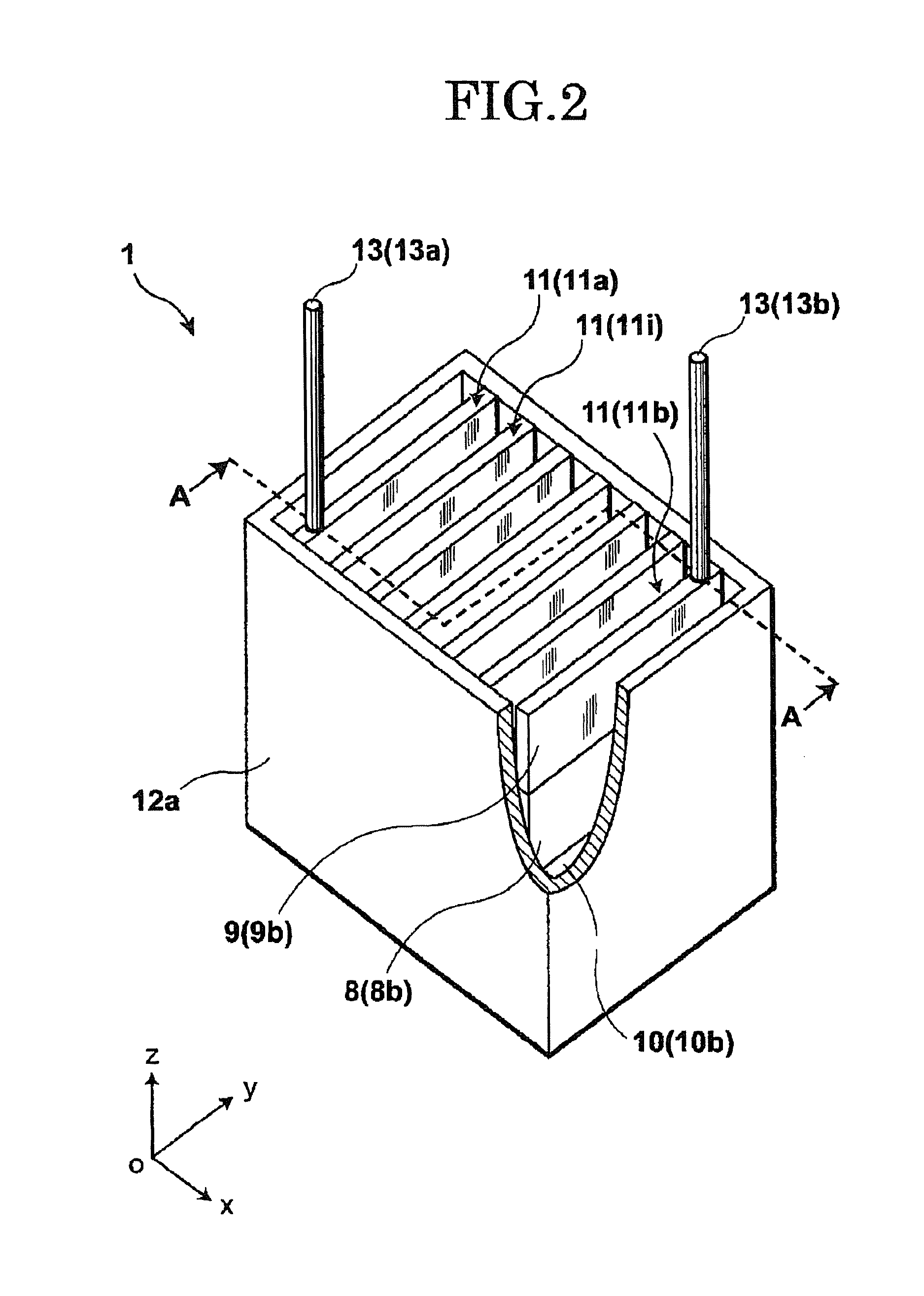

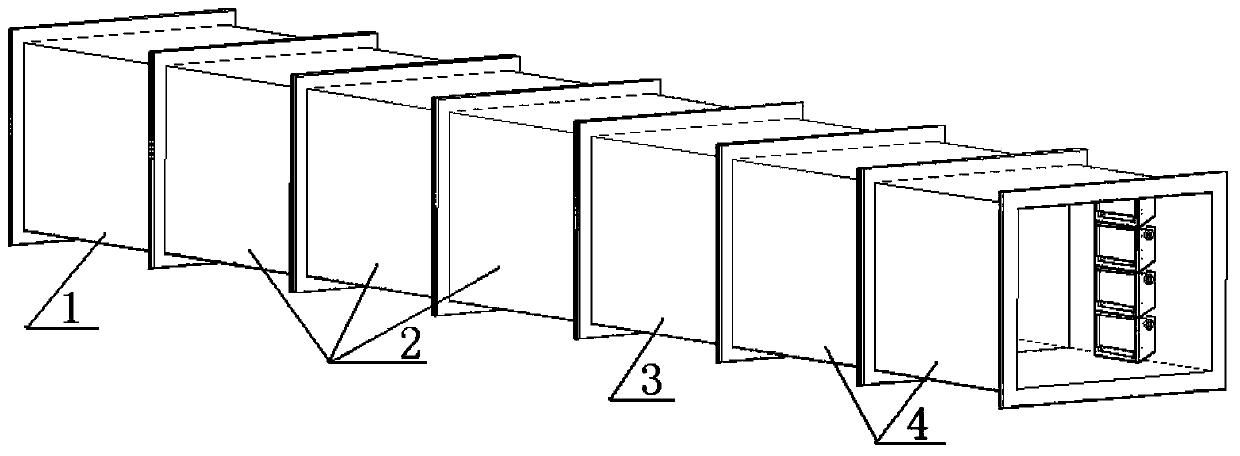

Electrolysis system and method

InactiveUS8608914B2Reducing an ohmic lossIncrease currentCellsIsotope separationMetal chlorideElectrolysis

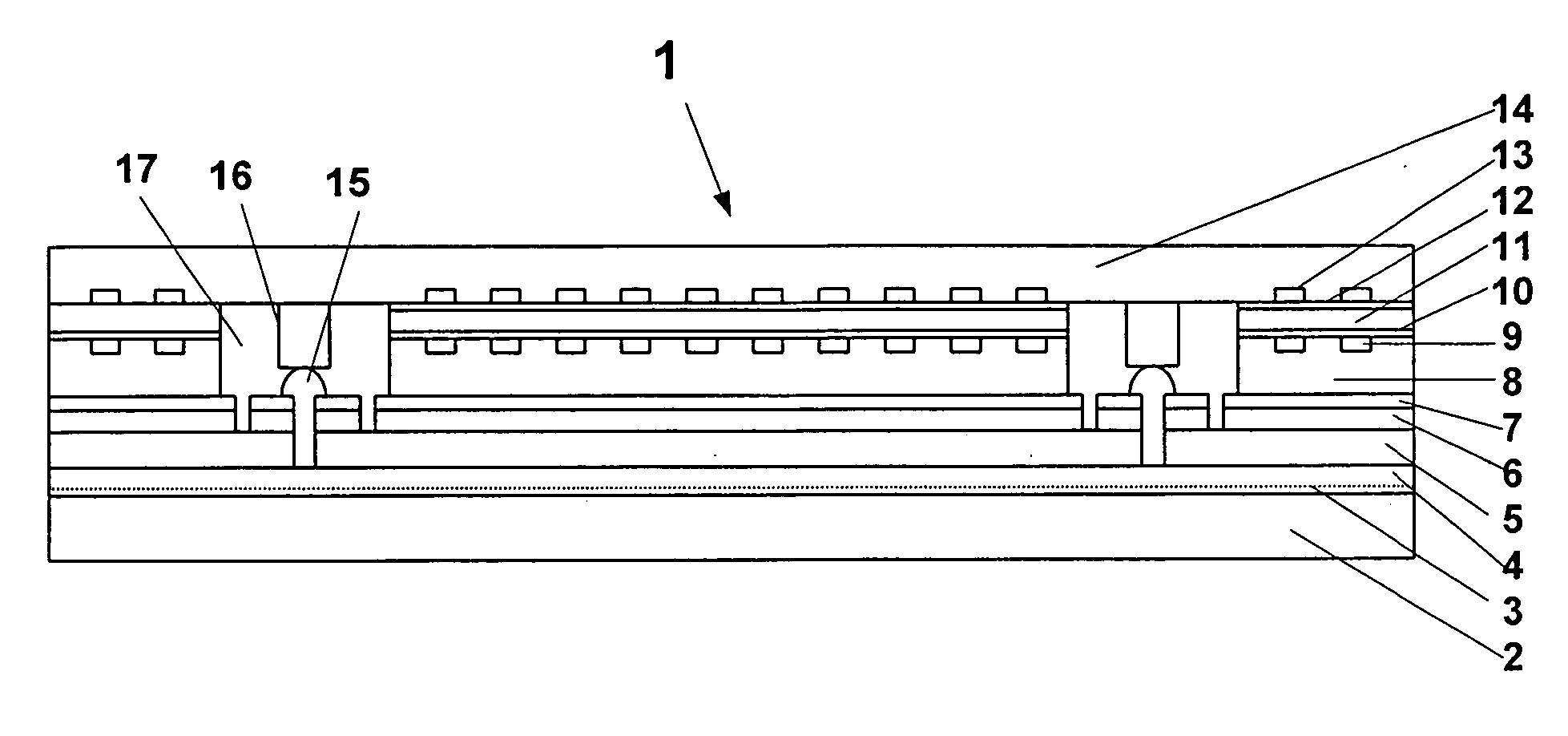

A molten salt electrolysis apparatus and a molten metal electrolyzing method using such a device are disclosed having an electrolysis vessel (4) accommodating melt electrolyte including melt metal chloride, and an electrode unit (1) having electrically conductive electrodes (8), first insulation members (9) covering upper end surfaces of the electrodes and fixed thereto while extending upward from the upper end surfaces, second insulation members (10) covering lower end surfaces of the electrodes and fixed thereto while extending downward from the lower end surfaces, and an electrode frame (12) composed of an insulating body surrounding the electrodes, the electrode unit being immersed in the melt electrolyte.

Owner:ASAHI GLASS CO LTD

Ion exchange membrane electrolyzer

ActiveUS20080053821A1Avoid displacementEfficient electrolysisCellsMachining electrodesEngineeringIon-exchange membranes

There is provided an ion exchange membrane electrolyzer, wherein at least one electrode is energized by coming into contact with plate spring bodies formed on the electrode side of an electrode holding member forming a space with an electrode chamber partition bonded to a plate-like electrode chamber partition by a strip-like bonded portion, the electrode has a connected portion extending from a plane parallel to the ion exchange membrane toward the electrode holding member side in a direction perpendicular to the electrode plane, the connected portion is provided with an engaging opening extending in a direction perpendicular to the electrode plane, and the engaging opening engages with an engaging member, permitting the electrode to move in a direction perpendicular to the electrode plane within the displacement range of the plate spring bodies.

Owner:TOSOH CORP

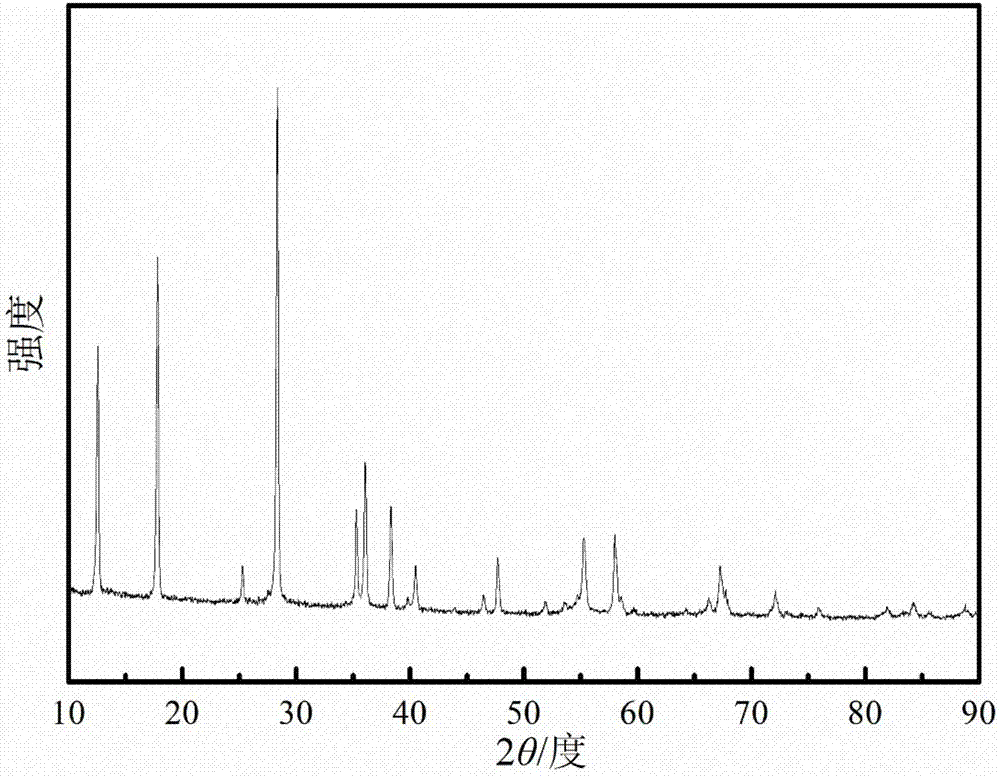

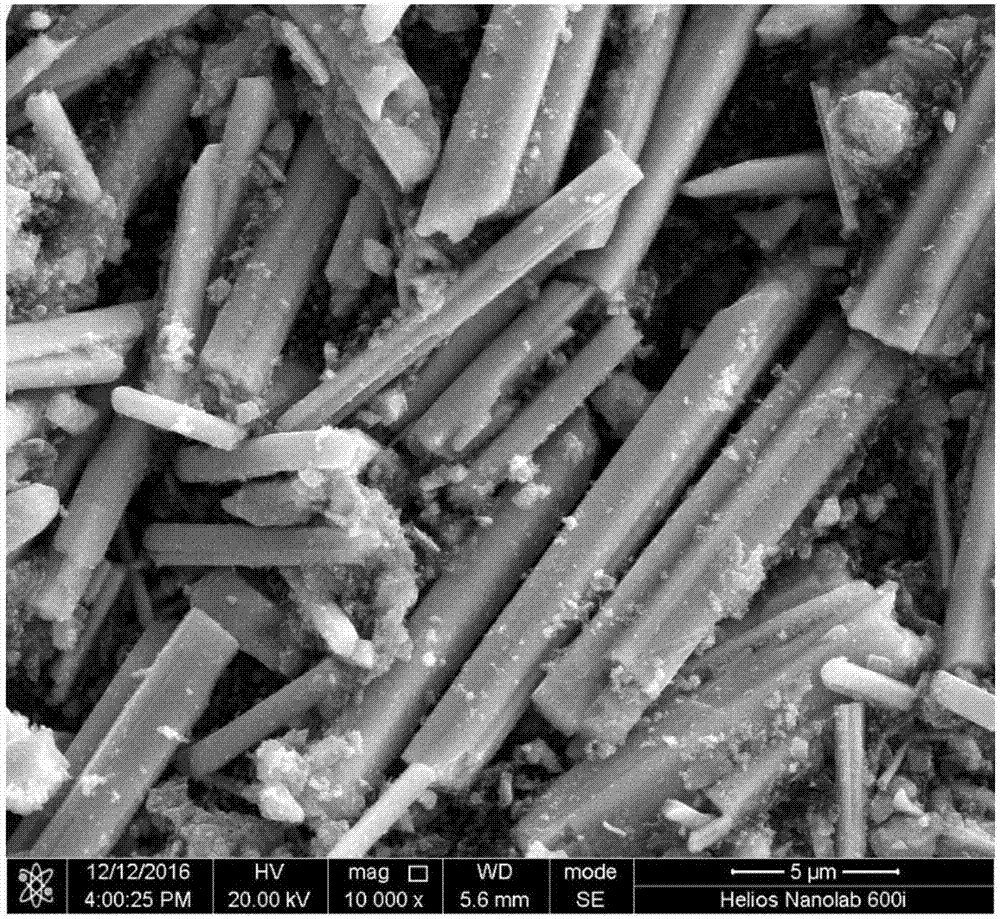

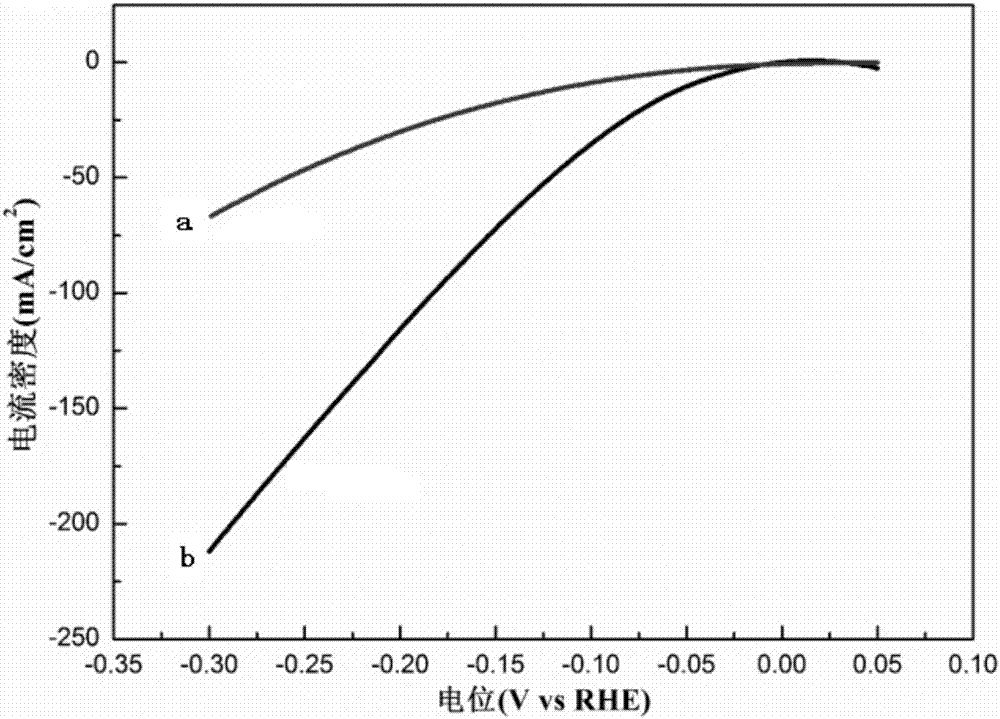

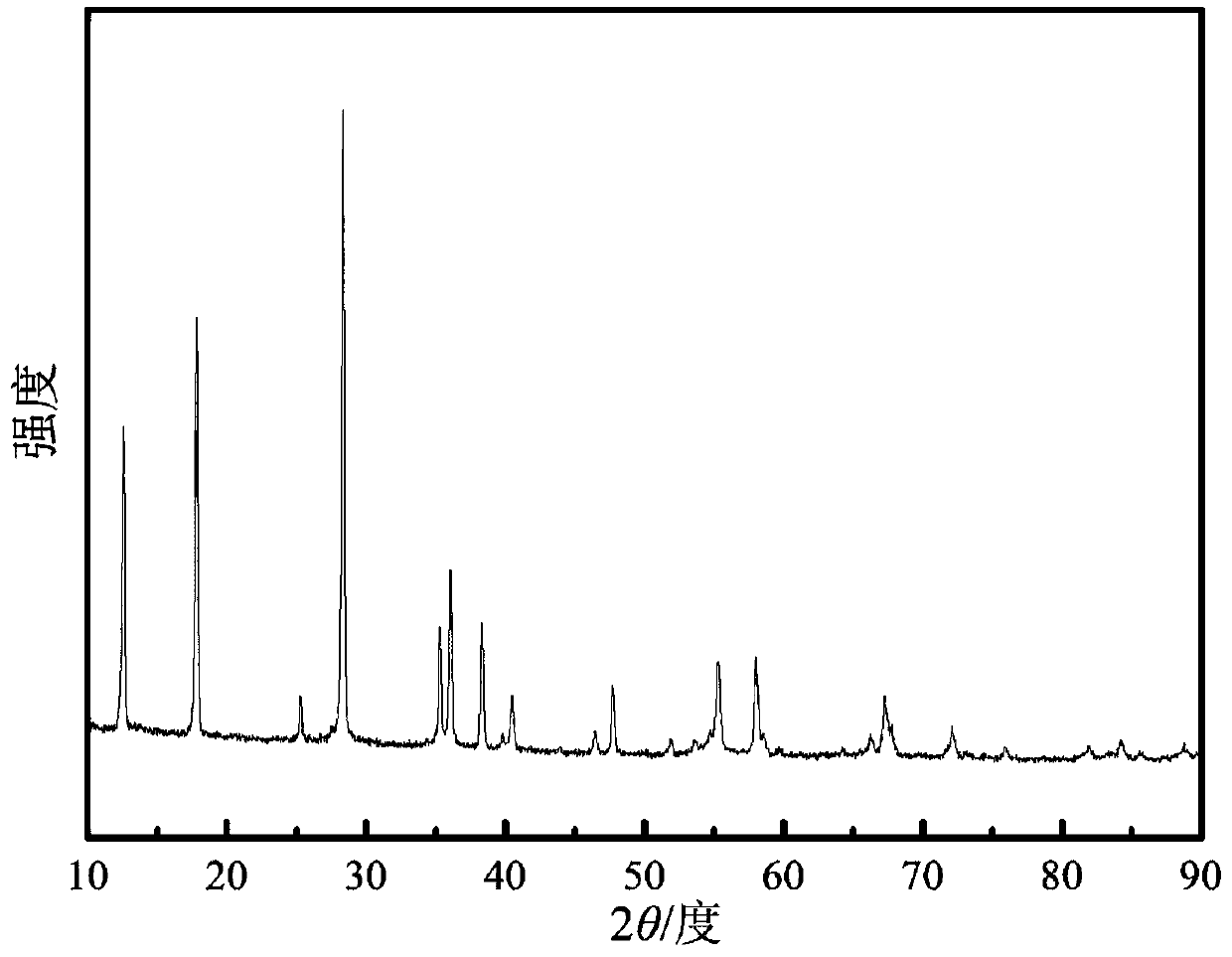

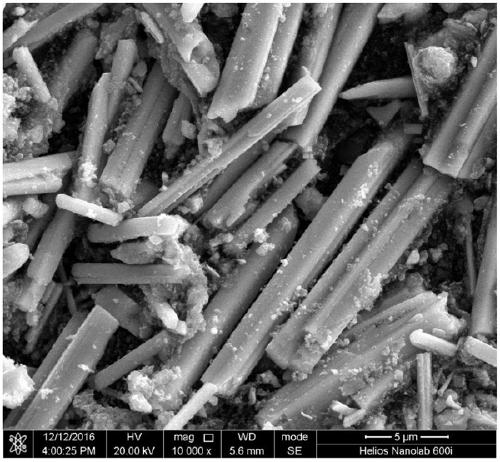

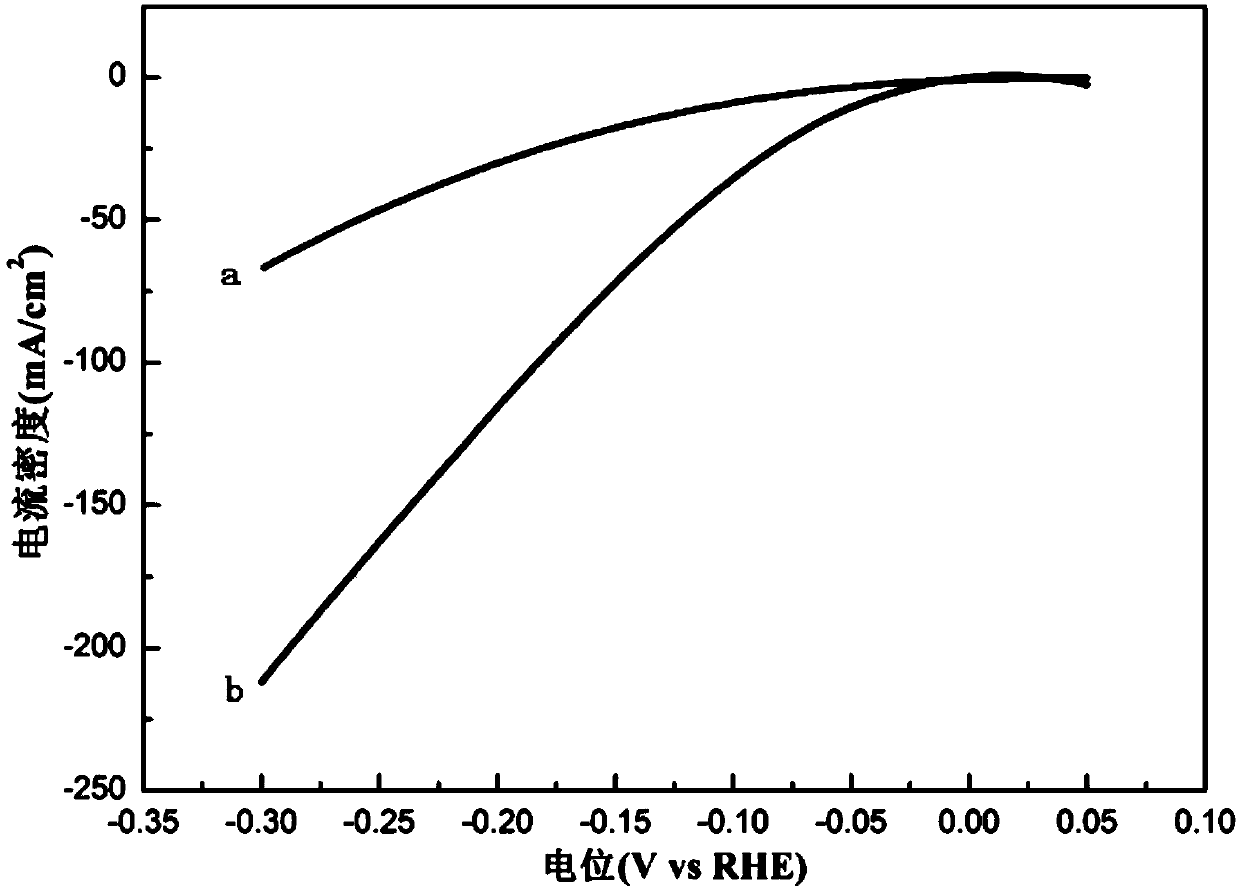

High-efficiency electrolytic water catalyst HRu4O8 microrod and preparation method thereof

ActiveCN106984305AHigh catalytic activityEfficient electrolysisWater/sewage treatment apparatusMetal/metal-oxides/metal-hydroxide catalystsNanoparticleNanometre

The invention discloses a high-efficiency electrolytic water catalyst HRu4O8 microrod and a preparation method thereof. The invention aims to solve the problem that the conventional electrocatalyst cannot simultaneously present excellent catalytic performance and stability on HER and OER. According to the HRu4O8 microrod disclosed by the invention, an atomic ratio of H to Ru to O is 1:4:8, and the HRu4O8 microrod has the diameter of 1-10 microns and the length of 5-100 microns. The preparation method comprises the following steps: 1, preparing RuO2 nanoparticles; 2, preparing a ruthenate microrod; 3, preparing the HRu4O8 microrod. The HRu4O8 microrod prepared by the invention can be applied to the HER and OER and is excellent in performance and stability. The high-efficiency electrolytic water catalyst HRu4O8 microrod and the preparation method disclosed by the invention are applied to the field of electro-catalysis.

Owner:HARBIN INST OF TECH

Method for gradient separation of titanium copper and titanium silicon from titaniferous slag through liquid copper cathode electrolysis

The invention discloses a method for gradient separation of titanium copper and titanium silicon from titaniferous slag through liquid copper cathode electrolysis, and belongs to the field of electrochemical metallurgy. The method comprises the following steps of placing copper powder or copper blocks at the bottom of a crucible to serve as a cathode, and placing the titaniferous slag above the copper powder or the copper blocks to serve as an electrolyte, wherein an inert electrode or a graphite electrode serves as an anode; using high-melting-point metals such as molybdenum and tungsten as a conductive rod, and using silicon nitride, zirconium oxide and other materials as protective sleeves for wrapping; placing the crucible filled with the cathode and the electrolyte in a high-temperature furnace, and installing the anode and the conductive rod; and raising the furnace temperature to be 20 DEG C-100 DEG C higher than the melting point of the titaniferous slag, keeping the temperature for 0.5 h-2 h, lowering a cathode conductive rod and the anode, and carrying out direct current electrolysis. When the titanium ion activity in the titaniferous slag is 10%-60%, titanium-copper alloy can be obtained through direct current electrolysis; when the titanium ion activity in the titaniferous slag is 1%-10%, titanium-silicon alloy can be obtained through direct current electrolysis; and when the titanium ion activity in the titanium-containing slag is less than 1%, the electrolysis is stopped. According to the method disclosed by the invention, metallurgical secondary resources are comprehensively recycled through utilizing an electrochemical metallurgy method; and meanwhile, the operation is simple and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

Steel plate alkali electrolyzer

An improved steel plate alkali electrolyzer uses an anode steel plate, by-polar steel plates, and a cathode steel plate (the number of bi-polar plated is determined by the voltage applied, the formula explained in Claim). The steel plate edges are wrapped with an insulating material to hold them in precise alignment. This unit is housed in a containment vessel, with the anode and cathode steel plates extending past the outside of the containment vessel to make electrical connections outside of liquid filled vessel. Shape and arrangement of the plates enables the gas production to create a circulating electrolyte (without the use of a pump) that produces a cooler operating and more efficient production of Brown's gas per watt, and less expensive to construction than any other known electrolyzer. Design is scalable allowing for a wide range of gas production and applications.

Owner:WARNER STANLEY WESLEY

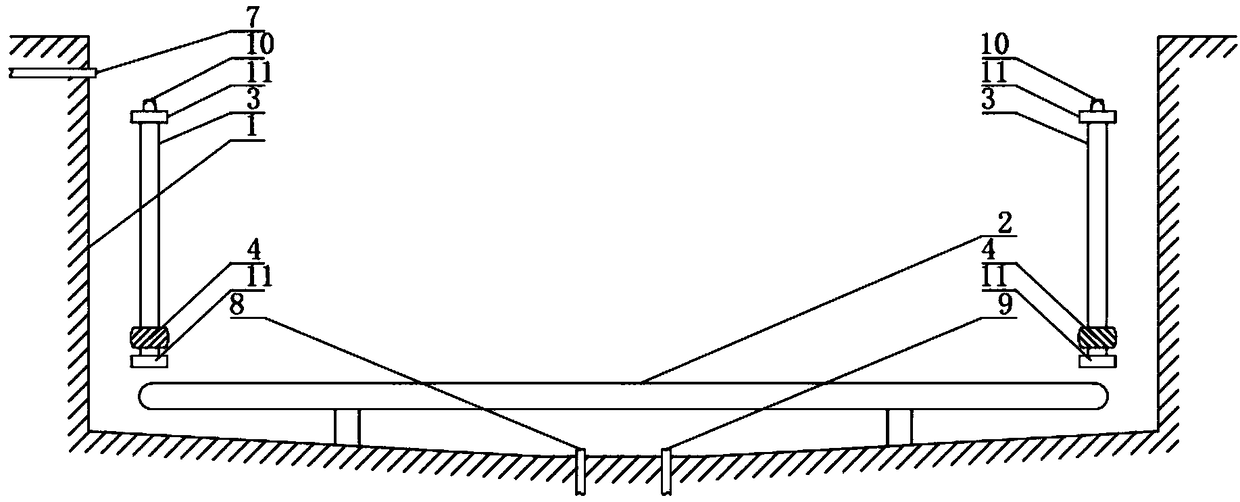

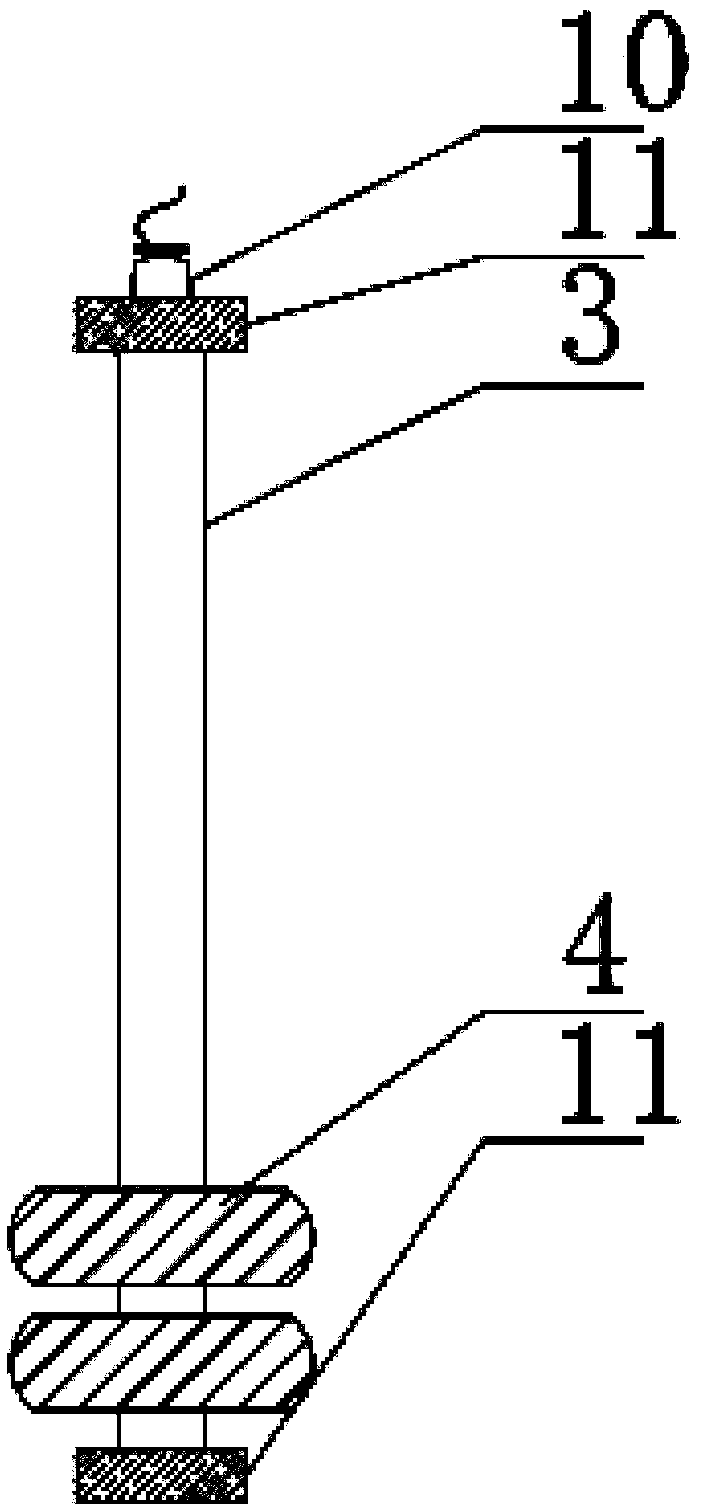

Electrochemical sewage treatment apparatus and electrode cleaning mechanism thereof

InactiveCN108911055AEfficient electrolysisEasy to cleanWater/sewage treatment apparatusElectricityStopped work

The invention discloses an electrochemical sewage treatment apparatus and an electrode cleaning mechanism thereof. The electrochemical sewage treatment apparatus comprises a treatment pool, an aeration device, electrode plates and decontamination beads, wherein the electrodes of the electrode plates on both sides of the treatment pool are opposite, the electrode plates installed on both sides havethe same number and are opposite, the outer side of the electrode plate is movably sleeved with the decontamination beads, or the decontamination beads arranged on the electrode plate can be producedinto the integration so as to form a decontamination plate when plural groups of the electrode plates arranged side by side exist, the decontamination bead comprises a decontamination bead body and decontamination brushes, the decontamination bead body has an abacus-bead-like structure, the decontamination brushes are uniformly arranged on the inner side wall of the decontamination bead body andcontacts the plate wall of the electrode plate, the gas bubbles generated by the aeration device at the beginning of the operation can drive the decontamination beads to move upward along the electrode plate, the generation of the gas bubbles is stopped when the aeration device stops working, and the decontamination beads move downward along the electrode plates under the action of gravity. According to the present invention, the electrode cleaning mechanism can efficiently electrolyze the electrolyte in sewage and conveniently clean the dirt of electrode plates, and is mainly used for electrochemical treatment of sewage.

Owner:江苏八达科技股份有限公司

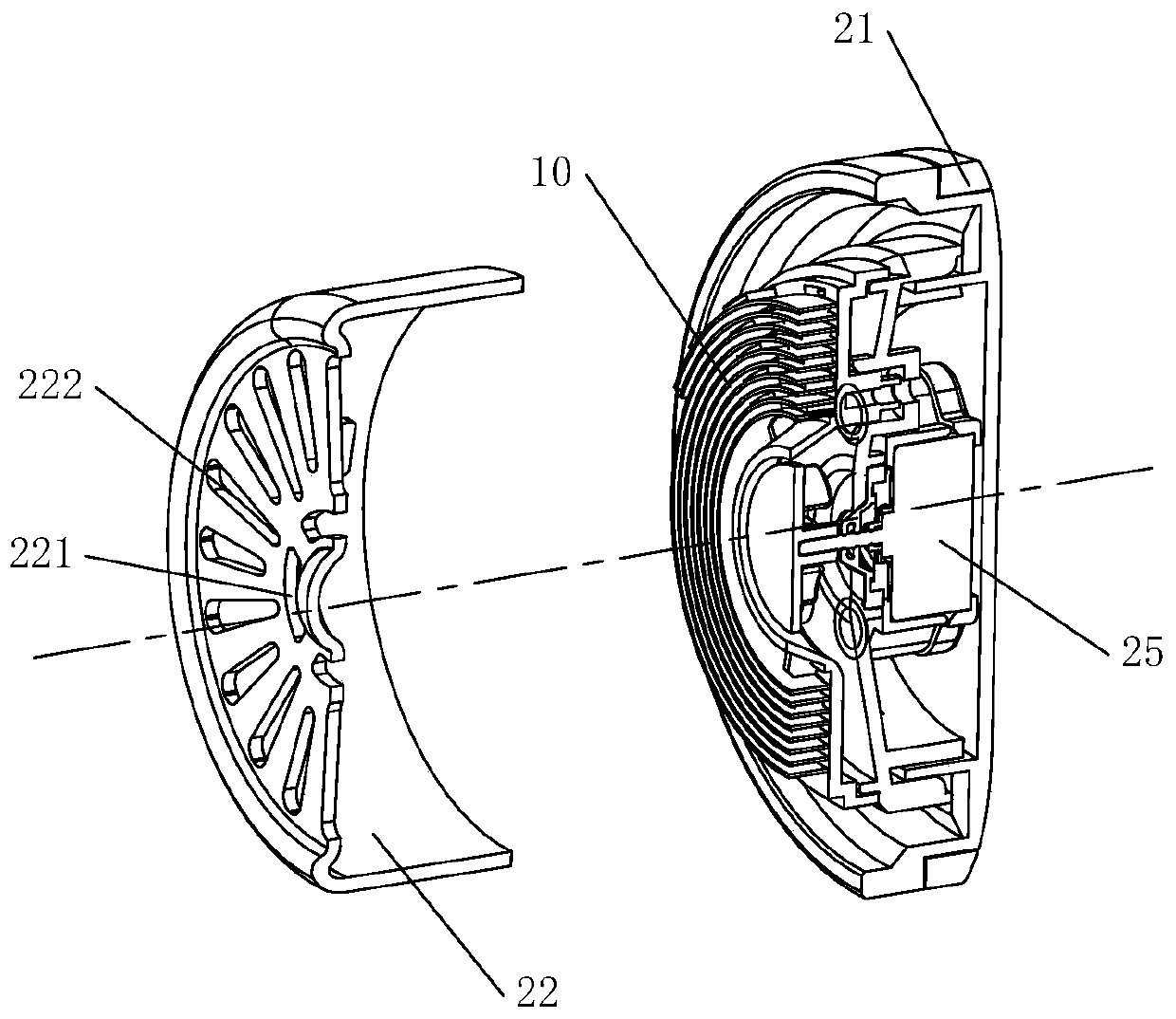

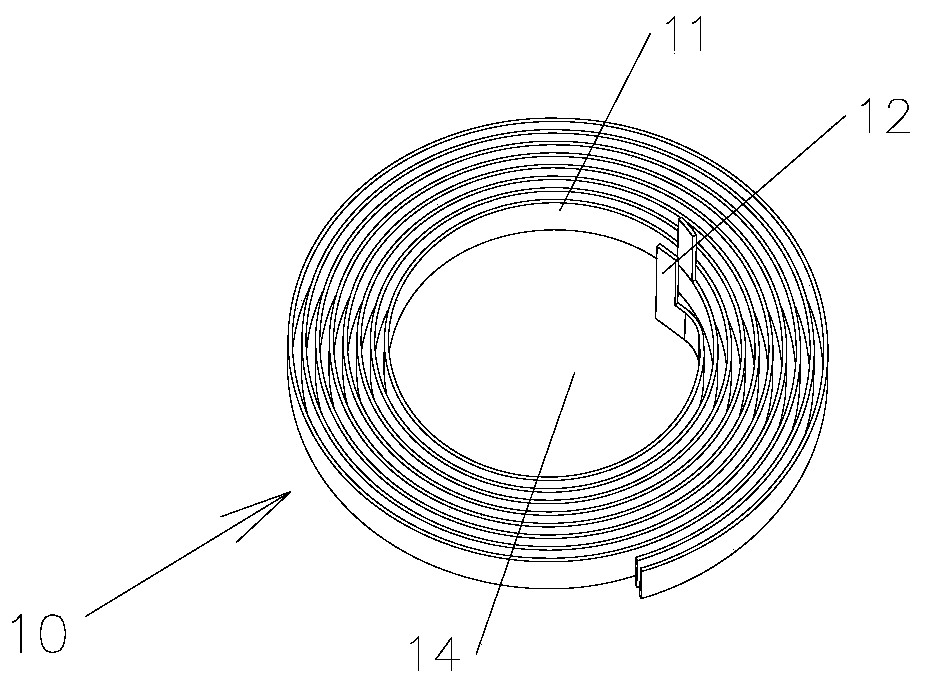

Water quality electrolyzer and cleaning machine

PendingCN111517426AImprove performanceThe principle is simpleWater/sewage treatmentKitchen equipmentChemistryProcess engineering

The embodiment of the invention provides a water quality electrolyzer and a cleaning machine. The water quality electrolyzer comprises a shell, the shell is internally provided with an electrolysis cavity; the water quality electrolyzer also comprises an electrolysis sheet arranged in the electrolysis cavity, wherein the middle part of the electrolysis sheet is provided with an inner hole; a powerassembly which comprises a power part and a stirring piece driven by the power part, the power part is fixed to the shell, and the stirring piece is located in the electrolysis cavity and extends into the inner hole so as to stir water in the electrolysis cavity and enable the water to quickly enter the electrolysis sheet. According to the water quality electrolyzer, the stirring piece capable ofstirring water flow is arranged in the center of the electrolysis sheet, water can be rapidly stirred into the electrolysis sheet, meanwhile, the electrolysis sheet with the large electrolysis area is matched, and therefore efficient electrolysis is achieved, and the performance of electrolyzed water quality is greatly improved.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

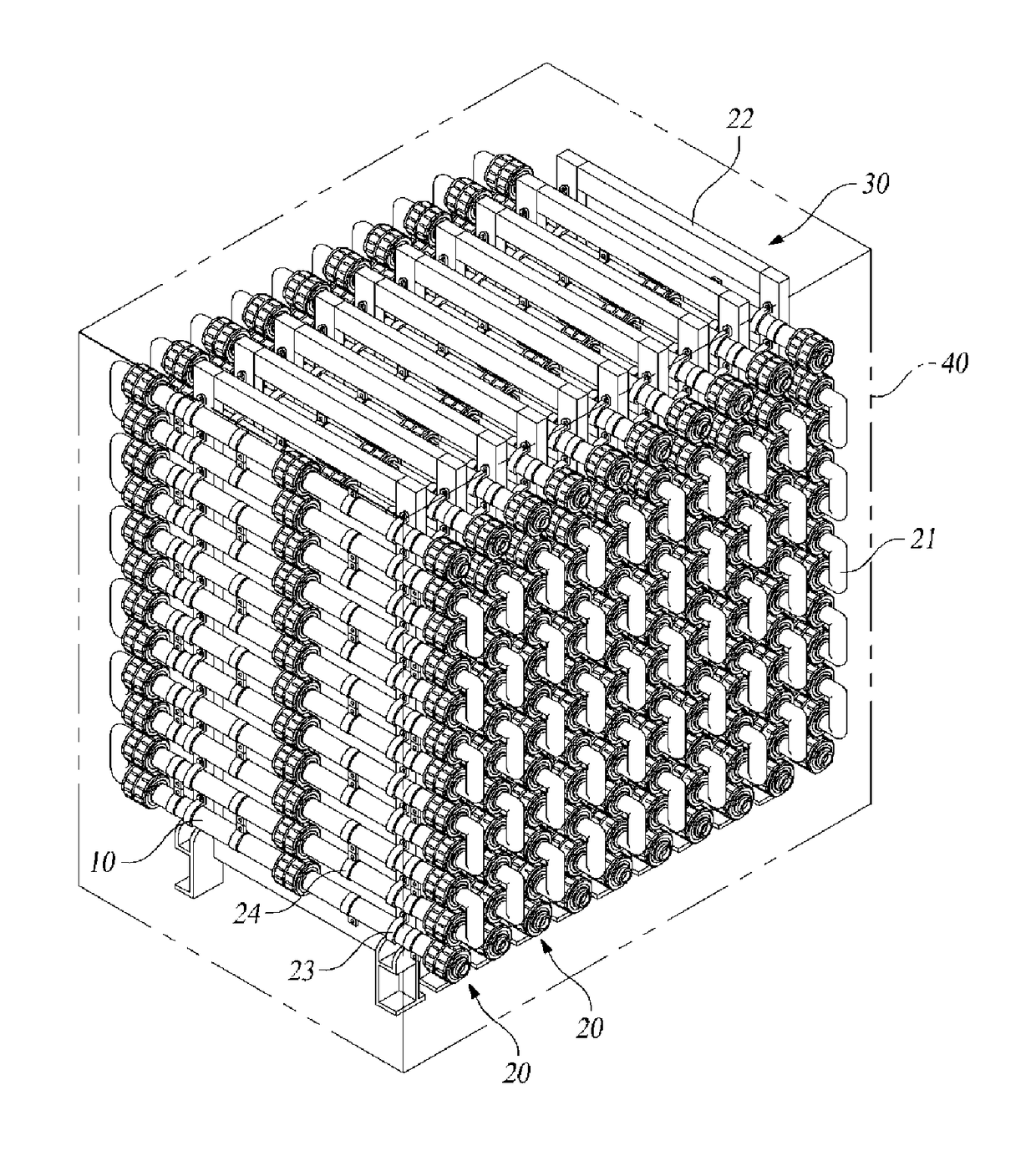

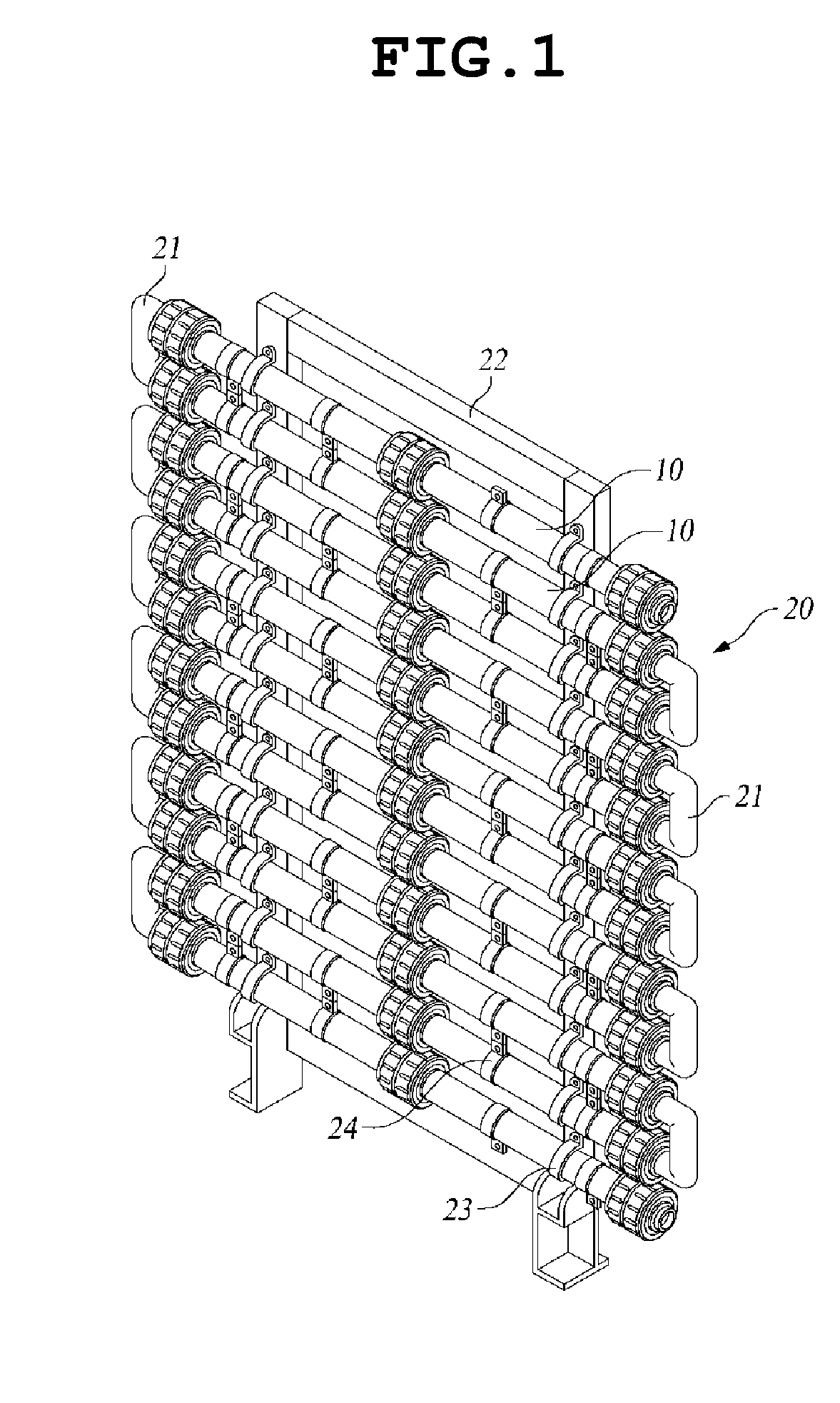

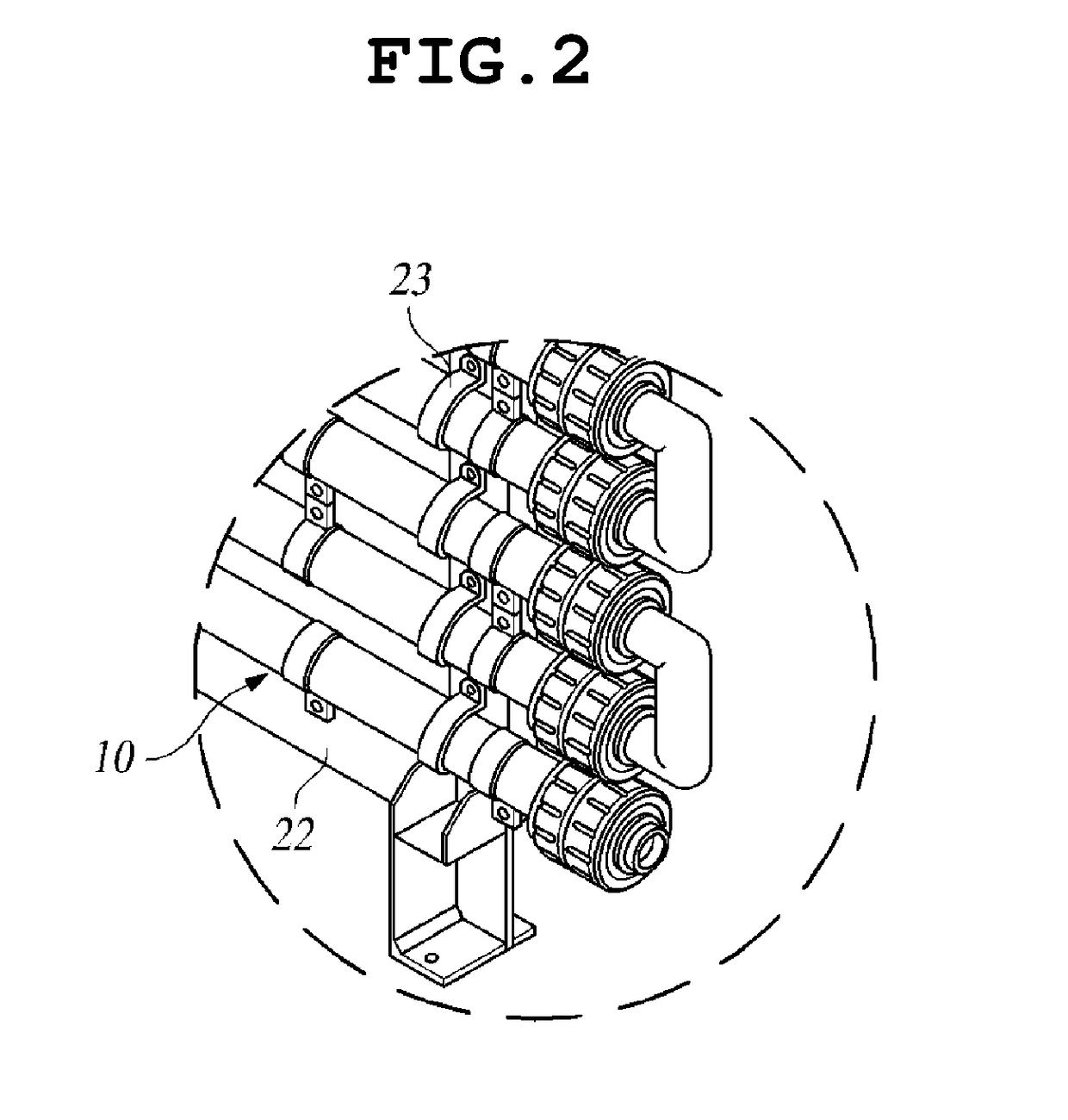

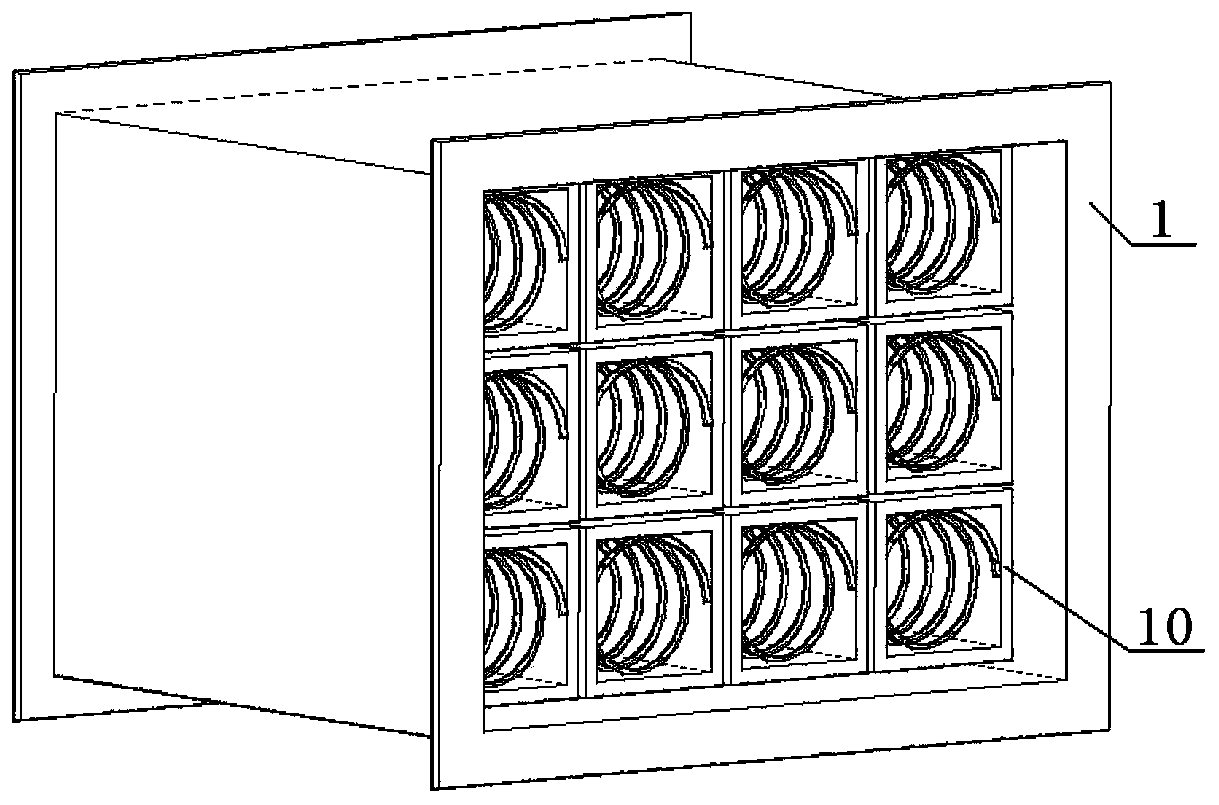

Electrolysis module

ActiveUS20170283284A1High trafficImprove electrolysis efficiencyCellsWater/sewage treatment apparatusElectrolysisPower cable

Disclosed is an electrolysis module including: an electrolysis unit module including a plurality of pipe-type electrolysis cells connected in series with each other; a molding case surrounding the periphery of the electrolysis unit module to protect the electrolysis module; a cell guide member installed in the molding case to support the electrolysis unit module; a power cable having a first end connected to the electrolysis unit module and a second end extending to an outside through the molding case; and a resin layer formed by filling the inside of the molding case to cover the outer surface of the electrolysis unit module disposed in the molding case.

Owner:TECHWIN

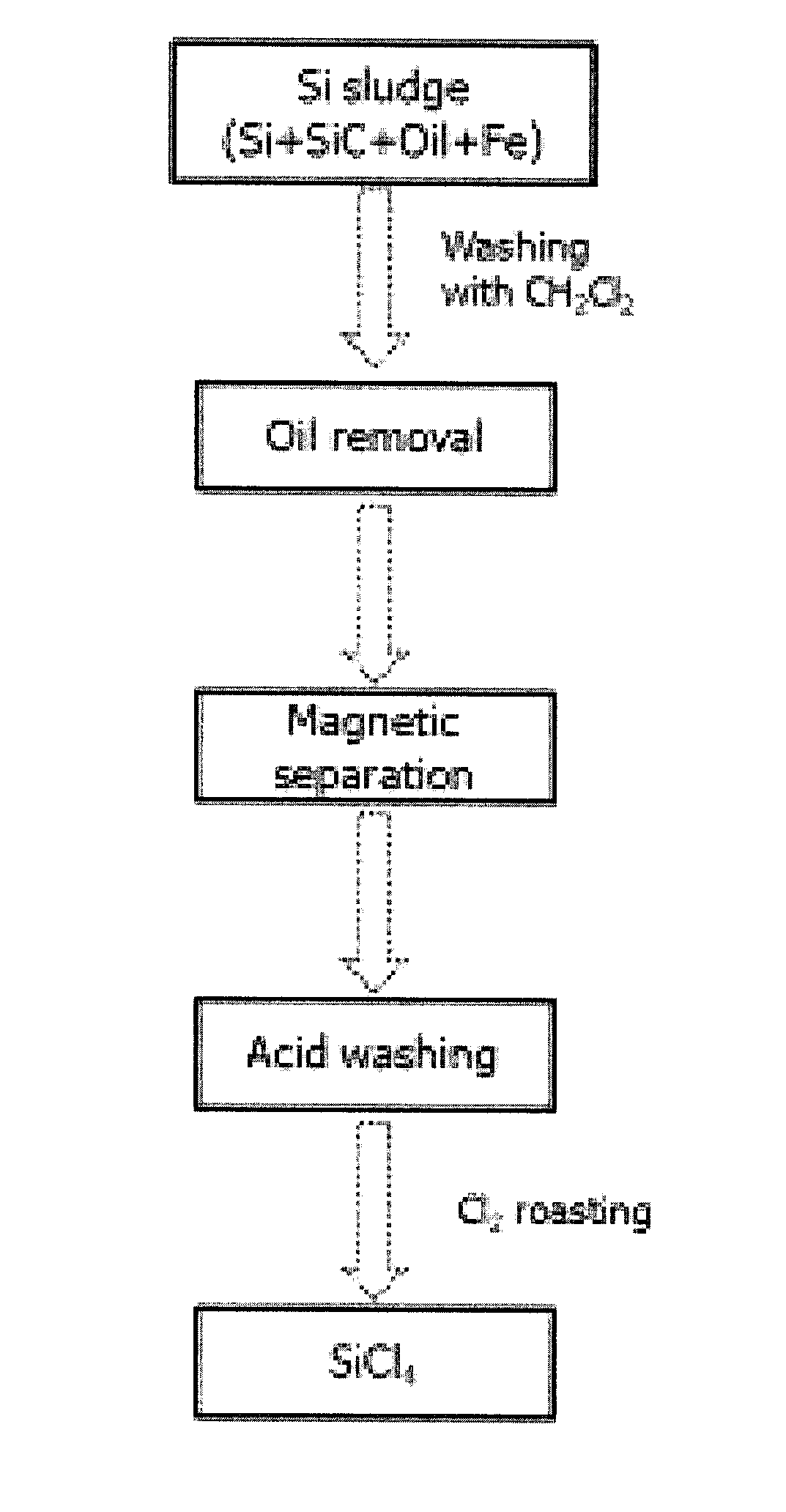

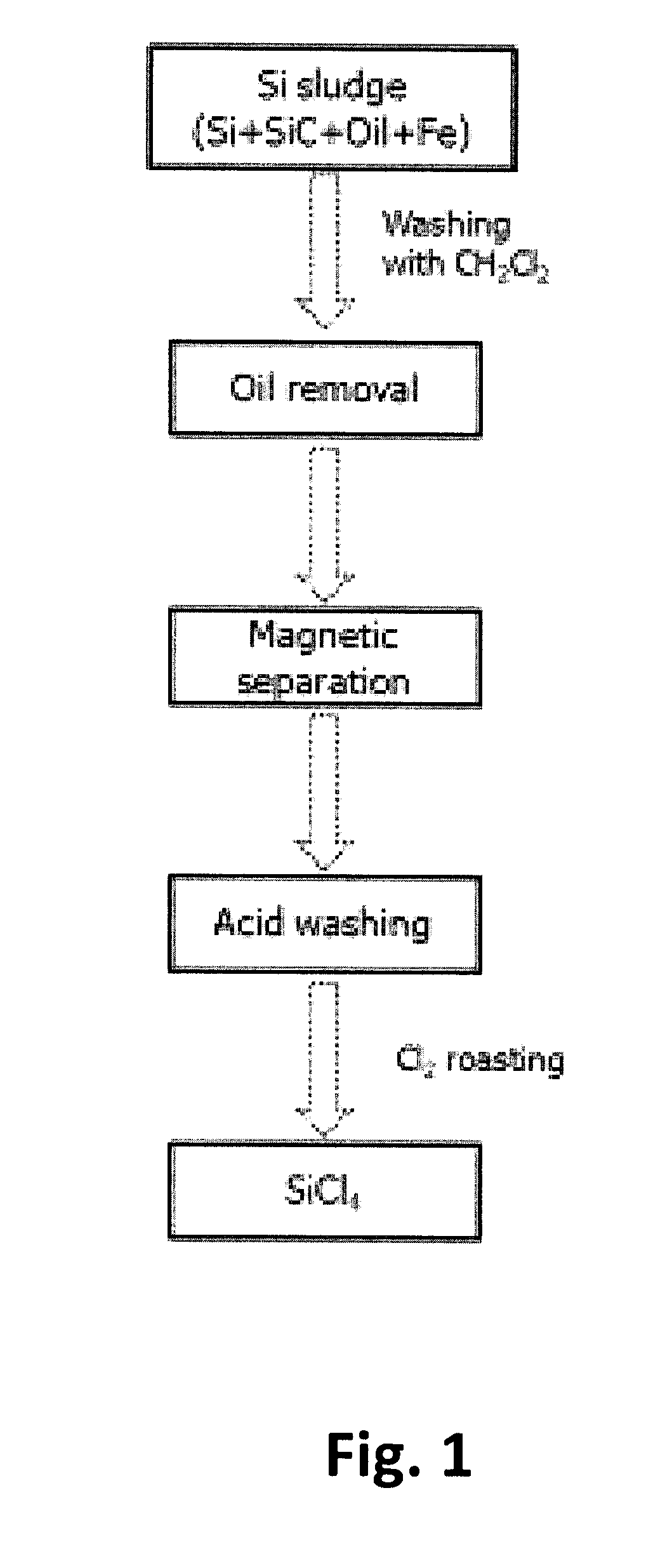

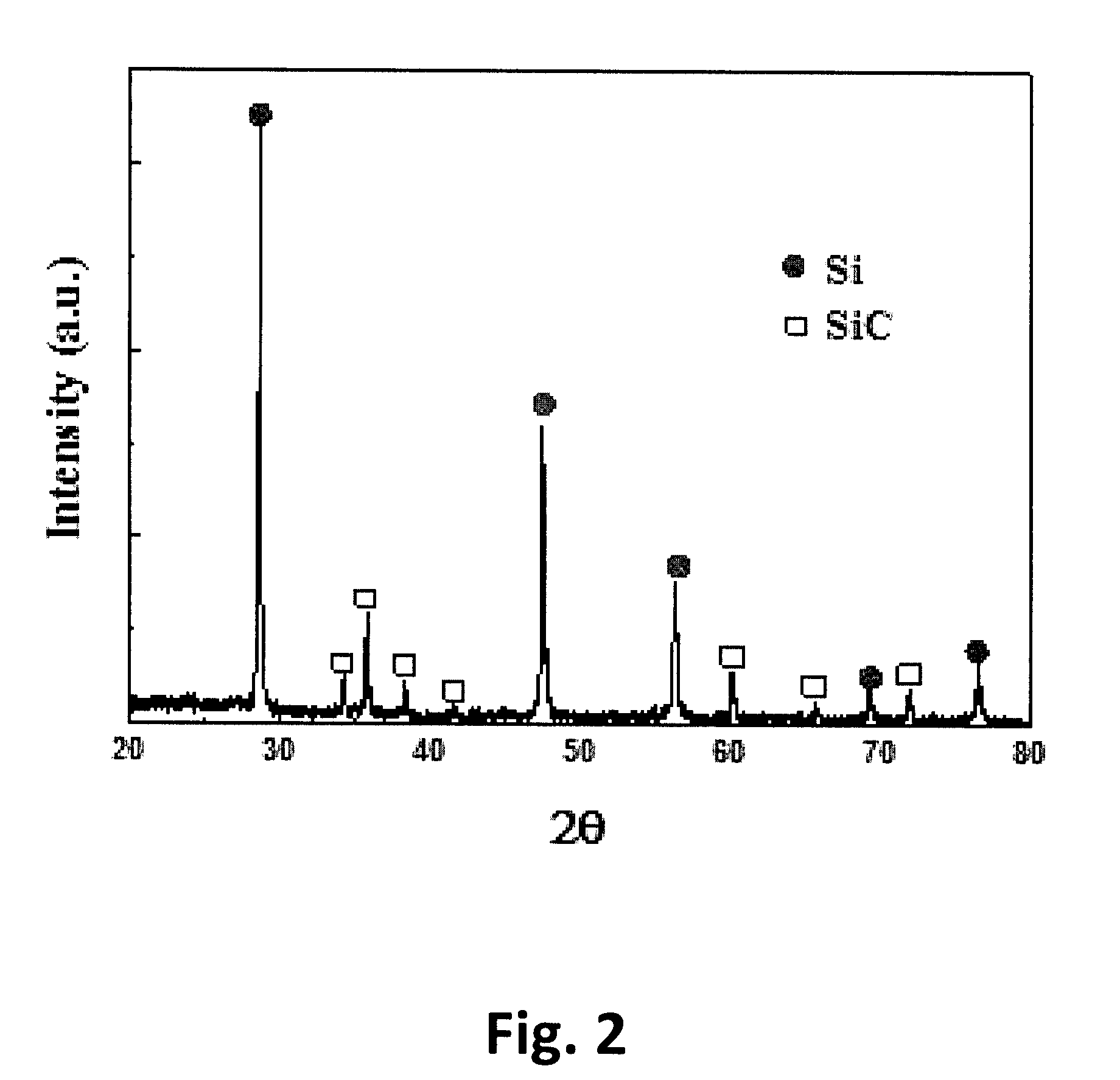

Method for recovering elemental silicon from silicon sludge by electrolysis in non-aqueous electrolyte

InactiveUS20140144784A1Efficient electrolysisEasy to controlElectrolysis componentsPhotography auxillary processesRecovery methodElectrolysis

The present invention relates to a method for recovering elemental silicon from silicon sludge by electrolysis in a non-aqueous electrolyte. The recovery method of silicon according to the present invention can achieve direct reduction of silicon by electrolysis at a low temperature (below 200° C.), control the structure of silicon by a simple process and a change in electrolysis conditions, and perform a continuous process by adding a silicon salt.

Owner:KUMOH NAT INST OF TECH IND ACADEMIC COOPERATION FOUND

A device for treating high-temperature carbonized tail gas of a tube furnace

ActiveCN108217853BImprove adsorption capacityPromote redox processDispersed particle filtrationWater/sewage treatmentMicrocontrollerMicrocomputer

The invention relates to the technical field of pollution tail gas processing, and especially relates to an apparatus for processing tail gas from high-temperature carbonation in a tubular furnace. The apparatus aims at solving the problems of complete processing and intelligent control of the tail gas from high-temperature carbonation in the tubular furnace and a substance, and is composed of a carbon fiber electrode, a turbidity sensor, a single-chip microcomputer, an air inlet pipe, a purifying exhaust system, a minisize inspiration pump, a soda acid automatic regulator, and an inverse suction-prevention apparatus, several intelligent parts are mutually cooperated, tail gas can be thoroughly and efficiently processed, and cycle usage of an acid-base solution is realized.

Owner:NANJING AGRICULTURAL UNIVERSITY

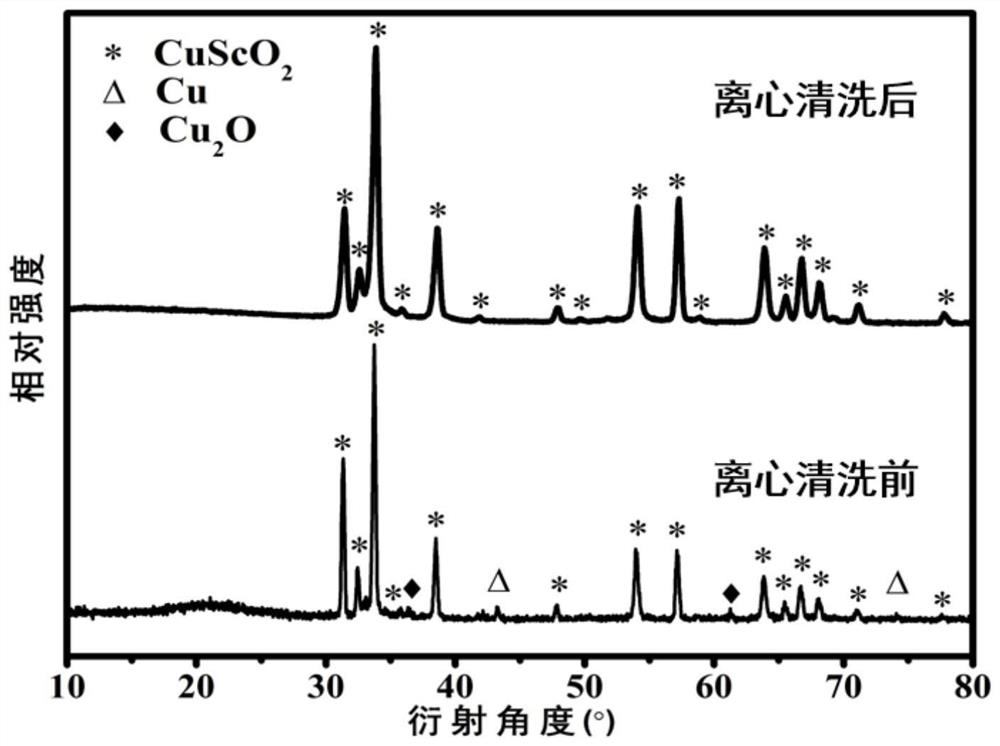

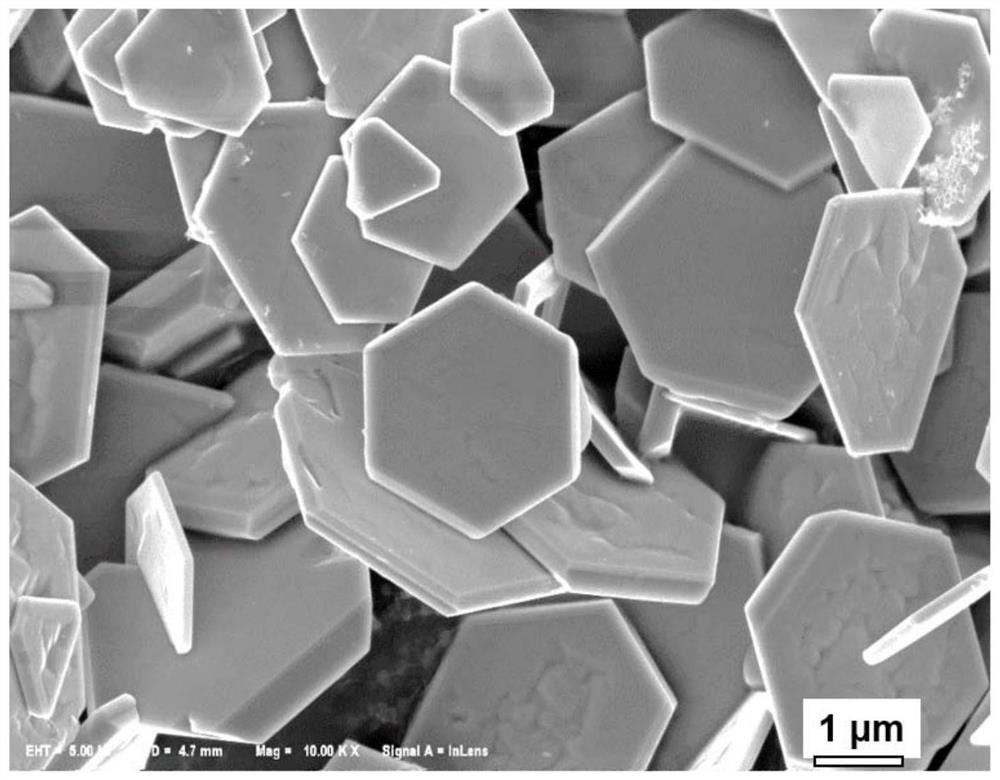

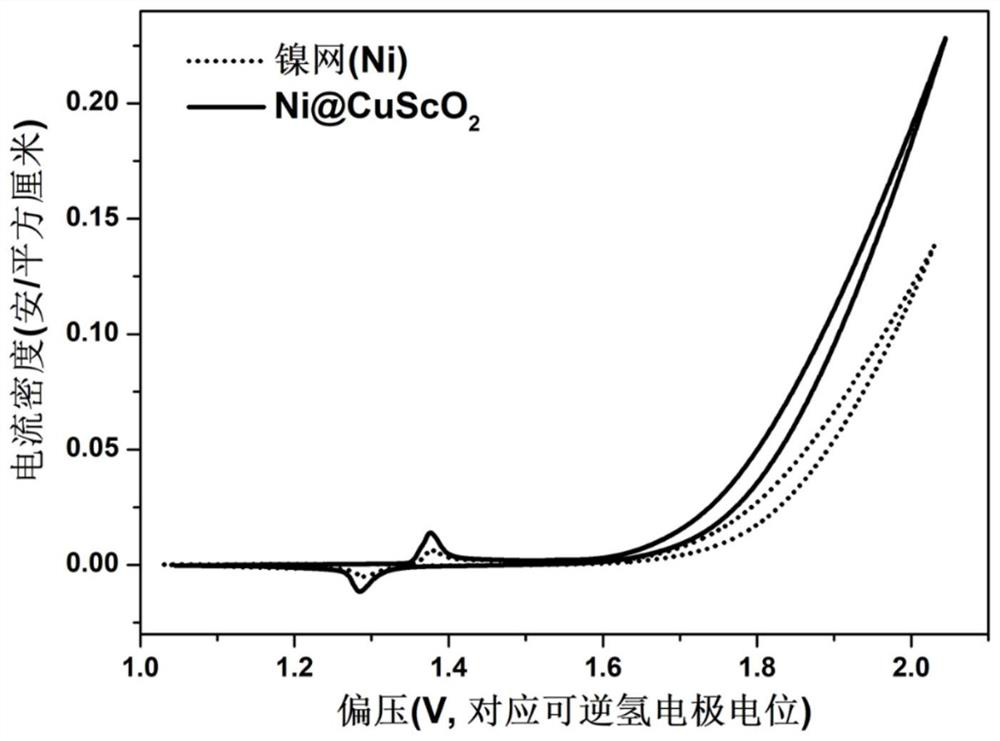

A p-type delafossite structure cusco 2 Crystal material and its preparation method and use

ActiveCN110980791BReduce the cost of large-scale productionWide variety of sourcesLight-sensitive devicesHeterogenous catalyst chemical elementsPtru catalystDissolution

The invention discloses a p-type delafossite structure CuScO 2 Crystal material and its preparation method and application, the method comprises: step 1, preparation of reaction precursor: with Cu 2+ Source reactants and Sc 3+ The source reactant is used as the raw material, deionized water is used as the reaction liquid, and the reducing agent and mineralizing agent are added and stirred until completely dissolved to prepare the reaction precursor; step 2, the reaction precursor is subjected to hydrothermal treatment at 210-240°C After reacting for 12 to 48 hours, the reaction product was centrifuged to obtain a precipitate, and the precipitate was dried to obtain the p-type delafossite structure CuScO 2 crystal material. The present invention utilizes the single reaction of hydrothermal method to prepare gram-level CuScO 2 Crystal material, no need to adjust the pH value of the precursor reactant; and the present invention explores CuScO for the first time 2 As a catalyst material in electrolytic water oxygen evolution, it shows good electrolytic water oxygen evolution activity and stability under alkaline conditions.

Owner:WUHAN UNIV OF TECH

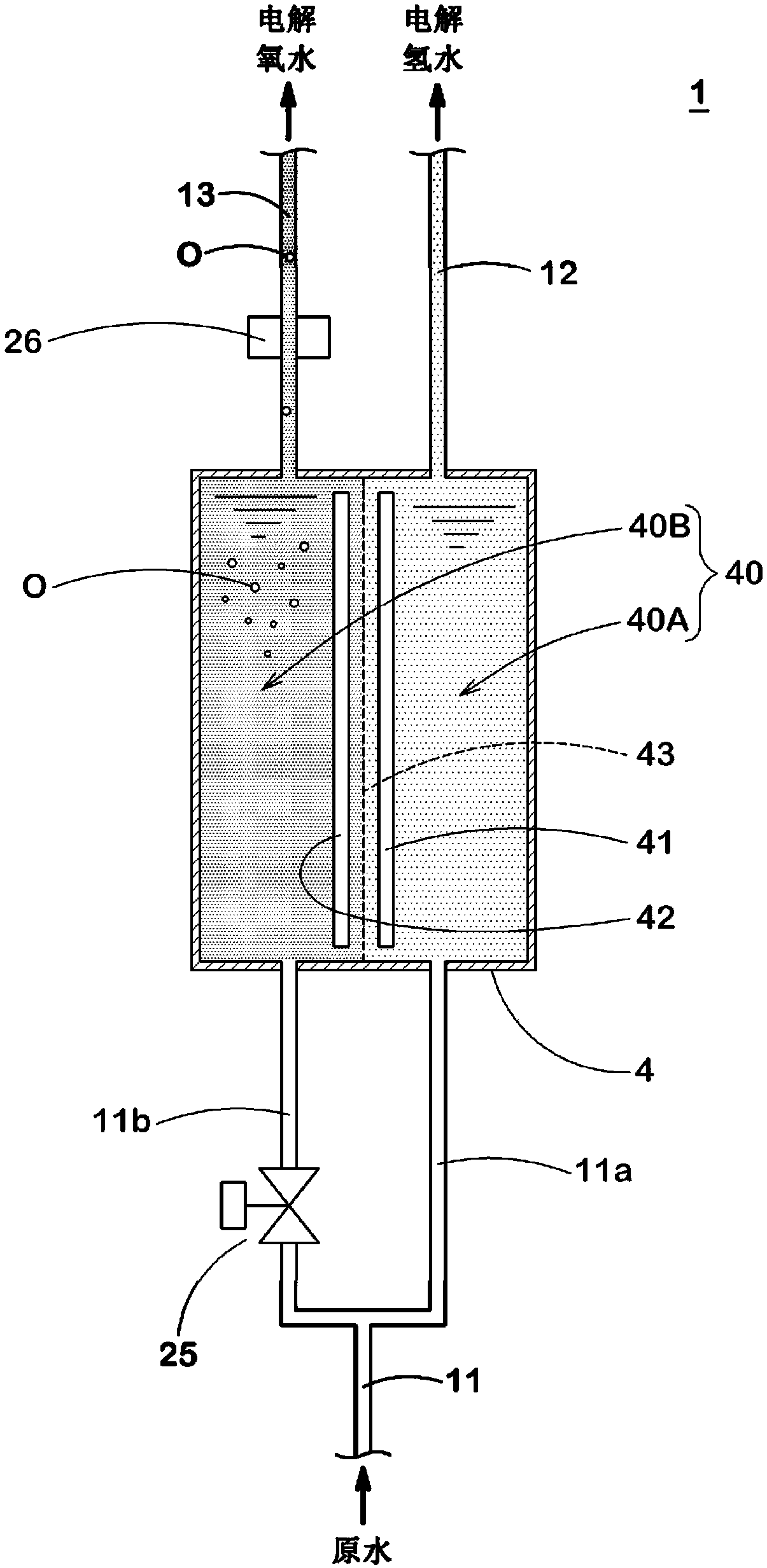

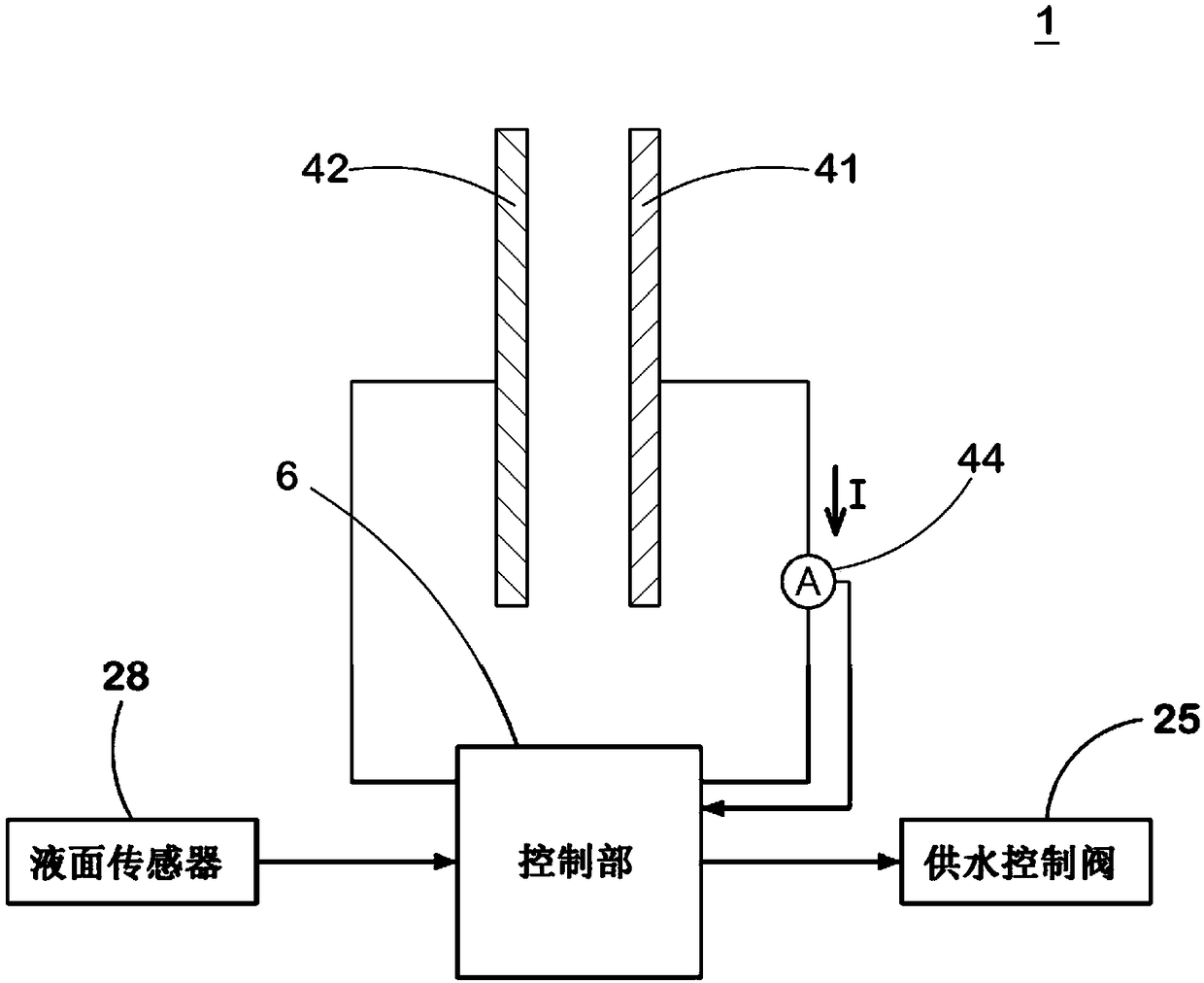

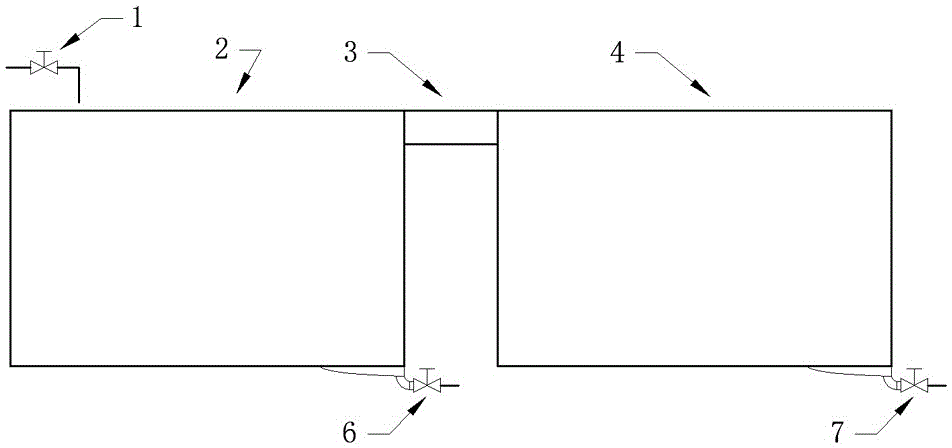

Electrolyzed water generation device

ActiveCN108541251AEfficient electrolysisAvoid damageWater/sewage treatment by electrochemical methodsWater/sewage treatment apparatusElectrolysed waterWater level

An electrolyzed water generation device 1 comprising: an electrolysis chamber (40) that generates electrolyzed water by electrolyzing water and is divided by a partitioning membrane (43), such as a solid polymer membrane, etc., into a first polar chamber (40A) having a first feeder (41) arranged therein and a second polar chamber (40B) having a second feeder (42) arranged therein; a first water supply path 11a connected to the first polar chamber (40A) and supplying water to be electrolyzed, to the first polar chamber (40A); a first water outlet path (12) connected to the first polar chamber (40A) and discharging electrolyzed water that has been electrolyzed, from the first polar chamber (40A); a second water supply path 11b connected to the second polar chamber (40B) and supplying water to be electrolyzed, to the second polar chamber (40B); and a second water outlet path (13) connected to the second polar chamber (40B) and letting out electrolyzed water that has been electrolyzed, from the second polar chamber (40B). The second outlet path (13) has provided therein a water level detection means (26) that detects the water level inside the second water outlet path (13).

Owner:NIKHON TRIM KO LTD

A high-efficiency electrolytic water catalyst hru4o8 micron rod and its preparation method

ActiveCN106984305BHigh catalytic activityEfficient electrolysisWater/sewage treatment apparatusMetal/metal-oxides/metal-hydroxide catalystsElectrolysisNanoparticle

A high-efficiency electrolysis water catalyst HRu 4 O 8 Micron rods, which involve a high-efficiency water electrolysis catalyst HRu 4 O 8 Micron rods and preparation methods thereof. The purpose of the present invention is to solve the problem that existing electrocatalysts cannot exhibit excellent catalytic performance and stability in both HER and OER. HRu of the present invention 4 O 8 The atomic ratio of H:Ru:O in the microrod is 1:4:8, HRu 4 O 8 The diameter of the micron rod is 1 to 10 μm and the length is 5 to 100 μm. The preparation method is: 1. Preparation of RuO 2 Nanoparticles; 2. Preparation of ruthenate microrods; 3. Preparation of HRu 4 O 8 Micron rods. HRu prepared by the present invention 4 O 8 Micron rods can be used in HER and OER and have excellent performance and stability. The invention is applied in the field of electrocatalysis.

Owner:HARBIN INST OF TECH

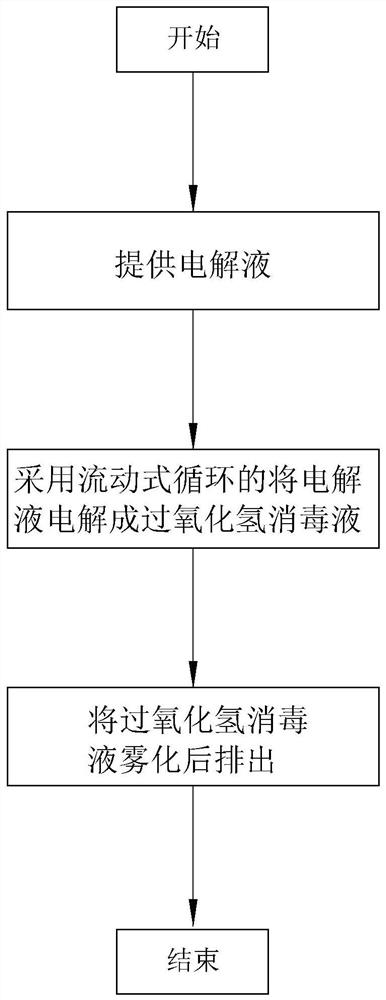

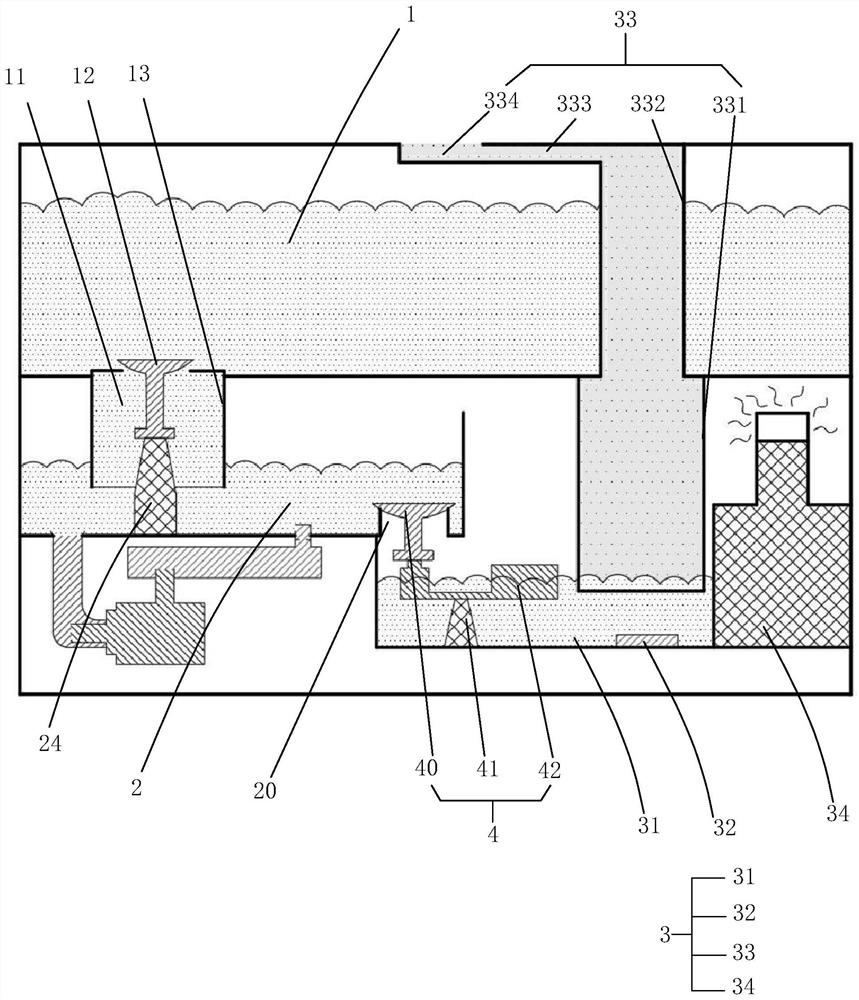

Atomization disinfection system and method

PendingCN114432484AReal-time generationDisinfection in real timeMechanical apparatusElectrolysis componentsElectrolytic agentProcess engineering

According to the atomization disinfection system and method, the electrolyte is firstly provided, the electrolyte is electrolyzed in a flowing type circulation mode to prepare the hydrogen peroxide disinfection solution, then the prepared hydrogen peroxide disinfection solution is atomized and guided out, the hydrogen peroxide disinfection solution is prepared in a flowing type circulation mode, the electrolysis effect can be improved, electrolysis is more thorough and more efficient, and the quality of the hydrogen peroxide disinfection solution is improved. Electric energy is directly converted into chemical energy to generate a disinfectant in real time and disinfect the environment in real time, the reaction module and the atomization module are integrated in the atomization disinfection system, the hydrogen peroxide disinfectant can be prepared in real time and can be synchronously atomized, the hydrogen peroxide disinfectant can be supplemented in time after being consumed, the disinfection steps are simplified, and the disinfection efficiency is improved. The invention provides a novel atomizing disinfection method which is economical, feasible, easy to prepare, green and environment-friendly, and a disinfectant can be generated in real time to disinfect the environment in real time.

Owner:浙江清越科技有限公司

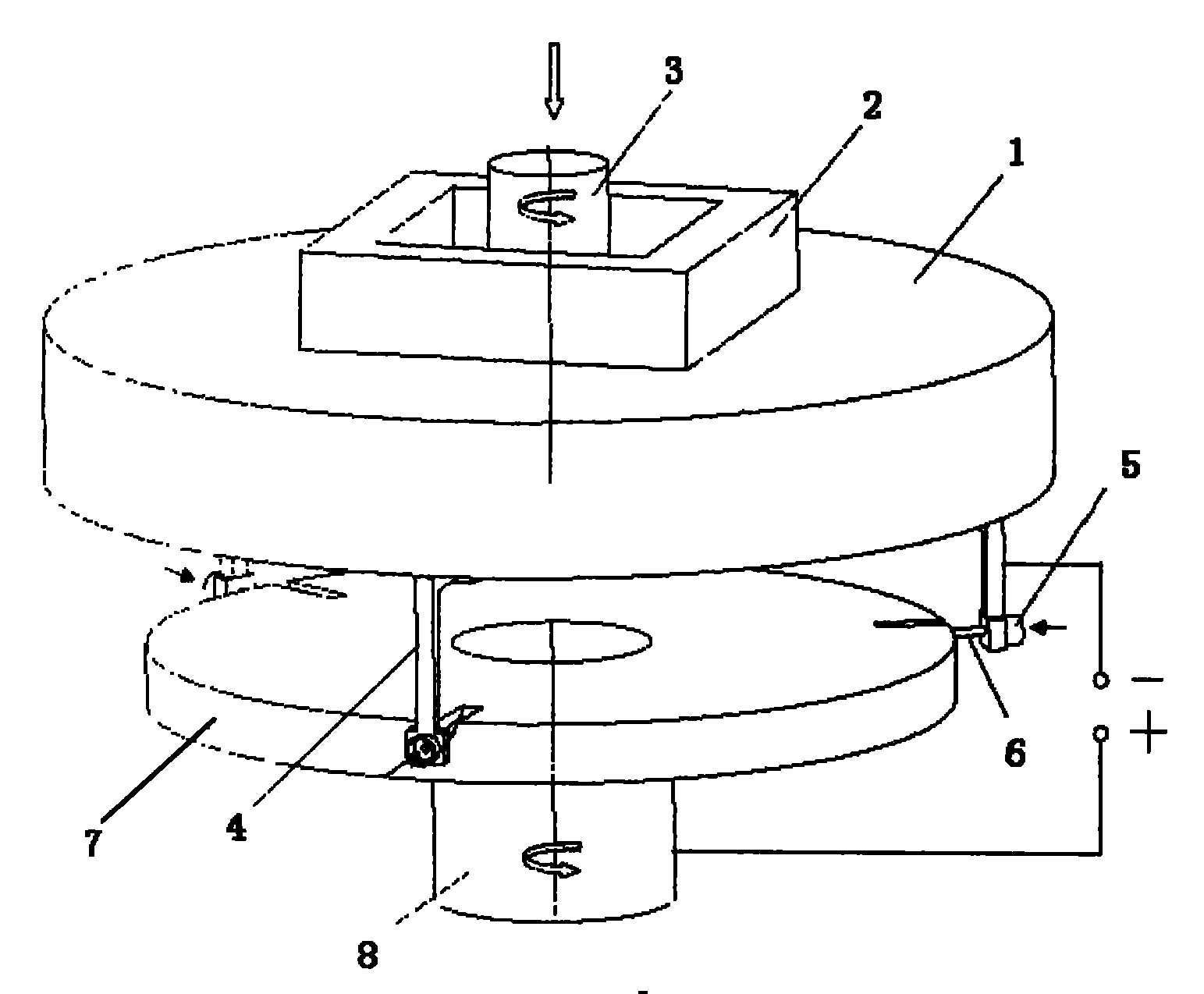

Magnetic disk stirring pulse, sine wave gear disk pulse and magnetic drum pulse type electrolysis impurity removing tank

InactiveCN105862085AGood removal effectWill not cause secondary pollutionPhotography auxillary processesElectrolysis componentsIon distributionLiquid storage tank

The invention discloses a magnetic disk stirring pulse, sine wave gear disk pulse and magnetic drum pulse type electrolysis impurity removing tank. An electrolytic manganese chemical combination leachate storage tank communicates with an electrolytic manganese qualification liquid storage tank through an impurity removing electrolytic tank; the impurity removing electrolytic tank is provided with an electrolysis pole plate with a cathode being stainless steel and an anode being lead alloy; a magnetic disk stirring pulse generator and a sine wave gear disk pulse generator are arranged; the impurity removing electrolytic tank is connected to a liquid inlet of a magnetic drum differential motion type circulating pump through a pipeline, and a liquid outlet of the magnetic drum differential motion type circulating pump communicates with the impurity removing electrolytic tank through a pipeline. According to the electrolysis impurity removing tank, the stainless steel serves as the cathode, the lead alloy serves as the anode, and ions of heavy metal such as copper, zinc, nickel, cadmium and cobalt in solutions are removed during cathodic deposition through electrolysis; through the multiple pulse generators installed in the electrolytic tank, bubble adhesion generated on the surface of the pole plate can be removed, ion distribution can be uniform, and efficient electrolytic impurity removal can be guaranteed; the impurity ion concentration can be lowered to be lower than 1 mg / L, the recovery rate of heavy metal can be higher than 95%, and secondary pollution can be avoided.

Owner:JISHOU UNIVERSITY

tunnel plasma device

ActiveCN104056532BEfficient electrolysisIncrease the areaDispersed particle separationEngineeringCatalytic efficiency

Owner:刘颖姝

Multi-electrode spiral feeding integral blade wheel inter-blade passage electrolytic machining method

InactiveCN101508047BImprove processing efficiencyShorten the manufacturing cycleImpellerElectrolysis

The invention relates to an electrolytic machining method for multi-electrode screw feeding integral impeller flow passages, and belongs to the technical field of electrolytic machining. The method adopts a plurality of tool electrodes which are positioned on the same plane and arranged on an electrolytic machining clamp. In the machining process, a translation stage of a machine tool drives the plurality of the tool electrodes to simultaneously feed linearly along the axes direction of an impeller blank, and a turn table on the translation stage drives the plurality of the tool electrodes torotate; meanwhile, the impeller blank rotates around the axes of the impeller blank, and the tool electrodes perform electrolytic machining along a motion trail determined by the resultant motion. The electrodes and the impeller blank keep a small clearance; electrolyte flows out at a high speed from gaps of the tool electrodes to continuously take away products of electrolysis; and a plurality of impeller flow passages are machined finally. The number and distribution positions of the tool electrodes can be adjusted to meet machining requirements of integral impellers in different types. Because the plurality of the electrodes are adopted to perform machining simultaneously, the machining efficiency for the integral impeller is greatly improved, and the rotation of the electrodes makes machining allowance more even at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Magnetic disk pulse, sine wave gear disk pulse and magnetic drum pulse type electrolysis impurity removing tank

InactiveCN105862086AEasy to removeEfficient electrolysisPhotography auxillary processesElectrolysis componentsIon distributionLiquid storage tank

The invention discloses a magnetic disk pulse, sine wave gear disk pulse and magnetic drum pulse type electrolysis impurity removing tank. An electrolytic manganese chemical combination leachate storage tank communicates with an electrolytic manganese qualification liquid storage tank through an impurity removing electrolytic tank; the impurity removing electrolytic tank is provided with an electrolysis pole plate with a cathode being stainless steel and an anode being lead alloy; a magnetic disk pulse generator and a sine wave gear disk pulse generator are arranged; the impurity removing electrolytic tank is connected to a liquid inlet of a magnetic drum differential motion type circulating pump through a pipeline, and a liquid outlet of the magnetic drum differential motion type circulating pump communicates with the impurity removing electrolytic tank through a pipeline. According to the electrolysis impurity removing tank, the stainless steel serves as the cathode, the lead alloy serves as the anode, and ions of heavy metal such as copper, zinc, nickel, cadmium and cobalt in solutions are removed during cathodic deposition through electrolysis; through the multiple pulse generators installed in the electrolytic tank, bubble adhesion generated on the surface of the pole plate can be removed, ion distribution can be uniform, and efficient electrolytic impurity removal can be guaranteed; the impurity ion concentration can be lowered to be lower than 1 mg / L, the recovery rate of the heavy metal can be higher than 95%, and secondary pollution can be avoided.

Owner:JISHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com