Method for efficiently separating and recycling sodium hydroxide from alkaline sodium silicate

A sodium hydroxide, recycling technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal silicates, chemical instruments and methods, etc., can solve the problem of difficult effective separation of solutions and small modulus of sodium metasilicate , low recycling efficiency and other issues, to achieve the effect of small loss, lower production cost, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention aims at existing fly ash production sodium metasilicate process existing: 1) sodium silicate and sodium hydroxide are difficult to effectively separate in alkaline sodium silicate solution, cause the sodium metasilicate modulus of production to be little, and purity 2) a single extractant has low extraction efficiency for high-concentration NaOH in alkaline sodium silicate, poor extraction effect, and low recycling efficiency.

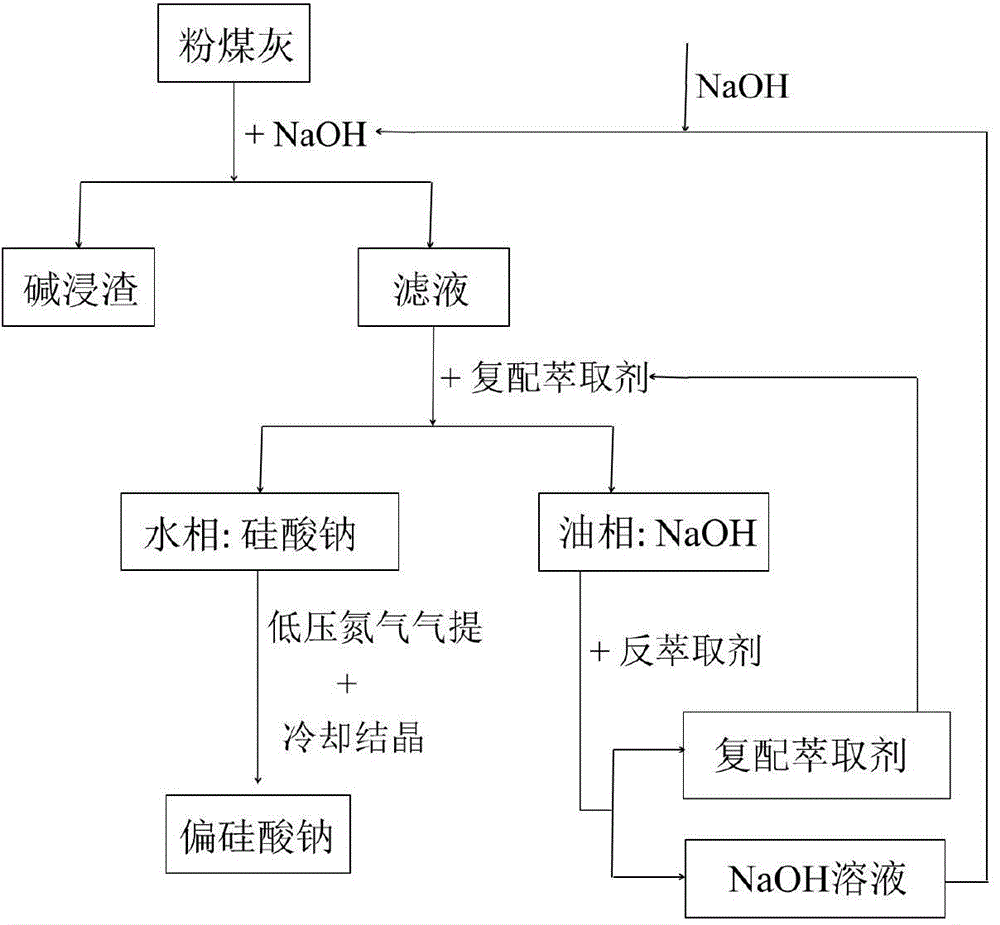

[0034] combined with figure 1 , a method for efficient separation and recycling of sodium hydroxide in alkaline sodium silicate in this embodiment is suitable for the production of high modulus sodium metasilicate extracted from pulverized coal. The steps are:

[0035] (A) A high-concentration alkaline sodium silicate solution was obtained after the fly ash was leached with a NaOH solution having a mass concentration of 25%. The mass concentration of NaOH in the alkaline sodium silicate solution is 20%. Add the compound ...

Embodiment 2

[0041] A method for efficient separation and recycling of sodium hydroxide in alkaline sodium silicate in this embodiment is basically the same as in embodiment 1, except that some parameters have been adjusted, and the same effect can still be achieved. details as follows:

[0042] In step (A), the fly ash is leached with a NaOH solution having a mass concentration of 30%, to obtain an alkaline sodium silicate solution. Wherein the mass concentration of the NaOH solution in the alkaline sodium silicate solution is 25%, and the extractant and the additive are compounded according to the volume ratio of 10:1 for extraction, wherein the extractant is n-hexanol and n-octanol The mixture, the mixing volume ratio is 2:1, the additive is C 18 Alkylphenol, the compound extractant is 3 times the volume of the filtrate, and the extraction temperature is 100°C.

[0043] The aqueous phase obtained in step (B) is stripped under 8bar pressure at 85°C, and after adding sodium metasilicate...

Embodiment 3

[0047] A method for efficient separation and recycling of sodium hydroxide in alkaline sodium silicate in this embodiment is basically the same as in embodiment 1, except that some parameters have been adjusted, and the same effect can still be achieved. details as follows:

[0048] In the step (A), the fly ash is leached with a NaOH solution having a mass concentration of 20%, to obtain an alkaline sodium silicate solution. Wherein the mass concentration of the NaOH solution in the alkaline sodium silicate solution is 15%, and the extractant and the additive are used for extraction according to a compound extractant compounded at a volume ratio of 10:1, wherein the extractant is composed of glycerin and C 10 Fatty alcohol composition, the volume ratio of the two is 1:1, and the additive is C 6 Alkylphenols and C 12 Alkylphenol mixture, the volume ratio of the two is 1:2, the volume of the compound extractant is 1.5 times the volume of the filtrate, and the extraction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com