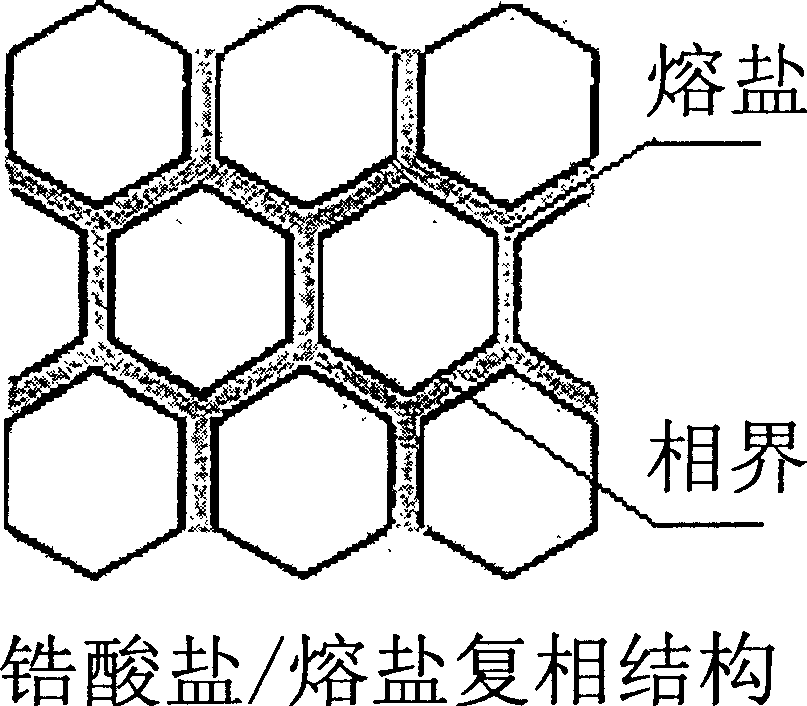

Multi-phase structure designed high-conductive electrical barium zirconate proton conductor and preparation method thereof

A high conductivity, proton conductor technology, applied in the direction of conductors, conductive materials, conductive materials, etc., can solve the problems of good stability, poor stability, etc., to improve grain boundary characteristics, increase proton conductivity, and enhance interfacial proton conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 1 mole of BaCO 3 , 0.95 mol ZrO 2 , 0.05 mole Y 2 o 3, using water as the medium for ball milling for 4 hours, drying, grinding, sieving, and calcining at 1200 for 12 hours to obtain the matrix material. Then add 0.01 mole of ZnO, ball mill and mix for 4 hours, then dry, grind and sieve, add 0.05 mole of NaOH in a manual grinding manner, and grind for 1 hour to ensure the uniformity of the mixture. The mixture was put into a mold for dry pressing at a pressure of 50 MPa, and then subjected to isostatic pressing at 200 MPa; sintered at 1200 °C in an air atmosphere with a heating rate of 2 °C / min, kept for 10 hours, and then naturally cooled to room temperature to obtain A zirconate proton conductor material with good conductivity, the conductivity reaches 5.86×10 at 700°C -5 S / cm.

Embodiment 2

[0020] Take 1 mole of BaCO 3 , 0.70 mol ZrO 2 , 0.30 mole Y 2 o 3 The matrix material was prepared, and mixed by ball milling with water for 10 hours, dried, ground, sieved, and calcined at 1400 for 4 hours. Then add 0.10 mole of ZnO, ball mill and mix for 10 hours, then dry, grind and sieve, add 0.50 mole of NaOH in a manual grinding manner, and grind for 1 hour to ensure the uniformity of the mixture. The mixture was put into a mold for dry pressing at a pressure of 120 MPa, and then subjected to isostatic pressing at 350 MPa; sintered at 1500 °C in an air atmosphere, with a heating rate of 10 °C / min, kept for 2 hours, and then naturally cooled to room temperature to obtain A zirconate proton conductor material with good electrical conductivity, with a conductivity of 4.29×10 at 700°C -4 S / cm. .

Embodiment 3

[0022] Take 1 mole of BaCO 3 , 0.90 mol ZrO 2 , 0.10 mole Y 2 o 3 , using water as the medium for ball milling and mixing for 6 hours, drying, grinding, sieving, and calcining at 1400 for 6 hours to obtain the matrix material. Then add 0.03 mole of ZnO, mix by ball milling for 6 hours, then dry, grind and sieve, add 0.40 mole of NaOH in a manual grinding manner, and grind for 1 hour to ensure the uniformity of the mixture. Put the mixture into a mold for dry pressing at a pressure of 120MPa, and then undergo isostatic pressing at 200MPa; sinter at 1350°C in an air atmosphere with a heating rate of 2°C / min, keep it warm for 4 hours, and then naturally cool to room temperature to obtain High conductivity zirconate proton conductor material, the conductivity reaches 3.25×10 at 700°C -4 S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com