Patents

Literature

38 results about "Rubidium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubidium hydroxide (+1) (RbOH) is a strong basic chemical and alkali that is formed by one rubidium ion and one hydroxide ion. Rubidium hydroxide does not appear in nature. However it can be obtained by synthesis from rubidium oxide. In addition, rubidium hydroxide is commercially available in form of an aqueous solution from a few suppliers.

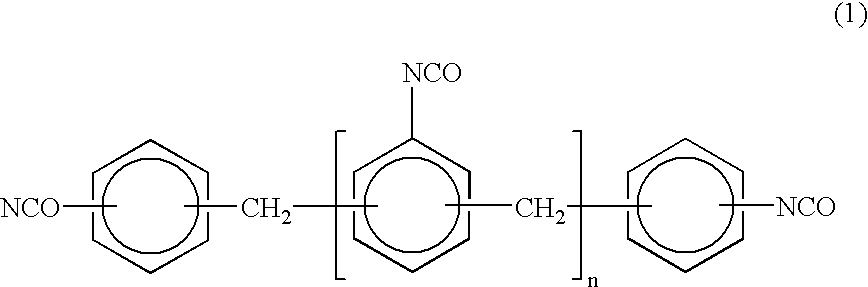

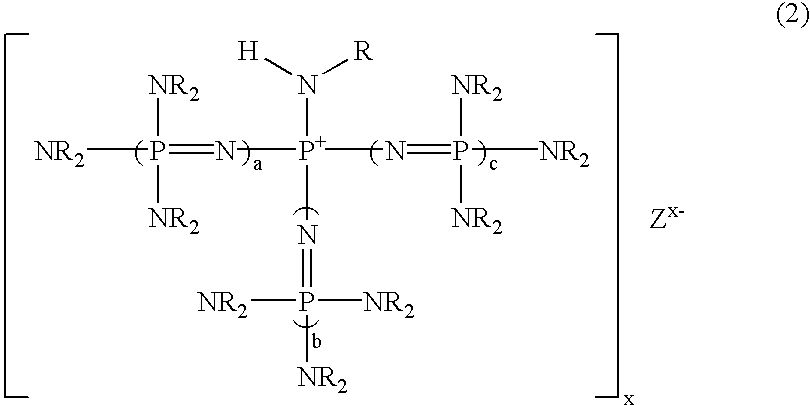

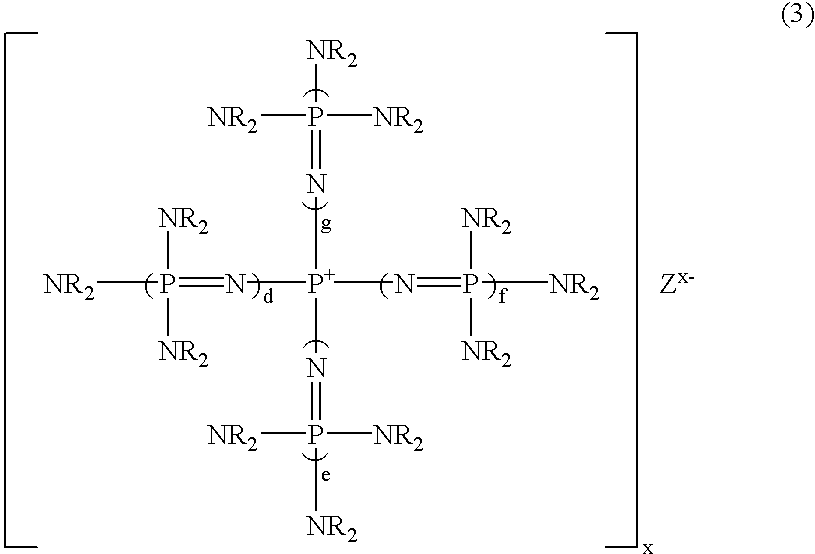

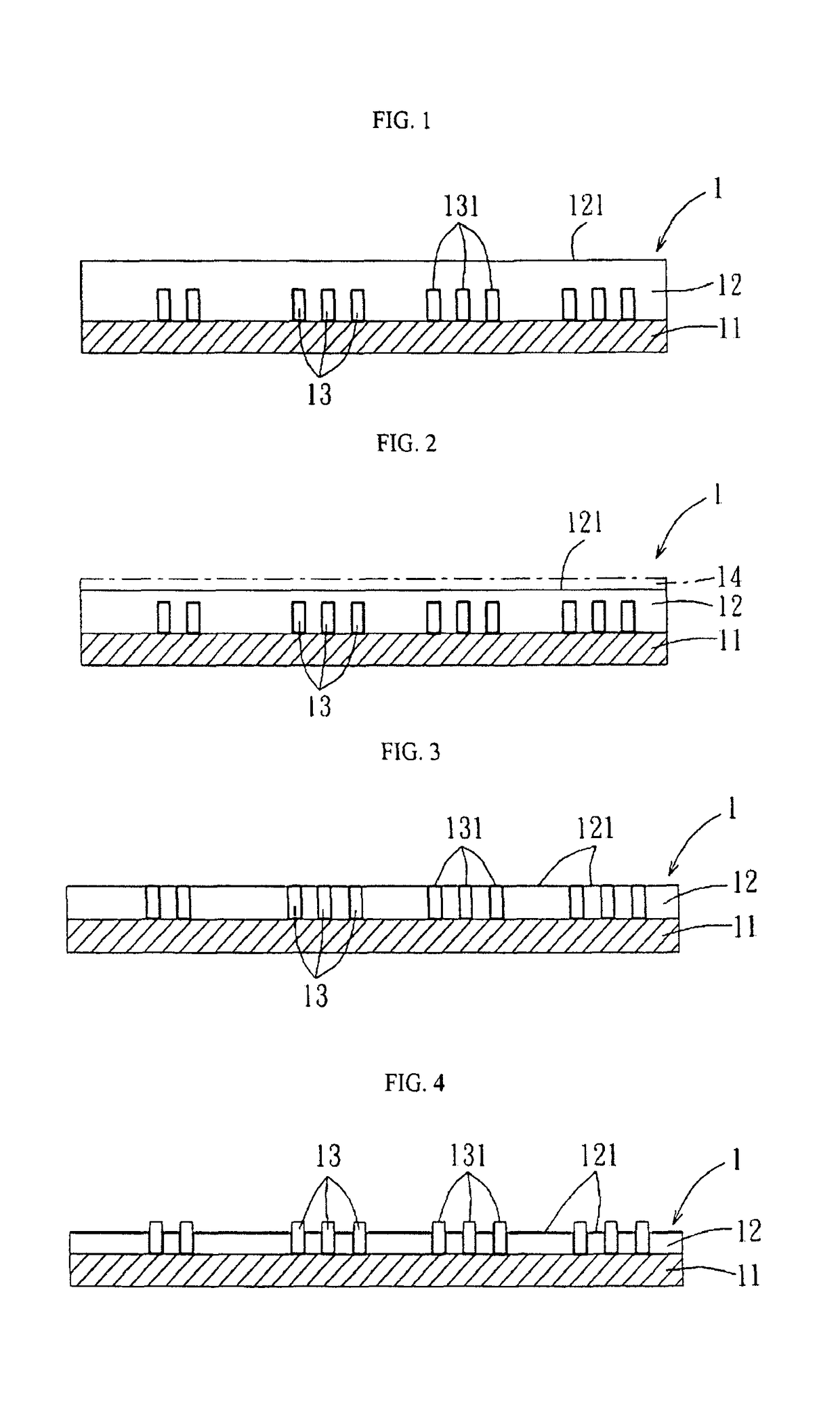

High-durability flexible polyurethane cold cure molded foam and process for producing the same

The high-durability flexible polyurethane cold cure molded foam of the invention has an overall density of not less than 35 kg / m3 and not more than 45 kg / m3 and a wet heat compression set of not more than 15%, and preferably has a hardness change ratio, as determined in a repeated compression test, of not more than 15%. This foam can be obtained by the process of the invention. The process of the invention is a process for producing a flexible polyurethane cold cure molded foam obtained from a polyol and / or a polymer polyol containing dispersed polymer microparticles obtained by radical polymerizing a compound having an unsaturated bond in the polyol, water, a catalyst and a polyisocyanate, wherein the polyol is a polyol synthesized by the use of a catalyst containing at least one compound selected from the group consisting of a compound having a nitrogen-phosphorus double bond, cesium hydroxide and rubidium hydroxide. The foam of the invention has a low density and is excellent in durability, particularly in hardness change ratio in a repeated compression test and wet heat compression set. According to the process of the invention, such a foam can be obtained.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

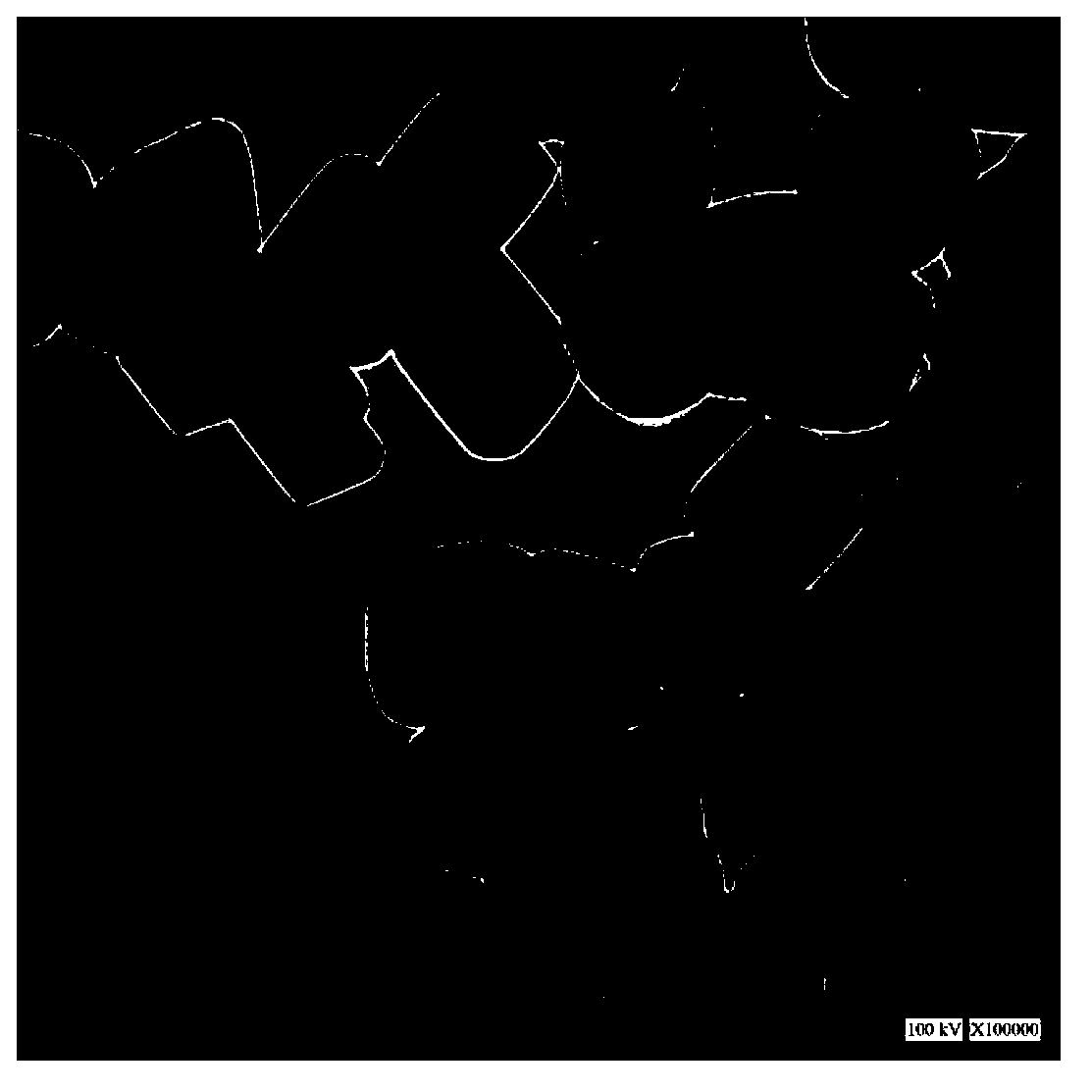

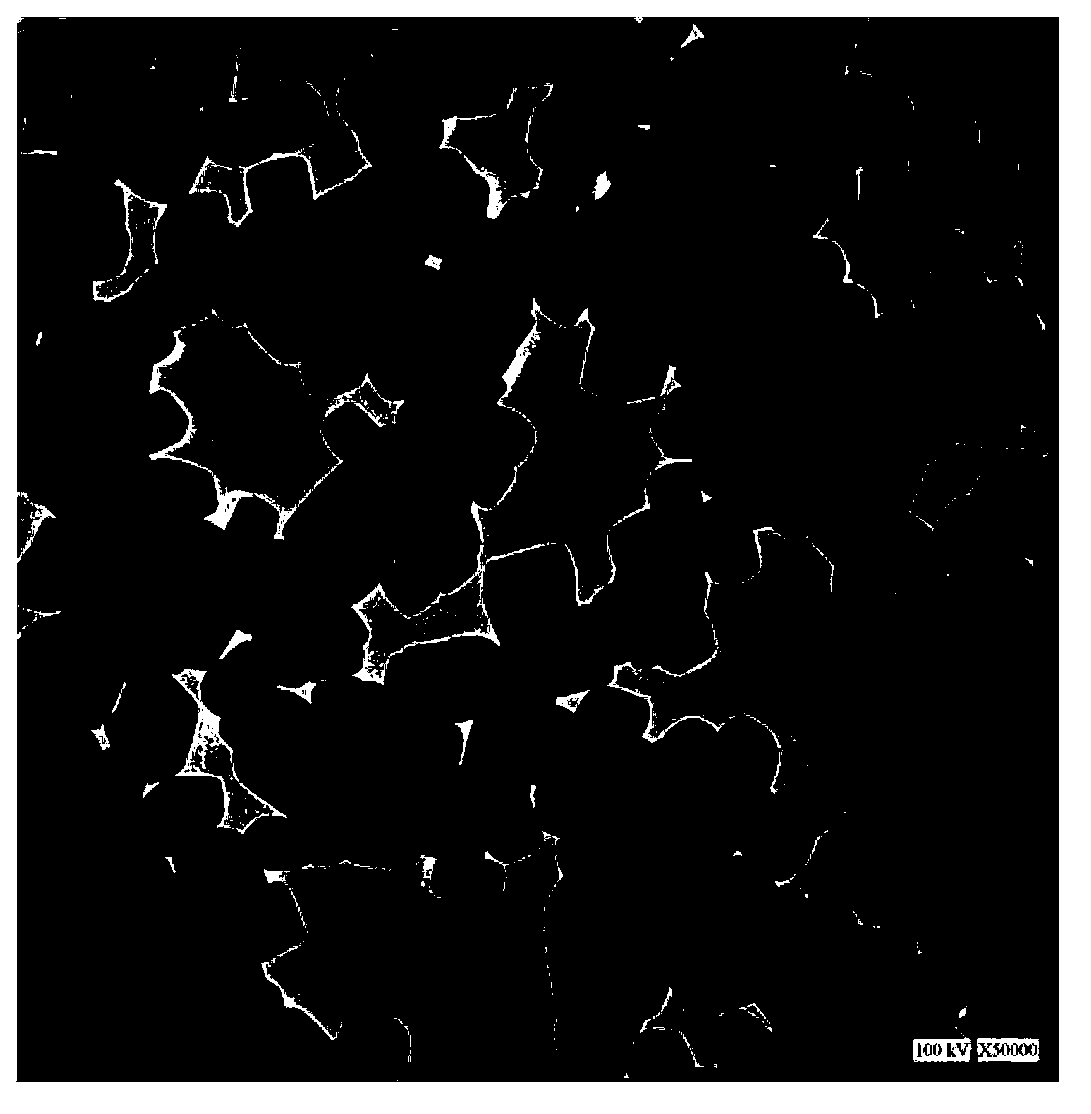

Preparation method of cubic ultra-fine calcium carbonate particles

ActiveCN103663527AParticle size controllableNarrow rangeCalcium/strontium/barium carbonatesNanotechnologySodium bicarbonateSucrose

The invention provides a preparation method of cubic ultra-fine calcium carbonate particles. The method comprises the following steps: (1) adding a nucleation promoter to calcium hydroxide suspension liquid, wherein the nucleation promoter is selected from more than one of glucose, sucrose or sodium citrate; (2) carbonizing by introducing carbon dioxide until the pH value is 8-12, adding a crystal modifier and ageing for 0.5-10 hours, wherein the crystal modifier is selected from one of sodium chloride, sodium carbonate, sodium bicarbonate or sodium hydroxide; (3) further introducing carbon dioxide and carbonizing until the pH value is 6.5-7.0; (4) coating by adding a coating agent, filtering and drying to obtain a product, wherein the coating agent is selected from a resin acid, a resin acid alkali metal salt, a fatty acid or a fatty acid alkali metal salt. According to the calcium carbonate particles, the particle sizes are 90-180nm, the calcium carbonate particles are in a cubic shape, and the specific surface area is 10-18m<2> / g. Thus, the cubic ultra-fine calcium carbonate particles can be used as functional fillers in coating, rubber, plastic and sealant industries.

Owner:建德华明科技有限公司

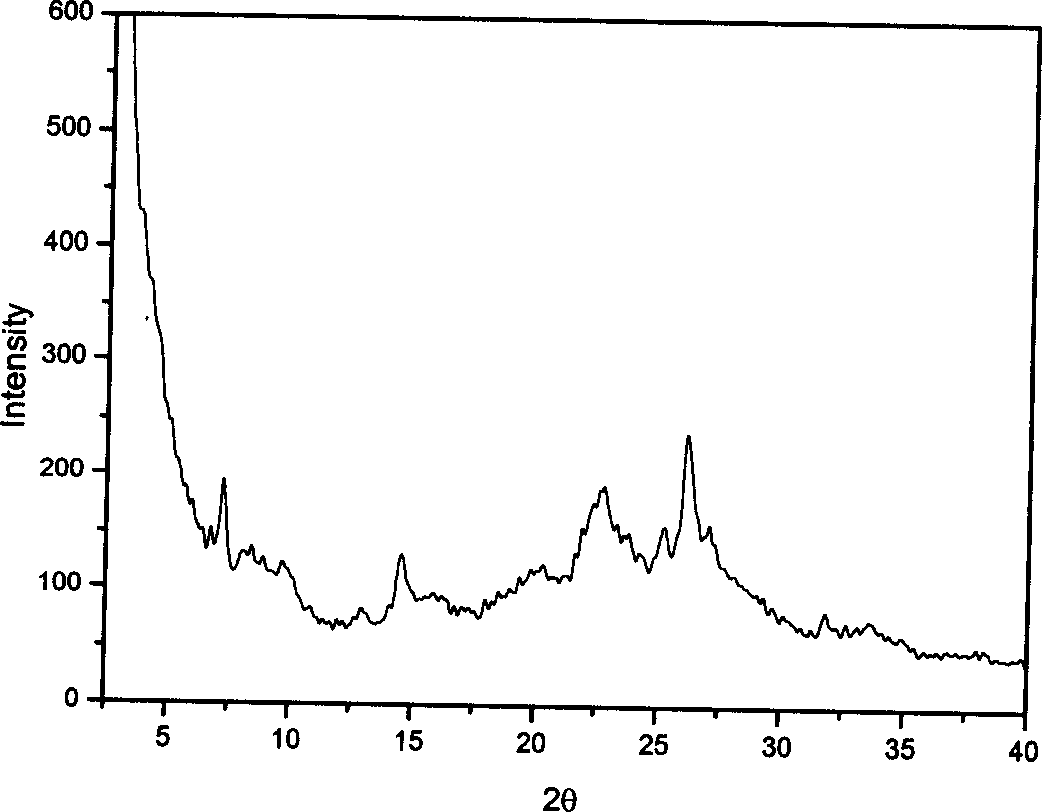

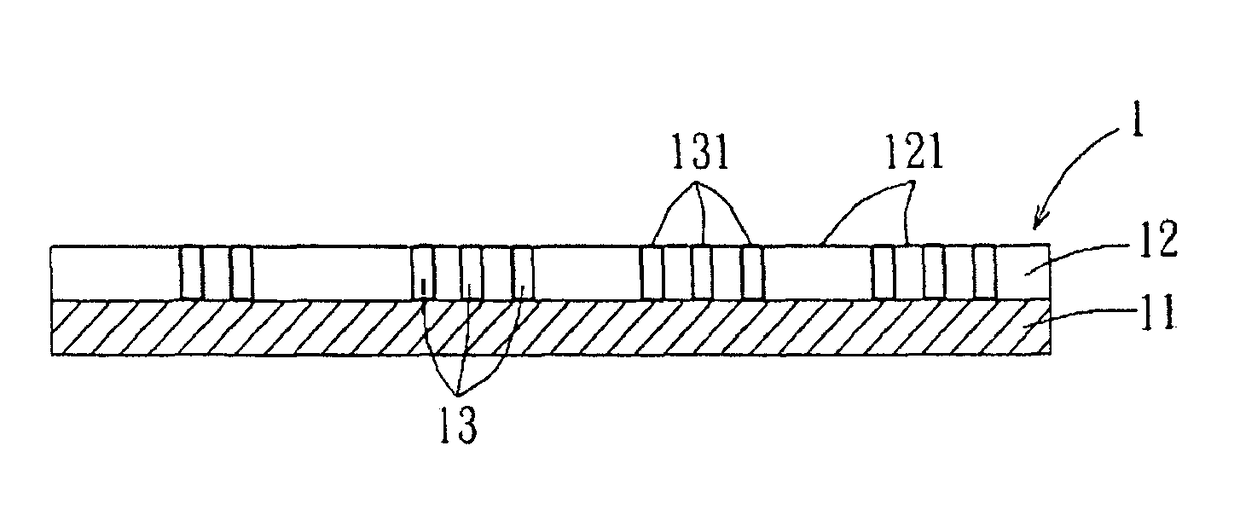

Porous material and its synthesis method

ActiveCN1751994AHas a compound pore structureMolecular sieve catalystsCrystalline aluminosilicate zeolitesSynthesis methodsAluminium hydroxide

A process material with compound artery is prepared from the Si source chosen from amorphous SiO2, si sol, silicon oxide solid, silicon gel, diatomite and water glass, the Al source chosen from sodium aluminate, sodium metaaluminate, aluminium sulfate, aluminium nitrate, etc, at least one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and template agent through proportional mixing, reaction, ageing and crystallizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

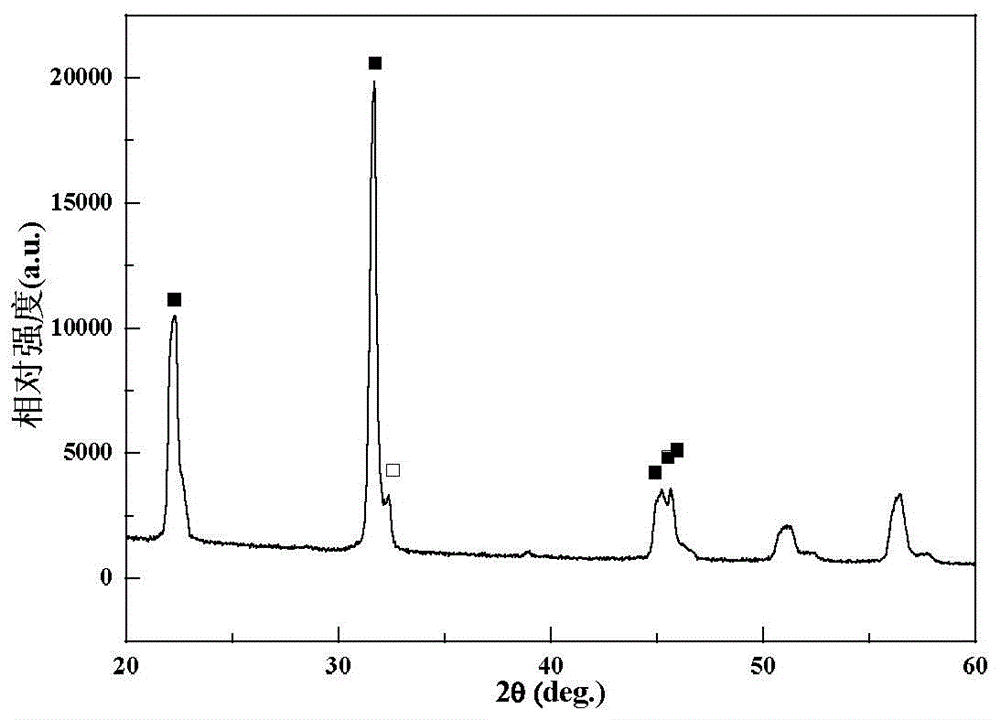

Preparation method of sodium manganese oxide

ActiveCN103896339AAdvantages of preparation methodHigh purityCell electrodesSecondary cellsChemical reactionMolecular level

The invention relates to a preparation method of a sodium manganese oxide, and particularly relates to a preparation method of a layered birnessite type sodium manganese oxide. The preparation method is as follows: reacting a two valent manganese salt with sodium hydroxide in an aqueous phase to obtain a Mn (OH)2 precipitate and / or MnOOH precipitate-containing suspension, then performing solvent evaporation to obtain a MnOOH precipitate and / or Mn (OH) 2 precipitate-containing mixture; grinding the mixture, and sintering at 600-1200 DEG C to obtain a sintering product; then performing washing and solid-liquid separation for multiple times, and finally drying to obtain a final product. According to the preparation method, molecular level mixing of manganese hydroxide and a sodium salt can be realized by a solution chemical reaction method, promotion of next-step solid phase reaction is facilitated, improvement of the purity of the product is facilitated, and the prepared sodium manganese compound can be used in a sodium ion battery using an aqueous solution as an electrolyte, and helps to improve the charge discharge performance of the battery.

Owner:紫石能源有限公司

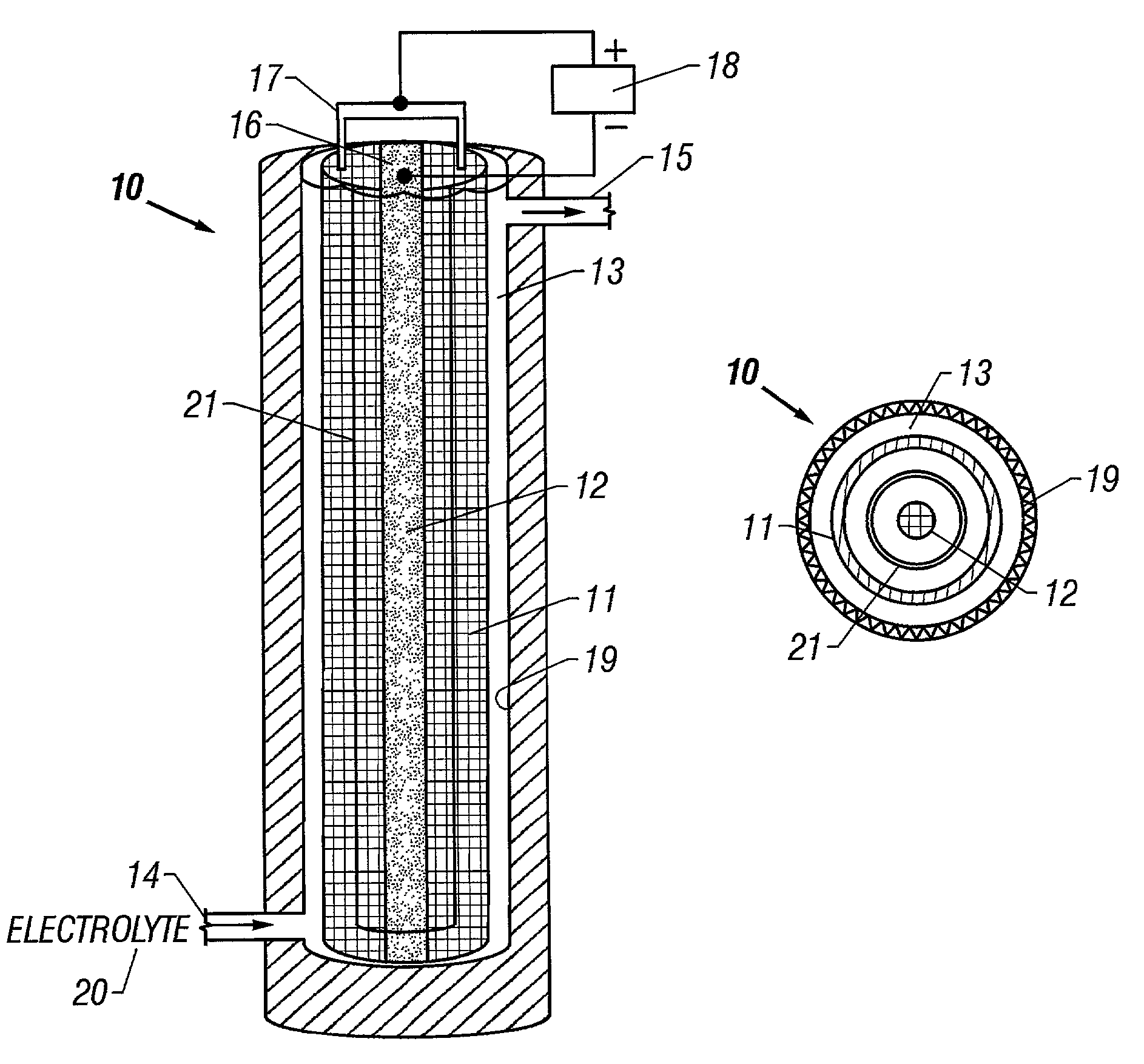

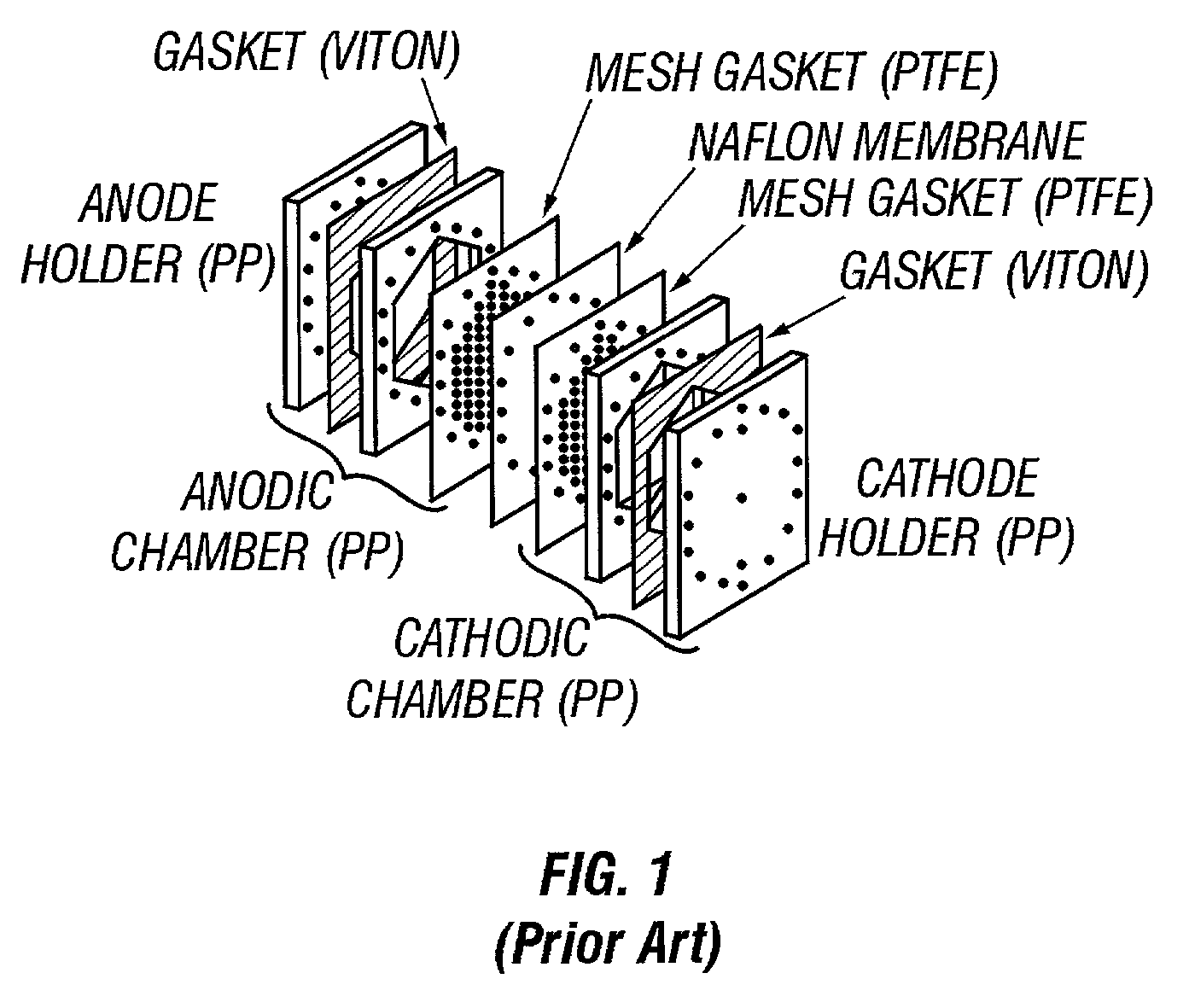

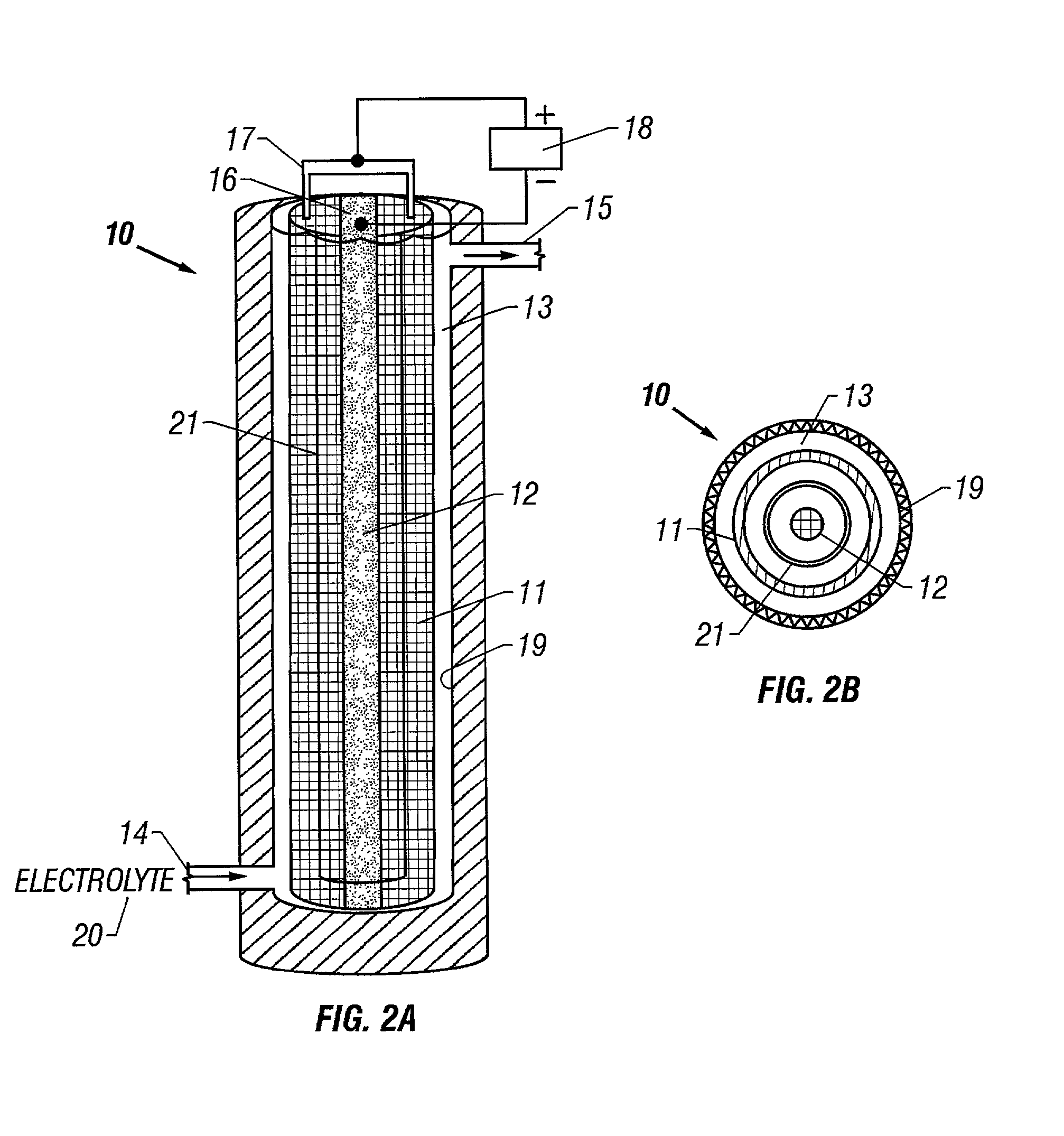

Electrochemical method for producing ferrate(VI) compounds

A method for the electrochemical production of ferrate salts in an aqueous electrolyte solution comprising one or more hydroxide components. Dramatically increased yields of ferrate salts are obtained from using a mixture of sodium hydroxide and potassium hydroxide. Preferably, both sodium hydroxide and potassium hydroxide are present in concentrations greater than 5 molar, most preferably at least 10 molar, i.e., 10 M NaOH and 10 M KOH. The anode is preferably a sacrificial anode made out of an iron-containing material to supply the iron necessary for the ferrate production reaction. The aqueous hydroxide solution, even a mixed potassium hydroxide (KOH) and sodium hydroxide (NaOH) solution, may be recycled and reused in the electrochemical cell, preferably after the extraction of the ferrate salt

Owner:LYNNTECH

Method for producing complexation metal salt of ethylenediamine tetra acetic acid

InactiveCN1431193AHigh purityReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationComplexonsZinc hydroxide

A process for preparing a high-purity metal salt of complexon as trace-element fertilizer includes adding complexon and alkali (sodium hydroxide, potassium hydroxide, or ammonia) to water, reaction while stirring to obtain complexon salt, adding metal salt (iron hydroxide, manganese hydroxide, etc.) at 150 deg.C for 0.5-5 hr, and filter to remove insoluble substance.

Owner:钟林 +2

Etchant Solutions and Method of Use Thereof

ActiveUS20160186058A1High Si etch rateReduce passivationSemiconductor/solid-state device manufacturingCable/conductor manufactureRubidium hydroxidePotassium hydroxide

Etching compositions and method of using the etching compositions comprising potassium hydroxide; one or more than one additional alkaline compounds selected from the group consisting of TEAH, TMAF and NH4OH; and water; or etching compositions comprising one or more than one inorganic alkali basic hydroxides selected from the group consisting of potassium hydroxide, cesium hydroxide, sodium hydroxide, rubidium hydroxide, or lithium hydroxide; optionally one or more than one additional alkaline compounds; water; and optionally one or more corrosion inhibitors; wherein the composition preferentially etches silicon present on a substrate as compared to silicon dioxide present on said substrate.

Owner:VERSUM MATERIALS US LLC

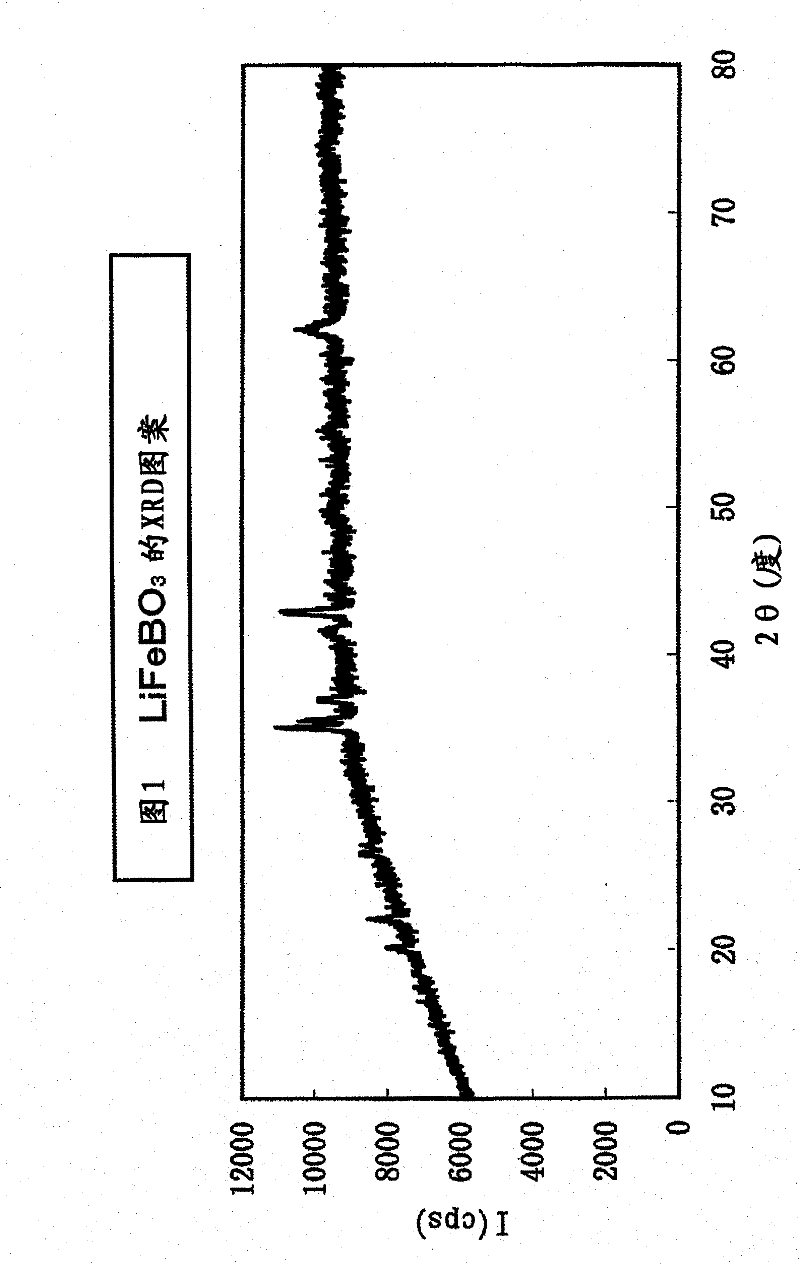

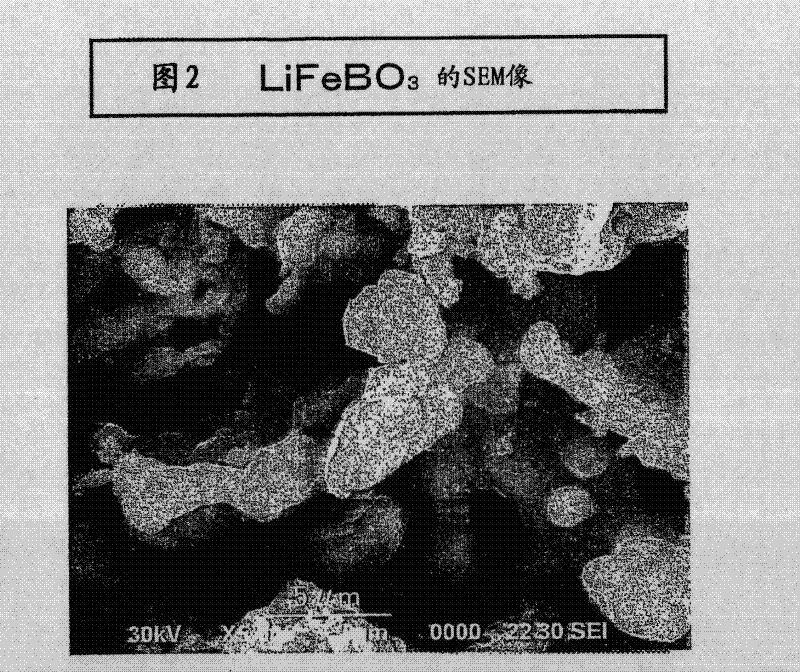

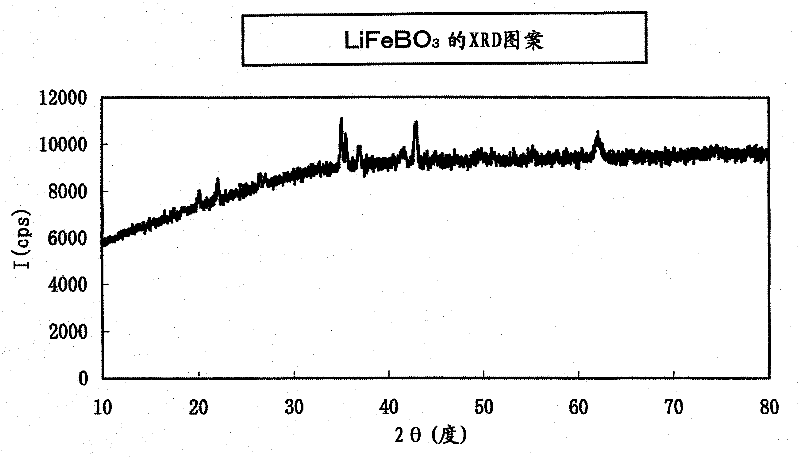

Process for producing lithium borate compound

InactiveCN102348640AReduce usageRich in resourcesMaterial nanotechnologyCell electrodesManganeseLithium compound

A process for producing, by a relatively simple means, a lithium borate material which is useful as a positive-electrode material for lithium-ion secondary batteries, etc. and has improved cycle characteristics, capacity, etc., and excellent performances. The process is characterized by reacting one or more divalent-metal compounds comprising at least one compound selected from a group consisting of compounds of divalent iron and compounds of divalent manganese with boric acid and lithium hydroxide in a reducing atmosphere at 400-650 DEG C in the melt of a carbonate mixture comprising lithium carbonate and at least one alkali metal carbonate selected from a group consisting of potassium carbonate, sodium carbonate, rubidium carbonate, and cesium carbonate.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

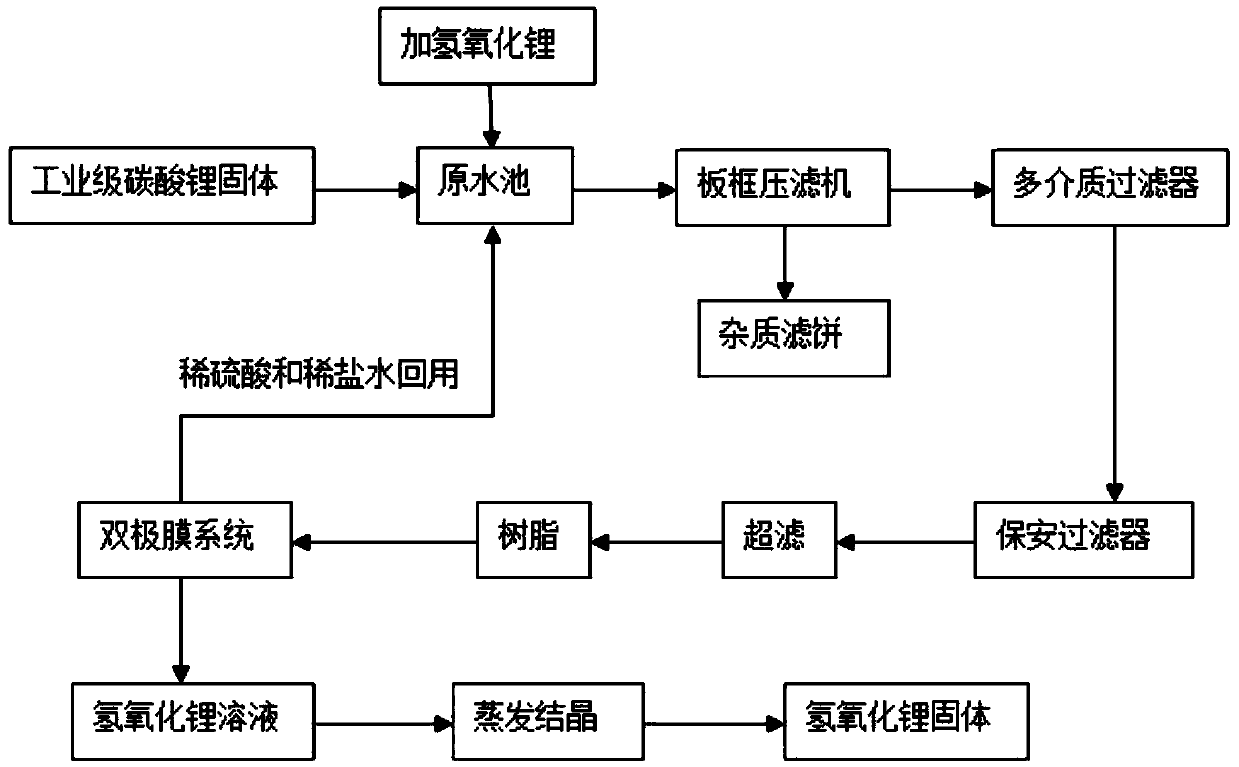

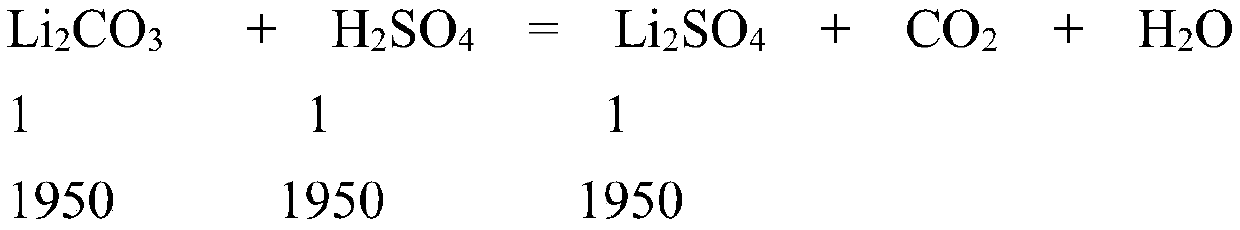

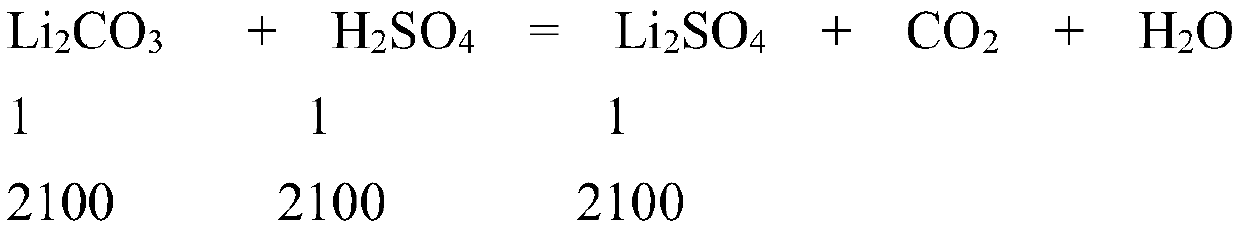

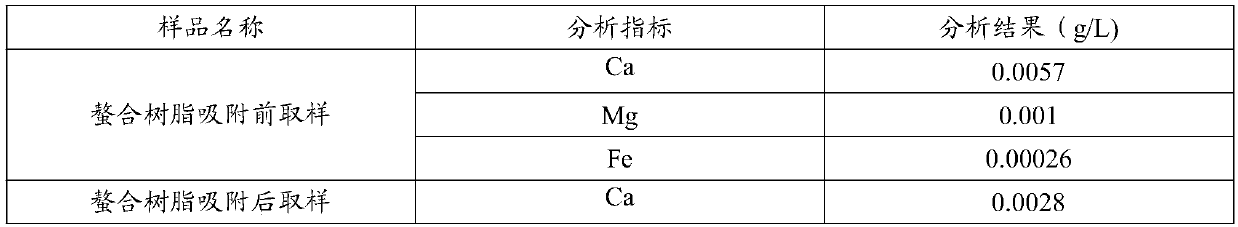

Method for preparing lithium hydroxide by industrial-grade lithium carbonate solid

ActiveCN109680295AAchieve purification effectAchieve separationElectrolysis componentsSulfate radicalsUltrafiltration

The invention provides a method for preparing lithium hydroxide by an industrial-grade lithium carbonate solid and belongs to the field of preparation of lithium hydroxide. The lithium hydroxide is prepared by taking the industrial-grade lithium carbonate solid as a raw material; solid impurities, sodium, calcium, magnesium, aluminum, iron and other ions in the industrial-grade lithium carbonate solid are removed through pH value regulation, plate and frame filtration, multi-medium filtration, ultra-filtration and chelate resin adsorption treatment; the plate and frame filtration can separatesolid from liquid; the multi-medium filtration is used for removing suspended matters, colloids, organic matters and the like; the ultra-filtration can further reduce the contents of residual COD, thesuspended matters and macromolecular dissolved matters to realize the purification and the separation of the liquid; chelate resin enables the content of high-valent ions in the liquid to meet the bipolar membrane water ingress requirements; sulfate radicals in a pre-electrolyte migrate to an acid chamber and are combined with hydrogen ions decomposed by the surface of a bipolar membrane to formsulfuric acids; lithium ions in the pre-electrolyte migrate to an alkaline chamber and are combined with hydroxyl ions decomposed by the surface of the bipolar membrane to generate the lithium hydroxide.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV +1

Production method of EDTA complex metal salt

InactiveCN1426998ATo achieve the purpose of removing inorganic saltsRaise the reaction temperatureOrganic compound preparationAmino-carboxyl compound preparationComplexonsIron sulfate

A process for preparing high-purity complexed metal salt of complexon used for trace-element fertilizer includes such steps as adding complexon and sodium hydroxide to water, stirring while reaction to obtain sodium salt of complexant, adding metal salt which is one of FeCl3, iron sulfate, manganese carbonate, alkaline copper carbonate, zinc oxide, etc., and reaction at 70-150 deg.C.

Owner:钟林 +2

Catalyst for biomass tar cracking and preparation method thereof

InactiveCN107661781AResolve separabilitySolving activityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionWater vaporCopper oxide

The invention relates to a catalyst for biomass tar cracking and a preparation method thereof. The catalyst is prepared from biomass semicoke, tar, chromium oxide green, copper oxide, cesium hydroxide, lithium hydroxide, barium hydroxide, rubidium hydroxide, manganese dioxide, nickel oxide, sodium oxide, and alumina binder. The invention solves the problem of catalyst inactivation, such as separation and aggregation of metal oxides and auxiliary components and coking and carbon deposition, and realizes the recycling of biological semicoke catalysts, using the biomass pyrolysis catalyst to assist microwaves to pyrolyze and gasify biomass can obtain a high gasification efficiency and high-quality synthetic gas product under low temperature, exogenous gas, such as vapor, is not introduced forconsumption into the whole process, and therefore the energy consumption and production cost of the process are remarkably reduced.

Owner:桂林市漓江机电制造有限公司

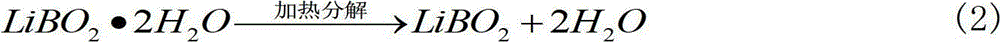

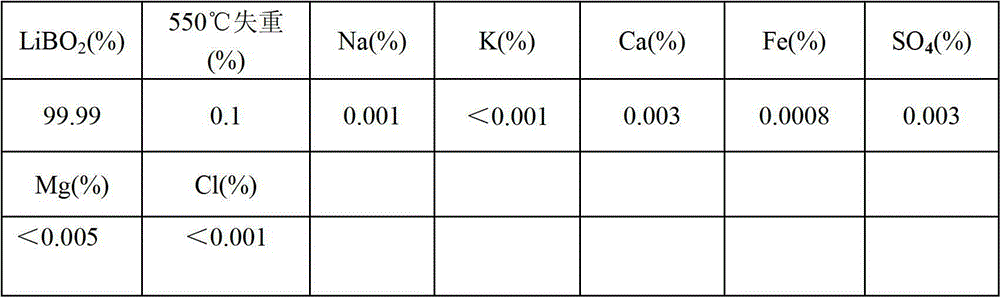

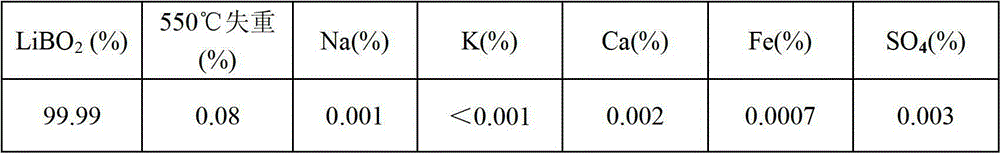

Preparation method of anhydrous lithium metaborate

The invention belongs to the technical field of preparation of inorganic compound lithium metaborate, and particularly discloses a preparation method of anhydrous lithium metaborate. The method comprises the following steps: dissolving lithium hydroxide in boiling water, and filtering to remove impurities; slowly adding boracic acid after being purified in hot lithium hydroxide solution, wherein the amount of boracic acid is slightly smaller than theoretical reacting weight; depositing so that the solution is cooled and crystallized to prepare lithium metaborate wet material; and then obtaining the finished product of anhydrous lithium metaborate through the steps of low-temperature primary drying, cracking, high-temperature secondary drying and the like. According to the method, lithium metaborate is prepared from lithium hydroxide and boracic acid through liquid phase reaction, the utilization rates of lithium hydroxide and boracic acid are improved, the yield coefficient of the system can reach more than 90%, the purity of the product can reach 99.99% and is higher than that of the product in the prior art, and the method is more suitable for the market requirements nowadays.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

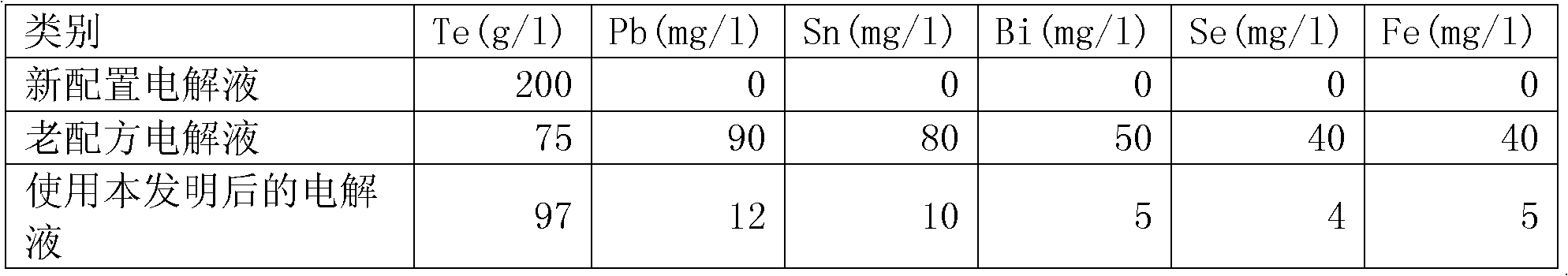

Preparation method for tellurium electrolyte

InactiveCN102492962ALess residual impuritiesExtended use timePhotography auxillary processesProcess efficiency improvementRubidium hydroxideCalcium electrolyte

The invention discloses a preparation method for a tellurium electrolyte. The invention aims to provide the preparation method for a tellurium electrolyte. The method is characterized by comprising the following steps: A, mixing tellurium dioxide, sodium hydroxide and pure water according to a solid-liquid weight ratio of 1: 0.5: 5, heating an obtained mixture to a temperature of 80 DEG C and allowing tellurium dioxide to dissolve after stirring so as to obtain an initial tellurium electrolyte, wherein the addition amount of sodium hydroxide is that 0.5 kg of sodium hydroxide is mixed with each 1 kg of tellurium dioxide; and B, sequentially adding solid sodium oxalate and solid potassium iodide into the initial tellurium electrolyte obtained in step A and dissolving solid sodium oxalate and solid potassium iodide so as to prepare the final tellurium electrolyte. The purity of tellurium dioxide used in the method is 99.99% and the purity of sodium hydroxide is also 99.99%. The method provided in the invention is mainly used for preparation of tellurium electrolyte with a purity more than 99.995%.

Owner:ZHUZHOU KENENG NEW MATERIAL CO LTD

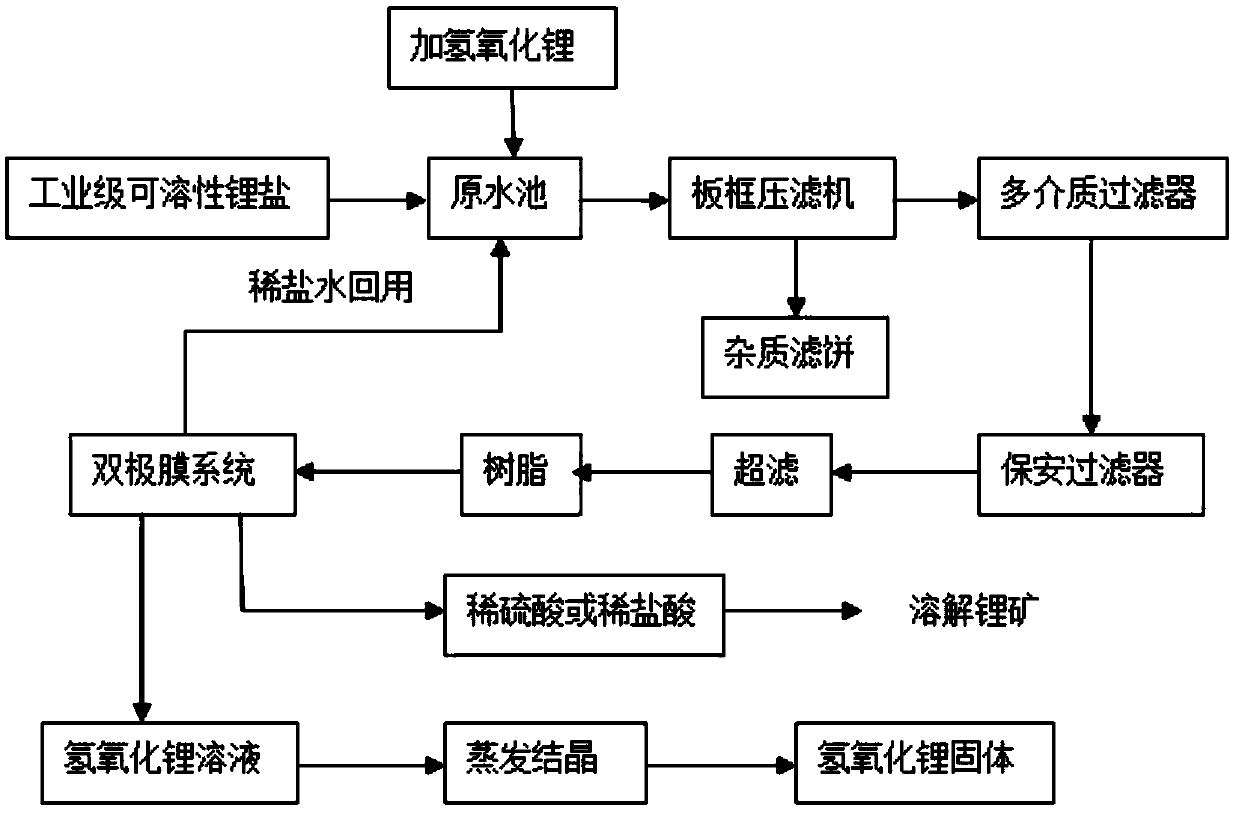

Method for preparing lithium hydroxide by industrial-grade soluble lithium salt

The invention provides a method for preparing lithium hydroxide by industrial-grade soluble lithium salt and belongs to the field of preparation of lithium hydroxide. The lithium hydroxide is preparedby taking the industrial-grade soluble lithium salt as a raw material; impurities, calcium, magnesium, aluminum, iron and other ions in the industrial-grade soluble lithium salt are removed through pH value regulation, plate and frame filtration, multi-medium filtration, ultra-filtration and chelate resin adsorption treatment; the plate and frame filtration can separate solid from liquid; the multi-medium filtration is used for removing suspended matters, colloids, organic matters and the like; the ultra-filtration can further reduce the contents of residual COD, the suspended matters and macromolecular dissolved matters to realize the purification and the separation of the liquid; chelate resin enables the content of high-valent ions in the liquid to meet the bipolar membrane water ingress requirements; anions in a pre-electrolyte migrates to an acid chamber and are combined with hydrogen ions decomposed by the surface of a bipolar membrane to form dilute acids; lithium ions in the pre-electrolyte migrate to an alkaline chamber and are combined with hydroxyl ions decomposed by the surface of the bipolar membrane to generate the lithium hydroxide.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV

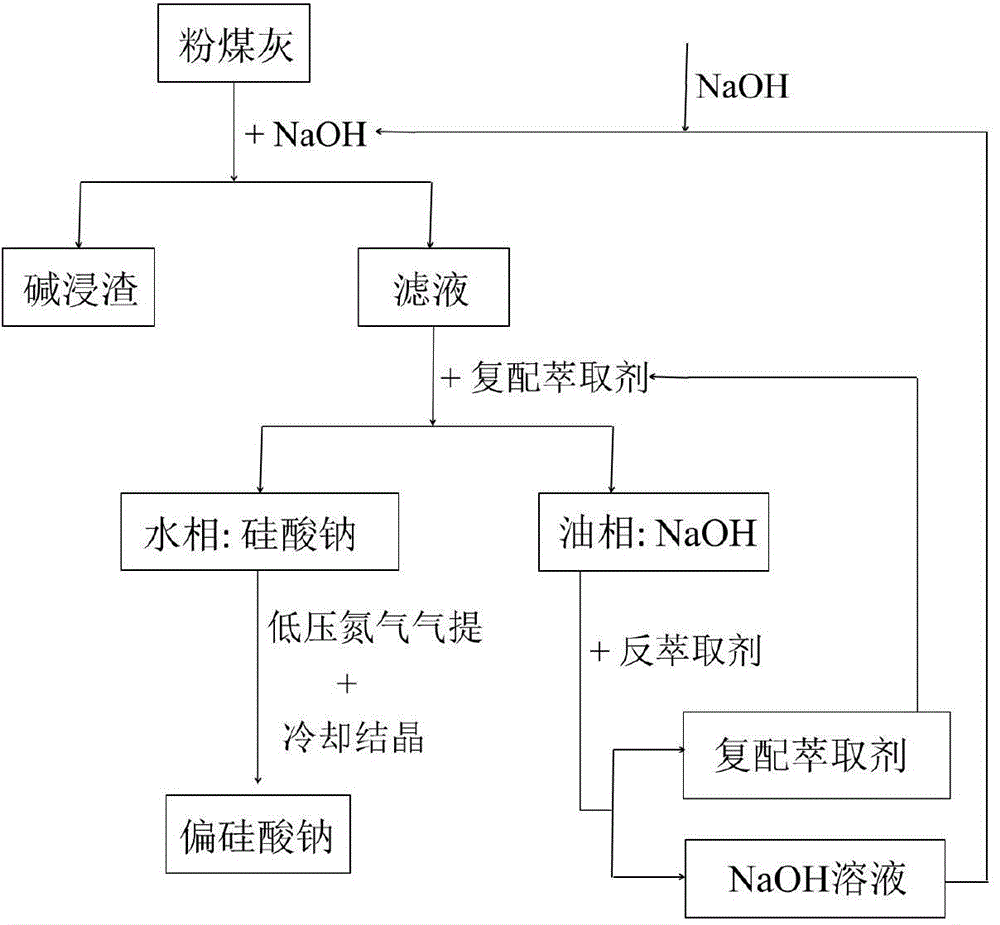

Method for efficiently separating and recycling sodium hydroxide from alkaline sodium silicate

ActiveCN104803392AOvercoming technical difficulties that are difficult to separateHigh modulusAlkali metal silicatesAlkali metal oxides/hydroxidesAlcoholRubidium hydroxide

The invention discloses a method for efficiently separating and recycling sodium hydroxide from alkaline sodium silicate and belongs to the field of alkaline sodium silicate recycling comprehensive utilization. An efficient compound extractant is utilized to extract sodium hydroxide from alkaline sodium silicate, and a high-purity and high-modulus sodium metasilicate product is recovered by virtue of low-temperature crystallization, so that efficient separation of sodium silicate and sodium hydroxide and recycling of sodium hydroxide are realized; the compound extractant is prepared by compounding an extractant and an additive at a certain ratio, wherein the extractant is one of or a mixture of more selected from short-chain alcohols and long-chain fatty alcohols; the additive is one of or a mixture of more selected from long-chain alkylphenol substances; after pure water is adopted for re-extraction, sodium hydroxide in extraction raffinate can be directly returned to a pulverized fuel ash alkaline leaching process so as to be used mechanically. Compared with the traditional sodium hydroxide extraction technology, the method has the advantages of high extraction efficiency, good extraction effect, high alkali liquor cyclic utilization rate and the like and is capable of recovering high-purity sodium metasilicate products.

Owner:NANJING UNIV

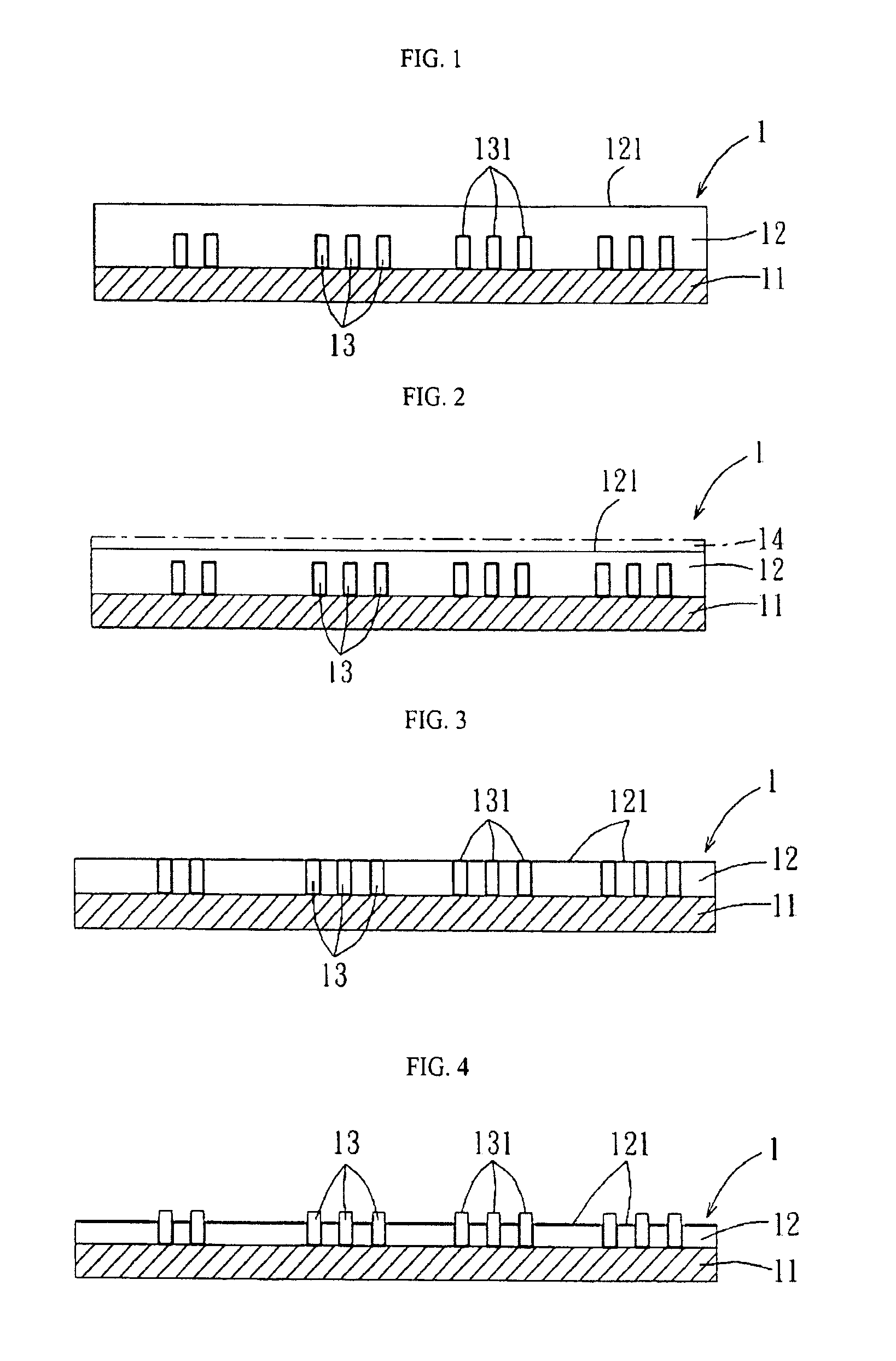

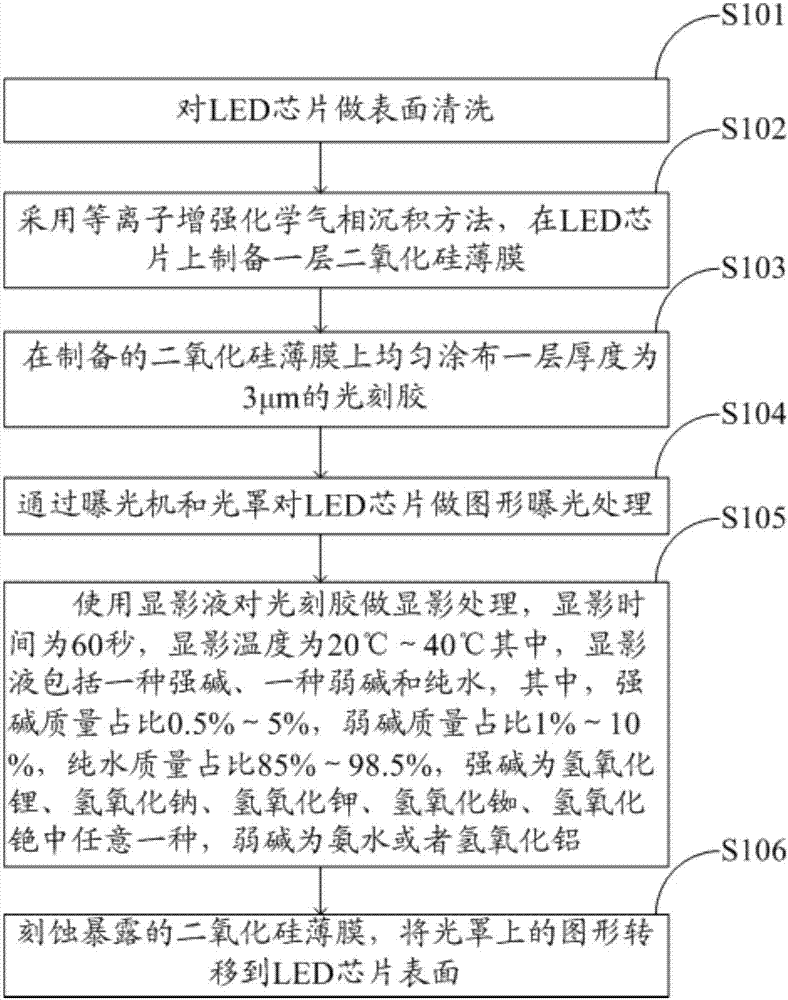

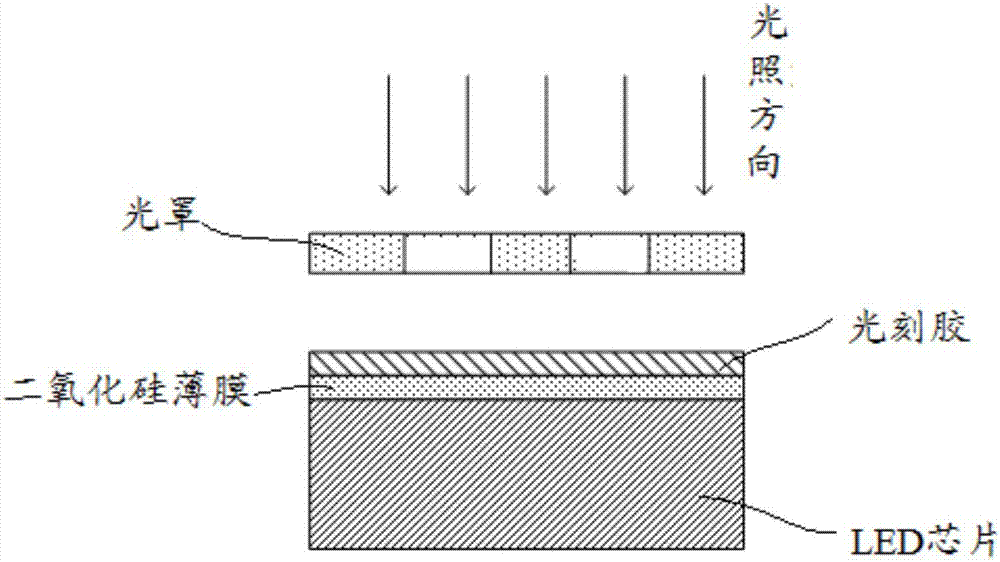

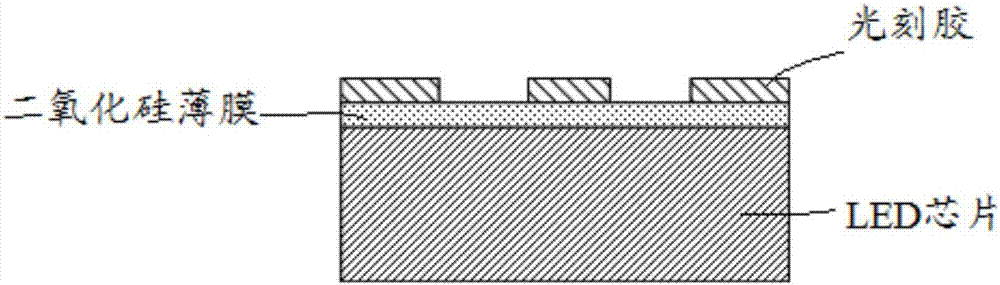

LED (Light Emitting Diode) chip photoetching developing method

InactiveCN107132733ALow costWide range of ratio optionsPhotomechanical coating apparatusPhotosensitive material processingGas phaseAluminium hydroxide

The invention discloses an LED (Light Emitting Diode) chip photoetching developing method which comprises the following steps: cleaning the surface of an LED chip; by using a plasma enhanced chemical vapor deposition method, preparing a layer of a silicon dioxide membrane on the LED chip; uniformly coating the prepared silicon dioxide membrane with a layer of a photoresist of 3mu m in thickness; performing graphic exposure treatment on the LED chip through an exposure machine and a light cover; performing development treatment on the photoresist by using a developing liquid, wherein the developing time is 60 seconds, the developing temperature is 20-40 DEG C, the developing liquid comprises strong base, weak base and pure water, the strong base accounts for 0.5-5% by mass, the weak base accounts for 1-10% by mass, the pure water accounts for 85-98.5% by mass, the strong base is any one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and the weak base is ammonia water or aluminum hydroxide; and etching the exposed silicon dioxide membrane, and transferring patterns on the light cover to the surface of the LED chip.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Porous material and its synthesis method

ActiveCN1314589CHas a compound pore structureMolecular sieve catalystsCrystalline aluminosilicate zeolitesRubidium oxideAluminium chloride

A process material with compound artery is prepared from the Si source chosen from amorphous SiO2, si sol, silicon oxide solid, silicon gel, diatomite and water glass, the Al source chosen from sodium aluminate, sodium metaaluminate, aluminium sulfate, aluminium nitrate, etc, at least one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and template agent through proportional mixing, reaction, ageing and crystallizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

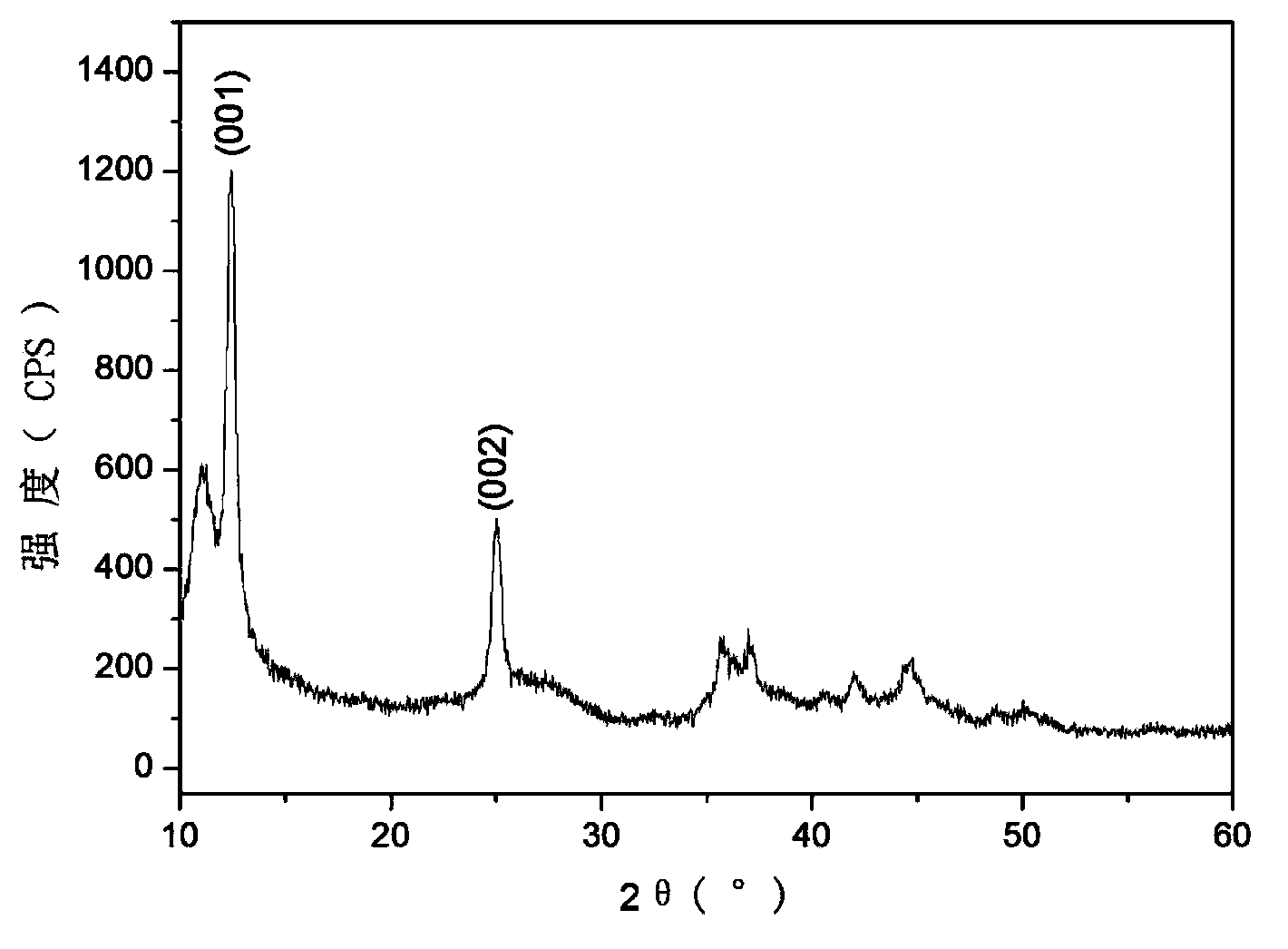

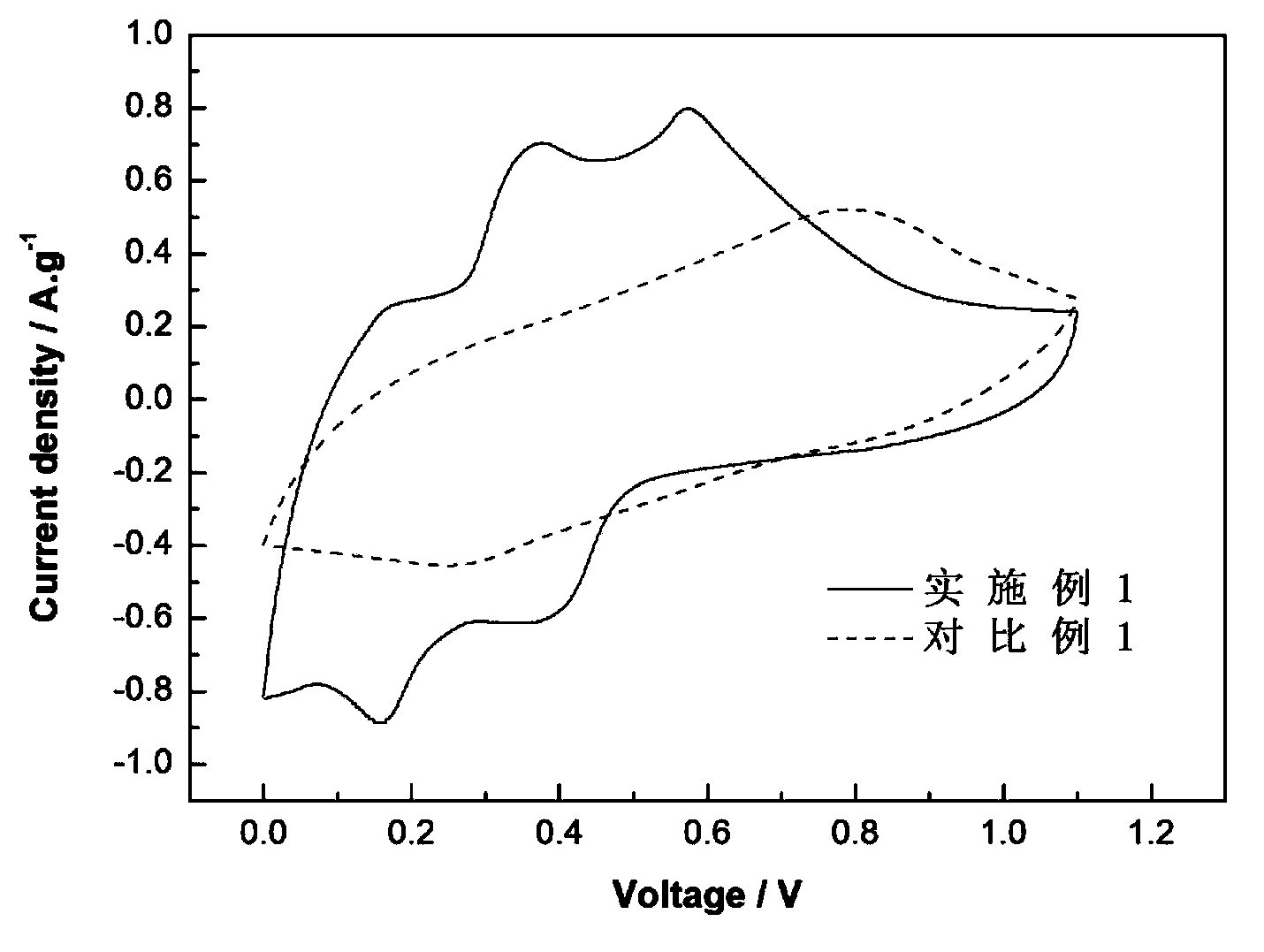

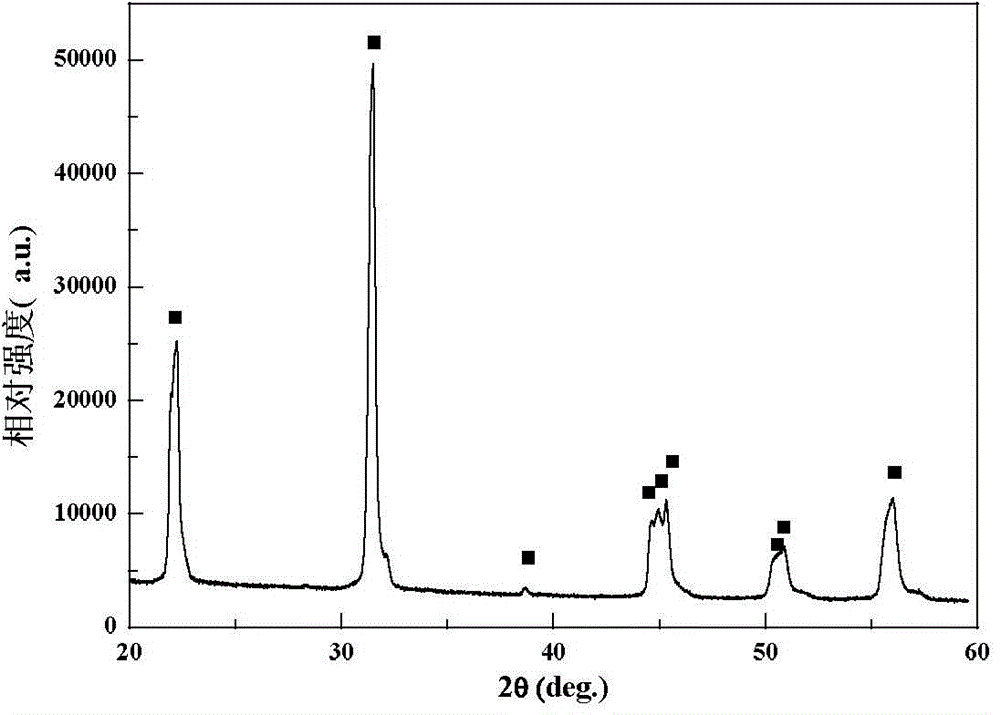

Inorganic nonmetal sodium ion battery cathode material and preparation method thereof

InactiveCN110444760AImprove stabilityImprove conductivityPhosphatesSecondary cellsSodium acetateMANGANESE ACETATE

The invention discloses an inorganic nonmetal sodium ion battery cathode material and a preparation method thereof, and particularly relates to the technical field of sodium battery cathode material.The inorganic nonmetal sodium ion battery cathode material comprises 10-20 parts of sodium carbonate, 5-16 parts of sodium acetate, 8-23 parts of sodium nitrate. 5-15 parts of sodium hydroxide, 5-16 parts of manganese carbonate, 8-16 parts of manganese acetate, 10-25 parts of manganese nitrate, 10-18 parts of manganese oxide, and 15-20 parts of ammonium molybdate. The cathode material prepared bymixing a solution obtained by mixing and stirring ammonium dihydrogen phosphate, ammonium phosphate, diammonium hydrogen phosphate and phosphoric acid and a solution obtained by dissolving ammonium molybdate and molybdenum oxide in an aqueous solvent improves the stability of the sodium battery during a charge-discharge process, and it can be obviously discovered that the conductivity and the charging efficiency are significantly improved and in a long-term test, the discharge specific capacity is still not significantly attenuated, thereby ensuring the stability of the sodium battery made ofthe cathode material in use.

Owner:许对兴

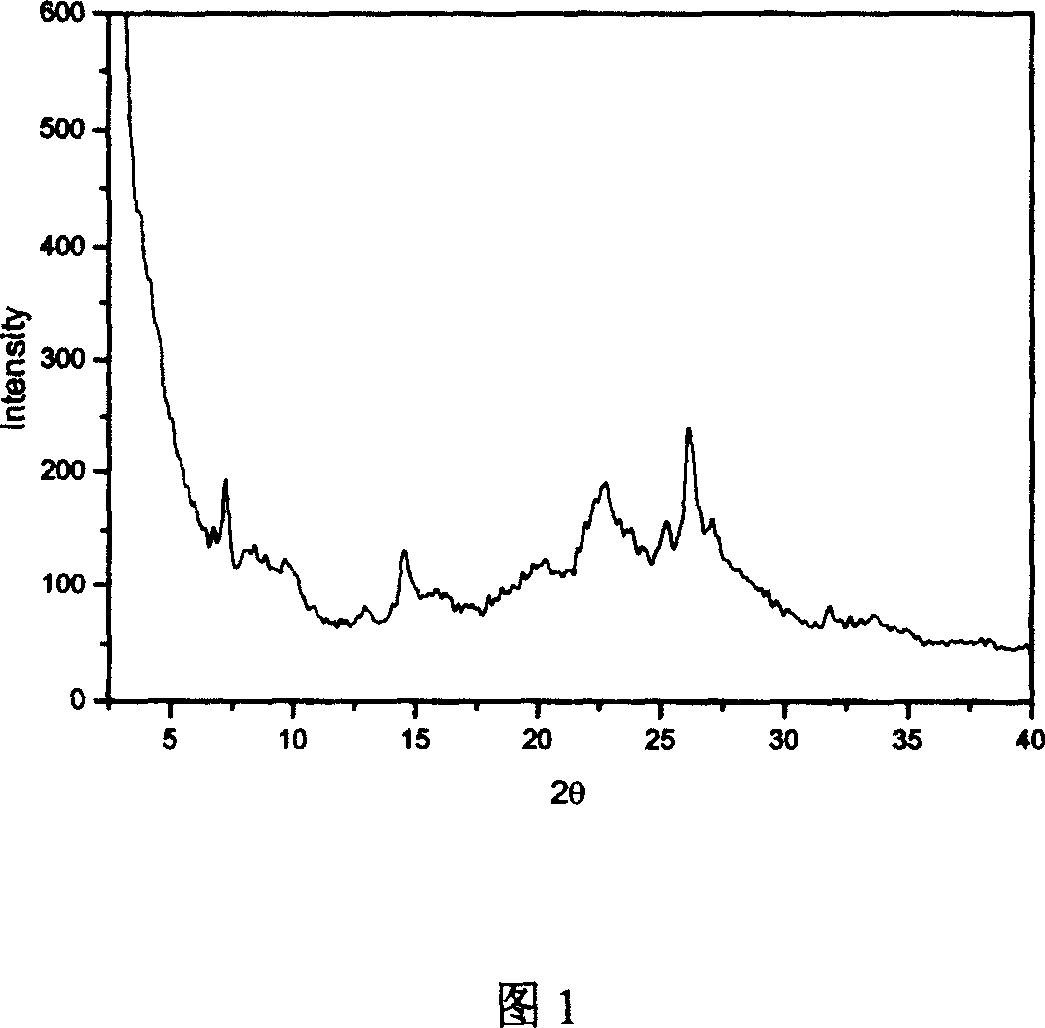

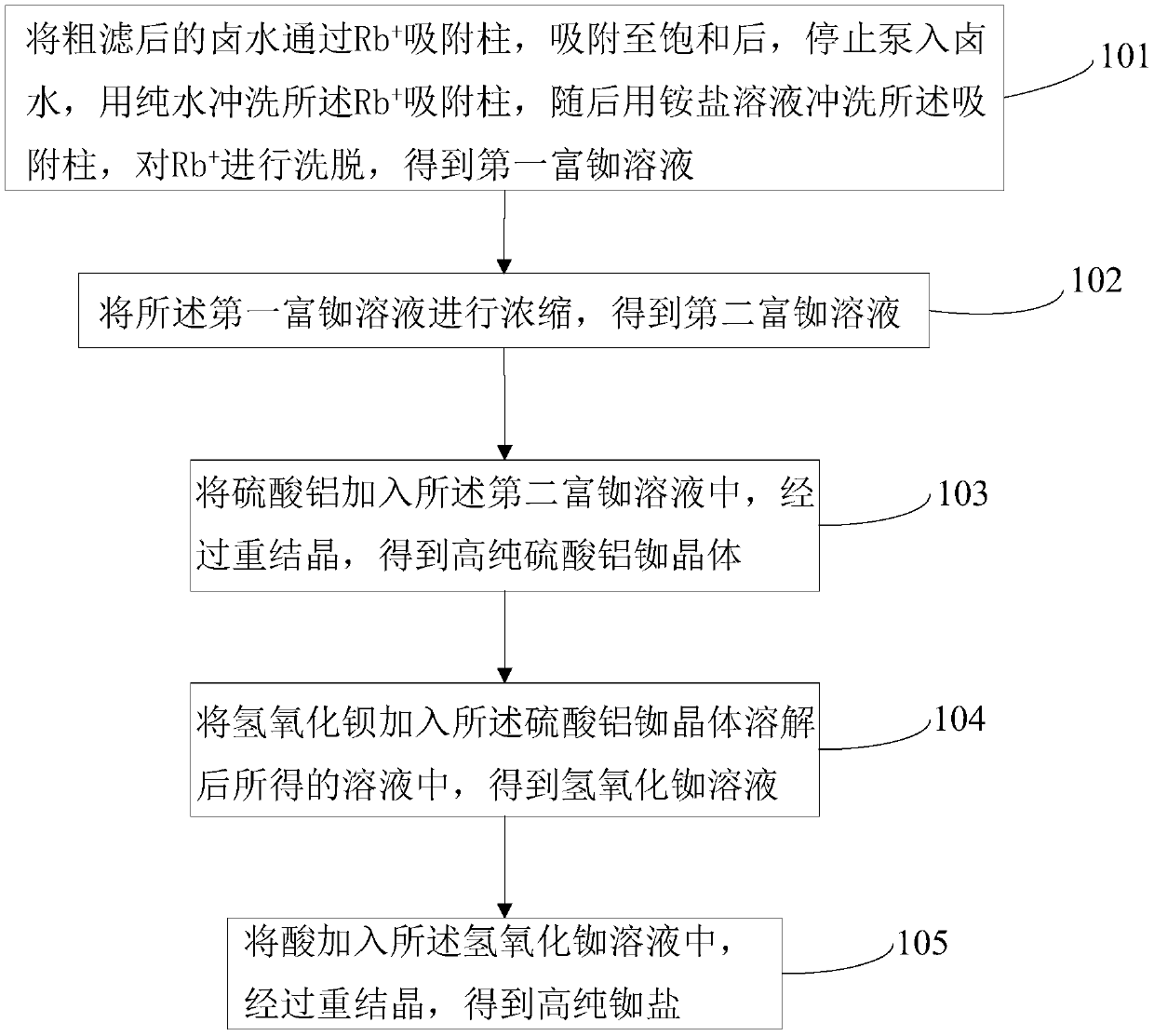

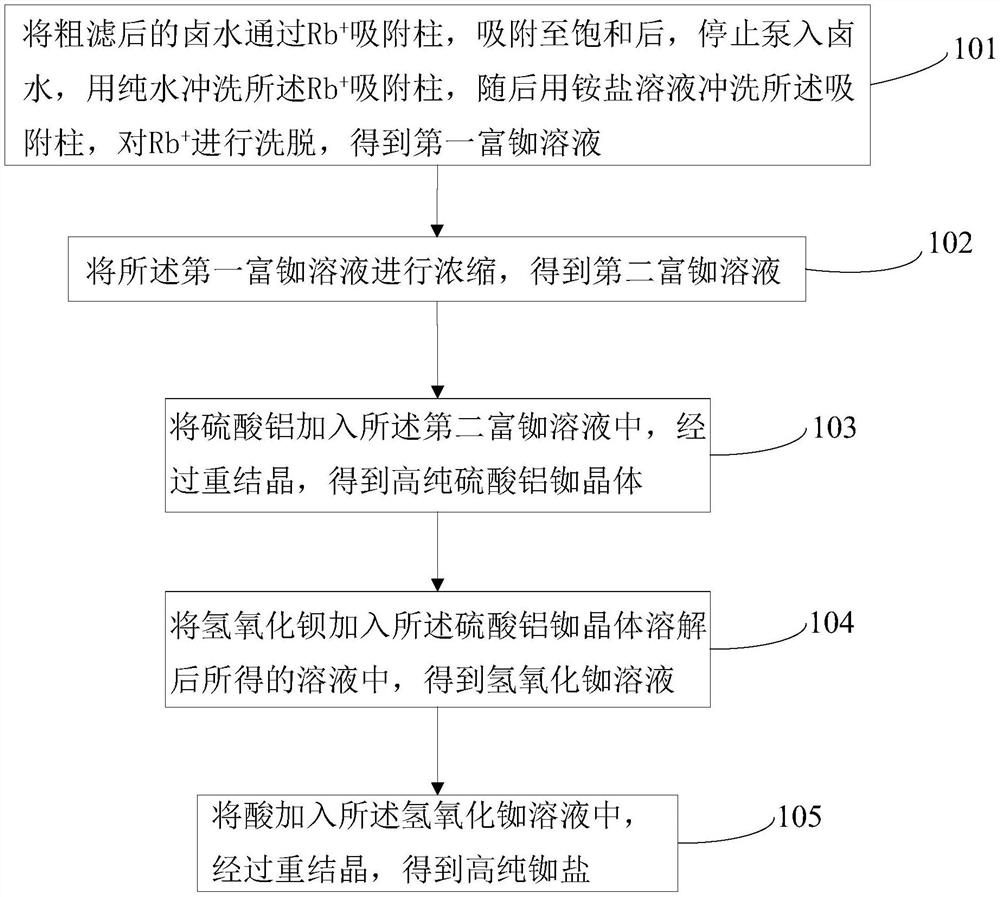

Method for extractingRb+ from low concentration brine and preparing high purity rubidium salt

ActiveCN109824068ASimple preparation processNo pollution in the processOther chemical processesRubidium/caesium/francium compoundsRubidium sulfateAluminium sulfate

The invention belongs to the technical field of hydrometallurgy, in particular to a method for extracting Rb+ from low concentration brine and preparing high purity rubidium salt, which comprises thefollowing steps: saturating crude filtered brine through Rb+ adsorption column; stopping pumping brine and rinsing the Rb+ adsorption column with pure water, then rinsing the adsorption column with anammonium salt solution, eluting the Rb+ to obtain a first rich rubidium solution; concentrating the first rich rubidium solution to obtain a second rich rubidium solution; adding aluminum sulfate tothe second rich rubidium solution and carrying out recrystallization to obtain a highly pure rubidium aluminum sulfate crystal; adding barium hydroxide to the solution obtained after dissolution of the aluminum rubidium sulfate crystal to obtain a rubidium hydroxide solution; and adding acid to the rubidium hydroxide solution and carrying out the recrystallization to prepare the high purity rubidium salt. The method for extracting the Rb+ from the low concentration brine and preparing the high purity rubidium salthas the advantages of being high in efficiency, environmental in process and capable of preparing a variety of rubidium salts with a purity up to 99.99%.

Owner:陕西省膜分离技术研究院有限公司

Etchant solutions and method of use thereof

ActiveUS9873833B2High rateReduce passivationDecorative surface effectsSemiconductor/solid-state device manufacturingRubidium hydroxidePotassium hydroxide

Etching compositions and method of using the etching compositions comprising potassium hydroxide; one or more than one additional alkaline compounds selected from the group consisting of TEAH, TMAF and NH4OH; and water; or etching compositions comprising one or more than one inorganic alkali basic hydroxides selected from the group consisting of potassium hydroxide, cesium hydroxide, sodium hydroxide, rubidium hydroxide, or lithium hydroxide; optionally one or more than one additional alkaline compounds; water; and optionally one or more corrosion inhibitors; wherein the composition preferentially etches silicon present on a substrate as compared to silicon dioxide present on said substrate.

Owner:VERSUM MATERIALS US LLC

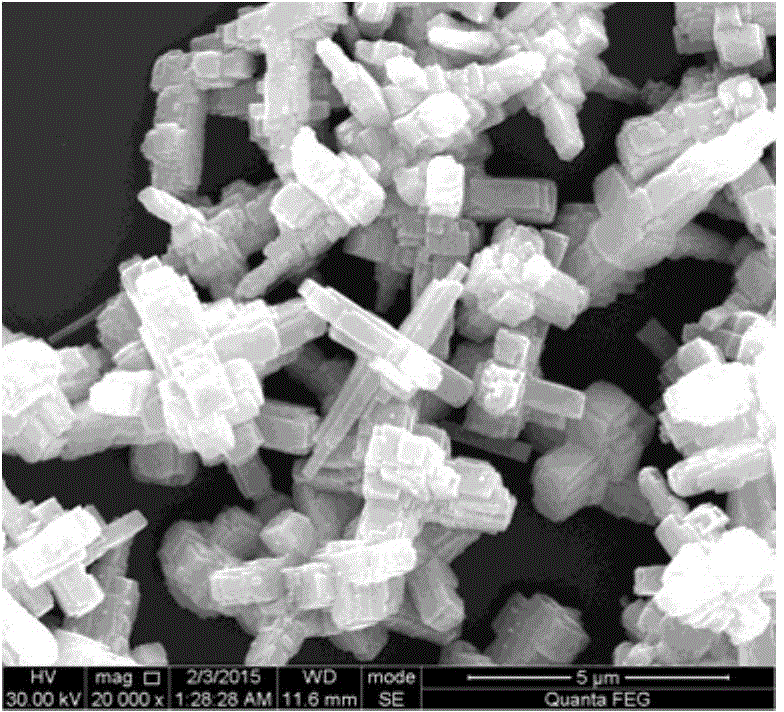

Synthetic method of sodium potassium columbate ferroelectric nano structure with monoclinic phase

ActiveCN104876269APrecise control ratioMaterial nanotechnologyNiobium compoundsSodium acetateNano structuring

The invention provides a synthetic method of a sodium potassium columbate ferroelectric nano structure with a monoclinic phase. The invention relates to a piezoelectric-ferroelectric nano material, and in particular relates to a synthetic method of a nano structure. The invention aims to solve the technical problems that during the preparation of an existing piezoelectric material, lead oxide is volatilized to result in poor consistency and high cost of a product and the toxicity of lead is high, and successfully prepare the sodium potassium columbate nano structure with the monoclinic phase. The synthetic method comprises the following steps: adding sodium acetate and potassium acetate into glycol, adding a niobium ethoxide solution, and drying to obtain a xerogel precursor; adding the xerogel precursor into an aqueous solution containing sodium hydroxide and potassium hydroxide; heating and preserving the heat; then cooling to the room temperature; taking out sodium potassium columbate powder; performing centrifugal washing for a plurality of times until the pH value is equal to 7; and then drying to obtain the sodium potassium columbate ferroelectric nano structure. The synthetic method provided by the invention adopts sodium potassium columbate sol prepared by a sol-gel method, so that the ratio of sodium ions to potassium ions to niobium ions in the nano structure can be accurately controlled; and hydro-thermal reaction is utilized, so that the sodium potassium columbate nano structure with a pure phase is obtained by virtue of low-temperature crystallization. The synthetic method provided by the invention belongs to the field of preparation of nano structures.

Owner:HARBIN INST OF TECH

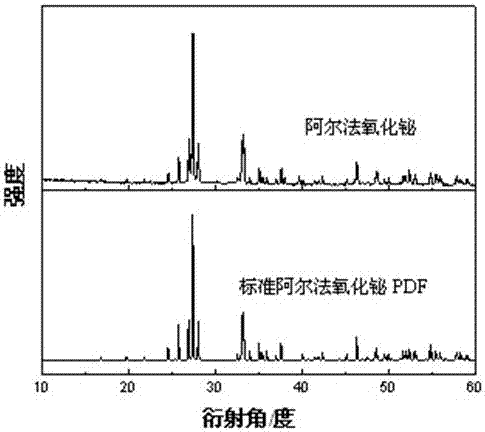

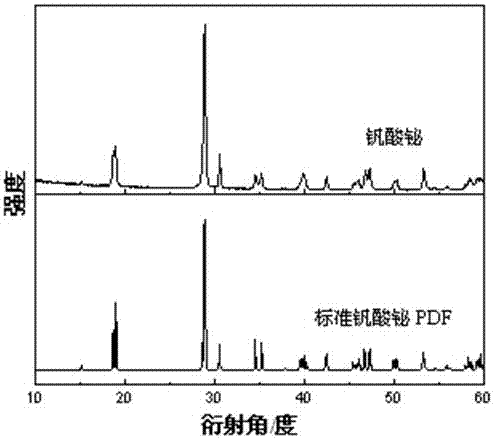

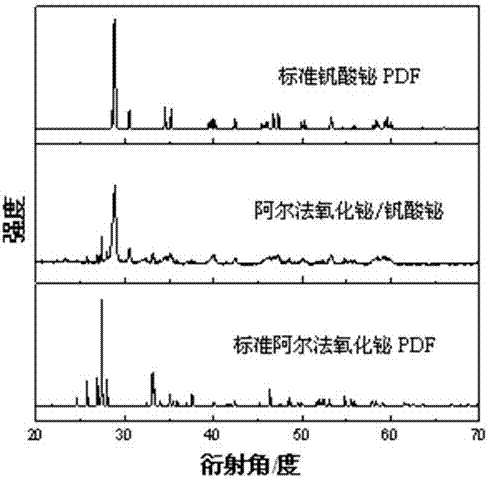

Alpha bismuth oxide/bismuth vanadate and preparation method thereof

InactiveCN107970912AThe ratio is easy to adjustReduce manufacturing costWater/sewage treatment by irradiationWater treatment compoundsRubidium hydroxideBismuth vanadate

The invention discloses alpha bismuth oxide / bismuth vanadate and a preparation method thereof. The preparation method provided by the invention comprises the following steps that firstly adding bismuth nitrate into nitric acid; adding ammonium metavanadate into a sodium hydroxide solution; mixing the two solutions for regulating and controlling the pH values; then, performing drying, grinding androasting to obtain bismuth vanadate; mixing the obtained bismuth vanadate powder with the bismuth oxychloride powder; performing dispersion; then, adding a sodium hydroxide solution; performing stirring, washing and drying; then, obtaining the alpha bismuth oxide / bismuth vanadate powder. The sodium hydroxide is used for performing in-situ conversion on the bismuth oxychloride to obtain the alpha bismuth oxide in the alpha bismuth oxide / bismuth vanadate. The method has the advantages that the proportioning ratio between two phases of ingredients can be easily regulated and controlled; the production cost is low; the process method is simple and convenient, and the like.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method of high purity cerium oxide powder, and CMP slurry containing the same

InactiveCN101873999BUniform particle size distributionTo achieve the effect of quality assuranceOther chemical processesCerium oxides/hydroxidesRare-earth elementCerium nitrate

The present invention relates to a method for preparing cerium oxide (CeO2) by forming high purity cerium nitrate hydrate (Ce(NO3)3·6H2O) which is an intermediate. More specifically, the method for preparing cerium oxide comprises: recovering precipitates by titrating sodium hydroxide in a cerium chloride composition and separating supernatants and precipitates; obtaining solid cerium precursors by finely spraying and filtering an excess of purified water, wherein the spraying and filtering process is performed to reduce praseodymium (Pr) contained in the precipitates; and obtaining cerium oxide using cerium nitrate hydrate formed by titrating nitric acids in the cerium precursors. In addition, the present invention provides high purity cerium oxide powder, a preparation method thereof, and CMP slurry containing the same. The cerium oxide is prepared using cerium nitrate hydrate as an intermediate, wherein the purity of the cerium nitrate hydrate is increased through purification by titrating sodium hydroxide and washing by finely spraying an excess of purified water, so the high purity cerium oxide powder contains virtually no impurities of various rare-earth elements, especially praseodymium which has an adverse effect on properties of CMP slurry.

Owner:NEW WELL

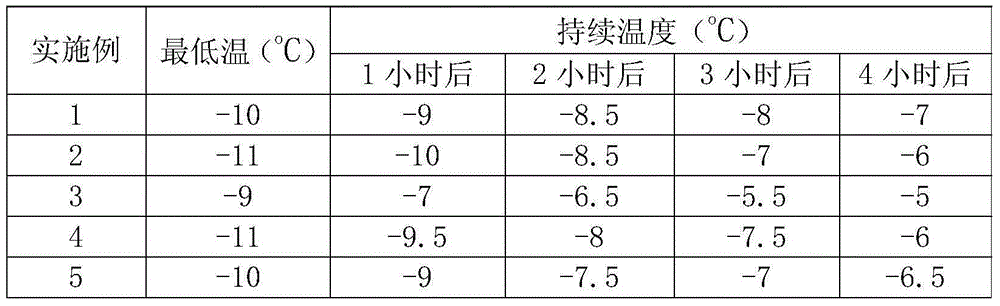

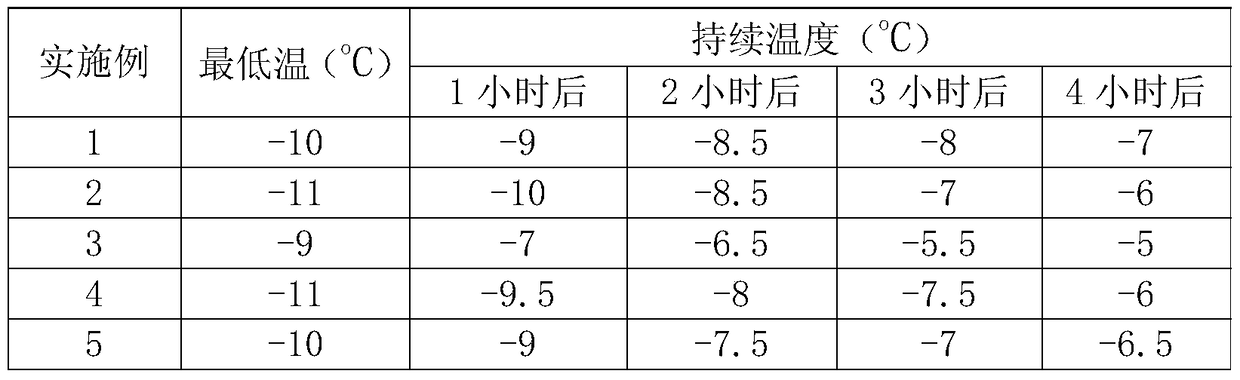

Sodium salt chemical ice bag and preparation method thereof

ActiveCN105038723AReduce lossesReduce the temperatureHeat-exchange elementsCarboxymethyl celluloseRubidium hydroxide

The invention discloses a sodium salt chemical ice bag and a preparation method thereof. The ice bag is composed of the following components in parts by weight: 40 to 50 parts of sodium nitrate, 10 to 20 parts of sodium borate, 20 to 30 parts of sodium sulfate decahydrate, 1 to 3 parts of sodium carboxymethyl cellulose, 1 to 3 parts of sodium silicate, 1 to 5 parts of sodium chloride, and 1 to 5 parts of sodium hydroxide. The preparation method comprises the following steps: precisely weighing the components according to the formula mentioned above, adding weighed sodium carboxymethyl cellulose into sodium borate, stirring, heating, stopping heating when the solution turns transparent so as to obtain a solution A; sequentially adding sodium nitrate, sodium sulfate decahydrate, and sodium silicate into the solution A under stirring, evenly stirring to obtain a solution B; adding sodium hydroxide into the solution B, evenly stirring, then adding sodium chloride, evenly stirring, when the solution becomes transparent, and packing the solution into bags. The provided chemical ice bag has the advantages of low refrigeration temperature and long refrigeration time.

Owner:GUILIN RONGTONG TECH CO LTD

Method for improving stability of high-concentration negative electrode electrolyte during operation of all-vanadium redox flow battery

ActiveCN109841885AImprove stabilityComposition No significant adverse effectsRegenerative fuel cellsHigh concentrationVanadium redox battery

The invention relates to a method for improving the stability of a high-concentration negative electrode electrolyte during the operation of an all-vanadium redox flow battery. A soluble alkaline substance is at least one in the group consisting of ammonia water, sodium hydroxide, potassium hydroxide, aluminum hydroxide, lithium hydroxide and rubidium hydroxide. The high-concentration negative electrode electrolyte is a sulfuric acid aqueous solution of divalent and / or trivalent vanadium, the vanadium ion concentration is 1.6-4 mol / L, and the sulfuric acid concentration is 0.5-3 mol / L. A stabilizer for improving the stability of the high-concentration negative electrode electrolyte used in the present invention can restore the H+ concentration in the high-concentration negative electrode electrolyte to a normal level in a short time, and the stability of the high-concentration negative electrode electrolyte is improved. The sources of raw materials used in the present invention are wide, the price is low, the process operation is simple, the reaction speed is controllable, and the long-term high-efficiency stable operation of the battery can be ensured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

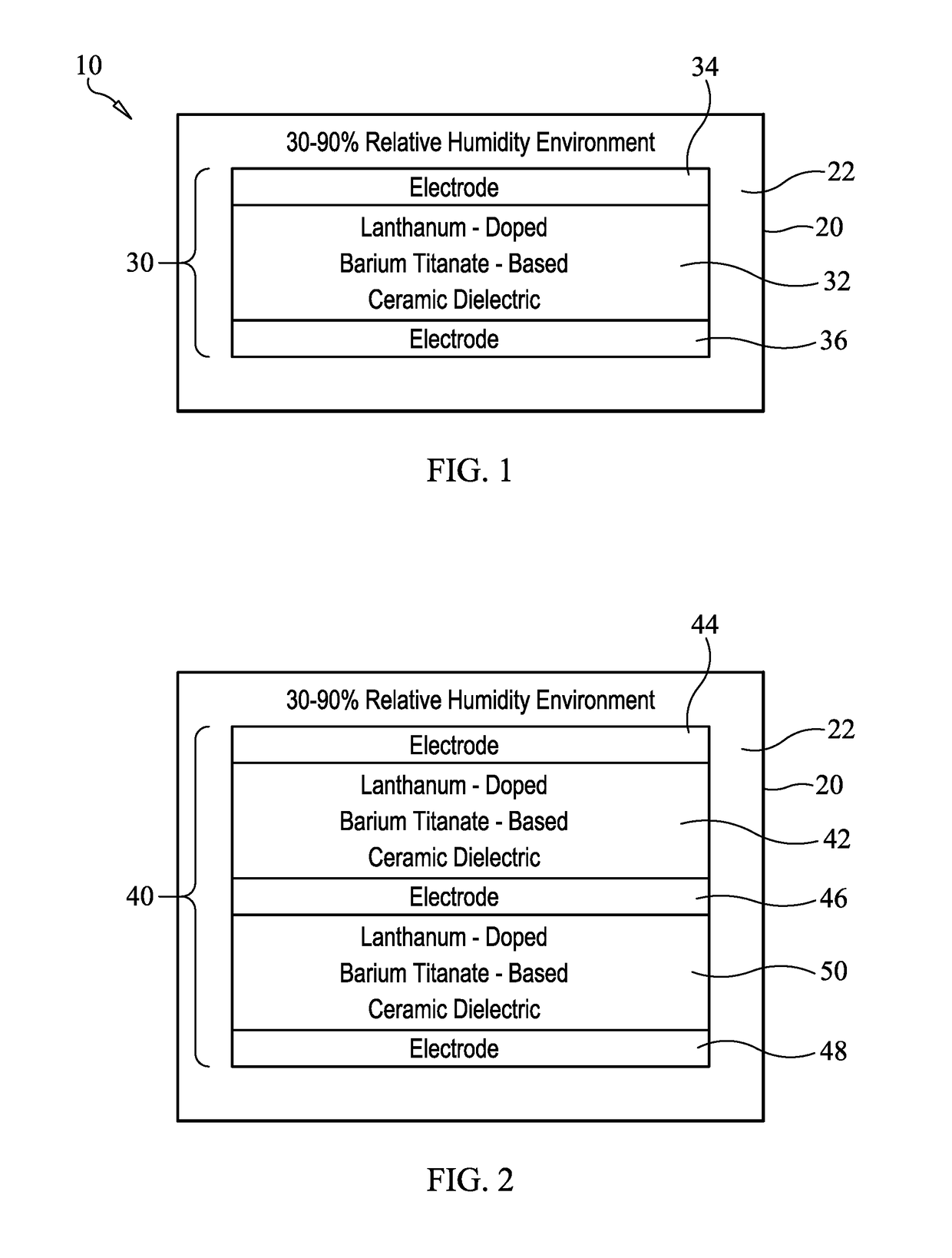

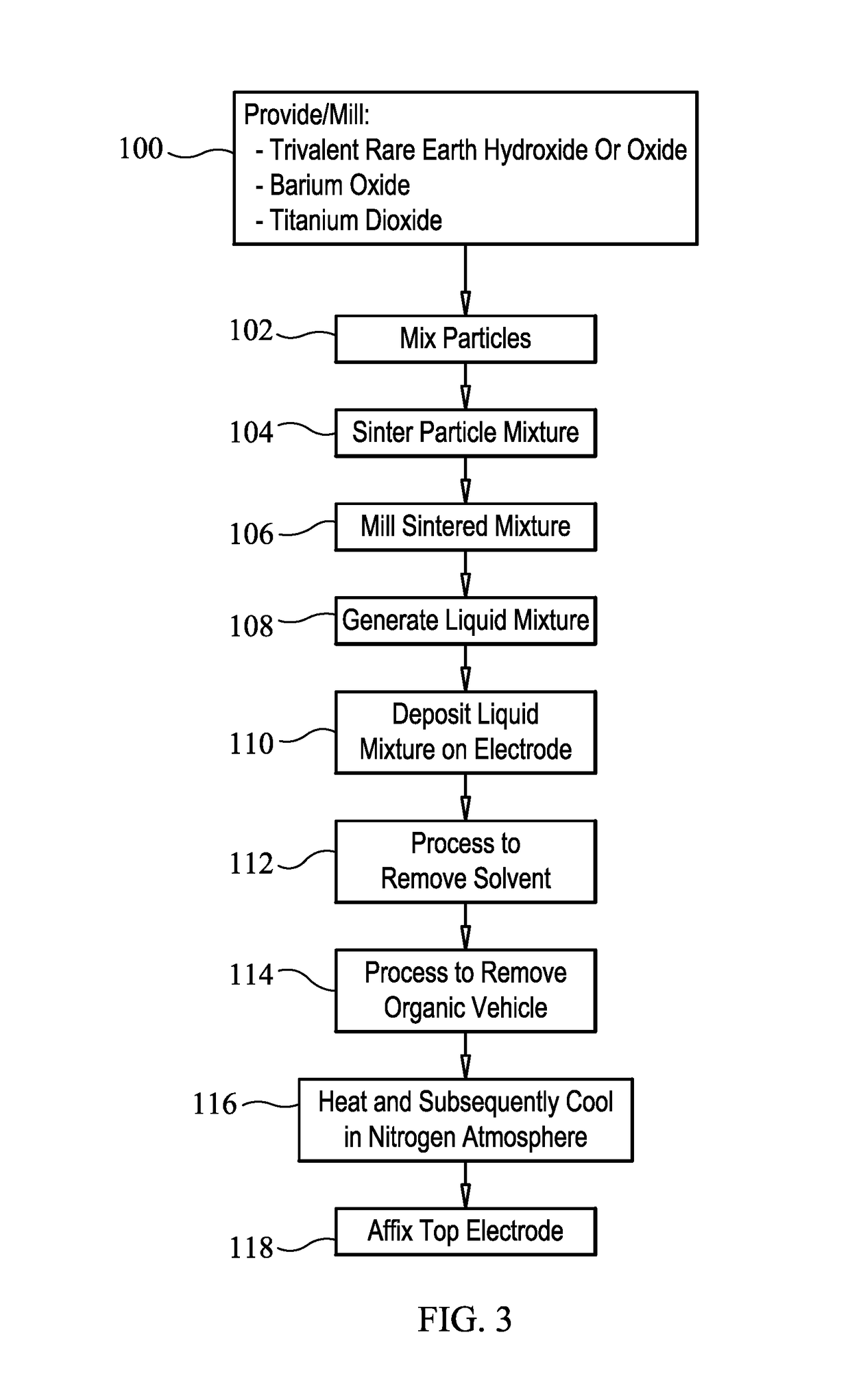

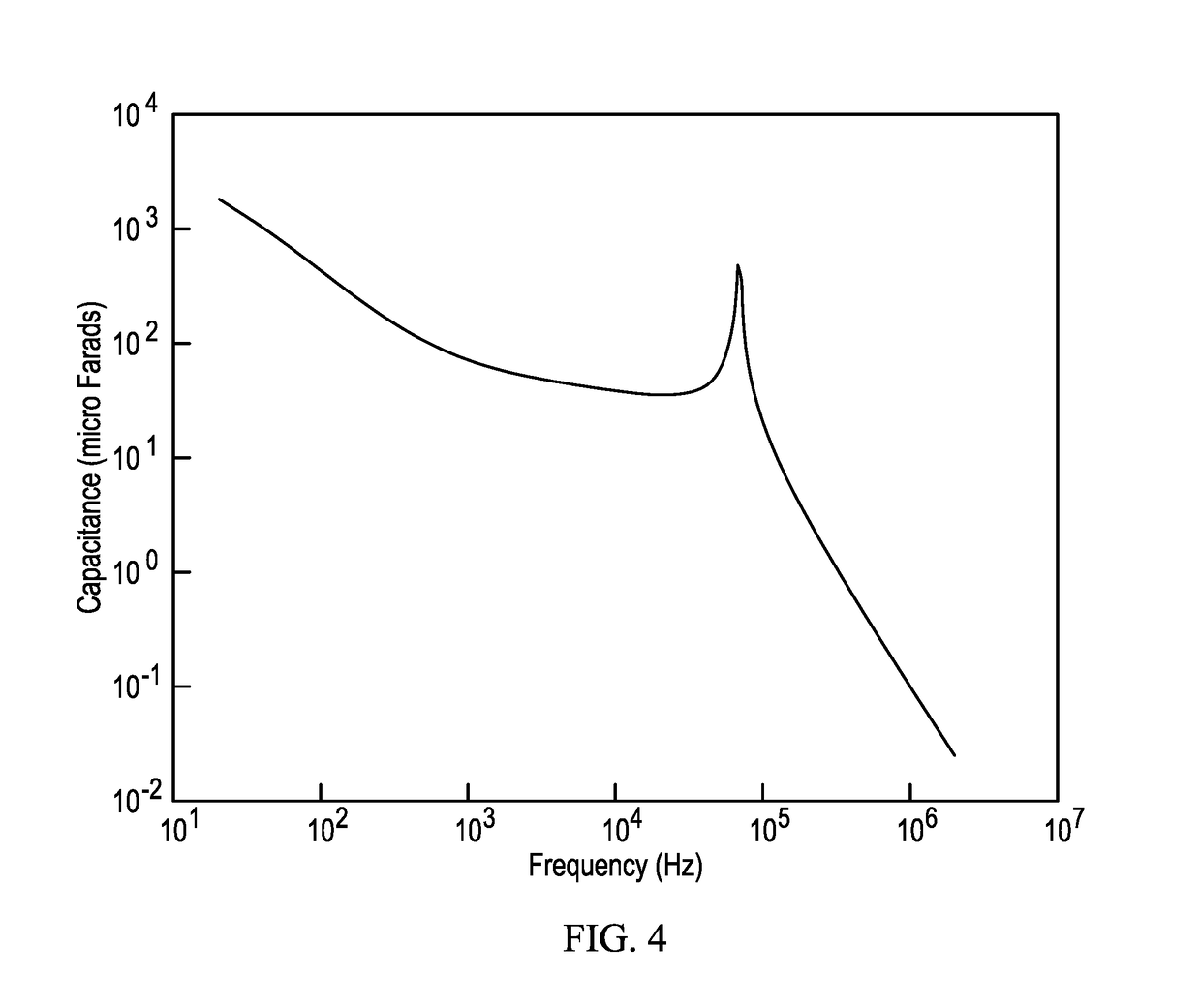

Solid Dielectric for Rechargeable Energy Storage Capacitor

A solid dielectric for an energy storage capacitor is a lanthanum-doped barium titanate-based ceramic material. A dopant is selected from the group consisting of lanthanum hydroxide and lanthanum oxide, and a co-dopant is an alkali hydroxide selected from the group consisting of potassium hydroxide, sodium hydroxide, rubidium hydroxide, and lithium hydroxide.

Owner:NASA

Method for Improving the Stability of High Concentration Negative Electrolyte in Operation of All-vanadium Redox Flow Battery

ActiveCN109841885BImprove stabilityComposition No significant adverse effectsRegenerative fuel cellsRubidium oxideElectrolytic agent

The invention relates to a method for improving the stability of a high-concentration negative electrode electrolyte during the operation of an all-vanadium redox flow battery. The soluble alkaline substance is ammonia water with a mass concentration of 20-35%, sodium hydroxide, potassium hydroxide, aluminum hydroxide, hydrogen At least one of lithium oxide and rubidium hydroxide. The high-concentration negative electrode electrolyte is divalent and / or trivalent vanadium sulfuric acid aqueous solution, wherein the vanadium ion concentration is 1.6-4mol / L, and the sulfuric acid concentration is 0.5-3mol / L. The stabilizer used in the present invention to improve the stability of the high-concentration negative electrode electrolyte can make the H in the high-concentration negative electrode electrolyte in a short time + The concentration returns to the normal level, and the stability of the high-concentration negative electrode electrolyte is improved; the raw materials used in the present invention have wide sources, low price, simple process operation, controllable reaction speed, and can ensure long-term high-efficiency and stable operation of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

A kind of sodium salt chemical ice pack and preparation method thereof

ActiveCN105038723BReduce lossesReduce the temperatureHeat-exchange elementsCarboxymethyl celluloseRubidium hydroxide

The invention discloses a sodium salt chemical ice bag and a preparation method thereof. The ice bag is composed of the following components in parts by weight: 40 to 50 parts of sodium nitrate, 10 to 20 parts of sodium borate, 20 to 30 parts of sodium sulfate decahydrate, 1 to 3 parts of sodium carboxymethyl cellulose, 1 to 3 parts of sodium silicate, 1 to 5 parts of sodium chloride, and 1 to 5 parts of sodium hydroxide. The preparation method comprises the following steps: precisely weighing the components according to the formula mentioned above, adding weighed sodium carboxymethyl cellulose into sodium borate, stirring, heating, stopping heating when the solution turns transparent so as to obtain a solution A; sequentially adding sodium nitrate, sodium sulfate decahydrate, and sodium silicate into the solution A under stirring, evenly stirring to obtain a solution B; adding sodium hydroxide into the solution B, evenly stirring, then adding sodium chloride, evenly stirring, when the solution becomes transparent, and packing the solution into bags. The provided chemical ice bag has the advantages of low refrigeration temperature and long refrigeration time.

Owner:GUILIN RONGTONG TECH CO LTD

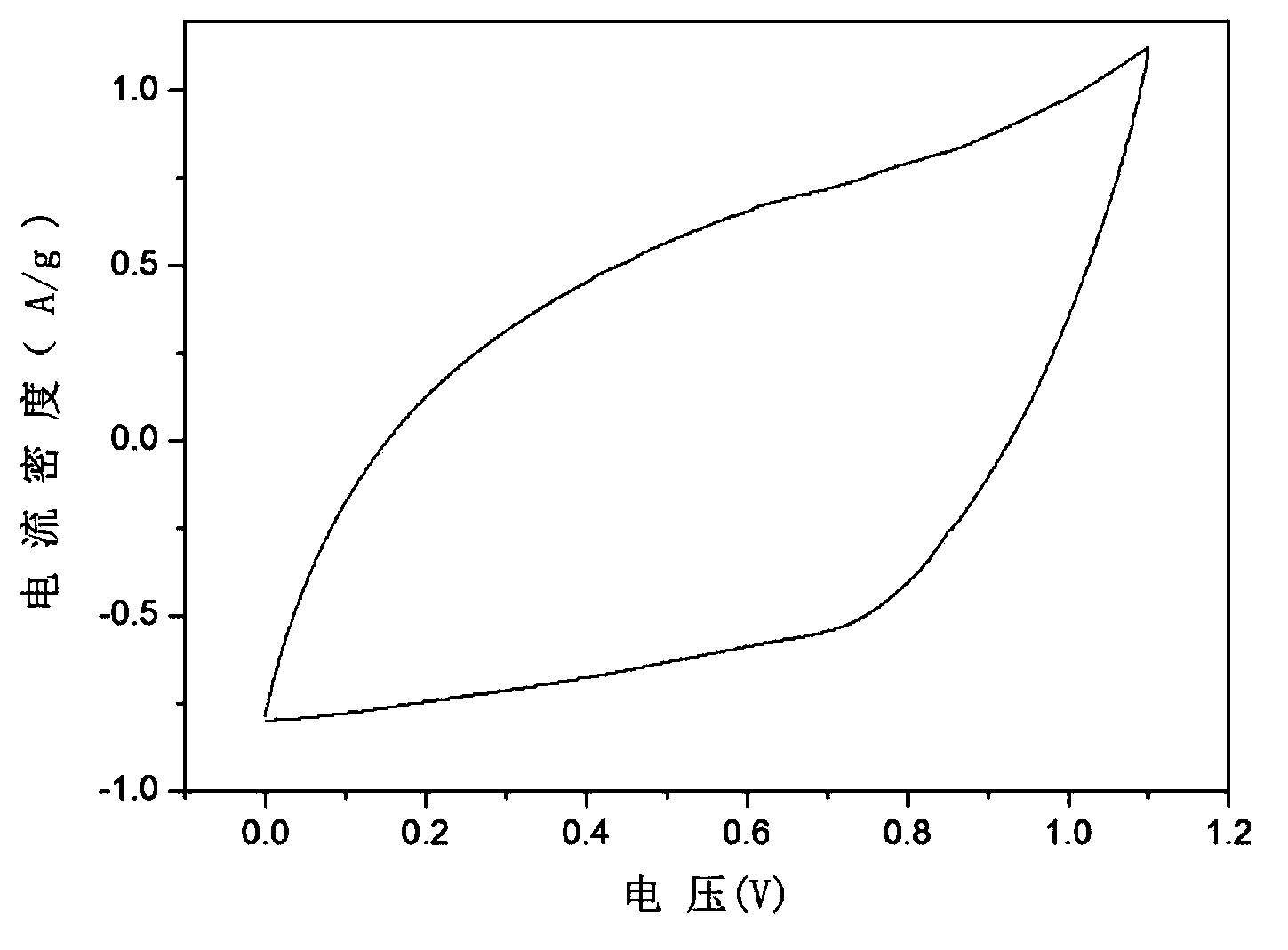

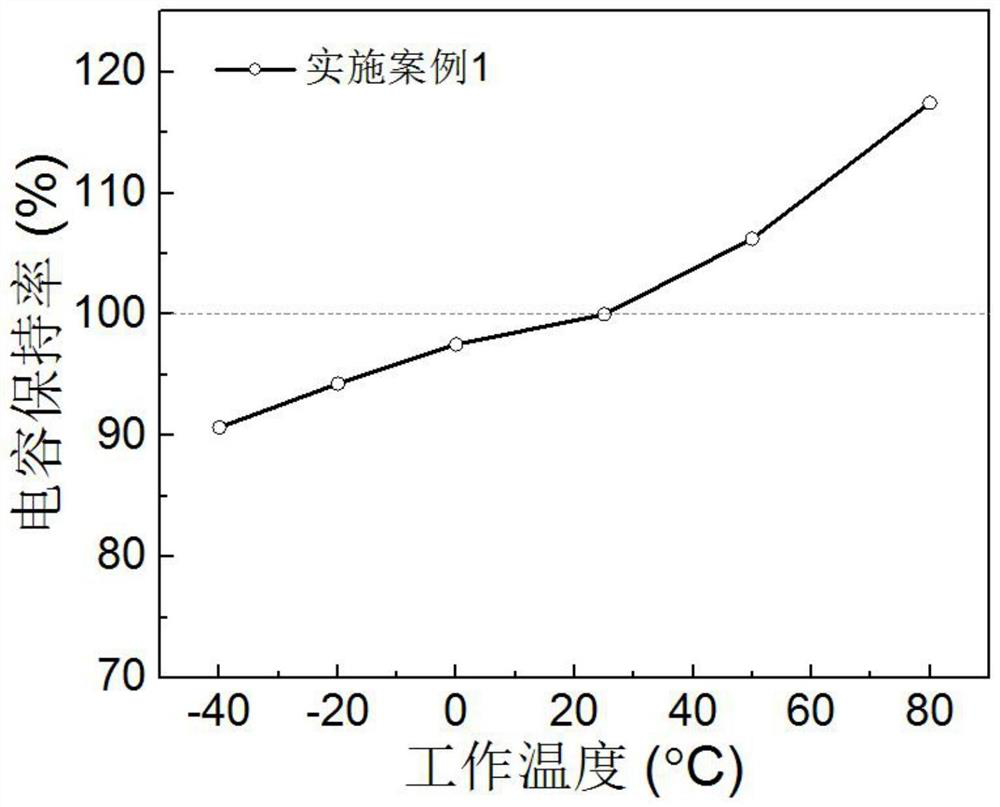

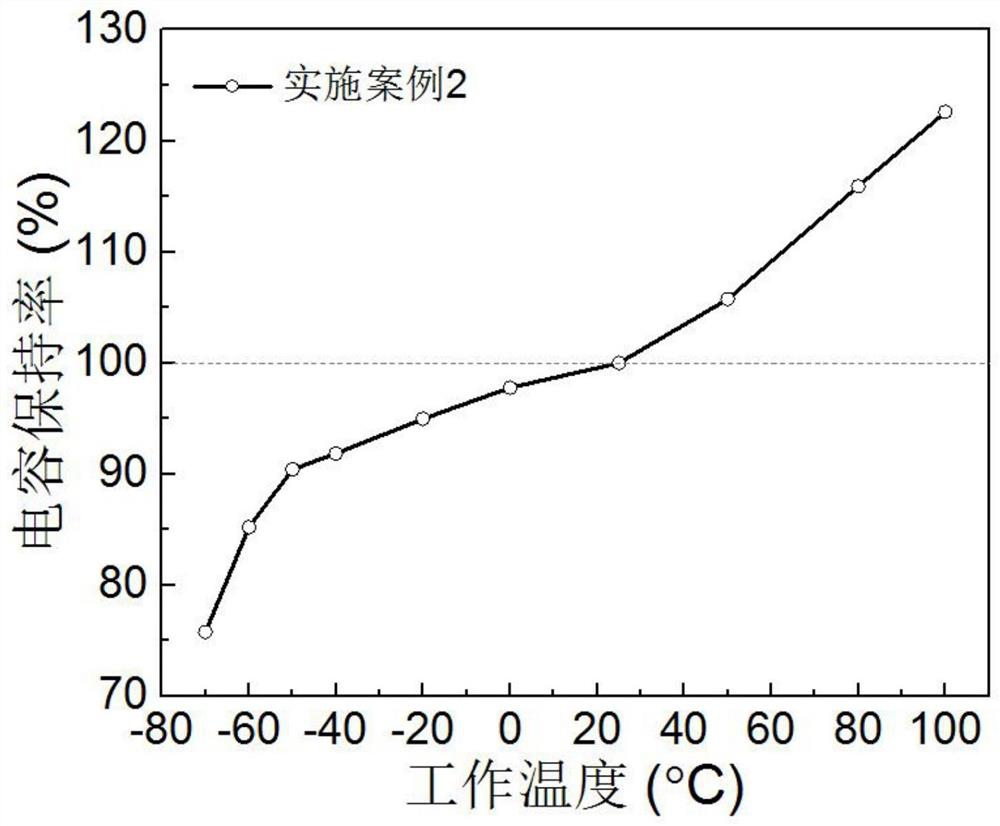

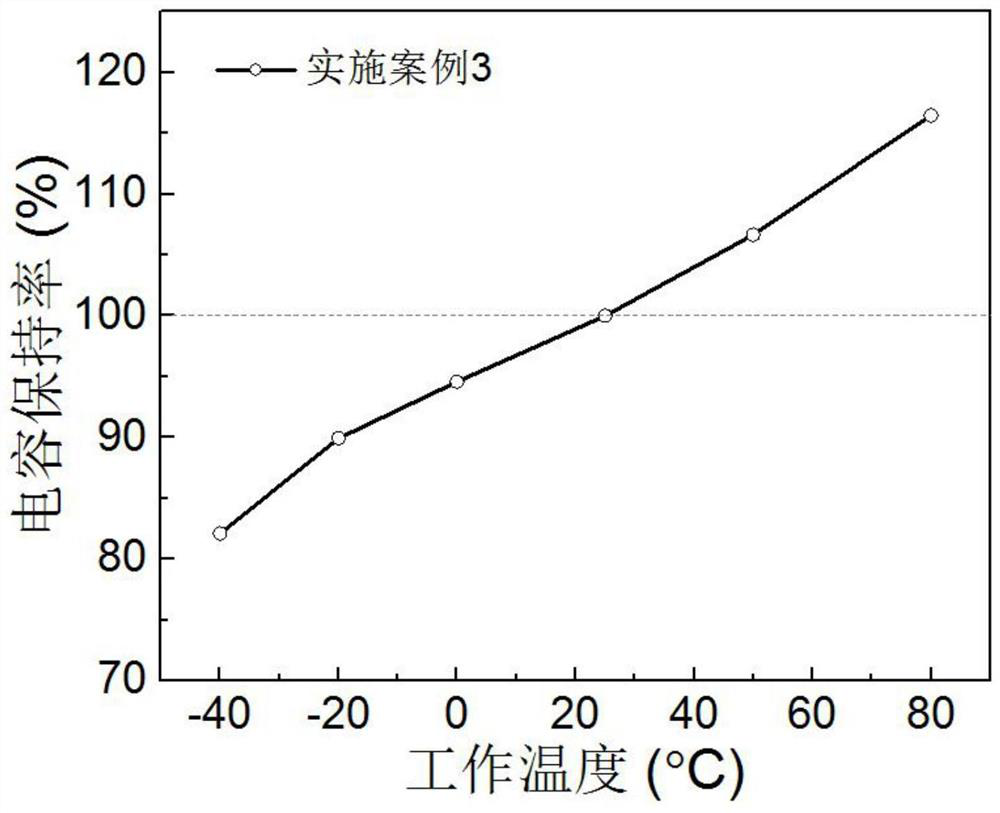

Supermolecule-based aqueous alkaline electrolyte with ultra-wide working temperature range and application thereof

ActiveCN113421777AStable energy storage performanceWide operating temperature rangeHybrid capacitor electrolytesElectrolytic agentRubidium oxide

The invention discloses a supermolecule-based aqueous alkaline electrolyte with an ultra-wide working temperature range and an application thereof. The aqueous alkaline electrolyte is a solution formed by mixing a solute and a solvent, the solute is one or more than two of alkali metal hydroxides, and the alkali metal hydroxides are lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide or cesium hydroxide; and the solvent is a supramolecular solvent composed of water and dimethyl sulfoxide. The supermolecule-based aqueous alkaline electrolyte with the ultra-wide working temperature range has an extremely wide working temperature range of-70 DEG C to 100 DEG C, is relatively stable in performance, and can greatly improve the applicability of electrochemical energy storage devices such as supercapacitors and batteries based on the aqueous alkaline electrolyte in the all-day, all-season and extreme temperature fields.

Owner:KUNMING UNIV OF SCI & TECH

Extract rb from low concentration brine + And the method for preparing high-purity rubidium salt

ActiveCN109824068BImprove hydrophilicityFully contactedOther chemical processesRubidium/caesium/francium compoundsRubidium hydroxideAluminum sulphate

The invention belongs to the technical field of hydrometallurgy, in particular to a method for extracting Rb from low-concentration brine + And prepare the method for high-purity rubidium salt, it comprises the following steps: the brine after the rough filtration is passed through Rb + The adsorption column is saturated, stop pumping brine and wash the Rb with pure water + Adsorption column, wash described adsorption column with ammonium salt solution subsequently, to Rb + eluting to obtain a first rubidium-rich solution; concentrating the first rubidium-rich solution to obtain a second rubidium-rich solution; adding aluminum sulfate to the second rubidium-rich solution and recrystallizing to obtain high-purity sulfuric acid aluminum rubidium crystals; adding barium hydroxide to the solution obtained by dissolving the aluminum rubidium sulfate crystals to obtain a rubidium hydroxide solution; adding acid to the rubidium hydroxide solution and recrystallizing to obtain a high-purity rubidium salt. A method for extracting Rb from low-concentration brine provided by the invention + Furthermore, the method for preparing high-purity rubidium salts has high preparation efficiency, an environmentally friendly technological process, and the preparation of various rubidium salts with a purity as high as 99.99%.

Owner:陕西省膜分离技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com