A kind of self-cleaning function, anti-ultraviolet sound insulation glass and preparation method thereof

A technology of anti-ultraviolet and sound-proof glass, which is applied in the field of thin film application, can solve the problems of complex preparation process of laminated glass and increase of production and manufacturing costs, and achieve the effect of easy control of preparation process parameters, less trouble, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

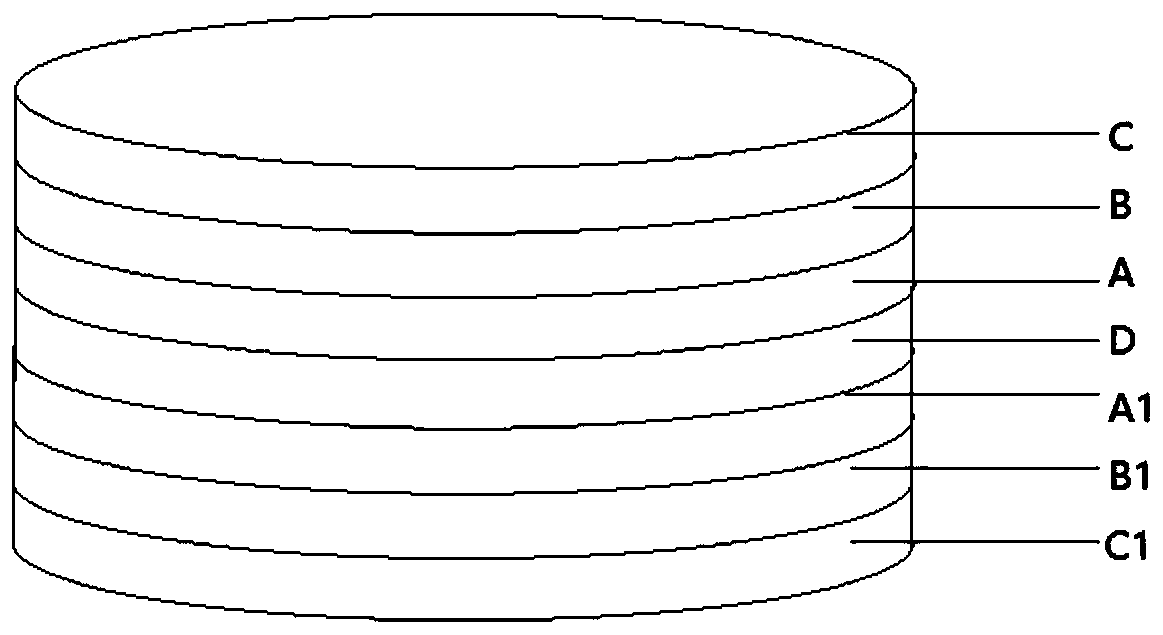

[0038] The preparation method of the above-mentioned self-cleaning function and anti-ultraviolet sound-insulating glass comprises the following steps:

[0039] 1) Put the transparent substrate A into detergent, acetone, alcohol, and deionized water in sequence for ultrasonic cleaning for 10-15 minutes, and then dry it with nitrogen after taking it out;

[0040] 2) Transfer the cleaned transparent substrate into the evaporation chamber and use vacuum evaporation V 2 o 5 etc. and electron beam evaporated SiO 2 , forming an anti-ultraviolet film layer, which is made of the oxide SiO 2 and V 2 o 5 Composition; the thickness of the anti-ultraviolet film produced by co-evaporation is 70-100nm.

[0041] 3) Put the evaporated substrate into a drying box to dry;

[0042] 4) Put the dried substrate into the vacuum chamber and evaporate TiO by electron beam 2 Etc thin film, electron beam evaporated material TiO 2 The thickness of etc. is 10-20nm. The film layer with self-cleanin...

Embodiment 1

[0050] The preparation process of the self-cleaning, UV-resistant glass is as follows:

[0051] 1. Put the soda-lime glass into detergent, acetone, alcohol, and deionized water in order to ultrasonically clean it for ten minutes, and then dry it with nitrogen after taking it out.

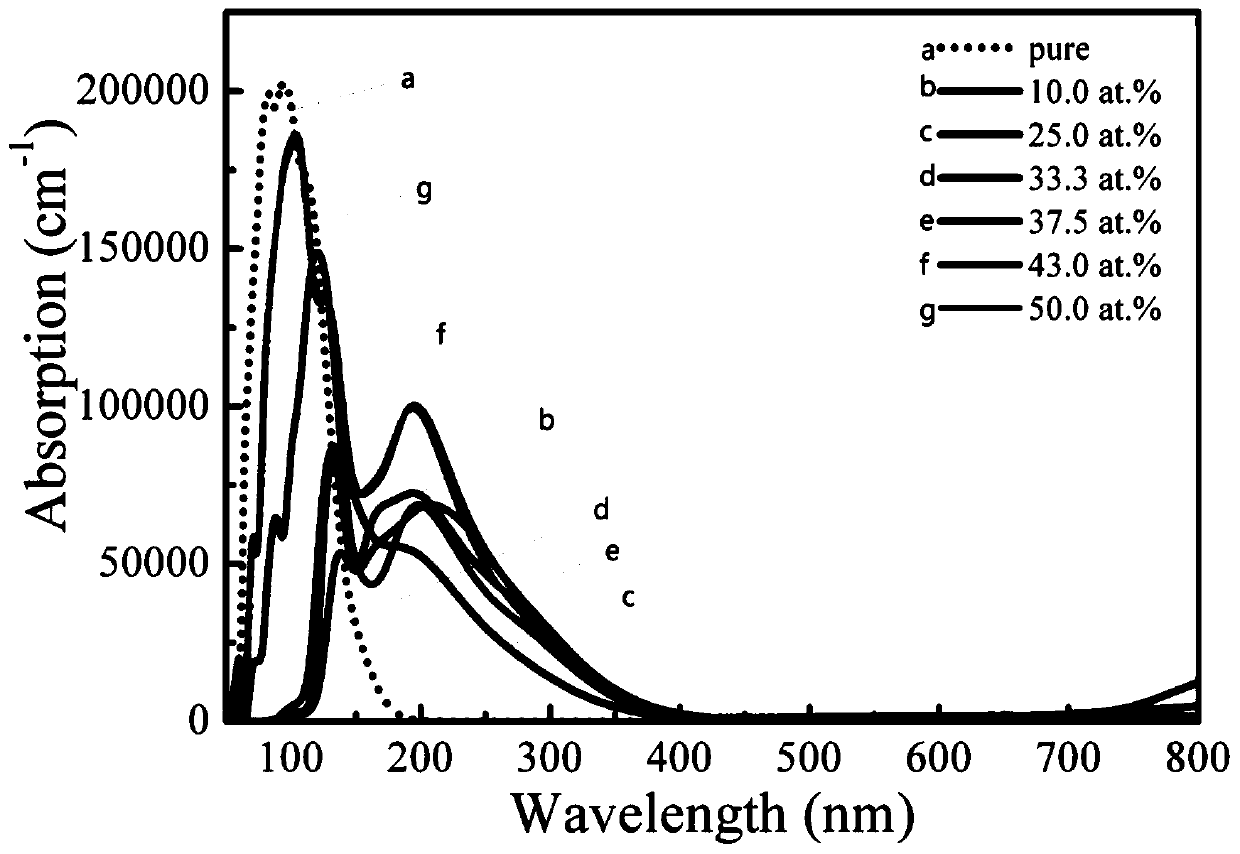

[0052] 2. Transfer the cleaned glass substrate into the evaporation chamber and use vacuum evaporation V 2 o 5 and electron beam evaporated SiO 2 , forming an ultraviolet thin film layer, which is made of the oxide SiO 2 and V 2 o 5 Composition, film thickness control is 70-100nm, V 2 o 5 SiO with a doping concentration of 10% 2 , the doping concentration is V 2 o 5 :SiO2 2 =3:4, the evaporation pressure is 5.0×10 -4 Pa;.

[0053] 3. Put the evaporated glass sheet into the drying box to dry;

[0054] 4. Put the dried glass sheet into the vacuum chamber and evaporate TiO by electron beam 2 , complete the film layer with self-cleaning function, the film thickness is 10-20nm, the evaporat...

Embodiment 2

[0059] The preparation process of the self-cleaning, UV-resistant glass is as follows:

[0060] 1. Put the soda-lime glass into detergent, acetone, alcohol, and deionized water in order to ultrasonically clean it for 15 minutes, and then dry it with nitrogen after taking it out.

[0061] 2. Transfer the cleaned glass substrate into the evaporation chamber and use vacuum evaporation V 2 o 5 and electron beam evaporated SiO 2 , forming an ultraviolet thin film layer, which is made of the oxide SiO 2 and V 2 o 5 Composition, film thickness control is 80-100nm, V 2 o 5 SiO with a doping concentration of 37.5% 2 , the doping concentration is V 2 o 5 :SiO2 2 =3:4, the evaporation pressure is 5.0×10 -4 Pa;.

[0062] 3. Put the evaporated glass sheet into the drying box to dry;

[0063] 4. Put the dried glass sheet into the vacuum chamber and evaporate TiO by electron beam 2 , complete the film layer with self-cleaning function, the film thickness is 15-20nm, the evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com