Electric flocculation unit, electric flocculation device and heavy metal wastewater treatment system

An electro-flocculation and wastewater technology, applied in water/sewage treatment, water/sewage multi-stage treatment, special compound water treatment, etc., can solve the problems of trouble, poor treatment effect, large sludge output, etc. The effect of reducing concentration polarization and uniform concentration distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

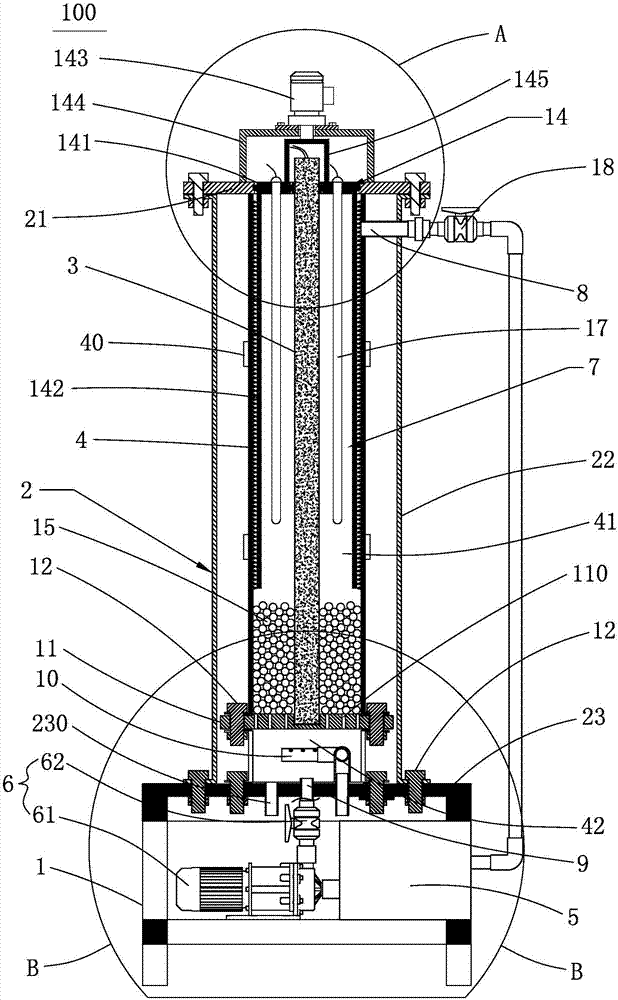

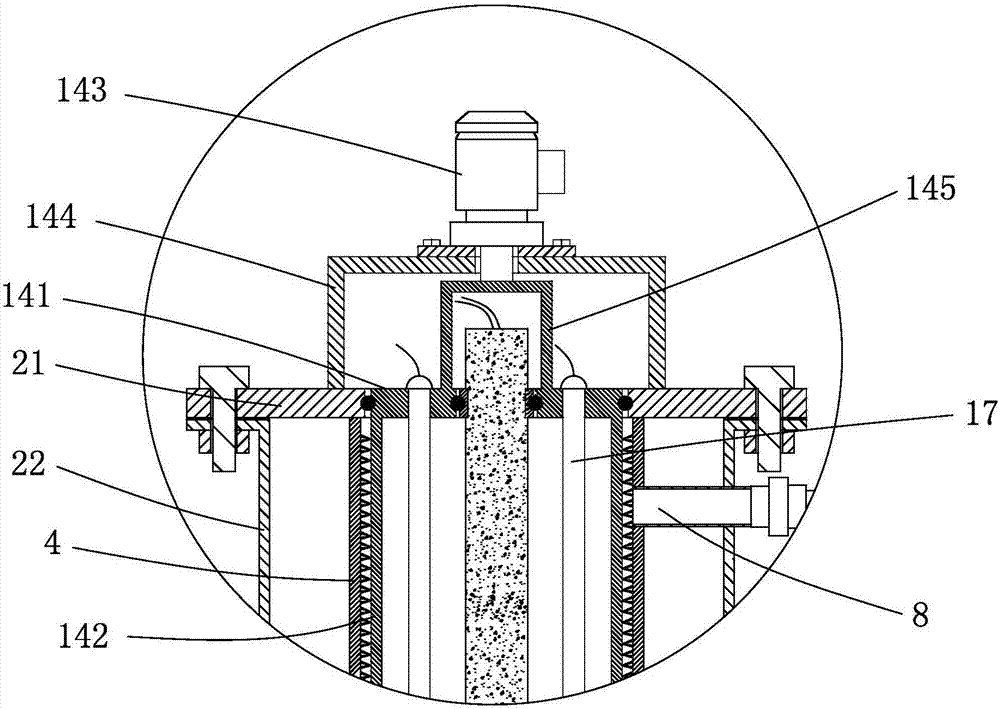

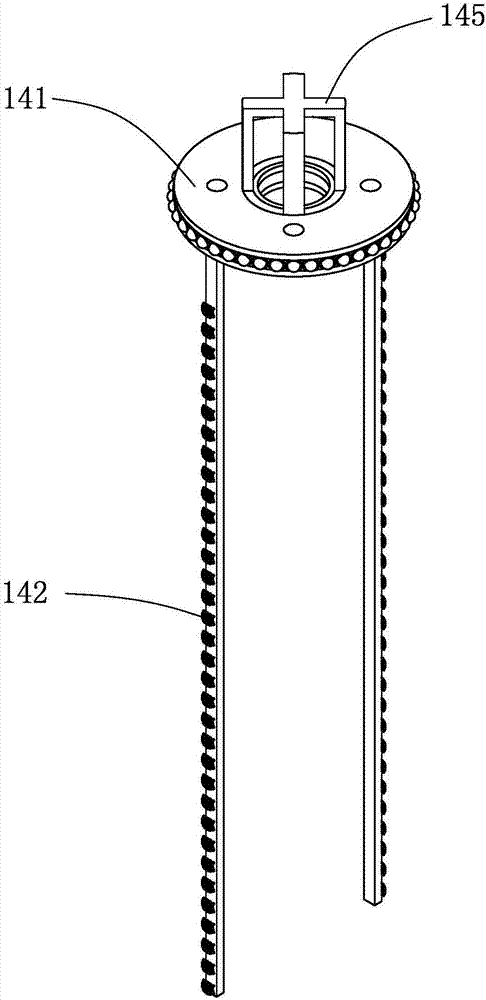

[0035] Such as Figure 1 to Figure 4 As shown, it is an electroflocculation unit 100 provided by the embodiment of the present invention. The electroflocculation unit 100 includes a housing 2, an anode rod 3, a cathode tube 4, iron carbon ball fillers 15, several ultraviolet lamps 17, and an aeration device 10. , a power supply module (not shown in the figure), a liquid delivery mechanism 6 and a rotary scraper device 14 for scraping off the heavy metal deposits adhering to the inner wall of the cathode tube 4 . Both the liquid delivery mechanism 6 and the liquid storage tank 5 are installed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com