A lead storage battery grid alloy containing nano-tungsten carbide material and its preparation method

A tungsten carbide material, nano-tungsten carbide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable energy saving, easy generation of lead slag, weak anti-oxidation ability, etc., to save energy, reduce intergranular corrosion, The effect of increasing the grain boundary area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

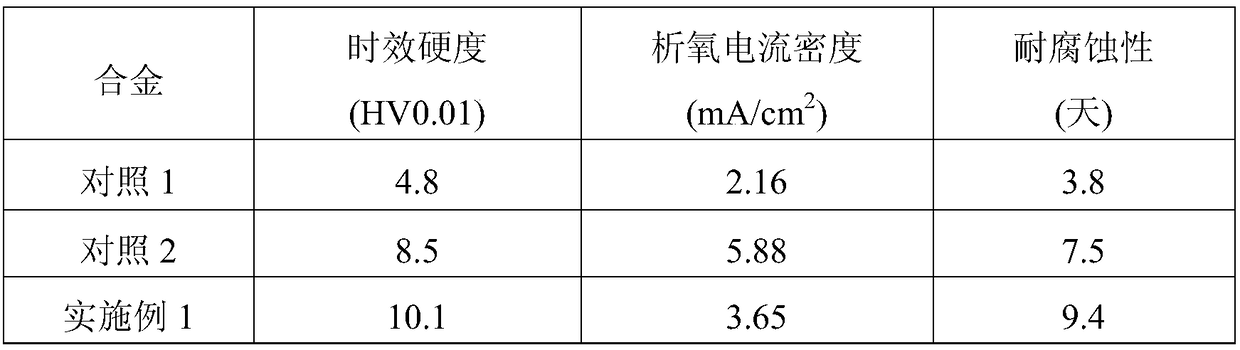

Examples

Embodiment 1

[0035] 1. Preparation of master alloy

[0036] The formula of the master alloy is as follows: tin: 5.0%, nanometer tungsten carbide 3.0%, lead as the balance, and the above ratios are all percentages by weight.

[0037] (1) according to above-mentioned proportioning, take metal tin, nano-tungsten carbide, lead;

[0038] (2) Add 2 / 3 of the raw material lead into the intermediate frequency smelting furnace and heat to 500°C to fully melt the lead pellets;

[0039] (3) Add metal tin to the melt, and stir at a low speed (magnetic or mechanical stirring) for 30 minutes, so that the metal tin is completely melted and mixed evenly;

[0040] (4) Cool down to 380°C, wrap the nano-tungsten carbide powder with the required mass ratio with lead skin, press it into the lead liquid, stir at a medium speed for 3 hours, so that the tungsten carbide powder is evenly dispersed in the lead liquid;

[0041] (5) Measure the composition of the master alloy, and cast the alloy ingot after reaching...

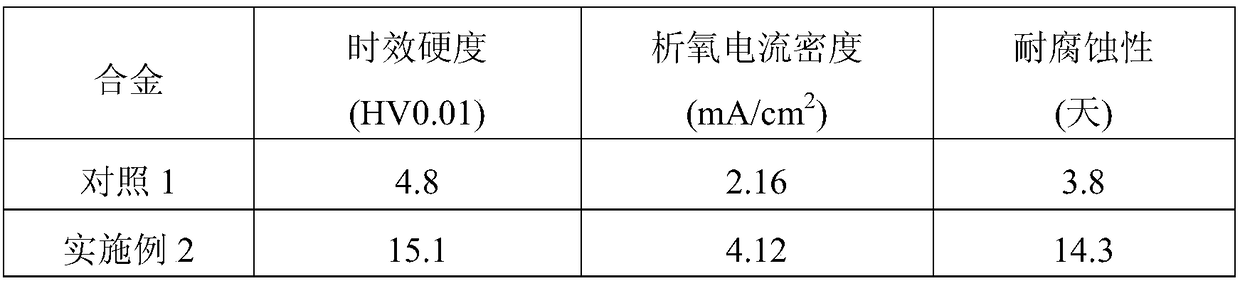

Embodiment 2

[0065] In terms of weight percentage, the composition is: 0.5% of tin, 0.5% of nano-tungsten carbide, and the balance of lead.

[0066] The preparation method and test method are the same as in Example 1, and the results are shown in Table 2.

[0067] Table 2

[0068]

[0069] The alloy formula of the above comparison 1 is a conventionally used grid alloy formula: 0.08% calcium, 1.0% tin, 0.05% aluminum, and the balance of lead.

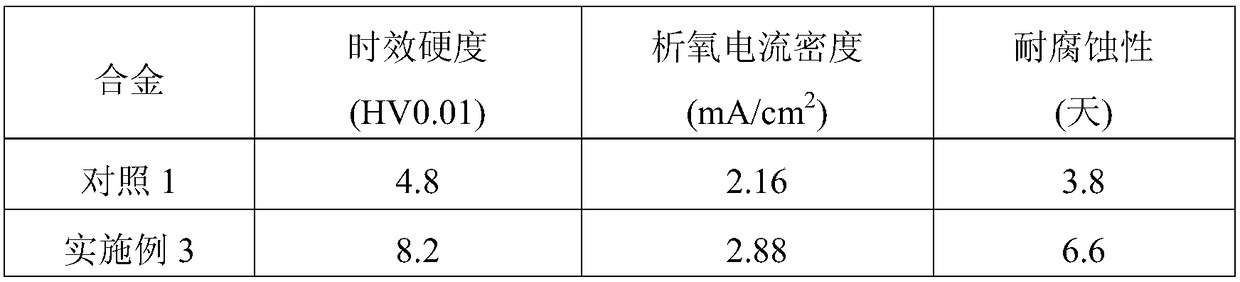

Embodiment 3

[0071] In terms of weight percentage, the composition is: 0.5% of tin, 0.1% of nano-tungsten carbide, and the balance of lead.

[0072] The preparation method and test method are the same as in Example 1, and the results are shown in Table 3.

[0073] table 3

[0074]

[0075] The alloy formula of the above comparison 1 is a conventionally used grid alloy formula: 0.08% calcium, 1.0% tin, 0.05% aluminum, and the balance of lead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com