Patents

Literature

57results about How to "Facilitate solid phase reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

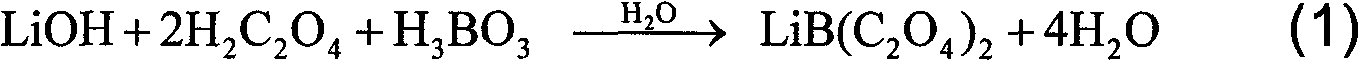

Preparation method of lithium bis(oxalato)borate

InactiveCN102627661AAvoid the disadvantage of being difficult to mix evenlyFacilitate solid phase reactionGroup 3/13 element organic compoundsOxalateBorate product

A preparation method of lithium bis(oxalato)borate relates to a preparation method of lithium bis(oxalato)borate for electrolyte of electrochemical equipment such as lithium ion batteries, comprising the following steps of: (1) uniformly mixing lithium salt and oxalate according to stoichiometric ratio, heating at 40-70 DEG C for 1-4h, adding a boron source into a mixture, thoroughly and uniformly mixing various kinds of materials; and (2) carrying out dry-pressing molding on the mixture at the pressure of 0.1MPa-10MPa, followed by heating reaction to obtain the lithium bis(oxalato)borate product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

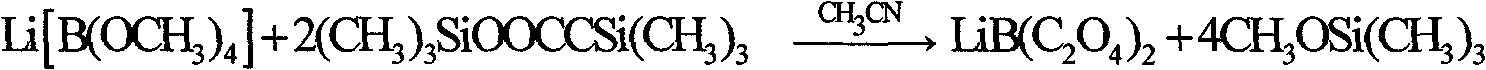

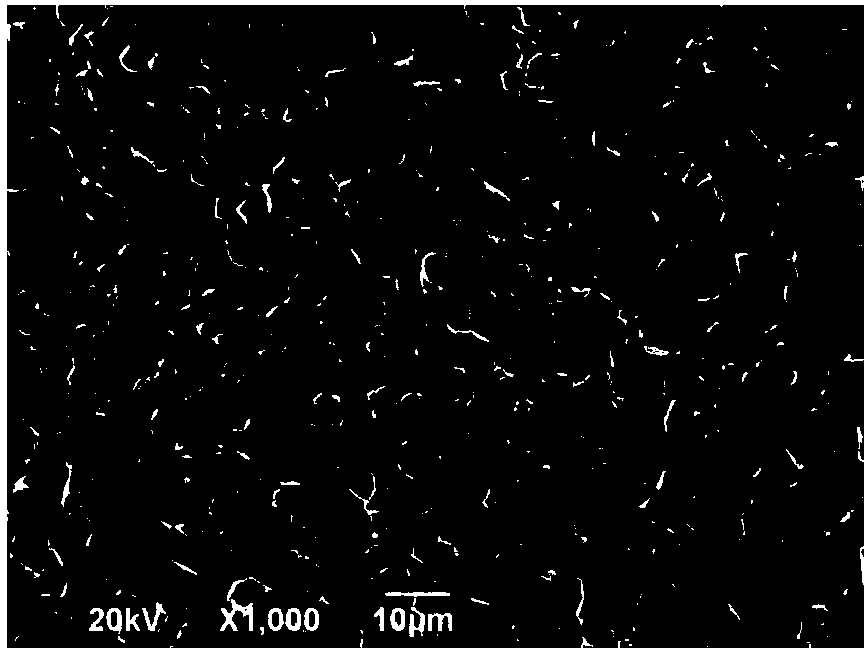

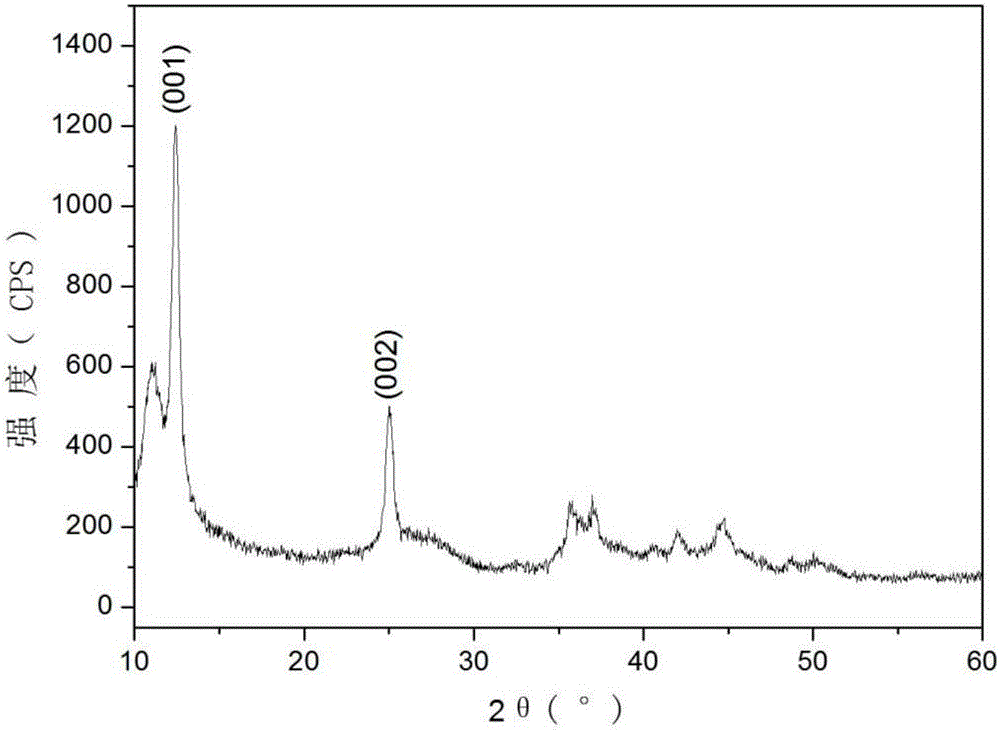

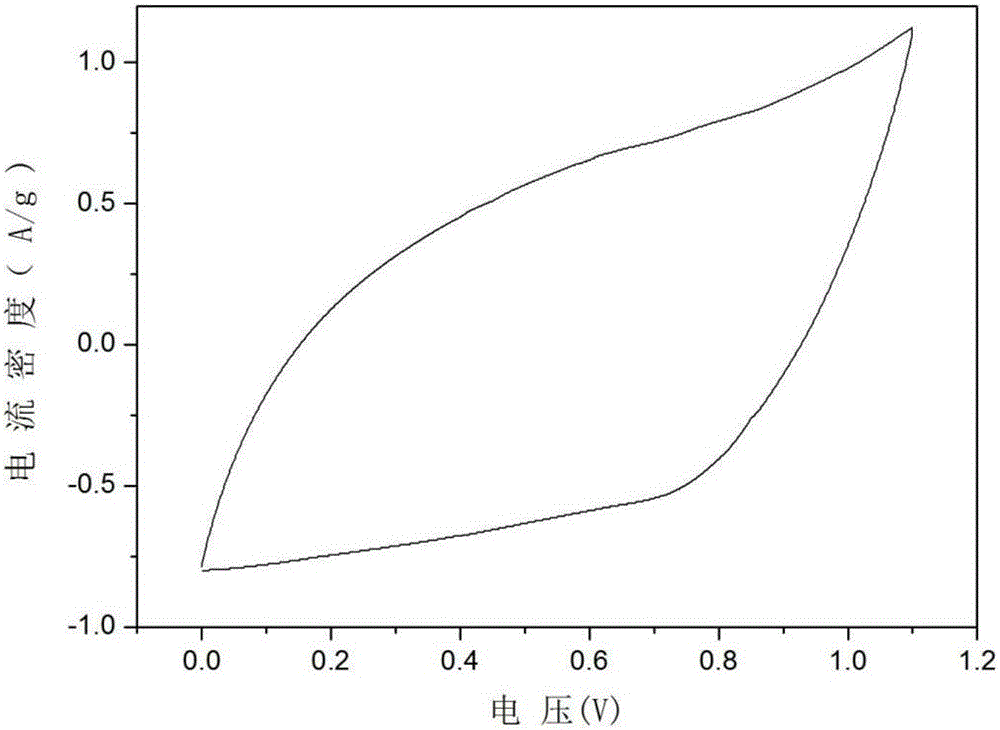

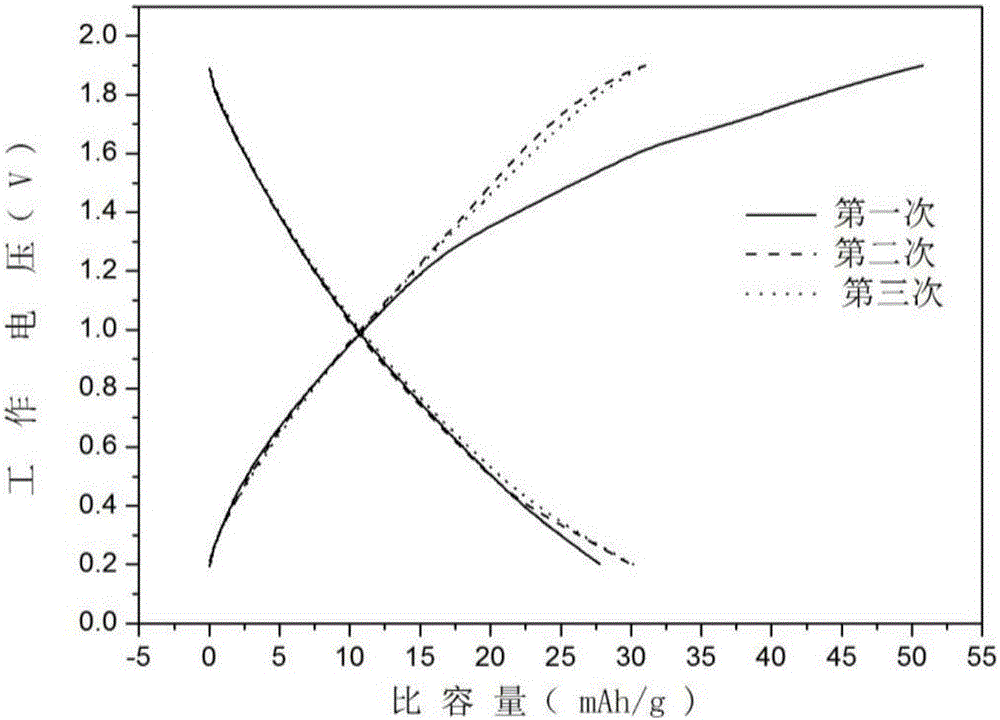

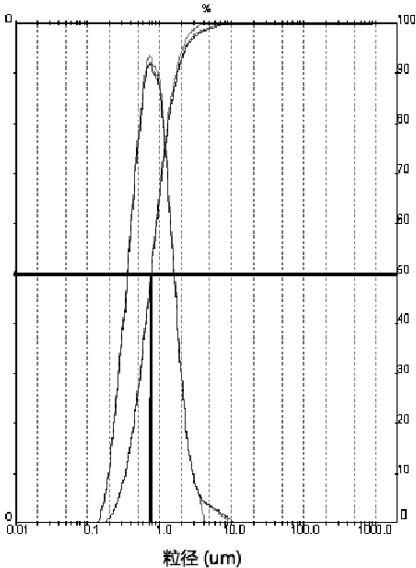

Preparation method of sodium manganese oxide

ActiveCN103896339AAdvantages of preparation methodHigh purityCell electrodesSecondary cellsChemical reactionMolecular level

The invention relates to a preparation method of a sodium manganese oxide, and particularly relates to a preparation method of a layered birnessite type sodium manganese oxide. The preparation method is as follows: reacting a two valent manganese salt with sodium hydroxide in an aqueous phase to obtain a Mn (OH)2 precipitate and / or MnOOH precipitate-containing suspension, then performing solvent evaporation to obtain a MnOOH precipitate and / or Mn (OH) 2 precipitate-containing mixture; grinding the mixture, and sintering at 600-1200 DEG C to obtain a sintering product; then performing washing and solid-liquid separation for multiple times, and finally drying to obtain a final product. According to the preparation method, molecular level mixing of manganese hydroxide and a sodium salt can be realized by a solution chemical reaction method, promotion of next-step solid phase reaction is facilitated, improvement of the purity of the product is facilitated, and the prepared sodium manganese compound can be used in a sodium ion battery using an aqueous solution as an electrolyte, and helps to improve the charge discharge performance of the battery.

Owner:紫石能源有限公司

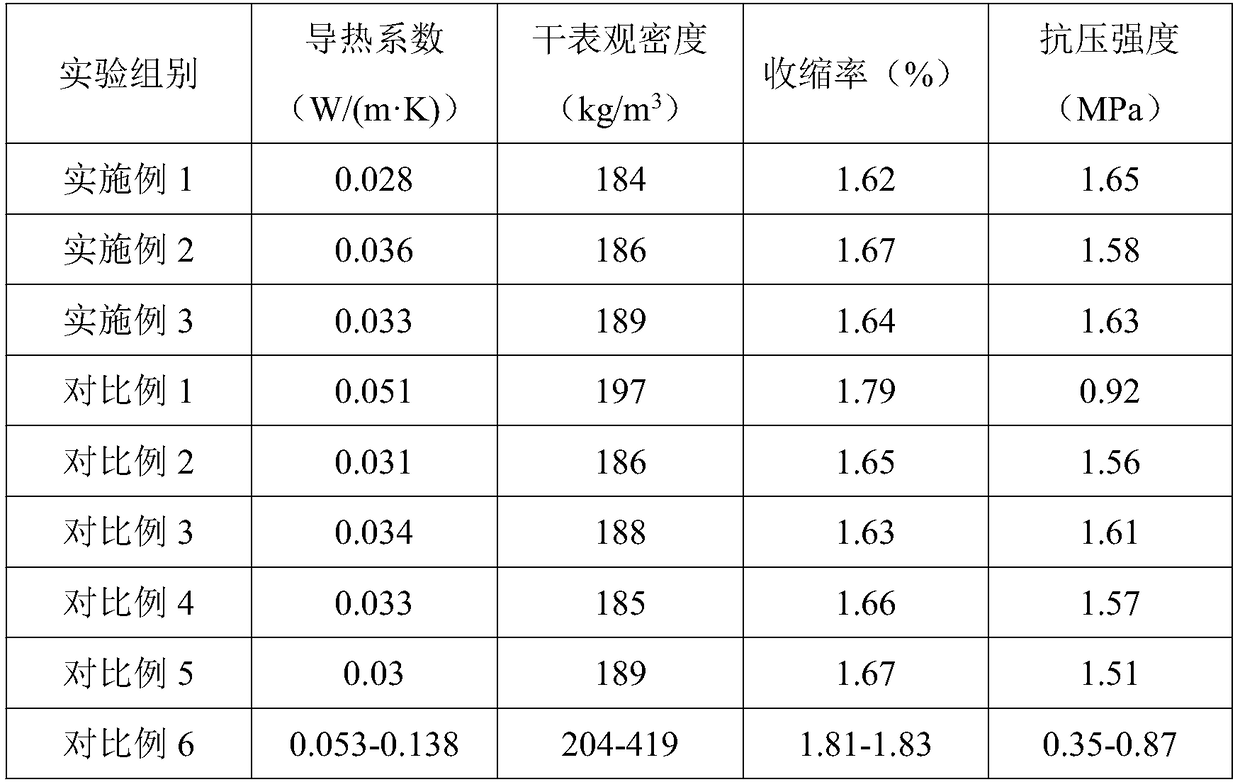

Nano porous ceramic for atomizing core and preparation method of nano porous ceramic

ActiveCN112592200AUnbreakableSolve the problem of cracking and oil leakageMedical atomisersTobaccoParaffin waxMolten state

The invention discloses nano porous ceramic for an atomizing core and a preparation method. The ceramic is prepared from 1 to 60 parts of nano silicon oxide, 10 to 80 parts of ceramic powder, 1 to 50parts of a pore-forming agent and 1 to 40 parts of a sintering aid. The preparation method comprises the steps of (1) weighing raw materials including nano silicon dioxide, ceramic powder, a pore forming agent and a sintering aid, and putting the raw materials into a ball milling device for mixing and ball milling; (2) baking and drying the ball-milled mixture to obtain mixed powder; (3) heating paraffin to a molten state, adding the mixed powder while stirring, and continuously stirring for 1-8 hours after the addition is finished so as to obtain paraffin slurry; (4) injecting the paraffin slurry into a pre-prepared mold, cooling and molding, and demolding to obtain a wax mold; (5) preheating the wax mold to remove wax to obtain a dewaxed sample; and (6) sintering the dewaxed sample, andcooling to obtain the nano-porous ceramic. The preparation method has the beneficial effects that the problem that the requirements of high porosity and high strength cannot be met simultaneously in the prior art is solved, and the problem that impurities and heavy metals are easy to separate out is solved.

Owner:HUIZHOU HAPPY VAPING TECH LTD

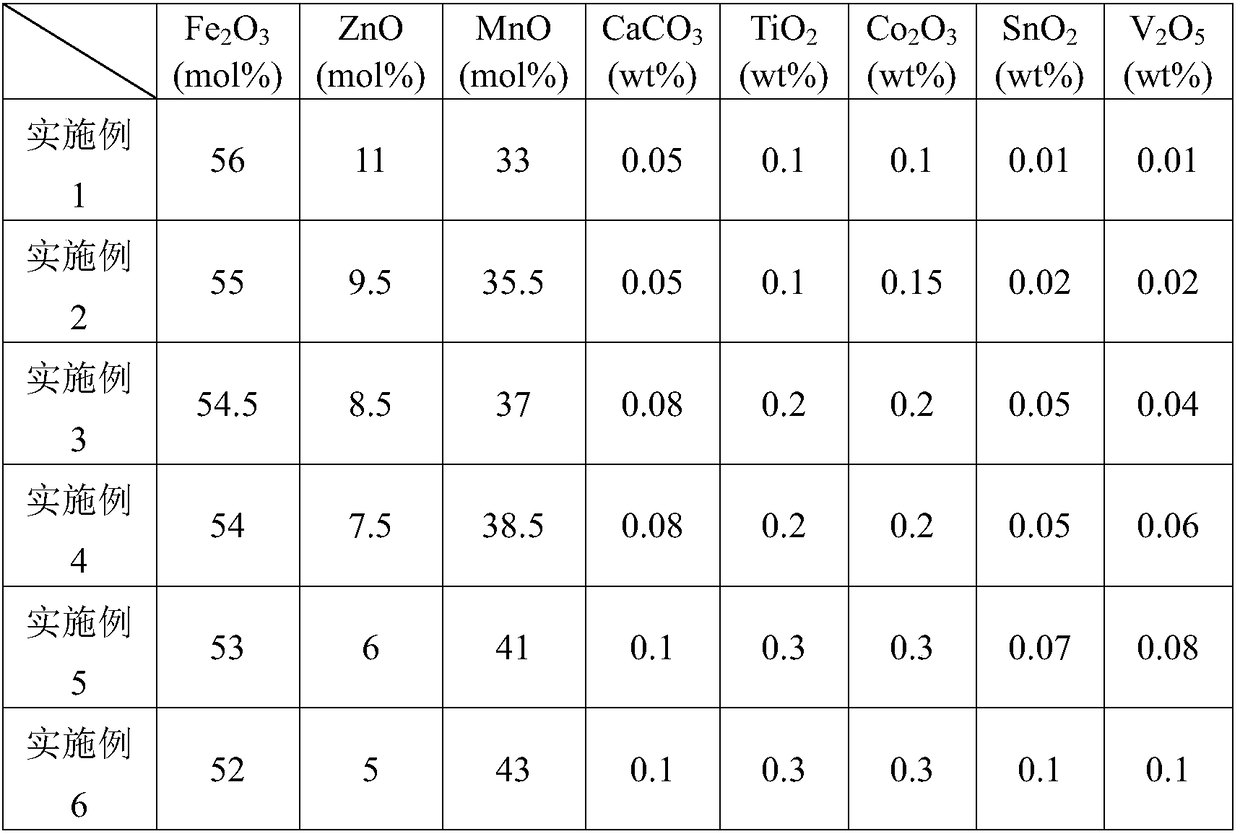

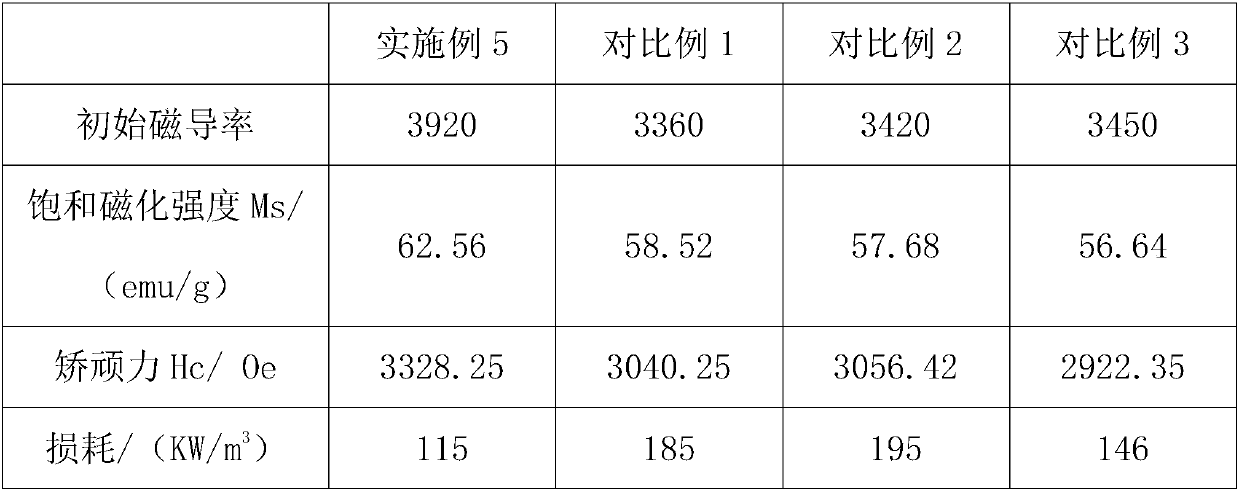

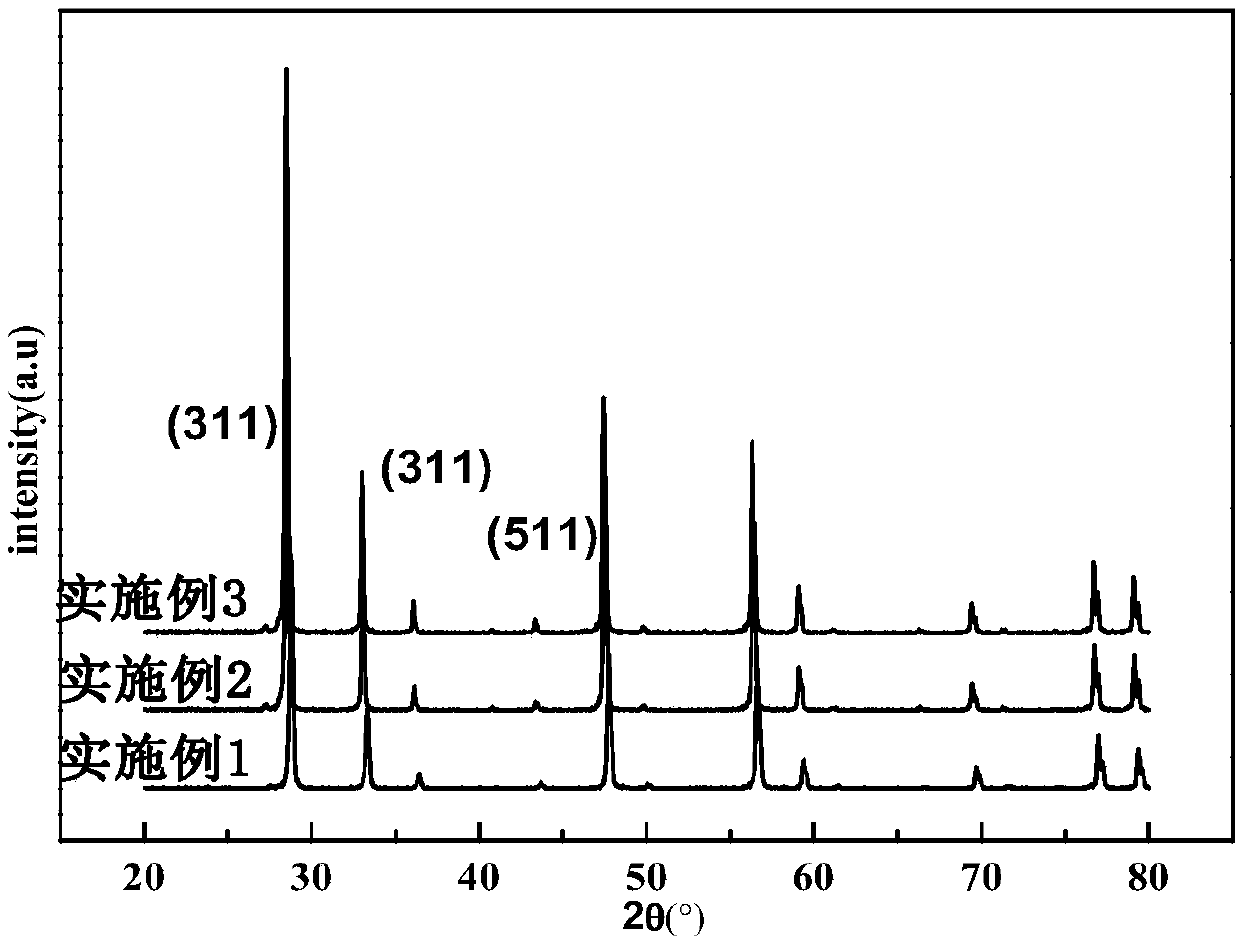

MnZn power ferrite for MHz-level switching mode power supply and preparation method of MnZn power ferrite

ActiveCN108424136AReduce lossReduce power lossInorganic material magnetismInductances/transformers/magnets manufactureDopantElectronic materials

The invention relates to a MnZn power ferrite for a MHz-level switching mode power supply and a preparation method of the MnZn power ferrite and relates to the electronic material technology. The ferrite is prepared from a main material and a dopant. The main material comprises in molar percentage of oxide as follows: 52mol%-56mol% of Fe2O3, 5mol%-11mol% of ZnO and 33mol%-43mol% of MnO; the dopantcomprises in molar percentage of oxide as follows: 0.05wt%-0.1wt% of CaCO3, 0.1wt%-0.3wt% of TiO2, 0.1wt%-0.3wt% of Co2O3, 0.01wt%-0.1wt% of SnO2 and 0.01wt%-0.1wt% of V2O5. The loss of the materialat high MHz frequency is effectively reduced, and the power loss is lower in the wideband range of 0.5-3 MHz and in the temperature range of 25-100 DEG C. Meanwhile, the preparation method has the advantages of being low in sintering temperature, energy-saving and environmentally friendly.

Owner:江西尚朋电子科技有限公司

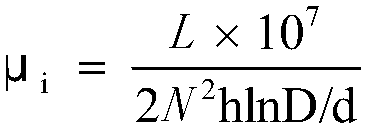

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

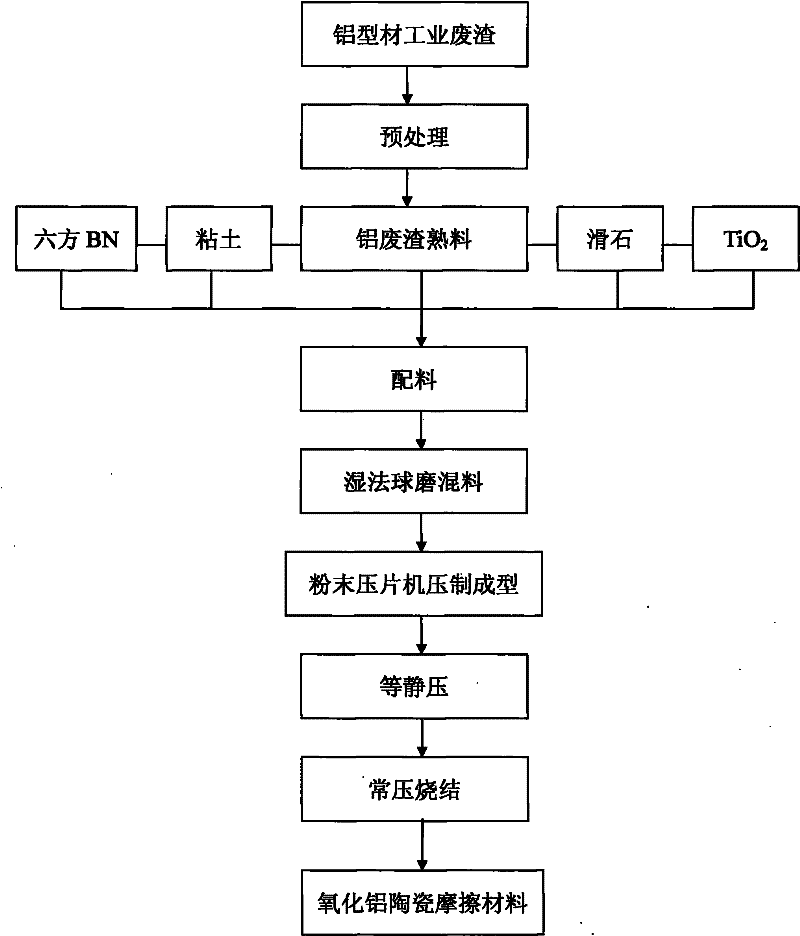

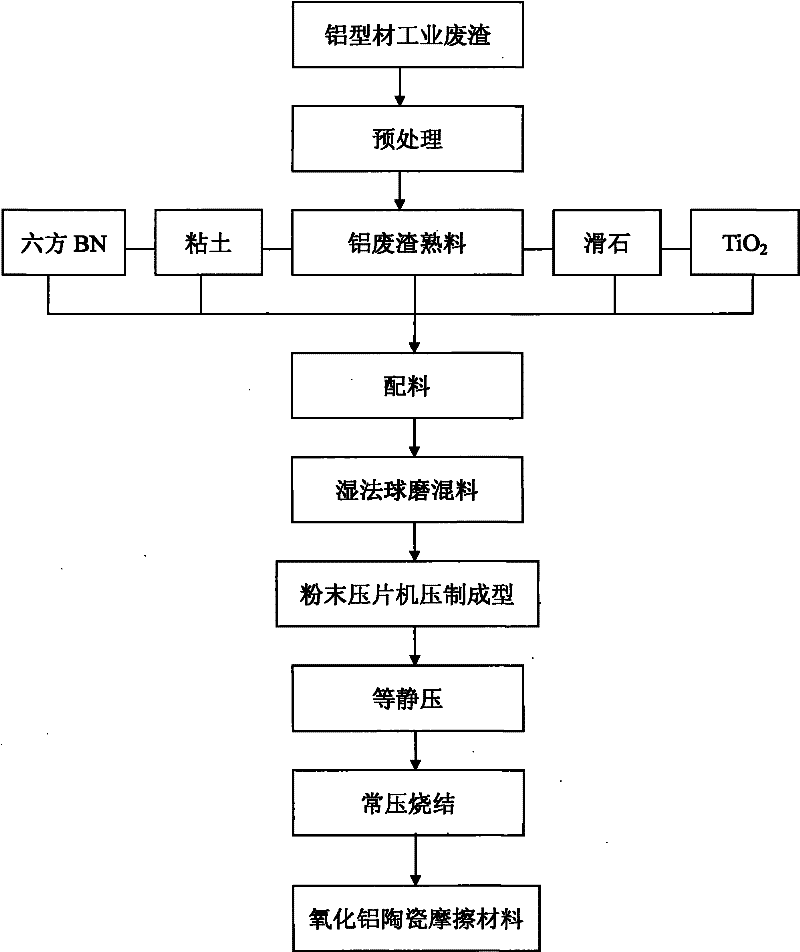

Aluminum oxide ceramic friction material prepared from aluminum profile industrial waste residue and preparation method thereof

The invention discloses a method for preparing an aluminum oxide ceramic friction material from aluminum profile industrial waste residue. The method comprises the following specific steps: (1) pretreating the aluminum profile industrial waste residue; (2) preparing the raw materials of the aluminum oxide ceramic friction material: preparing the raw materials, wherein the weight ratio of aluminum waste residue clinker to clay to talc to TiO2 to hexagonal boron nitride (BN) is (70-85):(5-20):(4-5):(1-2):4; performing the tertiary ball milling on the prepared raw materials, drying, and sieving with a 30-mesh sieve; (3) moulding the aluminum oxide ceramic friction material; and (4) sintering to obtain the aluminum oxide ceramic friction material. The friction material has the advantages of high mechanical strength and good friction and wear performance; the content of aluminum oxide in the aluminum profile industrial waste residue is up to 90%; the particles of the aluminum profile industrial waste residue are ultrafine and have high activity; and on the basis, a defined amount of sintering additive is added so as to effectively reduce the sintering temperature, save the energy and reduce the consumption.

Owner:SOUTH CHINA UNIV OF TECH

NiCuZn Ferrite material and preparation method and application thereof

InactiveCN107619271AImprove performanceGrowth inhibitionInorganic material magnetismInductances/transformers/magnets manufactureDopantMicrowave

The invention relates to NiCuZn ferrite material and a preparation method and application thereof and relates to the technical field of electronic materials. The NiCuZn ferrite material mainly comprises a main material and a dopant; the main material contains, by content of oxides, 48-49mol% of Fe2O3, 4-8mol% of CuO, 18-24mol% of ZnO, and the balance of NiO; the dopant contains, by the main material held to the temperature of 880-940 DEG C for 2-3 h, Bi2O3, CaO and Co2O3; the NiCuZn ferrite material has excellent features. The preparation method comprises: mixing the main material with deionized water, ball milling, drying, pre-sintering, adding the dopant, ball milling gain, adding a binder, granulating, compressing to obtain a base, sintering the base to obtain the NiCuZn ferrite material; integral performance of NiCuZn ferrite is effectively improved; through the application of the NiCuZn ferrite material in the production of Ka-band microwave devices, properties of the Ka-band microwave devices are effectively improved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Electric furnace bottom ramming mass

The invention discloses an electric furnace bottom ramming mass. The electric furnace bottom ramming mass contains the following raw materials in percentage by weight: 20-40% of 5-3mm fused magnesite or high-purity magnesite aggregate, 10-25% of 3-1mm fused magnesite or high-purity magnesite aggregate, 15-25% of 1-0mm fused magnesite or high-purity magnesite aggregate and 20-30% of <88 mu m fused magnesite fine powder or high-purity magnesite fine powder. Brine, which accounts for 4-6 wt% of the raw materials, is also added as a binder. The raw materials for producing the ramming mass combined with the brine are stable and easy to store. The ramming mass production process is simple, and the product quality is easy to control. The ramming mass has high MgO content, low impurity content, high fire resistance and higher corrosion resistance, and the service life can be prolonged from more than two hundred times to more than five hundred times in the electric furnace use process.

Owner:河南竹林耐材有限公司

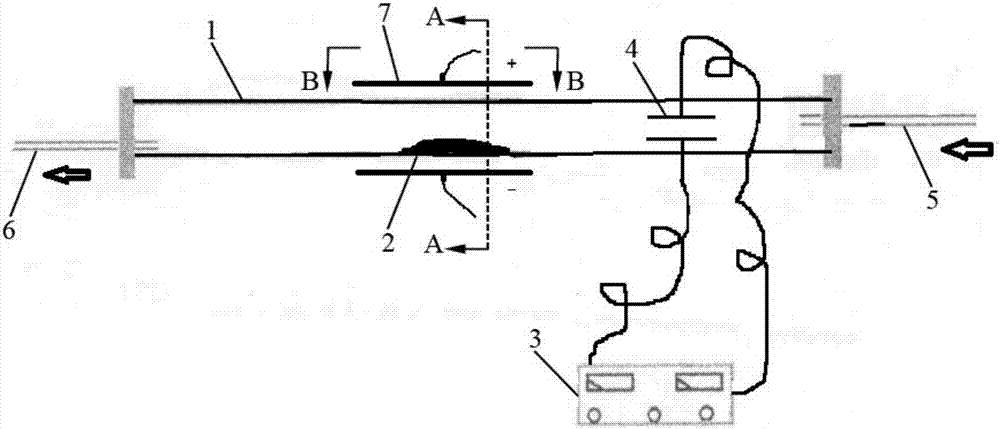

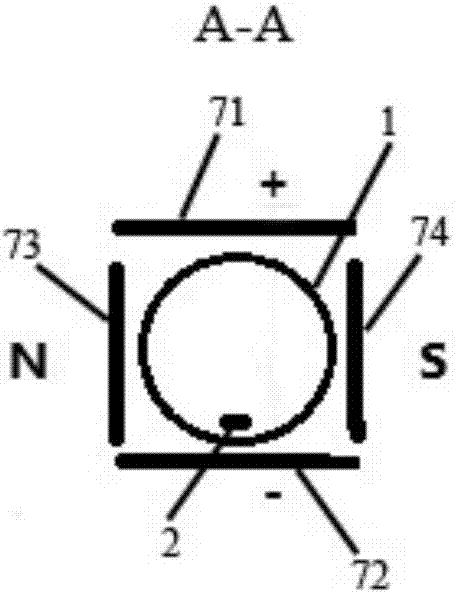

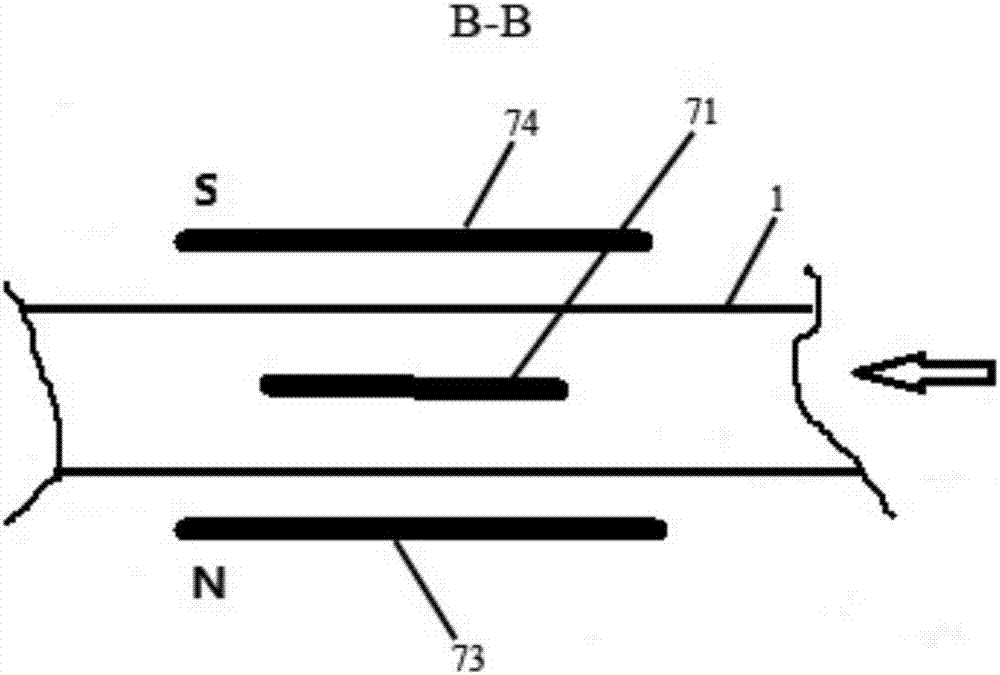

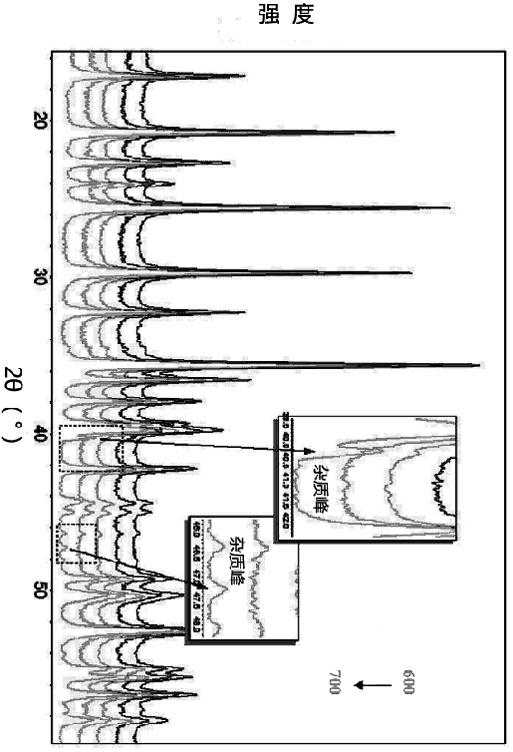

Electromagnetic field-constrained plasma enhanced oxidation calcination method of high-nickel positive electrode material of lithium ion battery

ActiveCN106992296AIncreased oxidation capacity and oxidation speedLow cost of preparationCell electrodesSecondary cellsLithium electrodeActive oxygen

The invention discloses an electromagnetic field-constrained plasma enhanced oxidation calcination method of a high-nickel positive electrode material of a lithium ion battery. The method comprises uniformly mixing a precursor and lithium source powder, placing the mixture into a calcination device, carrying out calcination, continuously feeding oxygen-containing gas into the calcination device so that the oxygen-containing gas produces active oxygen with positive charge through plasma discharging, and applying an electromagnetic field in the calcination device so that active oxygen movement produces deflection, active oxygen is constrained and enriched around the precursor and lithium source powder and the high-nickel positive electrode material is synthesized. The method utilizes lithium carbonate as a lithium source, can synthesize the high-nickel positive electrode material having excellent performances in air, and observably reduces a material preparation cost. The method has a great significance for improving comprehensive performances of the high-nickel positive electrode material and has effects of reducing a cationic mixing degree of the high-nickel positive electrode material, improving cycle performances and a rate capability of the material, reducing material alkalinity and improving material processing performances.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of high-performance permanent magnet ferrite magnet and magnet

InactiveCN107382303AImprove performanceInhibit growthInorganic material magnetismInductances/transformers/magnets manufactureRemanenceStrontium

The invention discloses a preparation method of a high-performance permanent magnet ferrite magnet and the magnet, belonging to the technical field of magnetic materials. The method comprises the steps of mixing and grinding a strontium ferrite pre-sintered material and an La-Ca-Sr-Co ferrite pre-sintered material in a certain weight proportion, wherein the La-Ca-Sr-Co ferrite material is prepared from the following components: La0.6Ca0.4-xSrxOn (Fe1-yCoy)2O3, wherein the x is more than or equal to 0.1 and is less than or equal to 0.4, the y is more than or equal to 0.2 and is less than or equal to 0.3, the n is more than or equal to 5.0 and is less than or equal to 6.0, the strontium ferrite material is prepared from the component of SrO.6(Fe2O3). When the strontium ferrite pre-sintered material is mixed with the La-Ca-Sr-Co ferrite pre-sintered material, the minimum remanence Br of the prepared permanent magnet ferrite is 418.7mT, and the maximum is 429.1mT; the minimum intrinsic coercivity is 350.3kA / m, and the maximum is 388.6kA / m, which fully meets the requirements of current use: the remanence Br is 415mT to 430mT, and the intrinsic coercivity is 350kA / m to 380kA / m.

Owner:MAANSHAN GAOKE MAGNETIC MATERIAL

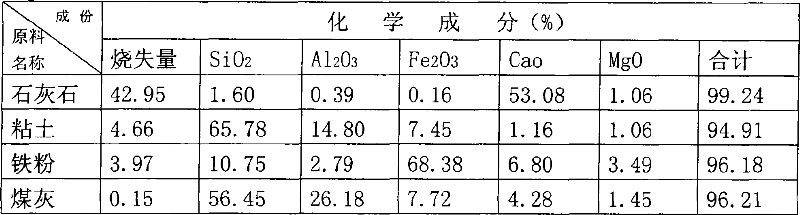

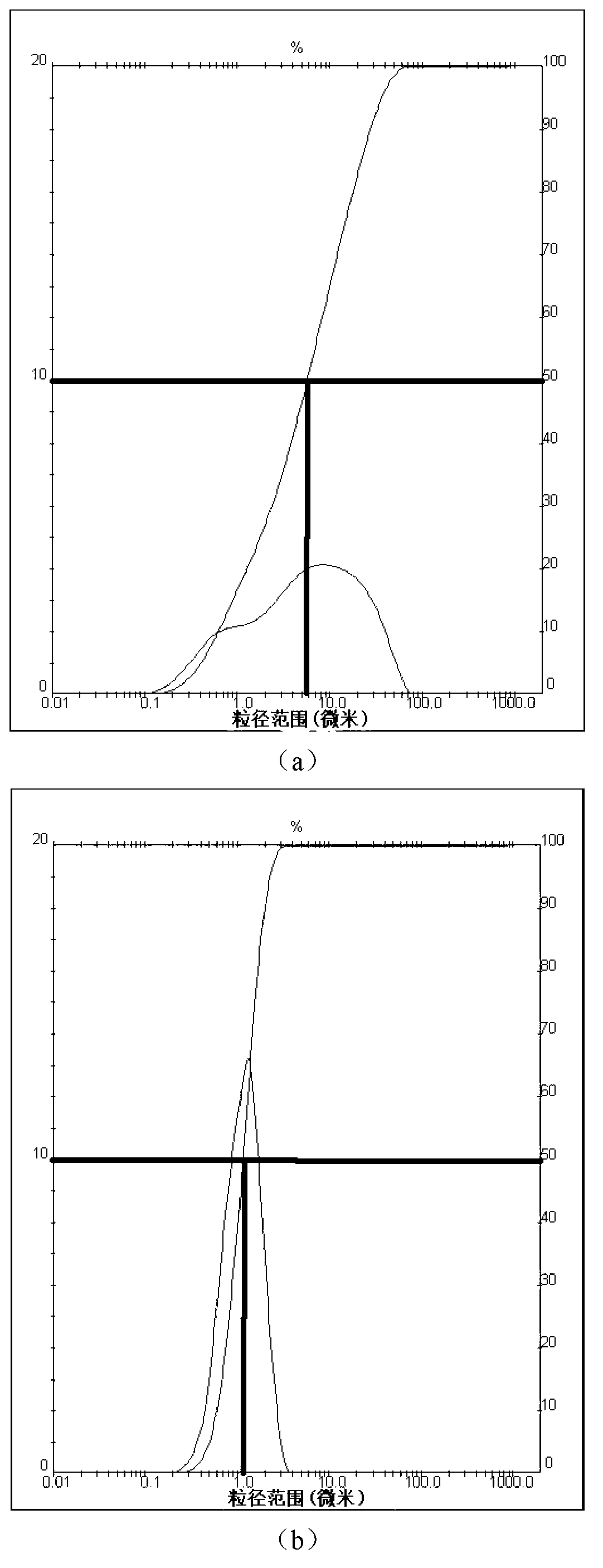

Additive applied to saving energy and increasing effect in cement production and preparation method thereof

ActiveCN102432209ARationalization of particle distributionGood dispersionNickel saltINCREASED EFFECT

The invention discloses an additive applied to saving energy and increasing effect in cement production. The additive is characterized by comprising the following components in percentage by weight: 60-80 percentage of triethanolamine, 8-12 percentage of monoethanolamine, 0.5-3 percentage of sodium polyacrylate, 0.5-3 percentage of sodium dodecyl sulfate, 0.5-1.5 percentage of abietin, 0.5-2.5 percentage of nickel salt, and 10-18 percentage of water. The additive has the main advantages of: 1, respectively improving output of a raw material grinder and a coal grinder for more than 10%, saving power consumption in grinding by more than 10%; 2, saving the coal consumption in the cement production process by more than 8%; 3, improving output of clinker by more than 8%; 4, improving the strength of the clinker at different ages for 2-5 MPa, and being capable of improving the stability of the clinker; 5, improving the comprehensive economic benefit of the clinker by more than 10 Yuan / ton; and 6, respectively reducing emission of CO2 and SO3 in the cement production by more than 8%.

Owner:长沙市保灵建材助剂有限公司

Preparation technology of high-performance nickel-zinc ferrite material

InactiveCN109851344AHigh initial permeabilityReduce internal and external porosityInorganic material magnetismInductances/transformers/magnets manufacturePolyvinyl alcoholNickel-zinc ferrite

The invention relates to the technical field of magnetic materials, and discloses a preparation technology of a high-performance nickel-zinc ferrite material. The preparation technology comprises thefollowing steps: mixing main materials comprising iron oxide, zinc oxide and nickel oxide, then adding a first additive, and carrying out dry mixing to obtain a mixture, wherein the first additive iscomposed of molybdenum oxide, diyttrium trioxide, tin oxide and titanium dioxide; pre-sintering the mixture, and cooling the pre-sintered mixture to obtain a pre-sintered material; mixing the pre-sintered material with a second additive, and then performing wet crushing to obtain a crushed material, wherein the second additive is composed of lead oxide, boron oxide, vanadium pentoxide, calcium oxide, silicon dioxide ad bismuth oxide; adding polyvinyl alcohol to the crushed material, and carrying out spray granulation to obtain granules; adding the granules into a mold, and pressing the granules to form a blank; and carrying out microwave sintering treatment on the blank, and cooling the treated blank to room temperature to obtain the high-performance nickel-zinc ferrite material. The high-performance nickel-zinc ferrite material prepared in the present invention has excellent magnetic properties.

Owner:ZHONGDE ELECTRONICS

Preparing method of high-magnetism low-loss soft magnetic ferrite material

InactiveCN109608184AWell mixedHigh degree of densificationInorganic material magnetismCompression moldingPolyvinyl alcohol

The invention discloses a preparing method of a high-magnetism low-loss soft magnetic ferrite material. The method comprises the following steps of S1, mixing Fe2O3, Ni2O3, Mn3O4 and SnO2, conductingprimary ball milling after water is added, and then conducting drying to obtain a material A; S2, mixing the material A with MoO3 and Bi2O3, and then conducting cooling after pre-sintering to obtain amaterial B; S3, mixing the material B with TiO2 and SiO2, conducting secondary ball milling after water is added, and then conducting drying to obtain a material C; S4, mixing the material C with anaqueous polyvinyl alcohol solution and zinc stearate, and conducting pelleting and compression molding to obtain a material D; S5, conducting high-temperature sintering on the material D, and then cooling to the room temperature to obtain the high-magnetism low-loss soft magnetic ferrite material. By means of the preparing method of the high-magnetism low-loss soft magnetic ferrite material, the obtained product is high in magnetism, the loss is low in the using process, and the service life is long.

Owner:ZHONGDE ELECTRONICS

Process for preparing lithium bis (oxalato) borate

PendingCN112409393AAchieve thorough mixingReduce control difficultySecondary cellsGroup 3/13 element organic compoundsOXALIC ACID DIHYDRATELithium hydroxide

The invention discloses a process for preparing lithium bis (oxalato) borate. The process comprises the following steps: 1, uniformly mixing lithium hydroxide or lithium carbonate with oxalic acid oroxalic acid dehydrate; 2, adding ortho-boric acid or metaboric acid into the uniformly reacted raw materials in the step 1, and uniformly mixing; 3, performing dry pressing on the raw materials obtained in the step 2 under pressure to form tablets, and placing the pressed tablets in a drying box; 4, continuously adding phosphorus pentoxide into the drying box, and continuously performing drying toobtain a semi-finished product of lithium bis (oxalato) borate; 5, dissolving the semi-finished product obtained in the step 4 with anhydrous acetonitrile, filtering out insoluble substances, evaporating and concentrating until a white solid appears, recovering acetonitrile, and drying the obtained white solid in a drying oven to obtain a high-purity lithium bis (oxalato) borate product. Comparedwith the prior art, the process for preparing lithium bis (oxalato) borate has the advantages of simple operation, economy, environmental protection, low by-product content in the reaction and high reaction efficiency.

Owner:临沂小篆新材料科技有限公司

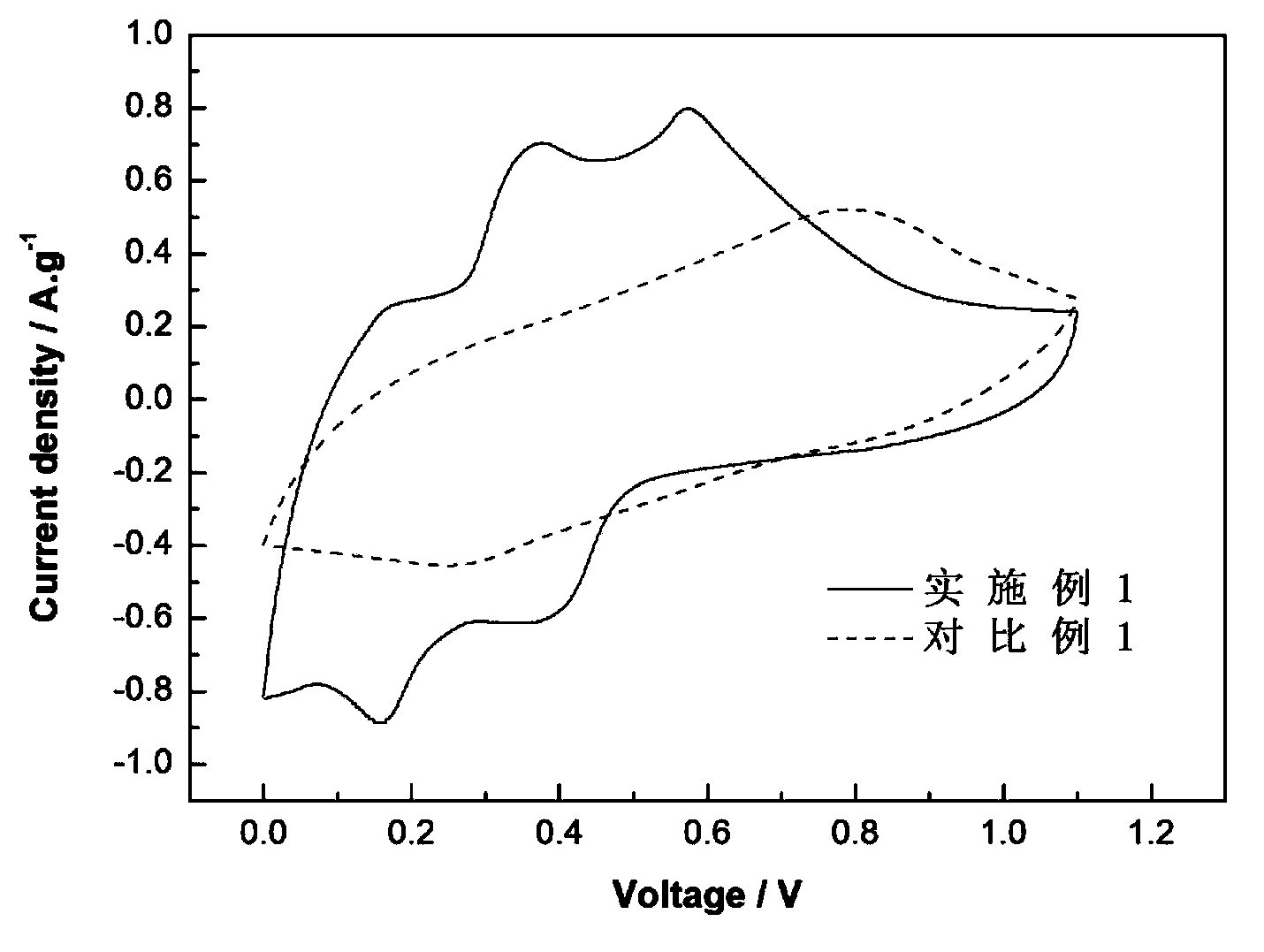

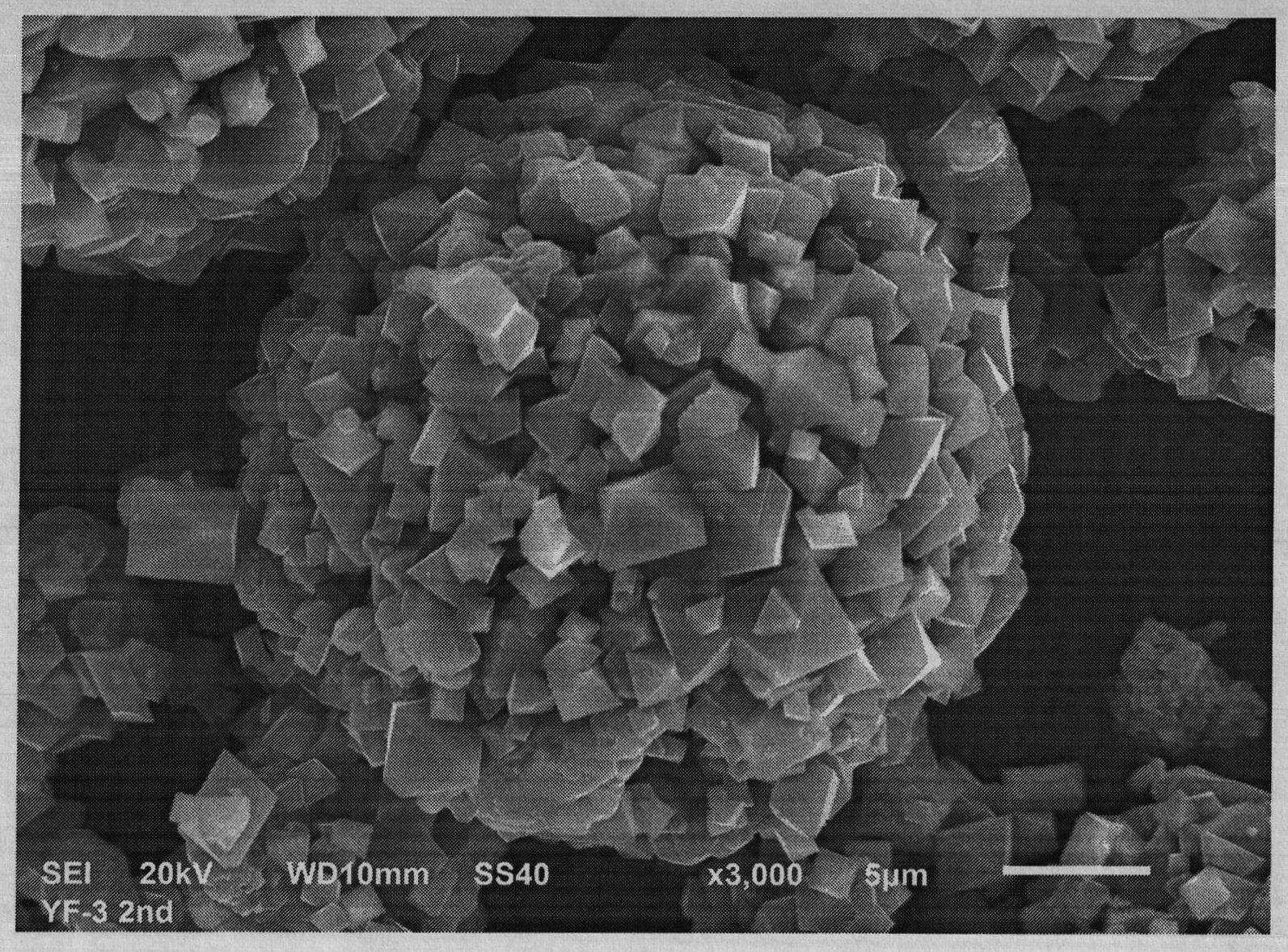

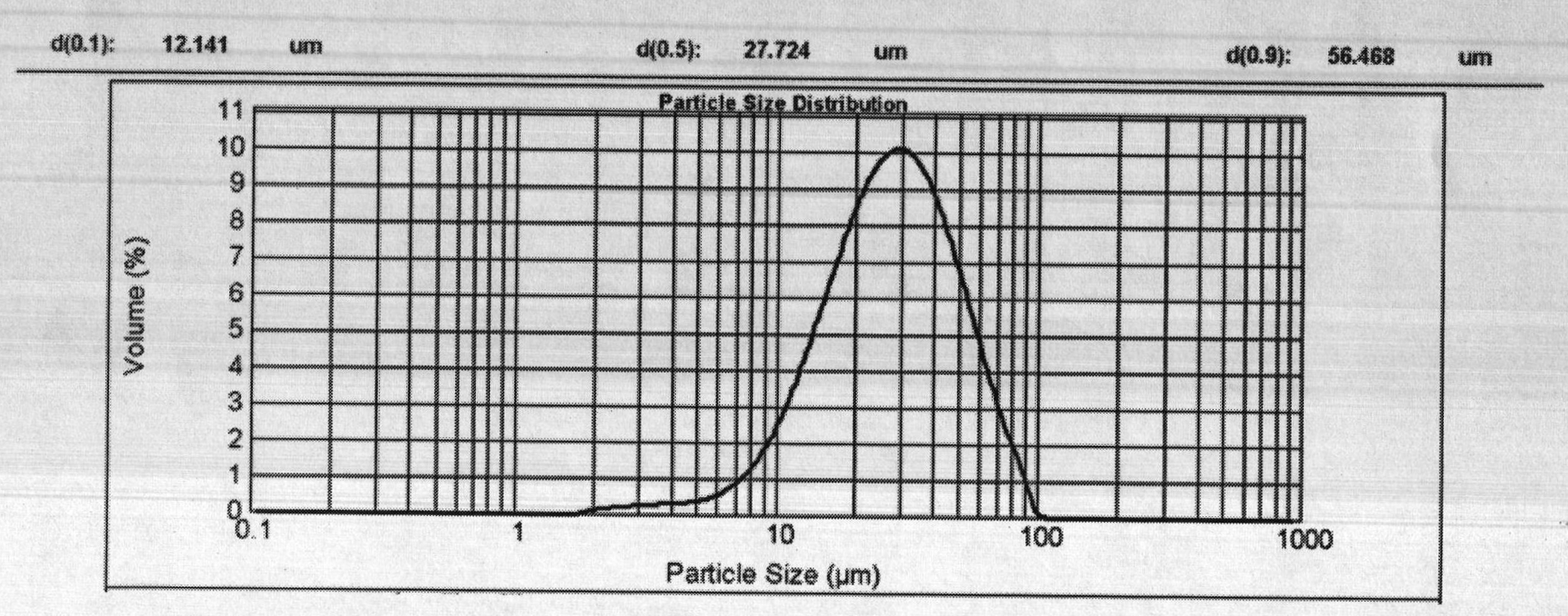

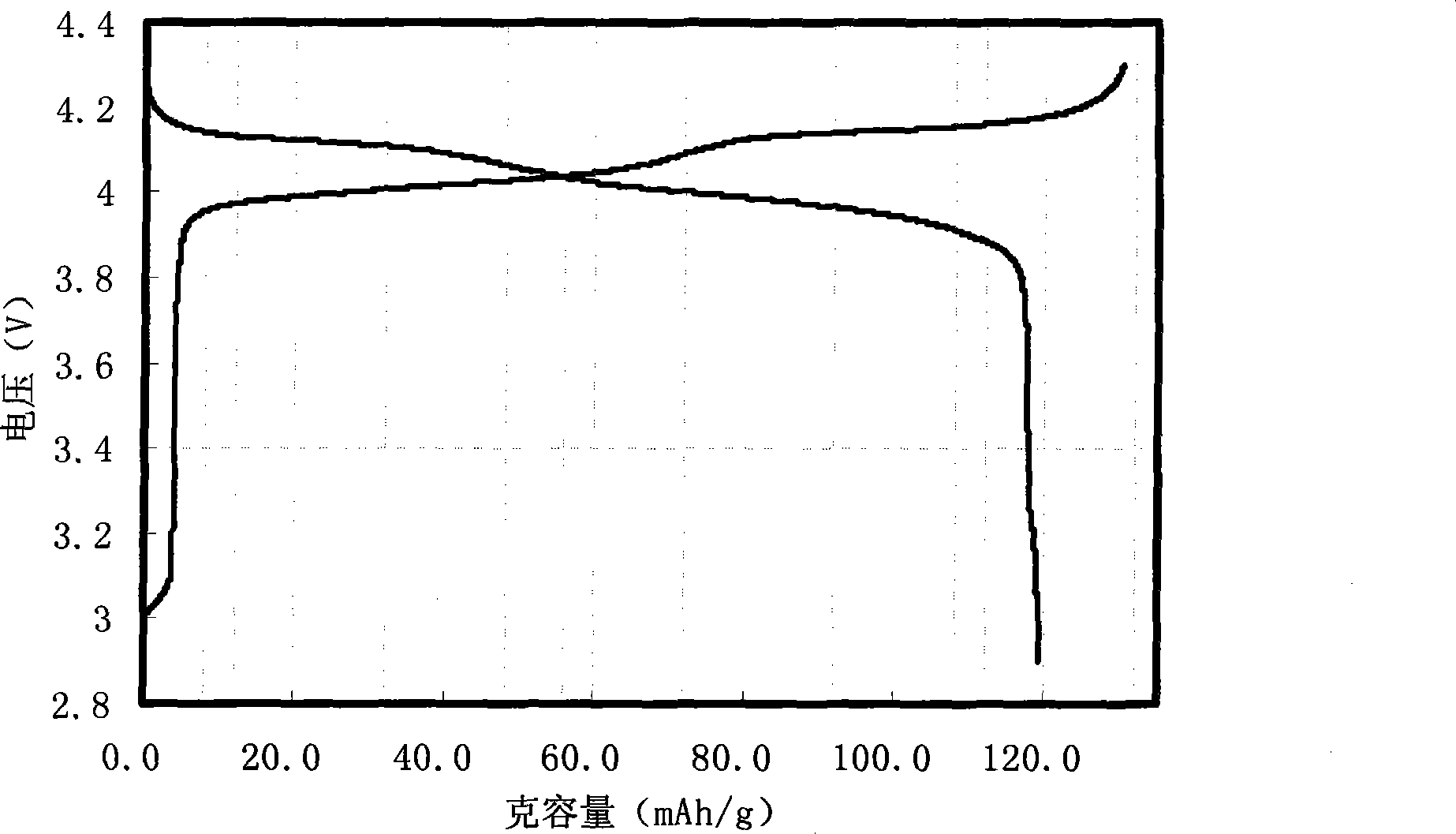

Method for preparing composite dopant LiMn2O4 by one-step sintering solid-phase reaction

ActiveCN102664254AImprove uniformityFacilitate solid phase reactionCell electrodesMineralogyElectrochemistry

The invention discloses a method for preparing composite dopant LiMn204 by one-step sintering solid-phase reaction. The method includes the following steps of (1) weighing a lithium source compound and one of dopant compounds to be placed in a high-speed mixed granulator with the mixing time set as 10-30 minutes according to a molar ratio of 0.5-0.6 of lithium to manganese; (2) adding another dopant compound to be mixed with the mixture with the mixing time set as 10-30 minutes; (3) adding the lithium source compound to be mixed fully with the mixing time set as 30-60 minutes; (4) adding binder to granulate all reactants by weight ratio after the reactants are mixed evenly; (5) feeding and drying fillings in a dryer; (6) placing the fillings in an atmosphere furnace to calcine after drying is completed; and (7) crushing and screening calcined fillings and performing each performance detection. Another substance is added to be mixed after each substance is added and is mixed for certain time, so that evenness of mixing materials is improved, solid-phase reaction is facilitated, and electrochemical performance of materials is improved. The method for preparing the composite dopant LiMn204 by the one-step sintering solid-phase reaction is simple in manufacturing process, capable of improving performance of the materials, and suitable for mass production of industrialization.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

Lanthanum zirconate-based ceramic granulated powder for atmospheric plasma spraying and preparation method thereof

The invention provides lanthanum zirconate-based ceramic granulated powder for atmospheric plasma spraying and a preparation method thereof. The preparation method comprises the steps that mixed materials with the particle size of 60 nm or below are pressed into blocks, the material point distance among powder particles is reduced, the content of pores is reduced, and the densification is improved; mixed oxide blocks are obtained, and a solid phase reaction in the following sintering process is conducted smoothly and conveniently. In combination of the sintering process, the solid phase reaction of different oxides in the mixed materials is achieved, a lanthanum zirconate-based material is obtained and further crushed, low-speed sanding with low energy consumption is conducted at first, the loss of grinding bodies is reduced, the preliminary refinement of the larger sintered particles after sintering is achieved, and further refinement is facilitated; in combination with high-speed sanding at the second stage, nano-powder is obtained, the dispersion is good, the particle size is even, and the granulation requirements are met. Subsequently, in strict accordance with a defined granulation mode, the ceramic granulated powder meeting APS requirements is obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

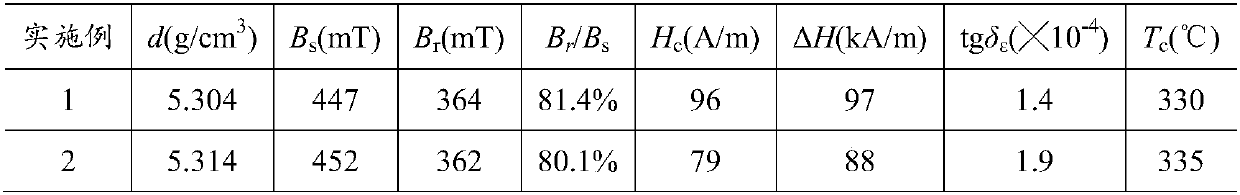

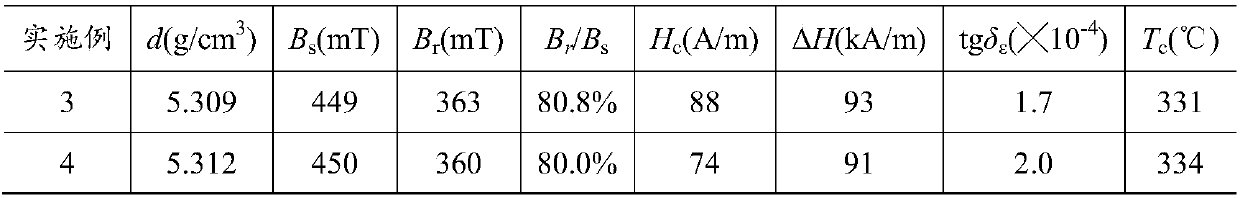

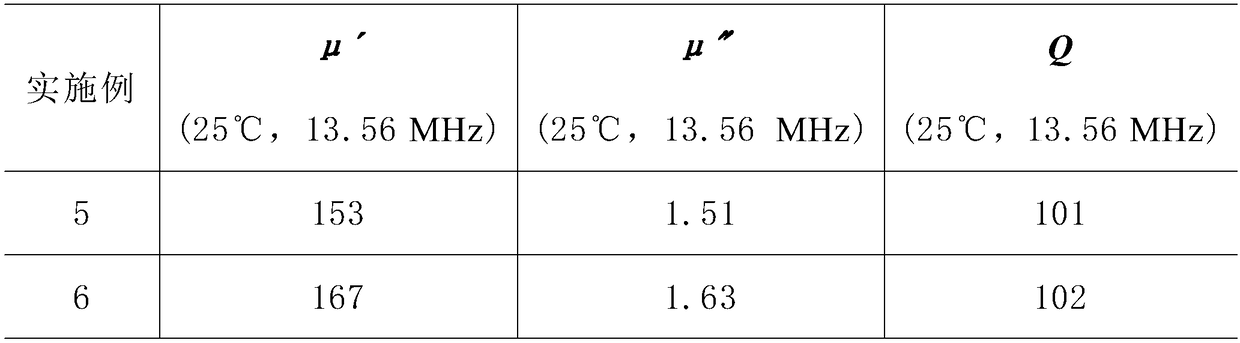

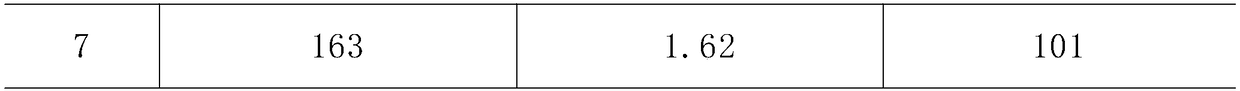

NiCuZn ferrite magnetic sheet for NFC and wireless charging

The invention discloses a NiCuZn ferrite magnetic sheet for NFC and wireless charging, and belongs to a method for manufacturing an electronic material. The method comprises the following steps of: carrying ball milling on 48-49 mol% of Fe2O3, 8-12 mol% of CuO, 15-18 mol% of NiO, the balance ZnO, doping 0.1-1wt% of Bi2O3, 0.01-0.1wt% of Co2O3, and 0.05-0.3% of SnO2, pre-sintering, carrying out curtain coating lamination and hydrostatic molding, discharging rubber, sintering, and the like to prepare the NiCuZn ferrite magnetic sheet. The ferrite magnetic sheet provided by the invention has highsaturation magnetic induction intensity, high residual magnetic induction intensity, high remanence ratio, low coercivity, low dielectric loss and low ferromagnetic resonance linewidth and can completely meet the applications of NFC and wireless charging.

Owner:GUIZHOU ZHENHUA HONGYUN ELECTRONICS

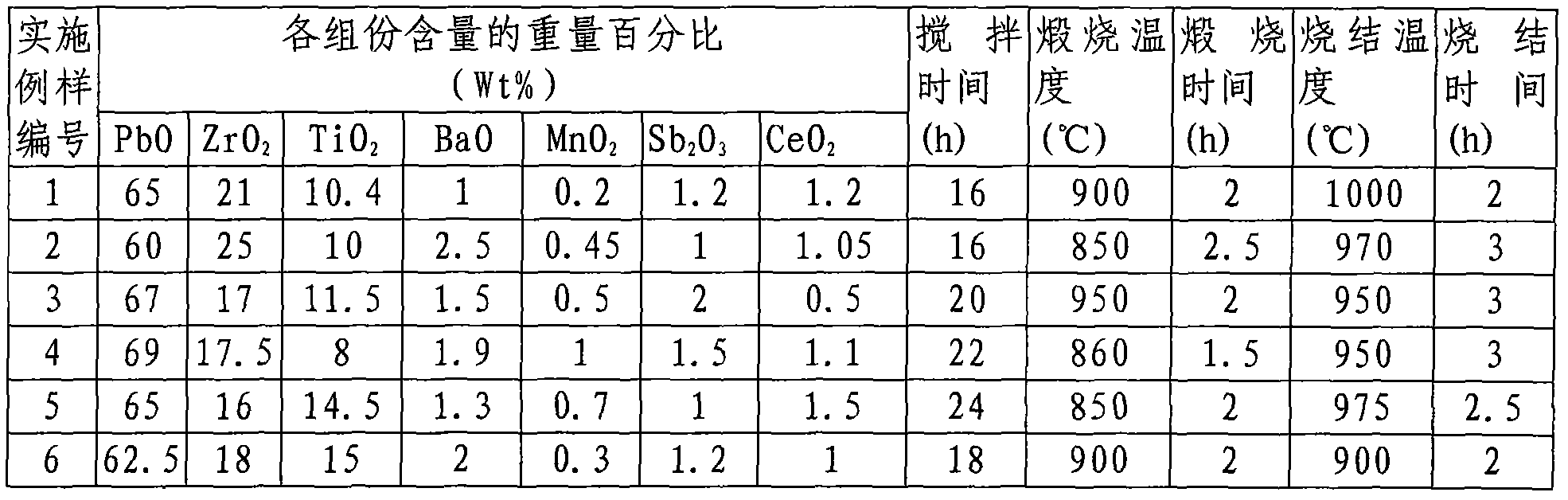

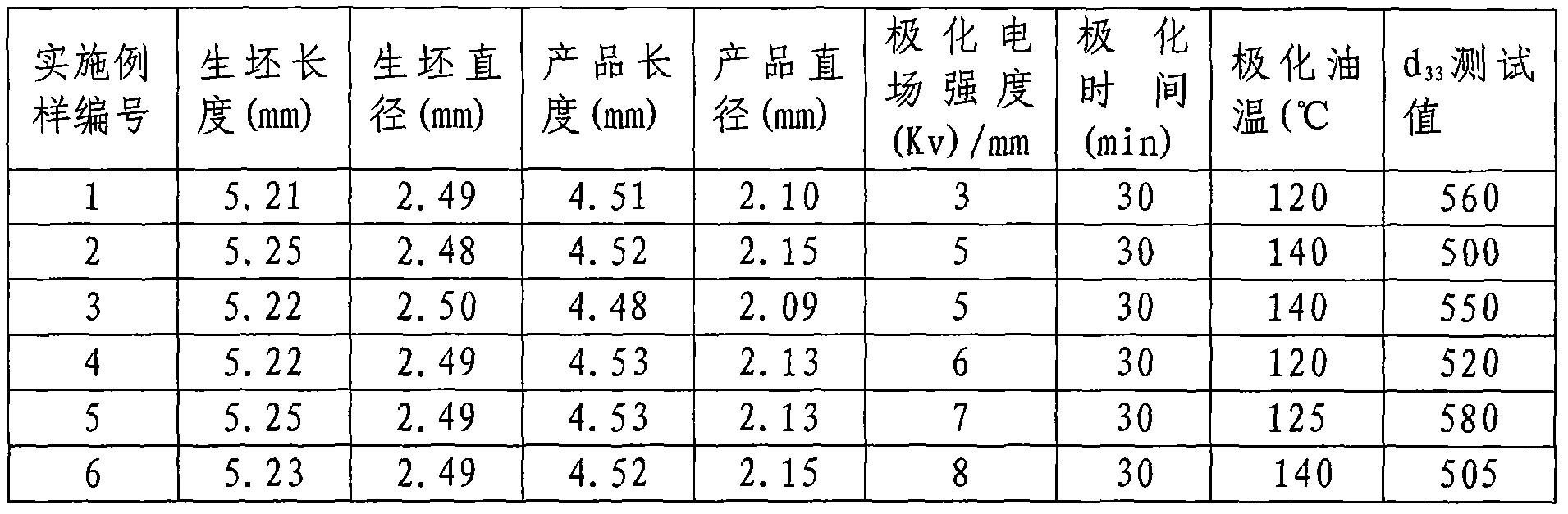

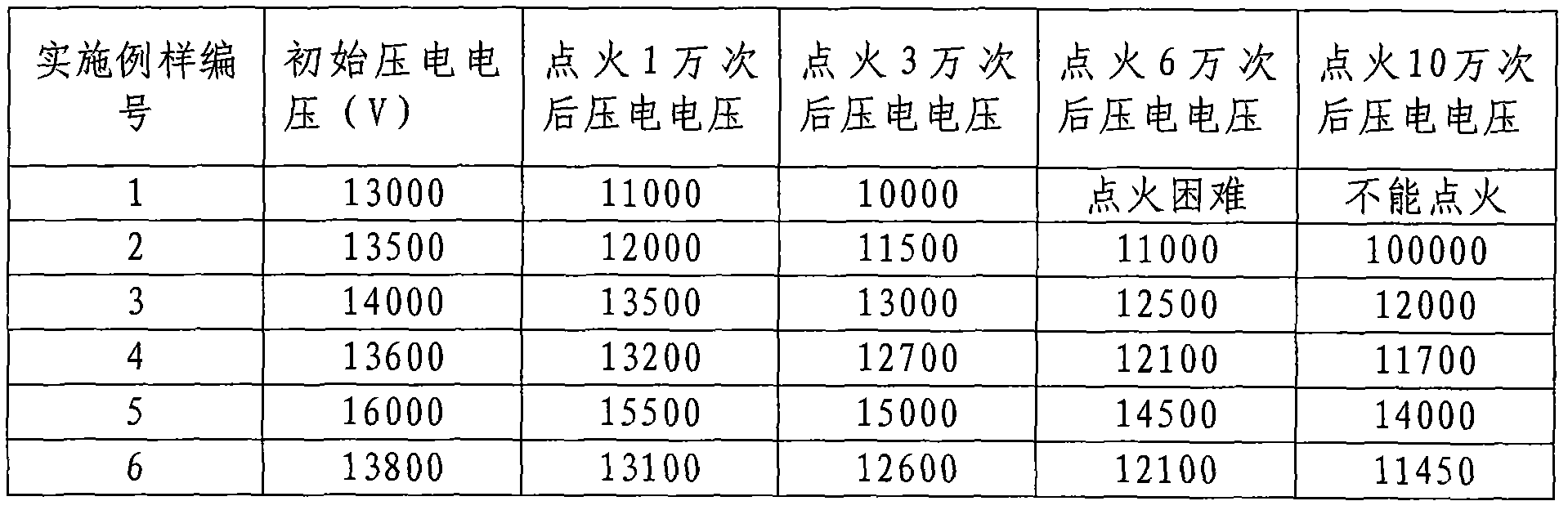

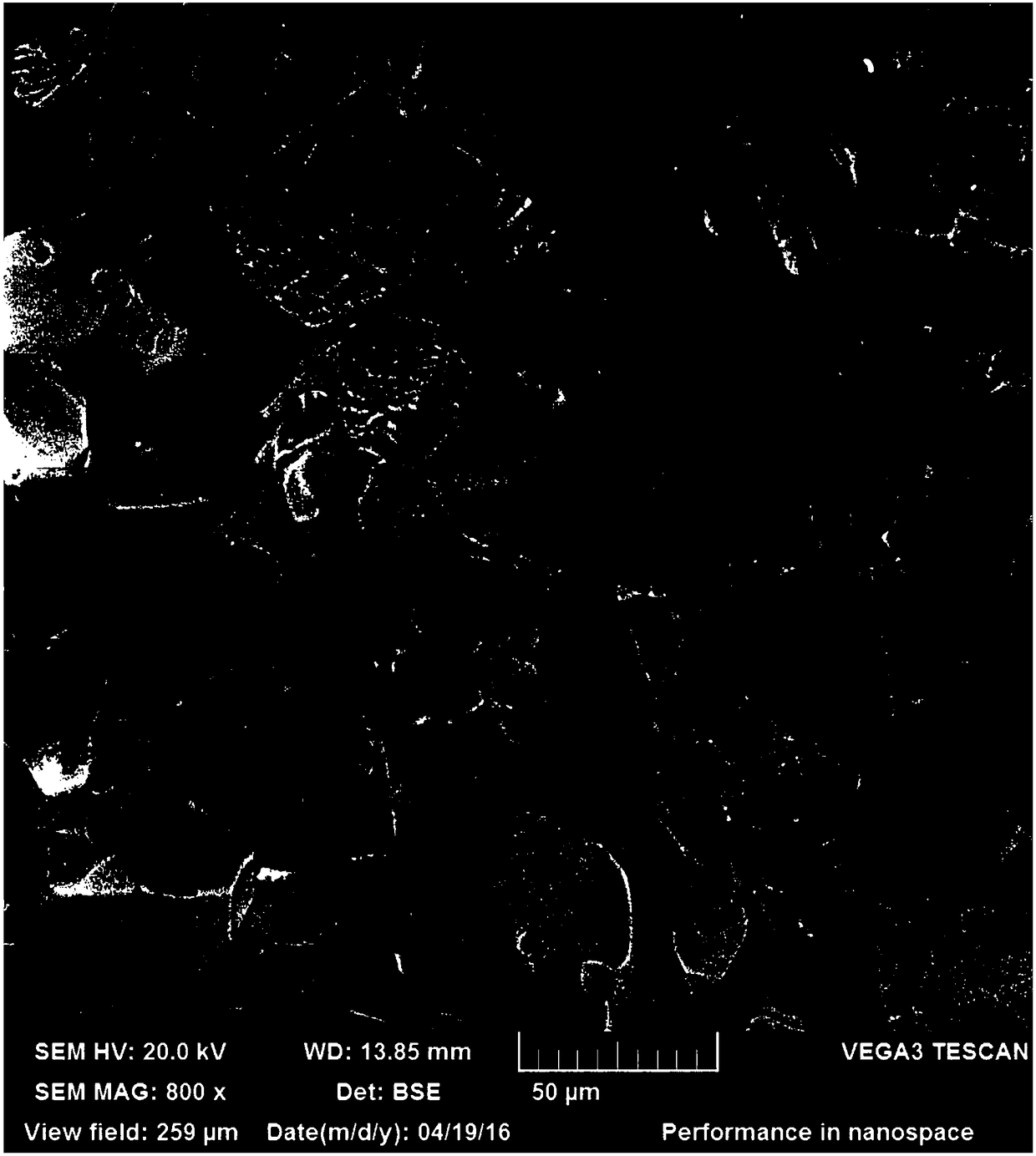

Gas ignition piezoelectric ceramics and manufacture process thereof

The invention relates to gas ignition piezoelectric ceramics and a manufacture process thereof, which can be mainly applied to a lighter, a piezolighter, an automatic gas stove and a bullet exploding device. The gas ignition piezoelectric ceramics comprises the following main raw materials of lead oxide (PbO), zirconium dioxide (ZrO2), titanium dioxide (TiO2) and barium oxide (BaO) and trace adding raw materials of cerium oxide (CeO2), antimonous oxide (Sb2O3) and manganese dioxide (MnO2). The manufacture process comprises the steps of: weighting the raw materials; ball-grinding; filter-pressing to form blocks; roasting; roasting powder; pelleting; dry-pressing for forming; loading green blocks into a pot; sintering; polishing; silver-plating; silver electrode firing; and polarizing to obtain the gas ignition piezoelectric ceramics. According to the invention, the sintering temperature is reduced, the environment pollution caused by lead oxide volatilization is decreased, dielectric and piezoelectric coefficients are improved, and the energy consumption is reduced during the sintering.

Owner:CHENZHOU GONGTIAN ELECTRONICS CERAMICS TECH

Technology for increasing volume density of tabular corundum

ActiveCN108191414AImproved grain boundary propertiesFacilitate solid phase reactionSolid phasesVolume density

The invention discloses a technology for increasing the volume density of tabular corundum. The technology comprises the steps that gamma-aluminum oxide and lanthanum oxide are mixed and ground, and ground powder is put into a ball forming machine, subjected to ball forming, dried and sintered to obtain tabular corundum, wherein the mass fraction of lanthanum oxide in the ground powder is 0.01-0.05%. According to the technology for increasing the volume density of tabular corundum, aiming at the characteristic that grain boundary migration influences crystal growth in solid-phase sintering inthe production process of tabular corundum, a small amount of lanthanum oxide is added to fine powder to improve the grain boundary characteristic, so that the aim of promoting sintering is achieved,the sintered product is high in volume density and good in crystal development, the liquid phase does not exist, and the sintering technology is easy to control.

Owner:山东恒嘉高纯铝业科技股份有限公司

Thermal insulating mortar and preparation method thereof

ActiveCN108069660AImprove responseLow thermal conductivityCeramicwareSodium BentonitePolystyrene particle

The invention discloses a thermal insulating mortar and a preparation method thereof and belongs to the technical field of preparation of building materials. The thermal insulating mortar is preparedfrom the following raw materials including silicate cement, coal ash, limestone powder, polystyrene particles, bentonite, thickener, heavy calcium carbonate powder, tackifier, carboxyethyl methylcellulose, lauryl sodium sulfate, calcium fluoride, styrene maleic anhydride copolymer and organosilicon-polyurethane copolymer, sodium carbonate and hydrochloric acid through the steps of mixing, stirringand the like. The thermal insulating mortar can improve the compressive strength and reduce dry apparent density, heat conductivity coefficient and water absorption per volume.

Owner:东至安东祥源新型建材有限公司

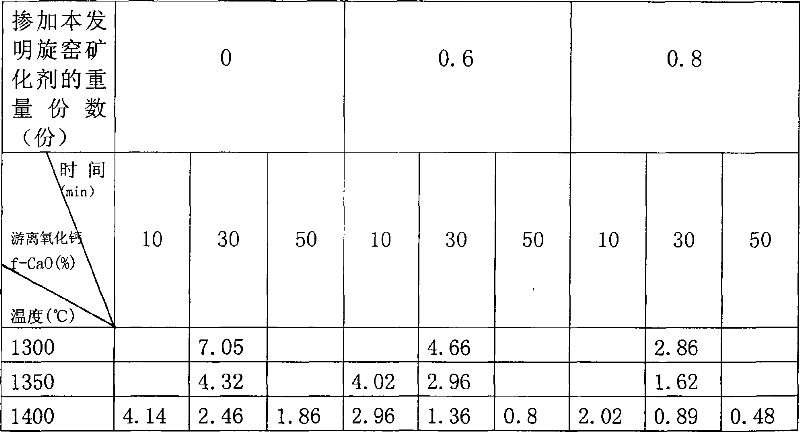

Rotary kiln mineralization agent and method for manufacturing same

The invention discloses an increasing production and energy-saving rotary kiln mineralizer of cement, allocating raw material according to mass percent as: 0-5 wt grammite, 5-15 wt sanbornite, 5-45 wt dolostone, 5-15 wt fayalite, 10-40 wt zeolite and 0-10 wt flour. This invention also discloses a preparing method of rotary kiln mineralizer, which comprises by the following steps: bruising separately; mixing dosage; packing; getting end product.

Owner:翟永生

A kind of preparation method of sodium manganese oxide

ActiveCN103896339BHigh purityIncrease the areaCell electrodesSecondary cellsChemical reactionCharge discharge

Owner:紫石能源有限公司

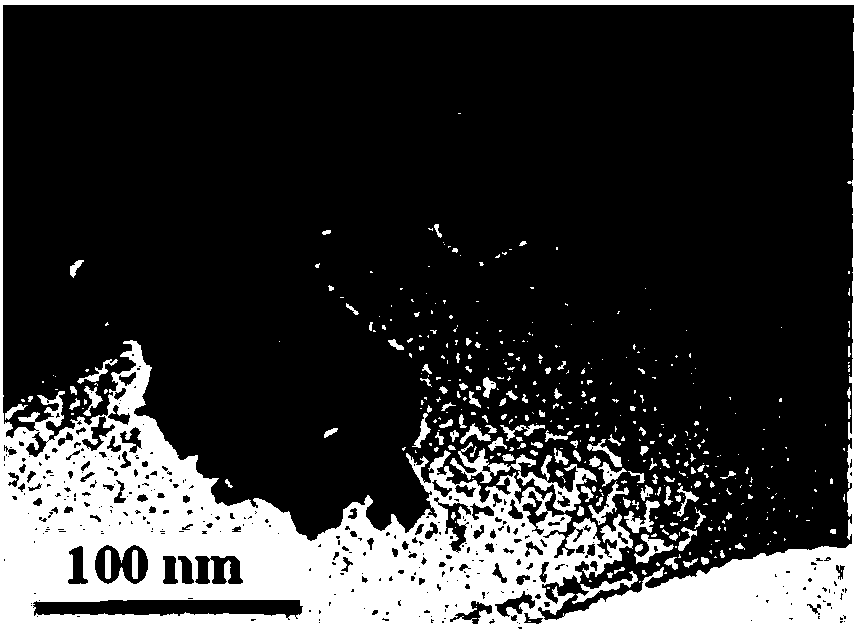

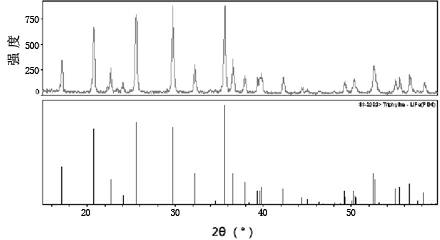

Low-temperature solid-phase synthesis method of nanoscale LiFePO4

InactiveCN102664257AShorten the diffusion processShorten the diffusion pathCell electrodesPhysical chemistryLithium-ion battery

The invention discloses a low-temperature solid-phase synthesis method of nanoscale LiFePO4 and relates to the technical field of lithium ion battery manufacture. The low-temperature solid-phase synthesis method is characterized in that at least one lithium salt, at least one ferric salt, at least one phosphor salt and at least one carbon source are subjected to ultrafine grinding and then is subjected to low temperature calcination in a non-oxidizing gas protective atmosphere to form the nanoscale LiFePO4. The low-temperature solid-phase synthesis method reduces a calcination temperature and shortens heat preservation time thereby reducing solid-phase reaction energy consumption, maintaining LiFePO4 activity and improving a yield and performance consistence of LiFePO4. The nanoscale LiFePO4 obtained by the low-temperature solid-phase synthesis method has good charge-discharge properties and a high gram volume more than 150mAh / g.

Owner:扬州奇峰纳米材料有限公司

Preparation of toughened nano permanent magnetic material

InactiveCN101475369BImprove puritySmall driving forceInorganic material magnetismSpray GranulationRare earth

The invention relates to a preparation method for plasticized type nanometer permanent magnetic material. The preparation method comprises the following steps: mixing nanometer SrCO3 and Fe2O3 according to a certain proportion, carrying out the intensive mixing and re-thinning of the raw material powder through ball milling, and adding rare earth oxides of La2O3 and Co2O3 during the ball milling according to a certain proportion; carrying out the spray granulation of the raw materials after ball milling, and placing the raw materials in a high temperature furnace for a solid phase reaction; carrying out a second ball milling of the synthesized Sr1-xLaxFe12-yCoyO19 powder, and carrying out the magnetic field forming of the powder after ball milling; and finally placing the formed powder inthe high temperature furnace for sintering. The preparation method adopts the nanometer level SrCO3 and Fe2O3 as the raw materials; compared with the conventional method adopting the raw materials at a micron level or with a greater particle size, the preparation method has the sufficient solid phase reaction, the high product purity and the low reaction temperature; and compared with other methods, the preparation method has a simple and economical process and a short production cycle, and is more suitable for the industrialized production.

Owner:LIAONING WUHUAN ENG TECH

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475BFlexible adjustment ratioHomogeneous coprecipitationCell electrodesAir atmosphereOXALIC ACID DIHYDRATE

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

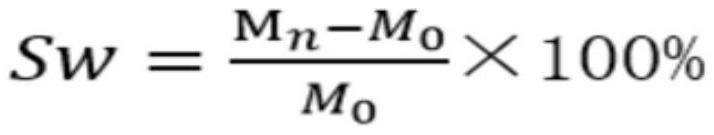

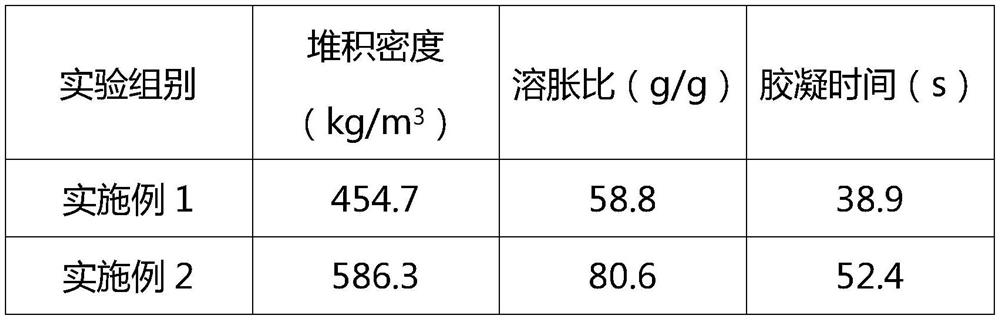

Plugging light sand and preparation method thereof

The invention discloses a plugging light sand. An inner core is made of construction waste, a layer of shell material wraps the outer portion of the inner core, and the shell material comprises the following raw materials in parts by weight: 10-20 parts of cement, 6-13 parts of silicon-containing sand, 1-3 parts of diatomite, 4-6 parts of sodium fluoride, 2-5 parts of polystyrene-butadiene copolymer, 7-10 parts of potassium bicarbonate, 0.2-0.4 part of lauroyl peroxide and 0.3-0.5 part of trimethylolpropane tris(3-aziridinylpropanoate). The plugging light sand is prepared by preparing construction waste, preparing an outer shell powder material, preparing spherical particles, and carrying out autoclaved curing and the like. The plugging light sand is extremely high in swelling ratio, rapidgelatinization can be achieved, and the plugging effect is improved.

Owner:DONGYING HUIYOU GASOLINEEUM NEW TECH DEV

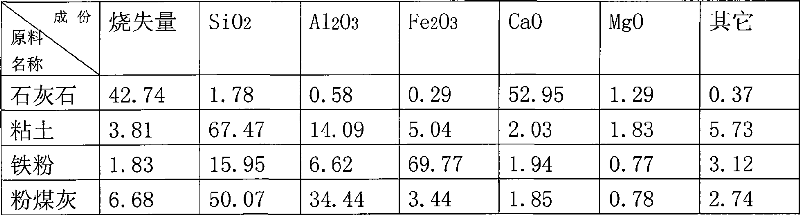

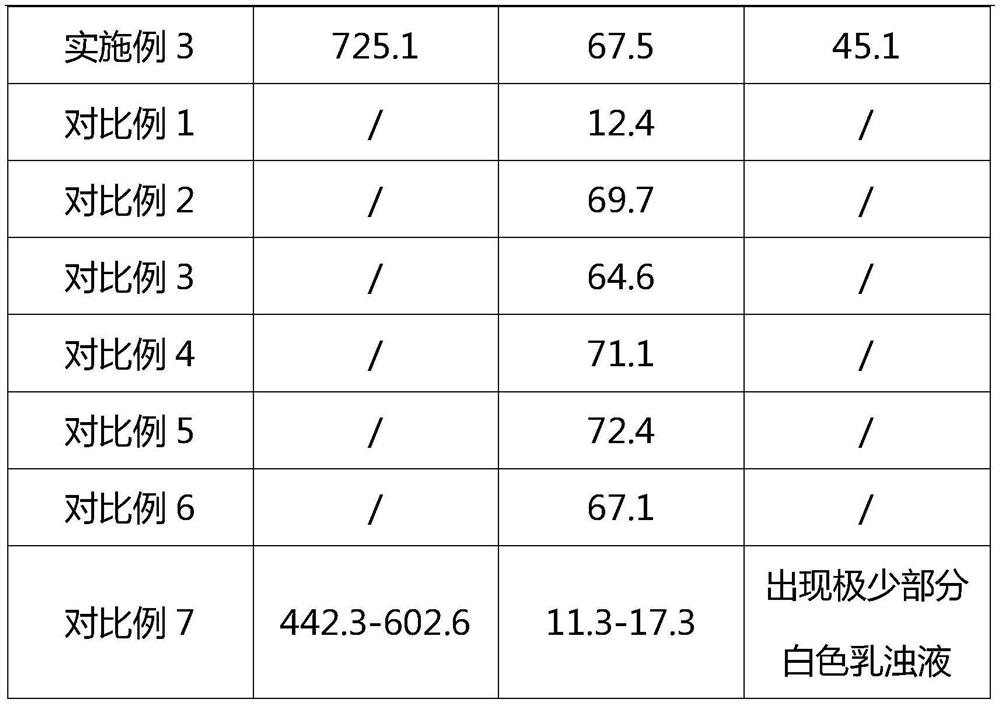

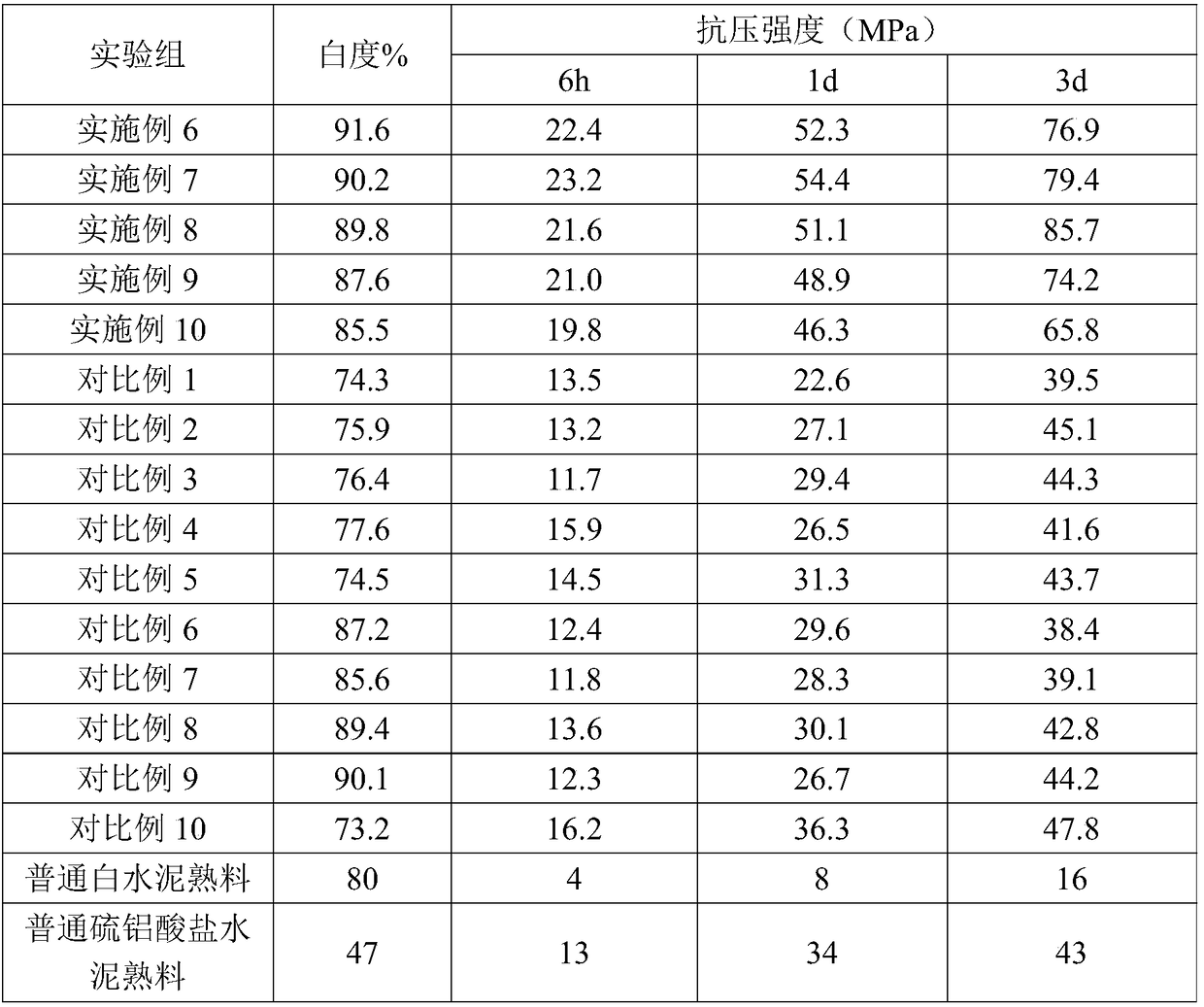

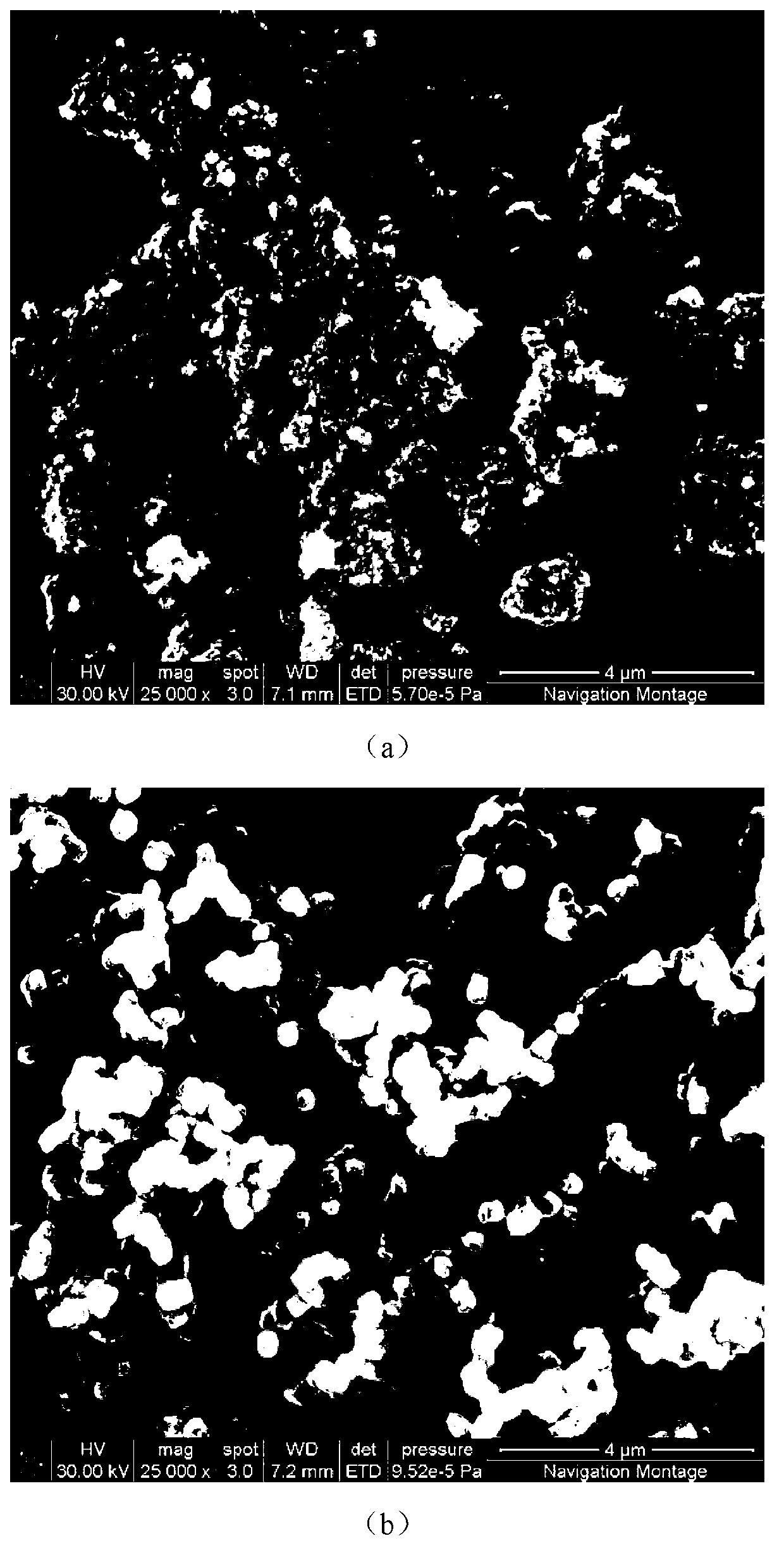

Composite mineralizing agent suitable for white sulphoaluminate cement clinker calcination and preparation method thereof

ActiveCN109354425AFacilitate solid phase reactionStable high temperature crystal phaseCement productionEnergy consumptionLiquid phase

The invention relates to a composite mineralizing agent suitable for white sulphoaluminate cement clinker calcination, and belongs to the technical field of cement mineralizing agents. The composite mineralizing agent comprises, by weight, 0.2-1.0 part of CaF2, 0.1-1.5 parts of SrO, 0.1-1.0 part of ZnO and 0.1-1.0 part of MgO. According to the composite mineralizing agent, the cooperative action with other mineralizing agents under low CaF2 doping to reduce the clinker sintering temperature can be achieved, energy consumption is reduced, liquid phase amount is improved, high-temperature crystalline phase is stabilized, and the performance of the white sulphoaluminate cement is significantly improved; the mineralizing agent has the advantages that the obtaining of raw materials is easy, thecost is low, the preparation method is simple, the implementation of the method is easy, and the composite mineralizing agent is suitable for industrialized production.

Owner:UNIV OF JINAN

Solid-phase sintering synthetic method of nano lithium iron phosphate (LiFePO4)

InactiveCN103280580AComplete restorationShorten the diffusion pathCell electrodesShielding gasSolid-phase synthesis

The invention discloses a solid-phase sintering synthetic method of nano lithium iron phosphate (LiFePO4). The method comprises the following steps of: stirring and mixing lithium salt, ferric oxide, phosphor salt and a carbon source; then adding a grinding medium for high-speed mechanical ball-milling to acquire solid-phase reaction hybrid precursor powder; and then directly sintering the hybrid precursor powder in the presence of a non-oxidizing protective gas to prepare the lithium iron phosphate without pre-sintering. Experimental results show that the lithium iron phosphate can be synthesized without a pre-sintering process of a traditional solid-phase sintering technology, and meanwhile, the sintering time can be shortened, the grain size is decreased, and the charge and discharge capacity of a battery is obviously improved under high magnification, so that the rapid charge and discharge performance of a LiFePO4 cathode material is improved. The solid-phase synthetic method provided by the invention is convenient and energy-saving.

Owner:NANJING UNIV

Strontium ferrite magnetic powder additive

The invention discloses a strontium ferrite magnetic powder additive and belongs to the technical field of magnetic material processing. The strontium ferrite magnetic powder additive is prepared from the following specific substances: bismuth trioxide, calcium chloride, vanadic oxide, magnesium oxide, sodium silicate, and barium carbonate. The prepared additive is capable of effectively improving the overall characteristic of the strontium ferrite magnetic powder, enhancing the intrinsic coercive force and magnetic remanence intensity thereof, reducing the processing temperature by about 200 DEG C and favorably saving the manufacturing cost, and is relatively high in popularization and use values.

Owner:马鞍山起劲磁塑科技有限公司

Preparation of toughened nano permanent magnetic material

InactiveCN101475369AImprove puritySmall driving forceInorganic material magnetismSpray GranulationSolid reaction

The invention relates to a preparation method for plasticized type nanometer permanent magnetic material. The preparation method comprises the following steps: mixing nanometer SrCO3 and Fe2O3 according to a certain proportion, carrying out the intensive mixing and re-thinning of the raw material powder through ball milling, and adding rare earth oxides of La2O3 and Co2O3 during the ball milling according to a certain proportion; carrying out the spray granulation of the raw materials after ball milling, and placing the raw materials in a high temperature furnace for a solid phase reaction; carrying out a second ball milling of the synthesized Sr1-xLaxFe12-yCoyO19 powder, and carrying out the magnetic field forming of the powder after ball milling; and finally placing the formed powder in the high temperature furnace for sintering. The preparation method adopts the nanometer level SrCO3 and Fe2O3 as the raw materials; compared with the conventional method adopting the raw materials at a micron level or with a greater particle size, the preparation method has the sufficient solid phase reaction, the high product purity and the low reaction temperature; and compared with other methods, the preparation method has a simple and economical process and a short production cycle, and is more suitable for the industrialized production.

Owner:LIAONING WUHUAN ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com