A preparation method of multi-component reinforced high-temperature titanium-based composite material

A titanium-based composite material and high-temperature technology, which is applied in the field of preparation of multi-component reinforced high-temperature titanium-based composite materials, can solve the problems of uneven precipitation of high-temperature titanium alloy silicide, easy growth, and high-temperature performance deterioration, and achieve short holding time , prevent agglomeration and growth, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0043] Embodiment 1: In this embodiment, a method for preparing a multi-element reinforced high-temperature titanium-based composite material is specifically carried out according to the following steps:

[0044] 1. Ultrasonic cleaning of titanium rods, high-purity aluminum and high-purity tin in alcohol and drying;

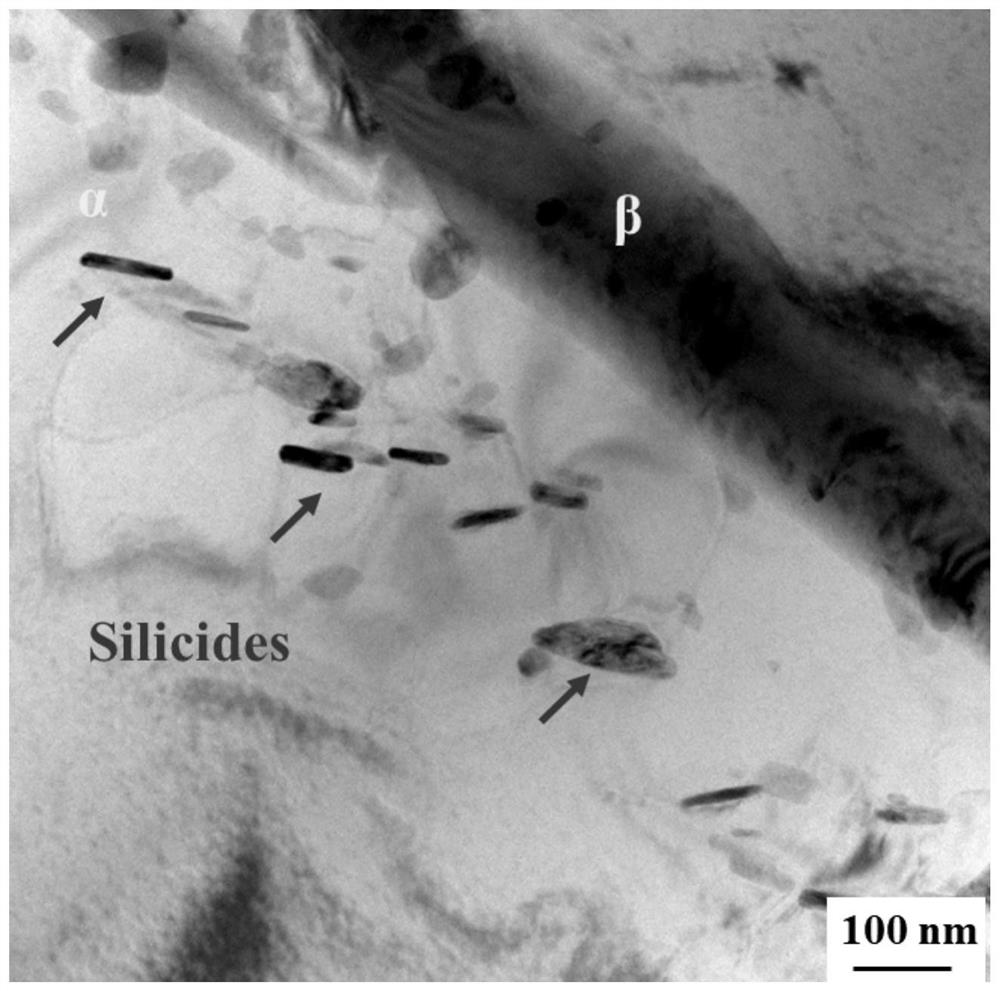

[0045] 2. According to the element weight percentage: Al is 5% to 6%, Sn is 2% to 5%, Zr is 2% to 8%, Mo is 0.6% to 1.0%, W is ≤1%, Nb is ≤1% , Si is 0.25% to 0.45% and the balance of Ti, weigh sponge titanium, sponge zirconium, high-purity silicon, aluminum-molybdenum master alloy, aluminum-tungsten master alloy, aluminum-niobium master alloy, titanium rod treated in step 1, high-purity Aluminum and high-purity tin;

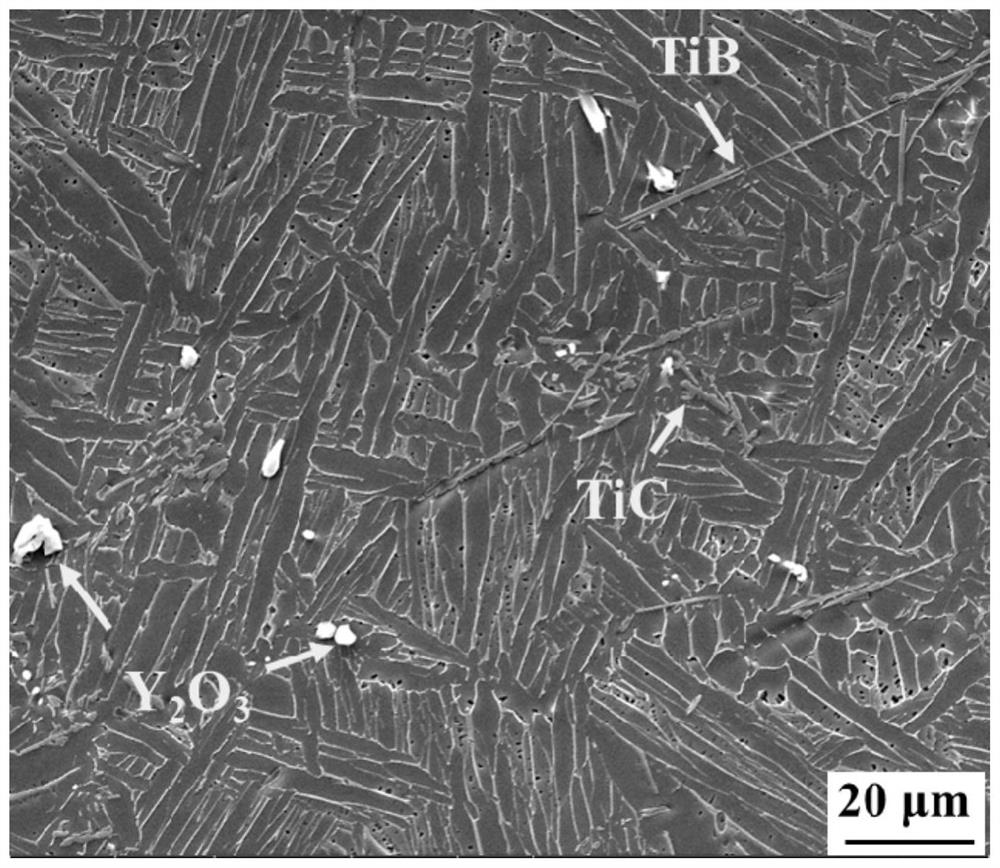

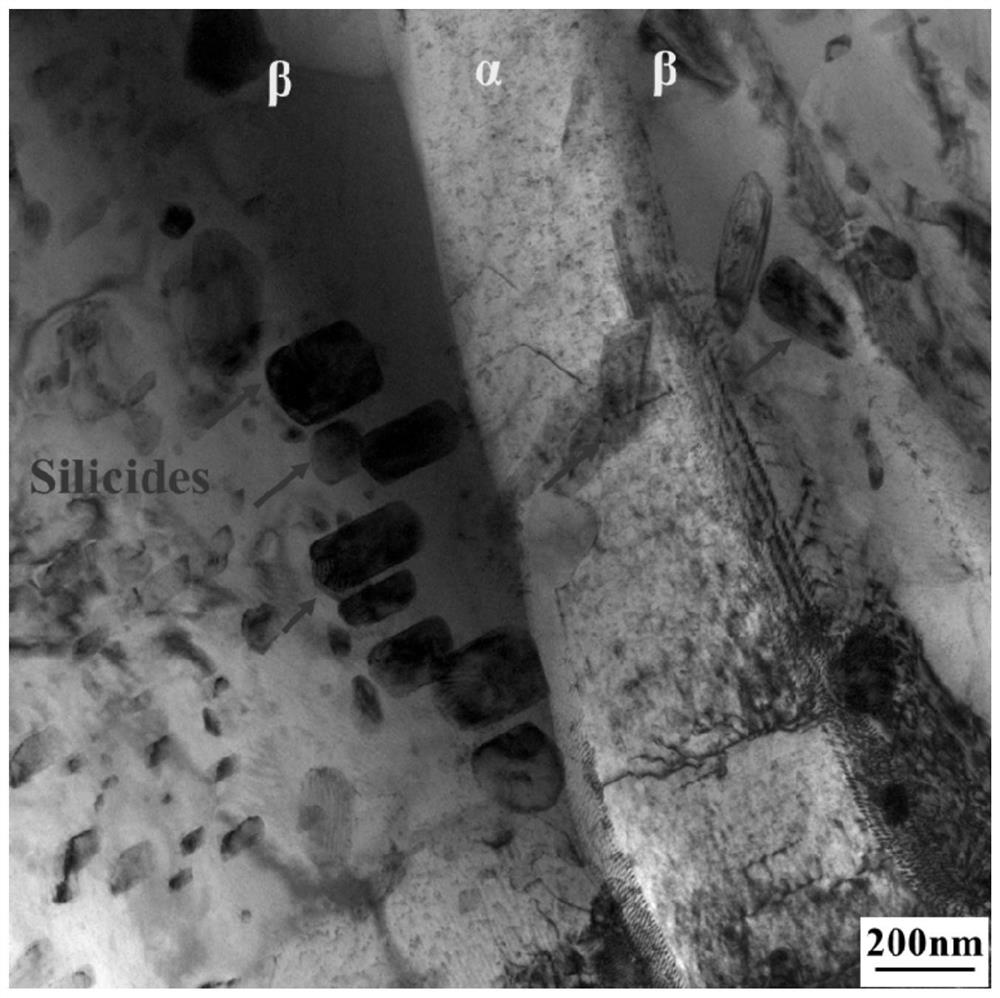

[0046] According to the volume percentage of the reinforcing phase: TiB is 1% to 2% and TiC is 1% to 2%, and B is weighed 4 C powder and C powder;

[0047] 3. Press the sponge titanium, high-purity aluminum, sponge zirconium, high-purity tin, hi...

specific Embodiment approach 2

[0059] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass content of Mo in the aluminum-molybdenum master alloy described in step 2 is 50.5%, the mass content of W in the aluminum-tungsten master alloy is 57.44%, and the aluminum-niobium master alloy has a mass content of 57.44%. The mass content of Nb in the alloy is 83.15%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0060] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: in step 2, the reinforcing phase is also added with nano-Y 2 O 3 powder, Y 2 O 3 The volume percentage of ≤0.5. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com