Technology for increasing volume density of tabular corundum

A technology of platy corundum and bulk density, which is applied in the field of refractory materials, can solve problems such as unsatisfactory results, achieve good results, promote solid-phase reactions, and have good high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Mix lanthanum oxide and γ-alumina powder and then co-grind to obtain a co-milled fine powder with a D50 of 7 μm, in which the mass ratio of lanthanum oxide to γ-alumina powder is 0.01:99.99;

[0039] 2. Add the fine powder to the Φ2.4m×6m drum type pelletizing machine, and continuously spray the pelletizing liquid to form small raw material pellets with a diameter of 10-12mm. After processing the pellets, add them to the pellets of the same specification. In the machine, under the same operation, a large raw material ball with a diameter of 20-25mm is formed, and the ball liquid is pure water;

[0040] 3. The large raw material balls are continuously dried at 400~450℃ and then sent to the shaft kiln. After being fired at 1850~1900℃, they are cooled to 80±5℃ and exit the kiln. After selection, they are broken into products of different specifications and sizes.

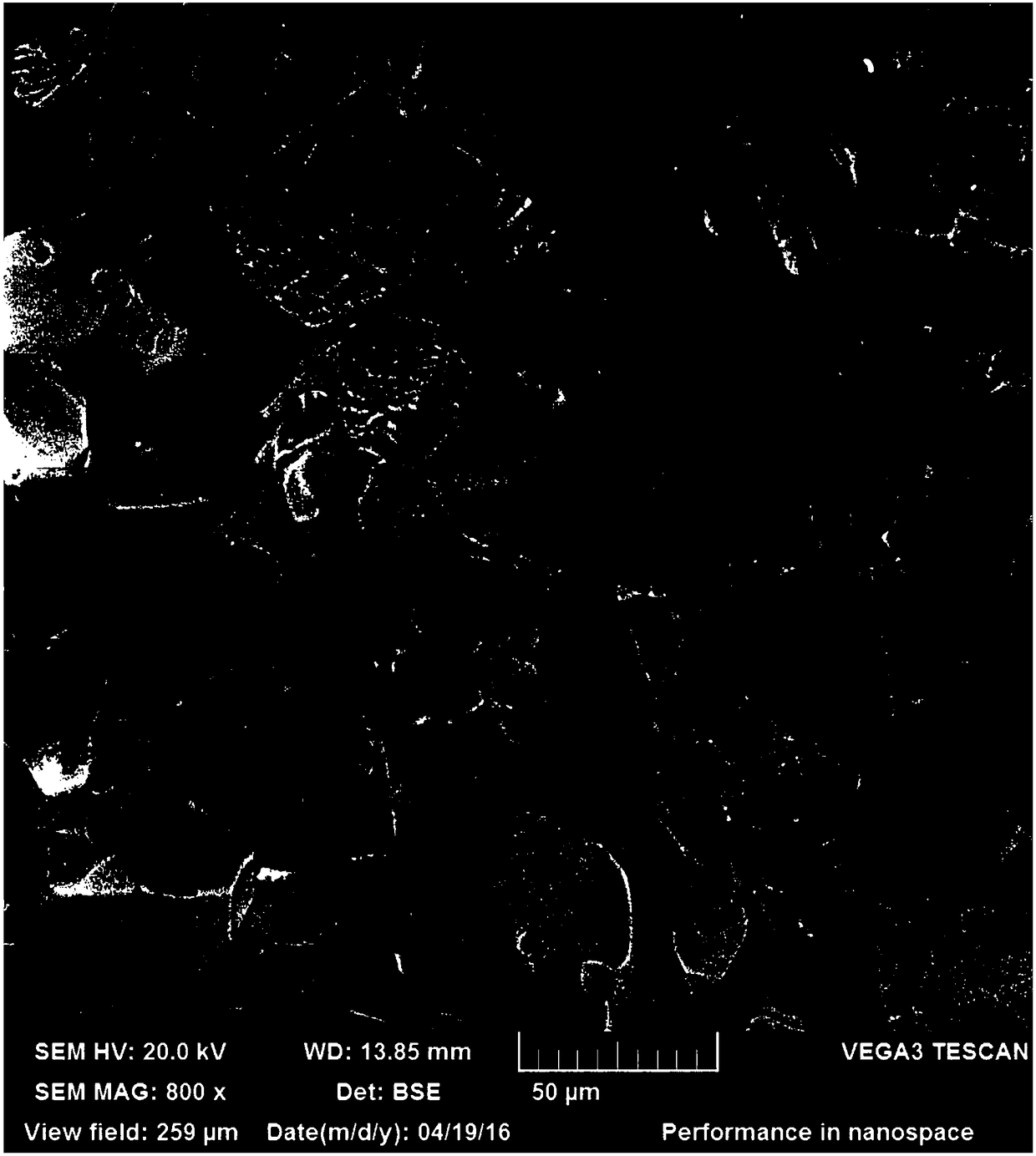

[0041] The burned products such as figure 1 As shown, the bulk density is 3.65g / cm 3 .

Embodiment 2

[0043] 1. Mix lanthanum oxide and γ-alumina powder and then grind together to obtain a co-milled fine powder with a D50 of 8μm, in which the mass ratio of lanthanum oxide to γ-alumina powder is 0.05:99.95;

[0044] 2. Add the fine powder to the Φ2.4m×6m drum type pelletizing machine, and continuously spray the pelletizing liquid to form small raw material pellets with a diameter of 10-12mm. After processing the pellets, add them to the pellets of the same specification. In the machine, under the same operation, a large raw material ball with a diameter of 20-25mm is formed, and the ball liquid is pure water;

[0045] 3. The large raw material balls are continuously dried at 400~450℃ and then sent to the shaft kiln. After being fired at 1850~1900℃, they are cooled to 80±5℃ and exit the kiln. After selection, they are broken into products of different specifications and sizes.

[0046] The bulk density of the burned product is 3.67g / cm 3 .

Embodiment 3

[0048] 1. Mix lanthanum oxide and γ-alumina powder and then grind together to obtain a co-milled fine powder with a D50 of 10 μm, in which the mass ratio of lanthanum oxide to γ-alumina powder is 0.025:99.975;

[0049] 2. Add the fine powder to the Φ2.4m×6m drum type pelletizing machine, and continuously spray the pelletizing liquid to form small raw material pellets with a diameter of 10-12mm. After processing the pellets, add them to the pellets of the same specification. In the machine, under the same operation, a large raw material ball with a diameter of 20-25mm is formed, and the ball liquid is pure water;

[0050] 3. The large raw material balls are continuously dried at 400~450℃ and then sent to the shaft kiln. After being fired at 1850~1900℃, they are cooled to 80±5℃ and exit the kiln. After selection, they are broken into products of different specifications and sizes.

[0051] The bulk density of the burned product is 3.66g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com