A kind of method of electroflocculation to remove chromaticity of anodic oxidation dyeing wastewater

A dyeing wastewater and anodic oxidation technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult decolorization, incomplete treatment of anodic dyeing wastewater, and secondary pollution. Achieve the effects of improving treatment efficiency, preventing dirt coverage, and delaying passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

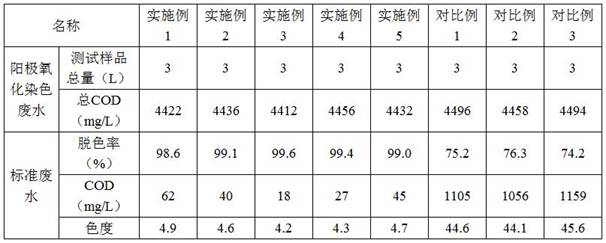

Embodiment 1

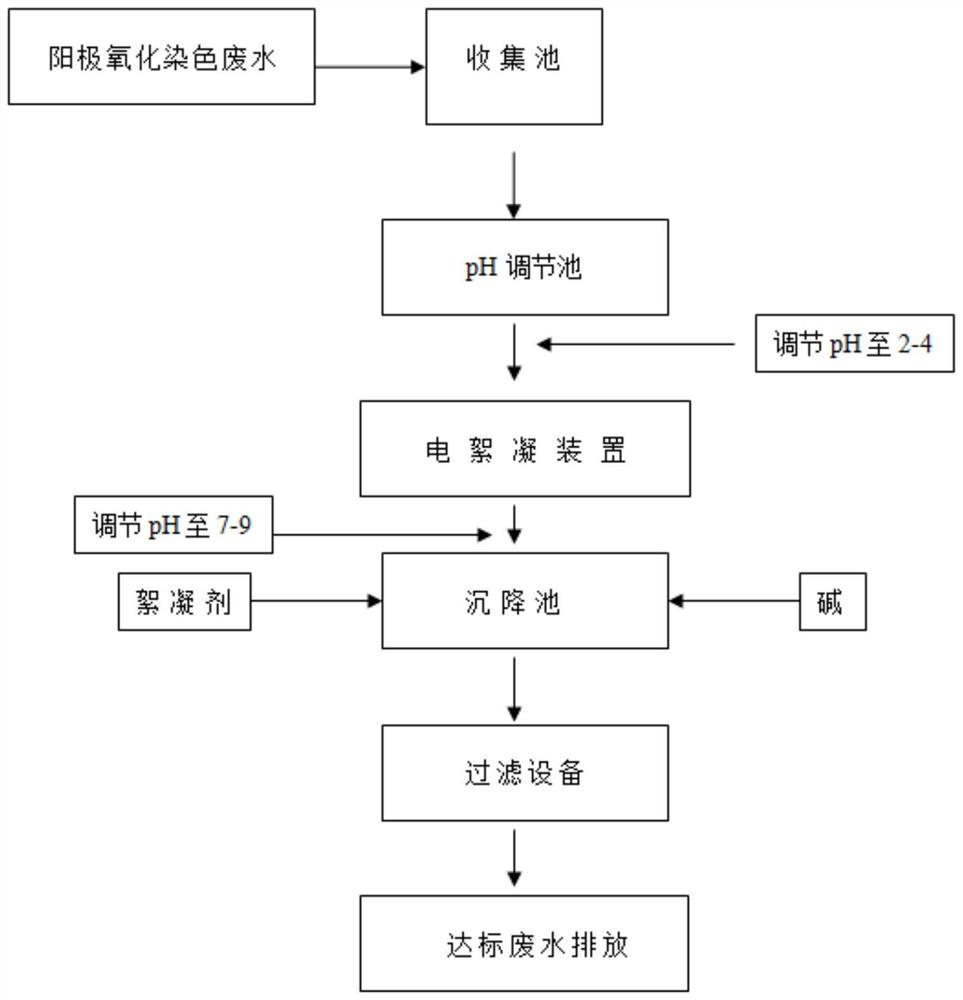

[0028] A method for removing the chroma of anodic oxidation dyeing wastewater by electrocoagulation, comprising the steps of:

[0029] 1) Pump the anodic oxidation dyeing wastewater into the pH adjustment tank, and adjust the pH value of the wastewater to 2 with sulfuric acid;

[0030] 2) Then, the wastewater regulated by sulfuric acid is pumped into the electrocoagulation device for electrocoagulation and electrooxidation reactions. After the reaction is completed, an alkali regulator is added to adjust the pH value of the wastewater after electrolysis to 7;

[0031] 3) Pump the wastewater oxidized by the electrocoagulation device into the sedimentation tank, add flocculant polyacrylic acid for coagulation and sedimentation treatment, and finally discharge the standard wastewater after passing through the filter equipment.

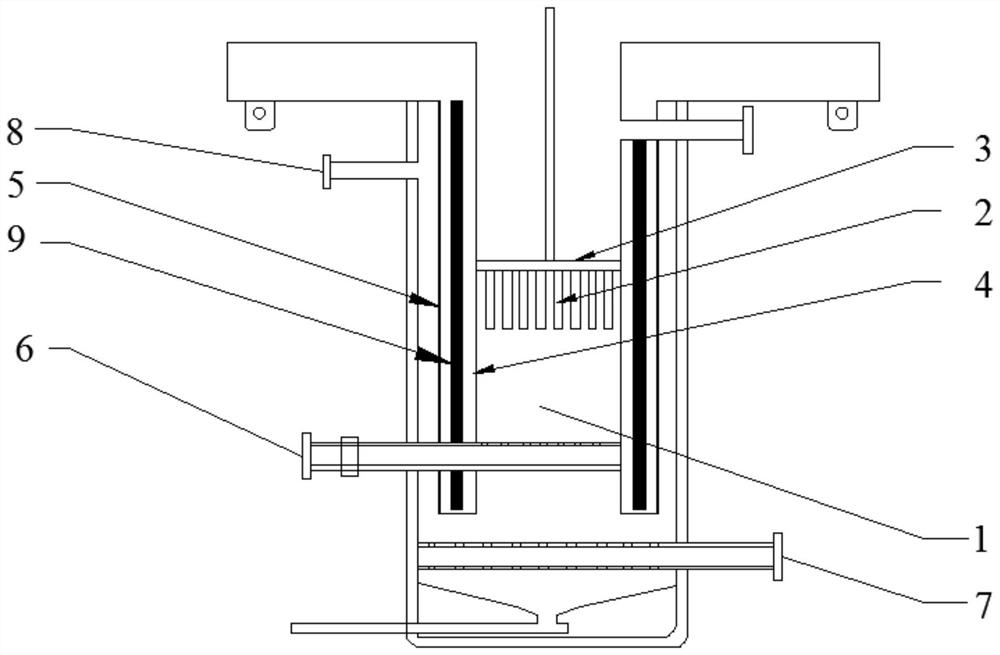

[0032] The electrocoagulation device includes a DC power supply, an electrolytic cell, an anode brush, a through-hole plate, an anode plate, a negative p...

Embodiment 2

[0035] A method for removing the chroma of anodic oxidation dyeing wastewater by electrocoagulation, comprising the steps of:

[0036] 1) Pump the anodic oxidation dyeing wastewater into the pH adjustment tank, and adjust the pH value of the wastewater to 2.5 with hydrochloric acid;

[0037] 2) Then, the wastewater regulated by sulfuric acid is pumped into the electrocoagulation device for electrocoagulation and electrooxidation reactions. After the reaction is completed, an alkali regulator is added to adjust the pH value of the wastewater after electrolysis to 7.5;

[0038]3) Pump the wastewater oxidized by the electrocoagulation device into the sedimentation tank, add flocculant calcium polyacrylate for coagulation and sedimentation treatment, and finally discharge the standard wastewater after passing through the filter equipment.

[0039] The electrocoagulation device includes a DC power supply, an electrolytic cell, an anode brush, a through-hole plate, an anode plate, a...

Embodiment 3

[0042] A method for removing the chroma of anodic oxidation dyeing wastewater by electrocoagulation, comprising the steps of:

[0043] 1) Pump the anodic oxidation dyeing wastewater into the pH value adjustment pool, and adjust the pH value of the wastewater to 3 with a mixture of sulfuric acid and hydrochloric acid at a ratio of 1:1 by weight;

[0044] 2) Then, the wastewater regulated by sulfuric acid is pumped into the electrocoagulation device for electrocoagulation and electrooxidation reactions. After the reaction is completed, an alkali regulator is added to adjust the pH value of the wastewater after electrolysis to 8;

[0045] 3) Pump the wastewater oxidized by the electrocoagulation device into the sedimentation tank, add flocculant sodium polyacrylate for coagulation and sedimentation treatment, and finally discharge the standard wastewater after passing through the filter equipment.

[0046] The electrocoagulation device includes a DC power supply, an electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com