A process for increasing the volume density of tabular alumina

A tabular corundum and bulk density technology, applied in the field of refractory materials, can solve problems such as unsatisfactory results, achieve good effects, improve grain boundary characteristics, and increase bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Co-milling after mixing lanthanum oxide and γ-alumina powder to obtain a co-milled fine powder with a D50 of 7 μm, wherein the mass ratio of lanthanum oxide and γ-alumina powder is 0.01:99.99;

[0039] 2. Add the fine powder into the Φ2.4m×6m drum-type ball forming machine, spray into the ball forming liquid continuously to form small raw material balls with a diameter of 10-12mm, and add the small balls to the ball forming machine of the same specification after treatment. In the machine, under the same operation, large raw material balls with a diameter of 20-25 mm are formed, and the ball forming liquid is pure water;

[0040] 3. The large raw meal balls are continuously dried at 400-450°C and then sent into the shaft kiln. After being fired at 1850-1900°C, they are cooled to 80±5°C and exit the kiln. After inspection, they are crushed into products of different specifications.

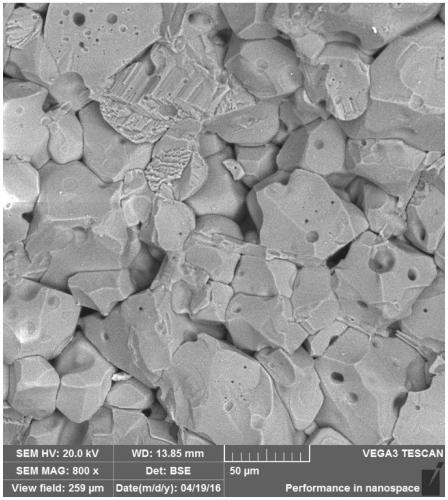

[0041] Burnt products such as figure 1 As shown, the bulk density is 3.65g / cm 3 . ...

Embodiment 2

[0043] 1. Co-milling after mixing lanthanum oxide and γ-alumina powder to obtain a co-milled fine powder with a D50 of 8 μm, wherein the mass ratio of lanthanum oxide and γ-alumina powder is 0.05:99.95;

[0044] 2. Add the fine powder into the Φ2.4m×6m drum-type ball forming machine, spray into the ball forming liquid continuously to form small raw material balls with a diameter of 10-12mm, and add the small balls to the ball forming machine of the same specification after treatment. In the machine, under the same operation, large raw material balls with a diameter of 20-25 mm are formed, and the ball forming liquid is pure water;

[0045] 3. The large raw meal balls are continuously dried at 400-450°C and then sent into the shaft kiln. After being fired at 1850-1900°C, they are cooled to 80±5°C and exit the kiln. After inspection, they are crushed into products of different specifications.

[0046] The bulk density of the burned product is 3.67g / cm 3 .

Embodiment 3

[0048] 1. Co-milling after mixing lanthanum oxide and γ-alumina powder to obtain a co-ground fine powder with a D50 of 10 μm, wherein the mass ratio of lanthanum oxide and γ-alumina powder is 0.025:99.975;

[0049]2. Add the fine powder into the Φ2.4m×6m drum-type ball forming machine, spray into the ball forming liquid continuously to form small raw material balls with a diameter of 10-12mm, and add the small balls to the ball forming machine of the same specification after treatment. In the machine, under the same operation, large raw material balls with a diameter of 20-25 mm are formed, and the ball forming liquid is pure water;

[0050] 3. The large raw meal balls are continuously dried at 400-450°C and then sent into the shaft kiln. After being fired at 1850-1900°C, they are cooled to 80±5°C and exit the kiln. After inspection, they are crushed into products of different specifications.

[0051] The bulk density of the burned product is 3.66g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com