Alpha bismuth oxide/bismuth vanadate and preparation method thereof

A technology of bismuth oxide and bismuth vanadate, which is applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as high cost, difficult industrialized production, etc., and achieves low production cost, easy ratio control, The effect of improving the decolorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

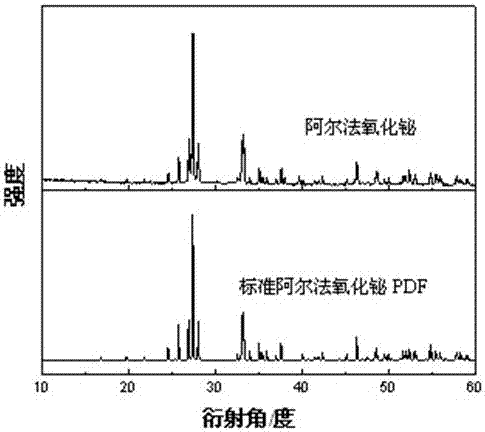

[0020] Add a certain amount of bismuth oxychloride powder into deionized water and ultrasonically disperse, then add sodium hydroxide solution to the above system, wherein the molar ratio of bismuth oxychloride to sodium hydroxide is 1:4, and use ethanol and deionized The ion water was washed repeatedly for 3 times, and the alpha bismuth oxide was obtained after drying.

Embodiment 2

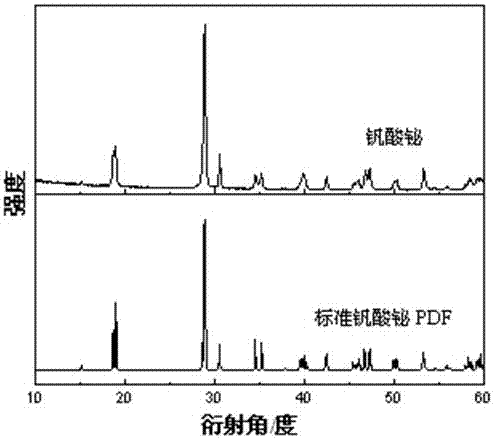

[0022] Step 1, add a certain amount of citric acid to 2 mol / L nitric acid, then add a certain amount of Bi(NO 3 ) 3 ·5H 2 O, stirred until uniform, where Bi(NO 3 ) 3 ·5H 2 The molar ratio of O and citric acid is 1:2, and the pH value is adjusted to 7 with ammonia water;

[0023] Step 2, a certain amount of NH 4 VO 3 Dissolve in sodium hydroxide solution, add the solution obtained in step 1 to the above solution, and adjust the pH value to 7 with ammonia water;

[0024] In step 3, the solution obtained in step 2 was first placed in a water bath at 80°C, and then dried at 135°C for 5 hours, and the powder obtained after grinding was calcined at 500°C for 4 hours to obtain bismuth vanadate.

Embodiment 3

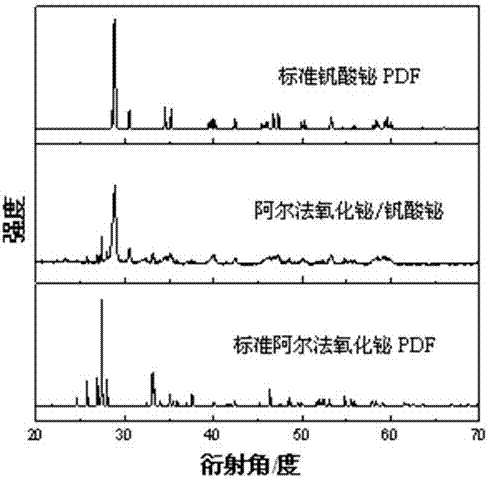

[0026] Step 1, add a certain amount of citric acid to 2 mol / L nitric acid, then add a certain amount of Bi(NO 3 ) 3 ·5H 2 O, stirred until uniform, where Bi(NO 3 ) 3 ·5H 2 The molar ratio of O and citric acid is 1:2, and the pH value is adjusted to 7 with ammonia water;

[0027] Step 2, a certain amount of NH 4 VO 3 Dissolve in sodium hydroxide solution, add the solution obtained in step 1 to the above solution, and adjust the pH value to 7 with ammonia water;

[0028] Step 3, the solution obtained in step 2 is first placed in a water bath at 80°C, then dried at 135°C for 5 hours, and the powder obtained after grinding is calcined at 500°C for 4 hours to obtain bismuth vanadate;

[0029] Step 5, mix bismuth oxychloride powder with the obtained bismuth vanadate, add deionized water and ultrasonically disperse, then add sodium hydroxide solution to the above system, wherein the molar ratio of bismuth vanadate to bismuth oxychloride is 1:0.25 , the molar ratio of bismuth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com