Preparation method of sodium manganese oxide

A sodium manganese oxide and hydroxide technology, applied in manganese compounds, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as unfavorable large-scale industrial production, and achieve improved specific surface area and surface activity, and improved product purity. , the effect of high charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 24.5 kg manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O) was dissolved in 100 L of deionized water, and while stirring, 33.4 L of 6 mol / L sodium hydroxide solution (Mn:OH molar ratio was 0.5) was added thereto. Increase the reaction temperature to 50°C and continue stirring for 3 hours to obtain a suspension containing brown precipitates; then dry the obtained suspension by spray drying at a drying temperature of 110°C to obtain a mixture containing the above brown precipitates .

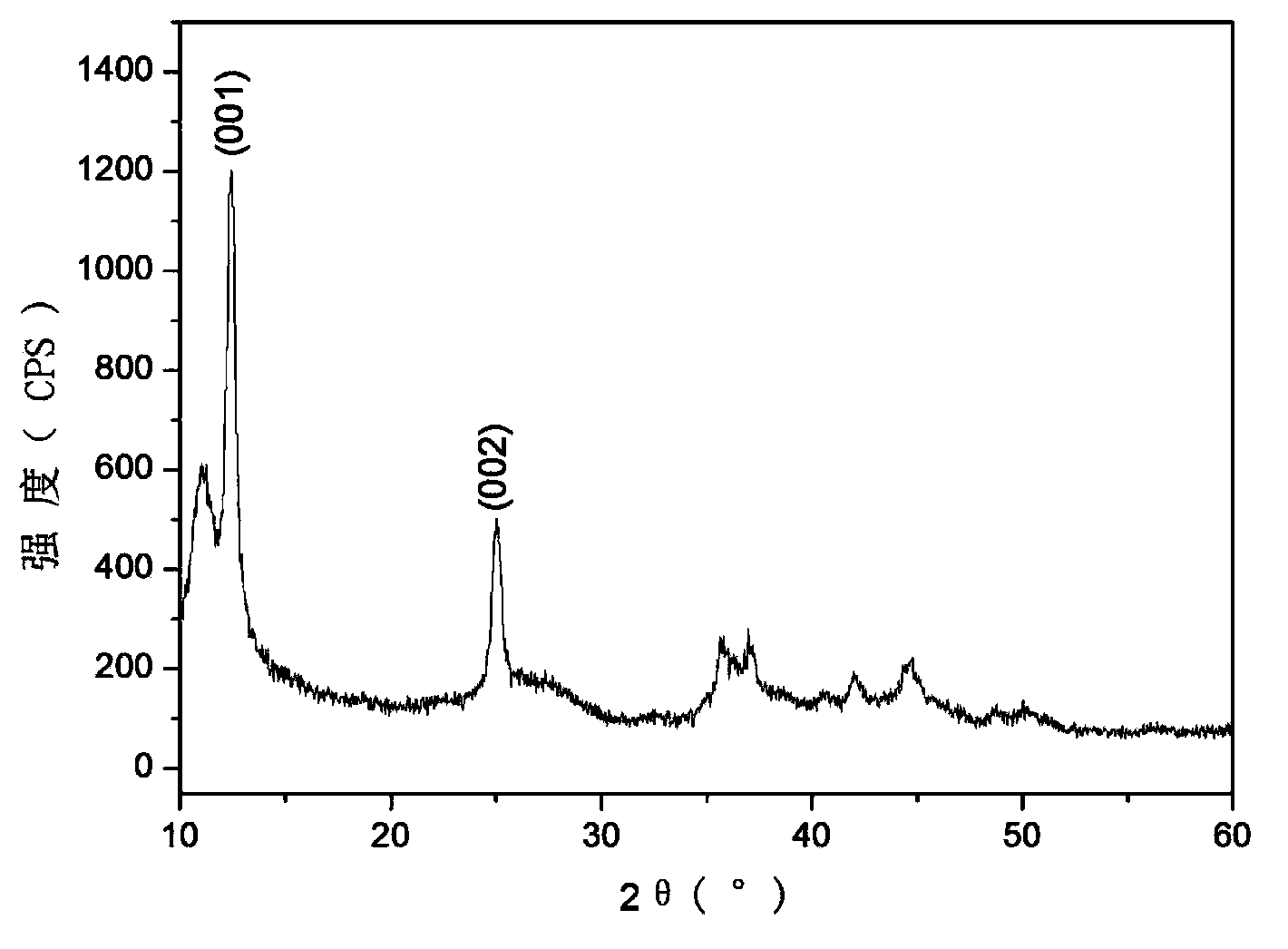

[0038] The obtained mixture was put into a stainless steel sagger for compaction, put into a box furnace, and the temperature was raised to 850°C at a rate of 8°C / min, and kept for 15 hours, and then cooled to room temperature with the furnace to obtain a black sintered product.

[0039] Put the obtained sintered product into a mixing tank equipped with zirconia balls and 80°C deionized water for 3 hours of wet ball milling to form a suspension to promote the dissolution of sol...

Embodiment 2

[0042] Weigh 15.1kg manganese sulfate and 1kg polyethylene glycol 2000 and dissolve them in 50 L of deionized water, while stirring, add 80 L of 6 mol / L sodium hydroxide solution (Mn:OH molar ratio is 0.2 ), after the addition of sodium hydroxide is completed, raise the reaction temperature to 50°C, and continue to stir for 3 hours to obtain a suspension containing brown precipitate; then dry the obtained suspension by vacuum drying at a drying temperature of 100°C , and dried to give a mixture containing the above brown precipitate.

[0043] Put the obtained mixture into a stainless steel sagger for compaction, put it into a box furnace, raise the temperature to 500°C at a rate of 8°C / min, keep it warm for 5 hours, and then raise the temperature to 1200°C at a rate of 12°C / min. And keep it warm for 10 hours, then cool down to room temperature with the furnace to obtain a black sintered product.

[0044] Put the obtained sintered product into a mixing tank equipped with zirco...

Embodiment 3

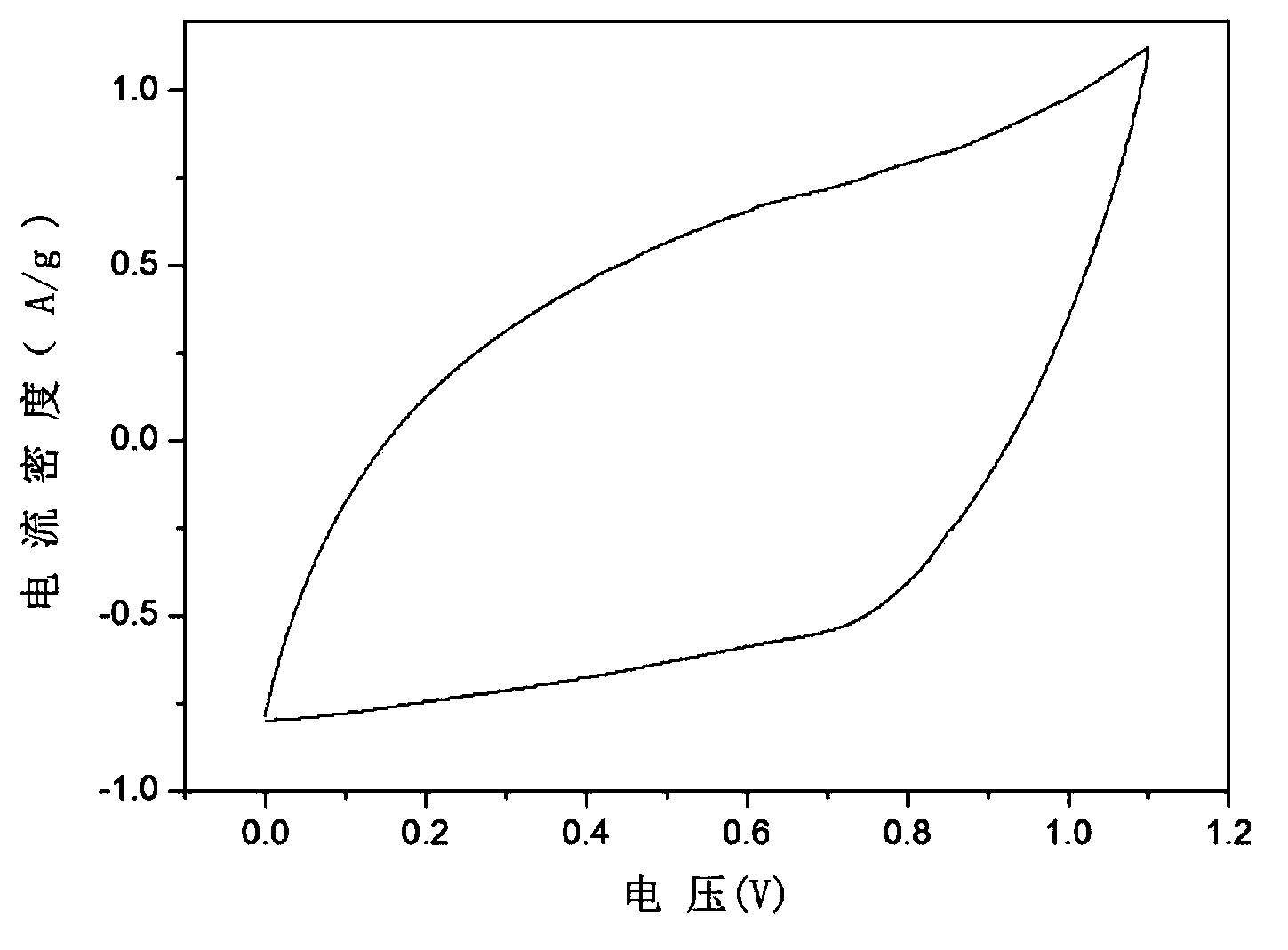

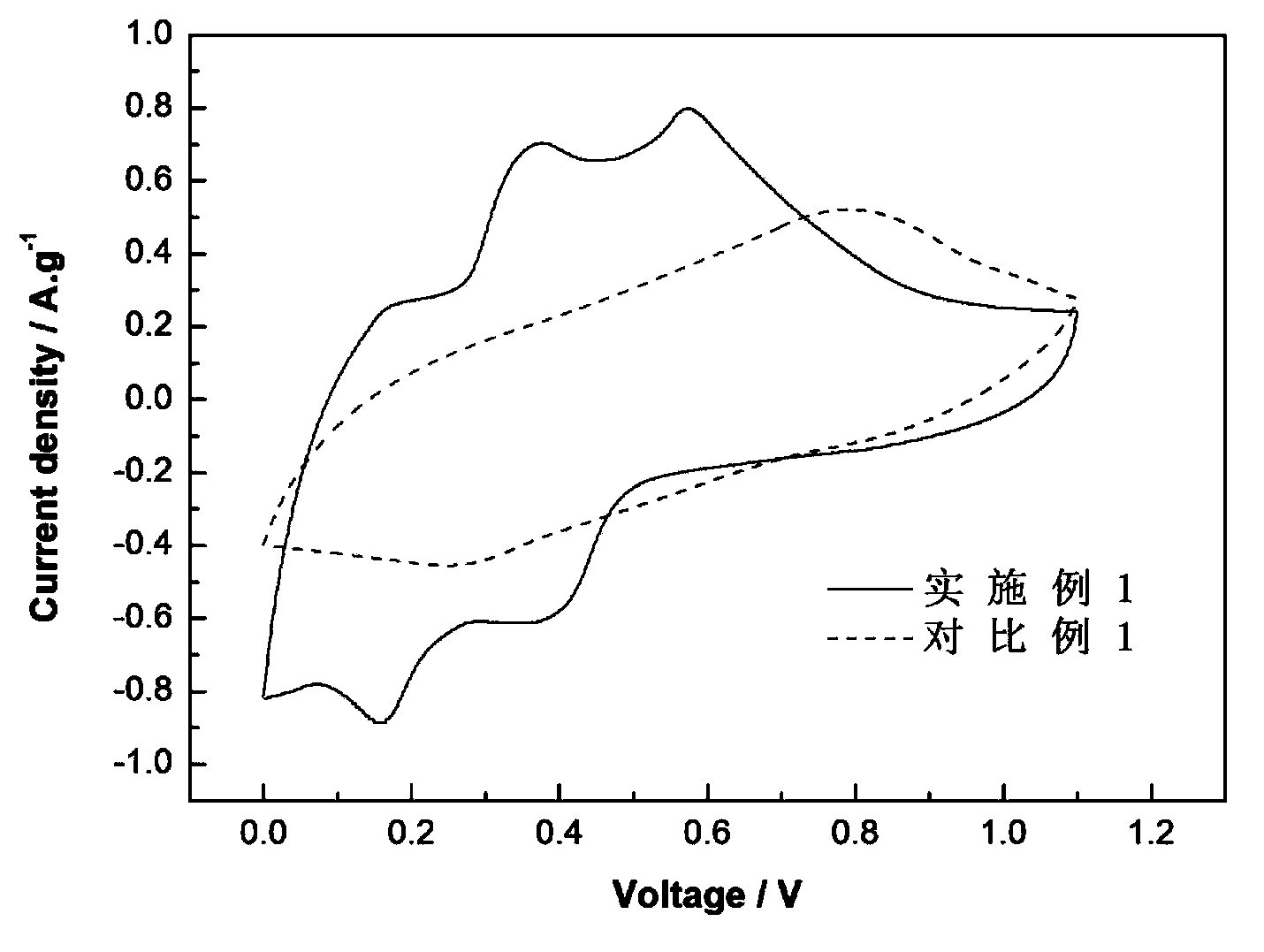

[0046] The layered Birnessite type sodium manganese oxide powder obtained in Example 1 is mixed with acetylene carbon black and polytetrafluoroethylene according to sodium manganese oxide powder: acetylene carbon black: polytetrafluoroethylene (molar ratio)=8: 1: 1, mix evenly, then add ethanol solvent and stir to prepare a slurry with moderate viscosity, then heat and evaporate the solvent, roll the obtained material into thin slices, put it in a vacuum drying oven and dry it at 120°C for 8 hours, then dry it Cut into 8mm × 8mm positive pole pieces (or punched into negative pole pieces with a diameter of 14 mm); combine activated carbon with acetylene carbon black and polytetrafluoroethylene according to activated carbon: acetylene carbon black: polytetrafluoroethylene (molar ratio) =8 : 1 : 1 ratio mixed evenly, and then according to the preparation method of the above-mentioned positive electrode sheet punched into a negative electrode sheet with a diameter of 14 mm; put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com