Plugging light sand and preparation method thereof

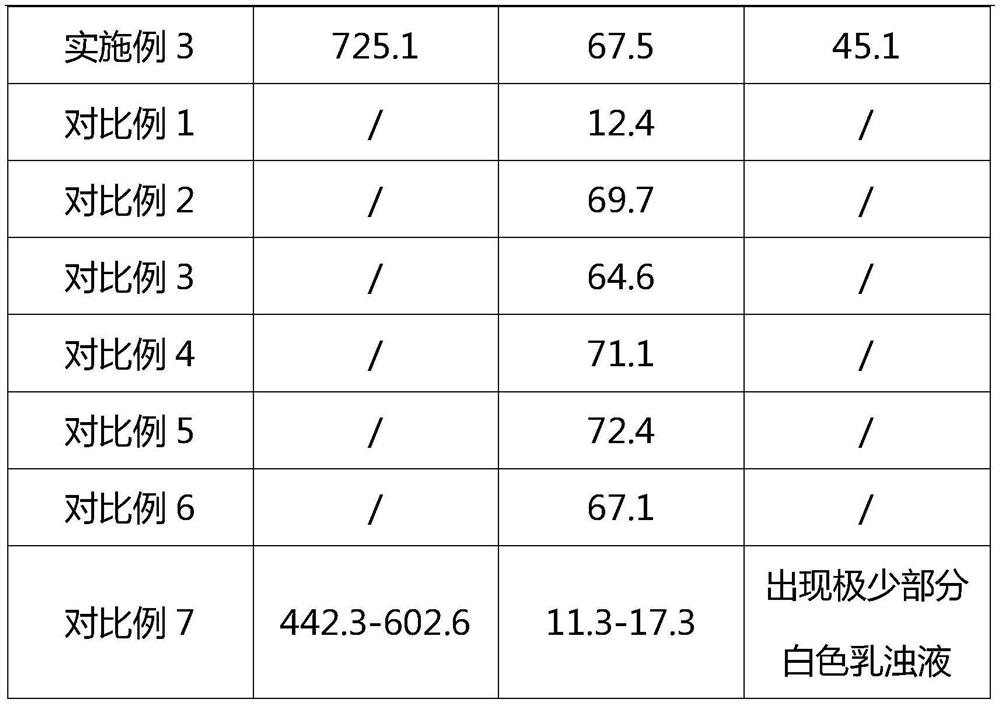

A technology of light sand and silica sand, which is applied in the field of plugging, can solve the problems of not being able to gel quickly and the swelling ratio is small, and achieve the effects of saving resources, increasing the swelling ratio, and shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the described plugging lightweight sand comprises the following steps:

[0029] (1) Construction waste is obtained by crushing waste construction aerated concrete to particles with a particle size of ≤6 mm;

[0030] (2) Cement, silica sand, diatomaceous earth, sodium fluoride, polystyrene butadiene copolymer, potassium bicarbonate, lauroyl peroxide, trimethylolpropane tris (3- aziridinyl propionic acid ester) after stirring for 5-8min at a rotating speed of 100-200r / min, the shell powder material is made;

[0031] (3) Pre-absorbing the construction waste prepared in step (1) until the water content is 14%-18%, put it into a ball forming pan, roll continuously in the ball forming pan, and spray 7-11 parts by weight of acrylic acid emulsion to make After the particle surface is wetted, evenly sprinkle the shell powder material prepared in step (2) into the ball forming area to form spherical particles;

[0032] (4) After the spherical particles...

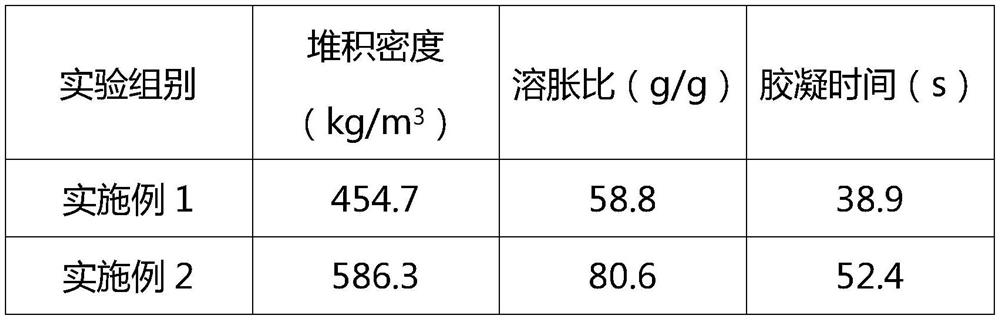

Embodiment 1

[0035] A plugging lightweight sand: the inner core is construction waste, and the construction waste is obtained by crushing construction waste aerated concrete, and the inner core is wrapped with a 0.05mm thick shell material, and the shell material is The unit is parts by weight, including the following raw materials: 12 parts of cement, 7 parts of silica sand, 1 part of diatomaceous earth, 4 parts of sodium fluoride, 3 parts of polystyrene butadiene copolymer, 7 parts of potassium bicarbonate, laurel peroxide Acyl 0.2 part, trimethylolpropane tris (3- aziridinyl propionate) 0.3 part; The described silicon-containing sand is river sand, and the particle size of the silicon-containing sand is 7-28 μm;

[0036] The preparation method of the described plugging lightweight sand comprises the following steps:

[0037] (1) Construction waste is obtained by crushing construction waste aerated concrete to particles with a particle size of ≤5.3mm;

[0038] (2) Cement, silica sand, d...

Embodiment 2

[0042] A plugging lightweight sand: the inner core is construction waste, and the construction waste is obtained by crushing construction waste aerated concrete, and the inner core is wrapped with a 0.08mm thick shell material, and the shell material is The unit is parts by weight, including the following raw materials: 16 parts of cement, 10 parts of silica-containing sand, 2 parts of diatomaceous earth, 5 parts of sodium fluoride, 4 parts of polystyrene butadiene copolymer, 8 parts of potassium bicarbonate, laurel peroxide Acyl 0.3 part, trimethylolpropane tris (3- aziridinyl propionate) 0.4 part; The described silicon-containing sand is Jiangsha, and the particle size of the silicon-containing sand is 4-32 μm;

[0043] The preparation method of the described plugging lightweight sand comprises the following steps:

[0044] (1) Construction waste is obtained by crushing waste construction aerated concrete to particles with a particle size ≤ 5.8mm;

[0045] (2) Cement, silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com