A device for treating high-temperature carbonized tail gas of a tube furnace

A tube furnace and exhaust gas technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve good redox and electrolysis capabilities, save time and labor, and improve electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

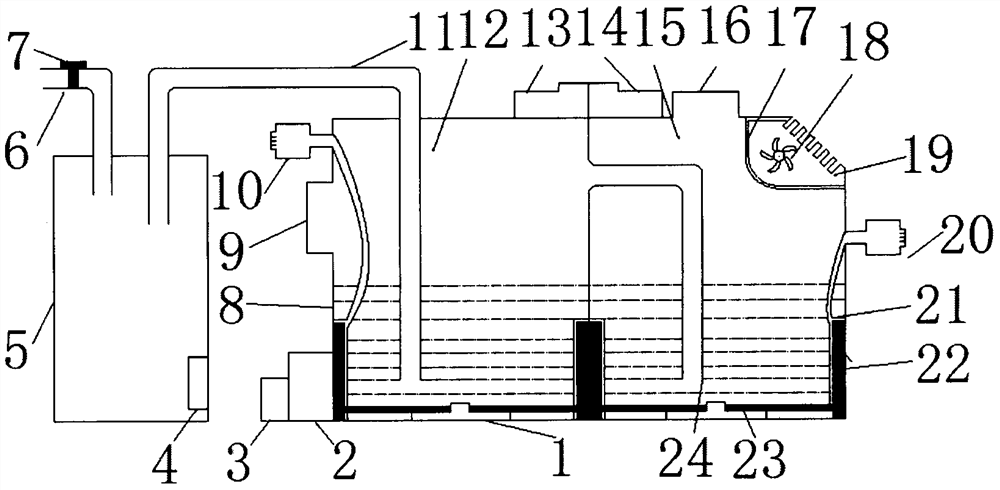

[0032] The device can efficiently remove the tail gas discharged from the carbon material prepared by the tube furnace. The device will be further described below in conjunction with the accompanying drawings and specific implementation examples.

[0033] A new experimental device for treating exhaust gas from carbon materials prepared by a tube furnace, mainly including: single chip microcomputer 2, power converter 3, automatic acid-base regulator-9, micro suction pump-10, air intake pipe-11, turbidity sensor One 13, turbidity sensor two 14, acid-base automatic regulator two 16, micro suction pump two 20, carbon fiber electrode 22, solid electrolyte 23 and intake pipe two 24;

[0034] The anti-suckback device is composed of a liquid level sensor 4, a glass bottle 5, an air intake pipe 6 and an air shut-off valve 7. When the liquid in the reflection room is sucked back to the glass bottle 5, the liquid level sensor 4 transmits a signal to the single-chip microcomputer 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com