Catalyst for biomass tar cracking and preparation method thereof

A technology for tar cracking and biomass, applied in the field of biomass tar cracking catalyst and its preparation, can solve problems such as reducing process energy consumption and production cost, and achieve the effects of reducing process energy consumption and production cost and high gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

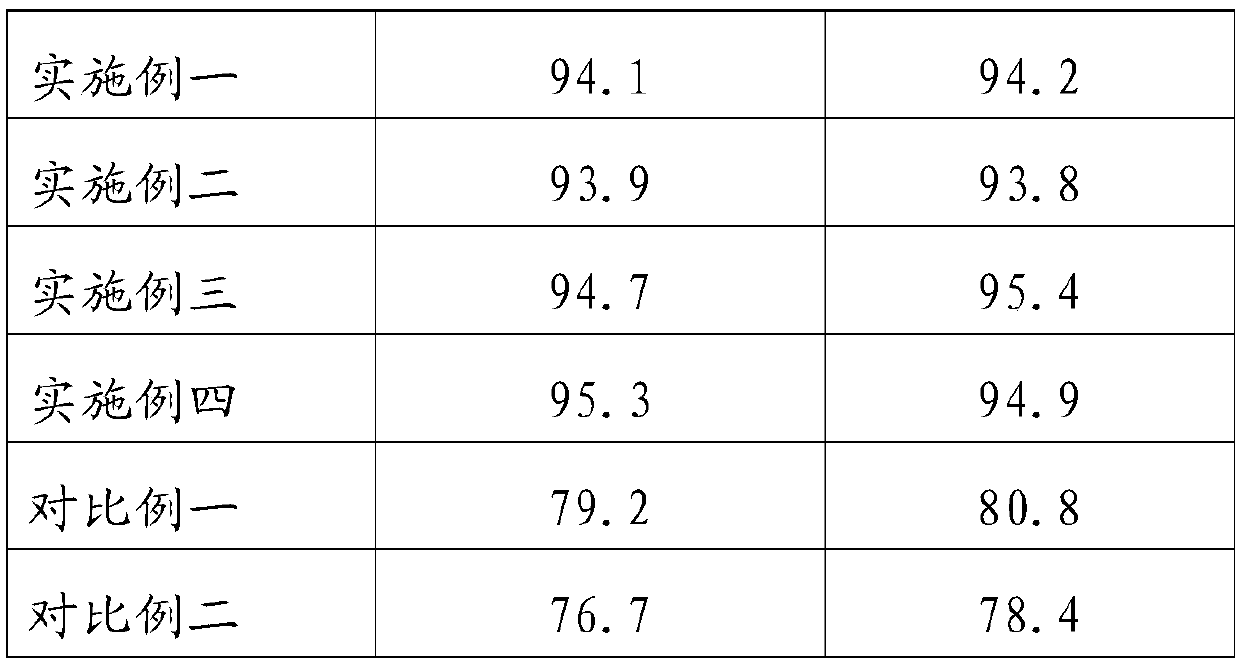

Examples

Embodiment 1

[0014] A catalyst for cracking biomass tar, comprising the following components by weight: 60 parts by weight of semi-coke for biomass, 20 parts by weight of tar, 20 parts by weight of chromium oxide green, 15 parts by weight of copper oxide, cesium hydroxide 10 parts by weight, 8 parts by weight of lithium hydroxide, 8 parts by weight of barium hydroxide, 6 parts by weight of rubidium hydroxide, 5 parts by weight of manganese dioxide, 1 part by weight of nickel oxide, and 1 part by weight of sodium oxide , The alumina binder is 15 parts by weight.

Embodiment 2

[0016] A catalyst for cracking biomass tar, comprising the following components by weight: 75 parts by weight of semi-coke for biomass, 30 parts by weight of tar, 23 parts by weight of chromium oxide green, 16 parts by weight of copper oxide, cesium hydroxide 13 parts by weight, 10 parts by weight of lithium hydroxide, 10 parts by weight of barium hydroxide, 8 parts by weight of rubidium hydroxide, 7 parts by weight of manganese dioxide, 2 parts by weight of nickel oxide, and 2 parts by weight of sodium oxide , The alumina binder is 20 parts by weight.

Embodiment 3

[0018] A catalyst for cracking biomass tar, comprising the following components by weight: 90 parts by weight of semi-coke for biomass, 40 parts by weight of tar, 26 parts by weight of chromium oxide green, 18 parts by weight of copper oxide, cesium hydroxide 16 parts by weight, 12 parts by weight of lithium hydroxide, 13 parts by weight of barium hydroxide, 10 parts by weight of rubidium hydroxide, 8 parts by weight of manganese dioxide, 3 parts by weight of nickel oxide, and 3 parts by weight of sodium oxide , The alumina binder is 25 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com