Insulating oil for low-chloride capacitor and preparing method for conductive oil

A capacitor and insulating oil technology, which is applied in the field of preparation of low-chlorine capacitor insulating oil and heat transfer oil, can solve problems such as the adverse effects of insulating oil and heat transfer oil, and achieve a mild and easy-to-control reaction process, few by-products, and easy adjustment of the ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

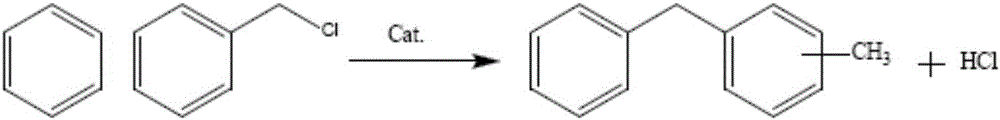

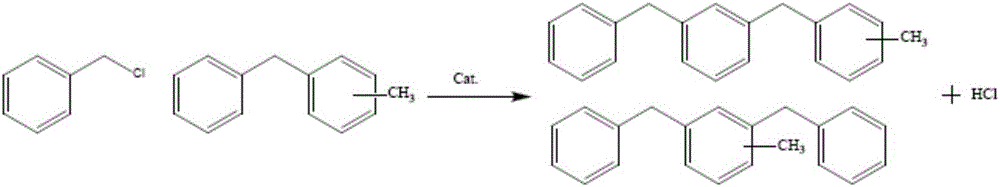

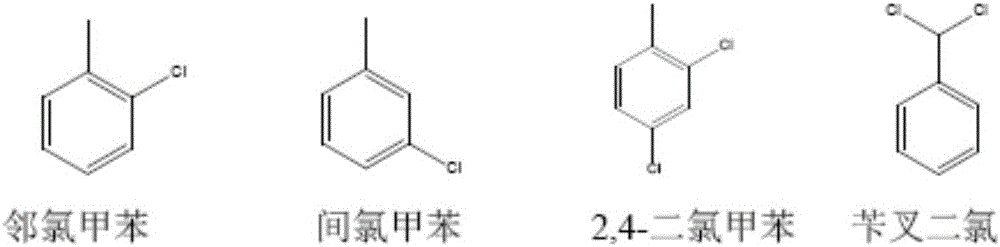

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is used to illustrate the preparation method of the capacitor insulating oil provided by the present invention.

[0035] Put 8kg of benzyltoluene mixture with a chlorine content of 690ppm and 800g of sodium hydride catalyst into a 10L reactor, start stirring at a stirring speed of 250r / min, turn on the heater, raise the temperature to 120°C, and keep the temperature for 24 hours; The material in the kettle was cooled to below 50°C, and the reaction liquid was filtered; the filtrate was refined to obtain low-chlorine capacitor insulating oil, with a chlorine content of 12.0ppm, and other physical and chemical performance indicators and electrical performance indicators were all qualified.

Embodiment 2

[0037] This embodiment is used to illustrate the preparation method of the capacitor insulating oil provided by the present invention.

[0038] Put 8kg of benzyltoluene mixture with a chlorine content of 690ppm and 800g of sodium hydride catalyst into a 10L reactor, start stirring at a stirring speed of 300r / min, turn on the heater, raise the temperature to 120°C, and keep the temperature for 24 hours; The material in the kettle is cooled to below 50°C, and the reaction liquid is filtered; the filtrate is refined to obtain low-chlorine capacitor insulating oil, the chlorine content is 9.0ppm, and other physical and chemical performance indicators and electrical performance indicators are all qualified.

Embodiment 3

[0040] This embodiment is used to illustrate the preparation method of the capacitor insulating oil provided by the present invention.

[0041] Put 8kg of benzyltoluene mixture with a chlorine content of 690ppm and 800g of sodium hydride catalyst into a 10L reactor, start stirring at a stirring speed of 300r / min, turn on the heater, and raise the temperature to 120°C, and keep the temperature for 16 hours; The material in the kettle is cooled to below 50°C, and the reaction liquid is filtered; the filtrate is refined to obtain low-chlorine capacitor insulating oil, the chlorine content is 10.0ppm, and other physical and chemical performance indicators and electrical performance indicators are all qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com